Page 1

Installation Instructions

Original Instructions

Armor GuardLogix Controller

Catalog Numbers

Topi c Pag e

Important User Information 2

About the Armor GuardLogix Controller 3

Prevent Electrostatic Discharge 3

Before You Begin 4

Install the Armor GuardLogix Controller 6

Mount the Controller 6

Ground the Controller 8

Open the Access Door 8

Remove and Install the SD Card 8

Connect to the USB Port 9

Make Network Connections 10

Make Power Connections 11

Set the Network IP Address of the EtherNet/IP Modules 12

Update the Controller 1 7

Status Indicators 18

Recover the Controller By Using a Memory Card 20

Specifications 22

Additional Resources 23

1756-L72EROMS

Page 2

2 Armor GuardLogix Controller

IMPORTANT

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and operation of

this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize themselves with

installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to be

carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requi rements associ ated wit h any pa rticu lar ins tallat ion, Roc kwell Au tomati on, Inc. cannot assume respon sibili ty or li abilit y for actual

use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNIN G: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injur y or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence.

Identifies information that is critical for successful application and understanding of the produc t.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for exampl e, a motor control center, to alert

people to potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective

Equipment (PPE). Follow ALL Regulatory requirements for safe work practi ces and for Personal Protective

Equipment (PPE).

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 3

Armor GuardLogix Controller 3

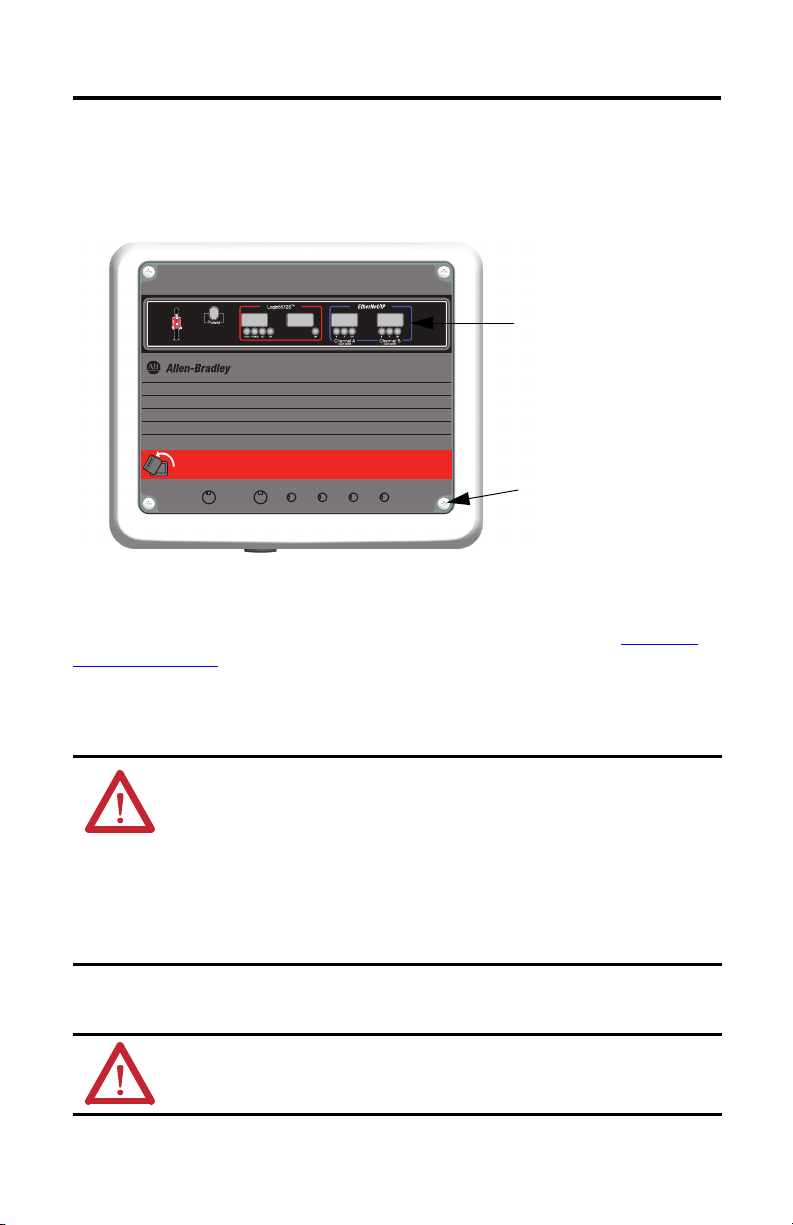

TM ®

Armor GuardLogix

24V

IN OUT

DC 24VDC

LNK1 LNK2

LNK1 LNK2

Channel A Channel B

Pull and Rotate

Counter Clockwise

TM

Display Window

Access Door Screws

About the Armor GuardLogix Controller

The Armor™ GuardLogix® controller combines a 1756-L72S GuardLogix controller and safety

partner with two Ethernet/IP DLR-capable communication channels in an IP67-rated housing

for mounting on a machine.

The Armor GuardLogix controller is certified for use in safety applications up to and including

Safety Integrity Level (SIL) 3 and Performance Level (e) in which the de-energized state is the

safe state. For information on operating a GuardLogix controller-based system, understanding

safety application requirements, and accessing the GuardLogix certificate, see the Additional

Resources on page 23.

Prevent Electrostatic Discharge

ATTENTION: This equipment is sensitive to electrostatic discharge that can cause internal damage

and affect normal operation. Follow these guidelines when you handle this equipment.

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wrist strap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation if available.

• Store the equipment in appropriate static-safe packaging when not in use.

