Philips EM5E-DVD Service Manual

Colour Television Chassis

EM5E-DVD

AA

Supplement on Service Manual EM5E

(3122 785 12560)

For DVD Module use Service Manual DVD SD-3

(3211 785 11010)

Contents Page

1. Technical Specifications, Connections & Chassis

Overview 2

2. Safety and Maintenace Instructions, Warnings and

Notes 3

3. Directions for Use 7

4. Mechanical Instructions 17

5. Faultfinding and Repair Tips 19

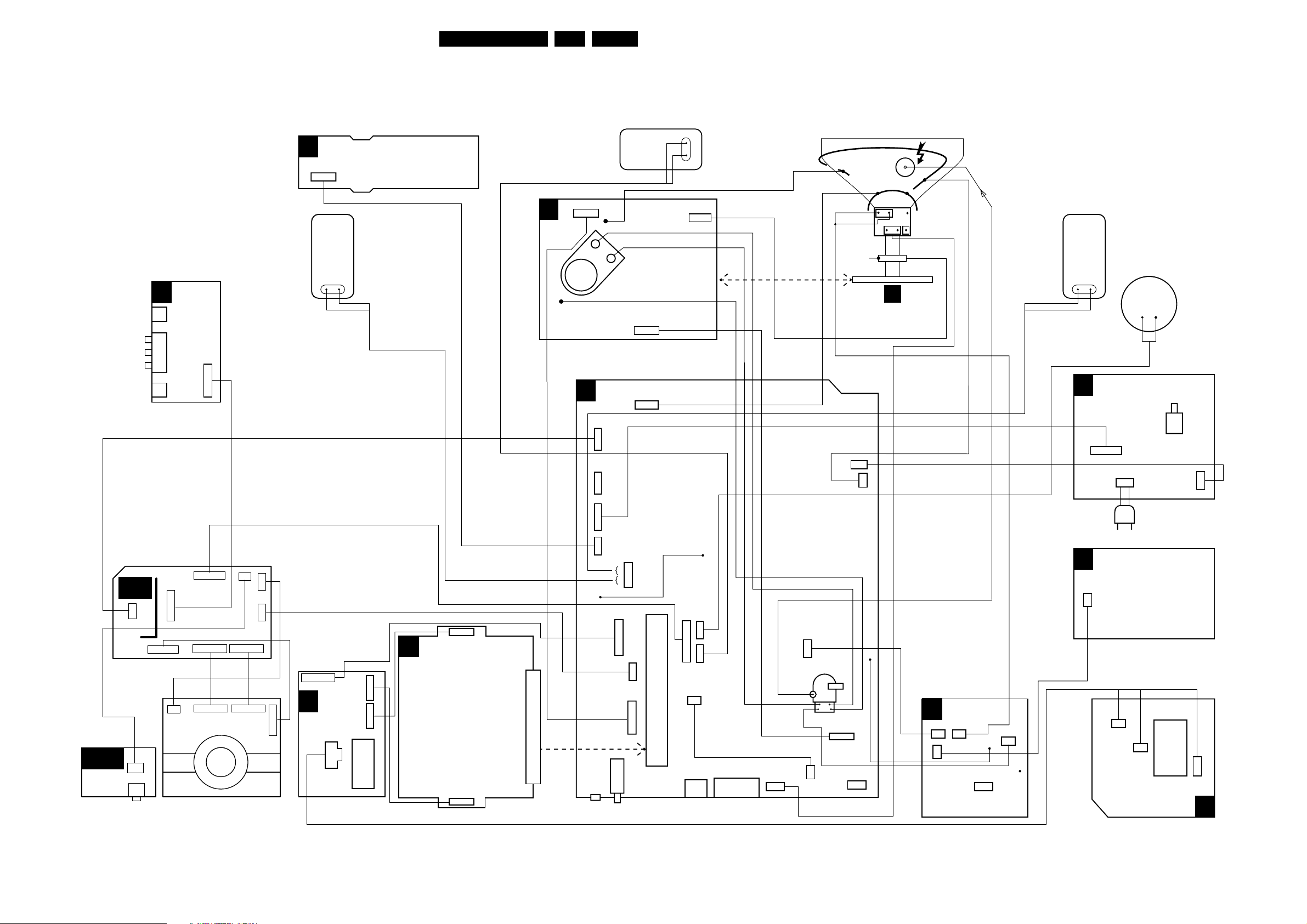

6. Block- and Wiring Diagrams

Wiring Diagram 17

Block Diagram DVD-Dolby Interface Panel 18

Block Diagram Video 19

Block Diagram Audio 20

2

C Overview 21

I

Supply Lines Overview 22

7. Electrical Diagram’s And PWB’s Diagram PWB

Mains Switch Panel (Diagram E) 23 24

CRT Panel (Diagram F) 25 26-27

DVD-Dolby Interface Audio (Diagram MM1) 28 31-32

DVD-Dolby Interface Video (Diagram MM2) 29 31-32

DVD-Dolby Interf. Power Supply(Diagram MM3) 30 31-32

DVD-Eject Button (Diagram MM4) 33 33

Side I/O Panel (Diagram O) 33 34

Top Control Panel (Diagram P) 35 35

Wireless Transmittter (Diagram R) 36 37

Wireless Receiver (Diagram U) 38 39

Amplifier Panel Surround Spk. (Diagram W1) 40 41

Supply Panel Surround Spk. (Diagram W2) 42 42

Connector Panel Surround Spk. (Diagram W3 43 43

Led Panel Surround Spk. (Diagram W4) 44 44

8. Alignments 45

9. Circuit Description and 45

List of Abbreviations 45

10. Spare Parts List 46

©

Copyright 2002 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by WO 0267 Service PaCE Printed in the Netherlands Subject to modification EN 3122 785 12890

EN 2 EM5E-DVD1.

