Rockwell Automation 1756-EN2F, 1756-EN2TP, 1756-EN2T, 1756-EN2TK, 1756-EN2TPK User Manual

...Page 1

User Manual

Original Instructions

ControlLogix EtherNet/IP Network Devices

Catalog Numbers 1756-EN2F, 1756-EN2T, 1756-EN2TK, 1756-EN2TP, 1756-EN2TPK, 1756-EN2TPXT, 1756-EN2TR, 1756EN2TRK, 1756-EN2TRXT, 1756-EN2TSC, 1756-EN2TXT, 1756-EN3TR, 1756-EN3TRK, 1756-EN4TR, 1756-EN4TRK, 1756EN4TRXT, 1756-ENBT, 1756-ENBTK, 1756-EWEB

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

Table of Contents

Table of Contents

ControlLogix EtherNet/IP

Network Device Overview

Connect to the EtherNet/IP

Network

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ControlLogix Network Device Features. . . . . . . . . . . . . . . . . . . . . . . . . . 7

EtherNet/IP Network Specifications. . . . . . . . . . . . . . . . . . . . . . . . 10

Electronic Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Protected Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Enabling Explicit Protected Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Disabling Explicit Protected Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Secure Digital Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Secure Digital Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Disable Secure Digital Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CIP Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2

Set the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Set the IP Address with Rotary Switches . . . . . . . . . . . . . . . . . . . . . . . . 18

Other Methods to Set the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Reset the Module IP Address to Factory Default Value . . . . . . . . . . . 19

ControlLogix Network Device

Status Indicators

Appendix A

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Single-Port Module Status Indicators . . . . . . . . . . . . . . . . . . . . . . . 24

Dual-Port Module Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . 25

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 3

Page 4

Table of Contents

Notes:

4 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 5

Preface

This manual describes how you can use ControlLogix® EtherNet/IP™

communication modules with a Logix 5000™ controller and communicate with

various devices on the Ethernet/IP network.

Use this manual if you program applications that use EtherNet/IP networks

with these Logix 5000 controllers:

• CompactLogix™ controller

•ControlLogix controller

Conventions

Additional Resources

Be sure to understand these concepts and tools:

•FactoryTalk® Linx

• Logix Designer

•ControlFLASH Plus™

•HMIs

•SNMP tools

These documents contain additional information concerning related products

from Rockwell Automation.

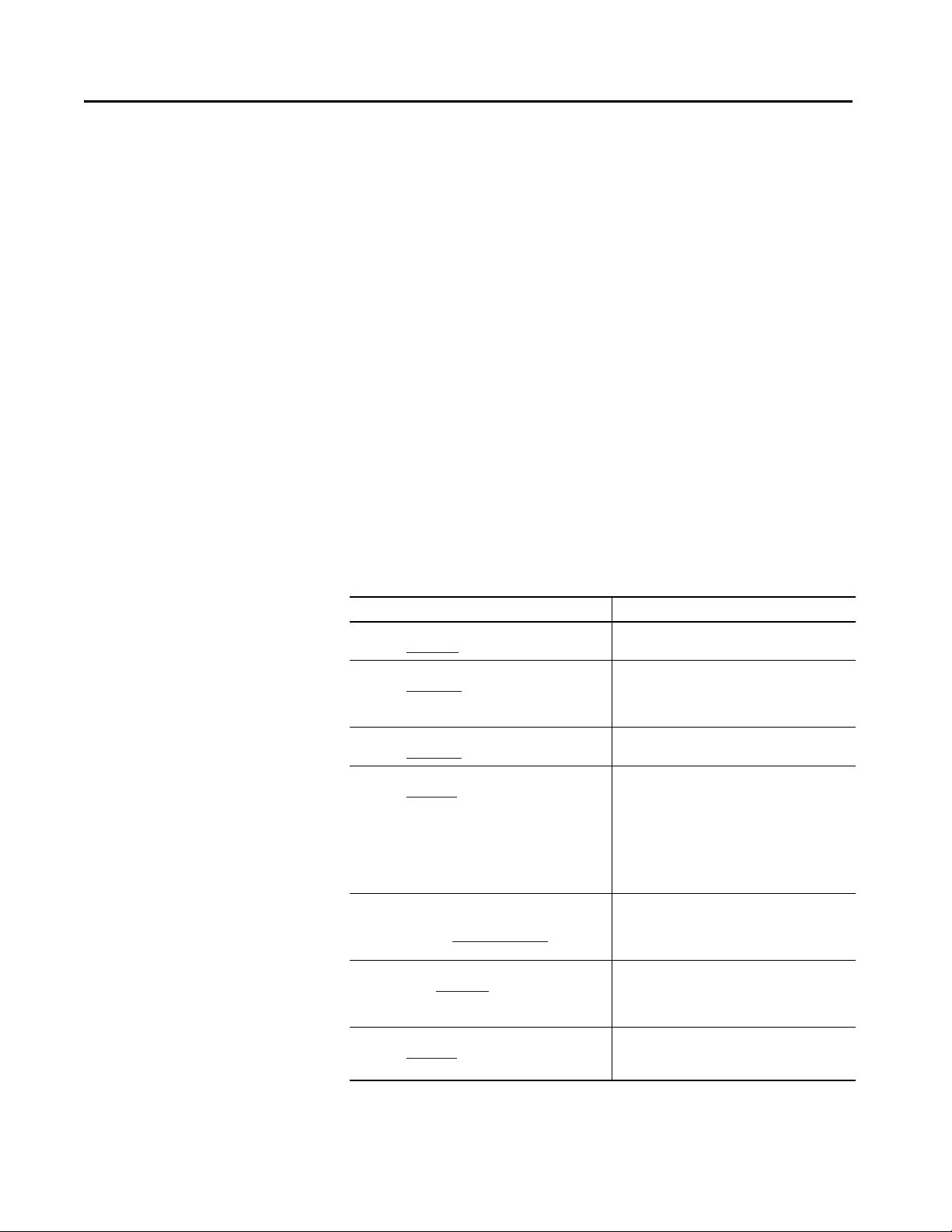

Resource Description

1756 ControlLogix Communication Modules Specifications,

publication 1756-TD003

Ethernet Design Considerations Reference Manual,

publication ENET-RM002

EtherNet/IP Network Devices User Manual,

publication ENET-UM006

EtherNet/IP Modules Installation Instructions,

publication ENET-IN002

EtherNet/IP Media Planning and Installation Manual

This manual is available from the Open DeviceNet® Vendor

Associati on (ODVA) at: http://www.odva.org.

EtherNet/IP Embedded Switch Technology Application

Guide, publication ENET-AP005

EtherNet/IP Device Level Ring Application Technique,

publication ENET-AT007

Specifications for ControlLogix communication

modules.

Provides details about how to use EtherNet/IP

communication modules with Logix 5000 controllers

and communicate with other devices on the

EtherNet/IP network.

Describes how to install, configure, and operate the

Compact 5000™ I/O EtherNet/IP adapters.

