Two-hand relays

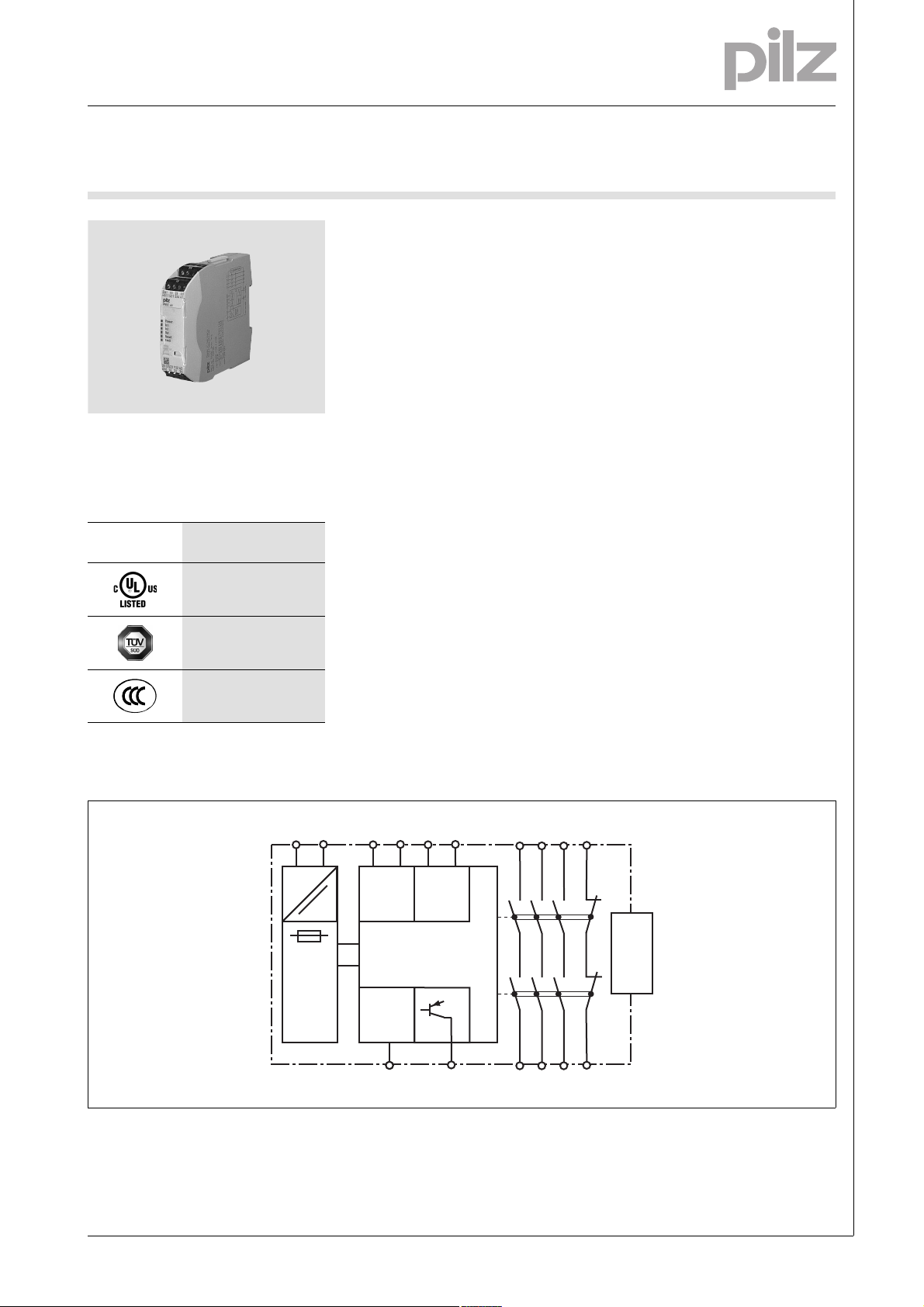

InputInput

A1 A2 S21 S22

=

Power

Feed-

back

(Reset)