Technical Specifications, Connections & Chassis Overview

1. Technical Specifications, Connections & Chassis Overview

1.1 Technical specifications

Standby consumption : 1.1 W TV set + 6.5 W

Surround speakers

1.2 Connections

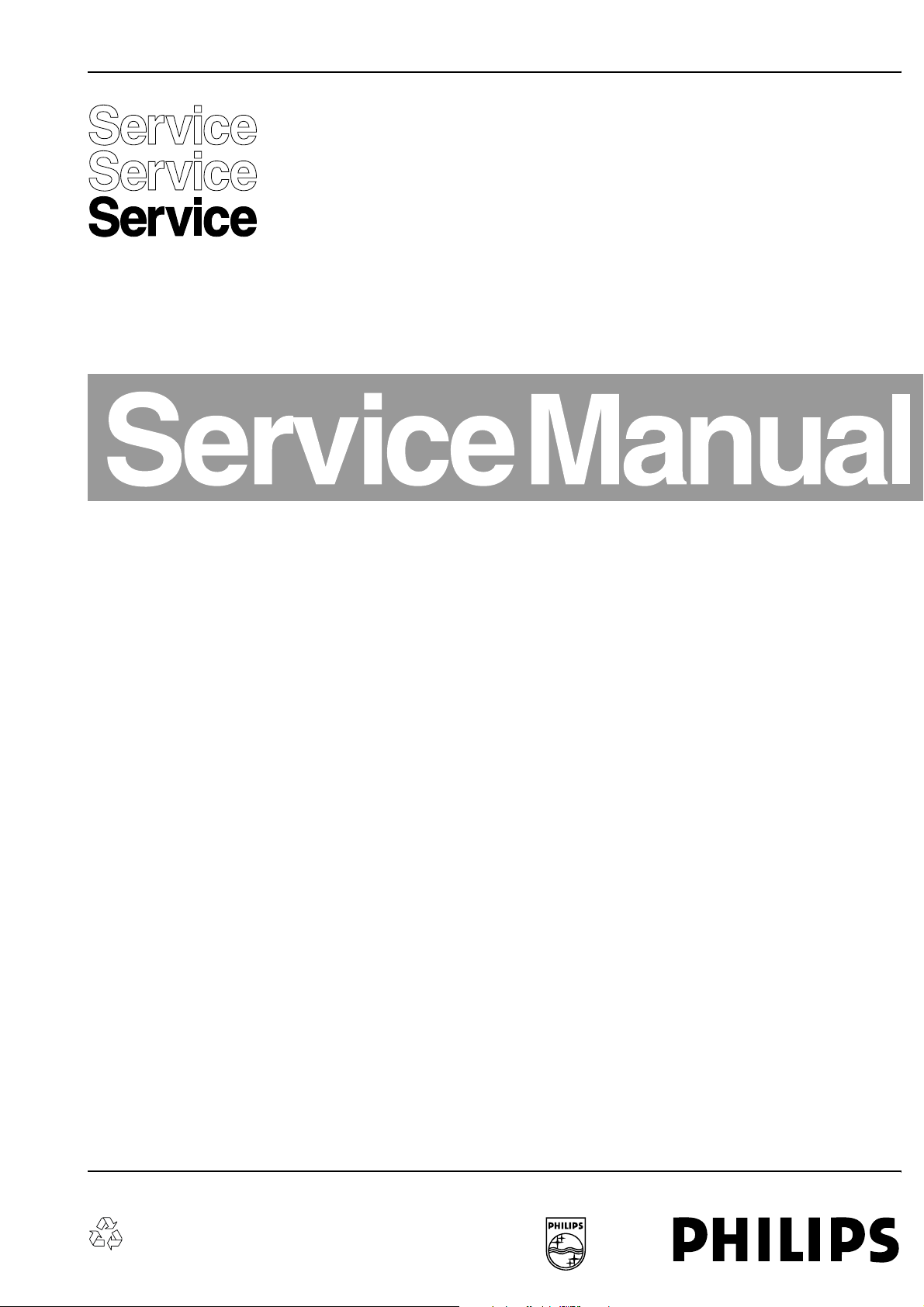

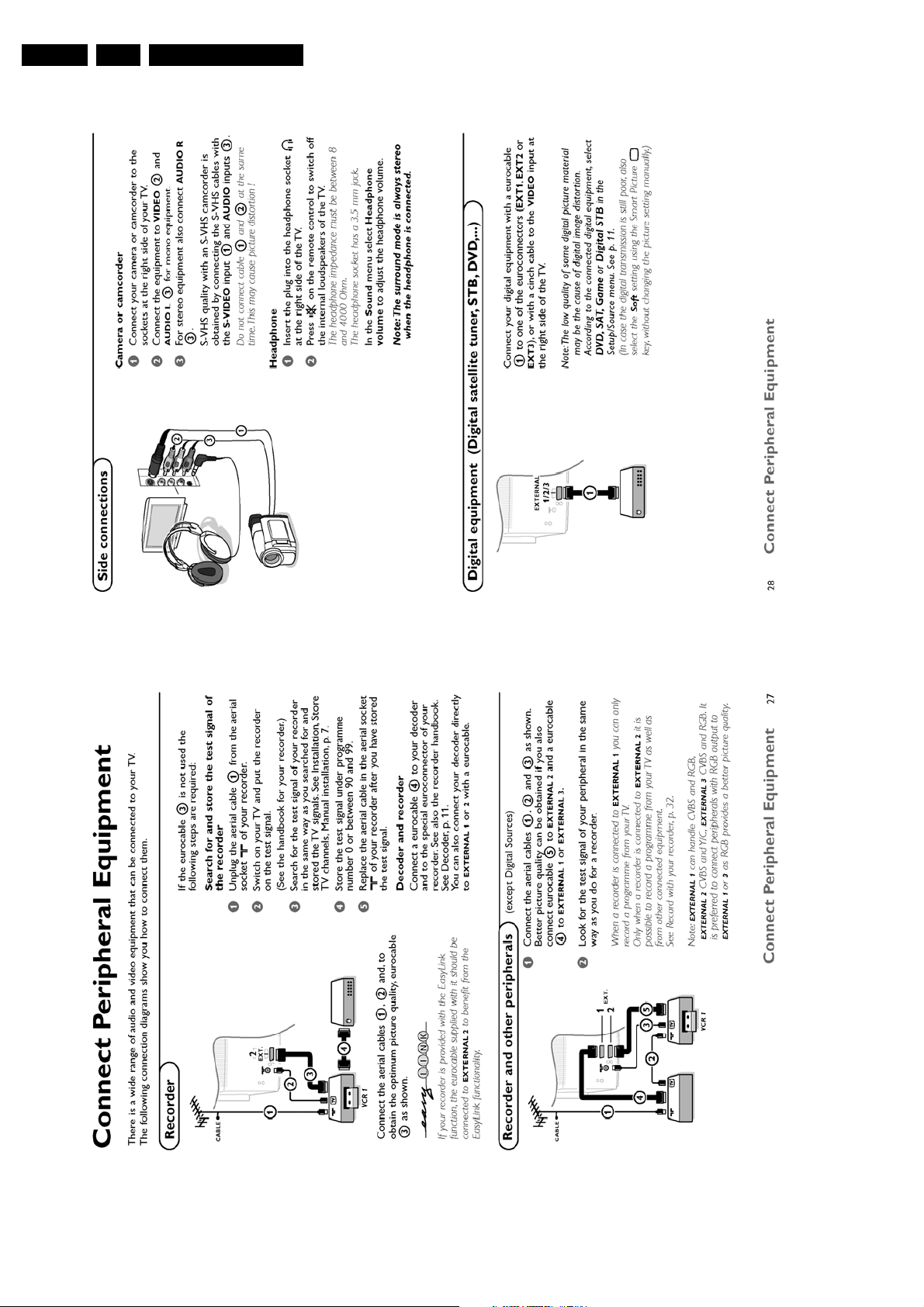

1.2.1 Rear Connections and Side I/O

DIGITAL AUDIO OUT

OPTICAL

COAXIAL

SERVICE

CONNECTOR

FRONT CONTROL

WIRELESS

TRANSMITTER

SURR.

AUDIO OUT

L

R

EXT1

EXT2

EXT3

TOP CONTROL

VOLUME-+ -+CHANNELMENU

SIDE I/OREAR CONNECTIONS

S-Video

Video IN

L

Audio

R

P

IR

LED

LIGHT SENSOR

Figure 1-1 Rear/ front view, top control and Side I/O.

1.2.2 Cinch - Digital Output

CDDA/LPCM : According IEC958

MPEG1/2, AC3, DTS : According IEC1937

: Digital output swing is

5Vpp.

