Page 1

Operating Manual PNOZ s30

Operating Manual PNOZ s30

PNOZ s30

Safety relays

Operating Manual — No. 1001715-EN-11

Page 2

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

SD means Secure Digital.

Preface

Page 3

Contents

Contents

Contents Page

Chapter 1 Introduction

1.1 Validity of documentation 1-1

1.2 Overview of documentation 1-2

1.3 Definition of symbols 1-3

Chapter 2 Overview

2.1 Unit structure 2-1

2.1.1 Range 2-1

2.1.2 Unit features 2-1

2.2 Front/side view 2-2

Chapter 3 Safety

3.1 Intended use 3-1

3.2 Safety regulations 3-2

3.2.1 Use of qualified personnel 3-2

3.2.2 Warranty and liability 3-2

3.2.3 Disposal 3-2

3.2.4 For your safety 3-2

Chapter 4 Function description

4.1 Introduction 4-1

4.2 Block diagram 4-2

4.3 Functions 4-3

4.4 Speed configuration 4-7

4.4.1 Select Inputs 4-9

4.4.2 Switch functions 4-10

4.4.3 Basic configuration 4-11

4.4.4 Chip card 4-13

4.5 Input device types 4-14

4.5.1 Proximity switch 4-14

4.5.2 Rotary encoders 4-14

4.5.2.1 Adapter for incremental encoders 4-15

Chapter 5 Installation

5.1 General installation guidelines 5-1

5.1.1 Dimensions 5-1

Chapter 6 Commissioning

6.1 Wiring 6-1

6.1.1 General wiring guidelines 6-1

6.1.2 Pin assignment of RJ45 socket 6-1

6.1.3 Supply voltage 6-1

6.1.4 Connection of proximity switches 6-1

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1

Page 4

Contents

6.1.5 Connection of a rotary encoder 6-2

6.1.5.1 Connect rotary encoder to speed monitor 6-2

6.1.5.2 Connect rotary encoder with Z index to

speed monitor

6.1.5.3 Connect rotary encoder to the speed monitor via an adapter

6.1.6 Connection of proximity switch and rotary

encoder

6.1.7 Reset circuit 6-5

6.1.8 Feedback circuit 6-5

6.1.9 Select inputs 6-6

6.1.10 Semiconductor outputs 6-6

6.2 Display menu - Configuration 6-7

6.2.1 Create configuration overview 6-7

6.2.2 Operate rotary knob 6-7

6.2.3 Configure Speed Monitor 6-8

6.2.4 Password protection 6-9

6.2.5 Use chip card 6-9

6.2.5.1 Insert chip card 6-10

6.2.5.2 Write data to chip card 6-11

6.2.5.3 Read data from chip card 6-11

6.2.5.4 Transfer device parameters 6-12

6.2.5.5 Duplicate chip card 6-12

6.2.6 Menu overview 6-12

6.2.6.1 Permanent display 6-12

6.2.6.2 Basic settings Ini pnp pnp 6-12

6.2.6.3 Basic settings for the rotary encoder 6-13

6.2.6.4 Settings 6-15

6.2.6.5 Advanced settings 6-20

6.2.6.6 Information 6-21

6.2.7 Example: Configure basic configuration 2 6-24

6-3

6-4

6-4

Chapter 7 Operation

7.1 Display elements for device diagnostics 7-1

7.1.1 LEDs 7-1

7.1.2 Display 7-1

7.1.2.1 Error stack entries 7-1

7.1.2.2 Current error messages 7-2

7.1.2.3 Open circuit message 7-6

7.1.2.4 Frequency difference message 7-7

Chapter 8 Technical details

8.1 Technical details 8-1

8.2 Service life graph of output relays 8-5

8.3 Categories 8-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

2

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 5

Contents

8.3.1 Safety level 8-6

8.3.2 Standard rotary encoder 8-6

8.3.3 Standard rotary encoder with additional di-

8.3.4 Safe rotary encoder 8-9

8.3.5 Standard rotary encoder and proximity

8.3.6 2 proximity switches 8-11

8.3.7 Safe rotary encoder with Z index 8-12

8.4 Order reference 8-14

Chapter 9 Examples

9.1 Connection of proximity switch 9-1

9.1.1 Features 9-1

9.1.2 Configuration overview 9-1

9.1.3 Connection 9-2

9.2 Incremental encoder connection 9-4

9.2.1 Features 9-4

9.2.2 Configuration overview 9-4

9.2.3 Connection 9-5

8-7

agnostics through the drive controller

8-10

switch

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3

Page 6

Contents

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

4

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 7

1 Introduction

1.1 Validity of documentation

11000IntroductionIntroduction1-1.1Validity of docume ntation1100Validity of documenta tion1-BA_Einfhrung

This documentation is valid for speed monitors PNOZ s30 from version

Einf Einleitung

Einf Aufbewahren

2.0. It is valid until new documentation is published.

This operating manual explains the function and operation, describes

the installation and provides guidelines on how to connect the product .

This documentation is intended for instruction and should be retained

for future reference.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-1

Page 8

1 Introduction

1.2 Overview of documentation

1.2Overview of documentation1200Overview of documentation1-Einf_Uebersicht_plus_Beispiele

1 Introduction

The introduction is designed to familiarise you with the contents, structure and specific order of this manual.

2 Overview

This chapter provides information on the device's most important features.

3 Safety

This chapter must be read as it contains important information on safety

and intended use.

4 Function Description

This chapter describes the mode of operation of the device.

5 Installation

This chapter explains how to install the device.

6 Commissioning

This chapter describes the device's commissioning and wiring.

7 Operation

This chapter describes how to operate the product and gives tips in the

case of a fault.

8 Technical Details

9 Examples

1-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 9

1 Introduction

1.3 Definition of symbols

1.3Definition of symbols1300Definition of symbols1-Einfhrung Zeichen

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation

that poses an immediate threat of serious injury and death and

indicates preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation

that could lead to serious injury and death and indicates preventive measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor

injury plus material damage, and also provides information on

preventive measures that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged

and also provides information on preventive measures that can

be taken. It also highlights areas within the text that are of particular importance.

INFORMATION

This gives advice on applications and provides information on

special features.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-3

Page 10

1 Introduction

1-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 11

2 Overview

2.1 Unit structure

22000OverviewOverview2-2.1Unit structure2100Unit structure2-

2.1.1 Range

Range2-Lieferumfang PNOZ s30

2.1.2 Unit features

Unit features2-Gerätemerkmale_Verwendung

Scope of supply:

Speed monitor PNOZ s30

Terminator

Connection terminals

Chip card

Chip card holder

][Bildunterschrift_Drehzahlwchter

Geraetemerkmale_Zusatz BA Einleitung

Gertemerkmale PNOZ s30

Using the product PNOZ s30:

Speed monitor for safe monitoring of standstill, speed, speed range, position and direction.

The product has the following features:

Measured value recorded by

– Incremental encoder

–Proximity switch

– Analogue voltage input

Measured variables

– Standstill

–Speed

–Speed range

– Position

–Direction

– Analogue voltage (track S)

Positive-guided relay outputs

– 2 safety contacts

– 2 auxiliary contacts

Semiconductor outputs

– 4 auxiliary outputs

Expansion interface for 2 more safe relay outputs

Can be configured via the display on the speed monitor

Configuration is stored on a chip card

Display

– Current frequencies

– Current position

– Warning and error messages

Status and fault LEDs

Rotary encoder connection technology:

RJ45 socket

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-1

Page 12

2 Overview

IN1

IN2 GND Y10

Y11

Y12Y13 Y30

A1

Y1 IY2 Y32

Y33

Y34Y35 Y31

X3X1

A2

S11 S21 11

23

13S34 21

12

24

14 22

PNOZ s30

X2X6

X4

A2

S11 S21 11

23

13S34 21

12

24

14 22

X4

X2X6

IN1

IN2 GND Y10

Y11

Y12Y13 Y30

A1

Y1 IY2 Y32

Y33

Y34Y35 Y31

X3X1

PNOZ s30

Power

In1

In2

Rel 1

Rel 2

Fault

X6

1

2

4

3

5

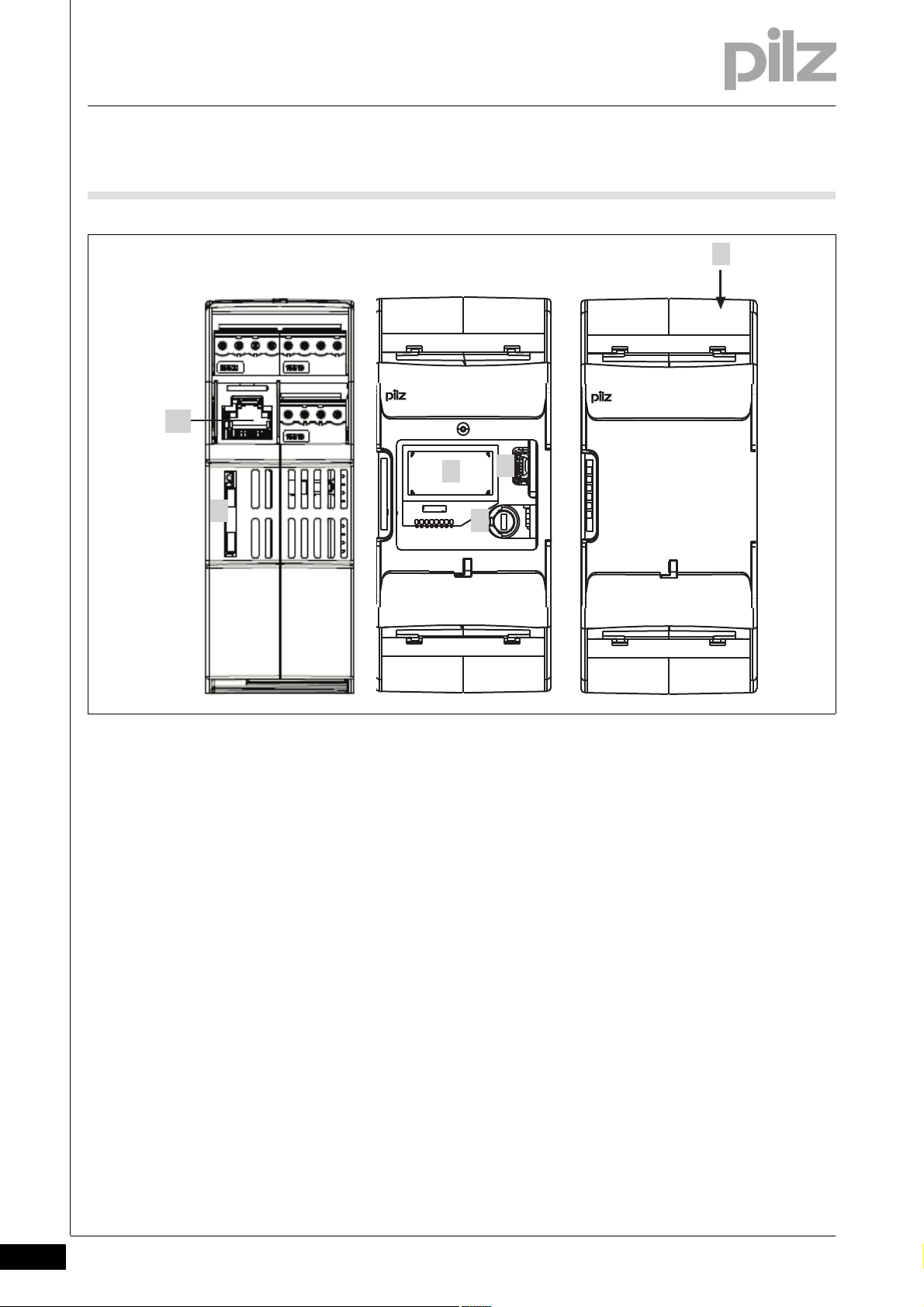

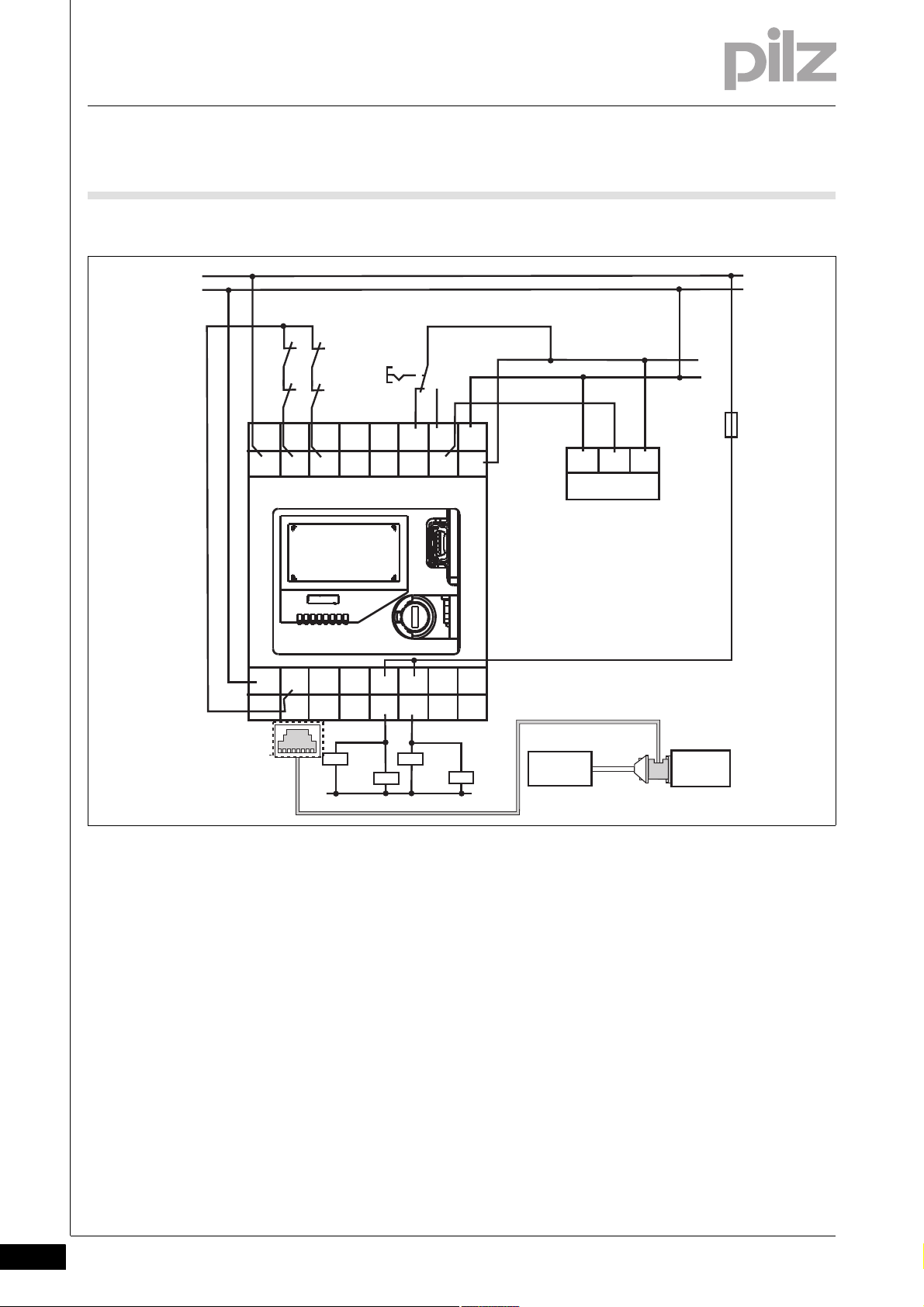

2.2 Front/side view

2.2Front/side view2200Front/side view2-Klemmenbelegung PNOZ s30

Fig. 2-1: Left: Side view, centre: Front view without cover, right:

Front view with cover

Legende

Legend:

A1, A2:

Supply connections

In1, In2, GND:

Proximity switch 1 - In1 (track A) and 2 - In2 (track B) and GND

Y10 ... Y13:

Select inputs (SEL1, SEL2, SEL4, SEL8)

13-14 and 23-24:

Relay outputs (safety contacts)

11-12 and 21-22:

Relay outputs (auxiliary contacts)

Y32 ... Y35: Semiconductor outputs (auxiliary outputs)

S11: +24 V / 30 mA (supply for S34, Y1 and Y2)

S21: 0 V (GND for S11, S34, Y1 and Y2)

S34: Reset input

Y30: 0 V ext (GND for select input and semiconductor outputs)

Y31: 24 V ext (supply for semiconductor outputs)

2-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 13

2 Overview

2.2 Front/side view

Y1, Y2:

Y1: Feedback input for Rel. 1

Y2: Feedback input for Rel. 2:

X6: RJ45 socket for connecting the encoder

(tracks A, /A, B, /B, Z, /Z, S and GND). Proximity switches can be connected via RJ45 socket or connection terminals.

1: Chip card

2: Display

3: USB connection (service only)

4: Rotary knob

5: Expansion interface for 2 more external relay outputs

LEDs:

–Power

–In1

–In2

–Rel 1

–Rel 2

–Fault

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-3

Page 14

2 Overview

2-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 15

3 Safety

3.1 Intended use

33000SafetySafety3-3.1Intended use3100Intended use3-Gertebeschreibung_Drehzahlwaechter_plus_Position_Bereich

S_DZW_Bestimmung/Gerteb eschreibung_Warnu ngen

The speed monitor monitors standstill, speed, speed range, position

and direction in accordance with EN ISO 13849-1 up to PL e and EN IEC

62061 up to SIL CL 3.

WARNING!

Users must take appropriate measures to detect or exclude

errors (e.g. slippage or broken shearpin) which cause the frequency of the encoder signal to no longer be proportional to the

monitored speed.

Appropriate measures are:

Using the monitored encoder to also control the drive

Mechanical solutions

Z-frequency monitoring with an additional proximity switch (Ini

pnp) on the same axis

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-1

Page 16

3 Safety

3.2 Safety regulations

3.2Safety regulations3200Safety regulations3-

3.2.1 Use of qualified personnel

Use of qualified personnel3-Sich Qualif. Personal

The products may only be assembled, installed, programmed, commissioned, operated, maintained and decommissioned by competent persons.

A competent person is someone who, because of their training, experience and current professional activity, has the specialist knowledge required to test, assess and operate the work equipment, devices,

systems, plant and machinery in accordance with the general standards

and guidelines for safety technology.

It is the company's responsibility only to employ personnel who:

Are familiar with the basic regulations concerning health and safety /

accident prevention

Have read and understood the safety guidelines given in this descrip-

tion

Have a good knowledge of the generic and specialist standards ap-

plicable to the specific application.

3.2.2 Warranty and liability

Warranty and liability3-Sich Gewhrleistung

3.2.3 Disposal

Disposal3-Si ch Entsorgung

All claims to warranty and liability will be rendered invalid if:

The product was used contrary to the purpose for which it is intended

Damage can be attributed to not having followed the guidelines in the

manual

Operating personnel are not suitably qualified

Any type of modification has been made (e.g. exchanging compo-

nents on the PCB boards, soldering work etc.).

In safety-related applications, please comply with the mission time t

M

in the safety-related characteristic data.

When decommissioning, please comply with local regulations regard-

ing the disposal of electronic devices (e.g. Electrical and Electronic

Equipment Act).

3-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 17

3 Safety

3.2 Safety regulations

3.2.4 For your safety

For your safety3-Zu Ihrer Sicherheit_Drehzahlwaechter

The device is designed exclusively for use in an industrial environ-

ment. It is not suitable for use in a domestic environment, as this can

lead to interference.

The guarantee is rendered invalid if the housing is opened or unau-

thorised modifications are carried out.

Sufficient fuse protection must be provided on all output contacts

with capacitive and inductive loads.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-3

Page 18

3 Safety

3-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 19

4 Function description

4.1 Introduction

44000Function descriptionFunction description4-4.1Introduction4100Introduc tion4-Funktionen_Einführung

Proximity switches or rotary encoders record measured values, which

are evaluated in the speed monitor PNOZ s30. There are 9 monitoring

functions (F1 ... F9), which are performed simultaneously.

Up to 16 different parameter sets (P0 ... P15) for the monitoring functions

can be selected via the select inputs.

Configuration of the monitoring functions is menu-driven, using a rotary

knob. The outputs switch depending on the configuration.

An interface is available to connect a contact expansion module

Sicherheitseigenschaften_multi_allgemein

PNOZsigma, enabling the number of outputs to be expanded.

The relay conforms to the following safety criteria:

The circuit is redundant with built-in self-monitoring.