S34

S11 S12

=

Y32

(~)*

K1

K2

13

23 33

24 34

14

41

42

Interface

expansion

unit

( )*

Up to PL e of EN ISO 13849-1

PNOZ s6

Gertebild

][Bildunterschrift_Zweihand

Two-hand control unit for press controllers and safety circuits

Approvals

PNOZ s6

Zulassungen

Unit features

Gertemerkmale

Positive-guided relay outputs:

– 3 safety contacts (N/O), instanta-

neous

– 1 auxiliary contact (N/C), instan-

taneous

1 semiconductor output

Connection options for:

– 2 operator elements (buttons)

A connector can be used to con-

nect 1 PNOZsigma contact expansion module

LED indicator for:

– Supply voltage

– Input status, channel 1

– Input status, channel 2

– Switch status, safety contacts

– Feedback circuit

– Error

Plug-in connection terminals (either

spring-loaded terminal or screw

terminal)

Unit description

][Gertebeschreibung_Zweihand

The two-hand control relay meets the

requirements of EN 574 Type IIIC. It

forces the operator to keep his hands

outside the danger zone area during

the hazardous movement. The unit is

suitable for use on controllers for metalworking presses as a component for

simultaneous switching.

It can be used in applications with

Mechanical presses (EN 692)

Hydraulic presses (EN 693)

Safety circuits in accordance with

EN 60204-1

Safety features

][Sicherheitseigenschaften_Zweihand

The two-hand control relay meets the

following safety requirements:

The circuit is redundant with built-in

self-monitoring

The safety function remains effec-

tive in the case of a component failure

The circuit prevents a further press

stroke in the case of:

– Relay failure

– Contact welding

– Coil defect on a relay

– Open circuit

– Short circuit

Sicherheitseigenschaften Zusatz - Sicherung DC_PNOZ

The unit has an electronic fuse.

