Perkins Engine 1106D Troubleshooting Manual

KENR6201-01

February 2010

Troubleshooting

1106D Electric Power Generation (EPG)

PJ (Engine)

This document is printed from SPI². Not for RESALE

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as “DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on the product and in this publication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure, work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the product will not be damaged or be made unsafe by the operation, lubrication, maintenance or repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that was available at the time that the publication was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and other items can change at any time. These changes can affect the service that is given to the product. Obtain the complete and most current information before you start any job. Perkins dealers or Perkins distributors have the most current information available.

When replacement parts are required for this product Perkins recommends using Perkins replacement parts.

Failure to heed this warning can lead to premature failures, product damage, personal injury or death.

This document is printed from SPI². Not for RESALE

KENR6201-01 |

|

|

3 |

|

|

|

Table of Contents |

||

Table of Contents |

|

Troubleshooting with a Diagnostic Code |

68 |

|

|

|

Diagnostic Code Cross Reference ....................... |

||

|

|

CID 0001 FMI 02 .................................................. |

70 |

|

Troubleshooting Section |

|

CID 0001 FMI 05 .................................................. |

70 |

|

|

CID 0001 FMI 06 |

71 |

||

|

|

|||

Electronic Troubleshooting |

|

CID 0001 FMI 07 .................................................. |

71 |

|

|

CID 0002 FMI 02 |

71 |

||

System Overview |

5 |

|||

CID 0002 FMI 05 |

72 |

|||

Glossary |

7 |

|||

CID 0002 FMI 06 |

72 |

|||

Electronic Service Tools |

11 |

|||

CID 0002 FMI 07 |

73 |

|||

Indicator Lamps |

13 |

|||

CID 0003 FMI 02 |

73 |

|||

Replacing the ECM |

16 |

|||

CID 0003 FMI 05 |

73 |

|||

Self-Diagnostics |

17 |

|||

CID 0003 FMI 06 |

74 |

|||

Sensors and Electrical Connectors |

17 |

|||

CID 0003 FMI 07 |

74 |

|||

Engine Wiring Information |

21 |

|||

CID 0004 FMI 02 |

75 |

|||

ECM Harness Connector Terminals |

24 |

|||

CID 0004 FMI 05 |

75 |

|||

|

|

|||

Programming Parameters |

|

CID 0004 FMI 06 .................................................. |

76 |

|

|

CID 0004 FMI 07 |

76 |

||

Programming Parameters |

26 |

|||

CID 0005 FMI 02 |

76 |

|||

Test ECM Mode |

26 |

|||

CID 0005 FMI 05 |

77 |

|||

Factory Passwords |

26 |

|||

CID 0005 FMI 06 |

77 |

|||

Flash Programming |

27 |

|||

CID 0005 FMI 07 |

78 |

|||

Injector Trim File |

27 |

|||

CID 0006 FMI 02 |

78 |

|||

Speed Demand Input Setup |

28 |

|||

CID 0006 FMI 05 |

78 |

|||

|

|

|||

Customer Specified Parameters |

|

CID 0006 FMI 06 .................................................. |

79 |

|

|

CID 0006 FMI 07 |

79 |

||

Customer Specified Parameters |

31 |

|||

CID 0041 FMI 03 |

80 |

|||

Customer Specified Parameters Table |

34 |

|||

CID 0041 FMI 04 |

80 |

|||

Customer Specified Parameters Worksheet |

35 |

|||

CID 0091 FMI 08 |

80 |

|||

|

|

|||

System Configuration Parameters |

|

CID 0100 FMI 03 .................................................. |

81 |

|

|

CID 0100 FMI 04 |

81 |

||

System Configuration Parameters |

36 |

|||

CID 0100 FMI 10 |

81 |

|||

|

|

|||

Troubleshooting without a Diagnostic Code |

|

CID 0110 FMI 03 ................................................... |

82 |

|

|

CID 0110 FMI 04 |

82 |

||

Alternator Noise |

37 |

|||

CID 0168 FMI 00 |

83 |

|||

Alternator Will Not Charge |

37 |

|||

CID 0168 FMI 01 |

83 |

|||

Battery |

38 |

|||

CID 0168 FMI 02 |

84 |

|||

Can Not Reach Top Engine RPM |

38 |

|||

CID 0172 FMI 03 |

84 |

|||

Coolant in Engine Oil |

40 |

|||

CID 0172 FMI 04 |

85 |

|||

Coolant Temperature Is Too High |

41 |

|||

CID 0190 FMI 08 |

85 |

|||

ECM Will Not Accept Factory Passwords |

42 |

|||

CID 0247 FMI 09 |

85 |

|||

ECM Will Not Communicate with Other Systems or |

||||

Display Modules |

43 |

..................................................CID 0253 FMI 02 |

86 |

|

CID 0261 FMI 11 |

86 |

|||

Electronic Service Tool Will Not Communicate with |

||||

ECM |

43 |

..................................................CID 0262 FMI 03 |

86 |

|

CID 0262 FMI 04 |

87 |

|||

Engine Cranks but Will Not Start |

44 |

|||

CID 0268 FMI 02 |

87 |

|||

Engine Has Early Wear |

48 |

|||

CID 0342 FMI 08 |

88 |

|||

Engine Misfires, Runs Rough or Is Unstable |

49 |

|||

CID 0526 FMI 05 |

88 |

|||

Engine Oil in Cooling System |

50 |

|||

CID 0526 FMI 06 |

88 |

