Page 1

®

Eaton Fuller

AutoShift Gen II Models

®

®

Automated Transmissions

Quick Reference Guide TRMT-0062

March 2000

For the most current information, visit the Roadranger web site at www.roadranger.com

Page 2

General Warnings:

Before starting a vehicle:

• Sit in the driver’s seat

• Place shift lever in neutral

• Set the parking brake

Before working on a vehicle or

leaving the cab wit

• Place shift lever in neutral

• Set the parking brake

• Block the wheels

h engine running:

O.E. Tool & Equipment Group/KentMoore SPX Corporatio

n

1 (800) 520-2584

Kent-Moore

. Description

Part No

5505027 Volt/Ohm Meter (Standard

commercially available VOM)

5505030 Hydraulic Test Kit

O.E. Tool & Equipment Group/KentMoore SPX Corporatio

n

1 (800) 328-6657

Do not release the parking brake or

attempt to select a gear until the air

pressure is at the correct level.

When parking the vehicle or leaving

the

cab:

• Place shift lever in neutral

• Set the parking brake

To avoid damage to the transmis-

during towing:

sion

• Place shift lever in neutral

• Lift the drive wheels off of the

ground or disconnect the driveline

Do not operate vehicle if alternator

lamp is lit or if gauges indicate low

voltage.

Suggested Tools:

Pressure Gauges:

• 0-100 PSI Air Pressure Gauge

Kent-Moore

Part No. Description

8 Eaton Test Adapter Kit

J-4331

J-38351-

J-4266

B Serial Link Adapter Kit

(RP-1202)

0 Parallel Data Module

(RP-1210A)