Block diagram

* only when UB = 48 – 240 VAC/DC

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Blockschaltbild

Zusatz WSNT

1001973-EN-03-2011-08

Two-hand relays

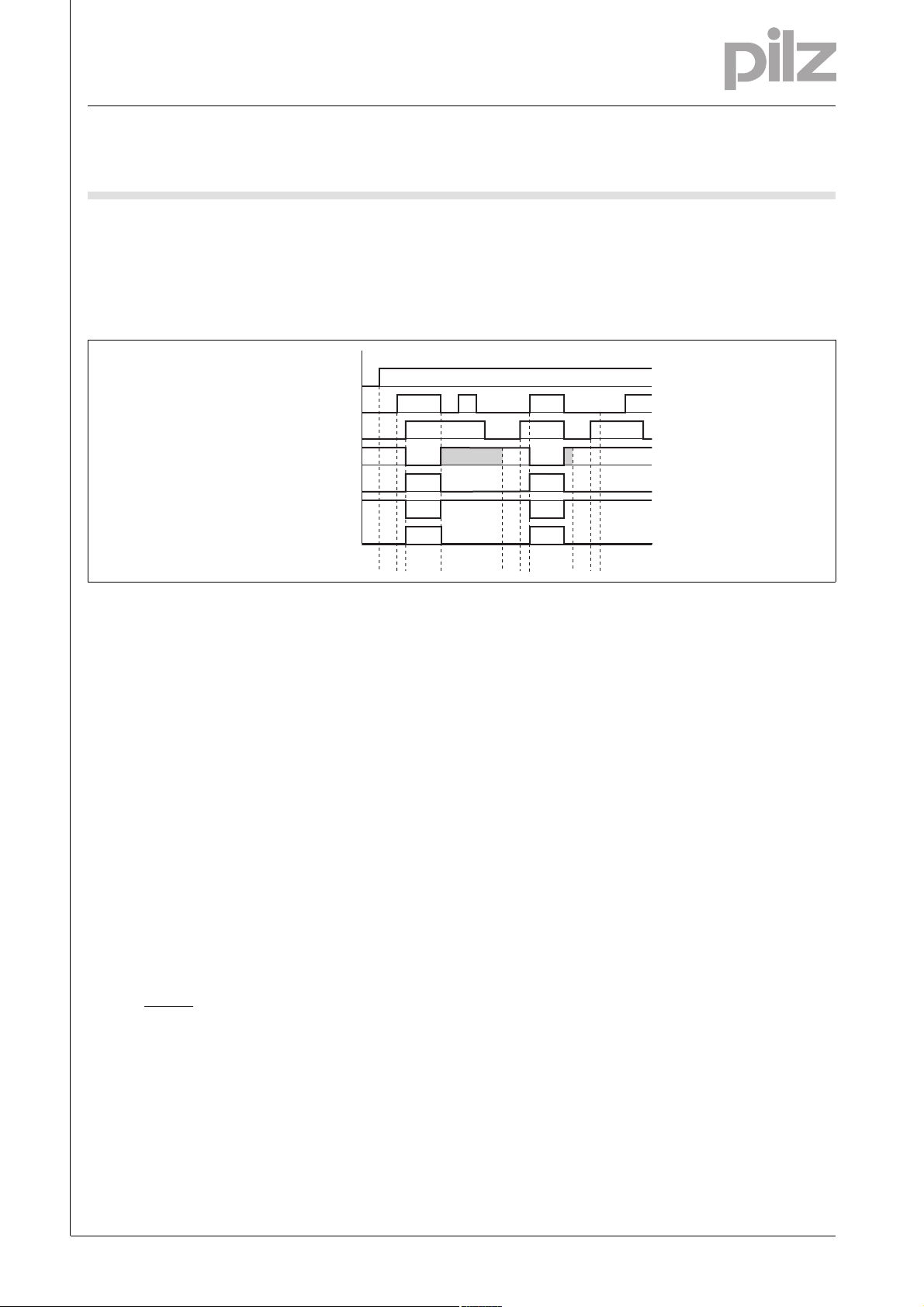

POWER

Feedback loop

Output safe

Button 1

t0 t1 t2 t3 t3 t1

Button 2

Out semi

Output aux.

t1

R

lmax

Rl / km

I

max

=

Up to PL e of EN ISO 13849-1

PNOZ s6

Function description

][Funktionen_Zweihand

The two-hand control relay must be

activated by simultaneously press-

Timing diagram

Key

POWER: Supply voltage

Button 1/Button 2: Input circuits

S11-S12, S21- S22

Feedback loop: Feedback loop S34

Output safe: Safety outputs 13-14,

23-24, 33-34

ing two buttons within 0.5 s. If one

or both of the buttons are released,

the unit interrupts the control command for the hazardous movement.

][Zeitdiagram_Zweihand_aux_semi

Output aux: Auxiliary contacts 41-

42

Out semi: Semiconductor output

switch status Y32

: Recovery time after power on

t

0

: Simultaneity, channel 1 and 2

t

1

Reactivation: The output relays will

not re-energise until both operator

elements have been released and

then re-operated simultaneously.

: Operating cycle ended through

t

2

button 1 or 2

: S34-S12 must be closed before

t

3

before the button is operated (recovery time)

