Page 1

Installation Instructions

SLC™ 500 4-Channel Thermocouple/mV Input

Module

(Catalog Number 1746-NT4, Series B)

Inside…............................................................................................Page

For More Information............................................................................... 3

Hazardous Location Considerations .........................................................4

Environnements dangereux ..................................................................... 4

Overview ...................................................................................................5

Required Tools and Equipment................................................................ 6

Electrostatic Damage............................................................................... 7

NT4 Power Requirements........................................................................ 7

Modular Chassis Considerations............................................................. 7

Fixed Expansion Chassis Considerations................................................. 8

General Considerations ........................................................................... 8

Terminal Block Removal........................................................................... 8

Module Installation and Removal.......................................................... 10

Terminal Wiring...................................................................................... 11

Thermocouple Junctions........................................................................ 12

Wiring Considerations ........................................................................... 13

Wiring Input Devices to the NT4 ........................................................... 15

Cold-Junction Compensation (CJC) ....................................................... 16

Module Addressing................................................................................ 17

Channel Configuration ........................................................................... 17

Specifications ........................................................................................ 19

Publication 1746-IN010D-EN-P - June 2004

Page 2

2 SLC™ 500 4-Channel Thermocouple/mV Input Module

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences between solid state equipment and

hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage,

or economic loss.

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information that is critical for successful application and understanding of the

product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the drive to alert people that dangerous voltage may

be present.

Labels may be located on or inside the drive to alert people that surfaces may be

dangerous temperatures.

Publication 1746-IN010D-EN-P - June 2004

Page 3

SLC™ 500 4-Channel Thermocouple/mV Input Module 3

For More Information

Related Publications

For: Refer to this Document: Pub. No.

A more detailed description on how to install and

use your SLC 500 4-Channel Thermocouple/mV Input

Module.

A more detailed description on how to install and

use your SLC 500 Modular Hardware Style Control

System.

A more detailed description on how to install and

use your SLC 500 Fixed Hardware Style Control

System.

Thermocouple/mV Input Module

User Manual

SLC™ 500 Modular Hardware

Style User Manual

SLC™ 500 Fixed Hardware Style

Installation and Operation Manual

If you would like a manual, you can:

• download an electronic version from the internet:

www.theautomationbookstore.com

• order a printed manual by:

– contacting your local distributor or Rockwell Automation representative

– visiting www.theautomationbookstore.com

– calling 1.800.963.9548 (USA/Canada) or 001.330.725.1574 (Outside

USA/Canada)

1746-6.6.1

1747-UM011

1747-6.21

Publication 1746-IN010D-EN-P - June 2004

Page 4

4 SLC™ 500 4-Channel Thermocouple/mV Input Module

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

non-hazardous locations only. The following WARNING statement applies to use in

hazardous locations.