EJECT

DVD-TRAY

CL 26532086_021.eps

050702

Technical Specifications, Connections & Chassis Overview

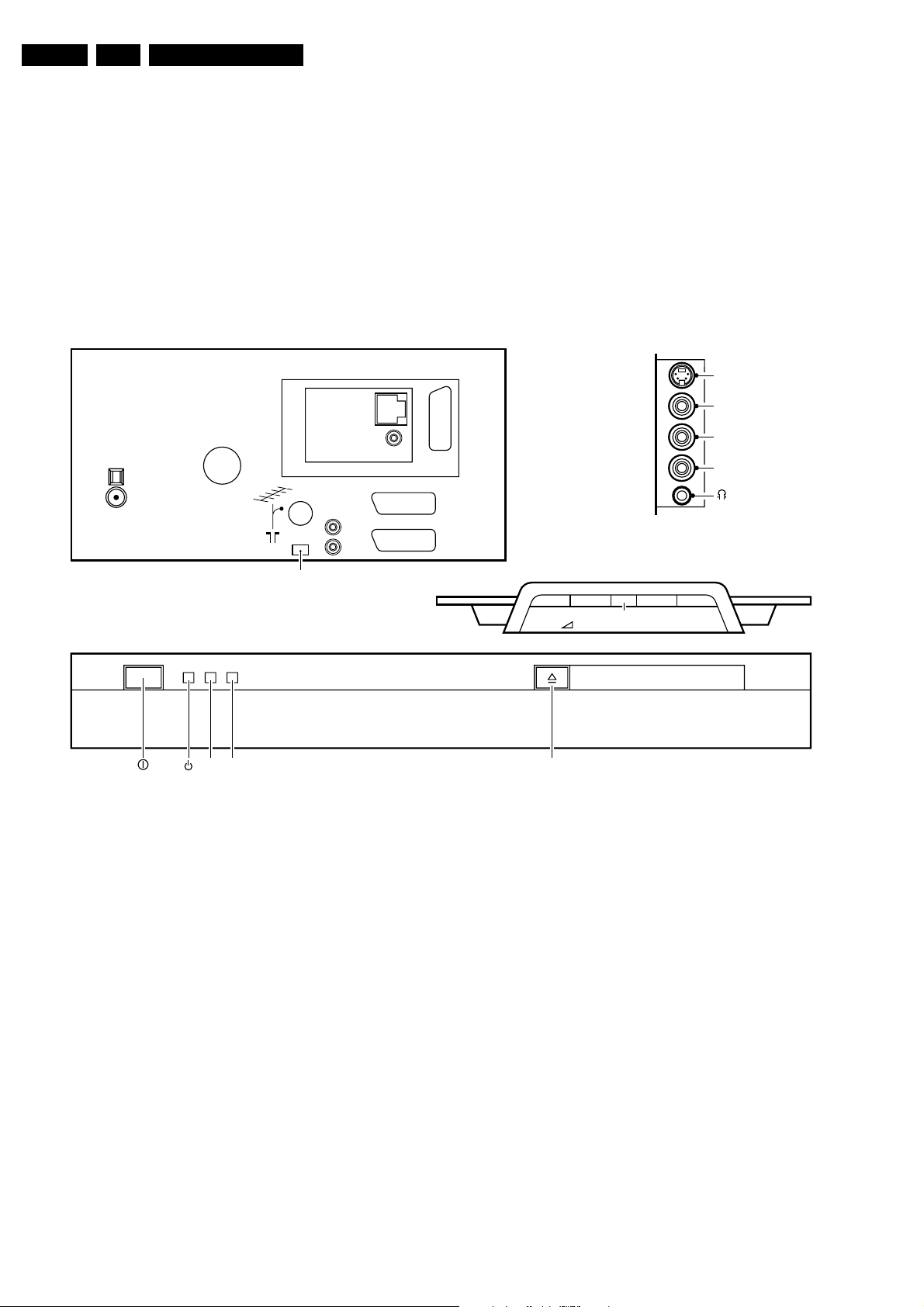

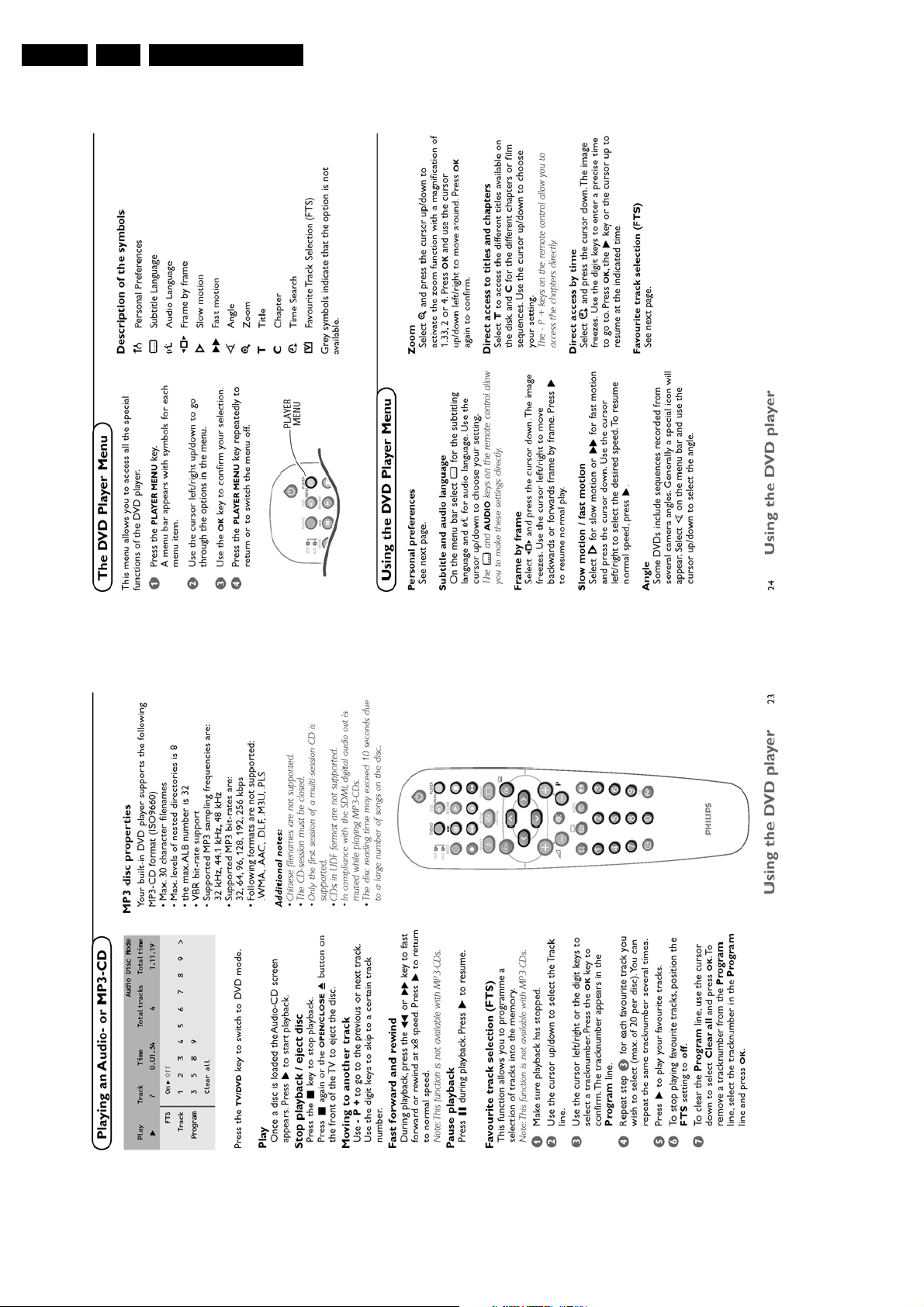

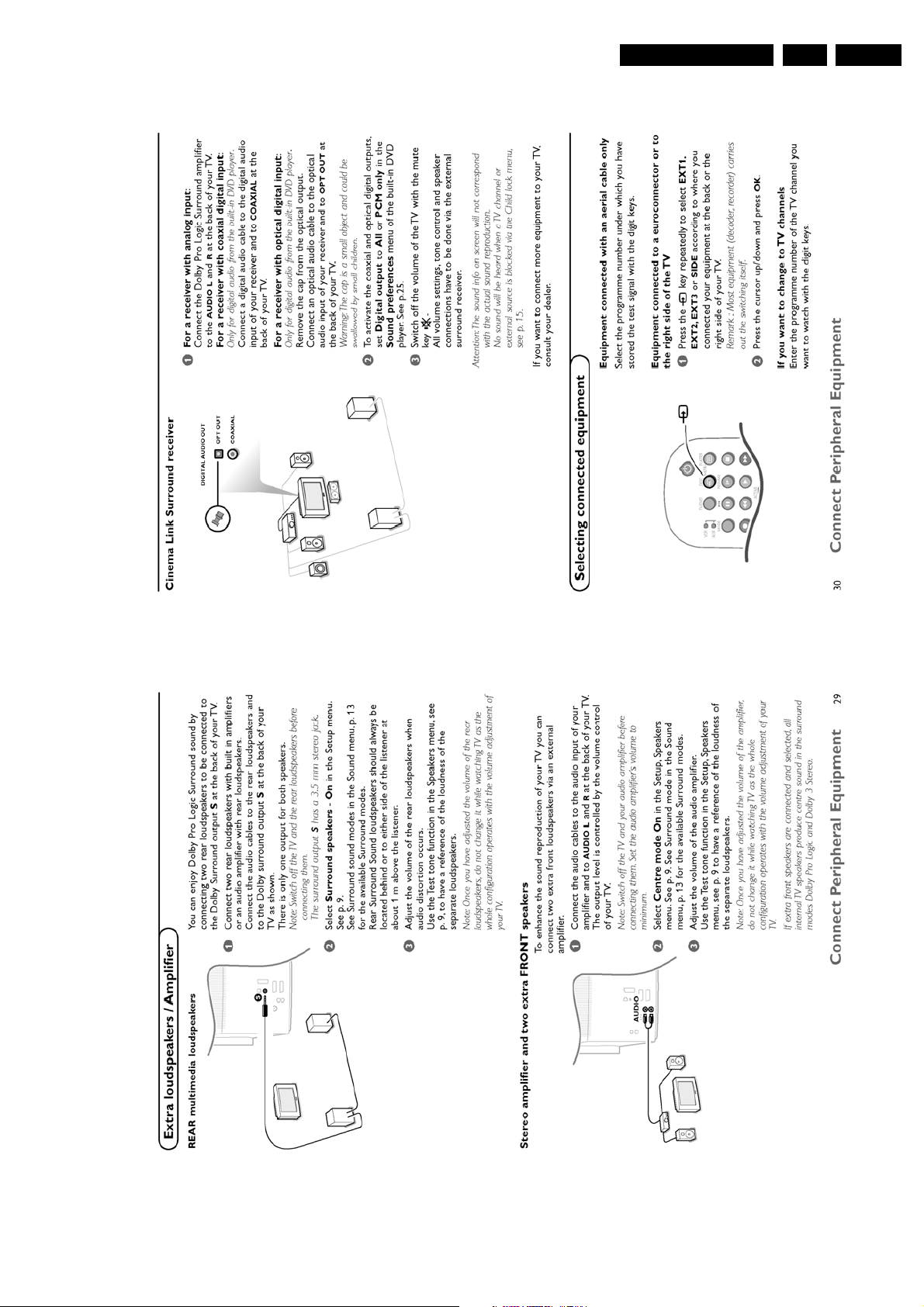

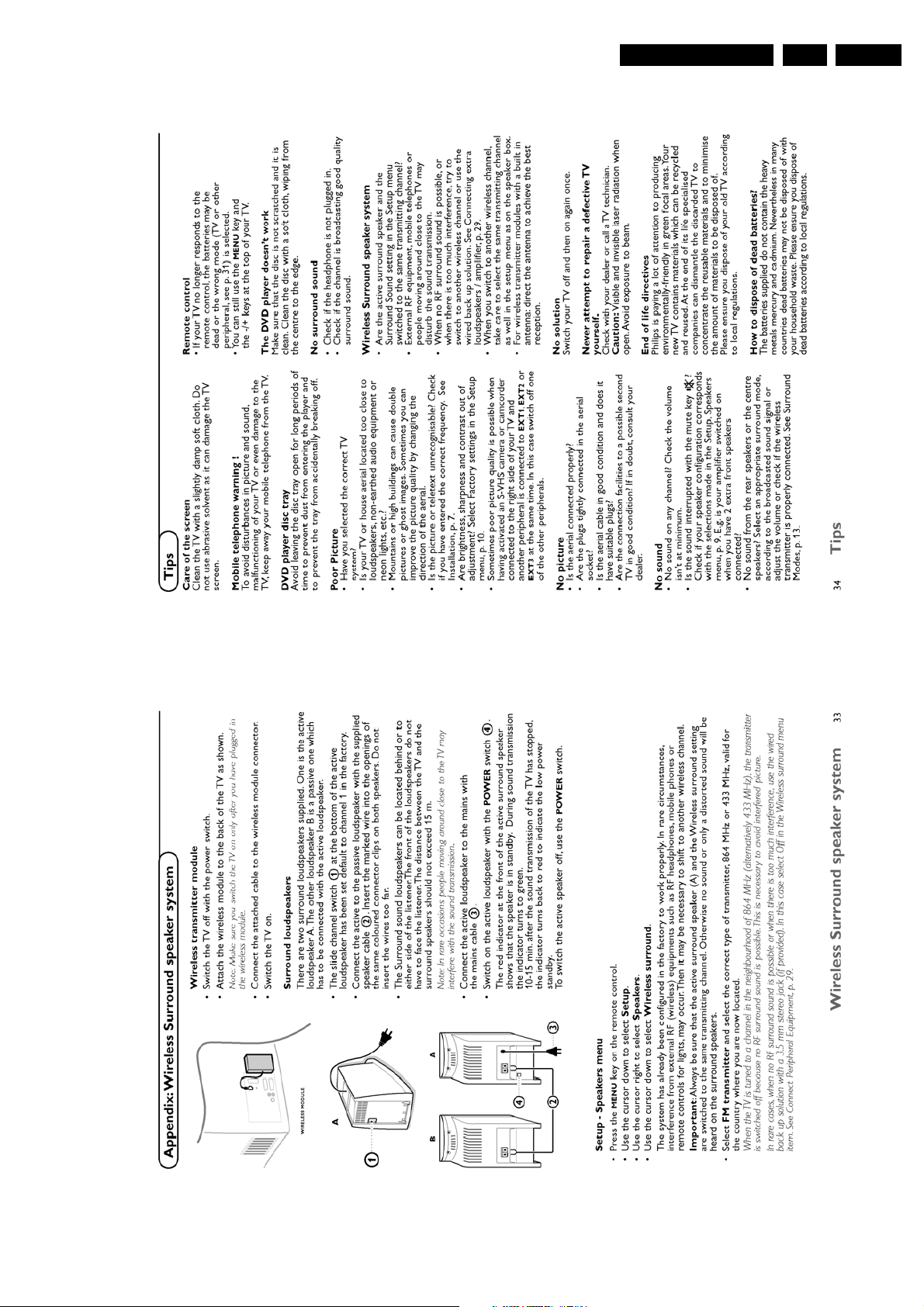

1.3 Chassis Overview

EN 3EM5E-DVD 1.

CRT PANEL

F

SIDE I/O PANEL

O

SMALL SIGNAL BOARD

B

DVD INTERFACE

MM

PANEL

I/O 3rd SCART

H

TOP CONTROL PANEL

DVD ENGINE

EJECT BUTTON

MAINS SWITCH PANEL

LARGE SIGNAL PANEL

DC-SHIFT

(optional)

DAF PANEL

CL 26532020_020.eps

P

MM

E

A

G

I

050702

Figure 1-2 PWB location

EN 4 EM5E-DVD2.

Safety and Maintenance Instructions, Warnings, and Notes

2. Safety and Maintenance Instructions, Warnings, and Notes

2.1 Safety Instructions

Safety regulations require that during a repair:

• Due to the chassis concept, a very large part of the circuitry

(incl. deflection) is 'hot'. Therefore, connect the set to the

mains via an isolation transformer.

• Replace safety components, indicated by the symbol

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

• Wear safety goggles when you replace the CRT.

Safety regulations require that after a repair, you must return

the set in its original condition. Pay, in particular, attention to

the following points:

• General repair instruction: as a strict precaution, we advise

you to re-solder the solder connections through which the

horizontal deflection current is flowing. In particular this is

valid for the:

1. Pins of the line output transformer (LOT).

2. Fly-back capacitor(s).

3. S-correction capacitor(s).

4. Line output transistor.

5. Pins of the connector with wires to the deflection coil.

6. Other components through which the deflection current

flows.

Note: This re-soldering is advised to prevent bad connections

due to metal fatigue in solder connections, and is therefore only

necessary for television sets more than two years old.

• Route the wire trees and EHT cable correctly and secure

them with the mounted cable clamps.

