Page 1

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Gertebild

][Bildunterschrift_Drehzahlwchter

Speed monitor for safe monitoring of

standstill, speed, position, speed

range and direction of rotation.

Approvals

PNOZ s30

SÜDDEUTSCHLAND

Pending

Pending

Unit features

Gertemerkmale PNOZ s30

` Measured value recorded by

– Incremental encoder

– Proximity switch

` Measured variables

– Standstill

– Rotational speed

–Position

– Speed range

– Direction of rotation

` Positive-guided relay outputs

– 2 safety contacts

– 2 auxiliary contacts

` Semiconductor outputs

– 4 auxiliary outputs

` Expansion interface for 2 more safe

relay outputs

` Can be configured via the display

on the speed monitor

` Configuration is stored on a chip

card

` Display

– Current frequency

– Current position

– Warning and error messages

` Status and fault LEDs

` Incremental encoder connection

technology:

RJ-45 female connector

][Gertemerkmale_Zusatz_Datenblatt

` See order reference for unit types

Unit description

Gertebeschreibung_Drehzahlwaechter_plus_Position_Bereich

The speed monitor monitors standstill,

speed, speed range, position and direction of rotation in accordance with

EN ISO 13849-1 up to PL e and

EN IEC 62061 up to SIL CL 3.

Safety features

Sicherheitseigenschaften_multi_allgemein

The relay conforms to the following

safety criteria:

` The circuit is redundant with built-in

self-monitoring.

` The safety function remains effec-

tive in the case of a component failure.

Zulassungen

Block diagram

A1 A2

~

Power

=

S34

Reset/

Start

Feed-

back

Y1 Y2

Blockschaltbild PNOZ s30

S11 S21

0 V

24 V

RJ45

Y32 Y33 Y34 Y35

In1 In2

X6

Inputs (SEL)

Y10 Y11 Y12 Y13 Y30 Y31

GND

Initiator

Input

Select

24 V ext

0 V ext

Relay

Control

Rel. 1

Rel. 2

13

14

11

12

23

24

21

Interface

Extended Relais

22

1001758-EN-01-2010-11

Page 2

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Function description

Funktionen_Einführung

Encoders record the measured values.

The monitoring functions are selected

via the select inputs and applied to the

measured values.

The monitoring functions are configured menu-driven using a rotary

switch. The outputs switch depending

on the configuration.

In order to extend the number of outputs an interface is available to which

a PNOZsigma expander module can

be connected.

Monitoring functions

Funktionen_Überwachungsfunktionen

The speed monitor monitors for:

` Standstill

With standstill monitoring, the output is switched on when the value

falls below the stated standstill value; if the standstill value is exceeded, the output switches off.

` Rotational speed

With overspeed monitoring, the

output switches off when the stated

value is exceeded.

` Position

Position monitoring is activated

through a monitored reset via the

reset input. The current position is

adopted and the output is switched

on.

The output will now stay switched

on provided the position is within

the configured range (position window) around position x.

` Speed range

With range monitoring, the output

switches off if the frequency is outside the configured range.

` Direction of rotation

If the direction of rotation is to be

safely detected, this function must

be linked to a safety contact.

– If "Clockwise" is configured, the

safety output is switched on during normal operation in clockwise rotation.

– If "Anti-clockwise" is configured,

the safety output is switched on

during normal operation in anti-

clockwise rotation.

A tolerance can be entered for both

directions of rotation. Within this

tolerance, the drive can run in the

wrong direction without the as-

signed output switching off.

Please note: No direction of rotation

can be detected if proximity switch-

es are used.

Incremental encoders or proximity

switches can be used to record the

values (see "Encoder types" chapter).

Reset modes

You can choose between the following

reset modes:

` Automatic reset

If an automatic reset is configured,

the output switches on automati-

cally if the speed does not reach the

limit value, for example.

` Monitored reset with rising edge

If a monitored reset with rising edge

is configured, the output switches

on if the speed does not reach the

limit value and a rising edge was

detected at S34.

` Monitored reset with falling edge

If a monitored reset with falling

edge is configured, the output

switches on if the speed does not

reach the limit value and then a fall-

ing edge was detected at S34.

Switch delay

A delay time of 0 ... 30 s can be set for

each output. The outputs will not

switch until the set time has elapsed. It

is possible to configure whether the

delay time is to be activated when

switching on, switching off, or switching on and off.

Feedback loop

The feedback loop is used to monitor

external contactors or relays. If an output is activated, it will not switch on

until the feedback loop is closed.

Hysteresis

A hysteresis of 0 ... 50 % can be entered for each function. This prevents

the outputs on the speed monitor from

bouncing if there are fluctuations

around the response value. The hysteresis becomes effective when the

output is switched on:

Switch-on value = switching threshold

– hysteresis

For the lower range limit:

Switch-on value = switching threshold

– hysteresis

Start-up suppression time

To avoid spurious output signals, during the machine's start-up phase the

evaluation of the encoder signals can

be delayed after the start (0 ... 30 s).

Switching direction on semiconductor outputs

The semiconductor outputs can be

operated in normally de-energised or

normally energised mode.

Units

The configured values can be entered

in various units. Various units can be

selected for speed and distance, depending on the axis type (linear or rotational axis).

Broken shearpin monitoring

To monitor for broken shearpins, an incremental encoder is connected to

track A and B and a proximity switch

to track Z.