Programmable Electronic Systems (PES)

ATT EN TIO N: Personnel responsible for the application of safety-related Programmable

Electronic Systems (PES) shall be aware of the safety requirements in the application of the

system and shall be trained in using the system.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 4

4 Armor GuardLogix Controller

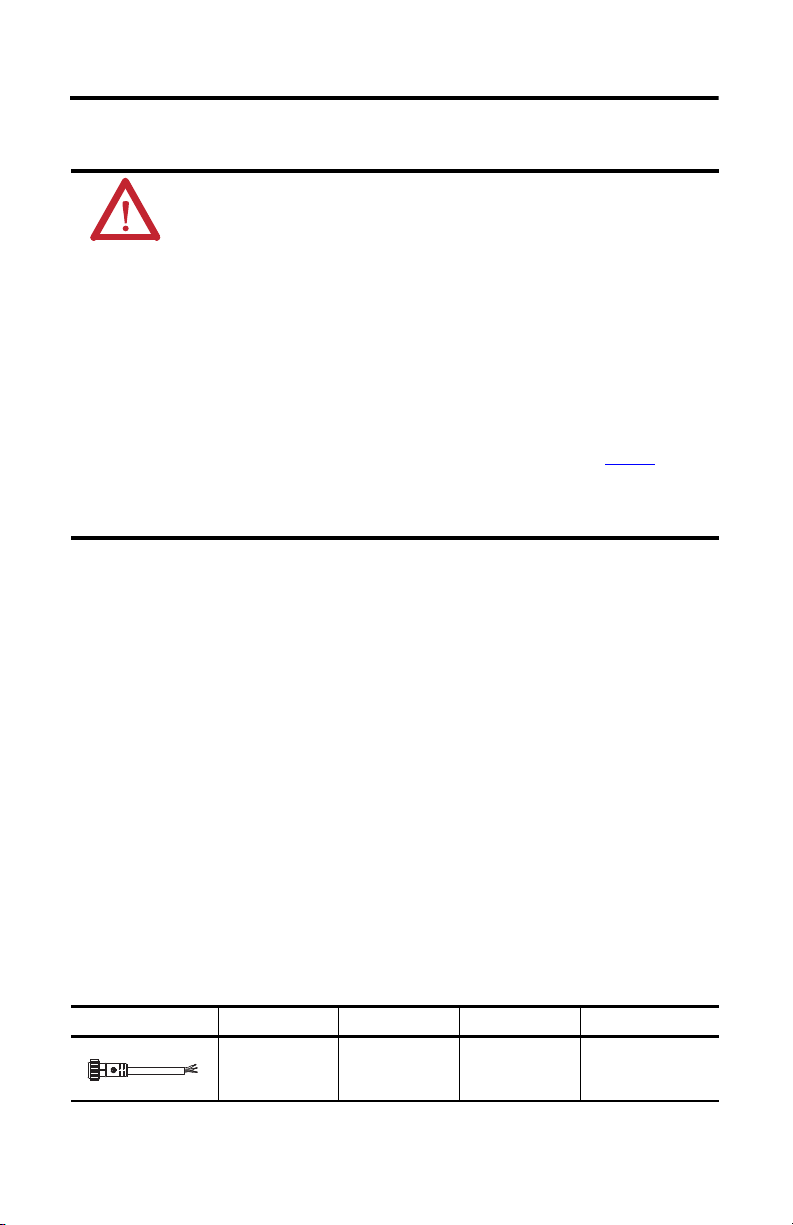

Environment and Enclosure

ATT EN TIO N: This equipment is intended for use in overvoltage Category II applications (as

defined in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is not intended for use in residential environments and may not provide

adequate protection to radio communication services in such environments.

This equipment is supplied as enclosed equipment. It should not require additional system

enclosure when used in locations consistent with the enclosure type ratings stated in the

Specifications section of this publication. Subsequent sections of this publication may contain

additional information regarding specific enclosure t ype ratings, beyond what this product

provides, that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1, for

additional installation requirements

• NEMA 250 and IEC 60529, as applicable, for explanations of the degrees of protection

provided by enclosure

Before You Begin

Before you begin, check to make sure you have all of the components you will need and plan your

network.

System Components

The controller ships with these parts installed:

• 1756-ESMCAP capacitor-based energy storage module (ESM)

• 1784-SD1 Secure Digital (SD) memory card, 1 GB

• 1747-KY key (shipped in a key holder inside the enclosure)

Control power and Ethernet communication cables are available separately.

Power Cables and Cordsets

Cordsets

No. of Pins Assembly Rating Straight Female Right Angle Female

(1)

4 600V, 10 A 889N-F4AFC-

(1) Replace (1) with 6 (6 ft), 12 (12 ft) or 20 (20 ft) for standard cable lengths.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

F

889N-R4AFC-

(1)

F

Page 5

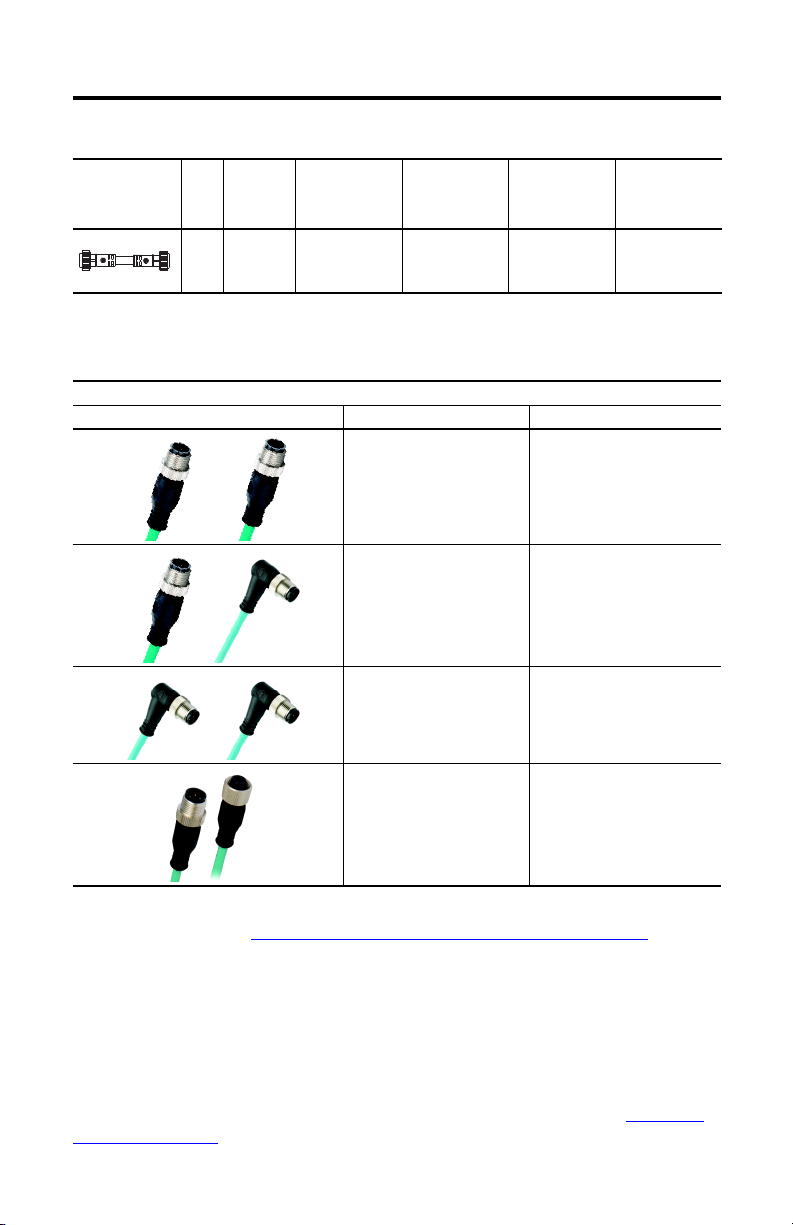

Patchc ords

TIP

No.