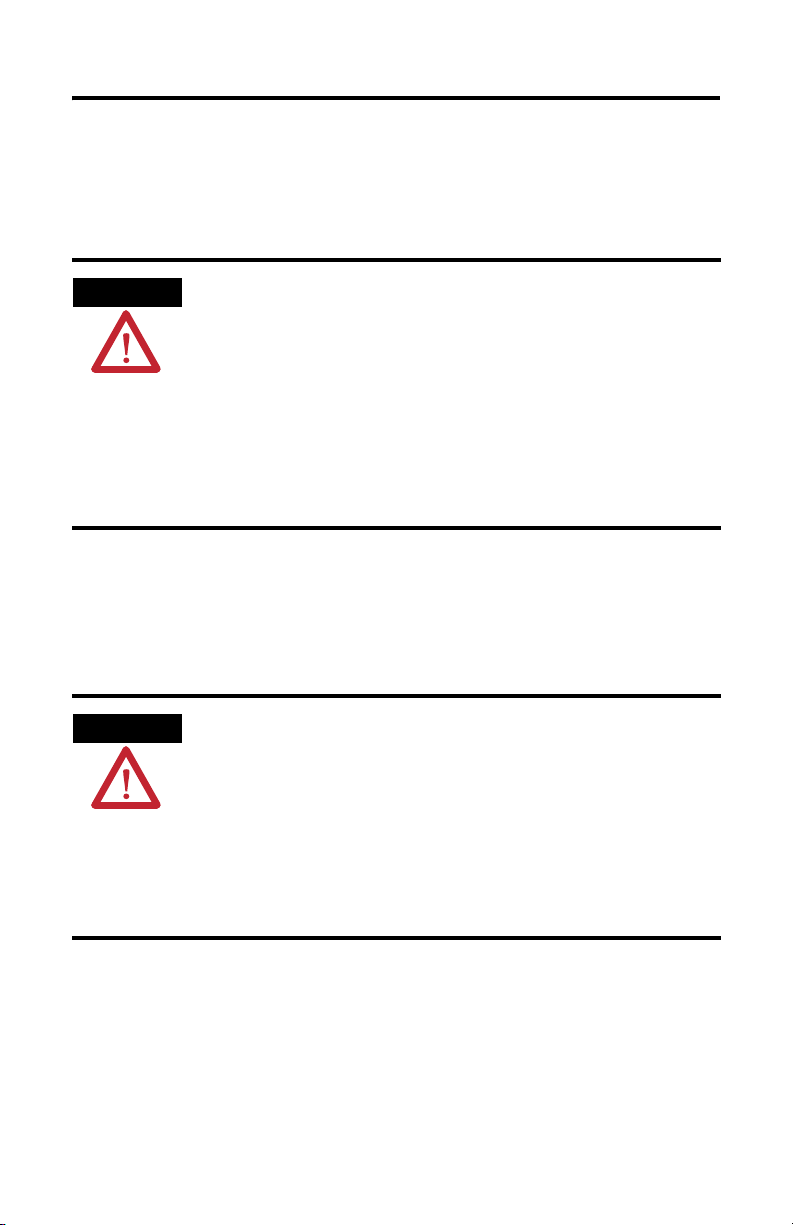

WARNING

EXPLOSION HAZARD

• Substitution of components may impair suitability for Class

I, Division 2.

• Do not replace components or disconnect equipment

unless power has been switched off or the area is known to

be non-hazardous.

• Do not connect or disconnect components unless power

has been switched off or the area is known to be

non-hazardous.

• All wiring must comply with N.E.C. article 501-4(b).

Environnements dangereux

Cet équipement est conçu pour être utilisé dans des environnements de Classe I,

Division 2, Groupes A, B, C, D ou non dangereux. La mise en garde suivante

s’applique à une utilisation dans des environnements dangereux.

WARNING

DANGER D’EXPLOSION

• La substitution de composants peut rendre cet équipement

impropre à une utilisation en environnement de Classe I,

Division 2.

• Ne pas remplacer de composants ou déconnecter

l'équipement sans s'être assuré que l'alimentation est

coupée.

• Ne pas connecter ou déconnecter des composants sans

s'être assuré que l'alimentation est coupée.

Publication 1746-IN010D-EN-P - June 2004

Page 5

SLC™ 500 4-Channel Thermocouple/mV Input Module 5

Overview

The thermocouple/mV input module receives and stores digitally converted

thermocouple and/or millivolt (mV) analog data into its image table for retrieval by

all fixed and modular SLC 500 processors. The module supports connections from

any combination of up to four thermocouple or mV analog sensors. See the input

specifications beginning on page 21 for thermocouple types, their associated

temperature ranges, and the analog input signal ranges that each 1747-NT4 channel

will support. Each input channel is individually configurable via software for a

specific input device and provides open-circuit, over-range, and under-range

detection and indication.

The module contains a removable terminal block with two cold-junction

compensation (CJC) sensors. There are no output channels on the module.

Configuration is done via the user program. There are no DIP switches.

Channel Status LEDs

Channel status LEDs indicate the status for channels 0 through 3. Related error

information is contained in the channel status word. This includes conditions such

as:

• normal operation

• channel-related configuration errors

• open-circuit errors

• out-of-range errors

All channel errors are recoverable errors.

Module Status LED

The module status LED shows diagnostic or operating errors related to the module.

These non-recoverable errors may be detected during power-up or during

operation. Once an error has been detected, the module no longer communicates

with the SLC processor. Channel states are disabled, and data words are cleared (0).

Failure of any diagnostic test results in a non-recoverable error and requires the

assistance of your local Allen-Bradley distributor or Rockwell Automation

representative.