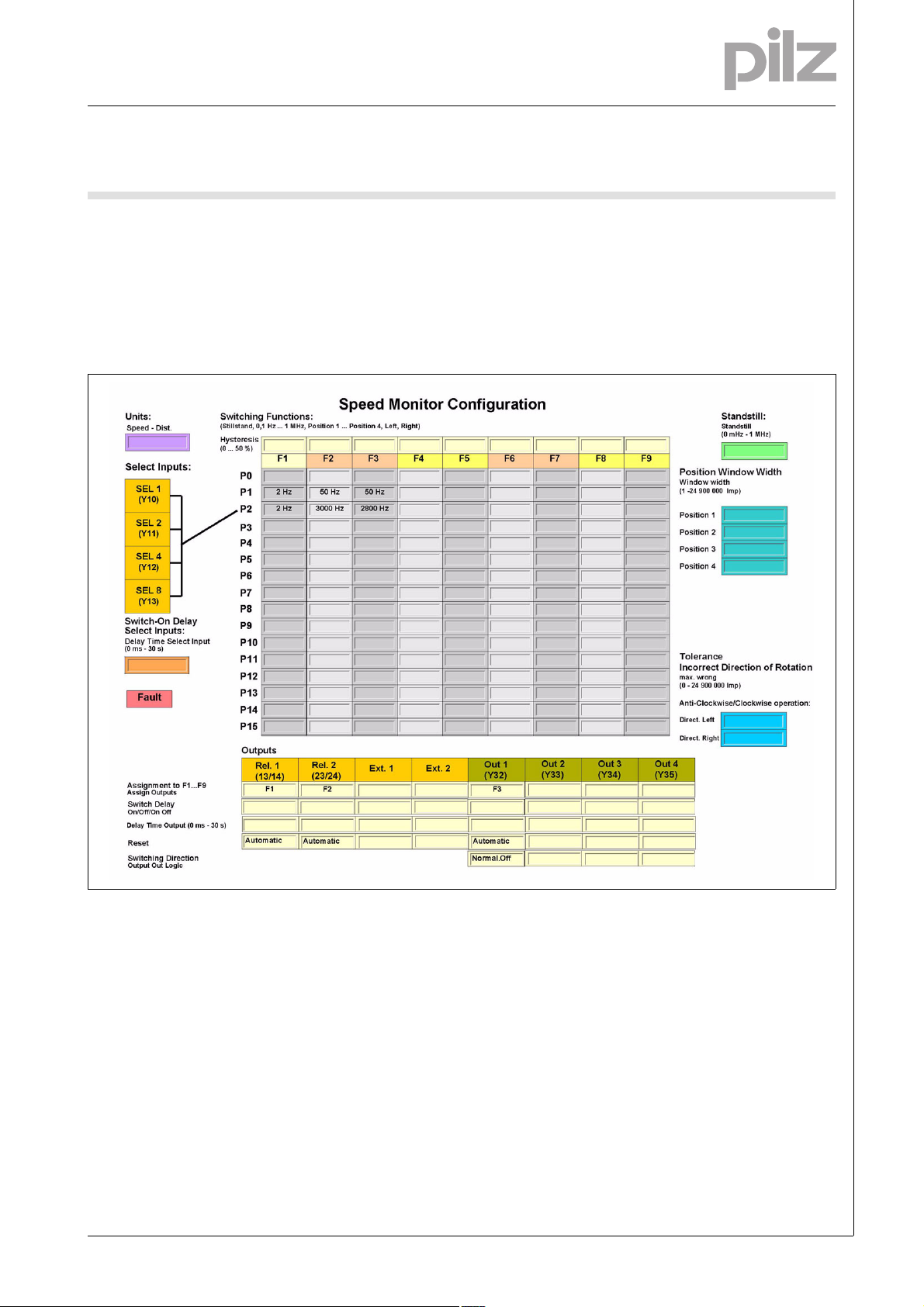

Speed configuration

Funktionen_Drehzahlkonfiguration

The speed monitor is configured using

the rotary knob at the device.

Up to 9 switch functions F1 ... F9 that

are monitored simultaneously can be

configured in a parameter set.

A switch function is comprised of:

` Configured speed/standstill

` Switching threshold

` Hysteresis

The standstill value is applied for configured switch functions for which no

value is entered.

The outputs are assigned to the switch

functions.

A switch delay and the reset behaviour

can be configured for each output.

For monitoring various operating

modes, for example, up to 16 parameter sets (P0 ... P15) can be configured

with max. 9 switch functions each.

The parameter set for which the switch

functions are to be monitored is then

selected via the 4 select inputs SEL1,

SEL2, SEL4, SEL8.

If only one parameter set is used, you

should configure the parameter set

P0. Then it is not necessary to connect

a select input.

1001758-EN-01-2010-11

-2

Page 3

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Example:

2 parameter sets for 2 operating

modes are configured:

` Set-up: P1

` Automatic mode: P2

The parameter set P2, "Automatic

mode", is selected for speed monitor-

ing (selection via the select inputs, see

next chapter "Select inputs").

The following switch functions are selected for the parameter set P2:

` F1: Standstill 2 Hz

` F2: Overspeed: 3000 Hz

` F3: Warning threshold: 2800 Hz

The following outputs are assigned to

the switch functions:

` F1: Relay output Rel. 1

` F2: Relay output Rel. 2

` F3: Semiconductor output Out 1

For a better overview of the device settings, we recommend that you fill in

the configuration overview before setting the device parameters (link to

form, see "Create configuration overview" chapter).