• Check the insulation of the mains cord for external

damage.

• Check the strain relief of the mains cord for proper function,

to prevent the cord from touching the CRT, hot

components, or heat sinks.

• Check the electrical DC resistance between the mains plug

and the secondary side (only for sets that have an isolated

power supply). Do this as follows:

1. Unplug the mains cord and connect a wire between the

two pins of the mains plug.

2. Turn on the main power switch (keep the mains cord

unplugged!).

3. Measure the resistance value between the pins of the

mains plug and the metal shielding of the tuner or the

aerial connection of the set. The reading should be

between 4.5 MΩ and 12 MΩ.

4. Switch the TV 'off' and remove the wire between the

two pins of the mains plug.

• Check the cabinet for defects, to prevent the possibility of

the customer touching any internal parts.

2.2 Maintenance Instructions

We recommend a maintenance inspection carried out by

qualified service personnel. The interval depends on the usage

conditions:

• When a customer uses the set under normal

circumstances, for example in a living room, the

recommended interval is three to five years.

• When a customer uses the set in an environment with

higher dust, grease, or moisture levels, for example in a

kitchen, the recommended interval is one year.

• The maintenance inspection includes the following actions:

1. Perform the 'general repair instruction' noted above.

2. Clean the power supply and deflection circuitry on the

chassis.

3. Clean the picture tube panel and the neck of the picture

tube.

,

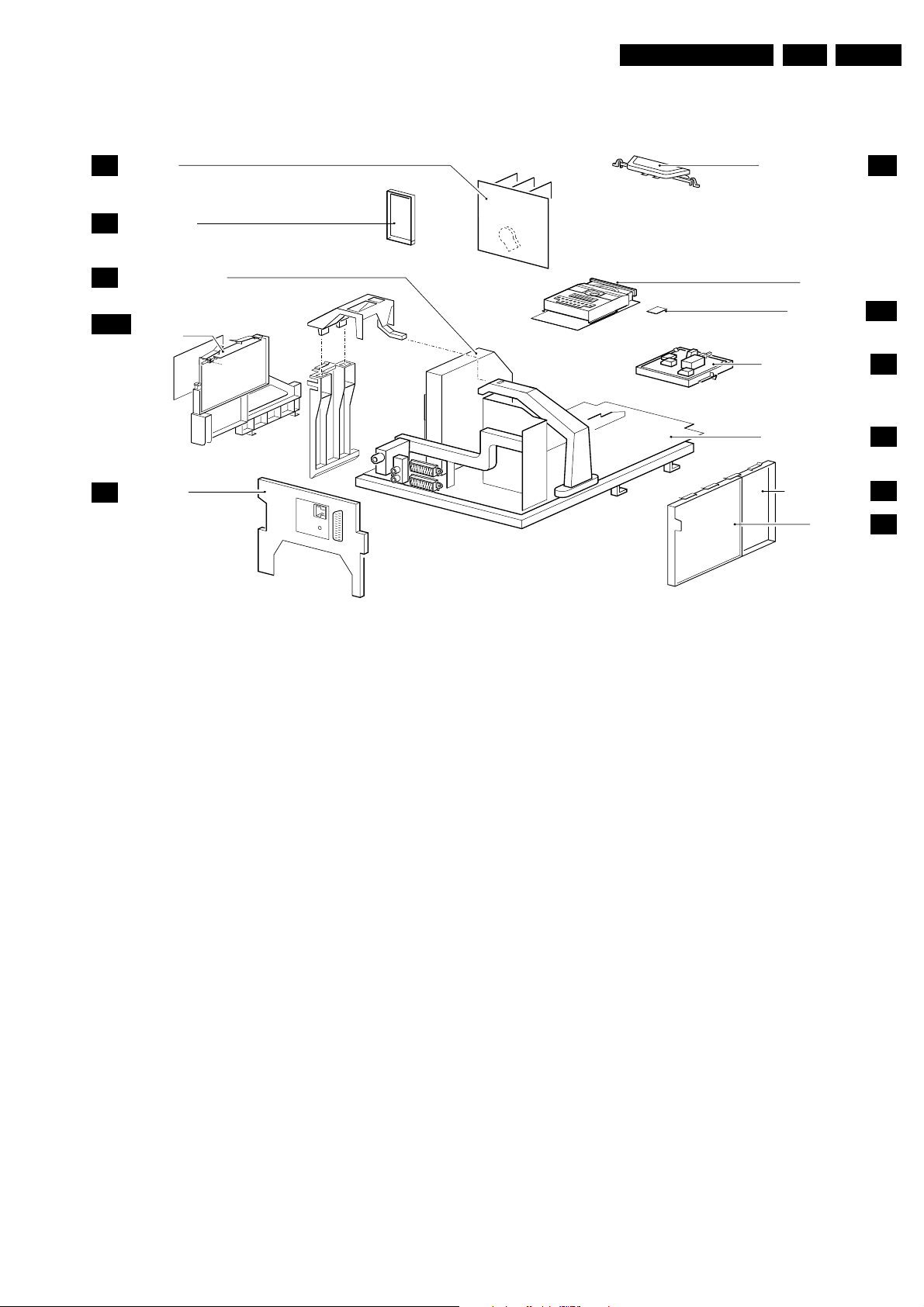

2.3 Warnings

• In order to prevent damage to ICs and transistors, avoid all

high voltage flashovers. In order to prevent damage to the

picture tube, use the method shown in Fig. 2-1, to

discharge the picture tube. Use a high voltage probe and a

multi-meter (position VDC). Discharge until the meter

reading is 0 V (after approx. 30 s).