Publication 1746-IN010D-EN-P - June 2004

Page 6

6 SLC™ 500 4-Channel Thermocouple/mV Input Module

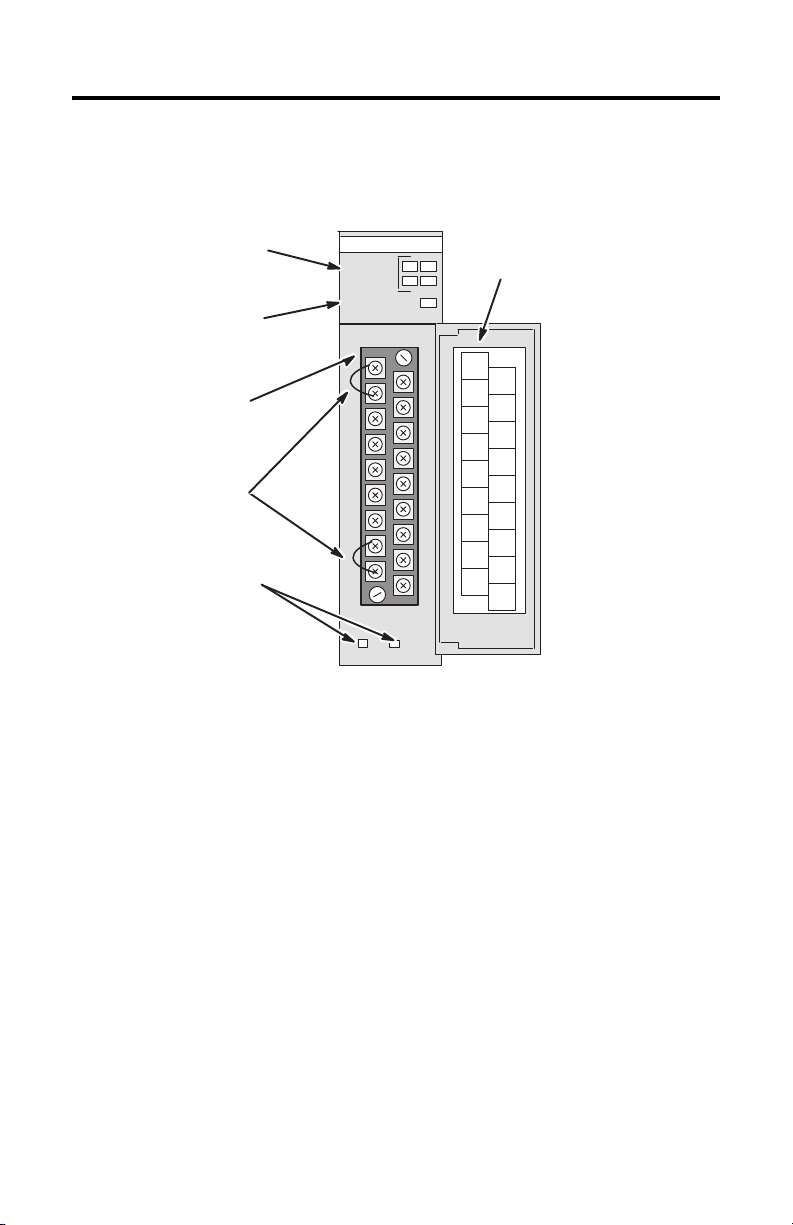

1747-NT4 Thermocouple Module Hardware Features

Channel Status

LEDs (Green)

Module Status

LED (Green)

INPUT

CHANNEL

STATUS

MODULE STATUS

THERMOCOUPLE/mV

012

3

Removable

Ter m ina l Bl ock

CJC Sensors

Cable Tie Slots

Required Tools and Equipment

Have the following tools and equipment ready:

• medium blade screwdriver

• medium cross-head screwdriver

• thermocouple or millivolt sensor

• appropriate thermocouple extension wire (if needed)

• thermocouple/mV input module (1746-NT4)

• programming equipment

Door Label

CJC A+

Do Not

Remove

CHL0+

CJC A±

Do Not

Remove

CHL0-

SHIELD

CHL1+

SHIELD

CHL1-

SHIELD

CHL2+

SHIELD

CHL2-

SHIELD

CHL3+

CJC B±

Do Not

CHL3-

Remove

CJC B+

Do Not

Remove

ANLG

COM

Publication 1746-IN010D-EN-P - June 2004

Page 7

SLC™ 500 4-Channel Thermocouple/mV Input Module 7

Electrostatic Damage

Electrostatic discharge can damage semiconductor devices inside this module if you

touch backplane connector pins. Guard against electrostatic damage by observing

the following precautions.

ATTENTION

• Wear an approved wrist strap grounding device when handling the module.

• Touch a grounded object to rid yourself of electrostatic charge before

handling the module.

• Handle the module from the front, away from the backplane connector. Do

not touch backplane connector pins.

• Keep the module in its static-shield bag when not in use, or during

shipment.

Electrostatic discharge can degrade performance or cause

permanent damage. Handle the module as stated below.

NT4 Power Requirements

The thermocouple module receives its power through the SLC 500 chassis

backplane from the fixed or modular +5V dc/+24V dc chassis power supply. The

maximum current drawn by the module is shown in the table below.

5V dc Amps 24V dc Amps

0.060 0.040

When you are using a modular system configuration, add the values shown in the

table above to the requirements of all other modules in the SLC chassis to prevent

overloading the chassis power supply.

When you are using a fixed system controller, refer to the important note on page 8

about module compatibility in a 2-slot fixed expansion chassis.