The safety function remains effective in the case of a component fail-

ure.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-1

Page 20

4 Function description

A1 A2

Y10 Y11 Y12 Y13 Y30 Y31

Power

Reset/

Start

S34

=

~

Rel. 1

13

11

12

14

23

24

21

22

Feed-

back

Y32 Y33 Y34 Y35

Initiator

Input

In1 In2

GND

24 V

0 V

S11 S21

Inputs (SEL)

Select

Interface

Extended Relais

24 V ext

0 V ext

X6

RJ45

Y1 Y2

Rel. 2

Relay

Control

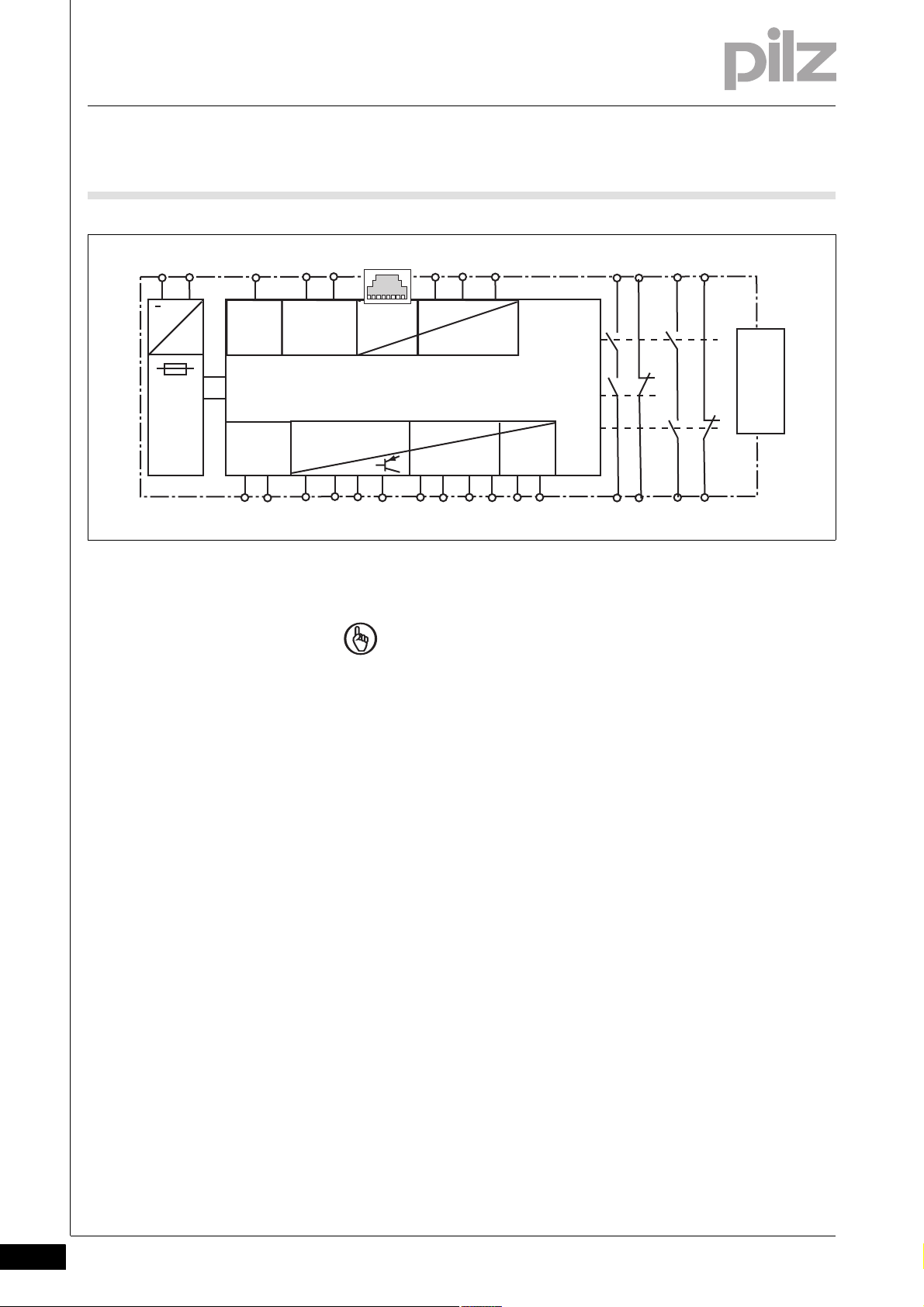

4.2 Block diagram

4.2Block diagram4200Block diag ram4-Blockschaltbild PNOZ s30

NOTICE

The individual blocks are galvanically isolated from each other:

Supply voltage: A1, A2

Encoder and initiator inputs: GND, In1, In2, RJ45 socket and

shield

Reset and feedback circuits: S21, S11, S34, Y1, Y2

Semiconductor outputs and select inputs: Y30, Y31, Y32, Y33,

Y34, Y35, Y10, Y11, Y12, Y13

Relay output 13, 14

Relay output 11, 12

Relay output 23, 24

Relay output 21, 22

If possible, the connections for the various earth potentials

(GND, S21, Y30 and A2) should not be connected, as noise susceptibility can be increased significantly as a result.

4-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 21

4 Function description

Reference

Position

X

Window Width

Position

Window

4.3 Functions

4.3Functions4300Functions4-Funktionen_Überwachungsfunktionen

The following monitoring functions can be configured:

Standstill

With standstill monitoring, the output is switched on when the value falls

below the stated standstill value; if the standstill value is exceeded, the

output switches off.

Speed

With overspeed monitoring, the output switches off when the stated value is exceeded.

Speed range

With range monitoring, the output switches off if the rotational speed

(velocity, frequency) is outside the configured range.

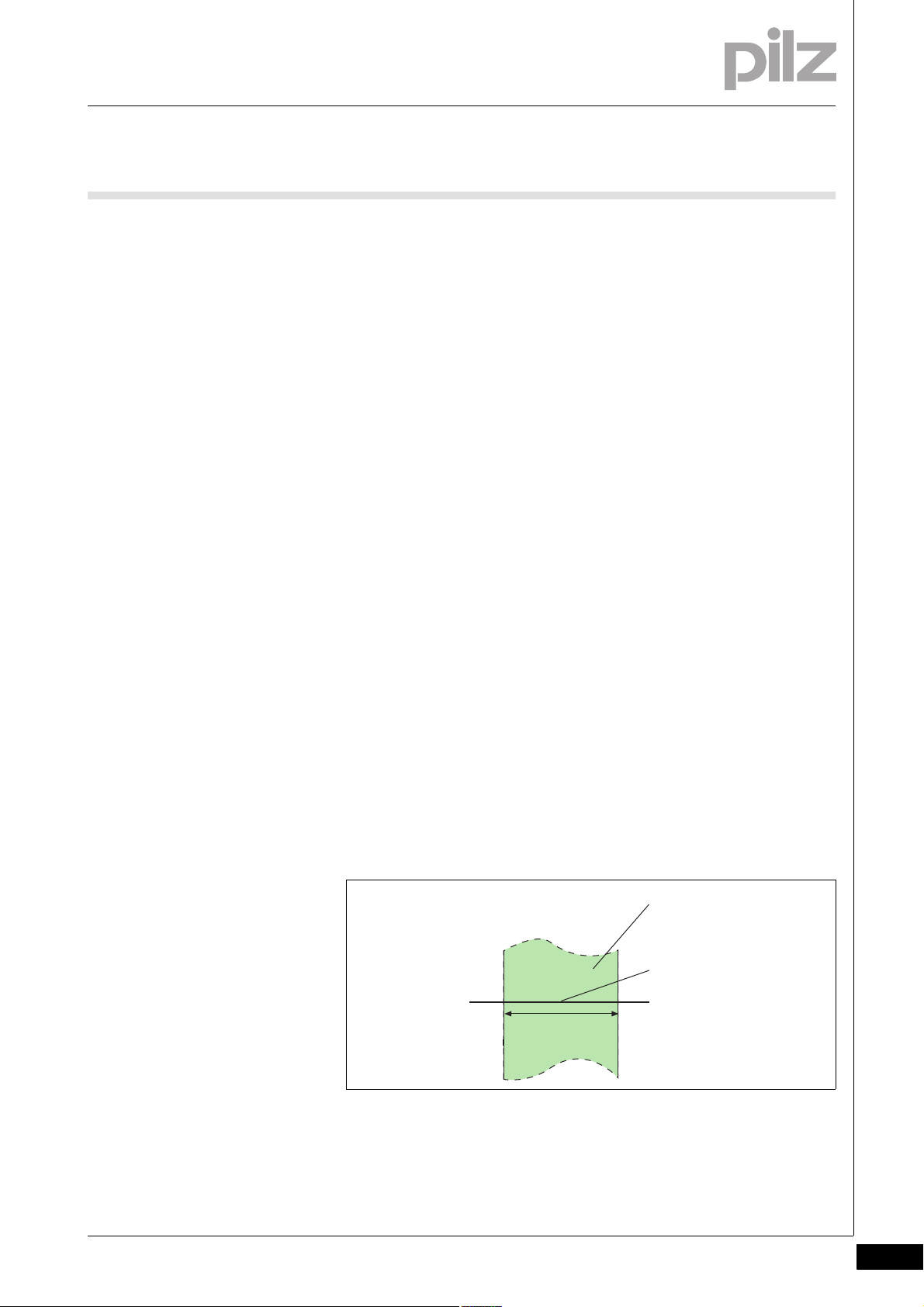

Position

Position monitoring is activated via a rising edge at the reset input. The

current position is adopted as a reference position in the middle of the

position window (configured window width) and the assigned output is

switched on.

The output will stay switched on provided the value is within the position

window.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-3

Page 22

4 Function description

4.3 Functions

If the value moves outside the configured range, position monitoring is

reset and the assigned outputs are switched off. Position monitoring can

be restarted via a rising edge at the reset input

A max. of 4 positions can be configured to be monitored simultaneously.

Please note:

Active position monitoring is not restarted by another rising edge at

the reset input.

Position monitoring cannot be used if proximity switches are em-

ployed.

Direction

If the direction is to be detected safely, this function must be linked to a

safety contact.

If "Direct. Right" is configured, the safety output is switched on during

normal operation in clockwise rotation.

If "Direct. Left" is configured, the safety output is switched on during

normal operation in anti-clockwise rotation.

For both directions, a tolerance can be entered for the wrong direction.

In other words, the drive can run in the wrong direction up to the set tolerance value, without the assigned output switching off.

If an output has been switched off, it cannot switch back on again until

the drive has been run in the right direction up to the tolerance value.

Please note: Direction cannot be detected if proximity switches are

used.

Monitoring for broken shearpins

An additional proximity switch can be connected to track Z to monitor

for broken shearpins

Hysteresis

For each switching function F1 ... F9 (with the exception of direction and

position), a hysteresis can be configured. This prevents the outputs on

the speed monitor from bouncing if there are fluctuations around the response value. The hysteresis becomes effective when the output is

switched on:

Switch-on value = switching threshold – hysteresis

For the lower range limit:

Switch-on value = switching threshold + hysteresis

4-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 23

4 Function description

4.3 Functions

Reset modes

You can choose between the following reset modes:

Automatic reset

If an automatic reset is configured, the output switches on automatically if the speed does not reach the limit value, for example.

Monitored reset with rising edge

If a monitored reset with rising edge is configured, the output switches on if the speed does not reach the limit value and then a rising

edge is detected at S34.

Monitored reset with falling edge

If a monitored reset with falling edge is configured, the output switches on if the speed does not reach the limit value and then a falling

edge is detected at S34.