Shaded area: Status irrelevant

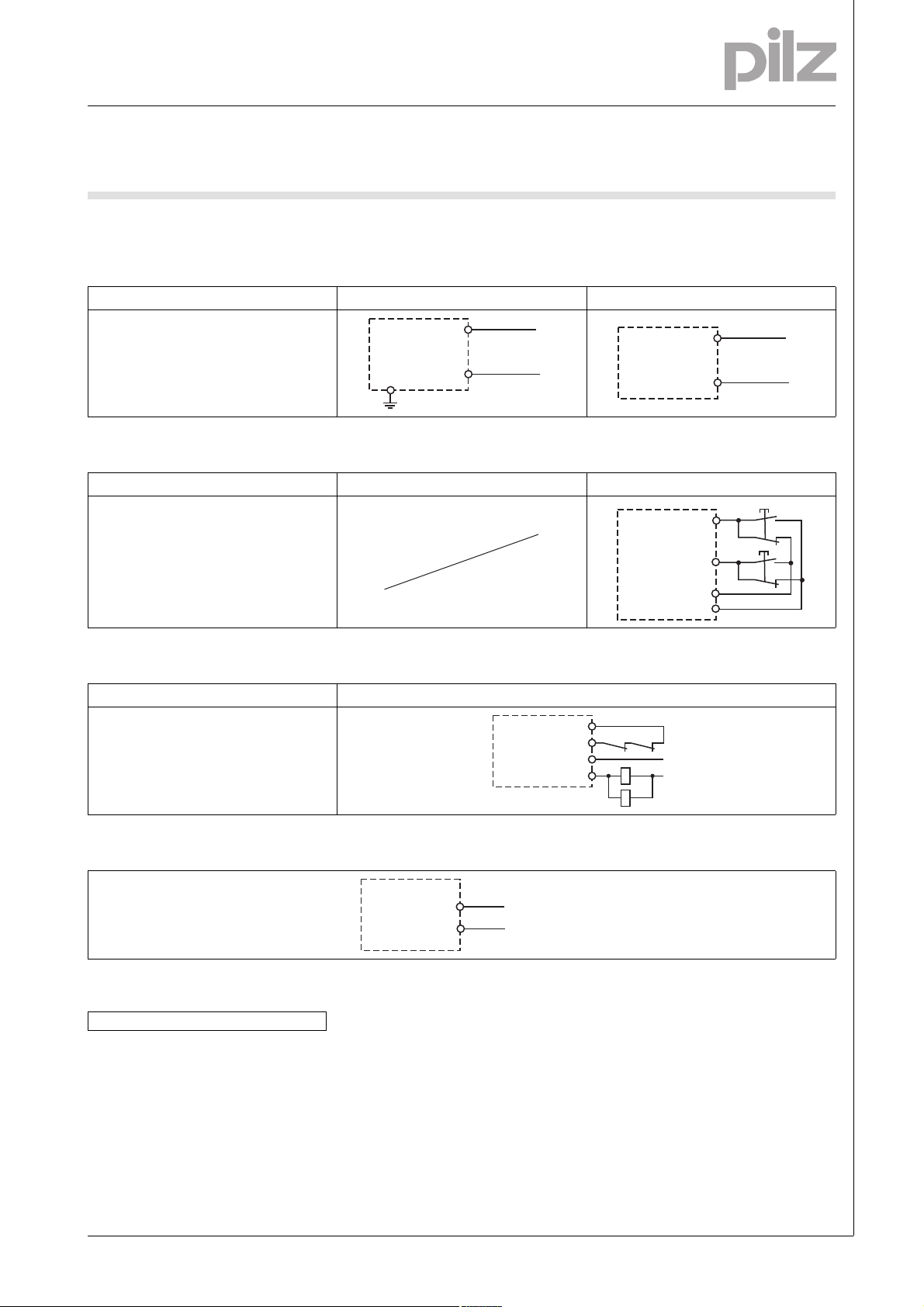

Wiring

][Verdrahtung_Si_unverz_1Hi_unverz

Please note:

Information given in the “Technical

details” must be followed.

Outputs 13-14, 23-24, 33-34 are

safety contacts, output 41-42 is an

auxiliary contact (e.g. for display).

To prevent contact welding, a fuse

should be connected before the

output contacts (see technical details).

Calculation of the max. cable runs

in the input circuit:

l

max

R

= max. overall cable resist-

lmax

ance (see technical details)

/km = cable resistance/km

R

l

Use copper wire that can withstand

60/75 °C.

Sufficient fuse protection must be

provided on all output contacts with

capacitive and inductive loads.