Modular Chassis Considerations

Place your thermocouple module in any slot of an SLC 500 modular, or modular

expansion chassis, except for the extreme left slot (slot 0) in the first chassis. This

slot is reserved for the processor or adapter modules.

Publication 1746-IN010D-EN-P - June 2004

Page 8

8 SLC™ 500 4-Channel Thermocouple/mV Input Module

Fixed Expansion Chassis Considerations

IMPORTANT

The 2-slot, SLC 500 fixed I/O expansion chassis (1746-A2) will

support only specific combinations of modules. If you are using

the thermocouple module in a 2-slot expansion chassis with

another SLC I/O or communication module, refer to the

SLC 500™Thermocouple/mV Input Module User Manual,

1746-6.6.1

General Considerations

Most applications require installation in an industrial enclosure to reduce the effects

of electrical interference. Thermocouple inputs are highly susceptible to electrical

noises due to the small amplitudes of their signal (microvolt/°C).

Group your modules to minimize adverse effects from radiated electrical noise and

heat. Consider the following conditions when selecting a slot for the thermocouple

module. Position the module:

• in a slot away from sources of electrical noise, such as hard-contact switches,

relays, and AC motor drives

• away from modules which generate significant radiated heat, such as

32-point I/O modules

In addition, route shielded, twisted-pair thermocouple or millivolt input wiring

away from any high-voltage I/O wiring.

Terminal Block Removal

When installing the module in a chassis, it is not necessary to remove the terminal

block from the module. However, if the terminal block is removed, use the write-on

label located on the side of the terminal block to identify the module location and

type.

ATTENTION

Publication 1746-IN010D-EN-P - June 2004

Disconnect power to the SLC before attempting to install,

remove, or wire the removable terminal wiring block.

To avoid cracking the removable terminal block, alternate the

removal of the slotted terminal block release screws.

Page 9

SLC™ 500 4-Channel Thermocouple/mV Input Module 9

To remove the terminal block:

1. Loosen the two terminal block release screws.

2. Grasp the terminal block at the top and bottom and pull outward and down.

When removing or installing the terminal block, be careful not to damage

the CJC sensors.

Terminal Block Release Screws

CJC Sensors

Max. Torque = 0.7 to 0.9 Nm (6 to 8

in-lb)

Publication 1746-IN010D-EN-P - June 2004

Page 10

10 SLC™ 500 4-Channel Thermocouple/mV Input Module

Module Installation and Removal

Module Installation Procedure

1. Align the circuit board of the thermocouple module with the card guides

located at the top and bottom of the chassis.

2. Slide the module into the chassis until both top and bottom retaining clips

are secured. Apply firm even pressure on the module to attach it to its

backplane connector. Never force the module into the slot.

3. Cover all unused slots with the Card Slot Filler, Catalog Number 1746-N2.

Top and Bottom Module

Card

Guide

Module Removal Procedure

1. Press the releases at the top and bottom of the module and slide the module

out of the chassis slot.

2. Cover all unused slots with the Card Slot Filler, Catalog Number 1746-N2.

Publication 1746-IN010D-EN-P - June 2004

Page 11

SLC™ 500 4-Channel Thermocouple/mV Input Module 11

Terminal Wiring

The thermocouple module contains a green, 18-position, removable terminal block.

The terminal pin-out is shown below.

ATTENTION

Disconnect power to the SLC before attempting to install,

remove, or wire the removable terminal wiring block.

(Terminal Block Spare Part Catalog Number 1746-RT32)

CJC Assembly

Shield

Shield

Shield

Shield

Shield

CJC Assembly

Release Screw Max. Torque =

0.7 to 0.9 Nm (6 to 8 in-lb)

CJC A+

CJC A-

CJC B+

CJC B-

Release Screw Max. Torque =

0.7 to 0.9 Nm (6 to 8 in-lb)

Channel 0+

Channel 0-

Channel 1+

Channel 1-

Channel 2+

Channel 2-

Channel 3+

Channel 3-

Analog Common

(1)

below]

[see

(1) Replacing a Series A thermocouple module with a Series B module requires that the bottom right terminal (which was

SHIELD on Series A modules) no longer be connected to CHASSIS GROUND if it was previously. Use one of the other

SHIELD terminals.

Terminal screws accept a maximum of two #14 AWG (2 mm

2

) wires. Tighten

terminal screws only tight enough to immobilize wires. Maximum torque on

terminal screws is 0.7 to 0.9 Nm (6 to 8 in-lbs).

Publication 1746-IN010D-EN-P - June 2004

Page 12

12 SLC™ 500 4-Channel Thermocouple/mV Input Module

Thermocouple Junctions

There are three types of thermocouple junctions:

• Grounded Junction - The measuring junction is physically connected to the

protective metal sheath providing electrical continuity between junction and

sheath.