|||

Engine Vibration |

51 |

|||

CID 1690 FMI 08 |

89 |

|||

Engine Will Not Crank |

52 |

|||

CID 1779 FMI 05 |

89 |

|||

Excessive Black Smoke |

53 |

|||

CID 1779 FMI 06 |

89 |

|||

Excessive Engine Oil Consumption |

55 |

|||

CID 1779 FMI 08 |

90 |

|||

Excessive Fuel Consumption |

56 |

|||

CID 1785 FMI 03 |

90 |

|||

Excessive Valve Lash |

58 |

|||

CID 1785 FMI 04 |

90 |

|||

Excessive White Smoke |

58 |

|||

CID 1785 FMI 10 |

91 |

|||

Intake Air Temperature Is Too High |

59 |

|||

CID 1797 FMI 03 |

91 |

|||

Intermittent Engine Shutdown |

61 |

|||

CID 1797 FMI 04 |

92 |

|||

Intermittent Low Power or Power Cutout |

62 |

|||

CID 1834 FMI 02 |

92 |

|||

Low Engine Oil Pressure |

63 |

|||

CID 2246 FMI 06 |

92 |

|||

Low Power |

64 |

|||

|

|

|||

Mechanical Noise (Knock) in Engine .................... |

66 |

Troubleshooting with an Event Code |

|

|

Noise Coming from Cylinder |

67 |

|

||

Event Codes ........................................................ |

94 |

|||

This document is printed from SPI². Not for RESALE

4 |

|

KENR6201-01 |

Table of Contents |

|

|

E085 |

Engine Shutdown Overridden ..................... |

94 |

E255 |

Diagnostic Reset ......................................... |

94 |

E264 |

Emergency Stop Activated .......................... |

94 |

E360 |

Low Engine Oil Pressure ............................. |

95 |

E361 |

High Engine Coolant Temperature .............. |

96 |

E362 |

Engine Overspeed ....................................... |

97 |

E396 |

High Fuel Rail Pressure .............................. |

98 |

E398 |

Low Fuel Rail Pressure ............................... |

99 |

E539 |

High Intake Manifold Air Temperature ......... |

99 |

Diagnostic Functional Tests |

|

|

5 Volt Sensor Supply Circuit - Test ..................... |

101 |

|

CAN Data Link Circuit - Test ............................... |

107 |

|

Data Link Circuit - Test ......................................... |

110 |

|

ECM Memory - Test ............................................. |

116 |

|

Electrical Connectors - Inspect ............................ |

117 |

|

Engine Pressure Sensor Open or Short Circuit - |

|

|

Test |

................................................................... |

121 |

Engine Speed/Timing Sensor Circuit - Test ........ |

128 |

|

Engine Temperature Sensor Open or Short Circuit - |

||

Test |

................................................................... |

135 |

Fuel Rail Pump Solenoid - Test .......................... |

140 |

|

Ignition Keyswitch Circuit and Battery Supply Circuit - |

||

Test |

................................................................... |

144 |

Indicator Lamp Circuit - Test ............................... |

150 |

|

Injector Data Incorrect - Test ............................... |

154 |

|

Injector Solenoid Circuit - Test ............................ |

156 |

|

Speed Control (Analog) - Test ............................ |

163 |

|

Speed Control (PWM) - Test ............................... |

166 |

|

Starting Aid (Glow Plug) Relay Circuit - Test ...... |

168 |

|

Wastegate Solenoid - Test .................................. |

172 |

|

Index Section |

|

|

Index |

................................................................... |

177 |

This document is printed from SPI². Not for RESALE

KENR6201-01 |

5 |

|

Troubleshooting Section |

Troubleshooting Section

Electronic Troubleshooting

i03805210

System Overview

System Operation

Illustration 1 |

|

|

|

g01808033 |

|

|

|

|

|

||

(1) Electronic Unit Injector |

(6) |

Primary Speed/Timing Sensor |

(11) Coolant Temperature Sensor |

||

(2) |

Solenoid for the Fuel Rail Pump |

(7) Intake Manifold Pressure Sensor |

(12) |

Diagnostic Connector (if equipped) |

|

(3) |

Wastegate Regulator (if equipped) |

(8) |

Fuel Rail Pressure Sensor |

(13) |

Electronic Control Module (ECM) |

(4) |

Secondary Speed/Timing Sensor |

(9) |

Engine Oil Pressure Sensor |

|

|

(5) Fuel Rail Pump |

(10) Intake Manifold Temperature Sensor |

|

|

||

This document is printed from SPI². Not for RESALE

6 |

KENR6201-01 |

Troubleshooting Section |

|

The 1106D engine was designed for electronic control. The engine has an Electronic Control Module (ECM), a fuel rail pump and electronic unit injectors. All of these items are electronically controlled. There are also a number of engine sensors. Turbocharged engines can be equipped with an electronically controlled wastegate for the turbocharger. The ECM controls the engine operating parameters through the software within the ECM and the inputs from the various sensors. The software contains parameters that control the engine operation. The parameters include all of the operating maps and customer selected parameters.