Switch delay

A delay time can be set for each output (see technical details). The outputs will not switch until the set time has elapsed. It is possible to configure whether the delay time is to be activated when switching on,

switching off, or switching on and off.

WARNING!

Potential loss of safety function due to increased reaction

time

The output switch-off delay (t

will increase the speed monitor's reaction time by the stated

value (see technical details). This must not delay the arrival of a

safe condition by more than the permitted time. The configuration of the switch-off delay must be considered in the risk

assessment as regards hazards, reaction time and safety distance.

, Off) when overspeed is reached

do

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-5

Page 24

4 Function description

4.3 Functions

Feedback loops

Feedback loops are used to monitor external contactors or relays. If a

relay output is activated, it will not switch on until the corresponding

feedback loop is closed.

Start-up delay

To avoid spurious output signals, during the machine's start-up phase,

evaluation of the encoder signals can be delayed after the supply voltage is switched on (see technical details).

Switching direction on semiconductor outputs

The semiconductor outputs can be operated in normally de-energised

or normally energised mode.

Units

The values to be configured can be entered in various units. Depending

on the axis type (linear or rotational axis), various units can be selected

for speed and distance (see chapter entitled "Menu overview").

4-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 25

4 Function description

4.4 Speed configuration

4.4Speed configuration4400Speed configuration4-Funktionen_Drehzahlkonfiguration

The speed monitor is configured using the rotary knob on the device.

Up to 16 parameter sets (P0 ... P15), each with a max. of 9 switch functions (F1 ... F9) can be configured to monitor various operating modes,

for example.

One of the 16 parameter sets is selected via 4 select inputs SEL1 (Y10),

SEL2 (Y11), SEL4 (Y12), SEL8 (Y13).

The switch functions are monitored simultaneously.

Each of a switch function's 16 parameters can be configured as

Standstill limit

Speed limit

Upper or lower limit of speed range

Right-hand direction monitoring

Left-hand direction monitoring

Position monitoring 1 to 4 with width of position window 1 to 4

Exactly one switch function can be assigned to each output. The same

switch function can be assigned to several outputs. With range monitoring, a range is assigned to an output (F2-F3, F4-F5, F6-F7 or F8-F9).

A switch delay and reset mode can be configured for each output.

If only one parameter set is used, configure the parameter set P0. Then

it is not necessary to connect a select input.

INFORMATION

2 basic configurations are available for standard applications, for

simple configuration within the display menu. A basic configuration contains limited menu functions adapted for standard applications, with partly pre-defined parameters. Further information

about basic configurations can be found in this chapter, under

"Basic configuration".

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-7

Page 26

4 Function description

4.4 Speed configuration

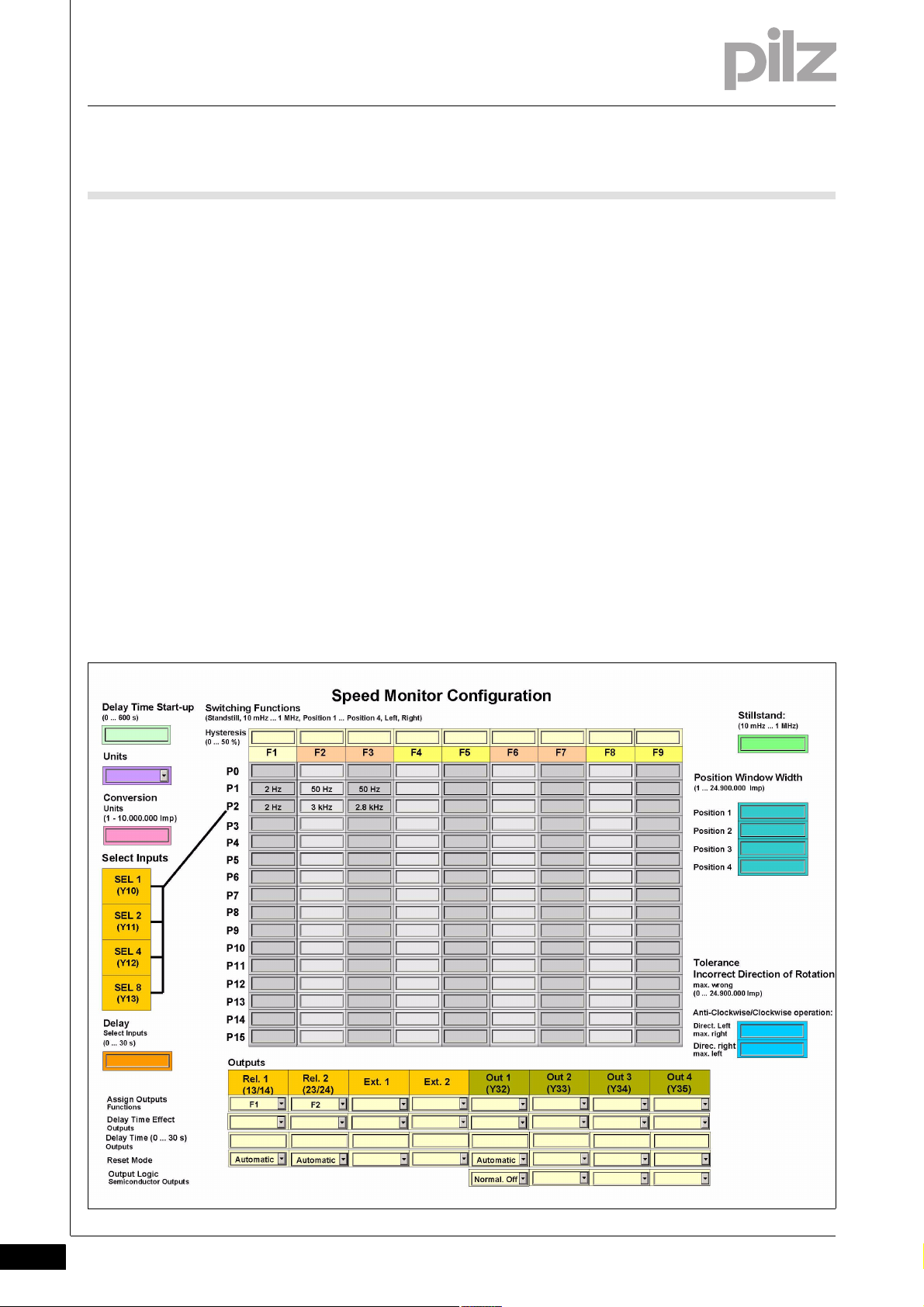

Example configuration:

2 parameter sets for 2 operating modes are configured:

Set-up: P1

Automatic mode: P2

The parameter set P2, "Automatic mode", is selected for speed monitoring (selection via the select inputs, see next chapter "Select inputs").

The following switch functions are selected for the parameter set P2:

F1: Standstill 2 Hz

F2: Overspeed: 3000 Hz

F3: Warning threshold: 2800 Hz

The following outputs are assigned to the switch functions:

F1: Relay output Rel. 1

F2: Relay output Rel. 2

F3: Semiconductor output Out 1

4-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 27

4 Function description

4.4 Speed configuration

For documentation and a better overview of the device settings, we recommend that you fill in this configuration overview before setting the device parameters (link to form, see "Create configuration overview"

chapter).

4.4.1 Select Inputs

Select Inputs4-Funktionen_Select-Eingaenge

The parameter sets are selected via the 4 select inputs SEL1 (Y10), SEL2

(Y11), SEL4 (Y12), SEL8 (Y13). Only one of the configured parameter

sets can be selected.

For applications up to PL e of EN ISO 13849-1 and up to SIL CL 3 of

EN IEC 62061 max. 4 parameter sets can be configured: P1, P2, P4 and

P8 (or P0 if only 1 parameter set is used).

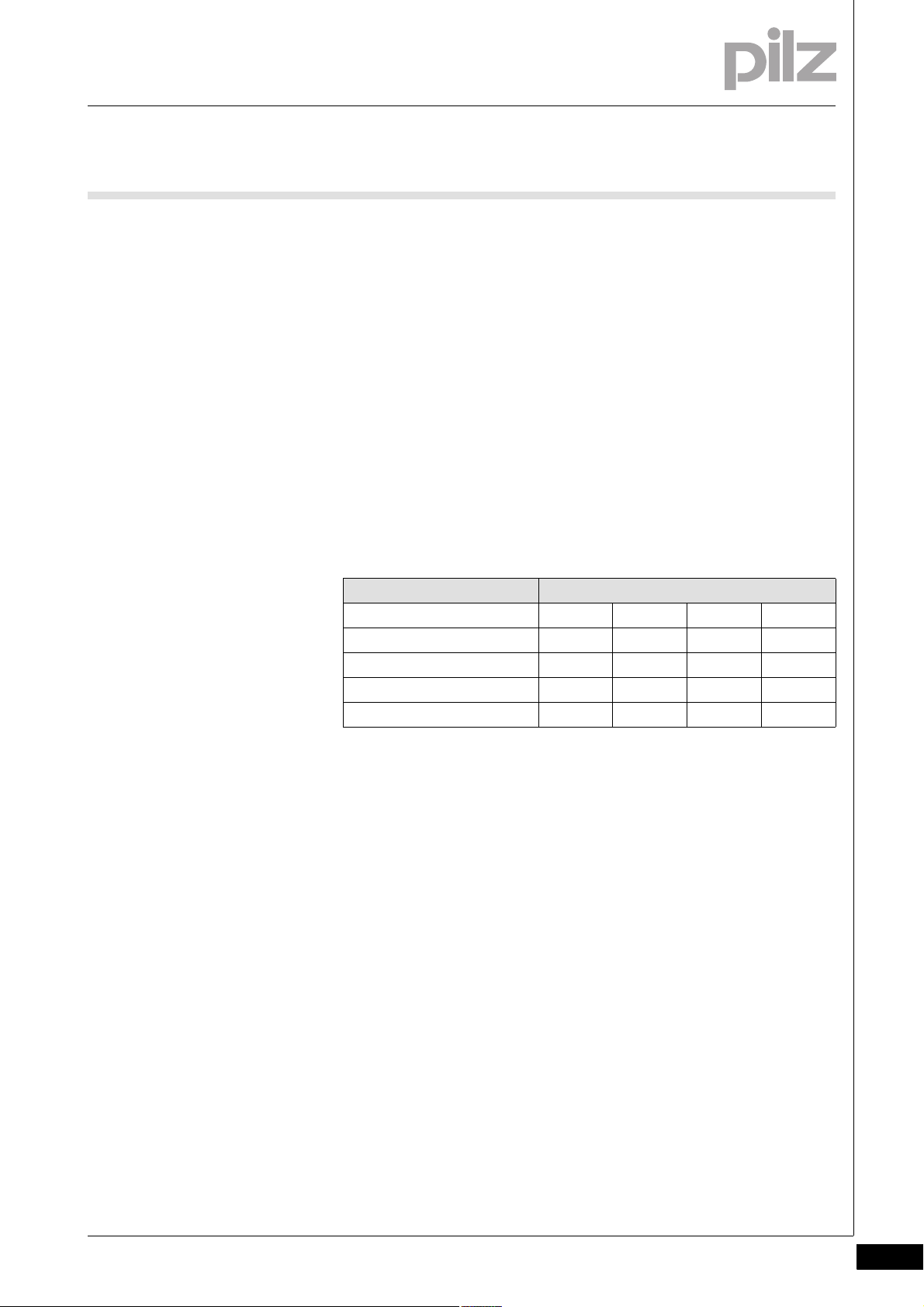

Parameter set Signal states of the select inputs

SEL 8 SEL 4 SEL 2 SEL 1

P1 0001

P2 0010

P4 0100

P8 1000

In all other parameter sets (P0, P3, P5 ... P7, P9 ... P15), the default value

"Standstill" must be configured for each switch function.

