Philips IntelliVue Quick Reference Service Manual

Philips Telemetry System

Quick Reference Service Guide

Contents

This Quick Reference Service Guide is a pocket sized

quick reference of the mos t used informat ion for the

Philips Telemetry System. It includes th e following:

Troubleshooting Overview. . . . . . . . . . . . . . . 2

Transmitter Non-RF Application Problems . . 5

Transmitter SpO2 Problems . . . . . . . . . . . . 12

Receiver Mainframe/System Faults . . . . . . 15

Other Problems . . . . . . . . . . . . . . . . . . . . . . 22

RF Troubleshooting Procedures . . . . . . . . . 24

RF Troubleshooting Tools . . . . . . . . . . . . . . 33

Part Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Contents

1

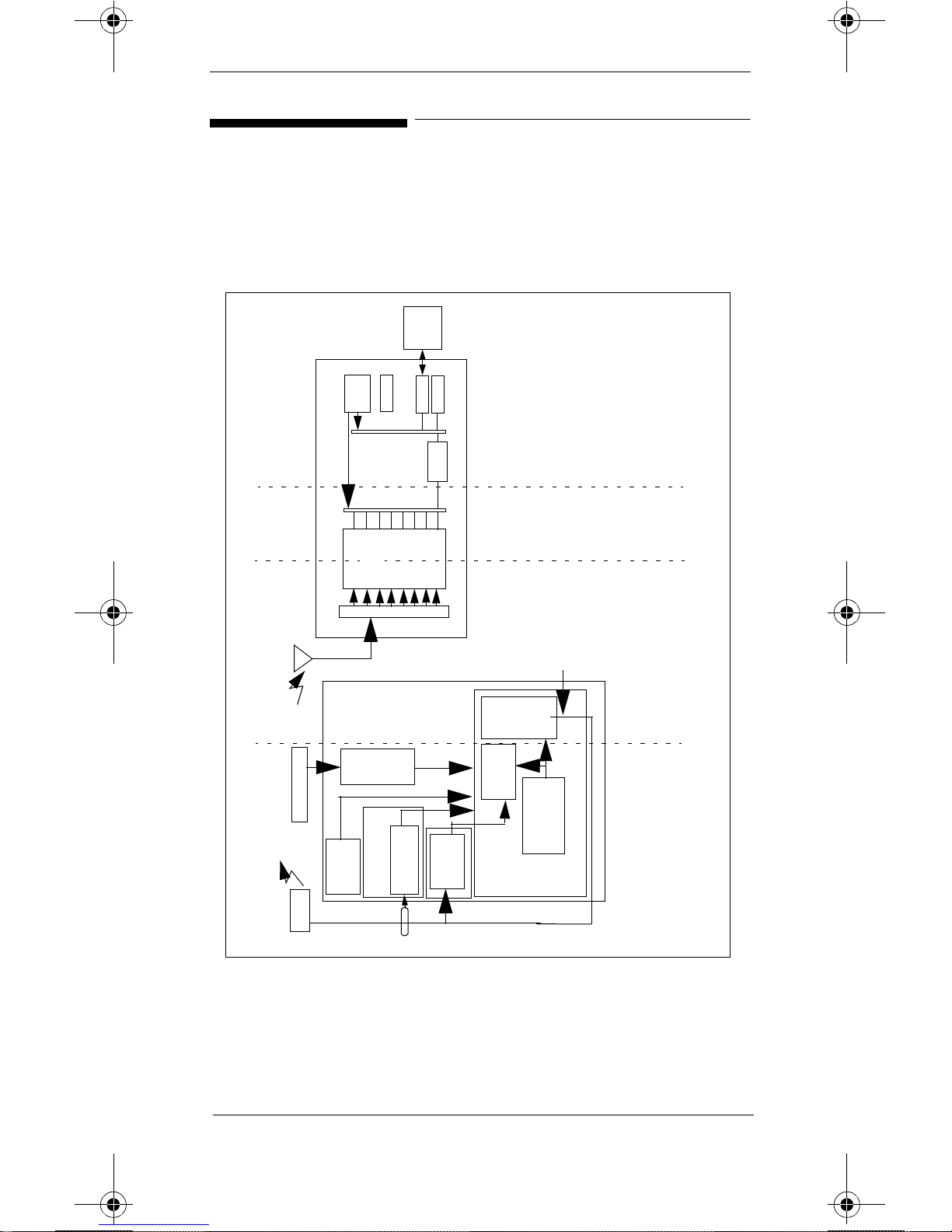

Troubleshooting Overview

Troubleshooting Map

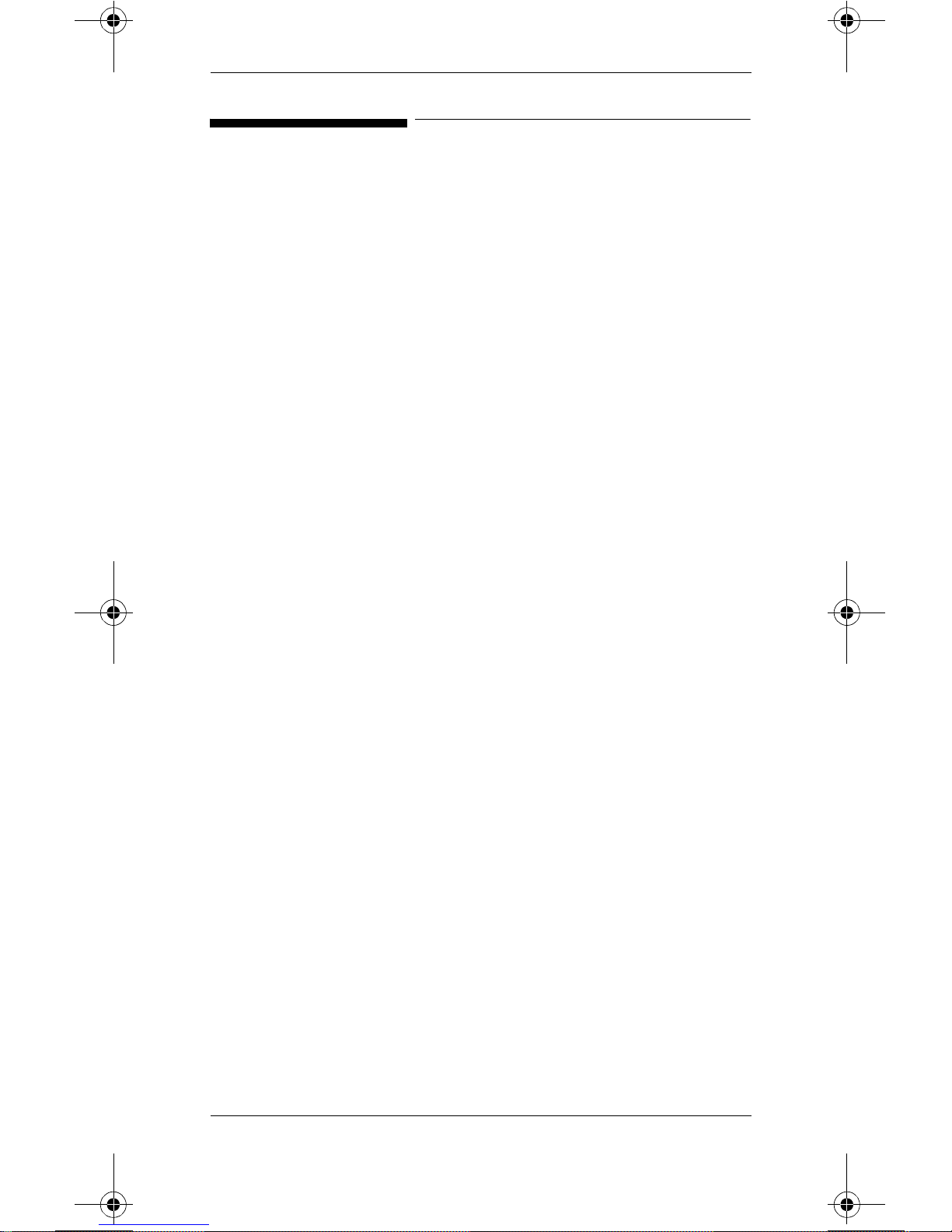

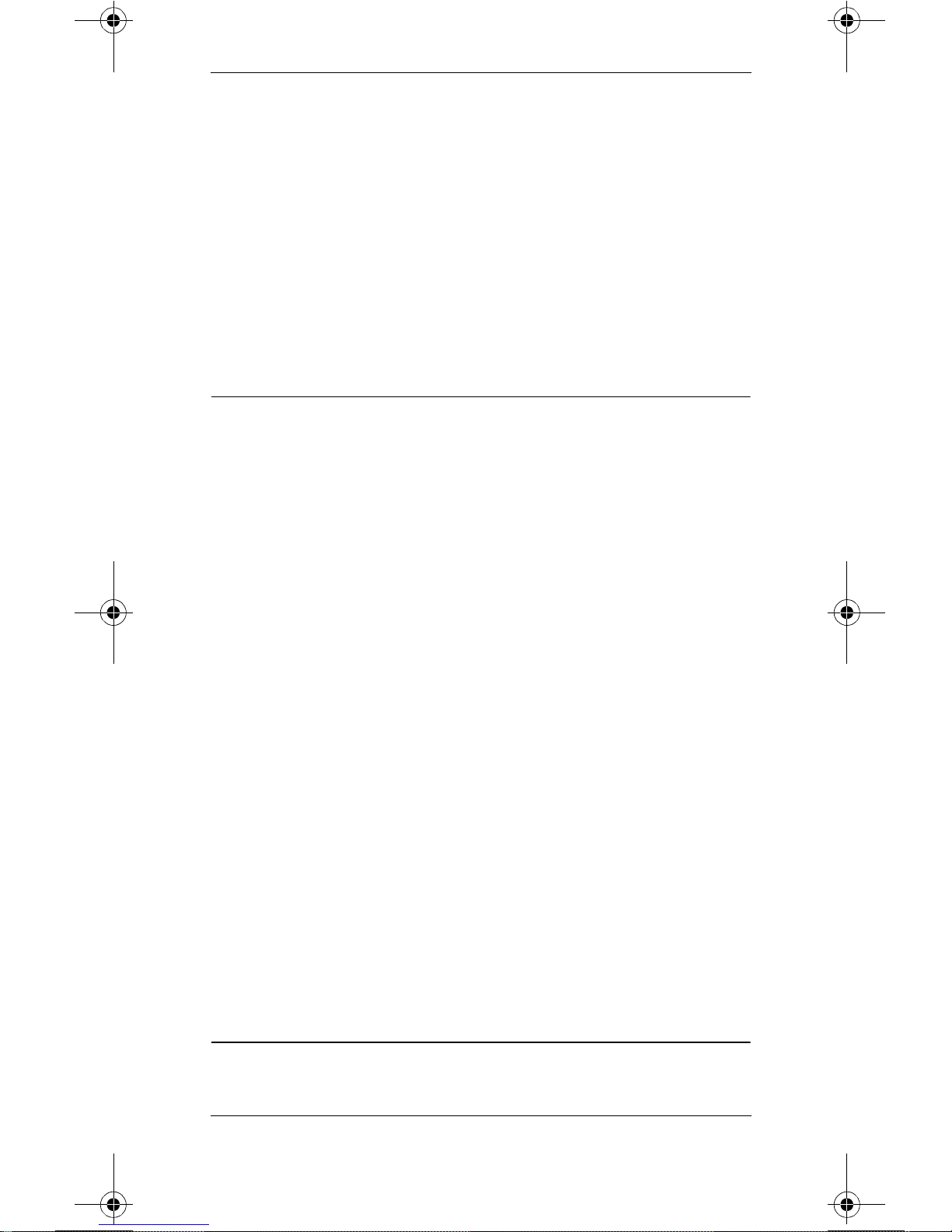

Figure 1 provides an overview map of areas of the

Telemetry System where problems can occur.

Sta tion

Central

CPC

SDN

Power

Supply

Utility

Digital Backplane

- Receiver Mainframe

Receiver

- System

Non-RF

M2604A Receiver Ma inframe

Digital

Section

Module

(up to 8)

Receiver

RF

Section

Rack

Interface

Receiver Backplane

Antenna Distribution Board

Trans mits

Via Leadset

- NO DATA FROM BED

- No Receiver

-No Power at Receiver Main-

frame

Malfunction

- Receiver

RF

- No Signal

- Tel Cannot Analyze

- Weak Signal

- Invalid Signal E01

RF

M2601A

Transmitter

2

PCB

SpO

Transducer

Button

Patient

- Transmitter non-RF

Leadset

- Application

Switch

3/5 Leadset

Front En d Assembly

ECG PCB

tion

Sec-

Digital

Section

and Battery

Power Supply

Main PCB

- LEADS OFF

- Interference

INOPs

2

- BATTERY INOPs

-ECG EQUIP MALF INOP

-TRANSMITTER MALF INOP

-SpO

TRANSMITTER OFF

INVALID LEADSET

ARRHY REQUIRED

Figure 1 Telemetry System Troubleshooting Map

2

Troubleshooting Overview

Troubleshooting Messages

The following Troubleshooting Messages are de scribed

in the following sections on the page indicated.