Provides information about how to complete these

tasks with EtherNet/IP communication modules in a

Logix 5000 control system:

• Install the module

• Configure initial application setup

• Troubleshoot application anomalies that are

related to EtherNet/IP communication module use

Provides details about how to install, configure, and

maintain linear and Device Level Ring (DLR) networks

by using Rockwell Automation EtherNet/IP devices

that are equipped with embedded switch technology.

Provides details about how to install, configure, and

maintain linear and Device Level Ring (DLR) networks

by using Rockwell Automation EtherNet/IP devices

that are equipped with embedded switch technology.

Describes DLR network operation, topologies,

configuration considerations, and diagnostic

methods.

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 5

Page 6

Preface

Resource Description

EtherNet/IP Socket Interface Application Technique,

publication ENET-AT002

Troubleshoot EtherNet/IP Networks Application Technique,

publication ENET-AT003

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://

www.rockwellautomation.com/global/certification/

overview.page

Describes the socket interface that you can use to

program MSG instructions to communic ate between a

Logix5000 controller via an EtherNet/IP module and

Ethernet devices that do not support the EtherNet/IP

application protocol, such as bar code scanners, RFID

readers, or other standard Ethernet devices.

Provides details about how to assign IP addresses to

and how to troubleshoot EtherNet/IP networks and

devices.

Provides general guidelines for installing a Rockwell

Automation industrial system.

Provides declarations of conformity, certificates, and

other certification details.

You can view or download publications at

http://www.rockwellautomation.com/global/literature-library/overview.page

To order paper copies of technical documentation, contact your local

Allen-Bradley distributor or Rockwell Automation sales representative.

.

6 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 7

Chapter 1

ControlLogix EtherNet/IP Network Device

Overview

Top ic Pag e

Overview 7

ControlLogix Network Device Features 7

Electronic Keying 11

Protected Mode 12

Secure Digital Card 13

CIP Security 15

Overview

ControlLogix Network Device Features

EtherNet/IP™ networks are communication networks that offer a

comprehensive suite of messages and services for many automation

applications.

This open network standard uses commonly available Ethernet

communication products to support real-time I/O messaging, information

exchange, and general messaging.

The ControlLogix® EtherNet/IP network devices:

• Facilitate high-speed data transfer between some Logix 5000™

controllers and remote I/O modules.

• Connect to multiple EtherNet/IP network topologies.

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 7

Page 8

Chapter 1 ControlLogix EtherNet/IP Network Device Overview

STATUS

NET

LINK 1

LINK 2

5094-AENTR

EtherNet/IP™ Adapter

FLEX 5000TM I/O

PRP

DLR

POWER

X100

X10

X1

IP ADDRESS

STATUS

POWER

DIGITAL 16 INPUT 24 VDC

5094-IB16

1

1

TB3

FLEX 5000TM I/O

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

STATUS

POWER

DIGITAL 16 OUTPUT 24 VDC

5094-OB16

1

2

TB3

FLEX 5000TM I/O

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

STATUS

POWER

RELAY 8 OUTPUT ISOLATED

5094-OW8I

2

2

TB3W

FLEX 5000TM I/O

0 1 2 3 4 5 6 7

Logix5575

Redundancy Module

EtherNet/IP

PRI COM OK

ControlNet

EtherNet/IP

ControlNet

OKFORCESDRUN

R

U

N

R

E

M

P

R

O

G

1 2

LNK1 LNK2 OK

10/100 BASE T

LNK NET OK

EtherNet/IP

LNK NET OK

Switch

Distributed I/O

1756-EN4TR

1756 I/O Modules

1794-AENT

1794 I/O Modules

Work stat ion

ControlLogix 5580 Controller

1756 I/O Modules

1769-L27ERM

1769 I/O Modules

5069-AEN2TR

5069 I/O Modules

5069-L340ERM

5069 I/O Modules

1783-ETAP

PanelView™ Terminal

1783-ETAP

Work stat ion

Stratix® 5400

5094-IB16

FLEX 5000™ I/O

1734-AENTR

1734 I/O Modules

1738-AENTR

1738 I/O Modules

PowerFlex®

Drive

Kinetix® 6500

Servo Drive

Star Topology

1769-L18ERM

1734 I/O Modules

DLR Topology

1756-EN4TR

ControlLogix Controller

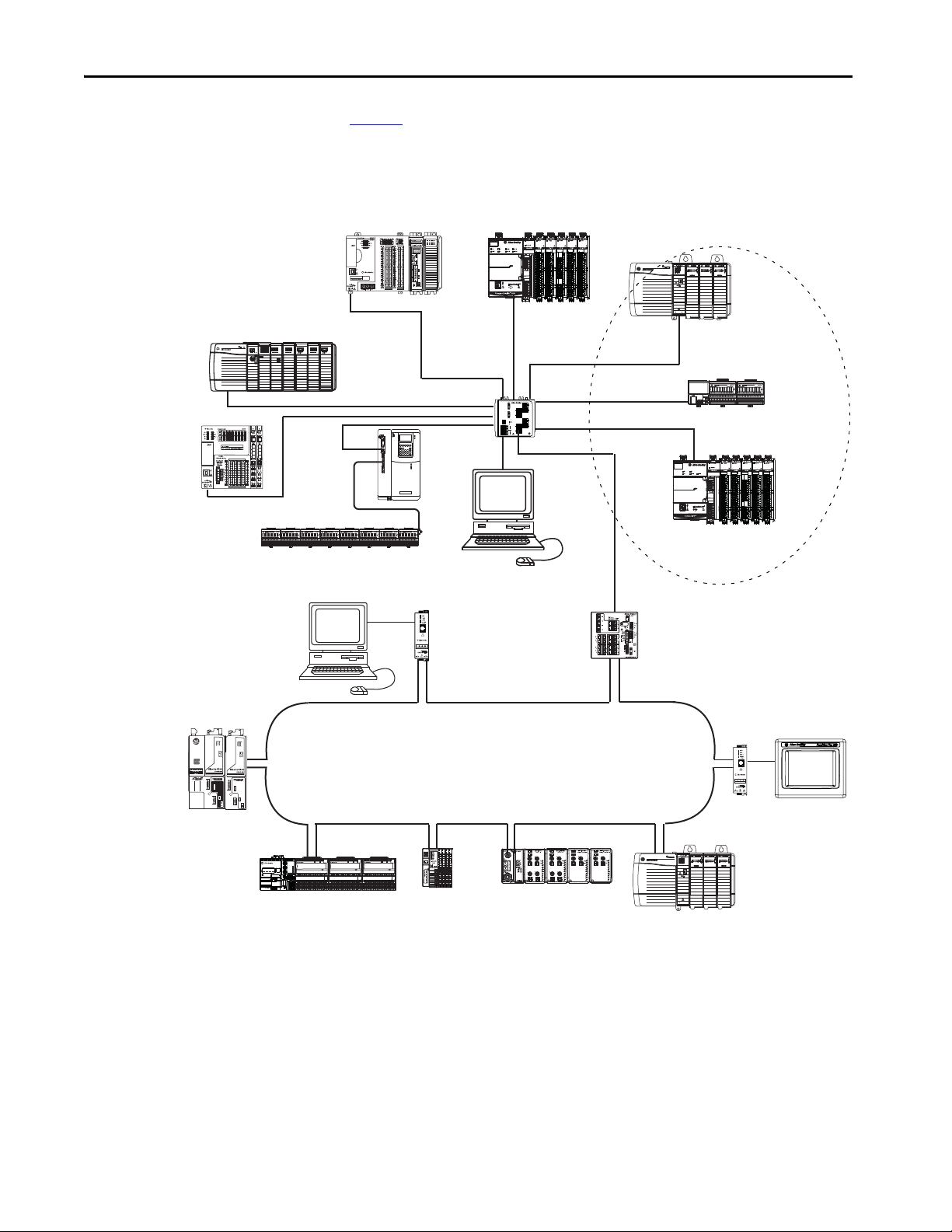

Figure 1 shows how Rockwell Automation EtherNet/IP communication

modules fit into a control system.