The electronic system consists of the ECM, the engine sensors and inputs from the parent machine. The ECM is the computer. The personality module is the software for the computer. The personality module defines the following characteristics of the engine:

•Engine power

•Torque curves

•Engine speed (rpm)

•Engine Noise

•Smoke and Emissions

Engine Speed Governor

The ECM determines the injection timing, the amount of fuel that is delivered to the cylinders and the intake manifold pressure if an electronically controlled wastegate is installed on the turbocharger. These decisions are based on the actual conditions and the desired conditions at any given time.

The governor has software that compares the desired engine speed to the actual engine speed. The actual engine speed is determined through the primary speed/timing sensor and the secondary speed/timing sensor. If the desired engine speed is greater than the actual engine speed, the governor injects more fuel in order to increase engine speed.

Timing Considerations

Fuel injection timing is determined by the ECM after considering input from the following components:

•Engine coolant temperature sensor

•The sensor for the intake manifold air temperature

•The sensor for the intake manifold pressure

•Speed/timing sensors

•Speed control device

At start-up, the ECM determines the top center position of the number 1 cylinder from the secondary speed/timing sensor in the fuel rail pump. The ECM decides when fuel injection should occur relative to the top center position. The ECM optimizes engine performance by control of each of the electronic unit injectors so that the required amount of fuel is injected at the precise point of the engine's cycle. The electronic unit injectors are supplied high pressure fuel from the fuel rail. The ECM also provides the signal to the solenoid in the fuel rail pump. The solenoid in the fuel rail pump controls a valve in the fuel rail pump. This valve controls the pressure in the fuel rail. Fuel that is not required for the engine is diverted away from the fuel rail pump back to the fuel tank.

The ECM adjusts injection timing and fuel pressure for the best engine performance, the best fuel economy and the best control of exhaust emissions. The actual timing can be viewed with an electronic service tool. Also, the desired timing can be viewed with an electronic service tool.

Fuel Injection

The personality module inside the ECM sets certain limits on the amount of fuel that can be injected.

The Fuel Ratio Control Limit is a limit that is based on intake manifold air pressure and engine rpm. The FRC Limit is used to control the air/fuel ratio in order to control the engine's exhaust emissions. When the ECM senses a higher intake manifold air pressure, the ECM increases the FRC Limit. A higher intake manifold air pressure indicates that there is more air in the cylinder. When the ECM increases the FRC Limit, the ECM allows more fuel into the cylinder.

The Rated Fuel Limit is a limit that is based on the power rating of the engine and on the engine rpm. The Rated Fuel Limit enables the engine power and torque outputs to conform to the power and torque curves of a specific engine model.

These limits are in the personality module and these limits cannot be changedby the operator.

Diagnostic Codes

When the ECM detects an electronic system problem, the ECM generates a diagnostic code. Also, the ECM logs the diagnostic code in order to indicate the time of the problem's occurrence. The ECM also logs the number of occurrences of the problem. Diagnostic codes are provided in order to indicate that the ECM has detected an electrical problem or an electronic problem with the engine control system. In some cases, the engine performance can be affected when the condition that is causing the code exists.

This document is printed from SPI². Not for RESALE

KENR6201-01 |

7 |

|

Troubleshooting Section |

If the operator indicates that a performance problem occurs, the diagnostic code may indicate the cause of the problem. Use the electronic service tool to access the diagnostic codes. The problem should then be corrected.

Event Codes

Event Codes are used to indicate that the ECM has detected an abnormal engine operating condition. The ECM will log the occurrence of the event code. This does not indicate an electrical malfunction

or an electronic malfunction. For example, if the temperature of the coolant in the engine is higher than the permitted limit, then the ECM will detect the condition. The ECM will then log an event code for the condition.

Programmable Parameters

Certain parameters that affect the engine operation may be changed with electronic service tools. The parameters are stored in the ECM, and the

parameters are protected from unauthorized changes by passwords. These parameters are System Configuration Parameters.