Assembly

of

Rating

Pins

4 600V, 10 A 889N-F4AFNM-

(1) Replace (1) with 1 (1 m), 2 (2 m ), 5 (5 m), and 10 (10 m) for standard cable lengths.

Straight Female

Straight Male

Straight

Femal e, Right

Angle Male

(1)

889N-F4AFNE-

Industrial Ethernet Media

Patchcords and Cordsets IP67

M12 D Code Connector Type Cat. No. Unshielded

(1)

Armor GuardLogix Controller 5

Right Angle

Femal e,

Straight Male

889N-R4AFNM-

Right Angle

Femal e, Right

Angle Male

(1)

889N-R4AFNE-

(1)

Male Straight

Male Straight

Male Straight

Male Right Angle

Male Right Angle

Male Right Angle

Male Straight

Femal e Straigh t

(1) Available in 0.3, 0.6, 1, 2, 5, 10, 15, and increments of 5 meters up to 75 meters.

to

to

to

to

1585D-M4TBDM-

1585D-M4TBDE-

1585D-E4TBDE-

1585D-M4TBDF-

(1)

(1)

(1)

(1)

Refer to http://ab.rockwellautomation.com/Connection-Devices/EtherNet-Media for more

information on Industrial Ethernet Media.

Plan Your Network

The two EtherNet/IP networks in the enclosure let the Armor GuardLogix controller be used in

a variety of EtherNet/IP network topologies, including linear, star, and device level ring (DLR)

as a ring node or ring supervisor.

For more information on EtherNet/IP networks, see the publications listed in the Additional

Resources on page 23.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 6

6 Armor GuardLogix Controller

30 mm (1.18 in.)

30 mm (1.18 in.)

30 mm (1.18 in.)

30 mm (1.18 in.)

Install the Armor GuardLogix Controller

The controller ships with the power switch inside the enclosure set to ON and the controller in

Remote Program mode. You can make power connections and EtherNet/IP network

connections without opening the access door on the enclosure. However, if you need to access

the power switch, USB port, or SD card, you will need to open the enclosure door.

Follow these steps, described in this publication, to install the controller.

1. Mount the Controller

2. Ground the Controller

3. Open the Access Door, optional

4. Remove and Install the SD Card

5. Connect to the USB Port

6. Make Network Connections

7. Make Power Connections

8. Set the Network IP Address of the EtherNet/IP Modules

9. Update the Controller

ATT EN TI ON : Make sure all connectors and caps are securely tightened to properly seal

connections against leaks and maintain IP67 requirements.

, optional

, optional

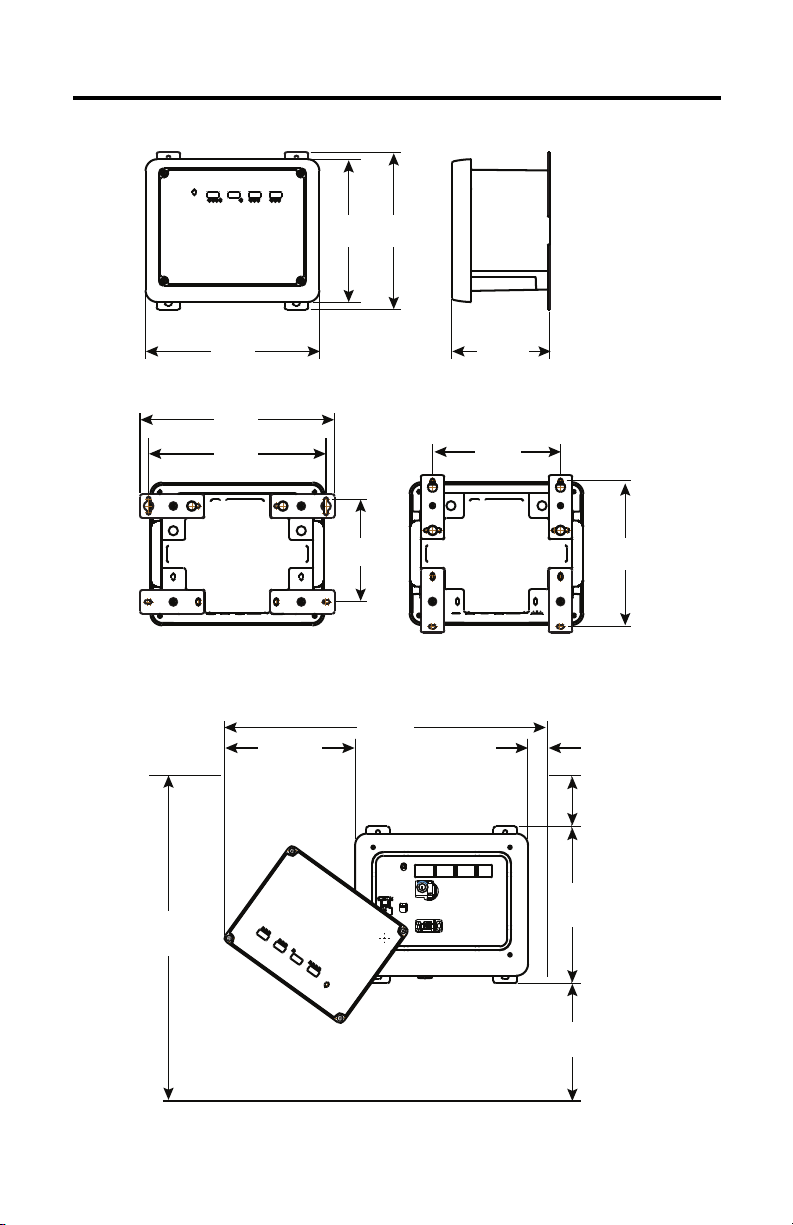

Mount the Controller

Observe these minimum spacing

requirements around the enclosure.