Figure 1 - EtherNet/IP Communication Modules in a Control System

8 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 9

ControlLogix EtherNet/IP Network Device Overview Chapter 1

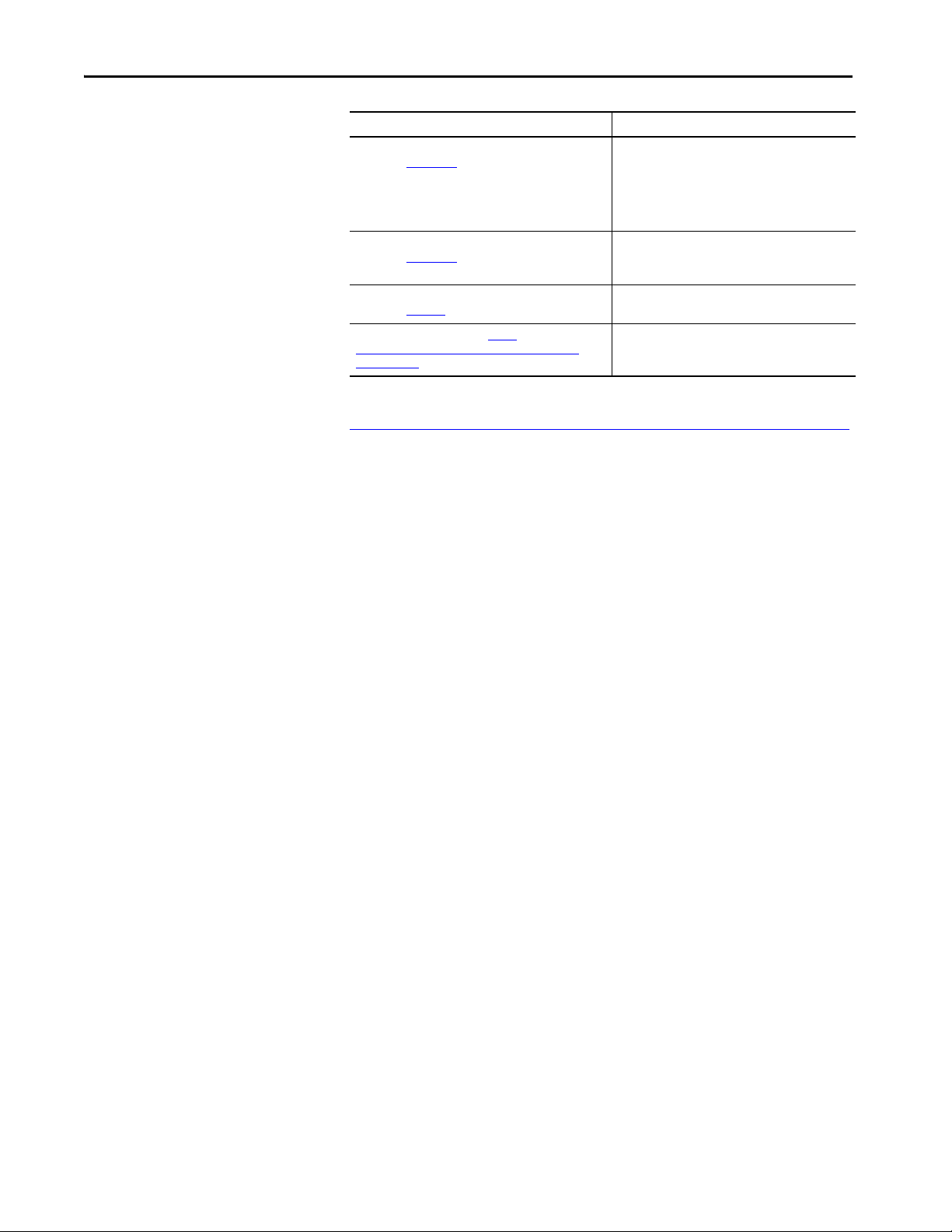

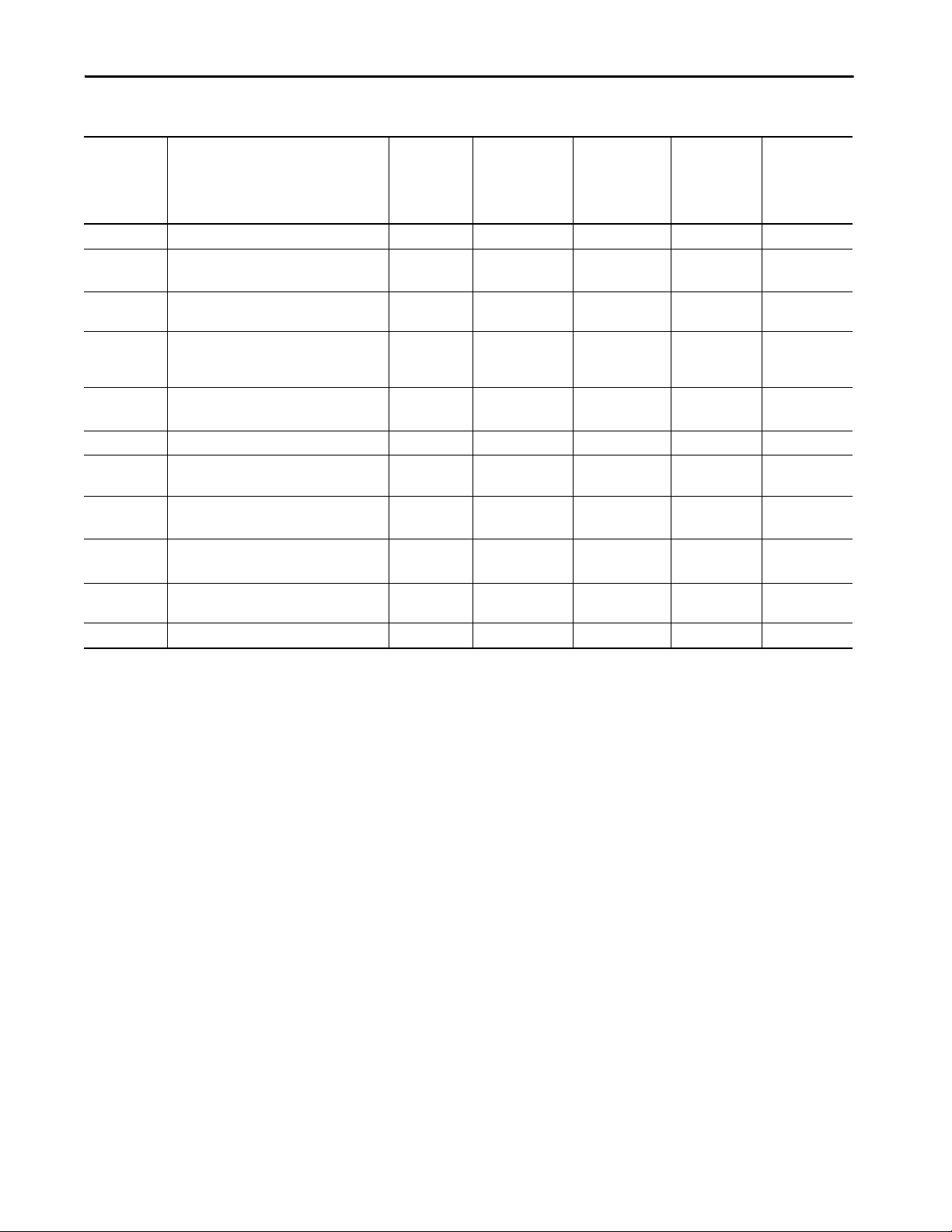

Table 1 - EtherNet/IP Communication Modules

(1)

Cat. No.

Description Media Communication

Rate

Integrated

Motion on the

EtherNet/IP

Network Axes,

Max

1756-EN2F EtherNet/IP bridge, fiber Fiber 10/100 Mbps 8 128 256

1756-EN2T

EtherNet/IP bridge, copper Copper 10/100 Mbps 8 128 256

1756-EN2TK

1756-EN2TR,

EtherNet/IP bridge, embedded switch, copper Dual copper 10/100 Mbps 8 128 256

1756-EN2TRK

1756-EN2TXT ControlLogix-XT™, extended temperature

Copper 10/100 Mbps 8 128 256

EtherNet/IP bridge, copper, for extreme

environments

1756-EN2TRXT ControlLogix-XT, extended temperature

Dual copper 10/100 Mbps 8 128 256

EtherNet/IP bridge, embedded switch, copper

1756-EN2TSC EtherNet/IP secure communication module Copper 10/100 Mbps — 128 256

1756-EN3TR,

EtherNet/IP bridge, embedded switch, copper Dual copper 10/100 Mbps 128 128 256

1756-EN3TRK

1756-EN4TR,

1756-EN4TRK

1756-EN4TRXT ControlLogix-XT, extended temperature

1756-ENBT,

EtherNet/IP bridge, embedded switch, copper Copper 10/100 Mbps

256 512 1000 I/O

1 Gbps

EtherNet/IP bridge, embedded switch, copper

Copper 10/100 Mbps

1 Gbps

256 512 1000 I/O

EtherNet/IP bridge, copper Copper 10/100 Mbps — 64 128

1756-ENBTK

1756-EWEB Ethernet web server module Copper 10/100 Mbps — 64 128

(1) A catalog number ending in a K denotes a conformal coating.