Message Page

LEADS OFF INOP

TRANSMITTER OFF INO

INVALID LEADSET INOP

NO SIGNAL INOP and an RF OUT OF LOCK INOP

at Telemetry Service Tool or Wave Viewer

Battery INOPs

ECG EQUIP MALF INOP

TRANSMITTER MALF INOP

ARRHY REQUIRED INOP

ECG EQUIP MALF INOP

SpO2 ERRATIC INOP

SpO2 INTERFERENCE INOP

SpO2 NO TRANSDUCER INOP

SpO2 NOISY SIGNAL INOP

5

6

7

8

9

11

11

11

11

12

13

13

14

SpO2 NON-PULSATILE INOP

SpO2 TRANS MALF INOP

Power does not come on when Receiver Mainframe

Power On/Off Button is pressed

NO DATA FROM BED INOP

NO RECEIVER INOP

RECEIVER MALF INOP

Transmitter Button is pressed, but desired result

does not occur

INVALID SIGNAL E01INOP

Troubleshooting Overview

14

14

15

15

20

21

22

24

3

Message Page

Frequent Dropouts and NO SIGNAL, WEAK

25

SIGNAL, and TEL CANNOT ANALYZE INOPs on a

Single Channel

Frequent Dropouts and NO SIGNAL, WEAK

29

SIGNAL, and TEL CANNOT ANALYZE INOPs with

Multiple Channels

Frequent Dropouts along with TEL CANNOT

30

ANALYZE and INTERFERENCE INOPs

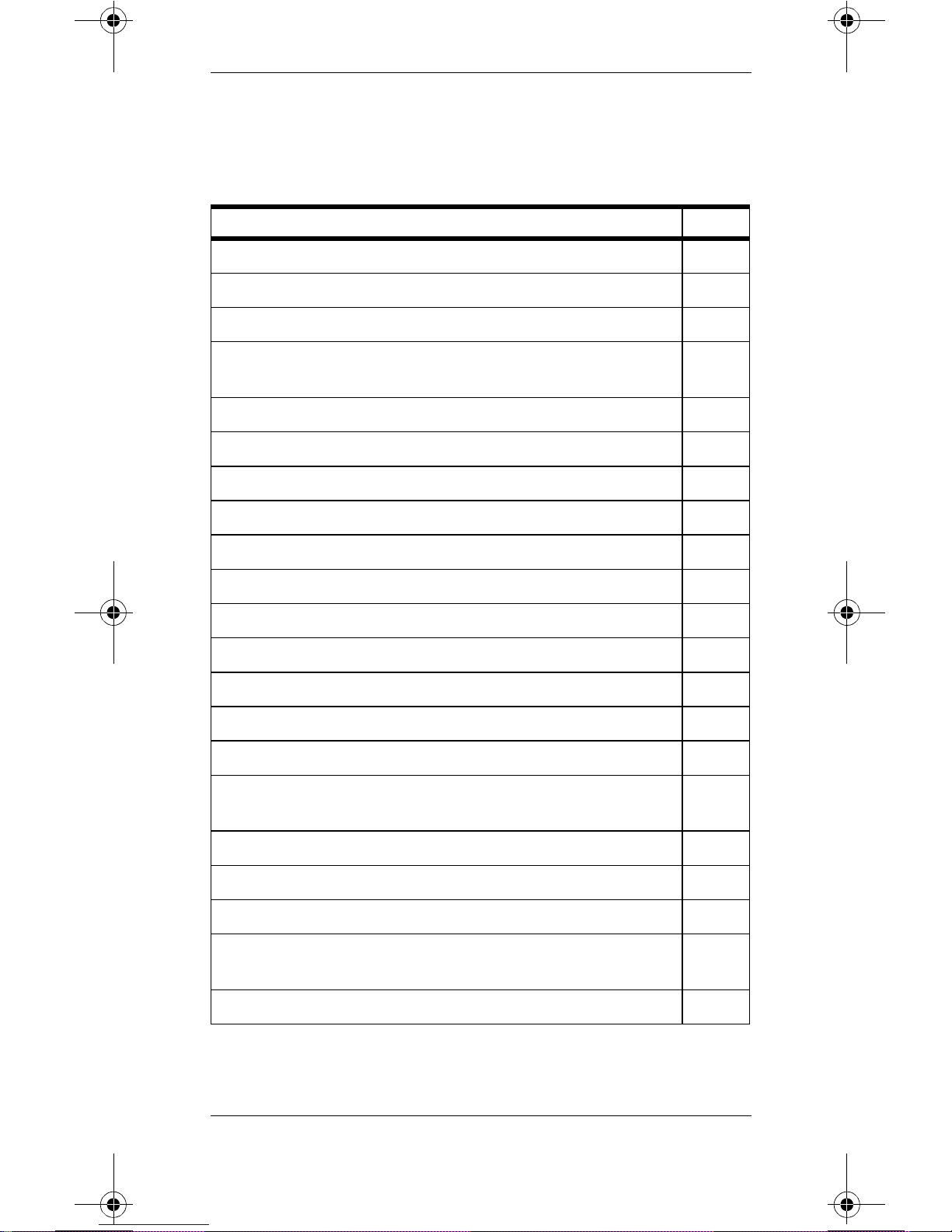

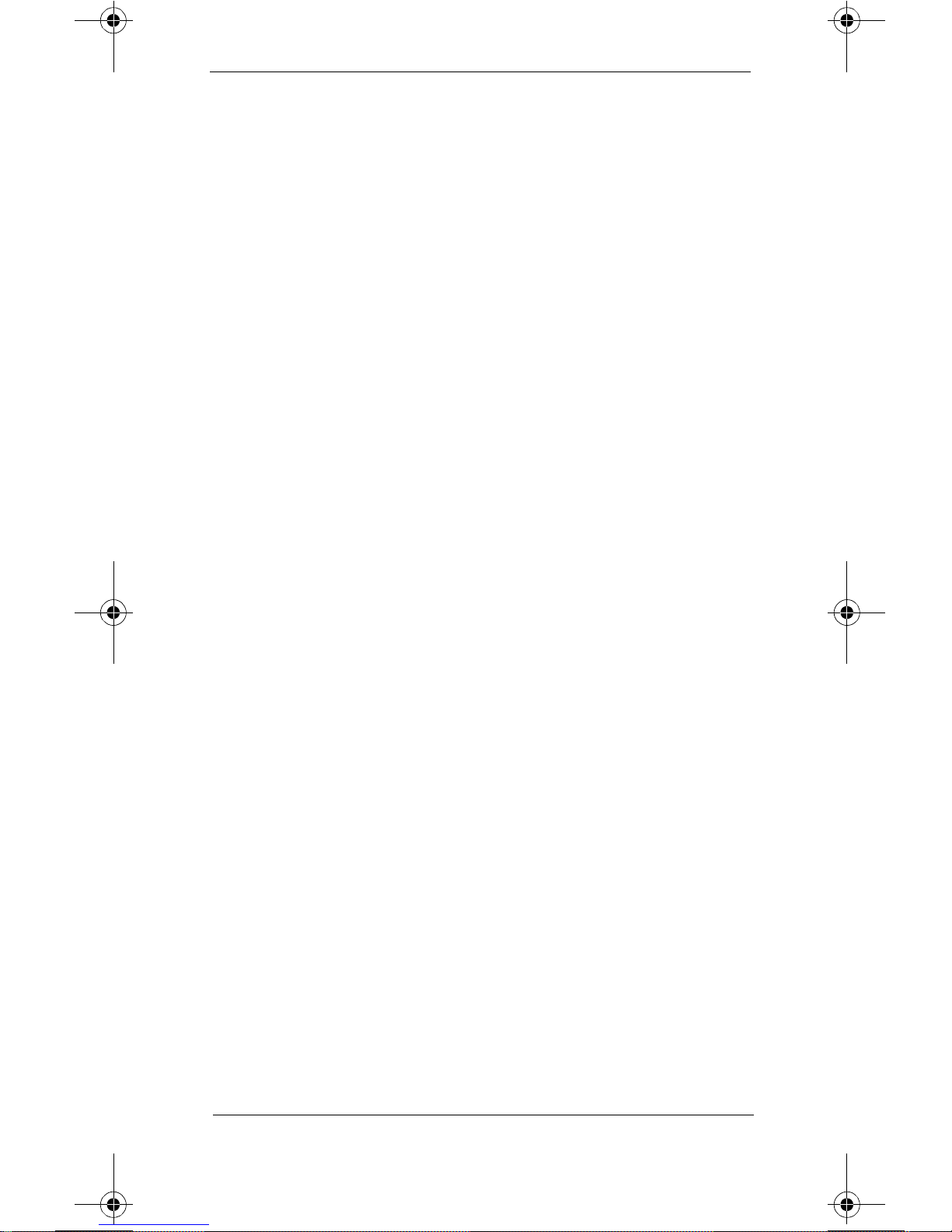

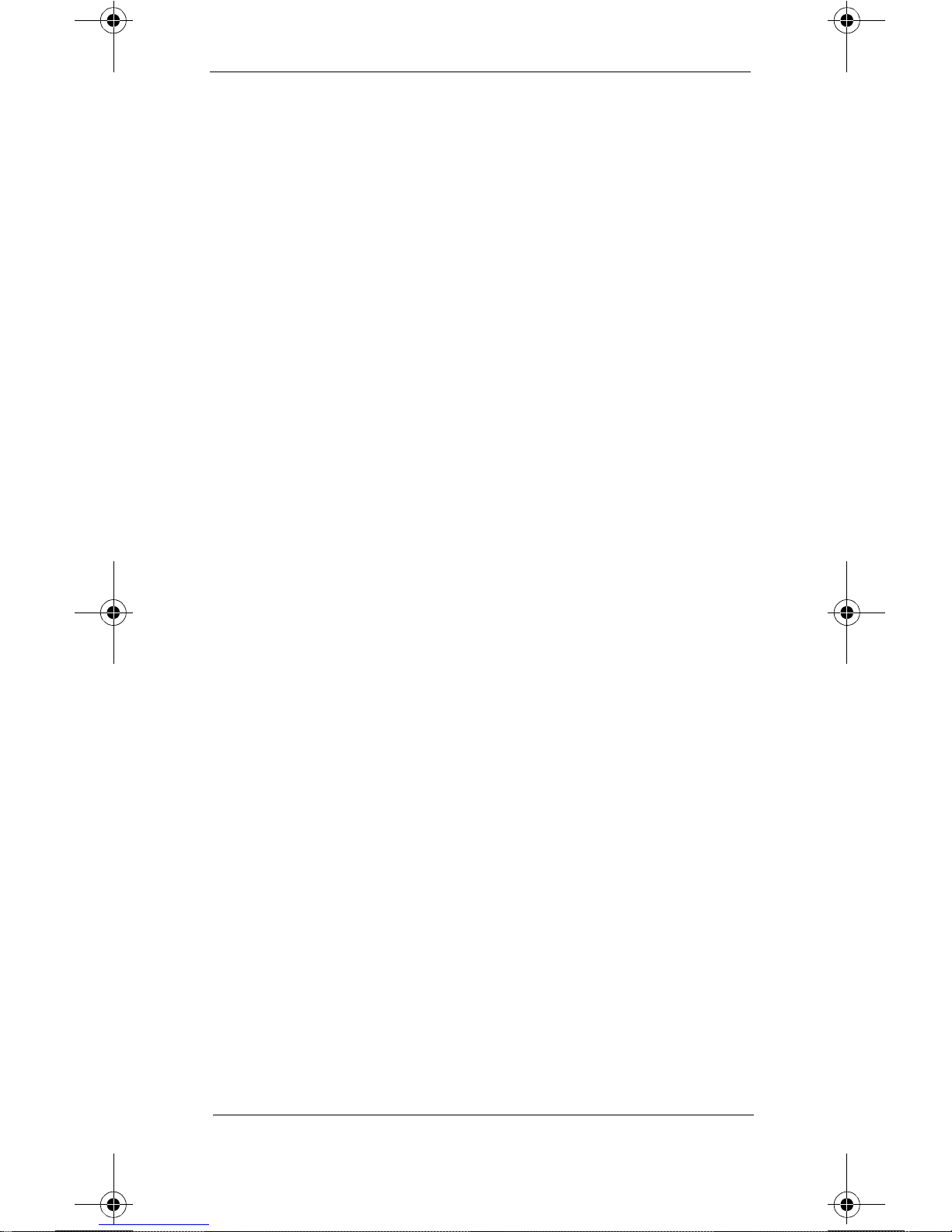

Transmitter Torque Requirements

If the transmitter is disassembled, certain screws must be

re-installed at specific torqu e specifications.

shows the torque requirements in the transmitt er .

Conversion Chart

2 inch-pounds = 0.23 joules

3 inch-pounds = 0.34 joules

6 inch-pounds = 0.68 joules

3 inch-

pounds

Figure 2

6 inch-

pounds

3 inch-

pounds

2 inch-

pounds

Figure 2 Torque Requirements

4

Troubleshooting Overview

Transmitter Non-RF Application

Problems

LEADS OFF INOP

This INOP generally means that one of the patient leads

has fallen off the patient. It can also indicate a fault

within the transmitter.

1. A lead may have become disconnected from the

electrode. Go to the transmitter generating the

INOP and m ake certain that all leads are connected

to the electrodes on the patient’s body. The LEDs

on the front of the transmitter should be off if all

lead wires are attached properly.

If the leads are correctly connected, use the

Telemetry Service Tool or Wave Viewer at the

bedside to make cert ain there is a good waveform.

The transmitter can also be connected to a patient

simulator, if this is more convenient. Using the

Telemetry Service Tool or Wave Viewer, check the

following:

a. All available leads. If there is an ECG waveform

but no LEADS OFF-Check Transmitter INOP

on the Telemetry Service Tool or Wave Viewer,

the leads are connected.

b. If there is not a good waveform, check the leads

again and make certain they are applied properly

before continuing with the procedures. Proper

application of electrodes includes:

– Proper skin preparation.

– Using “moist electrodes”. I f the gel on the

electrodes is not mo i st, the electrodes are too

dry to get a good signal.

– Making certain the c onnections are not dirty.

Transmitter Non-RF Application

5

2. If all leads are connected and there is not a good

signal, there may be a broken lead wire or the

connection between the leadset an d the t ra nsmi tte r

is compromised due to dirt or corrosion. Remove

the leadset and make c ertain the leadset connector

in the top of the transmitter is not dirty or

corroded. If it is, clea n or replace the conn ector.

If there is no dirt or corrosion, check that a leadset

with a telemetry leadset combiner block with latch

is used. Attach the leadset, (the leadset will click

when it locks). T hen change the lea dset. Check to

see if this fixes the problem.

If it does not, perform the fol lowing substeps:

a. Make certa i n the Front End Assembly to the

ECG PCB cable is connected (red tab

connector) properly or not broken. If the cable

is broken, replace the defective assembly

(ECG PCB or Fron t E nd Assembly).

b. Make cert ain that the 3/5 Lead Switch

connector is plugged-in prop er ly. If it is,

replace the ECG PCB.

c. If replacing the ECG PCB d oes not resolve the

problem, replace the Front End Assembly.

TRANSMITTER OFF INO