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1001973-EN-03-2011-08Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

-2

Two-hand relays

A1

L

A2

N

S22

A1

L+

A2

L-

S12(+)

S11

S21

S22(-)

S1

S2

K5

K6

K5

L1

N

K6

S12

13 (23,33)

S34

14 (24,34)

Y32

PLC Input

S22

Gnd

Up to PL e of EN ISO 13849-1

PNOZ s6

Preparing for operation

Betriebsbereitschaft herstellen PNOZs

Supply voltage

Supply voltage AC DC

Input circuit

Input circuit Single-channel Dual-channel

Two-hand button

with detection of shorts across contacts

Feedback loop

Contacts from external contactors

Semiconductor output

Key

S1/S2 Two-hand button

Feedback loop

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1001973-EN-03-2011-08

Two-hand relays

120 (4.72")

* 100 (3,94")

98 (3.86")

22,5

(0.88")

Up to PL e of EN ISO 13849-1

PNOZ s6

Terminal configuration

Klemmenbelegung

Installation

][Montage_PNOZsigma

Install base unit without contact expander module:

Ensure that the plug terminator is

inserted at the side of the unit.

Connect base unit and PNOZsigma

contact expander module:

Remove the plug terminator at the

side of the base unit and at the contact expander module.

Connect the base unit and the con-

tact expander module to the supplied connector before mounting

the units to the DIN rail.

Installation in control cabinet

The safety relay should be installed

in a control cabinet with a protection type of at least IP54.

Use the notch on the rear of the unit

to attach it to a DIN rail (35 mm).

When installed vertically: Secure

the unit by using a fixing element

(e.g. retaining brakket or end angle).

Push the unit upwards or down-

wards before lifting it from the DIN

rail.

CAUTION!

The distance of the button connected

to the two-hand relay from the nearest

danger zone must be large enough

that if one of the buttons is released,

the dangerous movement is interrupted before the operator can reach into

the danger zone (see EN 999 "The positioning of protective equipment in respect of approach speeds of parts of

the human body").

Dimensions

Abmessungen

*with spring-loaded terminals

][Montage_Zusatz_Zweihand

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1001973-EN-03-2011-08Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

-4

Two-hand relays

D Nennbetriebstrom (A)

GB Nominal operating current (A)

F Courant coupé (A)

E Corriente nominal de servicio (A)

I Corrente di esercizio nominale (A)

NL Nominale bedrijfsstroom (A)

D Schaltspielzahl x 10

3

GB Cycles x 103F Nombre de manvres x 10

3

E Número de ciclos x 103I Numero dei cicli di commutazione x 10

3

NL Aantal schakelingen x 10

3

10000

1000

100

10

0,2 0,5 1 2 3 4 5 6 7 8 9 10

DC-13: 24V

DC-1: 24V

AC-1: 230V

AC-15: 230V

Up to PL e of EN ISO 13849-1

PNOZ s6

NOTICE

][WICHTIG_PDB_al t

This data sheet is only intended for use

during configuration. For installation

and operation, please refer to the operating instructions supplied with the

unit.

Service life graph

Lebensdauerkurve_Rela is_Text vor Kurv e

The service life graphs indicate the

number of cycles from which failures

due to wear must be expected. The

wear is mainly caused by the electrical

load; the mechanical load is negligible.

UB 24 V DC

Lebensdauerkurve

Lebensdauerkurve_Relais_Text nach Kurve_SIF Bsp

Example

Inductive load: 0,2 A

Utilisation category: AC15

Contact service life: 2,000,000 cy-

cles

Provided the application requires fewer than 2,000,000 cycles, the PFH value (see technical details) can be used

in the calculation.

To increase the service life, sufficient

spark suppression must be provided

on all output contacts. With capacitive

loads, any power surges that occur

must be noted. With contactors, use

freewheel diodes for spark suppression.