TCP

Connections

Logix

Connections

528 Messaging

528 Messaging

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 9

Page 10

Chapter 1 ControlLogix EtherNet/IP Network Device Overview

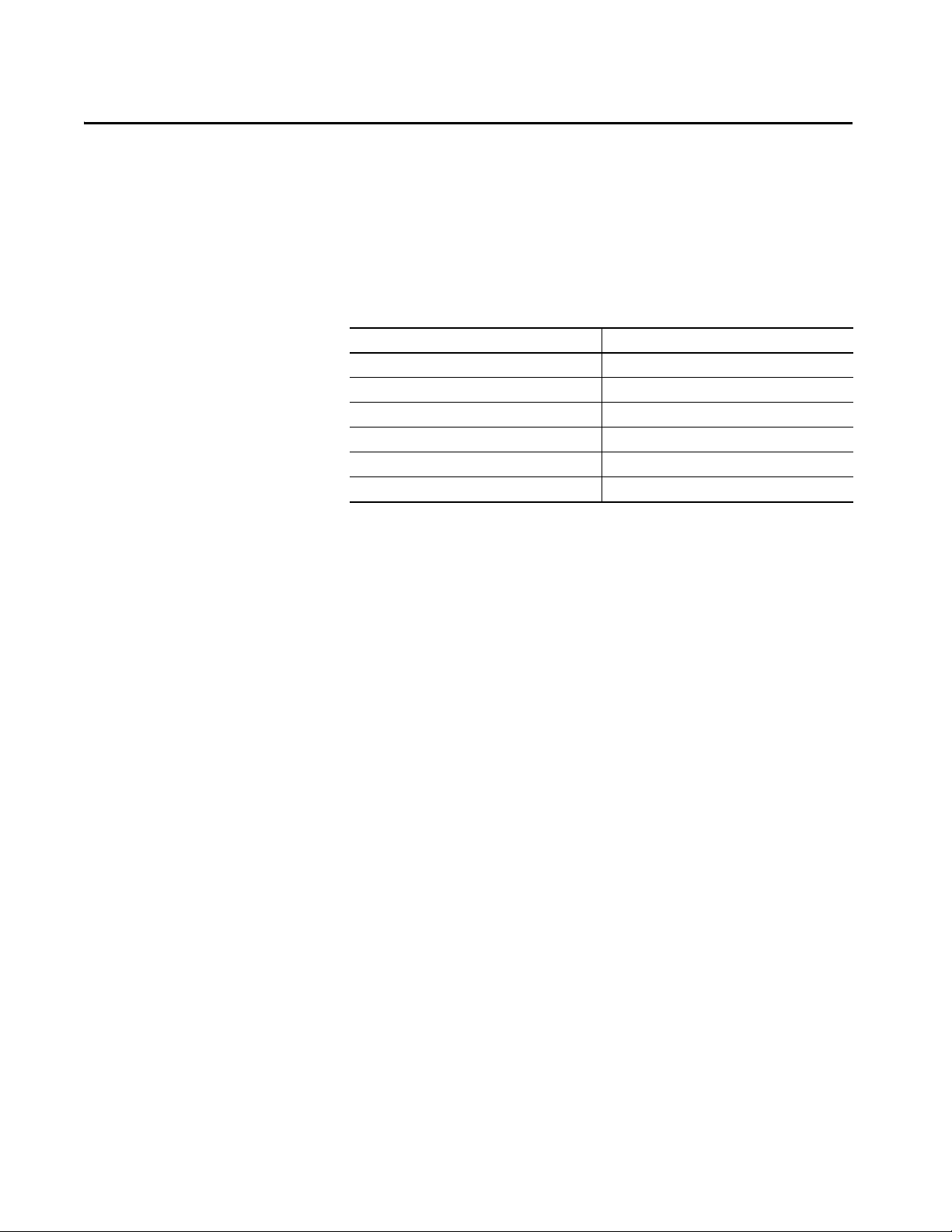

EtherNet/IP Network Specifications

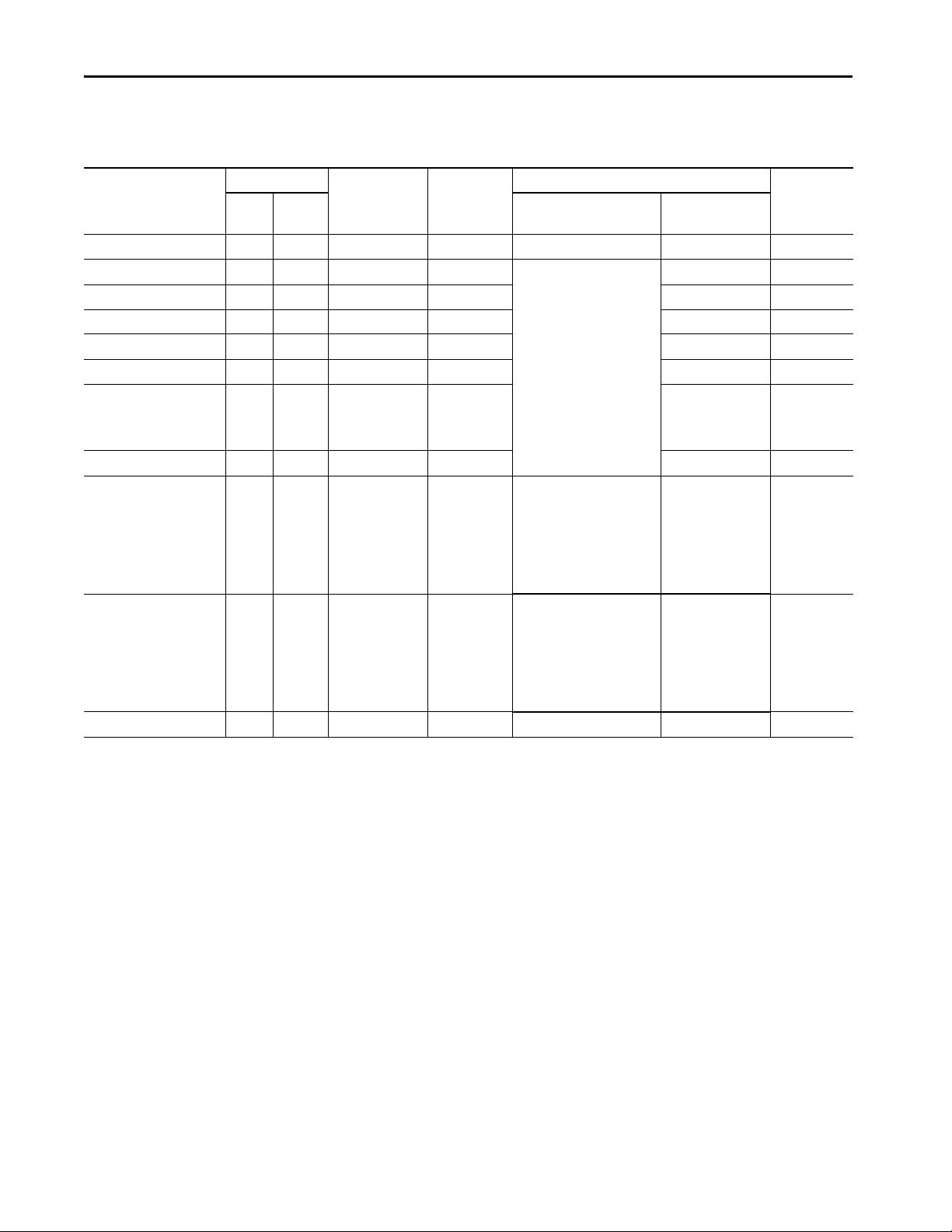

Table 2 - EtherNet/IP Network Specifications

Cat. No. Connections CIP Unconnected

TCP CIP I/O HMI and MSG

Messages

(backplane +

Ethernet Node

Count, Max

Packet Rate Capacity (packets/second)

Ethernet)

528

(1)

64 + 64 — 5000 900 Yes

(1)

128 + 128 — IMPORTANT: Packet rates for

(1)

128 + 128 — 2000 Yes

(1)

128 + 128 — 2000 Yes

(1)

128 + 128 — 2000 Yes

(1)

128 + 128 — 2000 Yes

(1)

128 + 128 — • 1800 without

(1)

128 + 128 — 2000 Yes

256+256 — • 50,000 without CIP Security

(2)

ControlLogix EtherNet/IP

communication modules

depend on series and firmware

revisio n.

• 25,000 with integrity

1756-ENBT 64 128

1756-EN2F 128 256

1756-EN2T 128 256

1756-EN2TXT 128 256

1756-EN2TR 128 256

1756-EN2TRXT 128 256

1756-EN2TSC 128 256

1756-EN3TR 128 256

1756-EN4TR 512 1000 I/O

• 15,000 with integrity and

confidentiality

1756-EN4TRXT 512 1000 I/O

528

256+256 — • 50,000 without CIP Security

(2)

• 25,000 with integrity

• 15,000 with integrity and

confidentiality

1756-EWEB 64 128

(1) CIP connections can be used for all explicit or all implicit applications. For example, a 1756-ENBT module has a total of 128 CIP connections that can be used for any combination of connections.

(2) There are 1000 CIP I/O connections and 528 CIP messaging connect ions.

(3) Total packet rate capacity = I/O Produced Tag, max + HMI/MSG, max. Packet rates vary depending on packet size. For more detailed specifications, see the EDS file for a specific catalog number.

(1)

128 + 128 — — 900 Yes

(3)

SNMP Support

(password

required)

2000 Yes

Yes

encryption

• 930 with

encryption

• 3,700 without CIP

Yes

Security

•2,700 with

integrity

•1,700 with

integrity and

confidentiality

• 3,700 without CIP

Yes

Security

•2,700 with

integrity

•1,700 with

integrity and

confidentiality

10 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 11

ControlLogix EtherNet/IP Network Device Overview Chapter 1

Electronic Keying

Electronic Keying reduces the possibility that you use the wrong device in a

control system. It compares the device that is defined in your project to the

installed device. If keying fails, a fault occurs. These attributes are compared.

Attribute Description

Vendor The device manufacturer.

Device Type The general type of the product, for example, digital I/O module.

Product Code The specific type of the product. The Product Code maps to a catalog number.

Major Revision A number that represents the functional capabilities of a device.

Minor Revision A number that represents behavior changes in the device.

The following Electronic Keying options are available.