When using these 4 parameter sets, the following safety features are

met:

If there is an error when activating the select inputs, such as

Short circuits and shorts between contacts

Open circuit

Input drift

a parameter set other than P1, P2, P4 or P8 is selected. This means that

standstill is monitored.

If necessary, the number of parameter sets can be increased to max. 16.

These can only be used for applications up to max. PL d of

EN ISO 13849-1 and up to SIL CL 2 of EN IEC 62061.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-9

Page 28

4 Function description

4.4 Speed configuration

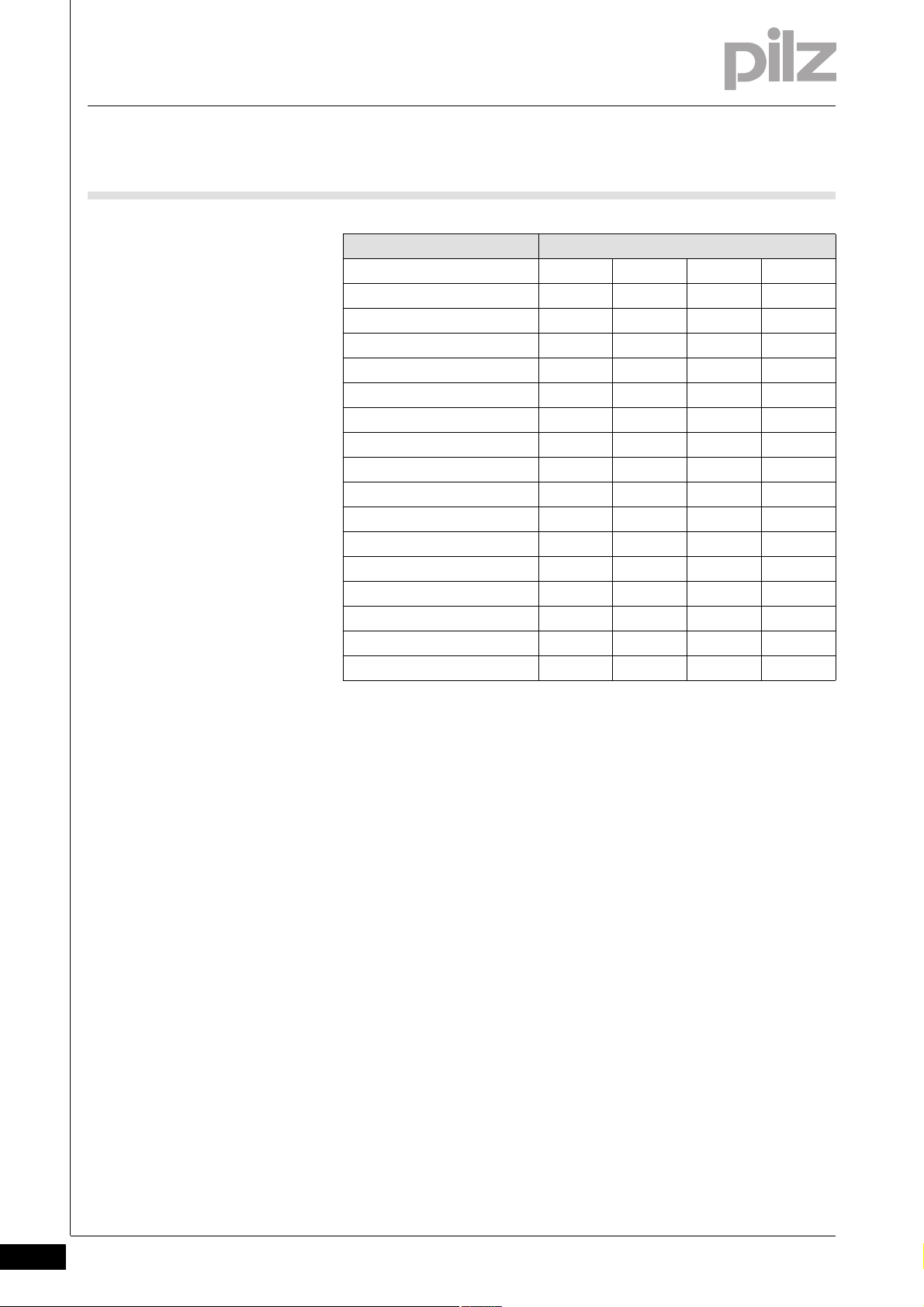

Parameter set Signal states of the select inputs

P0 0000

P1 0001

P2 0010

P3 0011

P4 0100

P5 0101

P6 0110

P7 0111

P8 1000

P9 1001

P10 1010

P11 1011

P12 1100

P13 1101

P14 1110

P15 1111

SEL 8 SEL 4 SEL 2 SEL 1

When using the expanded parameter sets, please note:

If an open circuit occurs when the select inputs are activated, the system

will switch to a parameter set with a lower number (e.g. P7 -> P3 if an

open circuit occurs at SEL4).

The limit values for the switch functions should therefore be entered in

ascending order. (Parameter set P0 -> lowest values, parameter set P15

-> highest values).

Delay on the select inputs

A reaction time can be entered for the select inputs. That way it is possible to filter out invalid signals (e.g. contact bounce) that occur when

switching.

4-10

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 29

4 Function description

4.4 Speed configuration

4.4.2 Switch functions

Switch functions4-_Dummy-Vorlage

Funktionen_Drehzahlkonfiguration_Stillstand

Funktionen_Drehzahlkonfiguration_Drehzahl

Funktionen_Drehzahlkonfiguration_Bereichsüberwachung

Funktionen_Drehzahlkonfiguration_Positionsüberwachung

Funktionen_Drehzahlkonfiguration_Drehrichtung

The following switch functions can be configured:

Standstill

The standstill frequency is configured centrally. The standstill frequency should be the lowest frequency in the configuration.

All switch function parameters are pre-configured to the default setting "Standstill" ex works.

Speed

Limit values can be configured to monitor for overspeed.

Limit values should be entered in ascending order (Parameter set P0

-> lowest values, parameter set P15 -> highest values)

Speed range

Up to 4 speed ranges can be monitored simultaneously.

Configure two switch functions to monitor a range:

–F2 and F3,

–F4 and F5,

–F6 and F7 or

–F8 and F9.

The switch function with the lower number (e.g. F2) operates as the

lower range limit; the switch function with the higher number (e.g. F3)

operates as the upper range limit.

Both switch functions can be assigned to one or more outputs.

Position

Up to 4 different position windows can be monitored: Position 1 ...

Position 4.

Each position to be monitored can be entered as often as necessary

in parameter sets P0 to P15 and switch functions F1 to F9.

Direction

The monitoring functions "Direct. Left" and "Direct. Right" can be

configured as a switch function as often as necessary.

For both directions, a tolerance can be entered for the wrong direc-

tion.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-11

Page 30

4 Function description

4.4 Speed configuration

4.4.3 Basic configuration

Basic configuration4-Funktion en_Basiskonfiguration

Two basic configurations are available for standard applications, for

simple configuration within the display menu. A basic configuration contains limited menu functions adapted for standard applications, with

partly pre-defined parameters.

The following basic configurations are available:

Basic configuration 1: Ini pnp pnp (proximity switch)

Pre-defined settings and configuration options:

Encoder type

2 pnp type proximity switches

Switch functions

– Standstill (F1)

Standstill frequency configurable in Hz

–Speed (F2)

Max. frequency (v max) configurable in Hz

Parameter set/select input

P0, select inputs must be "0" (unconnected)

Hysteresis

Standstill and speed, 2 % each

Output assignment

– Standstill: Relay output Rel. 1 and semiconductor output Out 1

– Speed: Relay output Rel. 2 and semiconductor output Out 2

Reset mode

– Rel. 1, Rel. 2 Out 1, Out 2: Automatic reset

Switch delay

None

Max. encoder frequency

3.5 kHz

4-12

Basic configuration 2: Rotary encoder

Encoder type

Rotary encoder

Rotary encoder type configurable

Switch functions

– Standstill (F1)

Standstill frequency configurable in Hz

–Speed (F2)

Max. frequency (v max) configurable in Hz

–Direction (F3)

Direction left

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 31

4 Function description

4.4 Speed configuration

Tolerance for wrong direction = 10 Imp

–Direction (F4)

Direction right

Tolerance for wrong direction = 10 Imp

Parameter set/select input

P0, select inputs must be "0" (unconnected)

Hysteresis

Standstill and speed, 2 % each

Output assignment

– Standstill: Relay output Rel. 1 and semiconductor output Out 1

– Speed: Relay output Rel. 2 and semiconductor output Out 2

– Direction left: External output Ext. 1 and semiconductor output Out

3

– Direction right: External output Ext. 2 and semiconductor output

Out 4

Reset mode

– All outputs: Automatic reset

Switch delay

None

Max. encoder frequency

1 MHz

4.4.4 Chip card

Chip card4-Funktionen_Chipkarte

For details of how to configure the basic configurations, see the chapter

entitled Commissioning/Display Menu - Configuration.

The set parameters, the name of the configuration and the passwords

are stored on the chip card (see section entitled "Using the chip card").

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-13

Page 32

4 Function description

Proximity switch 1

Proximity switch 2

4.5 Input device types

4.5Input device types4500Input device types4-

4.5.1 Proximity switch

Proximity switch4-S_DZW_Anford_Naeherungsschalter

The following proximity switches can be used:

–pnp

–npn

The proximity switches must be fitted so that at least one is always

activated. In other words, the proximity switches must be fitted such

that the recorded signals overlap.

The supply voltage of the proximity switches should be monitored via

track S.

CAUTION!

Appropriate installation measures should be taken to prevent a

foreign body coming between the signal encoder and the proximity switch. If not, the foreign body could cause invalid signals.

Please note the values stated in the technical details

The maximum frequency of the used encoders must be entered for a

complete configuration ("Encoder" Menu -> "Track AB" -> "Track AB

fmax" / "Track Z" -> "Track Z fmax").