Eaton Service Parts

1 (888) 880-0970 Ext. 1

Part No. Description

MF-KIT-04 Data Link Tester

TBD Service Ranger PC Based

Service Tool Software

Related Publications

AutoShift

Installation Guid

Installation Guide AS

Service Manua

AutoShift

Driver Instructions Eaton TRDR-0062

Driver Instructions AS

Autoshift II Direct Parts

Shipment

e Eaton TRIG-0062

T Eaton TRIG-0092

l Eaton TRSM-0062

T Eaton TRDR-0092

Program Eaton TRIP-0062

2

For additional help 1-888-880-0970

Page 3

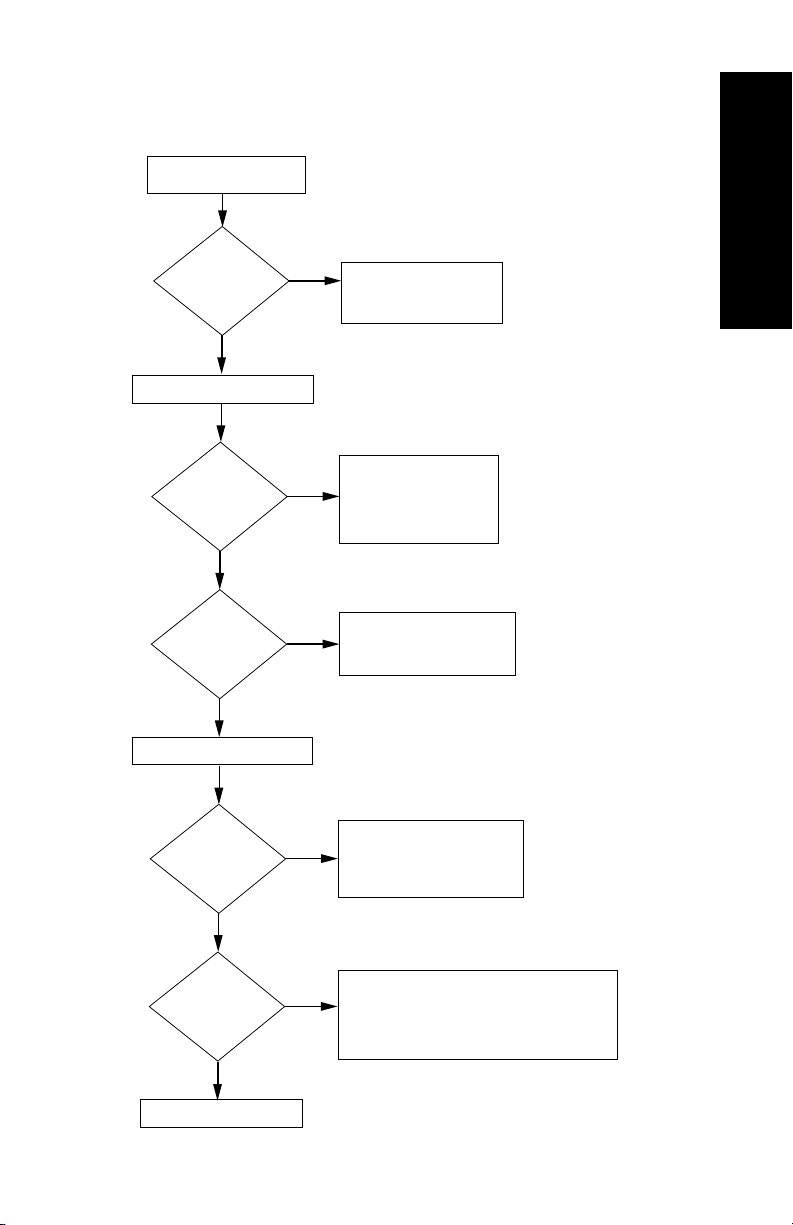

Diagnostics Procedure

Key on.

Introduction

If service lamp

lights for one

second and

turns off.

YES

Retrieve active codes.

Active codes?

NO

Is the "N" solid

on the gear display

and the "N" lit up

on the shift

control?

YES

Retrieve inactive codes.

Inactive codes?

• Verify OEM wiring is OK.

• Perform Electrical Pretest.

NO

• Refer to Troubleshooting

Guide

• Verify OEM wiring is OK.

• Perform Electrical Pretest.

• Perform Air Pretest

YES

NO

YES

(if required)

• Refer to Troubleshooting

Guide

• Verify OEM wiring is OK.

• Perform Electrical Pretest.

• Refer to Troubleshooting

Guide

• Verify OEM wiring is OK.

• Perform Electrical Pretest.

• Perform Air Pretest (if required)

• Refer to Troubleshooting

Guide

NO

Symptom?

NO

Test complete.

• Verify OEM wiring is OK.

• Perform Electrical Pretest.

• Perform Air Pretest (if required)

YES

• Verify ECU has correct software, use ServiceRanger

• Refer to Troubleshooting

Guide

3

Page 4

Step A Procedure Condition Action

1. Key on.

2. If service lamp lights

for one second and then

turns off.

Note: Some vehicle

configurations do not

have service lamps. In

this case Go to Step B.

If service lamp lights for

one second and turns

off.

Go to Step B.

If service lamp never

comes on

The fuse for the ignition

power may be blown or

the AutoShift may have a

bad ground. Do the

Electrical Pretest.

If Service lamp is

Flashing

The AutoShift has

detected an active

component code. Verify

the wiring is totally

correct on the vehicle

first. You may have to

refer to OEM drawings.

Then refer to the

Troubleshooting Guide.

Do not go straight to the

Troubleshooting Guide

before you verify the

vehicle wiring or you may

replace the incorrect

component.