Keying Option Description

Compatible

Module

Disable Keying Indicates that the keying att ributes are not considered when attempting to communicate with

Exact Match Indicates that all keying attributes must match to establish communication. If any attribute

Lets the installed device accept the key of the device that is defined in the project when the

installed device can emulate the defined device. With Compatible Module, you can typically

replace a device with another device that has the following characteristics:

• Same catalog number

• Same or higher Major Revision

• Minor Revision as follows:

– If the Major Revision is the same, the Minor Revision must be the same or higher.

– If the Major Revision is higher, the Minor Revision can be any number.

a device. With Disable Keying, communication can occur with a device other than the type

specified in the project.

ATT EN TI ON : Be cautious when using Disable Keying; if used incorrectly, this option can lead

to personal injury or death, property damage, or economic loss.

We strongly recommend that you do not use Disable Keying.

If you use Disable Keying, you must take full responsibility for understanding whether the

device being used can fulfill the functional requirements of the application.

does not match precisely, communication with the device does not occur.

Carefully consider the implications of each keying option when selecting one.

IMPORTANT

Changing Electronic Keying parameters online interrupts connections to the device

and any devices that are connected through the device. Connections from other

controllers can also be broken.

If an I/O connection to a device is interrupted, the result can be a loss of data.

For more detailed information on Electronic Keying, see Electronic Keying in

Logix 5000 Control Systems Application Technique, publication LOGIX-

AT001.

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 11

Page 12

Chapter 1 ControlLogix EtherNet/IP Network Device Overview

Protected Mode

The1756-EN2T, 1756-EN2TP, 1756-EN2TR, and 1756-EN4TR support

(1)

explicit protected mode.

configuration changes.

When in this mode, the module does not allow any

Enabling Explicit Protected Mode

To enable the module in an “explicit protected mode state”, follow these steps.

1. Set the rotary switches

2. Power up the device, and wait for the display to scroll, “Protected Mode

– Change Switch Settings”.

3. Power down the device.

4. Set the switches for normal operation.

5. Power up the device.

6. The device is now in Explicit Protected Mode.

Operation in Explicit Protected Mode

While working in protected mode, the module rejects any CIP™ explicit

messages that would change the configuration of the module. For example, you

cannot change the IP address, speed, or duplex settings when the module had

Explicit Protected Mode enabled.

to position ‘900’.

Disabling Explicit Protected Mode

To disable the “explicit protected mode state”, follow these steps.

1. Set the rotary switches on position ‘000’.

2. Power up the device, and wait for the display to scroll, “Unprotected

Mode – Change Switch Settings”.

3. Power down the device.

4. Set the switches for normal operation.

5. Power up the device.

6. The device is now in Unprotected Mode.

(1) Versions 11.001 and later.

12 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 13

ControlLogix EtherNet/IP Network Device Overview Chapter 1

SD Card inside front panel.

Secure Digital Card

Secure Digital Card

The 1756-EN4TR EtherNet/IP Bridge supports the use of a Secure Digital

(SD) card to store configuration data, for example, the IP address or network

communication rate for each port.

The SD card slot is inside the front panel of the module.

When the card is powered up, the device uses the configuration from the card if

the configuration does not exist in the device. When a blank card is inserted, or

powered up, the configuration is copied from the device to the card that was

inserted.

If the module powers up with a configuration that does not match the

configuration on the already inserted SD card, the configuration on the SD

card is used.

If the module is already powered, and an SD card is inserted, a warning message

is displayed.

TIP To see other potential error messages, see Table4 on page 25

To change these results, do one of two things. One option is to do an out of box

reset on the module, if you want to use the configuration on the SD card. A

second option is to modify one of the configuration settings on the device, if

you want to use the configuration on the device.

.

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 13

Page 14

Chapter 1 ControlLogix EtherNet/IP Network Device Overview

Enable/Disable Secure Digital Card

To enable or disable the SD card, use one of the following methods.

• Using a CIP Generic Message

– To enable, set Attribute 4 (‘SOCKET DISABLED’) to ‘0’ (‘False’) of

Removable Media Socket Object instance (0x3A4, 932 decimal)

– To disable, set Attribute 4 (‘SOCKET DISABLED’) to ‘1’ (‘True’)

of Removable Media Socket Object instance (0x3A4, 932 decimal).

• Enable/Disable using the Add-on Profile.

The adapter supports the use of a 1784-SD1 (1 GB) and 1784-SD2 (2 GB)

card. You can use third-party SD cards with the controller. You can use SD

cards with as much as 32 GB of memory.

IMPORTANT Rockwell Automation does not test the use of third-party SD cards with the

device.

If you use an SD card other than those cards that are available from

Rockwell Automation, unexpected results can occur. For example, you can

experience data corruption or data loss.

SD cards that are not provided by Rockwell Automation can have different

industrial, environmental, and certification ratings as those cards that are

available from Rockwell Automation. These cards can have difficulty with

survival in the same industrial environments as the industrially rated versions

available from Rockwell Automation.

14 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 15

ControlLogix EtherNet/IP Network Device Overview Chapter 1

CIP Security

CIP Security™ is a standard, open-source communication method that helps to

provide a secure data transport across an EtherNet/IP network.

The secure data transport is used between certain connected devices to help

protect the devices from threats posed by unauthorized users with malicious

intent.

CIP Security uses encryption to secure communication on an EtherNet/IP

network, resulting in greater data integrity and confidentiality.

Rockwell Automation uses the following products to implement CIP Security:

• FactoryTalk® Policy Manager

•FactoryTalk Linx

• Studio 5000® Design Environment

• CIP Security-enabled Rockwell Automation® products, for example, the

product described in this publication

(1)

For more information on CIP Security, including which products support CIP

Security, see the CIP Security Application Technique, publication SECURE-

AT001.

(1) In this document, CIP Security is applicable to 1756-EN4TR, 1756-ENRTRK, and 1756-EN4TRXT m odules.

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 15

Page 16

Chapter 1 ControlLogix EtherNet/IP Network Device Overview

Notes:

16 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 17

Chapter 2

Connect to the EtherNet/IP Network

Top ic Pag e

Set the IP Address 18

Set the IP Address with Rotary Switches 18

Other Methods to Set the IP Address 19

Reset the Module IP Address to Factory Default Value 19

EtherNet/IP™ networks are communication networks that offer a

comprehensive suite of messages and services for many automation

applications.

The following are examples of applications that use EtherNet/IP networks:

•Real-Time Control

• Time Synchronization

•Motion

This open network standard uses commonly available Ethernet

communication products to support real-time I/O messaging, information

exchange, and general messaging.

EtherNet/IP networks also support CIP Safety™, which makes the

simultaneous transmission of safety and standard control data and diagnostics

information over a common network possible.

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 17

Page 18

Chapter 2 Connect to the EtherNet/IP Network

Set the IP Address

Set the IP Address with Rotary Switches

The following conditions are required to set the IP address.

Requirements

To set the IP address, have the following:

• EtherNet/IP or USB drivers that are installed on the programming

workstation

• MAC ID from the device, which is on the label on the side of the device

• Recommended IP address for the device

This graphic shows the rotary switches on a 1756 EtherNet/IP communication

module. The three rotary switches at the bottom of the module, labeled X, Y,

and Z, can be used for setting the IP address. The rotary switch in the upper

left corner of the module is reserved for future configuration.