Lebensdauerkurve

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1001973-EN-03-2011-08

Two-hand relays

Up to PL e of EN ISO 13849-1

PNOZ s6

UB 48-240 V AC/DC

Lebensdauerkurve_Relais_Text nach Kurve_SIS_SIR_SLR Bsp

Example

Inductive load: 0,2 A

Utilisation category: AC15

Contact service life: 1,000,000 cy-

cles

Provided the application requires fewer than 1,000,000 cycles, the PFH val-

To increase the service life, sufficient

spark suppression must be provided

on all output contacts. With capacitive

loads, any power surges that occur

must be noted. With contactors, use

freewheel diodes for spark suppres-

sion.

ue (see technical details) can be used

in the calculation.

Technical details

Electrical data

Supply voltage

Supply voltage U

Supply voltage U

Voltage tolerance -15 %/+10 %

Power consumption at U

Power consumption at U

Frequency range AC 50 - 60 Hz

Residual ripple DC 20 %

Voltage and current at

Input circuit DC: 24.0 V

N/O contact 20 mA

N/C contact 10 mA

Feedback loop DC: 24.0 V 15.0 mA

Number of output contacts

Safety contacts (S) instantaneous: 3

Auxiliary contacts (N/C): 1

Type in accordance with EN 574 III C

DC 24 V

B

AC/DC 48 - 240 V

B

AC 7.0 VA No. 750136, 751136

B

DC 3.5 W

B

][Technische Daten PNO Zsigma_Zweihand

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1001973-EN-03-2011-08Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

-6

Two-hand relays

Up to PL e of EN ISO 13849-1

PNOZ s6

Electrical data

Utilisation category in accordance with EN 60947-4-1

Safety contacts: AC1 at 240 V I

Safety contacts: DC1 at 24 V I

Auxiliary contacts: AC1 at 240 V I

Auxiliary contacts: DC1 at 24 V I

Utilisation category in accordance with EN 60947-5-1

Safety contacts: AC15 at 230 V I

Safety contacts: DC13 at 24 V (6 cycles/min) I

Auxiliary contacts: AC15 at 230 V I

Auxiliary contacts: DC13 at 24 V (6 cycles/min) I

Contact material AgCuNi + 0.2 µm Au

External contact fuse protection (I

= 1 kA) to EN 60947-5-1

K

Blow-out fuse, quick

Safety contacts: 10 A No. 750106, 751106

Auxiliary contacts: 10 A No. 750106, 751106

Blow-out fuse, slow

Safety contacts: 4 A No. 750136, 751136

Auxiliary contacts: 4 A No. 750136, 751136

Circuit breaker 24 VAC/DC, characteristic B/C

Safety contacts: 4 A No. 750136, 751136

Auxiliary contacts: 4 A No. 750136, 751136

Semiconductor outputs (short circuit proof) 24.0 V DC,20 mA

Max. overall cable resistance R

per input circuit 30 Ohm

lmax

Safety-related characteristic data

PL in accordance with EN ISO 13849-1: 2006 PL e (Cat. 4)

Category in accordance with EN 954-1 Cat. 4

SIL CL in accordance with EN IEC 62061 SIL CL 3

PFH in accordance with EN IEC 62061 2.62E-09

SIL in accordance with IEC 61511 SIL 3

PFD in accordance with IEC 61511 3.32E-05

T

[year] in accordance with EN ISO 13849-1: 2006 20

M

Times

Delay-on de-energisation (reaction time in accordance with

EN 574)