System Configuration Parameters are set at the factory. System Configuration Parameters affect emissions or power ratings within the engine. Factory passwords must be obtained and factory passwords must be used to change the System Configuration Parameters.

Passwords

System Configuration Parameters are protected by factory passwords. Factory passwords are calculated on a computer system that is available only to Perkins distributors. Since factory passwords contain alphabetic characters, only an electronic service tool may change System Configuration Parameters. System Configuration Parameters affect the power rating or the emissions.

Refer to Troubleshooting, “Programming Parameters” and Troubleshooting, “Factory Passwords”.

i03805350

Adaptive Trim – This is a software process that is performed in the Electronic Control Module (ECM) that optimizes engine performance.

Alternating Current (AC) – Alternating current is an electric current that reverses direction at a regular interval that is reoccurring.

Before Top Center (BTC) – BTC is the 180 degrees of crankshaft rotation before the piston reaches the top dead center position in the normal direction of rotation.

Breakout Harness – A breakout harness is a test harness that is designed to connect into the engine harness. This connection allows a normal circuit operation and the connection simultaneously provides a Breakout T in order to measure the signals.

Bypass Circuit – A bypass circuit is a circuit that is used as a substitute circuit for an existing circuit. A bypass circuit is typically used as a test circuit.

CAN Data Link (see also J1939 CAN Data Link) –

The CAN Data Link is a serial communications port that is used for communication with other microprocessor based devices.

Code – Refer to “Diagnostic Code” or “Event Code”.

Communication Adapter Tool – The communication adapter provides a communication link between the ECM and the electronic service tool.

Component Identifier (CID) – The CID is a number that identifies the specific component of the electronic control system that has experienced a diagnostic code.

Coolant Temperature Sensor – The coolant temperature sensor detects the engine coolant temperature for all normal operating conditions and for engine monitoring.

Data Link – The Data Link is a serial communication port that is used for communication with other devices such as the electronic service tool.

Derate – Certain engine conditions will generate event codes. Also, engine derates may be applied. The map for the engine derate is programmed into the ECM software. The derate can be one or more of 3 types: reduction of rated power, reduction of rated engine speed, and reduction of rated machine speed for OEM products.

Desired Engine Speed – The desired engine speed is input to the electronic governor within the ECM. The electronic governor uses the signal from the throttle position sensor, the engine speed/timing sensor, and other sensors in order to determine the

desired engine speed.