1001758-EN-01-2010-11

Page 4

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

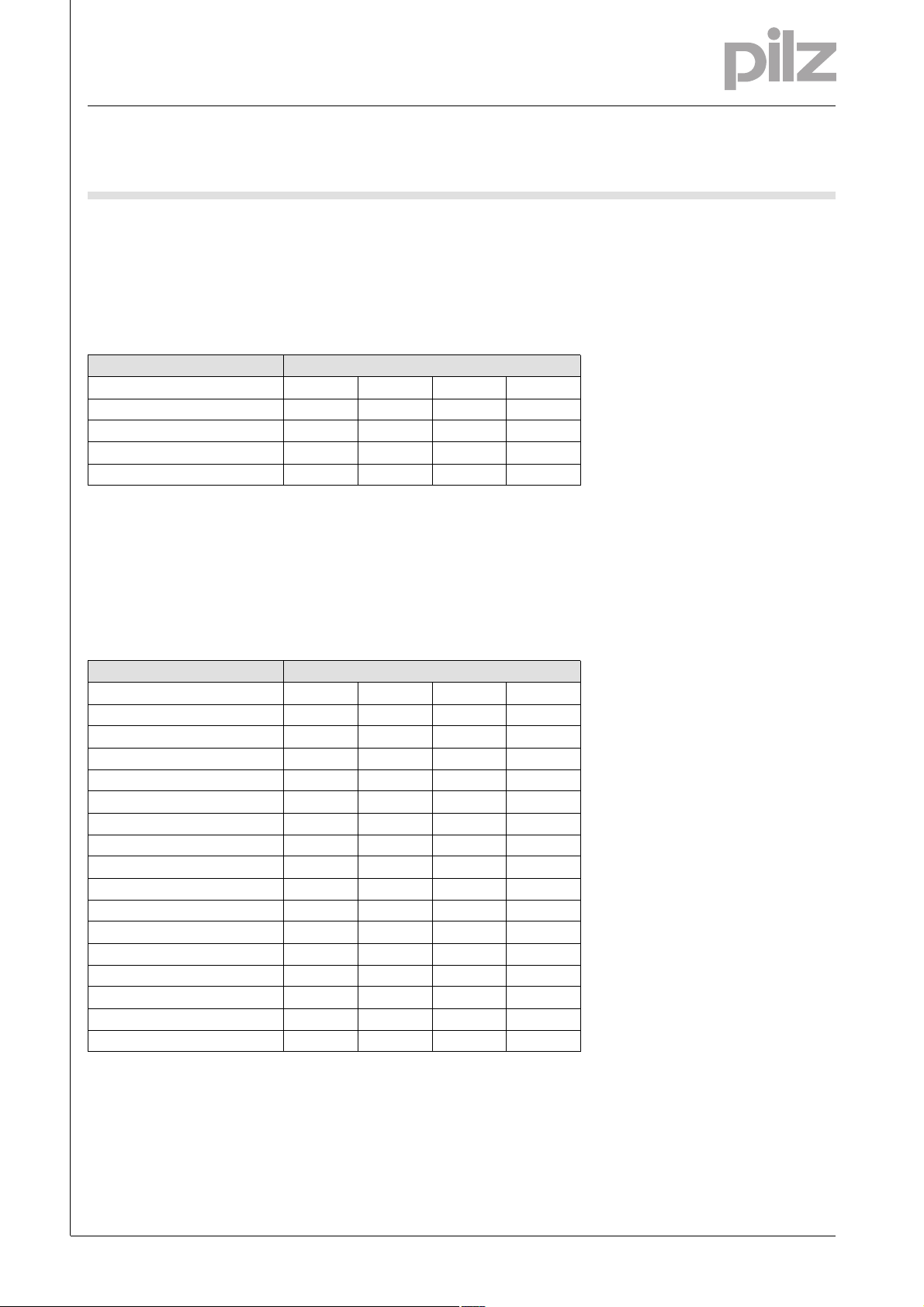

Select inputs

Funktionen_Select-Eingaenge

The parameter sets are selected via

the 4 select inputs SEL1, SEL2, SEL4,

SEL8. Only one of the configured parameter sets can be selected.

Parameter set Signal statuses of the select inputs

SEL 8 SEL 4 SEL 2 SEL 1

P1 0 0 0 1

P2 0 0 1 0

P4 0 1 0 0

P8 1 0 0 0

For applications up to PL e of

EN ISO 1349-1 and up to SIL CL 3 of

EN IEC 62061 max. 4 parameter sets

can be configured: P1, P2, P4 and P8

(or P0 if only 1 parameter set is used).

The default value "Standstill" must not

be changed for all other parameter

sets.

When using these 4 select inputs, the

following safety features are met:

` The 1 from n principle ensures that

none of the parameter sets P1, P2,

Parameter set Signal statuses of the select inputs

SEL 8 SEL 4 SEL 2 SEL 1

P0 0 0 0 0

P1 0 0 0 1

P2 0 0 1 0

P3 0 0 1 1

P4 0 1 0 0

P5 0 1 0 1

P6 0 1 1 0

P7 0 1 1 1

P8 1 0 0 0

P9 1 0 0 1

P10 1 0 1 0

P11 1 0 1 1

P12 1 1 0 0

P13 1 1 0 1

P14 1 1 1 0

P15 1 1 1 1

P4 or P8 are selected due to errors

in the actuation. In the event of an

error, monitoring for standstill always occurs.

` Short circuits will be detected

` P0 is selected in the event of an

open circuit.

If necessary, the number of parameter

sets can be increased to max. 16.

These can only be used for applications up to max. PL d of

EN ISO 13849-1 and up to SIL CL 2 of

EN IEC 62061.

1001758-EN-01-2010-11

-4

Page 5

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

When using the expanded parameter sets, please note:

If an open circuit occurs when activating the select inputs, the next lowest

value is activated.

The limit values for the switch functions must therefore always be entered in ascending order. (Parameter

set 1 -> lowest values, parameter set

15 -> highest values).

Switch-on delay of the select inputs

A reaction time of between 0 and 30 s

can be entered for the select inputs.

That way it is possible to avoid invalid

signals (e.g. contact bounce) that occur when switching.