Mounting feet can be attached in either

horizontal or vertical orientation as shown

in Product Dimension

the mounting feet to the enclosure by using

the four flat-head screws supplied with the

mounting feet. Torque screws to 8.5 N•m

(75.2 lb-in).

Mount the module directly to a machine by

using four mounting holes. The mounting

hole diameter on the mounting feet

included with the enclosure is 6.8 mm (0.27

in.). Use four M6 screws and torque screws

to 6.6 N•m (58 lb-in). See the Product Dimension

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

s on page 7. Attach

s on page 7.

Page 7

Product Dimensions

240 mm

(9.4 in.)

292 mm

(11.5 in. )

298 mm

(11.7 in.)

215 mm

(8.5 in.)

172 mm

(6.8 in.)

245 mm

(10 in.)

165mm

(6.5 in.)

265 mm

(10.4 in.)

327 mm

(12.9 in.)

550 mm

21.7 in.

32.25 mm

1.3 in.

86.55 mm

3.4 in.

265 mm

10 in.

550 mm

21.7 in.

198.9 mm

7.8 in.

225.75 mm

8.9 in.

Mounting feet in horizontal orientation Mounting feet in vertical orientation

Clearance for access door opening

Armor GuardLogix Controller 7

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 8

8 Armor GuardLogix Controller

IMPORTANT

IMPORTANT

TM ®

Armor GuardLogix

24VD

IN

OUT

DC 24VDC

LNK1 LNK2

LNK1 LNK2

Channel A Channel B

Pull and Rotate

Counter Clockwise

TM

Pivot Point

Logix 55xx

RUN

FORCE

SD

OK

Ground the Controller

You must provide a proper grounding path by using the ground lug on the bottom of the

enclosure.

PE Ground

Wire Size Tightening Torque

2

1.3…5.2 mm

(#16…#10 AWG) 2 N•m (17.7 in-lb)

Refer to Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

guidelines on installing an industrial control system.

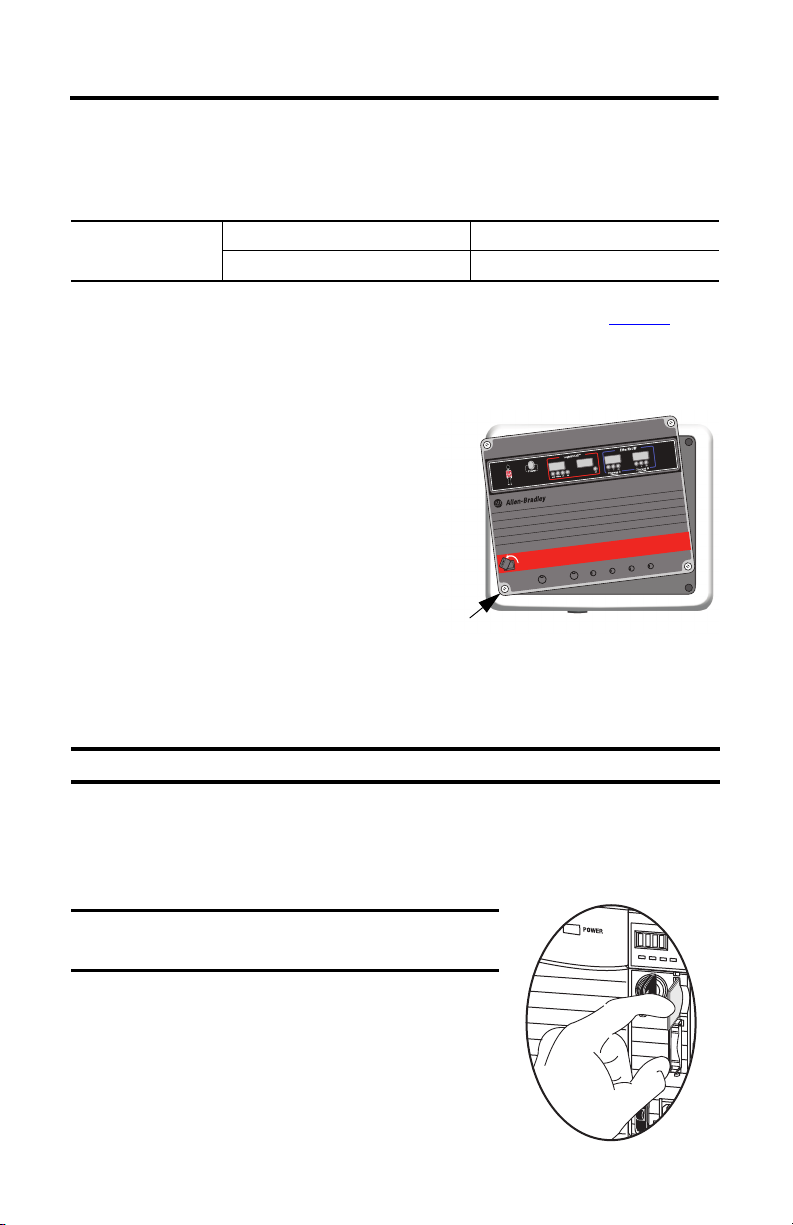

Open the Access Door

Open the enclosure door to access the power switch,

controller USB port, and SD memory card in the

controller.

1. Loosen the four (captive) screws on the front

of the enclosure.

2. Gently lift the door and rotate it counterclockwise from the pivot at the lower left

corner.

The door remains attached to the enclosure.

3. Close the access door on the enclosure and torque the four screws to 3.8 N•m

(33.5 lb-in).

When the access door is open, the Armor GuardLogix controller rating is Type 1.

for

Remove and Install the SD Card

If you want to remove the SD card, follow these steps.

Verify that the SD card status indicator is off and that

the card is not in use before removing it.

1. Open the enclosure door to access the controller.

2. Turn the keyswitch to the PROG position.

3. Press and release the SD card to eject it.

4. Remove the SD card.

5. Close the enclosure access door.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 9

Armor GuardLogix Controller 9

Unlocked

Locked

Logix 55xx

RUN

FORCE

SD

OK

Follow these steps to install the SD card.