• Ungrounded Junction - The measuring junction is electrically isolated from

the protective metal sheath. (Also called Insulated Junction.)

• Exposed Junction - Does not have a protective metal sheath so the

measuring junction is exposed.

The illustration that follows shows each of the three thermocouple types.

Extension Wire

Metal Sheath

Measuring Junction is isolated from sheath.

Measuring Junction has no sheath.

Measuring Junction is connected to sheath.

Grounded Junction

Ungrounded (Insulated)

Junction

Exposed Junction

Publication 1746-IN010D-EN-P - June 2004

Page 13

Wiring Considerations

SLC™ 500 4-Channel Thermocouple/mV Input Module 13

ATTENTION

Follow the guidelines below when planning your system wiring.

• To limit noise, keep thermocouple and millivolt signal wires as far away as

possible from power and load lines.

• To ensure proper operation and high immunity to electrical noise, always

use Belden™ 8761 (shielded, twisted-pair) or equivalent wire for millivolt

sensors or shielded, twisted-pair thermocouple extension lead wire specified

by the thermocouple manufacturer for the thermocouple type you are using.

Using the incorrect thermocouple extension wire type or not following the

correct polarity convention will cause invalid readings.

• Special considerations for using the analog common (ANALOG COM)

terminal based on thermocouple type:

(See page 12 for an explanation of thermocouple junctions.)

– When using grounded thermocouple(s), jumper the ANALOG COM

terminal to any single active grounded channel’s plus (+) or minus (-)

terminal.

– When using exposed thermocouple(s) that have the thermocouple

junction touching an electrically conductive material, jumper the

ANALOG COM terminal to any single active exposed channel’s plus (+)

or minus (-) terminal.

– When using ungrounded (shielded) or exposed thermocouples that are

not touching an electrically conductive material, do not use the

ANALOG COM terminal.

– When using a mix of grounded, ungrounded, and exposed

thermocouples, jumper the ANALOG COM terminal to any single active

grounded channel’s plus (+) or minus (-) terminal.

The possibility exists that grounded or exposed thermocouples

can become shorted to a potential greater than that of the

thermocouple itself. Due to possible shock hazard, care should

be taken when wiring these types of thermocouples. See

page 12 for definitions of thermocouple junctions.

Publication 1746-IN010D-EN-P - June 2004

Page 14

14 SLC™ 500 4-Channel Thermocouple/mV Input Module

– If millivolt inputs are used, the terminal should be biased to a level

within 2V of the signal of interest. Use 10KΩ resistors to create a resistive

voltage divider as shown in the following circuit diagram.

TIP

The Series A 1746-NT4 does not have an ANALOG COM

terminal and cannot be used with multiple grounded and/or

exposed thermocouples that touch electrically conductive

material. The Series A can be used with a single grounded

and/or exposed thermocouple that touches electrically

conductive material, or multiple grounded thermocouples that

have the protective sheath made of an electrically

non-conductive material such as ceramic.

+

NT4

Strain Gauge

Bridge

Input

(CHL 0, CHL 1, CHL

2, CHL 3)

Analog Com

+

-

fixed

fixed

Vcc

variable

fixed

10K Ω

10K Ω

• Ground the shield drain wire at one end only. The preferred location is to

the same point as the sensor ground reference.

– For grounded thermocouples or mV sensors, this is at the sensor.

– For insulated/ungrounded thermocouples, this is at the module.

– Refer to IEEE Std. 518, Section 6.4.2.7 or contact your sensor

manufacturer for additional details.

• If it is necessary to connect the shield at the module, each input channel has

a convenient shield connection screw terminal that provides a connection to

chassis ground. All shields are internally connected, so any shield terminal

can be used with channels 0-3. For maximum noise reduction, one shield

terminal must be connected to earth ground potential, i.e. mounting bolt on

1746 chassis.

Publication 1746-IN010D-EN-P - June 2004

Page 15

SLC™ 500 4-Channel Thermocouple/mV Input Module 15

• Tighten terminal screws using a flat or cross-head screwdriver. Each screw

should be turned tight enough to immobilize the wire’s end. Excessive

tightening can strip the terminal screw. The torque applied to each screw

should not exceed 6 - 8 in-lbs (0.7 - 0.9 Nm) for each terminal.

• The open thermocouple detection circuit injects approximately

12 nanoAmperes into the thermocouple cable. A total lead resistance of

25 Ω (12.5 one-way) will produce 0.3 mV of error. To reduce error, use large

gauge wire with less resistance for long wire runs.

• Follow system grounding and wiring guidelines found in your SLC 500

Installation and Operation Manual, publication number 1747-6.21 (Fixed

Hardware Style) or 1747-UM011 (Modular Hardware Style).