Safety guidelines for configuration

_Dummy-Vorlage

During the configuration for safety-related applications, please note:

` The maximum frequency of the en-

coders used must be entered for a

complete configuration ("Input Device type"-> "Track AB" -> "Track

AB fmax" or "Track Z" -> "Track Z

fmax" menu.)

` The standstill frequency must be

the smallest frequency entered in

the configuration.

` For parameter sets that aren't used,

the standstill values are automati-

cally transferred. These must not be

changed.

` The limit values must always be en-

tered in ascending order. (Parameter set 1 -> lowest values,

parameter set 15 -> highest values).

` During position monitoring, please

note:

– Monitored reset must be config-

ured for the position monitoring.

– A position monitoring function

must not be assigned to two outputs that are activated with different reset behaviour (one

output rising edge, one output

falling edge).

` The configurable output switch-off

delay (t

, Off) when overspeed is

do

reached will increase the speed

monitor's reaction time by the stated value (see technical details). This

must not delay the arrival of a safe

condition by more than the permitted time. The configuration of the

switch-off delay must be considered in the risk assessment as regards hazards, reaction time and

safety distance.

Chip card

Funktionen_Chipkarte

The set parameters, the name of the

configuration and the passwords are

stored on the chip card (see "Using the

chip card" chapter).

Integrated protection mechanisms

Sicherheitseigenschaften_multi_allgemein

The relay conforms to the following

safety criteria:

` The circuit is redundant with built-in

self-monitoring.

` The safety function remains effec-

tive in the case of a component failure.

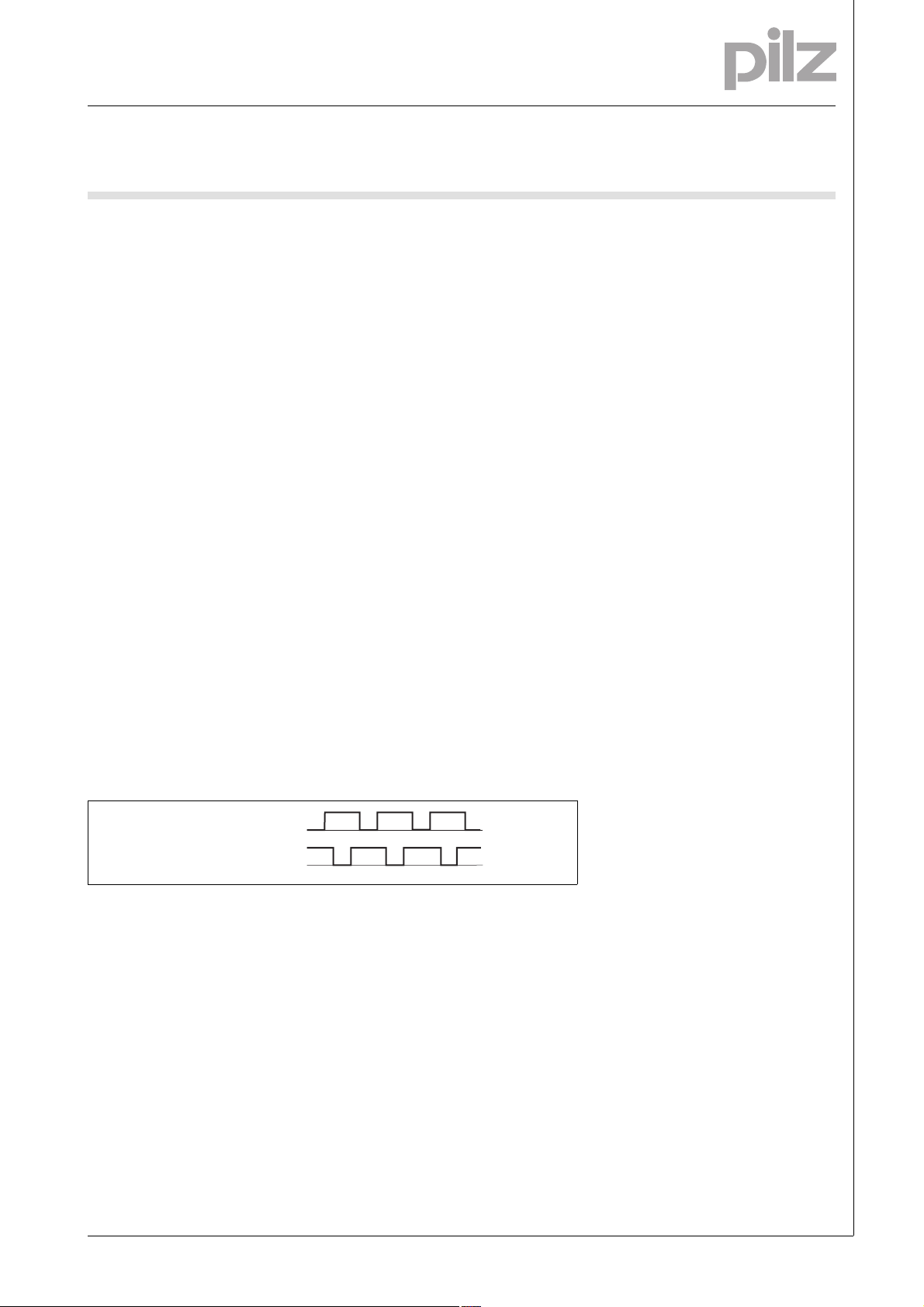

Proximity switch

S_DZW_Anford_Naeherungsschalter

` The following proximity switches

can be used:

–pnp

–npn

` The proximity switches must be fit-

ted so that at least one is always

activated.

` The proximity switches must be fit-

ted so that the recorded signals

overlap.

` The supply voltage of the proximity

switches should be monitored via

the track S.