This document is printed from SPI². Not for RESALE

8 |

KENR6201-01 |

|

Troubleshooting Section |

|

|

Diagnostic Code – A diagnostic code is sometimes |

Event Code – An event code may be activated |

|

referred to as a fault code. These codes indicate an |

in order to indicate an abnormal engine operating |

|

electronic system malfunction. |

condition. These codes usually indicate a mechanical |

|

Digital Sensor Return – The common line (ground) |

problem instead of an electrical system problem. |

|

Failure Mode Identifier (FMI) – This identifier |

||

from the ECM is used as ground for the digital |

||

sensors. |

indicates the type of failure that is associated with |

|

|

the component. The FMI has been adopted from the |

|

Digital Sensors – Digital sensors produce a pulse |

SAE practice of J1587 diagnostics. The FMI follows |

|

width modulated signal. Digital sensors are supplied |

the parameter identifier (PID) in the descriptions of |

|

with power from the ECM. |

the fault code. The descriptions of the FMIs are in |

|

Digital Sensor Supply – The power supply for the |

the following list. |

|

0 – The data is valid but the data is above the normal |

||

digital sensors is provided by the ECM. |

||

Direct Current (DC) – Direct current is the type of |

operational range. |

|

1 – The data is valid but the data is below the normal |

||

current that flows consistently in only one direction. |

||

DT, DT Connector, or Deutsch DT – This is a |

operational range. |

|

2 – The data is erratic, intermittent, or incorrect. |

||

type of connector that is used on the engine. The |

||

connectors are manufactured by Deutsch. |

3 – The voltage is above normal or the voltage is |

|

Duty Cycle – Refer to “Pulse Width Modulation”. |

||

shorted high. |

||

Electronic Engine Control – The electronic |

4 – The voltage is below normal or the voltage is |

|

engine control is a complete electronic system. |

shorted low. |

|

The electronic engine control monitors the engine |

|

|

operation under all conditions. The electronic engine |

5 – The current is below normal or the circuit is open. |

|

control also controls the engine operation under all |

6 – The current is above normal or the circuit is |

|

conditions. |

||

Electronic Control Module (ECM) – The ECM |

grounded. |

|

7 – The mechanical system is not responding |

||

is the control computer of the engine. The ECM |

||

provides power to the electronics. The ECM monitors |

properly. |

|

data that is input from the sensors of the engine. The |

|

|

ECM acts as a governor in order to control the speed |

8 – There is an abnormal frequency, an abnormal |

|

and the power of the engine. |

pulse width, or an abnormal time period. |

|

Electronic Service Tool – The electronic service |

9 – There has been an abnormal update. |

|

tool allows a computer (PC) to communicate with the |

10 – There is an abnormal rate of change. |

|

ECM. |

||

Engine Monitoring – Engine Monitoring is the part |

11 – The failure mode is not identifiable. |

|

of the electronic engine control that monitors the |

|

|

sensors. This also warns the operator of detected |

12 – The device or the component is damaged. |

|

problems. |

13 – The device or the component is not calibrated. |

|

Engine Oil Pressure Sensor – The engine oil |

||

|

||

pressure sensor measures engine oil pressure. The |

14 and 15 – These locations are reserved for a |

|

sensor sends an electronic signal to the ECM that is |

future assignment. |

|

dependent on the engine oil pressure. |

Flash Programming – Flash programming is the |

|

Engine Speed/Timing Sensor – An engine |

||

method of programming or updating an ECM with |

||

speed/timing sensor is a hall effect switch that |

an electronic service tool over the data link instead |

|

provides a signal to the ECM. The ECM interprets |

of replacing components. |

|

this signal as the crankshaft position and the engine |

|

|

speed. Two sensors are used to provide the speed |

Fuel Injector E-Trim – Fuel injector E-trim is a |

|

and timing signals to the ECM. The primary sensor |

software process that allows precise control of fuel |

|

is associated with the crankshaft and the secondary |

injectors by parameters that are programmed into |

|

sensor is associated with the camshaft. |

the ECM for each fuel injector. With the use of the |

|

Ether Relay – The ether relay is used to actuate the |

electronic service tool, the service technician can |

|

read status information for the E-Trim. Data for |

||

ether injection system. The ECM controls the relay. |

E-Trim can also be programmed. |

This document is printed from SPI². Not for RESALE

KENR6201-01 |

9 |

|

Troubleshooting Section |

FRC – See “Fuel Ratio Control”.

Fuel Pump – See “Fuel Rail Pump”.

Fuel Rail – This item is sometimes referred to as the High Pressure Fuel Rail. The fuel rail supplies fuel to the electronic unit injectors. The fuel rail pump and the fuel rail pressure sensor work with the ECM in order to maintain the desired fuel pressure in the fuel rail. This pressure is determined by calibration of the engine in order to enable the engine to meet emissions and performance requirements.

Fuel Rail Pressure Sensor – The fuel rail pressure sensor sends an electronic signal to the ECM that is dependent on the pressure of the fuel in the fuel rail.

Fuel Rail Pump – This item is sometimes referred to as the High Pressure Fuel Rail Pump. This is a device that supplies fuel under pressure to the fuel rail (high pressure fuel rail).

Fuel Rail Pump Solenoid Valve – This is sometimes referred to as the High Pressure Fuel Rail Pump Solenoid Valve. This is a control device in the high pressure fuel rail pump. The ECM controls the pressure in the fuel rail by using this valve to divert excess fuel from the pump to the fuel tank.

Fuel Ratio Control (FRC) – The FRC is a limit that is based on the control of the ratio of the fuel to air. The FRC is used for purposes of emission control.

When the ECM senses a higher intake manifold air pressure (more air into the cylinder), the FRC

increases the FRC Limit (more fuel into the cylinder).

Full Load Setting (FLS) – The FLS is the number that represents the fuel system adjustment. This adjustment is made at the factory in order to fine tune the fuel system. The correct value for this parameter is stamped on the engine information ratings plate. This parameter must be programmed.

Glow Plug – The glow plug is an optional starting aid for cold conditions. One glow plug is installed in each combustion chamber in order to improve the ability of the engine to start. The ECM uses information from the engine sensors such as the engine temperature to determine when the glow plug relay must provide power to each glow plug. Each of the glow plugs then provides a very hot surface in the combustion chamber in order to vaporize the mixture of air and fuel. This improves ignition during the compression stroke of the cylinder.

Glow Plug Relay – The glow plug relay is controlled by the ECM in order to provide high current to the glow plugs that are used in the starting aid system.

Harness – The harness is the bundle of wiring (loom) that connects all components of the electronic system.

Hertz (Hz) – Hertz is the measure of electrical frequency in cycles per second.

High Pressure Fuel Rail Pump – See “Fuel Rail

Pump”.

High Pressure Fuel Rail Pump Solenoid Valve –

See “Fuel Rail Pump Solenoid Valve”.

High Pressure Fuel Rail – See “Fuel Rail”.

Injector Codes – The injector codes or injector trim codes are numeric codes or alphanumeric codes that are etched or stamped on individual electronic unit injectors. These codes are used to fine tune the fuel delivery.