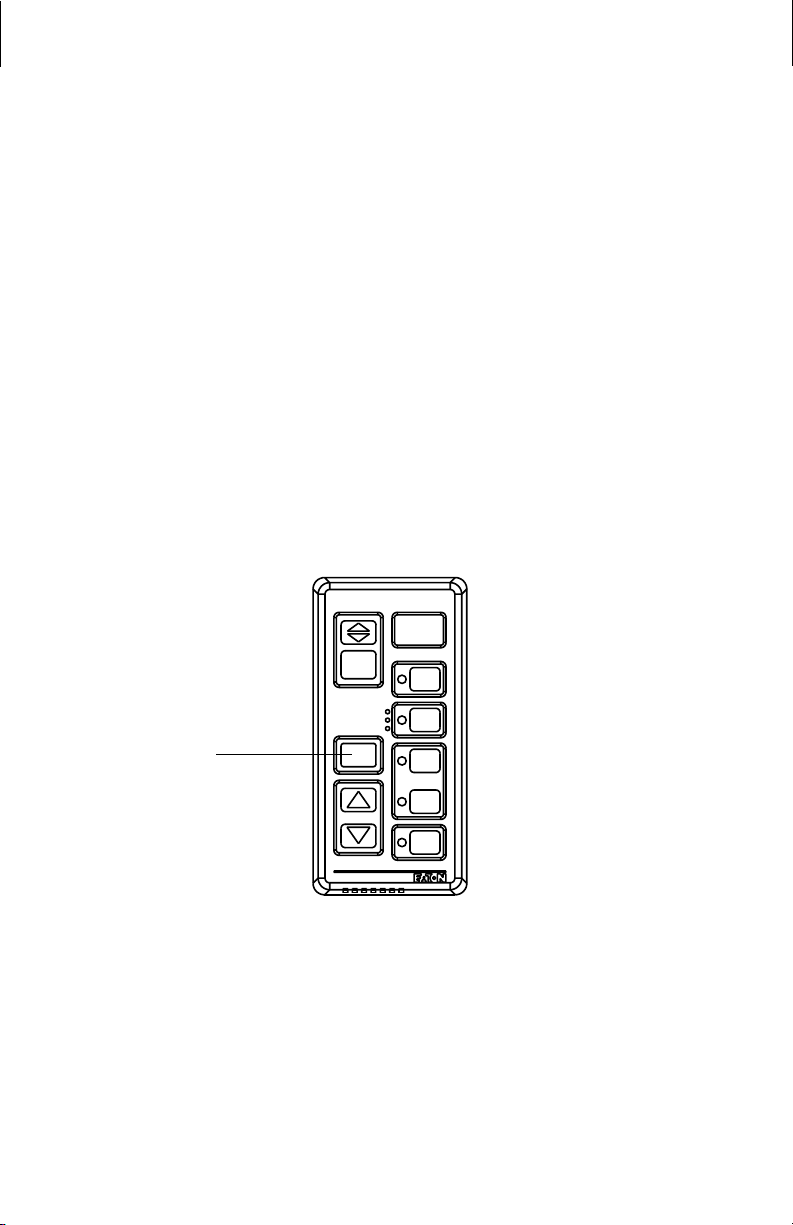

Replace the Push Button

Shift Control.

Service

Lamp

OPTIONS

CONTROL

R

N

SERVICE

SHIFT

EATON FULLER

TRANSMISSIONS

If the service lamp is on

steady

D

H

L

Note: Some vehicles are

equipped with an Eaton

shift lever or a OEM

shift lever. In this case

the software in the Push

Button Shift Control will

cause the service light

to be on steady. This is

4

normal.

Page 5

Step B Procedure Condition Action

1. Key on.

2. Make sure shift lever

is in Neutral.

3. Observe Gear display

Note: The Gear

Display may go through

serveral displays before it

stops.

If the Gear Display shows:

Blank Gear Display:

Transmission ECU and

the Push Button Shift

control are not communicating. Check the wiring

between the Transmission ECU and the Push

Button Shift Control.

Gear Display Lamp

check:

This is OK.

18

System Check

—

Dash on the Gear

Display:

Transmission ECU and

the Push Button Shift

control are communicating. The transmission is

trying to verify Neutral

and it can't. It may be

torque locked in gear. Or

bad Powers and

Grounds. The engine will

not start in this mode.

5

Page 6

Step B Procedure Condition Action

If the Gear Display shows:

"N" on the gear display:

This is good. The

AutoShift is powered up

N

F

completely. If the engine

does not start check the

start enable circuit.

Go to Step C.