Proximity switch 1

Proximity switch 2

CAUTION!

Appropriate installation measures

should be taken to prevent a foreign

body coming between the signal encoder and the proximity switch. If not,

the foreign body could cause invalid

signals.

` Please note the values stated in the

technical details

1001758-EN-01-2010-11

Page 6

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Incremental encoders

S_DZW_Anford_Geber

` The following encoders can be

used:

– TTL, HTL (single-ended or differ-

ential signals)

– sin/cos 1 Vss

– Hiperface

` The encoders can be connected

with or without Z index

` A proximity switch can also be con-

nected to track Z for monitoring

broken shearpins

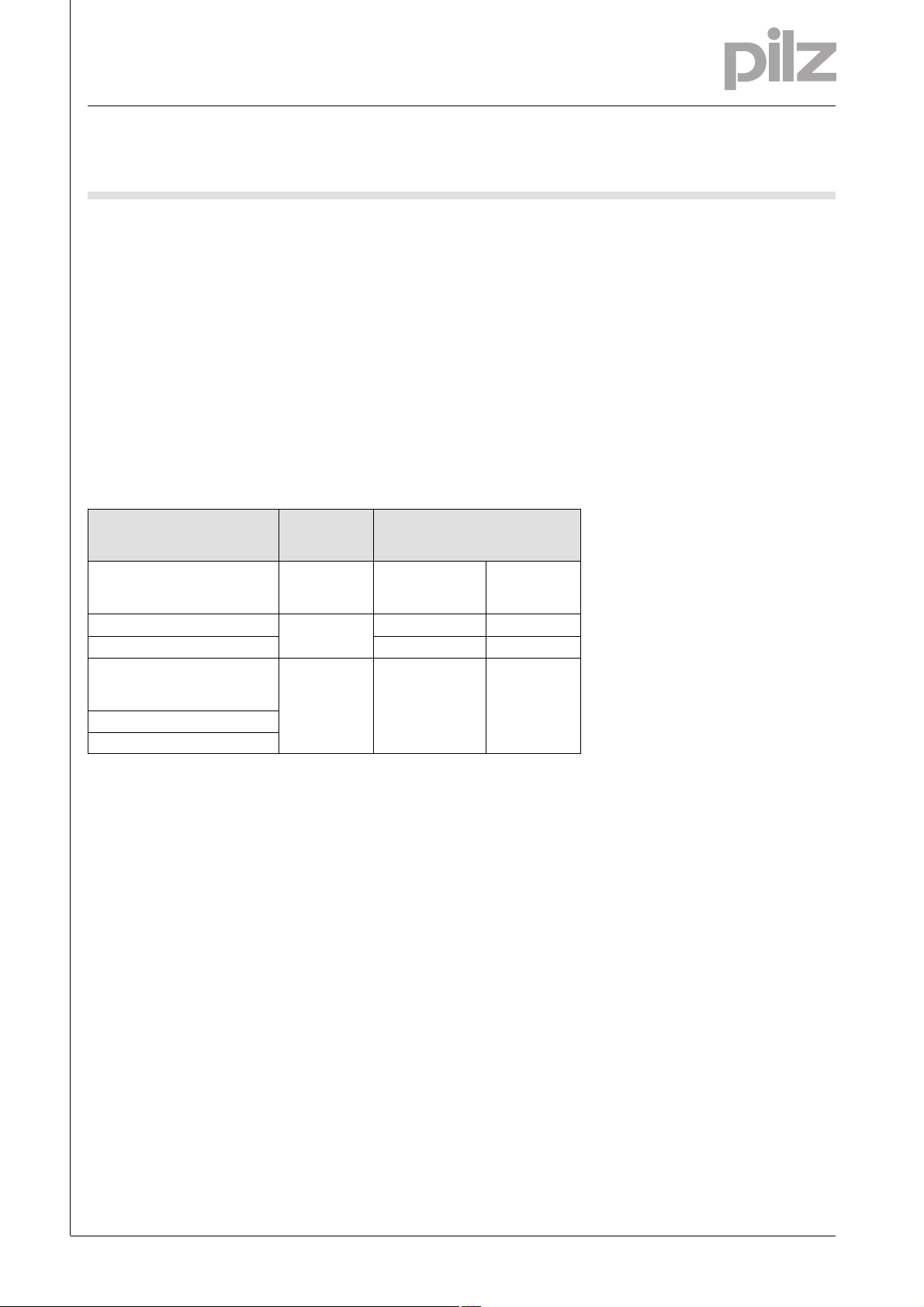

Input device Operating

Standard encoder Monitoring

Safe encoder

Standard encoder + proximity

switch feasibility

(Z frequency)

2 proximity switches

Safe encoders with Z index

*1)

*2)

mode

PNOZ s30

1 encoder

Monitoring

2 encoders

*1)

` An output can be connected at the

encoder via track S (e.g. for fault

monitoring).

Please note the values stated in the

technical details

Adapter for incremental encoders

Drehzahlwaechter_Inkrementalgeber_Adapter

The adapter records the data between

the incremental encoder and the drive

and makes it available to the speed

monitor via the RJ-45 female connector.

Pilz supplies complete adapters as

well as ready-made cable with RJ-45

Max. achievable values

EN ISO 13849-1 PLEN IEC

62061

SIL CL

PL c (Cat. 1) PL d (Cat. 2) SIL CL 2

PL e (Cat. 3) SIL CL 3

female connectors, which can be used

when making an individual adapter.

The range of products in this area is

constantly being expanded. Please

contact us about the range of adapters

that is currently available.

Categories

Sicherheitskategorien

The following table contains details on

the maximum safety-related characteristic data that can be achieved with

the PNOZ s30 depending on the encoder type, the wiring and the operating mode.