Injector Trim Files – Injector trim files are downloaded from a disk to the ECM. The injector trim files compensate for variances in manufacturing of the electronic unit injector. The serial number for the electronic unit injector must be obtained in order to retrieve the correct injector trim file.

Intake Manifold Air Temperature Sensor – The intake manifold air temperature sensor detects the air temperature in the intake manifold. The ECM monitors the air temperature and other data in the intake manifold in order to adjust injection timing and other performance functions.

Intake Manifold Pressure Sensor – The Intake Manifold Pressure Sensor measures the pressure in the intake manifold. The pressure in the intake manifold may be different to the pressure outside the engine (atmospheric pressure). The difference in pressure may be caused by an increase in air pressure by a turbocharger (if equipped).

Integrated Electronic Controls – The engine is designed with the electronic controls as a necessary part of the system. The engine will not operate without the electronic controls.

J1939 CAN Data Link – This data link is a SAE standard diagnostic communications data link that is used to communicate between the ECM and the electronic devices.

Logged Diagnostic Codes – Logged diagnostic codes are codes which are stored in the memory. These codes are meant to be an indicator of possible causes for intermittent problems. Refer to the

term “Diagnostic Code” in this glossary for more information.

OEM – OEM is an abbreviation for the Original Equipment Manufacturer. This is the manufacturer of the machine or the vehicle that uses the engine.

This document is printed from SPI². Not for RESALE

10 |

KENR6201-01 |

Troubleshooting Section |

|

Open Circuit – An open circuit is a condition that is caused by an open switch, or by an electrical wire or a connection that is broken. When this condition exists, the signal or the supply voltage can no longer reach the intended destination.

Parameter – A parameter is a value or a limit that is programmable. This helps determine specific characteristics or behaviors of the engine.

Password – A password is a group of numeric characters or a group of alphanumeric characters that is designed to restrict access to parameters. The electronic system requires correct passwords in order to change some parameters (Factory Passwords). Refer to Troubleshooting, “Factory Passwords” for more information.

Personality Module – This module is software that is inside the ECM. The module contains all the instructions (software) for the ECM and the module contains the performance maps for a specific engine. The personality module may be reprogrammed through flash programming.

Power Cycling – Power cycling refers to the action of cycling the keyswitch from any position to the OFF position, and to the START/RUN position.

Primary Speed/Timing Sensor – This sensor determines the position of the crankshaft during engine operation. If the primary speed/timing sensor fails during engine operation, the secondary speed/timing sensor is used to provide the signal.

Pulse Width Modulation (PWM) – The PWM is a signal that consists of pulses that are of variable width. These pulses occur at fixed intervals. The ratio of “TIME ON” versus total “TIME OFF” can be varied. This ratio is also referred to as a duty cycle.

Illustration 2 |

g00284479 |

|

Rated Fuel Limit – This is a limit that is based on the power rating of the engine and on the engine rpm. The Rated Fuel Limit enables the engine power and torque outputs to conform to the power and torque curves of a specific engine model. These limits are in the personality module and these limits cannot be changed.

Reference Voltage – Reference voltage is a regulated voltage and a steady voltage that is supplied by the ECM to a sensor. The reference voltage is used by the sensor to generate a signal voltage.

Relay – A relay is an electromechanical switch. A flow of electricity in one circuit is used to control the flow of electricity in another circuit. A small current or voltage is applied to a relay in order to switch a much larger current or voltage.

Secondary Speed/Timing Sensor – This sensor determines the position of the camshaft during engine operation. If the primary speed/timing sensor fails during engine operation, the secondary speed/timing sensor is used to provide the signal.

Sensor – A sensor is a device that is used to detect the current value of pressure or temperature, or mechanical movement. The information that is detected is converted into an electrical signal.

Short Circuit – A short circuit is a condition that has an electrical circuit that is inadvertently connected to an undesirable point. An example of a short circuit is a wire which rubs against a vehicle frame and this rubbing eventually wears off the wire insulation. Electrical contact with the frame is made and a short circuit results.

Signal – The signal is a voltage or a waveform that is used in order to transmit information typically from a sensor to the ECM.

Speed Demand Input – The speed demand input is a signal that is sent to the ECM in order to calculate desired engine speed.

Supply Voltage – The supply voltage is a continuous voltage that is supplied to a component in order to provide the electrical power that is required for the component to operate. The power may be generated by the ECM or the power may be battery voltage that is supplied by the engine wiring.

System Configuration Parameters – System configuration parameters are parameters that affect emissions and/or operating characteristics of the engine.

This document is printed from SPI². Not for RESALE

KENR6201-01 |

11 |

|

Troubleshooting Section |

Tattletale – Certain parameters that affect the operation of the engine are stored in the ECM. These parameters can be changed by use of the electronic service tool. The tattletale logs the number of changes that have been made to the parameter. The tattletale is stored in the ECM.