V

Figure 2-1 Discharge picture tube

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD, symbol w). Careless

handling during repair can reduce life drastically. Make

sure that, during repair, you are connected with the same

potential as the mass of the set by a wristband with

resistance. Keep components and tools also at this

potential. Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and ground cable)

4822 310 10671.

– Wristband tester 4822 344 13999.

• Together with the deflection unit and any multi-pole unit,

flat square picture tubes form an integrated unit. The

deflection and the multi-pole units are set optimally at the

factory. We do not recommend adjusting this unit during

repair.

• Be careful during measurements in the high voltage

section and on the picture tube.

• Never replace modules or other components while the unit

is 'on’.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.4 Notes

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (,), or hot ground (-), depending

on the tested area of circuitry.

• The voltages and waveforms shown in the diagrams are

indicative. Measure them in the Service Default Mode (see

chapter 5) with a colour bar signal and stereo sound (L: 3

kHz, R: 1 kHz unless stated otherwise) and picture carrier

at 475.25 MHz (PAL) or 61.25 MHz (NTSC, channel 3).

• Where necessary, measure the waveforms and voltages

with ()) and without (*) aerial signal. Measure the

voltages in the power supply section both in normal

operation (+) and in standby (/). These values are

indicated by means of the appropriate symbols.

• The picture tube panel has printed spark gaps. Each spark

gap is connected between an electrode of the picture tube

and the Aquadag coating.

CL96532156_040.eps

140501

Safety and Maintenance Instructions, Warnings, and Notes

E

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

• Manufactured under license from Dolby Laboratories.

‘Dolby’, ‘Pro Logic’ and the ‘double-D symbol’, are

trademarks of Dolby Laboratories.

Figure 2-2 Dolby Pro Logic Symbol

EN 5EM5E-DVD 2.

2.5 Laser Safety

LASER SAFETY

This unit employs a laser. Only a qualified service person should remove the cover or attempt to service this

device, due to possible eye injury.

LASER DEVICE UNIT

Type: Semiconductor laser GaAlAs

Wave length: 650 nm (DVD)

780 nm (VCD/CD)

Output Power: 7 mW (DVD)

10 mW (VCD/CD)

Beam divergence: 60 degree

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURE OTHER THAN THOS

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

AVOID DIRECT EXPOSURE TO BEAM

WARNING

The use of optical instruments with this product will increase eye hazard.

Repair handling should take place as much as possible with a disc loaded inside the player

WARNING LOCATION: INSIDE ON LASER COVERSHIELD

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYO NNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

!

Figure 2-3 Laser safety

CL 06532065_051.eps

230500

EN 6 EM5E-DVD3.