Flashing "F":

The AutoShift has

detected an active

component code. Verify

the wiring it totally

correct on the vehicle

first. You may have to

refer to OEM drawings.

Then refer to the

Troubleshooting Guide.

Do not go straight to the

Troubleshooting Guide

before you verify the

vehicle wiring or you

may replace the

incorrect component.

6

Page 7

Step C Procedure Condition Action

1. Key on.

2. Depress the master clutch.

3. Start engine.

4. Release the clutch pedal.

5. Depress the clutch fully to

the floor.

6. Select "D".

7. Observe the Gear Display

If the Gear Display shows.

Solid "N" on the Gear

Display:

The AutoShift has not

N

seen Input Shaft Speed.

Make sure you have

released the Clutch pedal

fully.

Make sure the lamp for

"D" is lit up on the Shift

Control. If not the shift

control may need to be

replace.

System Check

OPTIONS

CONTROL

SERVICE

SHIFT

EATON FULLER

TRANSMISSIONS

R

Lamp for "D"

N

D

H

L

7

Page 8

Step C Procedure Condition Action

If the Gear Display shows:

Down arrows with a

flashing "2":

The input shaft turning

2

2

faster than 150 rpm.

Make sure that the

Clutch is fully depressed. If problem

continues the Clutch is

not adjusted correctly.

Flashing "2":

The sliding clutch is

butting. Release the

clutch pedal slightly.

Solid "2":

The AutoShift is

engaged in gear and is

ready to go.

8

Page 9

Problem Possible Cause

The AutoShift will not shift until

you lift off the throttle.

The Autoshift will not shift

across the Dyno.

The AutoShfit is upshifting

automatically in "H" or manual

mode.

The OEM shift lever does not

work.

The AutoShift will not make

Automatic shifts even after

lifting off the throttle pedal.

The engine will not start.

The engine will start in any

gear.

J1939 data link is not working. Check to see if the

engine J1939 is turned on. Check the J1939 data

link harness, terminataing resistors. This is an OEM

issue.

Place the AutoShift in "D" and button up the

Maximum Start Gear. Then try it. If the AutoShift

still does not shift the dyno has too much drag. The

AutoShift needs to have the rolling inertia from the

vehicle. If the dyno has too much drag the rear

wheels slow down to fast. This is why the AutoShift

will not shift.

The only time the AutoShift will shift automatically

is when the input shaft speed is 300 rpm over rated

speed of the engine. The AutoShift may have the

incorrect engine configuration downloaded into the

Push Button Shift Control. This is corrected by

downloading the correct configuration into the

Push Button Shift Control, using VEPS or

ServiceRanger.

The Push Button Shift Control may not have the

correct software. The easiest way to tell is if the

Service Lamp is on solid, it is correct. The OEM

shift lever or the OEM wiring may be the problem.

The AutoShift has what is called RPM/Load based

shifting. Simply push the upshift button while the

shift control is still in "D". For more information

read the Drivers Instruction Guide.

Make sure there is an "N" on the Gear Display. The

problem is with the Start Enable circuit. Refer to

OEM wiring diagrams.

The problem is with the Start Enable circuit. Refer

to OEM wiring diagrams.

When the key is turned off the AutoShift seems to

calibrate forever. (X-Y Shifter) Several issues could

cause this.

• OEM wiring. Verify the OEM interface

harnesses.

• Bad Power and Ground. Perform the Electrical

Pretest.

• The incorrect transmission ECU. This can be

verified using ServiceRanger.

• The X-Y Shifter. The sensors could be bad.

Troubleshooting

9

Page 10

Problem Possible Cause

Miscellaneous AutoShift

complaints

After retrieving fault codes

the Gear Display that is

integrated in the dash is

displaying fault code 5.

There is no fault code 5.

There is an active fault code

44. Fault code 44 is for the

Inertia Brake. This

transmission does not have

an Inertia Brake.

There are active fault codes

present.

• Always verify the OEM wiring first.

• Check the installation of the AutoShift second.

• Check the AutoShift transmission third.