Throttle Position – The throttle position is the interpretation by the ECM of the signal from the speed controller.

Timing Calibration – The timing calibration is the adjustment of an electrical signal. This adjustment is made in order to correct the timing error between the camshaft and the engine speed/timing sensors or between the crankshaft and the engine speed/timing sensors.

Top Center Position – The top center position refers to the crankshaft position when the engine piston position is at the highest point of travel. The engine must be turned in the normal direction of rotation in order to reach this point.

Total Tattletale – The total tattletale is the total number of changes to all the parameters that are stored in the ECM.

Wastegate – This is a device in a turbocharged engine that controls the maximum boost pressure that is provided to the inlet manifold.

Wastegate Regulator (if equipped) – The wastegate regulator controls the pressure in the intake manifold to a value that is determined by the ECM. The wastegate regulator provides the interface between the ECM and the mechanical system that regulates intake manifold pressure to the desired value that is determined by the software.

i02517580

Electronic Service Tools

Perkins electronic service tools are designed to help the service technician:

•Retrieve diagnostic codes.

•Diagnose electrical problems.

•Read parameters.

•Program parameters.

•Install trim files.

Required Service Tools

Table 1

Required Service Tools

Part Number |

Description |

|

|

CH11155 |

Crimp Tool (12−AWG TO 18−AWG) |

|

|

2900A019 |

Wire Removal Tool |

|

|

27610285 |

Removal Tool |

|

|

- |

Suitable Digital Multimeter |

|

|

Two short jumper wires are needed to check the continuity of some wiring harness circuits by shorting two adjacent terminals together in a connector. A long extension wire may also be needed to check the continuity of some wiring harness circuits.

Optional Service Tools

Table 2 lists the optional service tools that can be used when the engine is serviced.

Table 2

Part Number |

Description |

|

|

U5MK1092 |

Spoon Probe Kit(MULTIMETER) |

|

|

- |

Suitable Digital Pressure Indicator |

or |

or |

- |

Engine Pressure Group |

|

|

- |

Suitable Battery Load Tester |

|

|

- |

Suitable Temperature Adapter |

|

(MULTIMETER) |

28170107 |

Bypass Harness As |

|

|

2900A038 |

Harness As |

|

|

Perkins Electronic Service Tool

The Perkins Electronic Service Tool can display the following information:

•Status of all pressure sensors and temperature sensors

•Programmable parameter settings

•Active diagnostic codes and logged diagnostic codes

•Logged events

•Histograms

The Electronic Service Tool can also be used to perform the following functions:

• Diagnostic tests

This document is printed from SPI². Not for RESALE

12 |

KENR6201-01 |

Troubleshooting Section |

|

•Sensor calibrations

•Programming of flash files

•Parameter programming

•Copy configuration function for ECM replacement

•Data logging

•Graphs (real time)

Table 3 lists the service tools that are required in order to use the Electronic Service Tool.

Table 3

Service Tools for the Use of the Electronic Service Tool

Part |

Description |

|

Number |

|

|

|

|

|

-(1) |

Single Use Program License |

|

-(1) |

Data Subscription for All Engines |

|

27610251 |

Communication Adapter (Electronic |

|

Service Tool to ECM interface) |

||

|

||

|

|

|

27610164 |

Adapter Cable As |

|

|

|

(1) Refer to Perkins Engine Company Limited.

Note: For more information regarding the use of the Electronic Service Tool and the PC requirements for the Electronic Service Tool, refer to the documentation that accompanies your Perkins Electronic Service Tool software.

Connecting the Electronic Service Tool

and the Communication Adapter II

Illustration 3 |

g01121866 |

|

(1)Personal Computer (PC)

(2)Adapter Cable (Computer Serial Port)

(3)Communication Adapter II

(4)Adapter Cable Assembly

Note: Items (2), (3) and (4) are part of the Communication Adapter II kit.

Use the following procedure in order to connect the Electronic Service Tool and the Communication Adapter II.

1.Turn the keyswitch to the OFF position.

2.Connect cable (2) between the “COMPUTER” end of communication adapter (3) and the RS232 serial port of PC (1).

Note: The Adapter Cable Assembly (4) is required to connect to the USB port on computers that are not equipped with a RS232 serial port.

3.Connect cable (4) between the “DATA LINK” end of communication adapter (3) and the service tool connector.

4. Place the keyswitch in the ON position. If the Electronic Service Tool and the communication adapter do not communicate with the Electronic Control Module (ECM), refer to the diagnostic procedure Troubleshooting, “Electronic Service

Tool Will Not Communicate With ECM”.

This document is printed from SPI². Not for RESALE

KENR6201-01 |

13 |

|

Troubleshooting Section |

i03787449

Indicator Lamps

Indicator Lamps

The functions of the indicator lamps are designed to display the maximum amount of information on the minimum number of lamps.