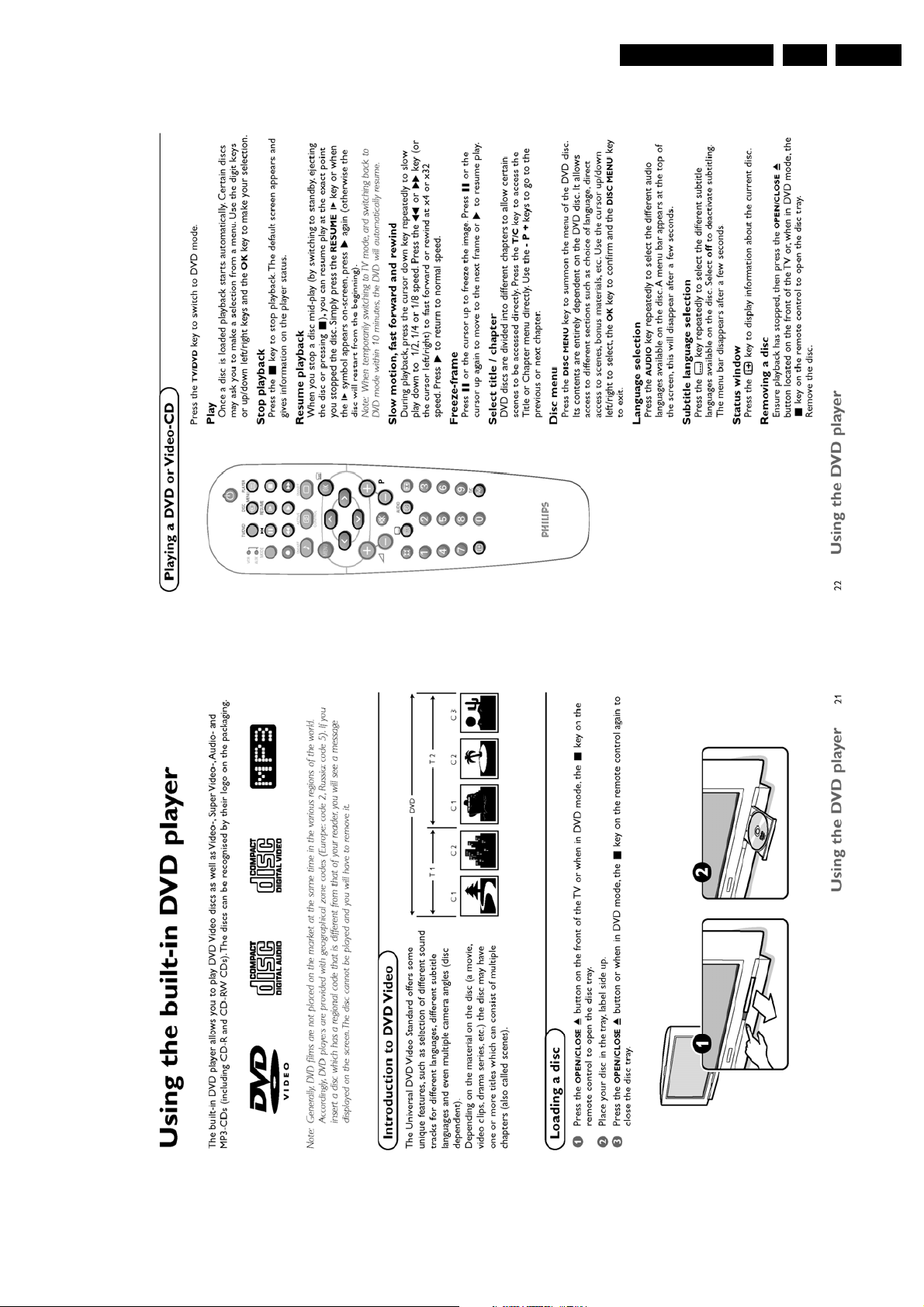

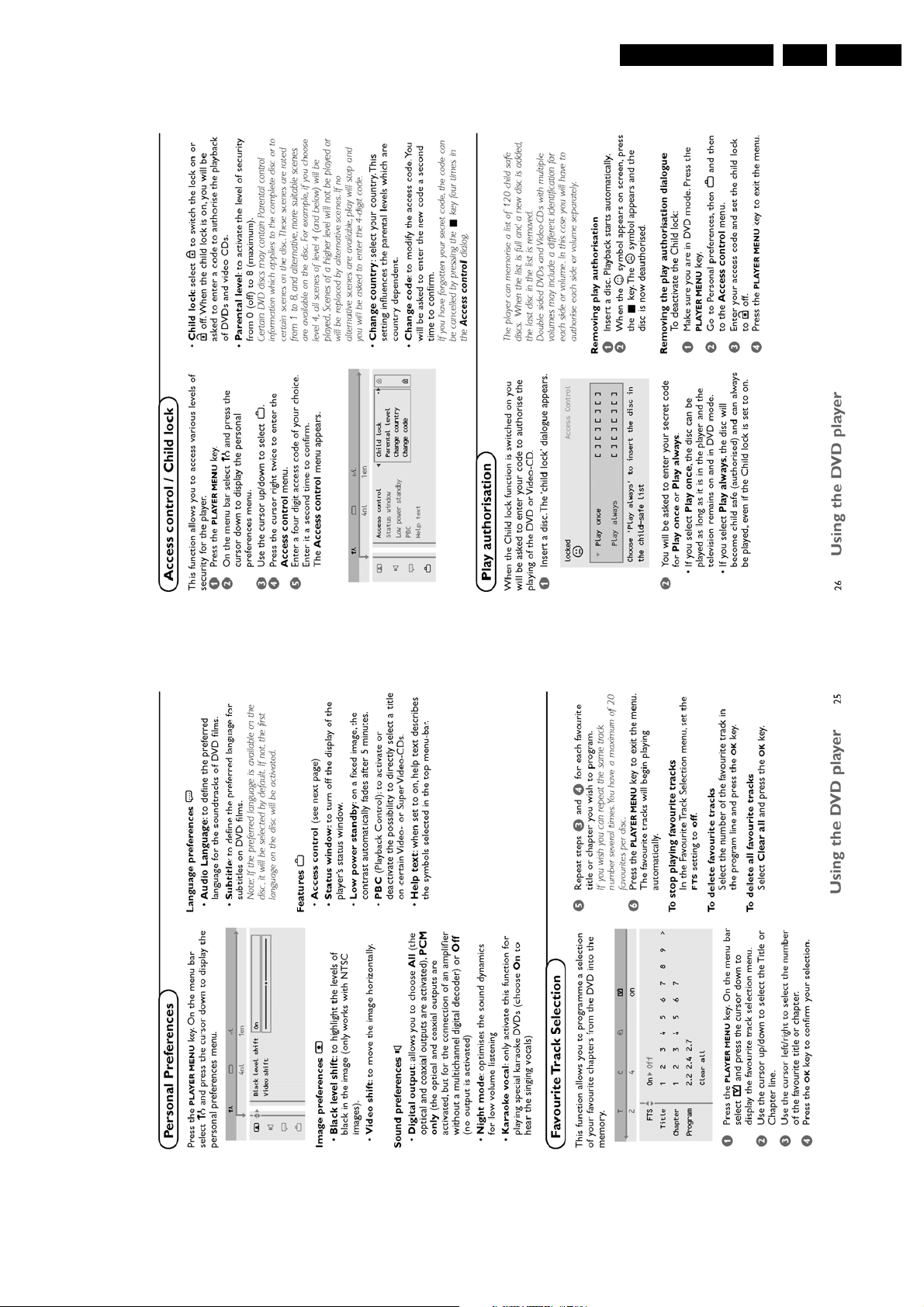

3. Directions for Use

Directions for Use

Directions for Use

EN 7EM5E-DVD 3.

EN 8 EM5E-DVD3.

Directions for Use

Directions for Use

EN 9EM5E-DVD 3.

EN 10 EM5E-DVD3.

Directions for Use

Directions for Use

EN 11EM5E-DVD 3.

EN 12 EM5E-DVD3.

Directions for Use

Directions for Use

EN 13EM5E-DVD 3.

EN 14 EM5E-DVD4.

Mechanical instructions

4. Mechanical instructions

4.1 Service Positions

The following PWB's or modules are added for DVD (see also

PWB location drawing):

1. DVD Interface panel.

2. DVD Module.

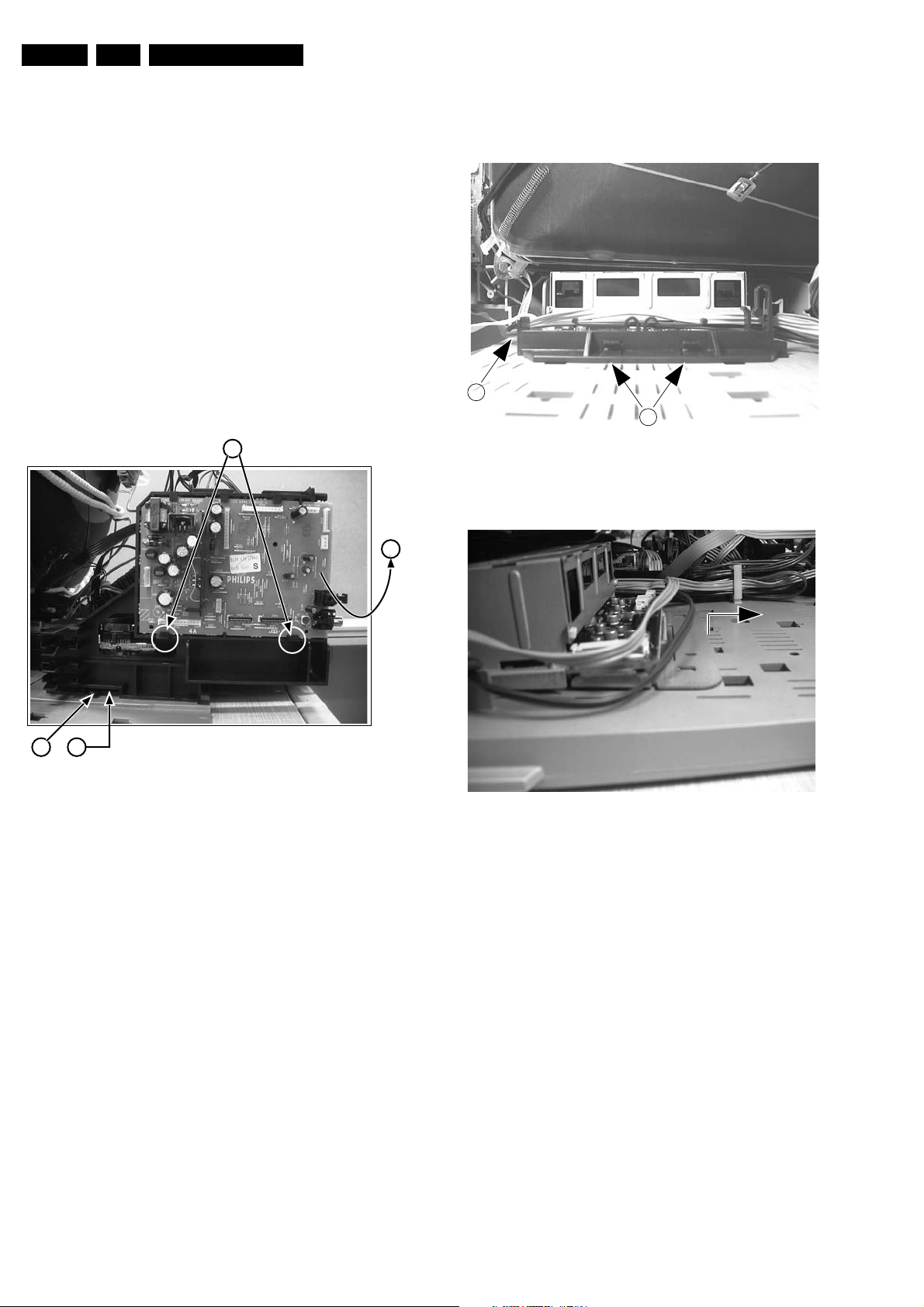

4.1.1 DVD Interface Panel

• For better accessibility of the panel, remove the complete

PWB from its bracket. Therefore release the two clamps at

the side of the bracket [1] and lift the panel out [2], (see

figure “DVD interface board”). (For measuring safely when

the LSP is in service position, remove the bracket from the

bottom tray by pulling it backward while lifting the clamp [3].

Then pull it upward [4], and replace the panel into the

bracket.)

1

1

2

Figure 4-2 DVD lock plate removal.

CL 26532086_023.eps

050702

3 4

CL 06532140_012.eps

Figure 4-1 DVD interface board.

4.1.2 DVD Module

• Remove the cables from connectors 1501, 1600, 1603 and

1604 on the DVD module.

• Remove the DVD lock plate [1]. Therefore lift the two

clamps [2] (see Figure “DVD lock plate removal”) and pull

back the lock plate.

• Remove the DVD-interface module from the bottom tray.

Therefore lift the backside of the module and pull the

module backwards, (see figures hereunder).

021100

2

CL 26532086_024.eps

Figure 4-3 Release DVD module.