ATT EN TIO N: If you are not sure of the contents of the memory card, before you install the

card, turn the keyswitch of the controller to the PROG position. Depending on the contents of

the card, a power cycle or fault could cause the card to load a different project or operating

system into the controller.

1. Open the access door on the enclosure.

2. Verify that the SD card is locked or unlocked according to your preference.

3. Insert the SD card into the SD card slot.

4. Gently press the card until it clicks into place.

5. Close the enclosure access door.

Connect to the USB Port

The controller has a USB port that uses a Type B receptacle. The port is USB 2.0-compatible and

runs at 12 M. To use the USB port of the controller, you must have RSLinx® software, version

2.59 or later, installed on your workstation.

Access the USB port by opening the enclosure door.

Use a USB cable to connect your workstation to the USB port. With this connection, you can

upgrade firmware and download programs to the controller directly from your workstation.

ATTENTION: The USB port is intended for only temporary local programming purposes and

not intended for permanent connection.

The USB cable must not exceed 3.0 m (9.84 ft) and must not contain hubs.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 10

10 Armor GuardLogix Controller

TIP

IMPORTANT

Virtual Chassis Driver

USB Port Driver

4

3

2

1

5

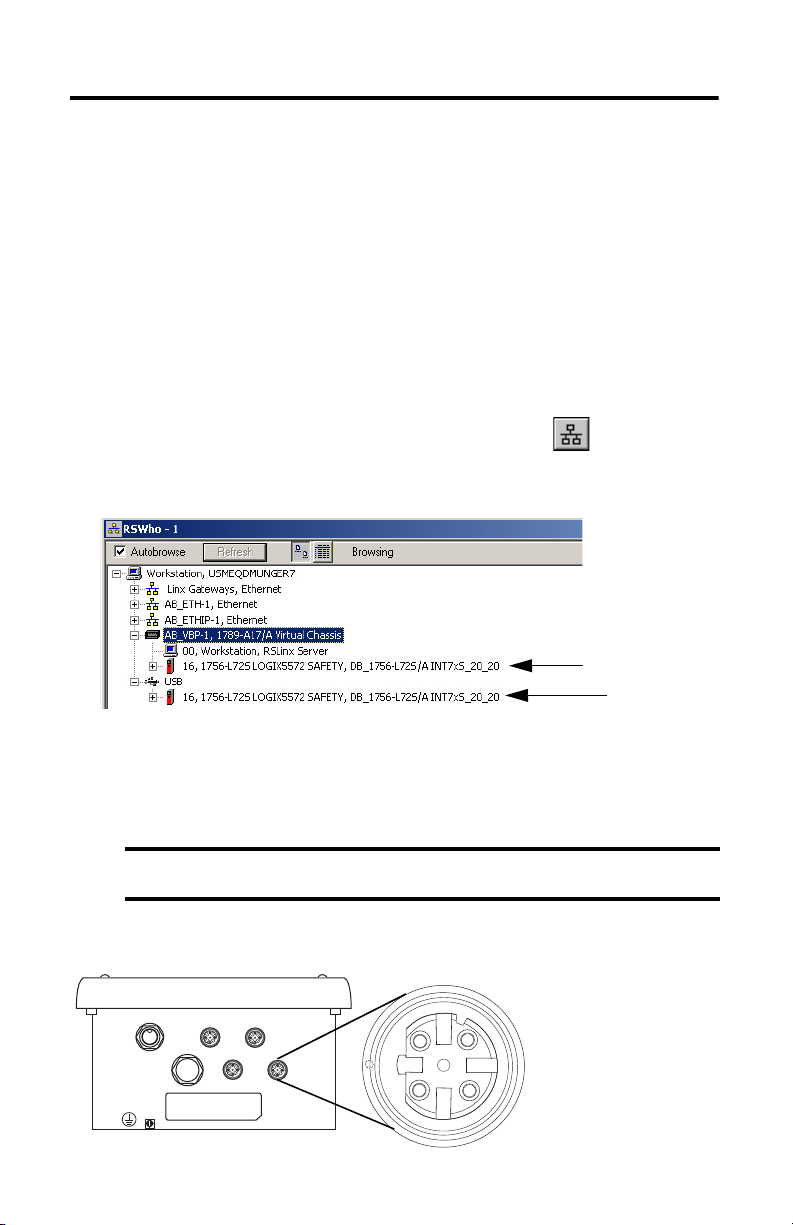

D-Code M12 Female Network Connec tor

44236

(View into Connector)

Pin 1 – M12_Tx+

Pin 2 – M12_Rx+

Pin 3 – M12_TxPin 4 – M12_RxPin 5 – Connector Shell Shield GND

To configure RSLinx software to use a USB port, you need to set up a USB driver. To set up a

USB driver, follow these steps. If you are using Windows 7 operating system, the driver is

automatically installed and you can proceed to step 5.

1. Connect your controller and workstation by using a USB cable.

2. On the Found New Hardware Wizard dialog box, click one of the Windows Update

connection options and click Next.

If the software for the USB driver is not found and the installation is canceled, verify that you

have installed RSLinx Classic software, version 2.59 or later.

3. Click Install the software automatically (Recommended) and click Next.

4. Click Finish.

5. To browse to your controller in RSLinx software, click RSWho .

In the RSLinx Workstation organizer, your controller appears under two different drivers, a

virtual chassis and the USB port. You can use either driver to browse to your controller.

Make Network Connections

1. Remove the dust caps from the 4 Ethernet connectors on the bottom of the enclosure.

If you disconnect network connections from these ports, re-attach the dust caps and

torque to 0.75 N•m (6.63 lb-in) to maintain IP67 protection.

2. Connect the cordsets you selected to the Ethernet communication ports on the bottom

of the enclosure and torque to 1 N•m (9 lb-in).

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 11

Armor GuardLogix Controller 11

IMPORTANT

IMPORTANT

IMPORTANT

IMPORTANT

D-Code M12 Pin Wire Color Signal 8-way Modular RJ45 Pin

1White-OrangeTX+ 1

2White-GreenRX+ 3

3OrangeTX- 2

4GreenRX- 6

Cordsets with Flying Leads (per SAE-J-1738A)

Armor GuardLogix Controller (per EN 50044)

Femal e Femal eMale Male

1-Black [V-] 2-White [E-] 3-Red [V+] 4-Green [E+ ] 1-Red [V+] 2-Green [E+] 3- Wh ite [E-] 4-Black [V-]

Use the 1585D–M4DC–H: Polyamide small body unshielded or the 1585D–M4DC–SH: Zinc

die-cast large body shielded mating connectors for the D-Code M12 female network connector.