*1) Safe encoders are encoders that

are certified in accordance with

EN 61508, EN 13849 and EN 62061.

Certain external errors must be detected in order to implement the safety

function. The encoder and evaluation

device must be compatible.

*2) The stated max. safety-related

characteristic data can only be

achieved if

` Diverse technologies / manufactur-

ers are used

` the encoder supply is evaluated via

track S.

Please note:

` The wiring must be performed in

accordance with the details in the

"Commissioning" chapter.

` A forced dynamisation must be per-

formed.

The monitored encoder must be

moved so that the signal changes

on all the connected tracks within

an 8 hour period.

Open circuits of every individual track

(A, A\, B, B\, Z, Z\ or S) are recognised

and lead to safe condition of the outputs.

For applications in accordance with

PL e and SIL CL 3, the "Overspeed"

output must be integrated into the

safety function in every operating

mode and evaluated so that a shutdown occurs if the output switches to

a safe condition.

1001758-EN-01-2010-11

-6

Page 7

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Example for safety-related applications

Incremental encoder

Proximity switch

PNOZ s30

Safety-related characteristic data:

Input device PNOZ s30

MTTFD = MTTF Values for

2 encoder evaluation

DC = 90 %

Assumptions for the encoder system:

` Encoder is swapped after the first

fault (non-repairable system)

` 100 % of the faults that occur are

see Safety-related characteristic

data in "Technical details" chapter

Wiring

Verdrahtung_Kupferdraht_75C

Note:

` Information given in the "Technical

details" must be followed.

hazardous (worst case)

` Use copper wire that can withstand

75 °C.

Pin assignment of the RJ45 female connector

Anschlussbelegung RJ45-Buchse

RJ45 female connector

8-pole

8 1

PIN Track

1 S

2 GND

3 Z

4 A

5 A/

6 Z/

7 B

8 B/

1001758-EN-01-2010-11

Page 8

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Supply voltage

Anschluss_Versorgungsspannung

Supply voltage AC DC

Connection of proximity switches

S_DZW_Betriebsb_Anschluss_Naeherungssch

The following proximity switches can

be connected:

` A: pnp, B: pnp

` A: npn, B: npn

` A: pnp, B: npn

` A: npn, B: pnp

24 V

0 V

RJ45

A

/A

B

/B

Z

/Z

GND

S

IN1

IN2

GND

L

N

S21

A1

A2

When connecting proximity switches

please note:

` The terminals In1, In2 and GND are

linked internally with the tracks A, B

and GND of the RJ-45 female con-

nector (see drawing).

INI_A

INI_B

A1

A2

L+

L-

` Track S should be used to monitor

the supply voltage (see drawing). A

permitted voltage range can be entered in the menu.

` Connect the proximity switch to 24

VDC of the power supply.

Connection of the incremental encoder

S_DZW_Betriebsb_Inkremen

Proceed as follows when connecting

the incremental encoder:

` The incremental encoder can be

connected via an adapter (e.g.

PNOZ msi6p) or can be connected

directly to the speed monitor.

` Use only shielded cables for all

connections

Connect incremental encoder to speed monitor

S_DZW_Betriebsb_Anschluss_Inkrementalgeber

Encoder types:

` TTL single ended

` HTL single ended

Please note:

` Tracks /A and /B must remain free

Input Device

B

A

GND

7

4

2

` Always connect GND from the in-

cremental encoder to GND from the

RJ-45 female connector.

PNOZ s30

X6

1001758-EN-01-2010-11

-8

Page 9

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Encoder types:

` TTL differential

` HTL differential

` sin/cos 1 Vss

` Hiperface

Input Device

GND

/B

B

/A

A

5

PNOZ s30

8

7

X6

4

2

Connect incremental encoder with Z index to speed monitor

S_DZW_Betriebsb_Anschluss_Inkrementalgeber_Z-Index

Encoder types:

` TTL single Z Index

` HTL single Z Index

Please note:

` Tracks /A and /B must remain free

Input Device

GND

B

A

Z

3

PNOZ s30

7

4

2

X6

Encoder types:

` TTL diff. Z Index

` HTL diff. Z Index

` sin/cos 1 Vss Z Index

Input Device

GND

PNOZ s30

/B

B

/Z

/A

A

Z

8

7

6

5

4

3

X6

2

1001758-EN-01-2010-11

Page 10

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Connect incremental encoder to the speed monitor via an adapter

S_DZW_Betriebsb_Anschluss_IInkremen_ueber_Adapt

The adapter (e.g. PNOZ msi6p) is connected between the incremental encoder and the drive. The output on the

adapter is connected to the RJ-45 female connector on the speed monitor.

Input Device

GND

A

/A

B

/B

Adapter

GND

18

X6

PNOZ s30

Connection of proximity switch and incremental encoder

S_DZW_Betriebsb_Anschluss_Inkrement_Naeherungssch

Encoder types:

` TTL single Z Freq. Ini pnp

` HTL single Z Freq. Ini pnp

Input Device

GND

B

A

4

3

PNOZ s30

7

X6

2

1

Drive

0 V

24 V

1001758-EN-01-2010-11

-10

Page 11

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Encoder types:

` TTL differential Z Freq. Ini pnp

` HTL differential Z Freq. Ini pnp

` sin/cos 1 Vss Z Freq. Ini pnp

` Hiperface Z Freq. Ini pnp

Input Device

GND

/B

B

/A

A

7

5

4

PNOZ s30

8

X6

3

2

1

0 V

24 V

Reset circuit

Anschluss_Startkreis

Automatic reset Monitored reset

must only be configured

Feedback circuit

Rueckfuehrkreis

S3

S11

S34

Link Contacts from external contactors

Y1

Y2

S11

Y1

Y2

S11

13 (23)