4-14

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 33

4 Function description

4.5 Input device types

4.5.2 Rotary encoders

Rotary encoders4-S_DZW_Anford_Drehgeber

The following rotary encoders can be used:

– TTL, HTL (single-ended or differential signals)

– sin/cos 1 Vss

– Hiperface

The rotary encoders can be connected with or without Z index (0 in-

dex)

A proximity switch can also be connected to track Z for monitoring

broken shearpins

Track S can be used:

– To connect an encoder's error output

– To monitor voltages between 0 V and 30 V for a permitted upper

and lower limit. For example, the encoder's supply voltage can be

monitored.

The maximum frequency of the used encoders must be entered for a

complete configuration ("Encoder" Menu -> "Track AB" -> "Track AB

fmax" / "Track Z" -> "Track Z fmax").

Please note the values stated in the technical details

4.5.2.1 Adapter for incremental encoders

Adapter for incremental encoders4-Drehzahlwaechter_Inkrementalgeber_Adapter

The adapter records the data between the incremental encoder and the

drive and makes it available to the speed monitor via the RJ45 socket.

Pilz supplies complete adapters as well as ready-made cable with RJ45

connector, which can be used when making your own adapter. The

range of products in this area is constantly being expanded. Please contact us about the range of adapters that is currently available.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-15

Page 34

4 Function description

4-16

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 35

5 Installation

5.1 General installation guidelines

55000InstallationInstallation5-5.1General installation guidelines5100General installation guidelines5-][Montage_Drehzahlwächter

Install base unit without contact expander module:

Ensure that the plug terminator is inserted at the side of the unit.

Connect base unit and PNOZsigma contact expander module:

Remove the plug terminator at the side of the base unit and at the

contact expander module.

Connect the base unit and the contact expander module to the sup-

plied connector before mounting the units to the DIN rail.

Control cabinet installation

The unit should be installed in a control cabinet with a protection type

of at least IP54.

It is preferable to install the device on a horizontal DIN rail in order to

ensure the best possible convection.

Use the locking element on the rear of the device to attach it to the

DIN rail.

Push the device upwards or downwards before lifting it from the DIN

Montage_EMV ESD

rail.

CAUTION!

Damage due to electrostatic discharge!

Electrostatic discharge can damage components. Ensure

against discharge before touching the product, e.g. by touching

an earthed, conductive surface or by wearing an earthed armband.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5-1

Page 36

5 Installation

120 (4.72")

* 100 (3,94")

98 (3.86")

45

(1.77")

5.1 General installation guidelines

5.1.1 Dimensions

Dimensions5-Abmessungen

*with spring-loaded terminals

5-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 37

6 Commissioning

8 1

A1

L1

N

A2

A1

L+

A2

L-

6.1 Wiring

66000CommissioningCommissioning6-6.1Wiring6100Wiring6-

6.1.1 General wiring guidelines

General wiring guidelines6-Verdrahtung_Kupferdra ht_75C

Note:

Information given in the "Technical details" must be followed.

Verdrahtung

6.1.2 Pin assignment of RJ45 socket

Pin assignment of RJ45 socket6-Anschlussbelegung RJ45-Buchse

Use copper wire that can withstand 75 °C.

The cable used to connect the rotary encoder and proximity switch

must be shielded (see connection diagrams in this chapter).

If possible, the connections for the various earth potentials (GND,

S21, Y30 and A2) should not be connected, as noise susceptibility

can be increased significantly as a result.

RJ45 socket

8-pin

6.1.3 Supply voltage

Supply voltage6-Anschluss_Versorgungsspannung

Supply voltage AC DC

PIN Track

1S

2GND

3Z

4A

5/A

6/Z

7B

8/B

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-1

Page 38

6 Commissioning

IN2

IN1

GND

24 V

0 V

INI_A

INI_B

RJ45

A

/A

B

/B

Z

/Z

GND

S

6.1 Wiring

6.1.4 Connection of proximity switches

Connection of proximity switches6-S_DZW_Betriebsb_Anschluss_Naeherungssch

The following proximity switch combinations can be connected:

A: pnp, B: pnp

A: npn, B: npn

A: pnp, B: npn

A: npn, B: pnp

When connecting proximity switches please note:

Proximity switches can either be connected to terminals In1, In2 and

GND or to tracks A and B plus GND on the RJ45 socket.

Track S should be used to monitor the supply voltage (see drawing).

A permitted voltage range can be entered in the menu.

Connect the proximity switch to 24 VDC of the power supply.

6-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 39

6 Commissioning

X6

PNOZ s30

2

4

7

A

B

GND

Input Device

X6

PNOZ s30

2

4

5

7

8

A

/A

B

/B

GND

Input Device

6.1 Wiring

6.1.5 Connection of a rotary encoder

Connection of a rotary encoder6-S_DZW_Betriebsb_Inkremen

Proceed as follows when connecting the rotary encoder:

The rotary encoder be connected via an adapter (e.g. PNOZ msi6p) or

can be connected directly to the speed monitor.

Use only shielded cables for all connections

Always connect GND on the rotary encoder to GND on the RJ45 con-

nector.

6.1.5.1 Connect rotary encoder to speed monitor

Connect rotary encoder to speed monitor6-S_DZW_Betriebsb_Anschluss_Inkrementalgeber

Encoder types:

TTL single ended

HTL single ended

Please note:

Tracks /A and /B must remain free

Encoder types:

TTL differential

HTL differential

sin/cos 1 Vss

Hiperface

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-3

Page 40

6 Commissioning

X6

PNOZ s30

2

4

7

A

B

GND

Input Device

3

Z

X6

PNOZ s30

2

4

5

7

8

A

/A

B

/B

GND

Input Device

3

Z

/Z

6

6.1 Wiring

6.1.5.2 Connect rotary encoder with Z index to speed monitor

Connect rotary encoder with Z index to speed monitor6-S_DZW_Betriebsb_Anschluss_Inkrementalgeber_Z-Index

Encoder types:

TTL single Z Index

HTL single Z Index

Please note:

Tracks /A, /B and /Z must remain free

Encoder types:

TTL diff. Z Index

HTL diff. Z Index

sin/cos 1 Vss Z Index

6-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 41

6 Commissioning

Input Device

A

/A

B

/B

X6

PNOZ s30

Drive

Adapter

GND

GND

18

24 V

0 V

X6

PNOZ s30

2

4

7

A

B

GND

Input Device

3

1

6.1 Wiring

6.1.5.3 Connect rotary encoder to the speed monitor via an adapter

Connect rotary encoder to the speed monitor via an adapter6-S_DZW_Betriebsb_Anschluss_IInkremen_ueber_Adapt

The adapter (e.g. PNOZ msi6p) is connected between the rotary encoder and the drive. The output on the adapter is connected to the RJ45

socket on the speed monitor.

6.1.6 Connection of proximity switch and rotary encoder

Connection of proximity switch and rotary encoder6-S_DZW_Betriebsb_Anschluss_Inkrement_Naeherungssch

Encoder types:

TTL single Z Freq. Ini pnp

HTL single Z Freq. Ini pnp

Please note:

Tracks /A, /B and /Z must remain free.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-5

Page 42

6 Commissioning

24 V

0 V

X6

PNOZ s30

2

4

5

7

8

A

/A

B

/B

GND

Input Device

3

1

S11

S34

S3

Y1

Y2

S11

K5

K6

K5

L+

L-

K6

Y1

13 (23)

Y2

14

S11

24

S21

6.1 Wiring

Encoder types:

TTL differential Z Freq. Ini pnp

HTL differential Z Freq. Ini pnp

sin/cos 1 Vss Z Freq. Ini pnp

Hiperface Z Freq. Ini pnp

Please note:

Track /Z must remain free!!

6-6

6.1.7 Reset circuit

Reset circuit6-Anschluss_Startkreis

Automatic reset Monitored reset

Automatic reset must only be configured

No wiring necessary!

6.1.8 Feedback circuit

Feedback circuit6-Rueckfuehrkreis

Link Contacts from external contactors

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 43

6 Commissioning

Y10 (Y11, Y12, Y13)

PLC Output

Y30

PLC 0 V

Y31

PLC +24 V

Y30

PLC 0 V

Y32 (Y33, Y34, Y35)

PLC Input

6.1 Wiring

6.1.9 Select inputs

Select inputs6-Anschluss_Eingangskreis

6.1.10 Semiconductor outputs

Semiconductor outputs6-Anschluss_Halbleiterausgang

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-7

Page 44

6 Commissioning

6.2 Display menu - Configuration

6.2Display menu - Configuration6200Display menu - Configuration6-Inbetriebnahme_Drehknopf_Funktion

The menu settings are made on the unit's display via a rotary knob. You

have the option to make the settings on the knob by hand or with a

screwdriver. If you make the settings with a screwdriver, the knob can

remain within the unit.

6.2.1 Create configuration overview

Create configuration overview6-S_DZW_Inbetriebnahme_Konfigurat ionsübersicht_erstellen

For a better overview, before entering the configuration values we recommend that they are entered in the attached form

PNOZ_s30_Config_Overview

:

6-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 45

6 Commissioning

A

1.

2.

B

6.2 Display menu - Configuration

6.2.2 Operate rotary knob

Operate rotary knob6-Inbetriebnahme_Drehknopf_Bild

Inbetriebnahme_Drehknopf_Funktion_heraus_und_zurck

The rotary knob:

(A) should be pulled out until it clicks into position

(B) then released and retracted back into the unit:

– Press the latch on the side of the rotary knob (1) towards the centre

of the knob. This releases the rotary knob.

– Press the knob downwards (2) while keeping the latch held down.

6.2.3 Configure Speed Monitor

Configure Speed Monitor6-Inbetriebnahme_Drehknopf_Funktion_drcken_drehen_anzeigen

The settings are made via the rotary knob, as follows:

Press the knob

Confirm selection/setting

Switch to menu

Rotate knob

Inbetriebnahme_Drehknopf_Funktion_drcken_drehen_konfigurieren

Inbetriebnahme_Drehknopf_Funktion_drehen_schnell_Menü-Deutsch

Select menu level

Set the parameter/numeric value

The speed with which you turn the knob affects the sequence of the

menu and numeric values:

Slowly: Units

Quickly: Tens

Very quickly:

– Setting the numeric value: Hundreds

– When switching the menu level: Jump to CANCEL

Inbetriebnahme_Display_W ichtig_Eingabepfli cht_s30

NOTICE

Please note that all parameters are set to their default values on

delivery.

Please check all the safety-related parameters at least, and

enter the values that correspond to your application.

Inbetriebnahme_Display_Info_Standardanzeige_30s_5min

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-9

Page 46

6 Commissioning

6.2 Display menu - Configuration

INFORMATION

If no value is set or amended within 30 s of a menu action, the

display reverts to the default display. The current setting remains

unchanged.