Use two twisted-pair CAT5E UTP or STP cable.

Make Power Connections

Male Connector (Power Input) Female Connector (Power Output) Pin Signal

1V+ Switched

2V+ Unswitched

3V- Unswitched Common

4 V- Switched Common

The bottom of the enclosure has two mini-sealed power connectors that operate in parallel with

one another to allow daisy-chaining of device power with other devices. The unit receives its

required power through the male connector. A female connector lets power be daisy-chained to

other Armor GuardLogix units.

On Machine end devices, such as the Armor GuardLogix controller, use the EN-50044 wiring

standard while On-Machine cordsets with flying leads use the SAE-J-1738A standard for wiring.

Use care to follow the pin numbering convention shown below before powering up the unit.

1. Remove the dust caps from the power connectors on the bottom of the enclosure.

2. Make power connections and torque to 12 N•m (106 lb-in).

If you disconnect power connections from these ports, re-attach the dust caps and

torque to 2 N•m (18 lb-in) to maintain IP67 protection.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 12

12 Armor GuardLogix Controller

IMPORTANT

Set the Network IP Address of the EtherNet/IP Modules

The EtherNet/IP communication modules reside in slots 2 and 3 of the ControlLogix chassis

within the enclosure. The modules are shipped with Bootstrap Protocol (BOOTP)/Dynamic

Host Configuration Protocol (DHCP) enabled and their rotary switches set to 999. You can use

the following methods to set the IP address of each module.

• BOOTP/DHCP server

• RSLinx Classic software

• Studio 5000 Logix Designer™ application

ATTENTION: The EtherNet/IP communication module must be assigned a fixed network address.

The IP address of this module must not be dynamically provided.

Failure to observe this precaution can result in unintended machine motion or loss of process

control.

Refer to the EtherNet/IP publications listed in the Additional Resources on page 23 for detailed

information on setting an IP address.

Use a BOOTP/DHCP Server

The BOOTP/DHCP server is a standalone server you can use to set an IP address. When used,

the BOOTP/DHCP server sets an IP address and other Transport Control Protocol (TCP)

parameters.

Access the BOOTP/DHCP server from one of these locations:

• Programs > Rockwell Software > BOOTP-DHCP Server

If you have not installed the server, you can download and install it from

http://www.ab.com/networks/ethernet/bootp.html.

• Tools directory on the Studio 5000™ environment installation CD

Before you start the BOOTP/DH CP server, make sure you have t he module’s hardware

(MAC) address. The hardware address is on the label on the bottom of the enclosure.

Follow these steps to set the module’s IP address with a BOOTP/DHCP server.

1. Start the BOOTP/DHCP software.

2. From the Tools menu, choose Network Settings.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 13

Armor GuardLogix Controller 13

3. Type the Subnet Mask of the network.

The Gateway address, Primary and/or Secondary DNS address, and Domain Name

fields are optional.

4. Click OK.

The Request History panel shows the hardware addresses of all modules issuing

BOOTP requests.

5. Select the appropriate module and click Add to Relation List.

6. On the New Entry dialog box, type an IP Address, Hostname, and Description for the

module.

7. Click OK.

8. To permanently assign this configuration to the module, wait for the module to appear

in the Relation List panel and select it.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 14

14 Armor GuardLogix Controller

IMPORTANT

9. Click Disable BOOTP/DHCP.

If you do not click Disable BOOTP/DHCP, the host controller clears the current IP

configuration and begins sending BOOTP requests again each time power is cycled.

Use RSLinx or the Logix Designer Application

This table describes when to set the network IP address with RSLinx software or the Logix

Designer application.

Conditions Use Page

A BOOTP server is not available.

The EtherNet/IP communication module is connected to another NetLinx network.

The Logix Designer project is online with a controller that communicates to or through

the EtherNet/IP communication module.

Set the Network IP Address with RSLinx Software

RSLinx software 14

Logix Designer application 16

Follow these steps to use RSLinx software to set the communication module’s IP address.

1. From the Communications menu, choose RSWho.

2. From the RSWho dialog box, navigate to the Ethernetnetwork.

3. Right-click the EtherNet/IP module and choose Module Configuration.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 15

Armor GuardLogix Controller 15

IMPORTANT

IMPORTANT

4. On the Module Configuration dialog box, click the Port Configuration tab.

5. For Network Configuration Type, click Static to permanently assign this configuration

to the port

.

If you click Dynamic, on a power cycle, the controller clears the current IP

configuration and resumes sending BOOTP requests.

6. Type the IP address in the IP Address field and add fill in additional fields, if needed.

7. Configure the port settings.

To Th en

Use the default port speed and duplex

settings

Manually configure your port’s speed

and duplex settings

Leave Auto-negotiate port speed and duplex checked.

This setting determines the actual speed and duplex setting.

Follow these steps.

1. Clear the Auto-negotiate port speed and duplex checkbox.

2. From the Current Por t Speed pull-down menu, choose a port speed.

3. From the Current Duplex pull-down menu, choose the appropriate

Duplex value, that is, Half Duplex or Full Duplex.

Consider the following when you configure the module’s port settings:

• If the module is c onnected to an unmanaged switch , leave Auto-negotiate port

speed and duplex checked or communication can be impaired.

• If you are forcing the port speed and duplex with a managed switch, the

corresponding port of the managed switch must be forced to the same settings

or the module will fail.

8. Click OK.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 16

16 Armor GuardLogix Controller

IMPORTANT

Set the Network IP Address with the Logix Designer application

Follow these steps to use the Logix Designer application to set the module’s IP address.

1. In the Controller Organizer, right-click the EtherNet/IP module and choose Properties.

2. On the Module Properties dialog box, click the Port Configuration tab.

3. In the IP Address field, type the IP address.

4. In the other fields, type the other network parameters, if needed.

The fields that appear vary from one EtherNet/IP module to another.