At powerup, the module reads the rotary switches to determine if they are set

to a valid number for the last portion of the IP address. Valid numbers range

from 001…254.

18 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 19

Connect to the EtherNet/IP Network Chapter 2

If the settings are a valid number, these conditions result:

• IP address = 192.168.1.xxx (where xxx represents the switch settings)

• Subnet mask = 255.255.255.0

• Gateway address = 0.0.0.0

TIP Some modules now provide a gateway address of 192.168.1.1 when the

network address is set with rotary switches.

• The module does not have a host name that is assigned to it, nor does it

use any Domain Name System

We recommend that you set the rotary switches to a valid number before

installing the module.

If the rotary switches are not set to a valid number, the module attempts to use

the BOOTP/DHCP server to set the IP address.

IMPORTANT For more information on how to use the BOOTP/DHCP server to set the IP

address, see EtherNet/IP Network Configuration Manual,

publication ENET-UM006

Other Methods to Set the IP Address

Reset the Module IP Address to Factory Default Value

The 1756-EN4TR module supports the following additional methods to

change the IP address:

• BOOTP/DHCP utility

• RSLinx® Classic software

• Using Secure Digital Card

• For more information on how to use these methods, see EtherNet/IP

Network Configuration Manual, publication ENET-UM006

You can reset the configuration of the module to its factory default value with

the following methods:

• If the module has rotary switches, set the switches to 888 and cycle

power.

.

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 19

Page 20

Chapter 2 Connect to the EtherNet/IP Network

Notes:

20 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 21

Appendix A

LINK NET OK

10/100 BASE T

EtherNet/IP

TM

LINK NET OK

OK Status Indicator

Module Status Display

Link Status

Indicator (LINK)

Network Status Indicator (NET)

Module Status Display

OK Status Indicator

Network Status Indicator (NET)

Link Status

Indicators (LINK)

ControlLogix Network Device Status Indicators

Top ic Pag e

Status Indicators 21

Single-Port Module Status Indicators 24

Dual-Port Module Status Indicators 25

Status Indicators

The following graphics show the status indicators for these modules (extendedtemperature versions not shown).

Figure 2 - 1756-EN2F, 1756-EN2T (Single-port Modules)

Figure 3 - 1756-EN2TR, 1756-EN3TR (Dual-port Modules)

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 21

Page 22

Appendix A ControlLogix Network Device Status Indicators

1756-EN2TP

Link Status

Indicators (LINK)

OK Status Indicator

Network Status Indicator (NET)

Module Status Display

VPN

Network Status Indicator (NET)

OK Status Indicator

Module Status Display

Link Status

Indicator (LINK)

Link Status

Indicators (LINK)

Network Status Indicator (NET)

OK Status Indicator

Module Status Display

Parallel Redundant Protocol

Status Indicator

Redundant Adapte r Status Indicator

SD Card Status Indicator

Figure 4 - 1756-EN2TP (Dual-port Module)

Figure 5 - 1756-EN2TSC (Single-port Module)

Figure 6 - 1756-EN4TR (Dual-port Module)

(1)

(1) Parallel Redundant Protocol and Redundant Adapter features are not available in the initial release. Check the

Product Compatibility and Download Center (PCDC)

to see if it is available in your firmware revision.

22 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 23

Figure 7 - 1756-ENBT (Single-port Module)

VPN

Module Status Display

OK Status Indicator

Network Status Indicator (NET)

Link Status

Indicator (LINK)

Link Status

Indicator (LINK)

Network Status Indicator (NET)

OK Status Indicator

Module Status Display

Figure 8 - 1756-EWEB (Single-port Module)

ControlLogix Network Device Status Indicators Appendix A

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 23

Page 24

Appendix A ControlLogix Network Device Status Indicators

Single-Port Module Status Indicators

Table 3 - Single-port Module Status Indicators

Status Indicator Description Status State

Module Status Display Alphanumeric display that scrolls messages. For example,

when a module is operating normally, the display scrolls

the module’s IP address.

Link Status (LINK) Indicates the current state of the module regarding

transmission of data on the EtherNet/IP™ network.

OK Status (OK) Indicates the current state of the module. For example, this

status indicator indicates if the module is executing

power-up testing, in the process of a firmware update or

operating normally.

Network Status (NET) Indicates if CIP™ connections are established. Off One of these conditions exists:

——

Off One of these conditions exists:

• The module is not powered.

– Verify that there is chassis power.

– Verify that the module is completely inserted

into the chassis and backplane.

– Make sure that the module has been

configured.

• No link exists on the port.

Flashing green Activity exists on the port.

Green The port is active, but not receiving traffic.

Off The module is not powered.

• Verify that there is chassis power.

• Verify that the module is completely inserted into

the chassis and backplane.

• Make sure that the module has been configured.

Flashing green The module is not configured. The Module Status

display scrolls: BOOTP or

DHCP<Mac_address_of_module>

For example: BOOTP 00:0b:db:14:55:35

Configure the module.

Green The module is operating correctly. The IP address

scrolls across the Module Status disp lay.

Flashing red The module detected a recoverable minor fault. Check

the module configuration. If necessary, reconfigure

the module.

Red The module detected an unrecoverable major fau lt.

Cycle power to the module. If this power cycle does not

clear the fault, replace the module.

• The module is not powered.

– Verify that there is chassis power.

– Verify that the module is completely inserted

into the chassis and backplane.

– Make sure that the module has been

configured.

• The module is powered but does not have an IP

address. Assign an IP address to the module.

Flashing green The controller has an IP address and one of these

conditions exists:

• The module has not established any CIP

connections.

If connections are configured for this module,

check the connection originator for the connection

error code.

• All connections to the device have timed out or

been closed.

24 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 25

ControlLogix Network Device Status Indicators Appendix A

Table 3 - Single-port Module Status Indicators

Status Indicator Description Status State

Network Status (NET) Indicates if CIP connections are established. Green The module has established at least 1 CIP connection

Red The module is in conflict mode. It shares an IP address

Flashing green/flashing

red

and is operating properly. The IP address scrolls across

the Module Status display.

with another device on the network. The current IP

address scrolls across the Module Status display. The

display scrolls: OK <IP_address_of_this_module>

Duplicate IP

<Mac_address_of_duplicate_node_detected>

For example: OK 10.88.60.196 Duplicate IP 00:00:BC:02:34:B4

Change the IP address of the module.

The module is performing its power-up testing.

Dual-Port Module Status Indicators

Table 4 - Dual-port Module Status Indicators

Status Indic ator Description Status State

Module Status Display Alphanumeric display that scrolls messages. For

example, when a module is operating normally, the

display scrolls the module’s IP address.

OK Indicates the current state of the module. For

example, this status indicator indicates if the module

is executing power-up testing, in the process of a

firmware update or operating normally.

——

Off The module is not powered.

• Verify that there is chassis power.

• Verify that the module is completely inserted into the chassis

and backplane.

• Make sure that the module has been configured.