N/O contact 30 ms

N/C contact 40 ms

Recovery time 250 ms

Simultaneity, channel 1 and 2 0.5 s

Supply interruption before de-energisation 20 ms

Environmental data

EMC EN 60947-5-1, EN 61000-6-2, EN 61000-6-4

Vibration to EN 60068-2-6

Frequency 10 - 55 Hz

Amplitude 0.35 mm

: 0.01 A , I

min

: 1500 VA

P

max

: 0.01 A , I

min

P

: 150 W

max

: 0.01 A , I

min

P

: 1500 VA

max

: 0.01 A , I

min

: 150 W

P

max

: 3.0 A No. 750136, 751136

max

5.0 A No. 750106, 751106

: 4.0 A No. 750136, 751136

max

5.0 A No. 750106, 751106

: 3.0 A No. 750136, 751136

max

5.0 A No. 750106, 751106

: 4.0 A No. 750136, 751136

max

5.0 A No. 750106, 751106

max

max

max

max

: 6.0 A

: 6.0 A

: 6.0 A

: 6.0 A

6 A No. 750136, 751136

6 A No. 750136, 751136

6 A No. 750106, 751106

6 A No. 750106, 751106

6 A No. 750106, 751106

6 A No. 750106, 751106

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1001973-EN-03-2011-08

Two-hand relays

Up to PL e of EN ISO 13849-1

PNOZ s6

Environmental data

Climatic suitability EN 60068-2-78

Airgap creepage in accordance with EN 60947-1

Pollution degree 2

Overvoltage category III

Rated insulation voltage 250 V

Rated impulse withstand voltage 4.00 kV

Ambient temperature -10 - 55 °C

Storage temperature -40 - 85 °C

Protection type

Mounting (e.g. cabinet) IP54

Housing IP40

Terminals IP20

Mechanical data

Housing material

Housing PC

Front PC

Cross section of external conductors with screw terminals

1 core flexible 0.25 - 2.50 mm² , 24 - 12 AWG No. 750106, 750136

2 core, same cross section, flexible:

with crimp connectors, without insulating sleeve 0.25 - 1.00 mm² , 24 - 16 AWG No. 750106, 750136

without crimp connectors or with TWIN crimp connectors 0.20 - 1.50 mm² , 24 - 16 AWG No. 750106, 750136

Torque setting with screw terminals 0.50 Nm No. 750106, 750136

Cross section of external conductors with spring-loaded termi-

nals: Flexible with/without crimp connectors

Spring-loaded terminals: Terminal points per connection 2 No. 751106, 751136

Stripping length 9 mm No. 751106, 751136

Dimensions

Height 100.0 mm No. 751106, 751136

Width 22.5 mm

Depth 120.0 mm

Weight 187 g No. 750106

Technische Daten_Satz No .

No. stands for order number.

0.20 - 2.50 mm² , 24 - 12 AWG No. 751106, 751136

98.0 mm No. 750106, 750136

190 g No. 751106

210 g No. 750136, 751136

Si-Kennzahlen_Zusatz_Relais_Lebensdauer_PDB

It is essential to consider the relay's

service life graphs. The relay outputs'

safety-related characteristic data is

only valid if the values in the service life

graphs are met.

All the units used within a safety function must be considered when calculating the safety characteristic data.

Technische Daten_Satz No rmen

The standards current on 2011-06 apply.

][Dauerstrom_ACDC

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

The PFH value depends on the switching frequency and the load on the relay

output.

If the service life graphs are not accessible, the stated PFH value can be

used irrespective of the switching frequency and the load, as the PFH value

already considers the relay's B10d value as well as the failure rates of the

other components.

Si_Kennzahlen_Erläute rung

1001973-EN-03-2011-08Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

-8

Two-hand relays

Up to PL e of EN ISO 13849-1

PNOZ s6

Conventional thermal current while loading several contacts

Number of contacts I

1 6.00 A 6.00 A No. 750136, 751136

2 6.00 A 6.00 A No. 750136, 751136

3 4.50 A No. 750136, 751136

Order reference

Type Features Terminals Order no.

PNOZ s6 24 VDC With screw terminals 750 106

PNOZ s6 C 24 VDC With spring-loaded terminals 751 106

PNOZ s6 48 – 240 VAC/DC With screw terminals 750 136

PNOZ s6 C 48 – 240 VAC/DC With spring-loaded terminals 751 136

at UBDC Ithat UBAC

th

4.50 A No. 750136, 751136

6.00 A No. 750106, 751106

Bestelldaten

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1001973-EN-03-2011-08

Loading...

Loading...