14

24

K5

K6

K5

K6

L+

L-

1001758-EN-01-2010-11

Page 12

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Terminal configuration

Klemmenbelegung PNOZ s30

5

X3X1

IN1

IN2 GND Y10

A1

Y1 IY2 Y32

PNOZ s30

Y12Y13 Y30

Y11

Y34Y35 Y31

Y33

X6

2

1

A2

S11 S21 11

X2X6

Left: Side view, centre: Front view without cover, right: Front view with cover

3

4

13S34 21

23

14 22

12

24

X4

X3X1

IN1

IN2 GND Y10

A1

Y1 IY2 Y32

PNOZ s30

Power

In1

In2

Rel 1

Rel 2

Fault

A2

S11 S21 11

X2X6

Y12Y13 Y30

Y11

Y34Y35 Y31

Y33

13S34 21

23

14 22

12

24

X4

1001758-EN-01-2010-11

-12

Page 13

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Installation

][Montage_Drehzahlwächter

Install base unit without contact expander module:

` Ensure that the plug terminator is

inserted at the side of the unit.

Connect base unit and PNOZsigma

contact expander module:

` Remove the plug terminator at the

side of the base unit and at the contact expander module.

` Connect the base unit and the con-

tact expander module to the supplied connector before mounting

the units to the DIN rail.

Control cabinet installation

` The unit should be installed in a

control cabinet with a protection

type of at least IP54.

` It is preferable to install the device

on a horizontal DIN rail in order to

ensure the best possible convection.

` Use the locking element on the rear

of the device to attach it to the DIN

rail.

` Push the device upwards or down-

wards before lifting it from the DIN

rail.

Dimensions

Abmessungen

*with spring-loaded terminals

98 (3.86")

* 100 (3,94")

120 (4.72")

45

(1.77")

1001758-EN-01-2010-11

Page 14

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Notice

][Wichtig_PDB

This data sheet is only intended for use

during configuration. Please refer to

the operating manual for installation

and operation.

Service life graph

Lebensdauerkurve_Rela is_Text vor Kurv e

The service life graphs indicate the

number of cycles from which failures

due to wear must be expected. The

wear is mainly caused by the electrical

load; the mechanical load is negligible.

Lebensdauerkurve_Relais_Text nach Kurve_SIS442 Bsp

Example

` Inductive load: 0.2 A

` Utilisation category: AC15

` Contact service life: 700 000 cycles

Provided the application requires fewer than 700 000 cycles, the PFH value

10

1

Courant coupé (A)

D Nennbetriebstrom (A)

GB Nominal operating current (A)

F

0.1

E Corriente nominal de servicio (A)

I Corrente di esercizio nominale (A)

NL Nominale bedrijfsstroom (A)

10 100 1000 10000

D Schaltspielzahl x 10

GB Cycles x 10

F Nombre de manuvres x 10

AC15: 230 V

DC13: 24 V

3

3

(see technical details) can be used in

the calculation.

To increase the service life, sufficient

spark suppression must be provided

on all output contacts. With capacitive

loads, any power surges that occur

Lebensdauerkurve PNOZ s30

DC1: 24 V

AC1: 230 V

E Número de ciclos x 10

I Numero dei cicli di commutazione x 10

3

NL Aantal schakelingen x 10

3

3

must be noted. With contactors, use

freewheel diodes for spark suppression.

Technical details PNOZsigma

3

Technical details

Electrical data

Supply Voltage

Supply voltage U

AC/DC 24 - 240 V

B

Voltage tolerance -15 %/+10 %

Power consumption at U

Power consumption at U

Max. inrush current at U

AC 9.0 VA

B

DC 5.5 W

B

B

10.00 A

Frequency range AC 50 - 60 Hz

Residual ripple DC 160 %

Continuous duty 100 %

Voltage and current at

Reset circuit DC: 24.0 V 5.0 mA

Feedback loop DC: 24.0 V 5.0 mA

Max. inrush current impulse

0.06 A

Feedback loop 0.06 A

Min. unit fuse protection 1.00 A

Max. unit fuse protection F1 Max. cable cross section

Proximity switch input

Number of inputs 2

1001758-EN-01-2010-11

-14

Page 15

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Proximity switch input

Input signal level

Signal level at "1" 11 - 30 V

Signal level at "0" -3 - 5 V

Input resistance 22 kOhm

Input's frequency range 0 - 1,000 kHz

Configurable monitoring frequency

without hysteresis 0 - 1,000 kHz

Input for incremental encoder/proximity switch (RJ45 connector)