Flashing green The module is not configured. The Module Status display scrolls:

Green The module is operating correctly. The Module Status display

Flashing red The module detected a recoverable minor fault. Check the

Red The module detected an unrecoverable major fault. Cycle power

Both of these

conditions exist:

•Status Indicator is

Red

•Module Status

Display is scrolling:

Image Update

Needed

Flashing red and green The module is performing its power-up testing.

BOOTP or DHCP<Mac_address_of_module>

For example: BOOTP 00:0b:db:14:55:35

Configure the module.

scrolls: OK <IP_address_of_this_module>

For example: OK 10.88.60.160

module configuration. If neces sary, reconfigure the module.

to the module. If this power cycle does not clear the fault, replace

the module.

The module’s main firmware image must be updated. Follow

these steps:

1. Update the firmware image.

2. Cycle power to the module.

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 25

Page 26

Appendix A ControlLogix Network Device Status Indicators

Table 4 - Dual-port Module Status Indicators

Status Indic ator Description Status State

Network Status (NET) Indicates if CIP connections are established.

IMPORTANT: The new-series 1756-EN2TR and

1756-EN3TR modules have a NET status indicator.

The older-series 1756-EN2TR and 1756-EN3TR

modules do not have a NET status indicator.

Link Status

(LINK 1, LINK 2)

Link Status

(LAN A, LAN B)

Off One of these conditions exists:

• The module is not powered.

• The module is powered but does not have an IP address.

Flashing green The controller has an IP address and one of these conditions

Green The module has established at least 1 CIP connection and is

Red The module is in conflict mode. It shares an IP address with

Flashing green/

flashing red

Off One of these conditions exists:

Flashing green Activity exists on the port.

Green One of these conditions exists:

Flashing red When the corresponding LAN A/B Parallel Redundancy Protocol

exists:

• The module has not established any CIP connections.

• All connections to the device have timed out or been closed.

operating properly. The IP address scrolls across the Module

Status display.

another device on the network. The module’s current IP address

scrolls across the Module Status display. The display scrolls: OK

<IP_address_of_this_module> Duplicate IP

<Mac_address_of_duplicate_node_detected>

For example: OK 10.88.60.196 Duplicate IP - 00:00:BC:02:34:B4

Change the module’s IP address.

The module is performing its power-up testing.

• The module is not powered.

• No link exists on the port.

•The port is administratively disabled.

• The port is disabled due to rapid ring faults (LNK2).

• A link exists on the port, but no traffic is being received.

• The ring network is operating normally on active ring

• A ring partial network fault was detected on the active ring

(PRP) Warning bit is set.

– Verify that there is chassis power.

– Verify that the module is completely inserted into the

chassis and backplane.

– Make sure that the module has been configured.

Assign an IP address to the module.

If connections are configured for this module, check the

connection originator for the connection error code.

– Verify that there is chassis power.

– Verify that the module is completely inserted into the

chassis and backplane.

– Make sure that the module has been configured.

supervisor (LNK2).

supervisor (LNK2).

26 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 27

Table 4 - Dual-port Module Status Indicators

Status Indic ator Description Status State

(1)

SD

Parallel Redundanc y

Protocol (PRP)

(1)

Redundant Adapter (RA)

(1) Status indicators only available on the 1756-EN4TR, 1756-EN4TRK, 1756-EN4TRXT.

The SD indicator shows if the SD card is in use Off No activity is occurring with the SD card. You can safely remove

the card, if necessary.

Flashing green The module is reading from or writing to the SD card.

Solid green

IMPORTANT: Do not remove the SD card while the module is

reading or writing. Let the read/write complete without

interruption. If you interrupt the read/write, data corruption or

loss can occur.

Flashing red One of the following exists:

• The SD card does not have a valid file system.

• The SD card drew excessive current and power has been

Solid red The module does not recognize the SD card.

Check Firmware Revision for availability of this feature.

(1)

Check Firmware Revision for availability of this feature.

ControlLogix Network Device Status Indicators Appendix A

removed from the card.

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 27

Page 28

Appendix A ControlLogix Network Device Status Indicators

Notes:

28 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 29

Index

A

additional resources 5

B

BOOTP/DHCP utility 19

C

CIP security 15

compatible modules

control system

conventions

8

5

D

device type 11

dual-port module

25

E

electronic keying 11

changing parameters

disable keying

EtherNet/IP 7

communication modules

connect to network

control system

EtherNet/IP network

module features

specifications

11

8

10

10

11

17

11

R

real-time I/O messaging 7

S

secure digital card (SD) 13

single-port module

specifications

EtherNet/IP network

status indicators

1756-EN2T

1756-EN2TP 22

1756-EN2TR

1756-EN2TSC

1756-EN4TR 22

1756-ENBT

1756-EWEB

dual-port

single-port

24

10

21

21

22

23

23

25

24

V

vendor 11

9

I

IP Address

factory default

requirements

rotary switches

set the IP address

19

18

18

18

M

major revision 11

minor revision

11

N

network

specifications

10

P

product code 11

protected mode

disabling

enabling explicit protected mode

operation in explicit protected mode

12

12

12

12

Rockwell Automation Publication 1756-UM004A-EN-P - March 2019 29

Page 30

Index

Notes:

30 Rockwell Automation Publication 1756-UM004A-EN-P - March 2019

Page 31

Page 32

Rockwell Automation Support

Use the following resources to access support information.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document, complete the

How Are We Doing? form at http://literature.rockwellautomation.com/idc/groups/literature/documents/du/ra-du002_-en-e.pdf

.

Technical Support Center

Knowledgebase Articles, How-to Videos, FAQs, Chat, User

Forums, and Product Notification Updates.

https://rockwellautomation.custhelp.com/

Local Technical Support Phone Numbers Locate the phone number for your country. http://www.rockwellautomation.com/global/support/get-support-now.page

Direct Dial Codes

Find the Direct Dial Code for your product. Use the code to

route your call directly to a technical support engineer.

http://www.rockwellautomation.com/global/support/direct-dial.page

Literature Library

Installation Instructions, Manuals, Brochures, and

Technical Data.

http://www.rockwellautomation.com/global/literature-library/overview.page

Product Compatibility and Download

Center (PCDC)

Get help determining how products interact, check

features and capabilities, and find associated firmware.

http://www.rockwellautomation.com/global/support/pcdc.page

.

Rockwell Automation maintains current product env ironmental information on its website at http://www.rockwellautomation.com/rockwellautomation/about- us/sustainability-ethics/product- environmental-compliance.page.

Allen-Bradley, Compact 5000, ControlFLASH Plus, CompactLogix, ControlLogix, FactoryTalk, FLEX 5000, Logix 5000, PanelView, PowerFlex, Rockwell Software, Rockwell Automation, and Stratix are trademarks of Rockwell Automation,

Inc.

CIP, DeviceNet, and EtherNet/IP are trademarks of ODVA, Inc.

Trademarks not belonging to Rockwell Automation are property of their respec tive companies.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Publication 1756-UM004A-EN-P - March 2019

Copyright © 2019 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...