Wiring Input Devices to the NT4

After the thermocouple module is properly installed in the chassis, follow the

wiring procedure below using the proper thermocouple extension cable, or

Belden 8761 for non-thermocouple applications.

Signal Wire

Signal Wire

Cable

Drain Wire

(Twist together, shrink wrap, and

connect to earth ground.)

Foil Shield

(Cut foil shield and

drain wire; then

insulate at cable

end.)

Signal Wire

Signal Wire

To wire your NT4 module, follow these steps.

1. At each end of the cable, strip some casing to expose the individual wires.

2. Trim the signal wires to 2-inch lengths. Strip about 4.76 mm (3/16 inch) of

insulation away to expose the end of the wire.

3. At one end of the cable, twist the drain wire and foil shield together, bend

them away from the cable, and apply shrink wrap. Then earth ground at the

preferred location based on the type of sensor you are using (see wiring

guidelines on page 13).

Publication 1746-IN010D-EN-P - June 2004

Page 16

16 SLC™ 500 4-Channel Thermocouple/mV Input Module

4. At the other end of the cable, cut the drain wire and foil shield back to the

cable and apply shrink wrap.

5. Connect the signal wires to the NT4 terminal block and the input.

6. Repeat steps 1 through 5 for each channel on the NT4 module.

Cold-Junction Compensation (CJC)

ATTENTION

Do not remove or loosen the cold junction compensating

thermistor assemblies located between the two upper and

lower CJC terminals on the terminal block. Both thermistor

assemblies are critical to ensure accurate thermocouple input

readings at each channel. The module will not operate in the

thermocouple mode if either assembly is removed.

To obtain accurate readings from each of the channels, the cold-junction

temperature (temperature at the module’s terminal junction between the

thermocouple wire and the input channel) must be compensated for. Two coldjunction compensating thermistors have been integrated in the removable terminal

block; they must remain installed to retain accuracy.

In case of accidental removal of either or both of the thermistor assemblies, make

sure to replace them by connecting each one across the CJC terminals located at the

top and bottom left side of the terminal block. When connecting the thermistor

assembly at the top of the terminal block (between terminals CJC A+ and CJC A-),

the lug containing the thermistor (marked with red epoxy) should attach to the

uppermost screw terminal (CJC A+). When connecting the thermistor assembly at

the bottom of the terminal block (between terminals CJC B+ and CJC B-), the lug

containing the thermistor should attach to the lowermost screw terminal (CJC B+).

CJC

Assembly

Thermistor

(Always attach red lug to

the CJC+ terminal.)

Bottom of Terminal Block

Publication 1746-IN010D-EN-P - June 2004

Page 17

SLC™ 500 4-Channel Thermocouple/mV Input Module 17

Module Addressing

The following memory map shows you how the output and input image tables are

defined for the thermocouple module.

SLC 5/0X

Data Files

Slot e

Output Image

Slot e

Input Image

Output

Scan

Input

Scan

Thermocouple

Module Image

Output Image

8 Words

Input Image

8 Words

(Class 1)

Bit 15 Bit 0

Channel 0 Configuration Word

Channel 1 Configuration Word

Channel 2 Configuration Word

Channel 3 Configuration Word

Output

Image

Input

Image

Bit 15 Bit 0

Words 4-7

(not defined)

Channel 0 Data Word

Channel 1 Data Word

Channel 2 Data Word

Channel 3 Data Word

Channel 0 Status Word

Channel 1 Status Word

Channel 2 Status Word

Channel 3 status Word

Word 0

Word 1

Word 2

Word 3

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Address

O:e.0

O:e.1

O:e.2

O:e.3

Address

I:e.0

I:e.1

I:e.2

I:e.3

I:e.4

I:e.5

I:e.6

I:e.7

Channel Configuration

Once the module is installed, each channel on the module can be configured to

establish the way the channel will operate. You configure the channel by entering

bit values into the configuration word using your programming software. Channels

0 through 3 on the NT4 are configured by entering bit values into output words 0

through 3 respectively. Output words 4 through 7 are not used. See the table on

page 18 for bit settings.

Publication 1746-IN010D-EN-P - June 2004

Page 18

18 SLC™ 500 4-Channel Thermocouple/mV Input Module

Channel Configuration Word - Bit Definitions

Define To Select

Make these bit settings in the Channel Configuration Word

(2)

15–12

11109876543210

Input type Thermocouple Type J

Thermocouple Type K

Thermocouple Type T

Thermocouple Type E

Thermocouple Type R

Thermocouple Type S

Thermocouple Type B

Thermocouple Type N

±50mV

±100mV

CJC temperature

Data format

Engineering units 1

Engineering units 10

Scaled-for-PID 10

Proportional Counts 11

(3)

(4)

Not Used

Open circuit Zero 00

Upscale 01

Downscale 10

Temperature

units

Channel

filter

frequency

Degrees C

Degrees F

10 Hz

50 Hz 01

60 Hz 10

(5)

(5)

0

1

00

250 Hz 11

Channel

enable

(1) Bit settings other than those shown in the table are invalid.