5. Click Set.

6. Click OK.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 17

Armor GuardLogix Controller 17

IMPORTANT

IMPORTANT

Update the Controller

The controller ships without firmware. Controller firmware is packaged with the Studio 5000

environment. In addition, controller firmware is also available for download from the Rockwell

Automation Technical Support website at: http://www.rockwellautomation.com/support/

You can upgrade your firmware by using either ControlFLASH™ software or by using the

AutoFlash feature of the Logix Designer application.

Use ControlFLASH Software to Update Firmware

The safety partner updates automatically when the primary controller is updated.

If the SD card is locked and the stored project’s Load Image option is set to On Power Up, the

controll er firmware is not updated as a result of these steps. Any previously-stored firmware

and projects are loaded instead.

1. Verify that the appropriate network connection is made and the network driver has been

configured in RSLinx software.

2. Start ControlFLASH software.

3. Click Next.

4. Select the catalog number of the controller and click Next.

5. Expand the network until you see the controller.

6. Select the controller and click Next.

.

7. Select the revision level to which you want to update the controller and click Next.

8. To start the update of the controller, click Finish and then click Yes.

After the controller is updated, the status dialog box displays ‘Update complete’.

Allow the firmware update to fully complete before cycling power or otherwise

interrupting the upgrade. If the ControlFLASH update of the controller is

interrupted, the controller reverts to boot firmware, that is firmware revision 1.xxx

and you will need to repeat the update process.

9. Click OK.

10. Close ControlFLASH software.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 18

18 Armor GuardLogix Controller

Use AutoFlash to Update Firmware

To update your controller firmware with the AutoFlash feature, follow these steps.

1. Verify that the appropriate network connection is made and your network driver is

configured in RSLinx software.

2. Use the Logix Designer application to create a controller project at the version you need.

3. Click RSWho to specify the controller path.

4. Select your controller and click Update Firmware.

5. Select the firmware revision you want.

6. Click Update.

7. Click Yes.

Allow the firmware update to complete without interruption. When the firmware update is

complete, the Who Active dialog box opens. You can complete other tasks in the Logix Designer

application.

Status Indicators

Status indicators are visible through the window on the front of the enclosure.

Controllers Status Indicators

The status of the primary controller is displayed via four status indicators.

Primary Controller Status Indicator Descriptions

Indicator Status Description

RUN Off No user tasks running. Controller is in PROGram mode.

Green Controller is in RUN mode.

FORCE Off No forces, standard or safety, are enabled on the controller.

Amber Standard and/or safety forces have been enabled.

Amber,

Flashing

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Use caution if you install (add) a force. If you install a force, it takes immediate effect.

One or more I/O addresses, standard and/or safety, have been forced to an on or off state, but

forces are not enabled.

Use caution if you enable I/O forces. If you enable I/O forces, all existing I/O forces also take effect.

Page 19

Primary Controller Status Indicator Descriptions

Indicator Status Description

SD Off No activity is occurring with the memor y card.

Green, Flashing The controller is reading from or writing to the memor y card. Do not remove the memory card

Green

Red, Flashing The memor y card does not have a valid file system.

Red The memo ry card is n ot recognized b y the controll er.

OK Off No power is applied.

Green The controller is operating with no faults.

Red, Flashing Nonrecoverable fault or recoverable fault not handled in the fault handler. All user tasks, both

Red The controller is completing power-up diagnostics

The safety partner has an OK status indicator.

while the controller is reading or writing.

standard and safety, are stopped.

If the controller is new, out-of-the-box, it requires a firmware upgrade. The status display

indicates Firmware Installation Required.

A nonrecoverable major fault occurred and the program was cleared from memory.

The charge of the capacitor in the Energy Storage Module (ESM) is being discharged upon

powerdown.

The controller is powered but inoperable.

The controller is loading a project to nonvolatile memory.

Armor GuardLogix Controller 19

Safety Partner Status Indicator

Indicator Status Description

OK Off No power is applied.

Green The safety partner is operating with no faults.

Red Powering up or nonrecoverable controller fault.

Controller Status Display

The controller status display scrolls messages that provide information about the controller’s

firmware revision, energy storage module (ESM) status, project status, and major faults.

For a list of status messages, refer to the GuardLogix 5570 Controllers User Manual, publication

1756-UM022

.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 20

20 Armor GuardLogix Controller

EtherNet/IP Module Status Indicators

The EtherNet/IP communication modules support these status indicators.

Indicator Status Description

Off One of these conditions exists:

LINK 1,

LINK 2

Flashing green Activity exists on the port.

Green One of these conditions exists:

Off The module is not powered.

Flashing green The module is not configured.

Green The modu le is operating correctly.

OK

Module Status Display

Flashing red The module detected a recoverable minor fault. Check the module configuration. If necessary,

Red The module detected an unrecoverable major fault. Cycle power to the module. If this does not

Red AND the

module status

display is scrolling

‘Image Update

Needed ‘

Flashing red and

green

• The module is not powered.

– Ve rify ther e is ch assi s pow er.

– Verify that the module is completely inser ted into the chassis and backplane.

– Make sure the module has been configured.

• No link exists on the port.

• The po rt is admin istratively disabled (LNK2).

• The port is disabled due to rapid ring faults (LNK2).

• A link exists on the port.

• The ring network is operating normally on active ring supervisor (LNK2).

• A ring partial network fault was detected on the active ring supervisor (LNK2).

• Ver ify th ere i s cha ssis power.

• Verify that the module is completely inserted into the chassis and backplane.

• Make sure the module has been configured.

The Module Status display scrolls: BOOTP or DHCP<Mac_address_of_module>

For example: BOOTP 00:0b:db:14:55:35

Configure the module.

The Module Status display scrolls: OK <IP_address_of_this_module>

For example: OK 10.88.60.160

reconfigure the module.

clear the fault, replace the module.

Follow these steps:

1. Update the firmware image.

2. Cycle power to the module.

3. If the status indicators remain the same, that is, red and scrolling Image Update Needed,

replace the module.

The module is performing its power-up testing.

Alphanumeric display that scrolls messages. For example, when a module is operating

normally, the display scrolls the module’s IP address.

Recover the Controller By Using a Memory Card

If you need to recover the controller, due to a corrupt program or other issue, you can do so by

creating a recovery SD card. This procedure requires the use of a second, user-supplied

1784-SD1 memory card. Perform this procedure on a separate controller that is not locked and is

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 21

Armor GuardLogix Controller 21

IMPORTANT

TIP

not corrupt, or preform the procedure prior to downloading any project to your Armor

GuardLogix controller.