Number of inputs 1

Input signal level 0.5 - 30.0 Vss

Phase position for the differential signals A,/A and B,/B 90° ±30°

Overload protection -30 - 30 V

Input resistance 20.0 kOhm

Input's frequency range 0 - 1,000 kHz

Configurable monitoring frequency

without hysteresis 0 - 1,000 kHz

Connection type (incremental encoder) RJ45 female connector, 8-pin

Select inputs

Number of inputs 4

Input signal level

Signal level at "1" 15 V

Signal level at "0" 5 V

Input current 5 mA

Semiconductor outputs

Number 4

Semiconductor outputs (short circuit proof) 24.0 V DC,50 mA

External supply voltage 24.0 V DC

Voltage tolerance -20% / +20%

Relay outputs

Number of output contacts

Safety contacts (S) instantaneous: 2

Auxiliary contacts (N/C): 2

Utilisation category in accordance with EN 60947-4-1

Safety contacts: AC1 at 240 V I

Safety contacts: DC1 at 24 V I

Auxiliary contacts: AC1 at 240 V I

Auxiliary contacts: DC1 at 24 V I

Utilisation category in accordance with EN 60947-5-1

Safety contacts: AC15 at 230 V I

Safety contacts: DC13 at 24 V (6 cycles/min) I

Auxiliary contacts: AC15 at 230 V I

Auxiliary contacts: DC13 at 24 V (6 cycles/min) I

Conventional thermal current 4.0 A

Contact material AgCuNi + 0.2 µm Au

: 0.01 A , I

min

: 1000 VA

P

max

: 0.01 A , I

min

: 100 W

P

max

: 0.01 A , I

min

P

: 1000 VA

max

: 0.01 A , I

min

: 100 W

P

max

: 3.0 A

max

: 4.0 A

max

: 3.0 A

max

: 4.0 A

max

max

max

max

max

: 4.0 A

: 4.0 A

: 4.0 A

: 4.0 A

1001758-EN-01-2010-11

Page 16

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Relay outputs

External contact fuse protection (IK = 1 kA) to EN 60947-5-1

Blow-out fuse, quick

Safety contacts: 6 A

Auxiliary contacts: 6 A

Blow-out fuse, slow

Safety contacts: 4 A

Auxiliary contacts: 4 A

Circuit breaker 24 VAC/DC, characteristic B/C

Safety contacts: 4 A

Auxiliary contacts: 4 A

Timers

Switch-on delay

with automatic reset typ. 35 ms

with automatic reset max. 50 ms

with automatic reset after power on typ. 3,000 ms

with automatic reset after power on max. 4,000 ms

with manual reset typ. 60 ms

with manual reset max. 100 ms

Delay-on de-energisation

with power failure typ. U

with power failure max. U

with power failure typ. U

with power failure max. U

after the safety function is triggered, typ. 8 ms

after the safety function is triggered, max. 15 ms

Recovery time at max. switching frequency 1/s

after power failure 1000 ms

Reaction time after limit value is exceeded 1/f_ist + 16 ms

Waiting period with a monitored reset

with rising edge 30 ms

with falling edge 30 ms

Min. start pulse duration with a monitored reset

with rising edge 30 ms

with falling edge 30 ms

Supply interruption before de-energisation 15 ms

Switch delay (selectable) 0 - 30 s

Switch-on delay on the function inputs (selectable) 0 - 30 s

Start-up suppression time (selectable) 0 - 30 s

Environmental data

EMC EN 60947-5-1, EN 61000-6-2, EN 61000-6-3

Vibration to EN 60068-2-6

Frequency 10 - 55 Hz

Amplitude 0.35 mm

Climatic suitability EN 60068-2-78

Airgap creepage in accordance with EN 60947-1

Pollution degree 2

Overvoltage category III / II

Rated insulation voltage 250 V

Rated impulse withstand voltage 4.00 kV

Ambient temperature -10 - 55 °C

Storage temperature -40 - 85 °C

Protection type

Mounting (e.g. cabinet) IP54

Housing IP30

Terminals IP20

AC/DC: 24 V 25 ms

B

AC/DC: 24 V 50 ms

B

AC : 240 V 100 ms

B

AC : 240 V 150 ms

B

1001758-EN-01-2010-11

-16

Page 17

Speed Monitor

Up to PL e of EN ISO 13849-1

PNOZ s30

Mechanical data

Housing material

Housing PC

Front PC

Cross section of external conductors with screw terminals

1 core flexible 0.25 - 2.50 mm² , 24 - 12 AWG No. 750330

2 core, same cross section, flexible:

with crimp connectors, without insulating sleeve 0.25 - 1.00 mm² , 24 - 16 AWG No. 750330

without crimp connectors or with TWIN crimp connectors 0.20 - 1.50 mm² , 24 - 16 AWG No. 750330

Torque setting with screw terminals 0.50 Nm No. 750330

Connection type spring-loaded terminal No. 751330

screw terminal No. 750330

Spring-loaded terminals: Terminal points per connection 2 No. 751330

Stripping length 9 mm No. 751330

Dimensions

Height 100.0 mm No. 751330

98.0 mm No. 750330

Width 45.0 mm

Depth 120.0 mm

Weight 410 g

Si-Kennzahlen_alle

Safety characteristic data

EN ISO 13849-1PLEN 954-1

Unit Operating mode

PNOZ s30 Monitoring 1 input de-

vice

PNOZ s30 Monitoring 2 input de-

vices

All the units used within a safety function must be considered when calculating the safety characteristic data.

Technische Daten_Satz No rmen

The standards current on 2009-06 apply.

Bestelldaten PNO Z s30

Order reference

Type Terminals Order No.

PNOZ s30 With screw terminals 750 330

PNOZ s30 C With spring-loaded terminals 751 330

Tools

PNOZ s terminator plug Terminator 10 pieces 750 010

PNOZmulti Chipcard Chip card 8 kB 779 201

PNOZmulti Chipcard Set Chip card 8 kB 10 pieces 779 200

PNOZmulti Chipcard Chip card 32 kB 779 211

PNOZmulti Chipcard Set Chip card 32 kB 10 pieces 779 212

Chipcard Holder Chip card holder 779 240

PNOZmulti Seal Chip card seal 10 pieces 779 250

PNOZ s Set3 Screw Loaded Terminals Set of plug-in screw ter-

PNOZ s Set3 Spring Loaded Terminals Set of plug-in spring-

PL d (Cat. 2) Cat. 2 SIL CL 2 3.28E-08 20

PL e (Cat. 3) Cat. 3 SIL CL 3 1.50E-08 20

Si_Kennzahlen_Erläuterung

minals

loaded terminals

Category

EN IEC 62061

SIL CL

1 piece 750014

1 piece 751014

PFH [1/h] tM [year]

1001758-EN-01-2010-11

Loading...

Loading...