(2) Ensure unused bits 12-15 are always set to zeros.

(3) For engineering units x 1, values are expressed in 0.1 degrees or 0.01 mV.

(4) For engineering units x 10, values are expressed in 1.0 degrees or 0.1 mV.

(5) When millivolt input type is selected, the bit setting for temperature units is ignored.

Channel Disabled 0

Channel Enabled 1

(1)

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1111

00

01

Publication 1746-IN010D-EN-P - June 2004

Page 19

SLC™ 500 4-Channel Thermocouple/mV Input Module 19

Specifications

Electrical Specifications

Backplane Current Consumption 60 mA at 5V dc

40 mA at 24V dc

Backplane Power Consumption 1.3W maximum (0.3W at 5V dc, 1.0W at 24V dc)

Number of Channels 4 (backplane isolated)

I/O Chassis Location Any I/O module slot except slot 0

A/D Conversion Method Sigma-Delta Modulation

Input Filtering Low pass digital filter with programmable notch (filter) frequencies

Normal Mode Rejection (between

[+] input and [-] input)

Common Mode Rejection

(between inputs and chassis

ground)

Input Filter Cut-Off Frequencies 2.62 Hz at 10 Hz filter frequency

Calibration Module autocalibrates at powerup and whenever a channel is enabled.

Isolation 500V dc one minute between inputs and chassis ground, and between

Maximum Channel-to-Channel

Common-Mode Separation

Greater than 100 dB at 50 Hz (10 Hz, 50 Hz filter frequencies)

Greater than 100 dB at 60 Hz (10 Hz, 60 Hz filter frequencies)

Greater than 150 dB at 50 Hz (10 Hz, 50 Hz filter frequencies)

Greater than 150 dB at 60 Hz (10 Hz, 60 Hz filter frequencies)

13.1 Hz at 50 Hz filter frequency

15.72 Hz at 60 Hz filter frequency

65.5 Hz at 250 Hz filter frequency

inputs and backplane.

Series B or later: 2V maximum between any two channels

Series A: 0V separation

Publication 1746-IN010D-EN-P - June 2004

Page 20

20 SLC™ 500 4-Channel Thermocouple/mV Input Module

Physical Specifications

LED Indicators 5 green status indicators, one for each of 4 channels and one for module

Module ID Code 3510

Recommended Cable:

for thermocouple inputs

for mV inputs Belden #8761 or equivalent

Maximum Wire Size Two 14 AWG wires per terminal

Maximum Cable Impedance 25 ohms maximum loop impedance, for <1LSB error

Removable Terminal Strip Allen-Bradley spare part Catalog Number 1746-RT32

(1) Refer to the thermocouple manufacturer for the correct extension wire.

status

Appropriate shielded, twisted-pair thermocouple extension wire

(1)

Environmental Specifications

Operating Temperature

Storage Temperature -40°C to +85°C (-40°F to +185°F)

Relative Humidity 5% to 95% (without condensation)

Certification UL listed

(1) When the NT4 module detects zero degrees (+/- 3°) at the CJC, it will detect an out of range condition and set values to

downscale -270°C (-454°F). It is recommended that ambient temperature surrounding the SLC 500 system be maintained

above 3°C (37.4°F) in order for the NT4 module to measure temperature correctly without detecting an out of range

condition.

0°C to +60°C (+32°F to +140°F)

CSA approved

Class I, Division 2, Groups A, B, C, D

CE compliant for all applicable directives when product or packaging is marked

(1)

Publication 1746-IN010D-EN-P - June 2004

Page 21

SLC™ 500 4-Channel Thermocouple/mV Input Module 21

Thermocouple Temperature and Millivolt Input Ranges

Input Type Temperature Range

Thermocouple Type J -210°C to +760°C (-346°F to +1400°F)

Thermocouple Type K -270°C to +1370°C (-454°F to +2498°F)

Thermocouple Type T -270°C to +400°C (-454°F to +752°F)

Thermocouple Type E -270°C to +1000°C (-454°F to +1832°F)

Thermocouple Type R 0°C to +1768°C (+32°F to +3214°F)

Thermocouple Type S 0°C to +1768°C (+32°F to +3214°F)

Thermocouple Type B +300°C to +1820°C (+572°F to +3308°F)