It is not fault code 5, it is fault code 25, which

means no code. The start up procedure for the dash

panel does not allow the 2 to be displayed.

Attempt to clear the code. If fault code 44 comes

right back the Transmission ECU may have been

configured for a transmission that requires an

Inertia Brake. This must be confirmed using Service

Ranger. If this is the case the Transmission ECU

will need to be replaced.

Record the fault codes. Clear the fault codes. If the

fault codes come right back as active codes.

• Always verify the OEM wiring first.

• Check the installation of the AutoShift second.

• Check the AutoShift transmission third.

10

Page 11

The following charts have what is supplied from Eaton as the default and what must

be re-calibrated by the OEM. VEPS or ServiceRanger can accomplish the re-calibration.

tluafeD

deriuqeR

For indicated transmission model - no need to touch

Re-calibration for this combination

enignE

ronrevoG

kaeP

euqroT

XSA-6

2noitareneGtfihSotuA

0071

0081

0091

0021

A/N

0002

0012

00220031

0032

dradnatSMPR0042

00410042

0052

00620061

enignE

ronrevoG

kaeP

euqroT

dradnatSMPR0062

2noitareneGtfihSotuA

XSA-7

Software Configuration

0071

0081

0091

0002

0012

0032

00620061

0021

A/N

dradnatSMPR001200220031

00410042

dradnatSMPR00420052

11

Page 12

enignE

ronrevoG

kaeP

euqroT

2SA-01

2noitareneGtfihSotuA

0071

0081

0091

0002

0012

00220031

0032

0042

0052

00620061

enignE

ronrevoG

0071

0081

0091

0021

dradnatSytuDyvaeH

dradnatSMPR0012

0041

dradnatSMPR0042

kaeP

euqroT

2SA-81

2noitareneGtfihSotuA

A/N

dradnatSMPR0081

0021

12

0002

0012

00220031

0032

0052

00620061

dradnatSMPR0002

dradnatSMPR0012

00410042

A/N

Page 13

Model Number

The model number gives basic information about the transmission and is explained

below. Use this number when calling for service assistance or replacement parts.

Model Number

6 Speed

Torque x 100

Design Level

7 Speed

Twin Countershaft

Torque x 100

Design Level

10 Speed

Roadranger

Twin Countershaft

Overdrive

Torque x 100

Design Level

18 Speed

Roadranger

Twin Countershaft

Low Inertia

Overdrive

Torque x 100

Design Level

Fuller

Overdrive

Overdrive

®

®

FO 84 6A0- X-XAS

®

T O 11 076- B-AS

R

TO-

T

LO-R

14 107 B-AS

18 189 A-AS

Inertia Brake

AutoShift™

Gear Ratio

Forward Speeds

X - Inertia Brake

AutoShift™

Gear Ratio

Forward Speeds

2

AutoShift™ II

(Second Generation)

AutoShift™

Gear Ratio

Forward Speeds

2

2-AutoShift™ II

(Second Generation)

AutoShift™

Gear Ratio

Forward Speeds

PREFIX KEY

®

F = Fuller

L = Low Inertia

O = Overdrive

R = Roadranger

T = Twin Countershaft

®

SUFFIX KEY

AS = AutoShift™

X = Inertia Brake

W = Wet Clutch

T = Torque Converter

2 = AutoShift™ II

(Second Generation)

13

Page 14

Retrieving and Clearing Fault Codes

During power-up, the service light will come on and go off. This is normal operation.

But, if the service light comes on and stays on or comes on while driving, it means the

transmission has detected a fault and you’ll want to get to a service facility as soon as

possible.

In the event there is a problem with the transmission, there are three primary tasks the

driver should perform.

• Driving Conditions: Note the driving condition under which the problem

occurred.

• Transmission Conditions: Note the condition of the transmisison under which

the problem occurred.

• Retrieve Codes / Reset System: Record fault codes and reset the transmission

as described below.

Retrieving Fault Codes

Retrieve transmission fault codes by enabling the transmission system’s selfdiagnostic mode.