To avoid inadver tently over-writing your application program, you must not use the 1784-SD1

memory card that shipped installed in the Armor GuardLogix controller.

Follow these steps to create the recovery memory card.

1. Update the Armor GuardLogix controller to the desired firmware revision by following

the instructions in Update the Controller

2. Remove the memory card that shipped with the controller by following the instructions

in Remove and Install the SD Card

3. Insert a new 1784-SD1 card.

Label this memory card ‘recovery’, so that you do not confuse it with the memory card that

shipped with the controller.

4. Load a blank project into the controller making sure to check the box to store the project

to the memory card and load on power-up.

5. Remove the ‘recovery’ memory card, store it in a secure location.

6. Re-insert the memory card that shipped with the Armor GuardLogix controller by

following the instructions in Remove and Install the SD Card

Follow these steps to use the recovery memory card to recover the controller.

1. Remove the memory card that shipped with the controller.

2. Insert the recovery memory card.

3. Cycle power to the controller.

The blank project on the recovery memory card overwrites the project in the controller.

on page 17.

on page 8.

on page 8.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 22

22 Armor GuardLogix Controller

Specifications

This section lists general specifications specific to the enclosure. Specifications for the

components in the Armor GuardLogix controller enclosure are in their respective Technical

Data publications, listed in the Additional Resources

Attribute 1756-L72EROMS

Input System Power - Unswitched (Pins 2 and 3) 18 …32V DC @ 8 A

Input Pass Through Power - Switched (Pins 1 and 4) 18…32V DC @ 8 A

Output External Power - Unswitched (Pins 2 and 3) 18…32V DC @ 6 A

Output Pass Through Power - Switched (Pins 1 and 4) 18…32V DC @ 8 A

Enclosure type rating Meets IP65/67 (when marked) with receptacle dust caps or cable

Temperature, operating 0…60 °C (32…140 °F)

Weight, approx 6.5 kg (14.3 lb)

Dimensions (HxWxD), approx 240 x 292 x 164.52 mm (9.4 x 11.5 x 6.5 in.)

termination

Machinery Directive

The controllers are in conformity with the essential requirements of the Machinery Directive

(2006/42/EC) when installed in accordance with the instructions contained in the product

documentation. The standards, and technical specifications referred to below have been applied

as indicated.

on page 23.

Standard/Technical Specification

EN 60204-1 Electrical equipment of machines

EN ISO 13849-1 Safety-related parts of control systems

EN 62061 Functional Safety of safety-related control systems

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 23

Armor GuardLogix Controller 23

Additional Resources

These documents contain additional information concerning related products from Rockwell

Automation.

Resource Description

Provides information on how to install, configure, program, and

use GuardLogix 5570 controllers in Studio 5000 Logix Designer

projects.

Provides information on safety application requirements for

GuardLogix 5570 controller in Studio 5000 Logix Designer

projects.

Provides declarations of conformity, certificates, and other

certification details.

Provides details about how to use EtherNet/IP communication

modules with Logix5000 controllers and communicate with

other devices on the EtherNet/IP network.

Describes how you can use EtherNet/IP communication modules

with your Logix5000 controller and communicate with various

devices on the Ethernet network.

Provides details about how to install, configure, and maintain

linear and Device-level Ring (DLR) networks by using Rockwell

Automation EtherNet/IP devices equipped with embedded

switch technology.

Provides details about how to use the required media

components and how to plan for, install, verify, troubleshoot,

and certify your EtherNet/IP network.

Provides product specifications, dimensions, environmental

data, and information on certifications for the Armor GuardLogix

controller.

Provides product specifications, dimensions, environmental

data, and information on certifications for the 1756-EN2T

modules.

Provides product specifications, dimensions, environmental

data, and information on certifications for the 1756-PB75 power

supply.

Provides product specifications, dimensions, environmental

data, and information on certifications for the chassis.

Provides general guidelines for installing a Rockwell Automation

industrial system.

Safety

Controlle rs

EtherNet/IP

Networks

Specifications

for Armor

GuardLogix

Component s

GuardLogix 5570 Controllers User Manual,

publication 1756-UM022

GuardLogix 5570 Controller Systems Safety

Reference Manual, publication 1756-RM099

Product Certifications website,

http://www.ab.com

Ethernet Design Consideration s Reference

Manual, publication ENET-RM002

EtherNet/IP Network Configuration User

Manual, publication ENET-UM001

EtherNet/IP Embedded Switch Technology

Application Guide, publication ENET-AP005

EtherNet/IP Media Planning and Installation

Manual

This manual is available from the Open

DeviceNet Vendor Association (ODVA) at:

http://www.odva.org.

1756 ControlLogix Controller Technical Data,

publication 1756-TD001

1756 ControlLogix Communication Modules

Specifications Technical Data, publication

1756-TD003

1756 ControlLogix Power Supplies

Specifications Technical Data, publication

1756-TD005

1756 ControlLogix Chassis Specifications

Technical Data, publication 1756-TD006

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

You can view or download publications at http://www.rockwellautomation.com/literature/

. To

order paper copies of technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 1756-IN060B-EN-P - November 2013

Page 24

Rockwell Automation Support

Rockwell Automation provides tec hnical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

service packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com/

and forums, technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more information, contact

your local distributor or Rockwell Automation representative, or visit http://w ww.rockwellautomation.com/services/online-phone

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the information that's contained in this manual.

You can also contact a special Customer Support number for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Wor ldwi de Loc ator

http://www.rockwellautomation.com/rockwellautomation/support/overview.page

local Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the manufacturing

facility. However, if your product is not functi oning and needs to be returned, follow these procedures.

you can find technical and application notes, sample code, and links to software

for software updates, support chats

at

, or contact your

.

United States

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Contact your distributor. You must provide a Customer Support case number (call the phone number

above to obtain one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

Allen-Bradley, Rockwell Software, GuardLogix, Armor, Logix5000, Studio 5000 Logix Designer, RSLinx, ControlFLASH, and Rockwell

Automation are trademarks of Ro ckwell Automation, Inc.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

November 1756-IN060B-EN-P - November 2013 PN-215016

Supersedes Publication 1756-IN060A-EN-P - November 2013 Copyright © 2013 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

, available at http://www.rockwellautomation.com/literature/.

Loading...

Loading...