If there is a TRANSMITTER OFF message at the central

station, this ind i cat es th a t th e t ra nsmitter has determined

that there has been a

for the last 10 minutes or longer and has gone into RF

auto-shutoff.

1. Re-attach the leads to the patient. The transmitter

will turn on automatically.

LEADS OFF condition on all leads

6

Transmitter Non-RF Application Problems

INVALID LEADSET INOP

This indicates that the transmitter has either detected a

4-wire leadset or an EASI

leadset attached. Do the following:

1. If a 4-wire leadset has been installed, monit oring is

not possible. Replace wit h a 3- or 5 wire leadset.

a. If the transmitter is a standard ECG transmitter,

replace with a 3- or 5-wire leadset.

b. If the transmitter is an EASIä ECG transmitter, a

5-wire must be used.

2. If the transmitter i s an EA S Iä ECG transmitter , this

INOP will appear if monitoring is attempted while a

3-wire leadset is attached to the transmitter. Attach

a 5-wire leadset.

3. If this is a standard ECG transmitter, it may be

configured as an EASI

configuration of the EASI parame te r using the

transmitter Service Tool or Wave Viewer, as

follows:

ä ECG transmitter has a 3-wire

ä transmitter. Check the

– Telemetry Service Tool: Connect the service

tool to the transmitter and move to

Transmitter Configuration Screen Two

– Wave Viewer: Connect a 5-wire leadset to the

transmitter and to an ECG simulat or. Establish

communication between the Wave Viewer and

the transmitter. If the ECG waveform is

labelled

EASI and has the lead selections of

AI, AS and ES, th e transmitte r is co nfigured

for EASI operation. If the ECG waveform is

labelled

Lead and has the lead selections: I, II,

III, aVR, aVL, aVF, MCL and V, the transmitter

is configured for standard ECG.

– If the transmitter is configured incorrectly,

reconfigure it using the Service Tool.

Transmitter Non-RF Application

7

4. If the problem is not solv ed by Steps 1 - 3, then

there may be a problem wit h the leadset switches

not being detect ed properly.

a. Check where the leadset attaches for dirt and clean

as necessary. Leadset switches are located next to

the reference and chest (standard ECG) or

reference and “E” (EASI) lead wires.

b. The 3/5 lead switch may not be connected to the

ECG PCB properly.

c. Replace the Front-End Assembly

d. Replace the Main PCB.

NO SIGNAL INOP and an RF OUT OF LOCK

INOP at Telemetry Service Tool or Wave

Viewer

This INOP means that the transmitter has determined

that the phase-lock loop in the transmitter is no longer

functioning (This condition also generates a

INOP at the Central Station). Replace the Main PCB.

NO SIGNAL

8

Transmitter Non-RF Application Problems

Battery INOPs

This module tells how to deal with INOPs related to

battery operation. These INOPs are:

BATTERY WEAK

REPLACE BATTERY

Normally, either one of these INOP messages simply

indicat es the need to replace the battery in the

transmi tter generating the message. But, if the battery is

replaced and the me ssage still occurs, do the fo llowing.

Note

Battery life depends on the transmitter being used, the

battery type, and the SpO2 sample rate (SpO

monitored). Refer to the spec ifications in

Service and Reference Guide to determine what

the

battery life to expect.

is being

2

Appendix A of

If the battery life is less than expected, things to check

are:

• Remember that simply unplugging the SpO

transducer and turning SpO

not shut off the SpO

must be set to

Manual using the Telemetry Service

sampling. The sampling rate

2

off at the central does

2

2

Tool or Wave Viewer.

• After making a manual SpO

measurement using

2

the Telemetry Service Tool or W ave Viewer,

terminate th e mea surem ent by select ing

otherwise, the SpO

function does not shut off.

2

End STAT;

• Remove the batteries from the transmitter when

they are not in use. The RF auto-shutoff feature

does not save battery life because the circuitry is

constantly checking to see if the unit has been

connected to a patient.