Note: You can also use a PC-based service tool, such as the ServiceRanger, to retrieve

transmission fault codes.

1. Place the shift lever in neutral.

2. Set the parking brake.

3. Turn the ignition key on but do not start the engine. If the engine is already

running, you may still retrieve codes, however, do not engage the starter if

engine stalls.

4. To Retrieve Active Codes: Start with the key in the on position.

Turn the key off and on two times within five seconds ending

with the key in the on position. After five seconds, the service

off

lamp begins flashing two-digit fault codes. If no codes are

active, the service light will flash code 25 (no codes).

To Retrieve Inactive Codes: Start with the key in the on

position. Turn the key off and on four times within five seconds

ending with the key in the on position. After five seconds, the

off

service lamp begins flashing two-digit fault codes. If no codes

are active, the service light will flash code 25 (no codes).

14

2 times

on

4 times

on

Page 15

5. Observe the sequence of flashes on the indicator lamp and record the

codes. A one to two second pause separates each stored code, and the

sequence automatically repeats after all codes have been flashed.

1 Flash

SERVICE

Short

pause

(1/2 sec)

3 Flashes

SERVICE SERVICE

SERVICE

Code 13 Code 21

SERVICE

Long Pause

(3-4 sec)

2 Flashes

SERVICE

1 Flash

SERVICE

Short

pause

(1/2 sec)

Clearing Fault Codes

The following procedure clears all inactive fault codes from the ECU’s memory.

(Active fault codes are automatically cleared when the fault has been corrected.)

Note: You can also use a PC-based service tool, such as the ServiceRanger, to clear

transmission fault codes.

1. Place the shift lever in neutral.

2. Set the parking brake.

3. Turn the ignition key on but do not start the engine.

4. Start with the key in the on position. Turn the key off and on six times within

five seconds, ending with the key in the on position.

6 times

off

on

Code Retrieving / Clearing

Note: If the codes have been successfully cleared, the service lamp will come

on and stay on for five seconds.

5. Turn key off and allow system to power down.

15

Page 16

Fault Code Description

11 Shift Control

12 Transmission Controller

16 Eaton Proprietary Link (EPL)

17 Start Enable Relay Coil

21 Interrupt Clutch Solenoid

22 Lock-up Clutch Solenoid

24 Hydraulic System Fault

25 No Code

32 Switched System Voltage

33 Battery Voltage Supply

35 J-1939 Data Link

41 Range Failed to Engage

42 Splitter Failed to Engage

43 Range Solenoid Valve

44 Inertia Brake Solenoid Coil

46 Splitter Valve

51 Rail Select Sensor

52 Gear Select Sensor

56 Input Shaft Speed Sensor

57 Main Shaft Speed Sensor

58 Output Shaft Speed Sensor

61 Rail Select Motor

63 Gear Select Motor

65 Logic Power

71 Stuck Engaged

72 Failed to Select Rail

73 Failed to Engage Gear

74 Failed to Synchronize

83 Shift Lever Missing

16

Page 17

Page 18

Page 19

Page 20

Copyright Eaton and Dana

Corporation, 2002. EATON AND

DANA CORPORATION hereby

grants its customers, vendors, or

distributors permission to freely

copy, reproduce and/or distribute

this document in printed format.

THIS INFORMATION IS NOT

INTENDED FOR SALE OR RESALE, AND THIS NOTICE MUST

REMAIN ON ALL COPIES.

The Roadranger® System is an unbeatable combination of the

best products from Eaton and Dana – partnering to provide you

the most advanced, most trouble-free drivetrain in the industry.

And it’s backed by the Roadrangers – the most experienced, most

expert, most accessible drivetrain consultants in the business.

For spec’ing or service assistance, call 1-800-826-HELP (4357)

24 hours a day, 7 days a week, (Mexico: 001-800-826-HELP

(4357)) for more time on the road. Or visit our web site at

www.roadranger.com.

TRMT-0062

3/00 PDF

Printed in USA

Loading...

Loading...