If the master password has been entered, this time increases to

5 minutes.

6.2.4 Password protection

Password protection6-Kennwortschutz

The configuration is protected through passwords. There is a master

password and a customer password.

Factory setting for both passwords: 0000

The password levels contain different authorisations:

Master password

Display: All settings

Edit: All settings

Customer password

Display: All settings

Edit:

– The customer password can be changed.

– The language can be changed.

– The settings can be reset to the factory settings.

No password

Edit:

– The language can be changed.

– The settings can be reset to the factory settings.

If the settings are reset to the factory settings, the passwords and the

language will also be reset to the factory settings.

The passwords can be changed at any time in the menu.

Enter a password containing 4 characters.

6-10

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 47

6 Commissioning

6.2 Display menu - Configuration

6.2.5 Use chip card

Use chip card 6-Inbetriebnahme_Chipkarte_verwenden_Konfiguration_deutsch

The parameters that are set on a unit can be stored on the chip card. The

data is stored along with a device identifier, the passwords, the name of

the configuration and the check sum. We recommend that you always

operate the unit with a chip card.

If the parameters on a device have been changed due to an error, they

can be restored using the backup copy on the chip card.

If a unit requires maintenance or needs to be exchanged, the chip

card can be used to download the parameters to another unit.

INFORMATION

If you operate the unit without a chip card, the "Fault" LED will

light and the following message will appear once only: Please

Insert SIM Card!. If you change the parameters, the Please

Insert SIM Card! message will reappear.

The message disappears after 30 s or by pressing the rotary

knob.

When the chip card is inside the unit:

The chip card is checked to verify the device identifier, valid parame-

ters, and ensure that the data is identical.

Unit parameters are automatically saved to the chip card during op-

eration. As a result, the chip card always contains a copy of the unit's

current internal data. Exception: If you select Write configuration to

SIM: No.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-11

Page 48

6 Commissioning

6.2 Display menu - Configuration

6.2.5.1 Insert chip card

Insert chip card 6-Inbetriebnahme_Chipkarte_einsetzen_1_wichtig_Kontaktflaeche_sauber

NOTICE

The chip card contact is only guaranteed if the contact surface is

clean and undamaged. For this reason please protect the chip

card's contact surface from

Contamination

Contact

Mechanical impact, such as scratches.

Inbetriebnahme_Chipkarte_einsetzen_3_Chipkarte_nicht verkantet

Make sure that you do not bend the chip card as you insert it into the

Inbetriebnahme_Chipkarte_einsetzen_4_Chipkarte_nicht verkantet_Bild_sigma

chip card slot.

6.2.5.2 Write data to chip card

Write data to chip card 6-Inbetriebnahme_Daten_auf_Chipkarte_schreiben_Text

If you are inserting a chip card which has not yet been written by a PNOZ

s30, you have the option to:

Inbetriebnahme_Daten_auf_Chipkarte_schreiben_zulassen_deutsch

Allow data to be written to the chip card

Insert chip

card

Please insert SIM

Card!

Write configuration to

SIM: No?

Inbetriebnahme_Daten_auf_Chipkarte_schreiben_nicht-zulassen_deutsch

Do not allow data to be written to the chip card

Insert chip card 1. Data is not written to the chip card

Please insert SIM Card! Write configura-

tion to SIM: No?

1. 2. Data is written to the chip

Write configuration to SIM:

Yes?

Insert rewritable SIM Card!

card

Current menu

6-12

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 49

6 Commissioning

6.2 Display menu - Configuration

6.2.5.3 Read data from chip card

Read data from chip card6-Inbetriebnahme_Daten_von_Chipkarte_lesen_Text-1

If you are inserting a chip card which has not yet been written by a PNOZ

s30, you have the option to:

Inbetriebnahme_Daten_von_Chipkarte_lesen_zulassen_deutsch

Allow data to be read from the chip card

Insert chip card (data on chip

card different from device)

Current

menu

SIM: Name of the configuration (8 characters)

CRC: 12345 (0 .. 65535)

Load SIM: No?

Inbetriebnahme_Daten_von_Chipkarte_lesen_nicht-zulassen_deutsch

Do not allow data to be read from the chip card

Insert chip card (Data on chip

card different from device)

Current menu SIM: Name of the configurati-

on (8 characters)

CRC: 12345 (0 .. 65535)

Load SIM: No?

1. 2. Data is read into the de-

vice

SIM: Name of

Current menu

the configuration (8 characters)

CRC: 12345 (0

.. 65535)

Load SIM:

Yes?

1. Data is not read into the device, data is written to

the chip card

Write configuration to SIM: No?

(for more details see "Write data to chip card)

6.2.5.4 Transfer device parameters

Transfer device parameters 6-Inbetriebnahme_Gerteparam eter_bertragen_deutsch

You can transfer device parameters from one device to another using

the chip card.

Proceed as follows:

Remove chip card containg the data from device 1.

Insert chip card in device 2.

Confirm the message Load SIM Yes?.

The data is transferred.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-13

Page 50

6 Commissioning

6.2 Display menu - Configuration

6.2.5.5 Duplicate chip card

Duplicate chip card6-_Dummy-Vorlage

You can also create copies of a chip card and its data.

Proceed as follows:

Remove chip card containg the device data.

Insert a new chip card into the device.

Confirm the message Write configuration to SIM Yes?.

The new chip card is written.

6.2.6 Menu overview

Menu overview6-Menue-Einstellungen-einf ührung

6.2.6.1 Permanent display

Permanent display6-Menu e-Einstellungen-D aueranzeige

The tables provide an overview of the menu settings.

The attached Excel file provides a detailed view of the setting options:

PNOZ_s30_Menu_Overview

.

If no settings are made, information regarding the configuration and current values are shown on the display.

You can change the permanent display on the display in the "Settings"

menu.

6-14

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 51

6 Commissioning

6.2 Display menu - Configuration

6.2.6.2 Basic settings Ini pnp pnp

Basic settings Ini pnp pnp6-Menue-Einstellungen-Basiskonfiguration1

Settings for basic configuration 1

Level Designation

on the display

1 Basic Param.

Ini pnp pnp

Default:

Load?

2 Standstill

Rel.1 Out 1

Default:

2.00 Hz

2 v max:

Rel.1 Out 2

Default:

500 Hz

Description Settings

Select the default settings with which

the basic configuration menu "Ini pnp

pnp" is to be called:

-Load: The basic parameters are

loaded. Switches afterwards to the

basic menu "Ini pnp pnp".

The basic parameters should always

be loaded when commissioning for

the first time.

-Change: The basic parameters are

not loaded, i.e. all parameters are retained. The basic menu parameters

can be changed within the permitted

boundaries.

-CANCEL: Exits the basic menu.

Enter standstill frequency 100 mHz ... 10.0 Hz

Enter the max. permitted speed 10 mHz ... 3.00 kHz

Other, pre-defined settings:

Encoder type

2 pnp type proximity switches

Parameter set/select input

P0, select inputs must be "0" (unconnected)

Hysteresis

Standstill and speed, 2 % each

Output assignment

– Standstill: Relay output Rel. 1 and semiconductor output Out 1

– Speed: Relay output Rel. 2 and semiconductor output Out 2

Reset mode

– Rel. 1, Rel. 2 Out 1, Out 2: Automatic reset

Switch delay

None

Max. encoder frequency

3.5 kHz

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-15

Page 52

6 Commissioning

6.2 Display menu - Configuration

6.2.6.3 Basic settings for the rotary encoder

Basic settings for the rotary encoder6-Menue-Einstellungen-Basiskonfiguration2

Settings for basic configuration 2

Level Designation

on the display

1 Basic Param.

Encoder:

Default:

Load?

2 InputDevice

Default:

TTL

Differential

2 Standstill

Rel.1 Out 1

Default:

100 Hz

2 v max:

Rel.2 Out 2

Default:

5.00 kHz

Description Settings

Select the default settings with which

the basic configuration menu "Rotary

encoder" is to be called:

-Load: The basic parameters are

loaded. Switches afterwards to the

basic menu "Rotary encoder".

The basic parameters should always

be loaded when commissioning for

the first time.

-Change: The basic parameters are

not loaded, i.e. all parameters are retained. The basic menu parameters

can be changed within the permitted

boundaries.

-CANCEL: Exits the basic menu.

Select rotary encoder type -TTL differential (A, /A, B, /B)

-TTL single ended

-HTL differential (A, /A, B, /B)

-HTL single ended

-sin/cos 1 Vss (A, /A, B, /B)

-Hiperface (A, /A, B, /B)

Enter standstill frequency 10 mHz to 1.00 kHz

Enter the max. permitted speed 10 mHz to 1.00 MHz

6-16

Other, pre-defined settings:

Switch functions

–Direction (F3)

Direction left

Tolerance for wrong direction = 10 Imp

–Direction (F4)

Direction right

Tolerance for wrong direction = 10 Imp

Parameter set/select input

P0, select inputs must be "0" (unconnected)

Hysteresis

Standstill and speed, 2 % each

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 53

6 Commissioning

6.2 Display menu - Configuration

Output assignment

– Standstill: Relay output Rel. 1 and semiconductor output Out 1

– Speed: Relay output Rel. 2 and semiconductor output Out 2

– Direction left: External output Ext. 1 and semiconductor output Out

3

– Direction right: External output Ext. 2 and semiconductor output

Out 4

Reset mode

– All outputs: Automatic reset

Switch delay

None

Max. encoder frequency

1 MHz

6.2.6.4 Settings

Settings6-Menue-Einstellungen-Eins tellungen

Level Designation

on the display

1 Permanent display

Default:

H : Min : Sec (system

time)

V (current speed of

track AB)

Position

1 Display Unit

Speed: Dist:

Default:

Hz - Imp

1 Conversion

Default:

1Hz =

1 Imp / s

Description Settings

Permanent display

Current values and information regarding configuration are displayed.

You can change the permanent display on the display

Select unit of speed and distance (position)

wählen.

Unit conversion.

Enter ratio of unit to pulses.