Transmitter Non-RF Application

9

1. The battery could be inserted improperly. Check

that the terminals of the battery are oriented

correctly with the battery contacts.

2. Open the bat tery door and check the battery

contact s. If they are corroded, clean them. If they

appear damaged, replace the batte ry contacts.

Also, check the screws that connect the battery

contacts to the Case Assembly.

3. Zinc-air batteries cannot be used in transmitters

with SpO

hardware because zinc-air batteries

2

cannot reliably supply enough curren t at sta rt - up of

the transmitter to make sure the transmitter

functions properly. Even if SpO

monitored, if the transmitter has the SpO

is not being

2

2

hardware installed, a zinc-air battery cannot be

used. A lithium or alkaline battery must be used .

4. Remove the battery a nd separate the case assembly

from the transmitter’s internal electronics. Using an

ohmmeter, check the resistance from the battery

contact inside th e case to its corresponding

external battery contact. The resistance should be

less than 1 ohm. If it is not, replace the battery

contacts.

5. SpO

10

SpO

might be affecting the battery. Replace the

2

PCB.

2

Transmitter Non-RF Application Problems

ECG EQUIP MALF INOP

This INOP indicates that either a software incompatibility

has been found or a fault has been detected in the ECG

hardware in the transmitter.

1. If the transmitter i s an EA S I

INOP indicates that the software in either the

receiver mainframe or the central station cannot

process EASI

a. Update the software in the receiver mainframe and

the central station to a compatible revision.

b. Downgrade the transmitter firmware to a revision

compatible with the mainframe and central station

2. If SpO2, cannot be monitored, replace the ECG

PCB.

3. If changing the ECG PCB does not correct the

problem, replace the Main PCB.

ä ECG data. Do one of the following:

ä ECG transmitter, this

TRANSMITTER MALF INOP

This INOP indicates that the self-test has discovered a

problem with the i nternal, non-RF circ uitry of the

transmitter. The problem probably lies in the Digital ASIC

or the RAM section of the Main PCB. If this INOP

appears , replace the Main PCB.

ARRHY REQUIRED INOP

This message indicates that arrhythmia monitoring has

been turned off for an EASI ECG transmitter.

1. Turn arrhythmia monitoring O N at the Information

Center.

2. If arrhythmia monitoring is not desired, then a

standard ECG transmitter must be used.

Transmitter Non-RF Application

11

Transmitter SpO2 Problems

SpO2 EQUIP MALF INOP

This INOP indicates there is a problem with the SpO2

circuits associated with the transmitter. The following

procedure describes how to troubleshoot this proble m:

1. The tr ansducer may be bad. Change the transducer

to see if this resolves the problem.

2. The SpO

adapter cable may be faulty. Replace the

2

cable to see if this fixes the problem.

3. Open the transmitter and make certain the SpO

Connector cable is connected to the SpO

Board.

2

2

Make certain it is not damaged. If the cable is

damaged, replace the Front End Assembly.

4. Make certa in that the Main PCB to SpO

Board

2

ribbon cable is connected properly and is not

damaged. If th e cable is damaged, replace the Main

PCB.

5. Replace the SpO

Board.

2

6. If the problem persists, replace the Main PCB.

SpO2 ERRATIC INOP

This INOP indicates that the SpO2 measurem ents are

erratic. This could be due to a faulty transducer or

incorrect positioning of the transducer . It could also be

caused by optical shun ting if the transducer is too big or

too small. If this INOP appears, do the fo llowing.

1. Verify that the transducer is appropriate for the

patient’s weight. If not, use a different transduc er

with the correct fit.

12

Transmitter SpO2 Problems

2. Make certain that the light source and photo

detector are opposite each other and that the light

passes through the ateriolar bed.

3. Reposition the transducer to a site with higher

perfusion.

4. Replace the transducer.

5. Replace the adapter cable.

SpO2 INTERFERENCE INOP

This INOP can be caused if the level of ambient light is so

high that the SpO

pulse rate. It can also be caused by an equipment

malfunction. If this INOP appea rs, do t he following.

1. Cover the transducer with a non-white opaque

material (e.g., pulse oximete r probe wraps - Posey

wrap or equivalent). If it does not solve the

problem, continue.

transducer cannot measure SpO2 or

2

2. Replace the transducer.

3. Replace the adapter cable.

4. This problem can also be caused by electrical

interference. Reduce or remove any sources of

electrical interference.

SpO2 NO TRANSDUCER INOP

This INOP can occur if the SpO2 transducer is

disconnected, dirty , o r broken. It can also be caused by a

transmitter failure. If this INOP appears, do the following.

1. If the transducer is disconnected, reconnect the

transducer.

2. Replace the transducer.

3. Replace the SpO

Board.

2

Transmitter SpO2 Problems

13

SpO2 NOISY SIGNAL INOP

This INOP can be caused by excessive patient movement

or electrical interference, which is seen as irregular pulse

patterns. If this INOP appears, do the following.

1. Move the transducer to a site with less movement.

2. Reduce or remove any sources of electrical

interference.

SpO2 NON-PULSATILE INOP

This INOP can be caused by a weak or non-detectable

pulse. Try the following to see if they resolve the

problem:

1. Relocate the sensor to a site with improved

circulation.

2. Warm the area to improve the circulation.

3. Try another sensor type.

SpO2 TRANS MALF INOP

This indicates that the SpO2 transducer is

malfunctioning . Do the following:

1. Chec k to see if the SpO

transducer or transmitter is dirty or corroded.

Clean them if required.

2. Replace the transducer or adaptor cable.

3. Replace the Front-end Assembly.

connecto r on the

2

14

Transmitter SpO2 Problems

Receiver Mainframe/System Faults

Power does not come on when Receiver

Mainframe Power On/Off Button is pressed

1. The receiver ma infr am e po wer cor d ma y be

disconnected or connected to a bad sourc e. Ma ke

certain that the power cord is plugged into the

correct power source.

2. Check the power-on LED on the rear of the

Mainframe to see if it is lighted.

3. The power supply may be bad. Repla ce the power

supply.

NO DATA FROM BED INOP

This INOP indicates that no information is getting to the

central station for a particular transmitter-receiver pair.

To effectively troubleshoot this problem, receiver

mainframe communica tion with the SDN must be

verified. This communication link determines the course

of action. However, there is another possibility to

consider before re-booting the mainframe. If the

telemetry system is being used with a Philips Information

Center, make certain that the telemetry bed or beds are

not in

Standby Mode.

If the beds are in

Take the beds out of

should disappear.

If NO DATA FROM BED INOPS occur intermittently,

check the mainframe status logs for error codes. See

Chapter 2 in the Service and Reference Guide for

information on how to acce ss the logs and

that manu al for the error codes.

Receiver Mainframe/System Faults

Standby Mode this INOP is generated.