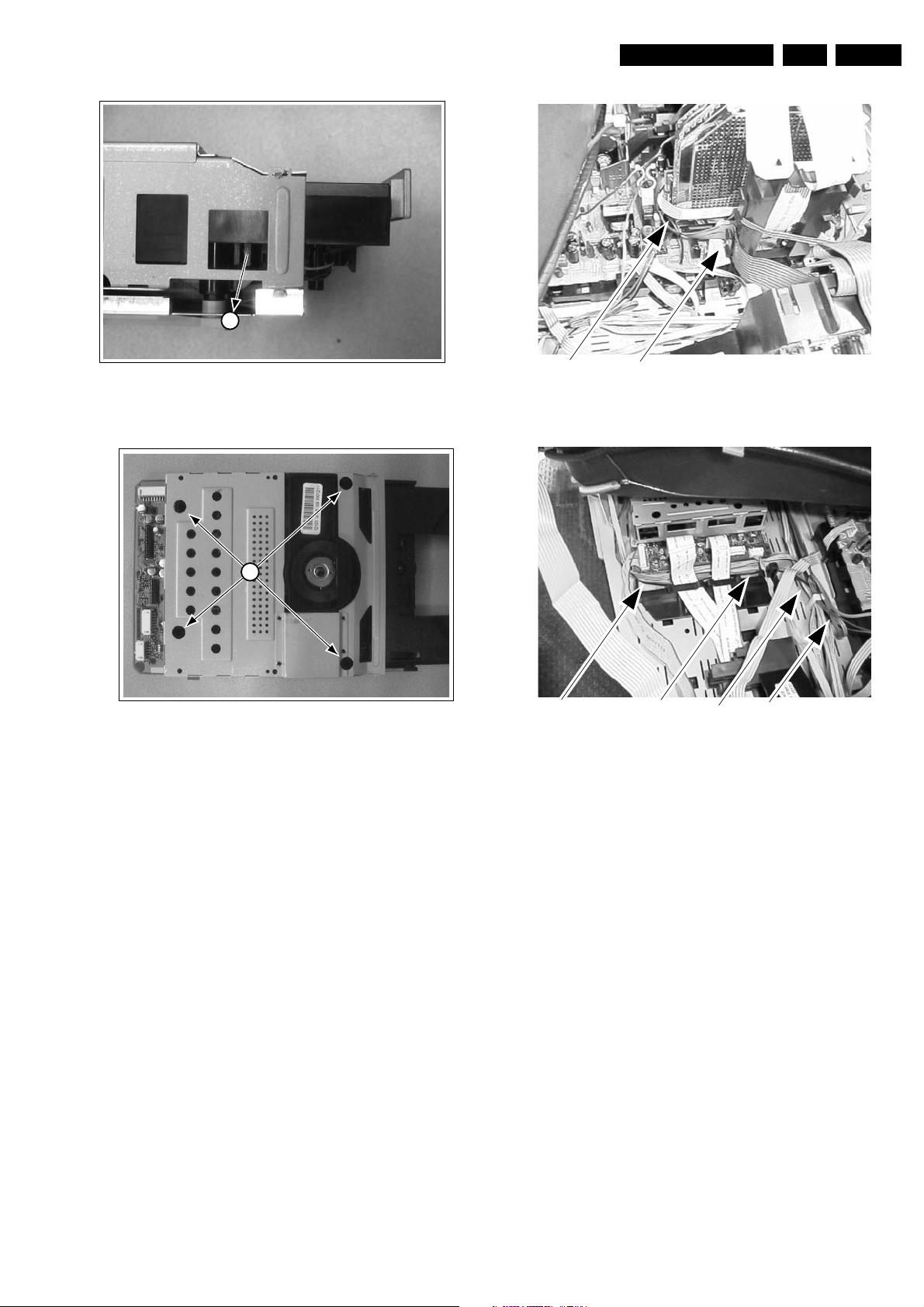

4.1.3 DVD Board

• Press the DVD-tray release catch [1] and slide the DVD

tray forward, (see figure “DVD-tray release catch.“). Be

sure to push it in far enough, a screwdriver might be

needed.

• Unscrew four fixation screws [1], and remove the screws,

(see figure “DVD fixation screws”).

• Remove 2 fixation screws, on metal bottom cover.

• Un-twist the three lugs and take off the metal cover. The

DVD board can now be accessed.

050702

Mechanical instructions

EN 15EM5E-DVD 4.

1

Figure 4-4 DVD-tray release catch.

Figure 4-5 DVD fixation screws.

4.1.4 DVD Eject Switch

CL 16532021_012.eps

300301

CL 26532086_025.eps

050702

Figure 4-6 Cable routing 1

1

CL 16532021_013.eps

300301

CL 26532086_026.eps

050702

Figure 4-7 Cable routing 2.

• To access the DVD eject switch, unscrew the two fixation

screws and pull the switch out of the cabinet. Remove the

switch cable if necessary. The switch panel can now be

removed.

• To reassemble the switch, make sure that the cable is fixed

before mounting.

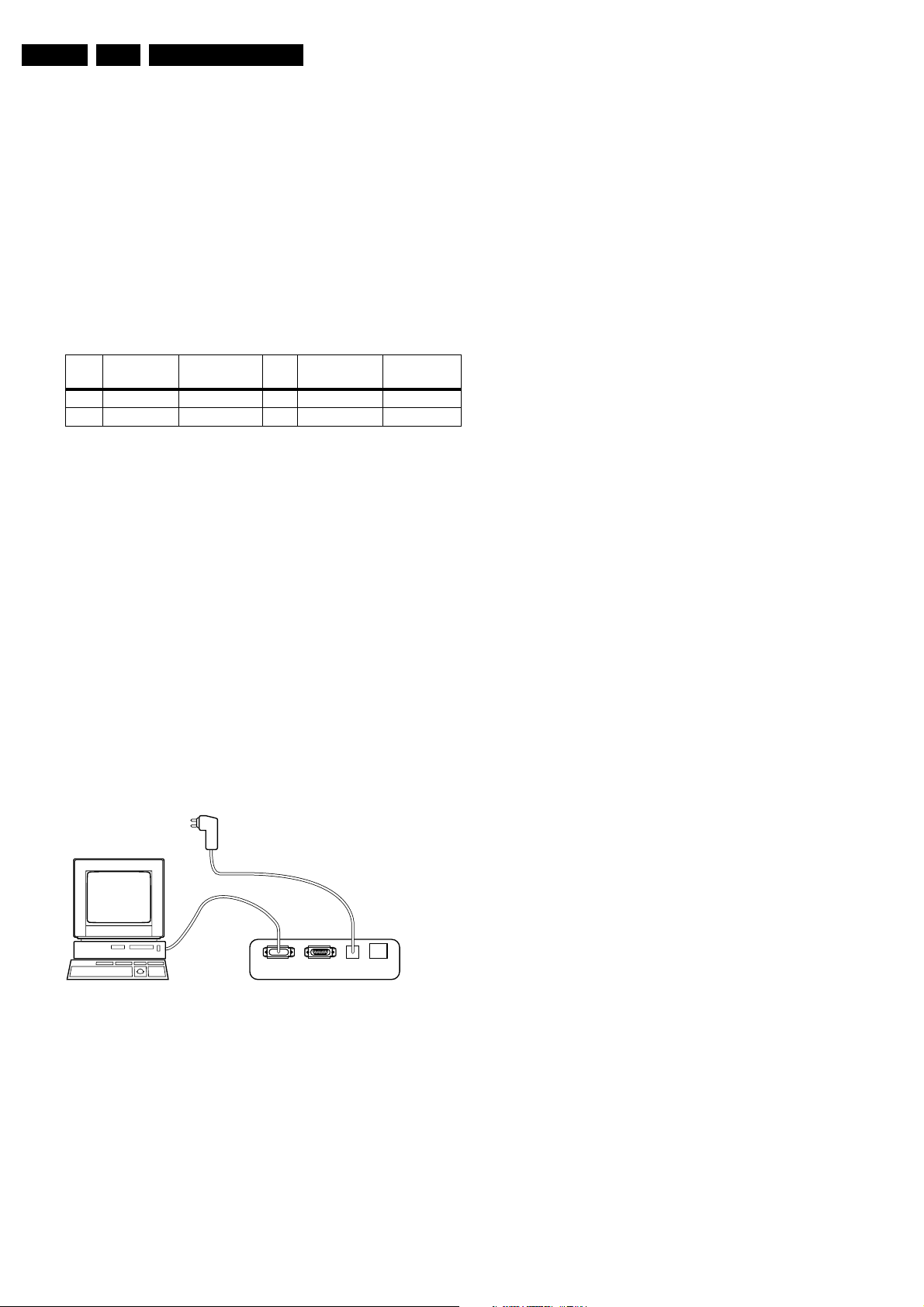

4.1.5 Attention Point

• The routing of some cables is very critical. So therefore,

take care that the cables are routed as shown in pictures

hereunder. Not routing the cables in this way can cause

problems like picture disturbance and EMC problems.

• Routing of the cable between LSP connector 1936 and

DVD Interface connector 0240 (blue 11-pins cable):

guide the cable as close as possible to the SSB

shielding en than between the cable relief of the

scavem-assy (Auto-scavem board itself is not present

in EM5E-DVD), and from there to the DVD-interface.

(See figure “Cable routing 1”)

• Routing of speaker cable and top control cable: make

sure this cables are routed between the DVD lock plate

and the DVD board. Also make sure to guide them

underneath the two flat foil cables. (See Figure “Cable

routing 2.”)

EN 16 EM5E-DVD5.

Fault Finding and Repair Tips

5. Fault Finding and Repair Tips

For additional technical information on the EM5E TV set, see

Service Manual ‘EM5E AA’ (3122 785 12560) and for additional

technical information on the DVD Module, see Service Manual

‘DVD Module SD-3’ (3122 785 11010) and Service Information

‘DVD SD3 Monoboard’ (3122 785 40490).

5.1 Error Codes

Two new error codes are introduced for the EM5E-DVD, Error

29 and 31, see table below.

Table 5-1 Error code table.

Error Device Description Def.

29 PCF8574AT DVD Interface 7150 DVD Interface MM1

31 -- DVD Engine DVD Engine DVD Engine

item

Defect. Module indication

5.2 ComPair

First install the ComPair Browser software before connecting

ComPair to the EM5E-DVD (see the ComPair Browser Quick

Reference Card for installation instructions). In the EM5E-DVD,

you must diagnose the TV (plus DVD-interface panel) and the

DVD-module separately. Always start the diagnosis by

connecting the ComPair tool to the TV set. If something is

wrong with the DVD-module, ComPair will explain how and

when to connect the ComPair tool to the DVD-module.