Thermocouple Type N 0°C to +1300°C (+32°F to +2372°F)

Millivolt Input: -50 mV dc to +50 mV dc

Millivolt Input: -100 mV dc to +100 mV dc

Input Specifications

Thermocouple Linearization IPTS-68 standard, NBS MN-125, NBS MN-161

Cold-Junction Compensation Accuracy ±1.5°C, 0°C to +85°C (+32°F to +185°F)

Input Impedance Greater than 10MΩ

Temperature Scale (Selectable) °C or °F and 0.1°C or 0.1°F

DC Millivolt Scale (Selectable) 0.1 mV or 0.01 mV

Open Circuit Detection Leakage Current 12 nA maximum

Open Circuit Detection Method Upscale

Module Update Time The sum of all enabled channel’s sample times plus one CJC

Channel Turn-On Time,

Reconfiguration Time

Channel Turn-Off Time Requires up to one module update time

Time to Detect Open Circuit 500 msec or 1 module update time, whichever is greater

update time. See channel sampling time table on page 22.

Requires up to one module update time plus one of the following:

• 250 Hz Filter = 82 milliseconds

• 60 Hz Filter = 196 milliseconds

• 50 Hz Filter = 226 milliseconds

• 10 Hz Filter = 946 milliseconds

Publication 1746-IN010D-EN-P - June 2004

Page 22

22 SLC™ 500 4-Channel Thermocouple/mV Input Module

Thermocouple/mV Input Module Accuracy

Input Type

J ±1.06°C ±1.91°F ±0.0193°C/°C, °F/°F

K ±1.72°C ±3.10°F ±0.0328°C/°C, °F/°F

T ±1.43°C ±2.57°F ±0.0202°C/°C, °F/°F

E ±0.72°C ±1.3°F ±0.0190°C/°C, °F/°F

S ±3.61°C ±6.5°F ±0.0530°C/°C, °F/°F

R ±3.59°C ±6.46°F ±0.0530°C/°C, °F/°F

B ±3.12°C ±5.62°F ±0.0457°C/°C, °F/°F

N ±1.39°C ±2.5°F ±0.0260°C/°C, °F/°F

±50 mV ±50 µV ±50 µV ±1.0 µV/°C, ±1.8 µV/°F

±100 mV ±50 µV ±50 µV ±1.5 µV/°C, ±2.7 µV/°F

(1) Assumes the module terminal block temperature is stable.

With Autocalibration

Maximum Error at

+25°C

(1)

Maximum Error at

+77°F

Without Autocalibration

Temperature Drift

(0°C to +60°C)

Filter Frequency and Step Response Time

Filter Frequency

10 Hz 100 dB 100 dB 2.62 Hz 300 msec

50 Hz 100 dB - 13.1 Hz 60 msec

60 Hz - 100 dB 15.72 Hz 50 msec

250 Hz - - 65.5 Hz 12 msec

(1) Normal Mode Rejection

50 Hz NMR

(1)

60 Hz NMR

1

Cut-Off

Frequency

Step Response

(1)

Channel Sampling Time for Each Filter Frequency

CJC Update Time

14 msec 12 msec 50 msec 60 msec 300 msec

(1) all values ±1 msec

Channel Sampling Time

250 Hz Filter 60 Hz Filter 50 Hz Filter 10 Hz Filter

Publication 1746-IN010D-EN-P - June 2004

(1)

Page 23

SLC™ 500 4-Channel Thermocouple/mV Input Module 23

Publication 1746-IN010D-EN-P - June 2004

Page 24

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in

using its products. At http://support.rockwellautomation.com

technical manuals, a knowledge base of FAQs, technical and application notes,

sample code and links to software service packs, and a MySupport feature that you

can customize to make the best use of these tools.

For an additional level of technical phone support for installation, configuration,

and troubleshooting, we offer TechConnect Support programs. For more

information, contact your local distributor or Rockwell Automation representative,

or visit http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of

installation, please review the information that's contained in this manual. You can

also contact a special Customer Support number for initial help in getting your

module up and running.

, you can find

United States 1.440.646.3223

Outside United

States

Monday – Friday, 8am – 5pm EST

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when

shipped from the manufacturing facility. However, if your product is not

functioning, it may need to be returned.

United States Contact your distributor. You must provide a Customer Support case number

Outside United

States

Rockwell Automation, Allen-Bradley, SLC, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 1746-IN010D-EN-P - June 2004 PN 40071-139-01(4)

Supersedes Pub lication 1746-IN010C-EN -P - November 2002 Copyright © 20 07 Rockwell Automation , Inc. All rights reserv ed. Printed in Singapore.

(see phone number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for return

procedure.

Loading...

Loading...