Display combinations:

- vz (current speed of track Z)

- v (current speed of track AB)

- Position

- Switch functions F1 ... F9

- v (current speed of track AB)

- Position

- Line 1/2: F1/F2, F3/F2, F5/F4, F7/F6 or F9/

F8

(parameters selected via select inputs).

v (current speed of track AB)

- H : Min : Sec (system time:)

- v (current speed of track AB)

- Position

Speed (rotional speed) - Dist. (distance/po-

sition)

Hz - Imp (pulse)

Hz - Edg (edge)

m/s - m

m/min - m

m/h - m

rps - rev

rpm - rev

Display

1 Hz = 1 Imp/s

1 Hz = 4 Edg/s

1m = x Imp (x = 1 ... 10.000.000 Imp)

1 rev = x Imp (x = 1 ... 10.000.000 Imp)

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-17

Page 54

6 Commissioning

6.2 Display menu - Configuration

Level Designation

on the display

1InputDevice

Settings

2 InputDevice

Default:

Undefined

Description Settings

Create encoder configuration for the

tracks A,

/A, B, /B, Z, /Z, S

Select pre-defined encoder types for

the tracks A, B and Z:

Proximity switch

Rotary encoder

- with and without inverted signals

- with or without Z index (0 index)

- with proximity switch at track Z

Note:

If "Undefined" is selected, an error

message is shown when you confirm

the menu

No encoder selected:

- Undefined

Proximity switch (Ini):

- Initiator A: pnp B: pnp

- Initiator A: npn B: npn

- Initiator A: pnp B: npn

- Initiator A: npn B: pnp

Rotary encoder:

TTL

- TTL differential (A, /A, B, /B)

- TTL single ended (A, B)

TTL with Z index

- TTL diff. Z index (A, /A, B, /B, Z, /Z)

- TTL single Z index (A, B, Z)

HTL

- HTL differential (A, /A, B, /B)

- HTL single ended (A, B)

HTL with Z index

- HTL diff. Z Index (A, /A, B, /B, Z, /Z)

- HTL single Z Index (A, B, Z)

Sin/Cos 1 Vss

- sin/cos 1 Vss (A, /A, B, /B)

Sin/Cos 1 Vss with Z index

- sin/cos 1 Vss Z Index (A, /A, B, /B, Z, /Z)

Hiperface

- Hiperface (A, /A, B, /B)

6-18

Rotary encoder + pnp proximity switch

TTL + pnp proximity switch

- TTL diff. (A, /A, B, /B), Z Freq Inipnp (Z)

- TTL single (A, B), Z Freq Inipnp (Z)

HTL + pnp proximity switch

- HTL diff. (A, /A, B, /B), Z Freq Inipnp (Z)

- HTL single (A, B), Z Freq Ini pnp (Z)

sin/cos 1 Vss + pnp proximity switch

- sin /cos 1 Vss (A, /A, B, /B), Z Freq Inipnp

(Z)

Hiperface + pnp proximity switch

- Hiperface (A, /A, B, /B), Z Freq Inipnp (Z)

2 Track AB Settings for tracks A and B

3 Type AB For information only:

Information on configured encoder

type on tracks A and B

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 55

6 Commissioning

6.2 Display menu - Configuration

Level Designation

on the display

3 Track /A/B For information only:

3 AB Direction

Default:

Normal

3 Track AB fmax

Default:

10 mHz

2 Track Z Settings for track Z

3 Type Z For information only:

3 Track /Z For information only:

3 Track Z fmax

Default:

10 mHz

Description Settings

Information on the use of the inverted

tracks /A and /B:

No track /A /B

or

Inverted (inverted tracks /A and /B

used)

or

external (e.g. "Hiperface" encoder

U

ref

type)

Select direction for tracks A and B In-

formation:

This function is used to display a forward movement as positive linear/rotational speed, irrespective of the

installation of the rotary encoder.

Enter max. frequency of the encoder

on tracks A and B

Important:

The frequency must be less than or

equal to the max. encoder frequency

specified in the encoder's data sheet

and less than the max. speed of the

monitored drive.

Information on configured encoder

type at track Z

Information on the use of the inverted

track /Z:

No track /Z

or

Inverted (inverted track /Z used)

Enter max. frequency of the encoder

on track Z

Important:

The frequency must be less than the

max. encoder frequency specified in

the encoder's data sheet

- Normal

- Inverted

10 mHz … 1.00 MHz

10 mHz … 1.00 MHz

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-19

Page 56

6 Commissioning

6.2 Display menu - Configuration

Level Designation

on the display

fAB/fZ Verh.

Default:

1,0000 : 1

2 Track S Settings for track S (error track)

3 Track S

Default:

Not used

3 Track S Umax

Default:

6.0 V

3 Track S Umin

Default:

2.0 V

1 Delay Time

Start-up

Default:

0.00 s

1 Function

Parameter

2 Standstill

v max:

Default:

2.00 Hz

2 (F1 … F9) Function

Parameter

3 (F1 ... F9) (P0 ... P15)

Parameter

Default:

Standstill

4 (F1 ... F9) (P0 ... P15)

Teach v max:

Display:

Current linear/rotational speed

Description Settings

Enter the ratio of the frequency on

tracks AB "fAB" to the frequency on

track Z "fZ".

Used to check the Z index or for frequency monitoring on track Z

Information

Calculating the frequency ratio:

Enter permanent display: "vz: v: Position:"

Switch on drive

Read vz and v

Divide v/vz

Enter result as ratio fAB to fZ

Use of track S:

- Not used (track S is not used)

- Evaluation (track S is used)

Enter max. voltage at track S.

If the voltage is > Umax, an error is

displayed and the outputs are

switched off.

Enter min. voltage at track S.

If the voltage is < Umin, an error is displayed and the outputs are switched

off.

Select start-up delay

(The start-up phase of the PNOZ s30

is extended by this time. The encoder

signals are not evaluated until after the

start-up phase.)

Select function parameter

Select standstill frequency 10 mHz ... 1.00 MHz

Enter parameter for the switch functions F1 ... F9

16 parameters P0 ... P15 can be configured for each switch function F1 ...

F9.

The current linear/rotational speed is

displayed and can be adopted as a

limit value.

0,0001 ... 400.000

- Not used

- Evaluation

0.0 V ... 30.0 V

0.0 V ... 30.0 V

0 ... 600 s

or the corresponding value in the selected

unit

6-20

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 57

6 Commissioning

6.2 Display menu - Configuration

Level Designation

on the display

4 (F1 ... F9) (P0 … P15)

v max:

Standstill

4 (F1 ... F9) (P0 … P15)

v max:

2.00 kHz

4 (F1 ... F9) (P0 … P15)

Function

Position (1 … 4)

4 (F1 ... F9) (P0 … P15)

(Direct. Left, Direct.

Right)

1 Assign

Outputs

2 Output

(Rel.1... Out 4)

Default:

Off

1 Reset Mode Select reset behaviour

2 Reset mode

(Rel.1... Out 4)

Default:

Monitored /

Description Settings

"Standstill" is displayed and can be

adopted

Information:

The standstill frequency is selected

globally in the menu "Standstill v

max:"

(see above)

Select linear/rotational speed limit 10 mHz ... 1.00 MHz

Select position monitoring 1 ... 4.

Select left-hand or right-hand direction monitoring

Assign functions to outputs

Each output can be assigned a switch

function (F1 ... F9) or a range (F2-F3,

F4-F5, F6-F7, F8-F9). Each output can

also be used as an error output (error)

or be switched off (off).

When used as an error output, the following applies:

Error: Output off

No error: Output on

For ranges, the following applies:

The lower range limit is the switch

function with the lower number (e.g.

F2),

The upper range limit is the switch

function with the higher number (e.g.

F3).

Outputs:

Rel.1: Relay output 1

Rel.2: Relay output 2

Ext.3: External output 1

Ext.4: External output 2

Out 1 … Out 4: Semiconductor outputs 1 ... 4

Select reset mode for each output

separately

Automatic: Automatic reset

Monitored /: Monitored reset with rising edge at S34

Monitored \: Monitored reset with falling edge at S34

or the corresponding value in the selected

unit

- Off

- F1 ... F9

- F2-F3

- F4-F5

- F6-F7

- F8-F9

- Error

- Automatic

- Monitored /

- Monitored \

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-21

Page 58

6 Commissioning

6.2 Display menu - Configuration

6.2.6.5 Advanced settings

Advanced settings6-Menue-Ein stellungen-erweite rte Einstellungen

Level Menu designation Description Settings

1Position

Parameter

2 Position (1 ... 4)

Window Width

Default:

1 Imp

1 Direction

Parameter

2 (Direct. Left

max. right,

Direct. Right

max. left)

Default:

0 Imp

1 Delay Time

Select Input

Default:

0 ms

1Function

Hysteresis

2 (F1 ... F9) Function

Hysteresis

Default:

1 %

1 Delay Time

Outputs tdO

2 Delay Time

Output

(Rel.1 ... Out 4)

Default:

On 0 ms (display only)

3 Delay TIme

Effect

(Rel.1 ... Out 4)

Default:

On delay

3 Delay TIme

(Rel.1 ... Out 4)

Default:

tdO: 0 ms

1 Outputs Out

Logic

Settings for position monitoring functions

Enter width of position window for position monitoring functions 1 ... 4

Settings for direction monitoring

Enter max. tolerated number of pulses

(or Edg, m, rev) in the wrong direction.

Enter delay time of the select inputs

Y10 – Y13

Information: The states of the select

inputs are only adopted if they were

unchanged during the set time.

Enter hysteresis for the switch functions F1 ... F9

(not effective with position and direction monitoring)

Setting for the delay effect and delay

time for the outputs

Setting for the delay time effect and

delay time for the respective output

Enter whether the delay time is to be

activated when switching on, switching off, or switching on and off.

Select delay time for the respective

output

Setting for the switching direction of

the semiconductor outputs

1 ... 24.900.000 Imp

or the corresponding value in the selected

unit

1 ... 24.900.000 Imp

or the corresponding value in the selected

unit

0 ... 30.0 s

0 ... 50 %

- On

- Off

- On Off

0 ... 30.0 s

6-22

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 59

6 Commissioning

6.2 Display menu - Configuration

Level Menu designation Description Settings

2 Output

(Out 1 ... Out 4)

Logic

Default:

N/O contact

1Name of

Configuration

Default:

Default

1Password

Settings

Select the switching direction of the

semiconductor outputs Out 1 ... Out 4:

N/O contact (normally energised

mode)

N/C contact (normally de-energised

mode)

Enter name of the configuration.

The name may be a max. of 8 characters in length

It is stored on the chip card

Change passwords

Note: In the "Default Settings" menu,

the passwords are reset to the default

setting: 0000.

- N/O contact

- N/C contact

........

2 Master

PW

2 Customer

PW

2 Language

Default:

English

1 Default

Settings

Change master password 0000 ... 9999

Change customer password 0000 ... 9999

Select menu language - English

- German

Select whether the values are to be reset to the default settings

Yes: All parameters are reset to the

default values. The language is set to

English and all passwords are set to

0000.

- CANCEL

- Yes?

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-23

Page 60

6 Commissioning

6.2 Display menu - Configuration

6.2.6.6 Information

Information6-M enue-Einstellunge n-Informationen/Me ldungen, die während der Konfiguration angezeigt werden k önnen

Level Menu designation Description Display/Settings

1 Power-on Time Time that the device is switched on xxx.xxx h

xx min xx s

1 Max. Speed

Track AB

1 Max. Speed

Track Z

1 Relais (Ctrl, 1, 2)

Cycles

1CRC of

Configuration

1 Error Stack Entries Error stack entries