Connection to the TV set:

1. Connect the RS232 interface cable to a free serial (COM)

port of the PC, and to the ComPair interface PC connector

(connector marked with ‘PC’).

2. Connect the mains adapter to the connector marked

‘POWER 9V DC’ of the ComPair interface.

3. Switch the ComPair interface OFF.

4. Switch the television set OFF with the mains switch.

5. Connect the interface cable (3122 785 90004) to the

connector on the rear side of the ComPair interface that is

marked ‘I2C’

Diagram

Connection to DVD-module:

1. Follow the instructions given on the screen for further

diagnosis.

2. Use the DVD ComPair interface cable (3122 785 90017) to

connect the DVD Module to the ComPair interface

(connector 1602).

5.3 Ordering ComPair

ComPair order codes:

ComPair interface cable (for EMX chassis): 3122 785 90004

ComPair interface cable (for DVD-module): 3122 785 90017

5.4 Reconnecting Cables to DVD Interface Panel

When all cables are removed from the DVD Interface Panel

attention has to be paid when reconnecting the 11 pins

connectors coming from the Side I/O panel and LSP. The

cables have to be connected as follows (for correct connection

see also wiring diagram):

• Connect cable (11p) from the LSP (pos. nr. 1936) to pos.

nr. 0240 on the DVD Interface Panel.

• Connect cable (11p) from the Side I/O panel (pos. nr. 0240)

to pos. nr. 0266 on the DVD Interface Panel.

PC VCR I2CPower

Figure 5-1 ComPair Interface Connection.

1. Connect the other end of the interface cable to the

ComPair connector on the rear-side of the set.

2. Plug the mains adapter in the mains outlet and switch ON

the interface. The green and red LEDs light up together.

The red LED extinguishes after approx. 1 second (the

green LED remains lit).

3. Start-up ComPair and select ‘File’ menu, ‘Open’..; select

‘EM5E-DVD’ and click ‘OK’.

4. Follow the instructions given on the screen for further

diagnosis (note that the OSD works but that the actual user

control is disabled).

9V DC

86532027_003.EPS

050898

5.5 Repair Tips

• When re-assembling the DVD board or DVD Interface

make sure the routing of the cables is as instructed in

chapter “Mechanical Instructions”. Incorrect routing can

lead to picture disturbance (vertical dark bars in DVD

mode) or EMC problems.

• When DVD door does not open, check Service Alignment

Mode - ‘Dealer Options’ - ‘Personal Options’ - ‘DVD door

lock’: this must be set to ‘NO’. This option can be used to

lock the DVD door in demonstration situations

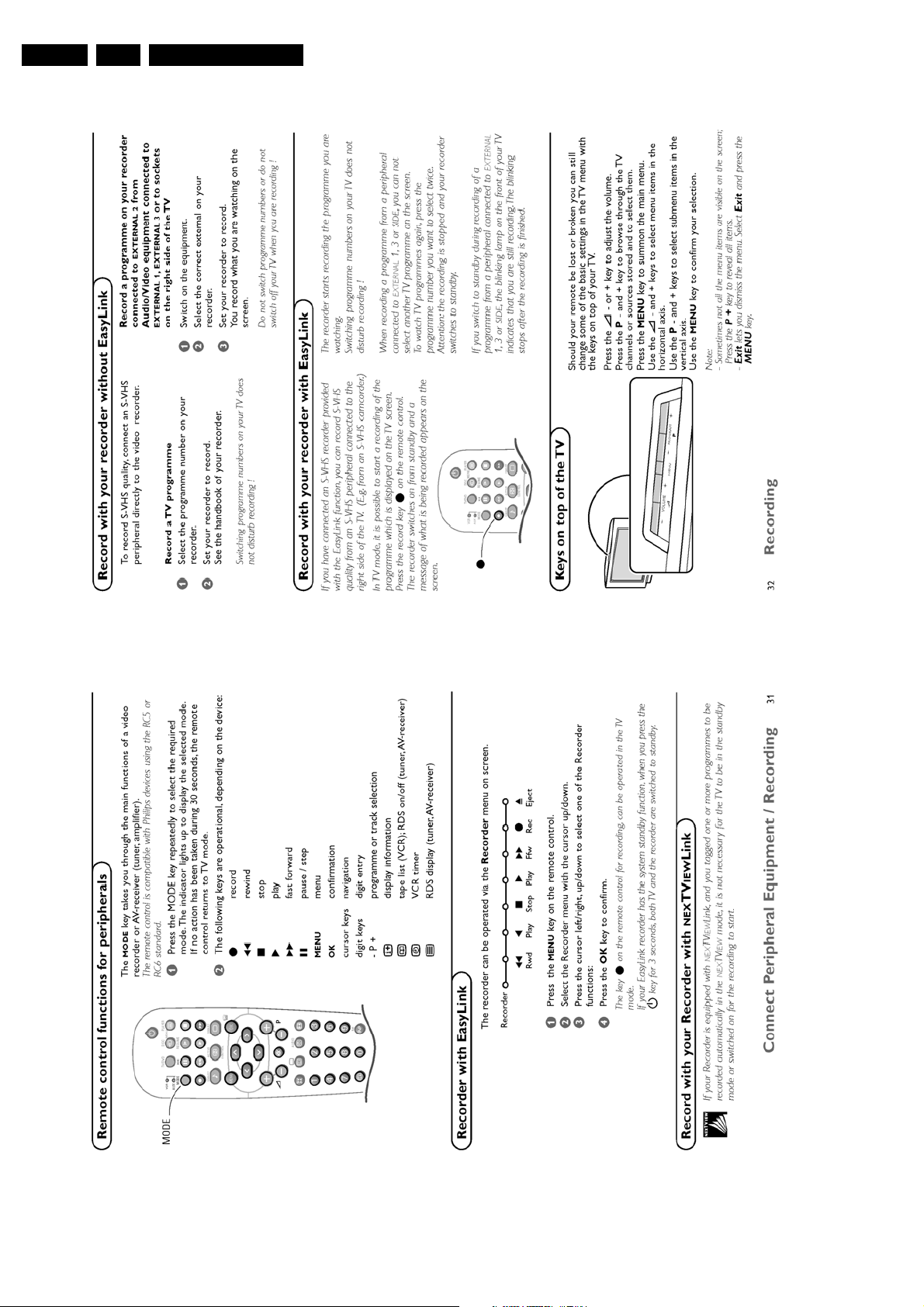

Wiring Diagram, Block Diagrams and Overviews

6. Wiring Diagram, Block Diagrams and Overviews

Wiring Diagram

17EM5E-DVD 6.

CVBS (YELLOW)

LEFT (WHITE)

RIGHT (RED)

MM4

EJECT

SVHS

HEADPHONE

DVD Interface Panel

MM

5P

3P

0267

0206

O

0265

SIDE

I/O PANEL

11P

0266

12P

3P

1501

0240

11P

11P

0240

16P 22P

0255 0254

16P 22P

1604 1603

DVD Module

(ASD 3.1)

0264

3P

0224

0221

6P

3P

1600

3x

12P

P

TOP CONTROL PANEL

0215

3P

RIGHT

SPEAKER

BLUE

BLUE

10P

1937

1402

H

1690

10P

1680

1992

3rd

SCART

21P

I/O 3rd

SCART

WIRELESS

TRANSMITTER

AQUADAG

1505

1502

1424

7P

DEGAUSSING COIL

CRT

BROWN

BLUE

SCAVEM

COIL

CRT PANEL

2P

2P

1491

1492

3P

N.C.

FRAME

ROTATION

COIL

1010

2P

1009

3P

F

1008

2P

I

EHT

CRT

HORIZONTAL

DAF PANEL

1417 1418

2P

2P

1419

2P

1492

N.C.

A (LOT)

1491

3P

1497

1P

1693

N.C.

BROWN

BROWN

LEFT

SPEAKER

MAINS SWITCH PANEL

E

0241

9P

0201

2P

DC SHIFT

G

(OPTIONAL)

0317

2P

3P

1415

SUB

WOOFER

SWITCH

MAINS

CORD

TX864B

1403

1P

1419

WIRELESS

TRANSMITTER

CL 26532086_004.eps

MAINS

0202

1407

2P

5P

R

050702

CENTRE

SPEAKER

(COMPONENT VIEW)

1940

1434

11X

1435

BLACK

RED

CRT

SOCKET

1424

7X

LSP(LARGE SIGNAL PANEL)

A

1146

1947

1946

1945

1943

3P

compair

interface

5P

N.C.

5P

9P

3P

2P

2P

1735

1937

10P

1955

1940

TUNER

1620

3P

4P

1205

3P

SSB

PANEL

11P

80P

F

F

CRT

PANEL

6P

1680

SSB

B

(SMALL SIGNAL BOARD)

1000

5P6P

80P

1402

5P

1936

1483

11P

1499

2P

2 x

CINCH

3P

1737

3P3P

1738

2x

SCART

1625

1417

2P

LOT

1498

2P

3P

Loading...

Loading...