Standby Mode and the problem

Appendix E of

15

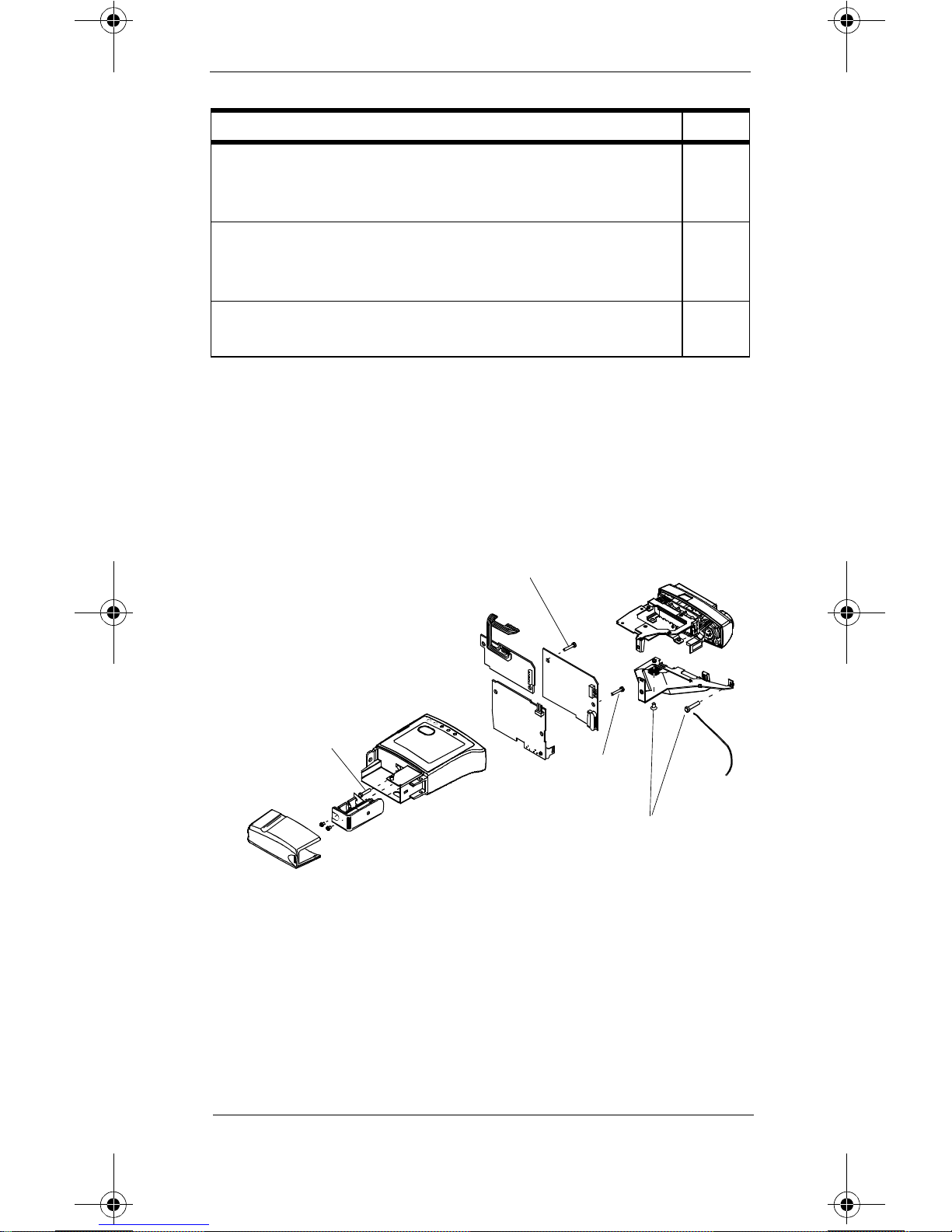

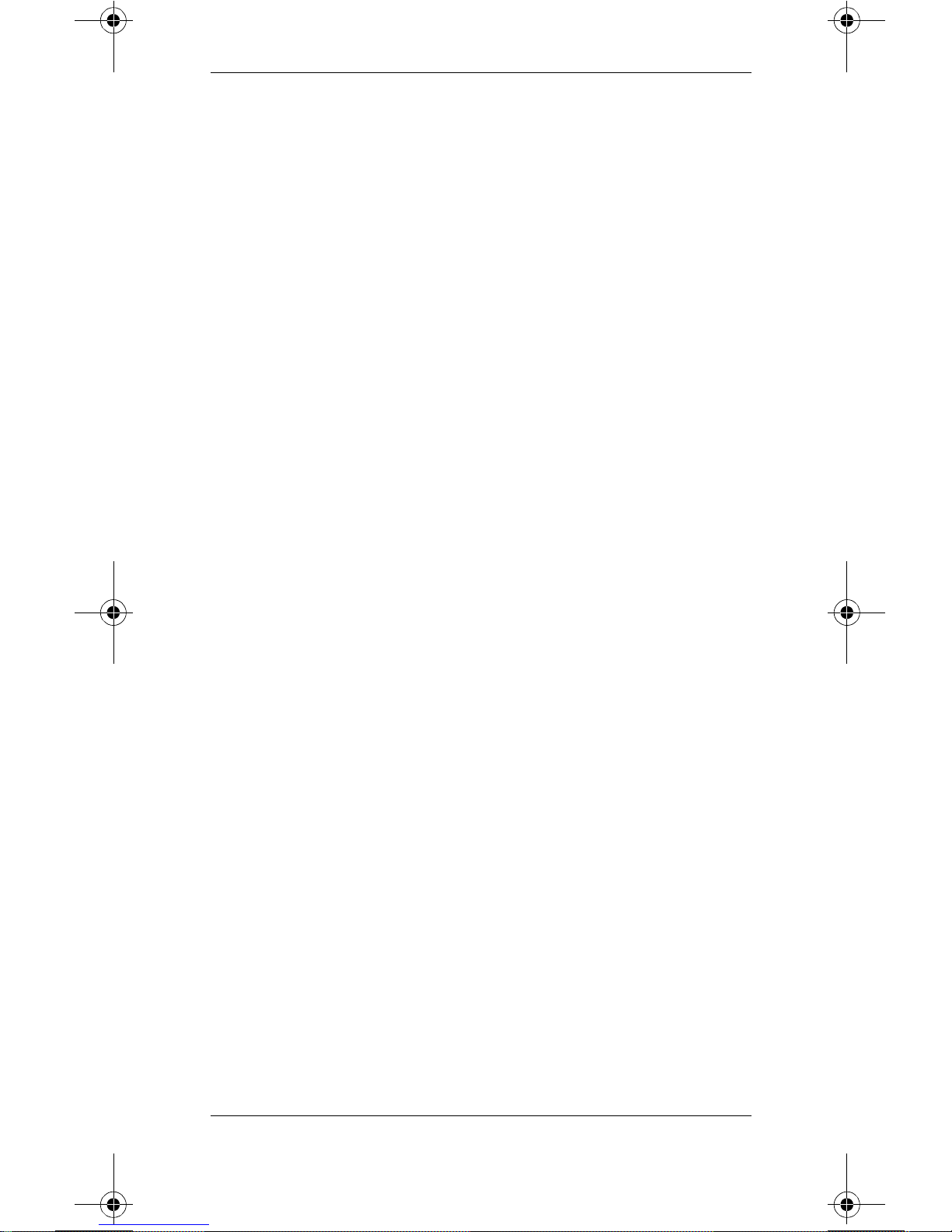

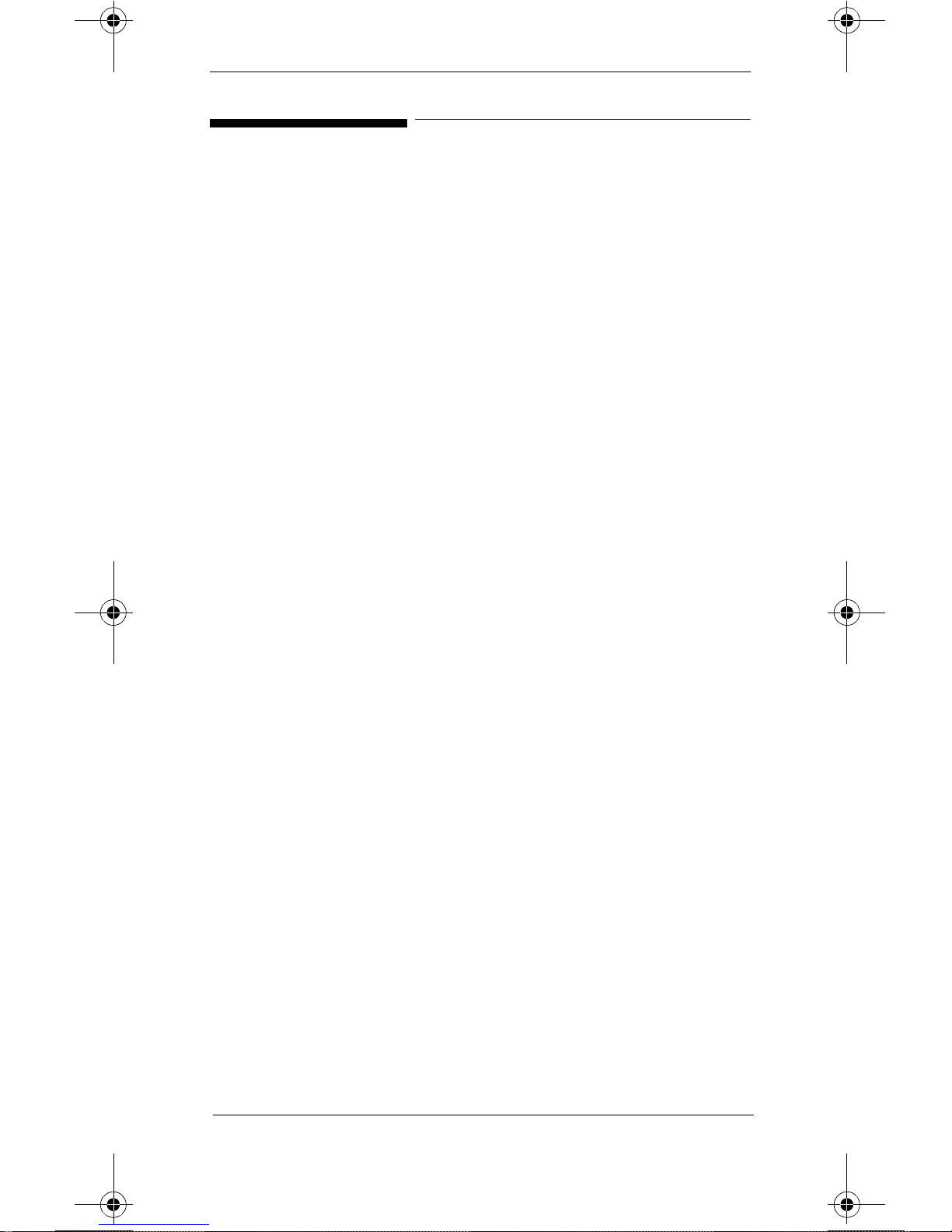

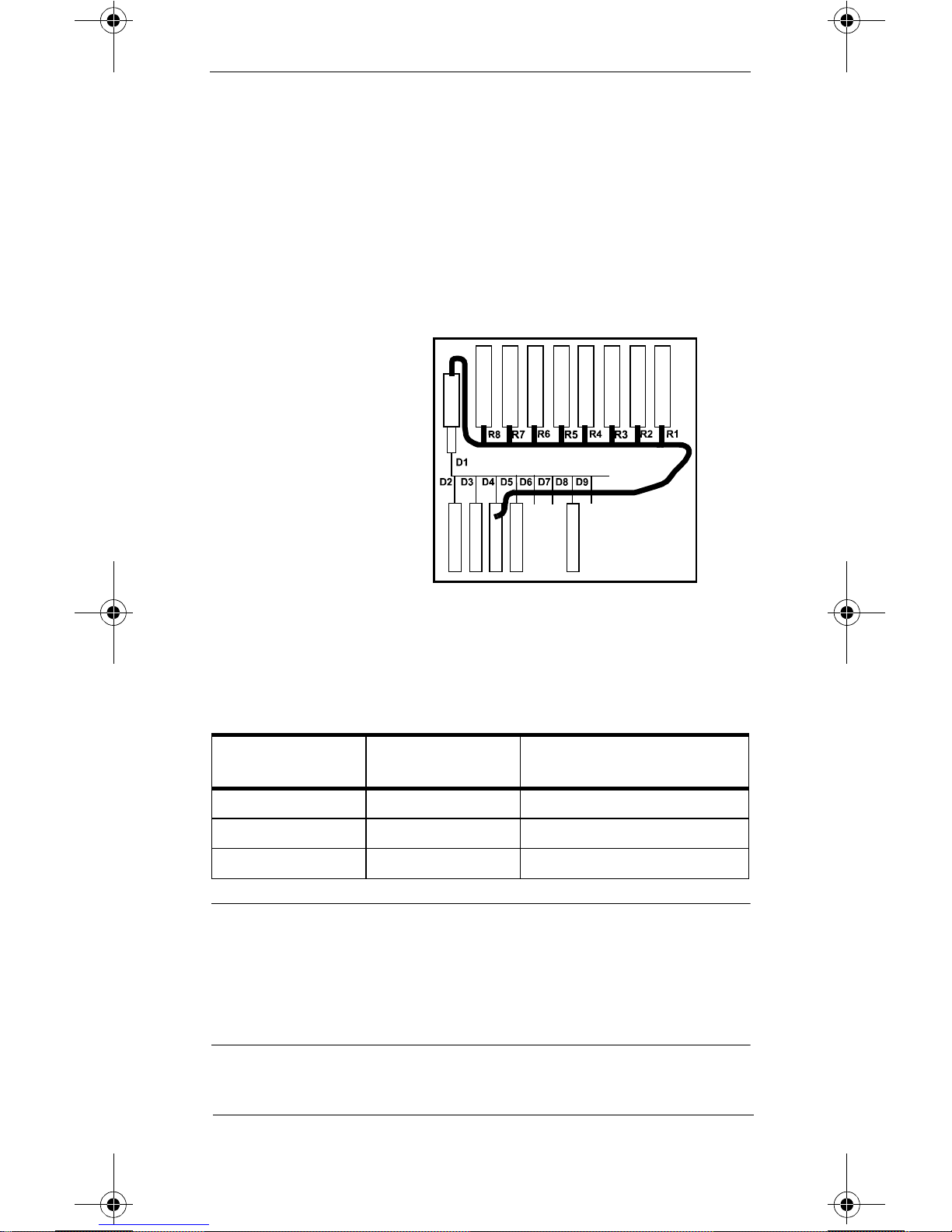

1. Check th e overall operation of the receiver

mainframe by re-booting it and observing th e LEDs

on the 40 MHz CPC card and the Utility CPU boa rd.

To re-boot the mainframe, push the power button

to remove power and then push it again to restore

power. See

Figure 3 for the Receiver Mainframe

Board location.

Receiver Mainframe Board Location Diagram

R1-R8: Receiver Slots

D1: Rack Interface PCB

D2: Utility CPU PCB

D3: SDN Interface PCB

D4: Analog Output PCB

(optional)

D5: CPC PCB

D6: Unused

D7: Unused

D8: Power Supply PCB

Figure 3 Receiver Mainframe Board Location

Diagram

The LEDs should behave as follows:

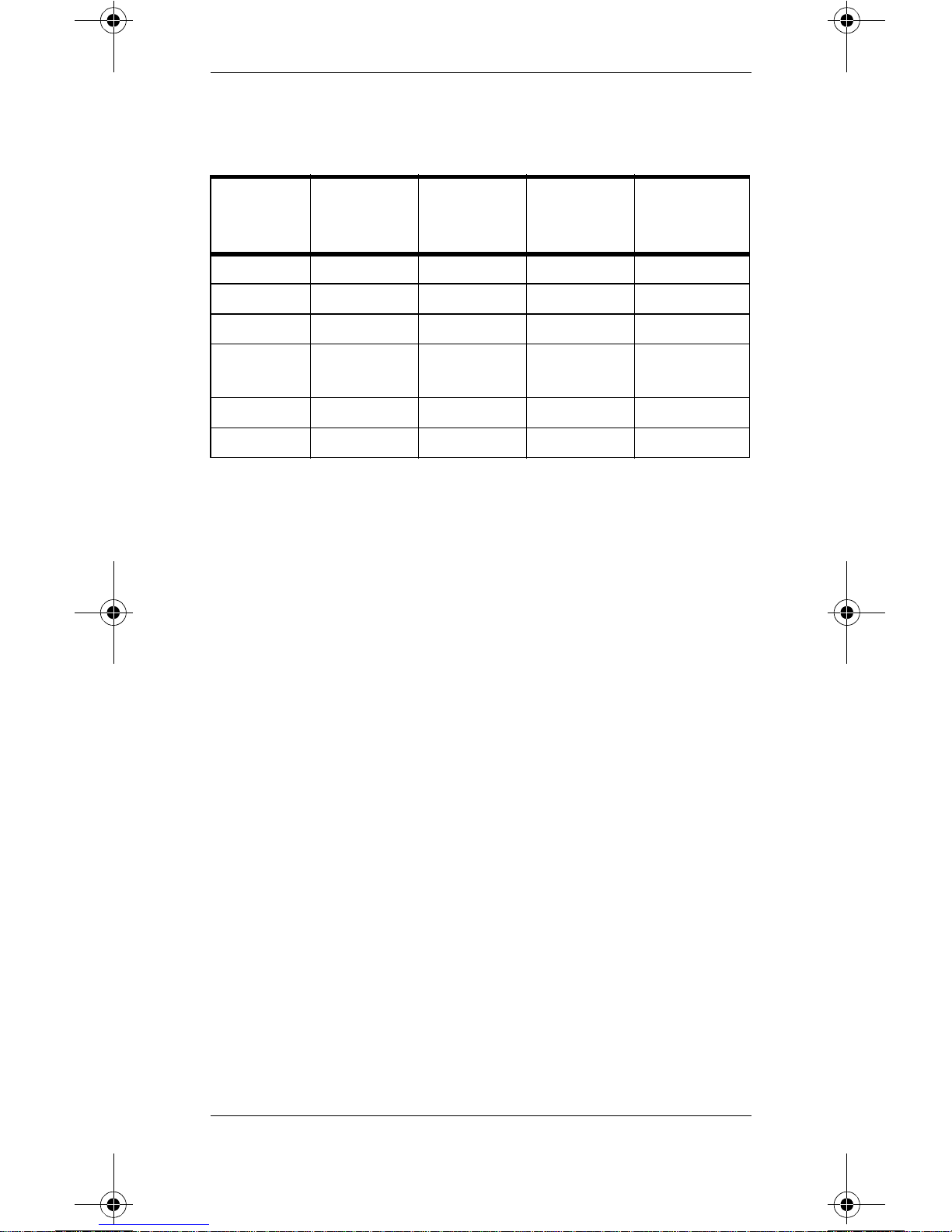

Table 1. 40 MHz CPC Card

LED Step 1

(Normal Operation)

1 Red ON OFF

2 Green ON Slow Blink

3 Green ON Slow Blink

Step 2

Note

The 3 upper green LEDs on the Utility CPU are for the

power supply and should remain Green whene ver power

is applied to the receiver mainframe.

16

Receiver Mainframe/System Faults

If the normal bootstrap sequence occu rs, receiver

Table 2. Utility CPU Board

Step 4

LEDs Step 1 Step 2 Step 3

1 Green ON ON ON ON

2 GreenONONONON

3 GreenONONONON

(Normal

Operation)

4 Green ON FAST

BLINK

5 Green ON OFF ON OFF

6 Red ON OFF OFF OFF

FAST

BLINK

FAST

BLINK

mainframe hardware is probably working cor rectly. This

means th at the problem is elsewhere. Do the following to

help isolate where the problem lies.

1. Check the SDN cable t o see if it is miss i ng or

defective. If it is, replace or install a new one as

required.

2. Make certain there are not duplicate SDN beds. If

there are , reconfig ure the receiver mainframe for

other branch es or move one bedside to another

branch.

3. Make certain that two receiver mainframes do not

have identical SDN Unit numbers. If they do,

reconfigure one receiver mainframe with another

SDN unit number.

4. If it is a non-SCC system, an SDC cable may have

been used instead of an LDC cable. Check the cable

to make certain an LDC cable is being used.

5. The breakaway board portion of the SDN board

could be broken. Replace the SDN board.

Receiver Mainframe/System Faults

17

If an abno rmal bootstrap sequence occurs, then the

problem lies in the receiv er mainframe. To troubleshoot

the mainframe, do the following:

1. Remove power to the receiver mainframe and

remove the 40 MHz CPC Card. Re-apply power to

the receiver mainframe and observe the following

LED pattern on the Utility CPU du ring the

bootstrap routine:

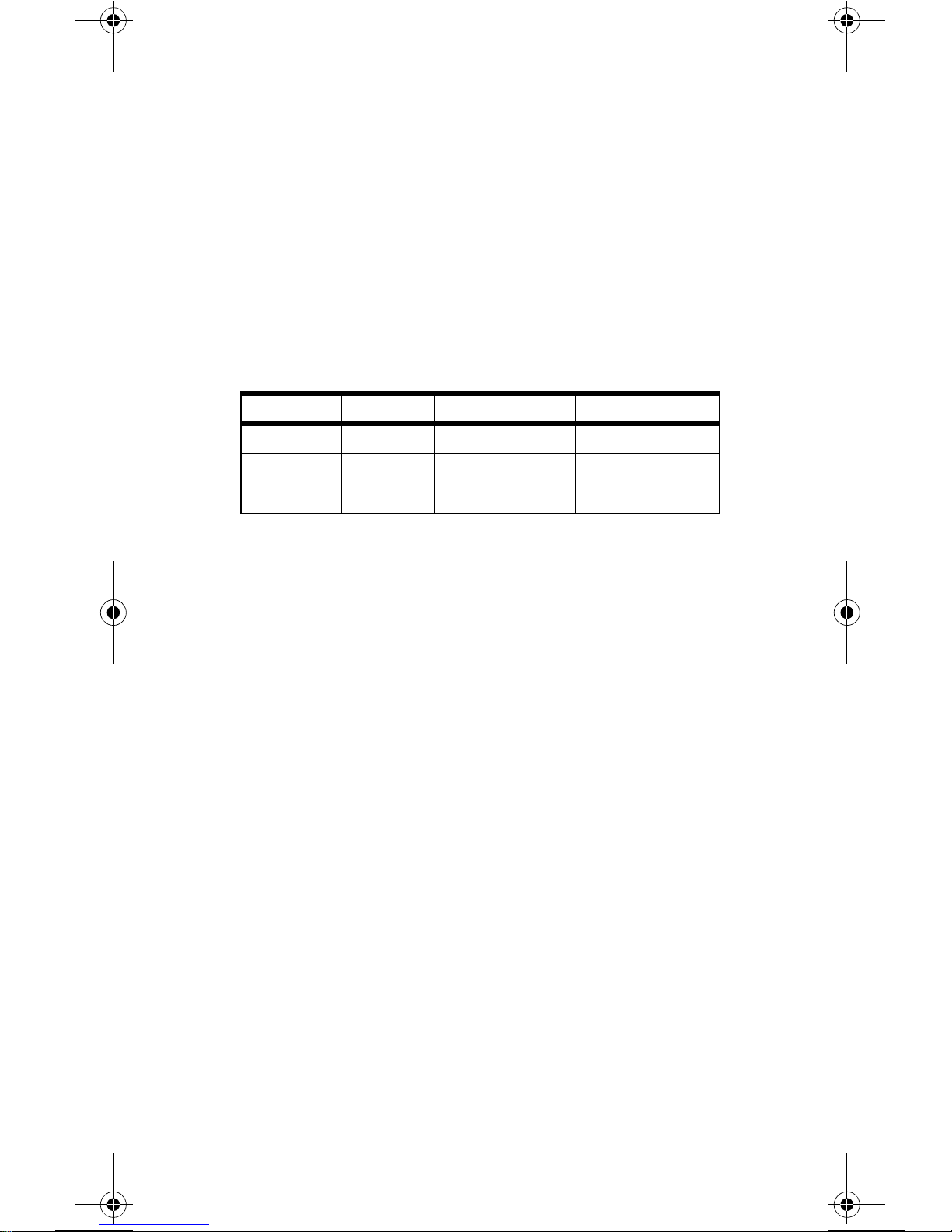

Table 3. Utility CPU LED Pattern without CPC Board

Installed

LED Step 1 Step 2 Step 3

4 Green ON FAST BLINK FAST BLINK

5 Green ON OFF SLOW BLINK

6 Red ON OFF OFF

2. If the sequence in the table occurs, following is the

probable cause of the problem.

a. Refer to the

Compatibility Matrix Service Note

Philips Telemetry System

to verify the

compatibility between the Utility CPU and the

CPC PCB.

b. The 40 MHz CPC Card was in the wrong slot.

Check the correct card placement and insert

the CPC Card into the correct slot. The CPC

belongs in the 4th slot from the left in the rear

of the mainframe. See

Figure 3 on page 16.

c. The 40 MHz CPC Card is faulty. Replace it.

18

Receiver Mainframe/System Faults

Loading...

Loading...