Eight lamps are available as options. The “Shutdown” lamp and the “Warning” lamp will normally be installed in the application. Dedicated optional lamps for other items may also be installed. The remaining optional lamps are “Low oil pressure”, “Overspeed”, “High Coolant Temperature”, “Diagnostic”, “Derate” and “Maintenance”.

The “Shutdown” lamp and the “Warning” lamp can also be used to indicate a diagnostic code by use of the “Flash Code” feature. The “Flash Code” feature can be used to indicate all active diagnostic codes and logged diagnostic codes.

Functions of the Lamps

Shutdown Lamp

Lamp check – When the keyswitch is turned to the ON position, the lamp will come on for two seconds. The lamp will then go off unless there is an active warning.

On – The lamp will be on when the shutdown level in the engine protection strategy has been reached.

Warning Lamp

Lamp check – When the keyswitch is turned to the ON position, the lamp will come on for two seconds. The lamp will then go off unless there is an active warning.

On – The lamp will be on when the warning level has been reached.

Low Oil Pressure

Lamp check – When the keyswitch is turned to the ON position, the lamp will come on for two seconds.

On – The lamp will come on when a low oil pressure event is detected. The “Warning” lamp and the “Shutdown” lamp may also come on.

High Coolant Temperature Lamp

Lamp check – When the keyswitch is turned to the ON position, the lamp will come on for two seconds.

On – The lamp will come on when a “high coolant temperature” event is detected. The “Warning” lamp and the “Shutdown” lamp may also come on.

Overspeed Lamp

Lamp check – When the keyswitch is turned to the ON position, the lamp will come on for two seconds. The lamp will then go off unless the engine overspeeds.

On – The lamp will come on when an “engine overspeed” event is detected. The “Warning” lamp and the “Shutdown” lamp may also come on.

Derate Lamp

Lamp check – When the keyswitch is turned to the ON position, the lamp will come on for two seconds.

On – The lamp will come on when the engine is derated.

Diagnostic Lamp

Lamp check – When the keyswitch is turned to the ON position, the lamp will come on for two seconds.

Flashing – The lamp will flash when a diagnostic code or an event code is active. Refer to “Flash Codes”.

Maintenance Lamp

Lamp check – When the keyswitch is turned to the ON position, the lamp will come on for two seconds. The lamp will then go off unless maintenance is due.

On – The lamp will come on when maintenance is due.

Color of Lamps

Typically, the “Shutdown” lamp is colored red and the “Warning” lamp is colored amber. The other lamps are optional.

This document is printed from SPI². Not for RESALE

14 |

KENR6201-01 |

Troubleshooting Section |

|

Operation of the Indicator Lamps

Table 4

Warning |

Shutdown |

Diagnostic |

Derate |

Lamp State |

Description of the Indication |

Engine State |

Lamp |

Lamp |

Lamp |

Lamp |

|

|

|

(Alert |

(Action |

|

|

|

|

|

Lamp) |

Lamp) |

|

|

|

|

|

|

|

|

|

Lamp Check |

When the keyswitch is switched on, |

The keyswitch is |

On |

On |

On |

On |

|

the lamps come on for a period of |

on but the engine |

|

2 seconds and the lamps will then |

has not yet been |

||||

|

|

|

|

|

||

|

|

|

|

|

go off. |

cranked. |

|

|

|

|

|

|

|

|

|

|

|

No Faults |

With the engine in operation, there |

The engine is |

Off |

Off |

Off |

Off |

|

are no active warnings, diagnostic |

operating with no |

|

|

|

|

|

codes or event codes. |

detected faults. |

|

|

|

|

|

|

|

|

|

|

|

Warning |

If the warning lamp comes on |

The engine |

|

|

|

|

(Warning |

during engine operation, and the |

is operating |

|

|

|

|

only) |

diagnostic lamp is flashing , the |

normally. |

|

|

|

|

|

lamps indicate that one or more of |

However, there is |

|

|

|

|

|

the warning values for the engine |

one or more of the |

On |

Off |

Flashing |

Off |

|

protection strategy have been |

monitored engine |

|

|

|

|

|

exceeded and that there is an |

parameters that |

|

|

|

|

|

active event code. However, the |

are outside of |

|

|

|

|

|

value has not been exceeded to a |

the range that is |

|

|

|

|

|

level that will cause a derate or a |

acceptable. |

|

|

|

|

|

shutdown. |

|

|

|

|

|

Derate |

If both the warning lamp and the |

The engine |

|

|

|

|

(Warning |

derate lamp come on during engine |

is operating. |

|

|

|

|

and Derate) |

operation, and the diagnostic lamp |

However, one |

|

|

|

|

|

is flashing, the lamps indicate that |

or more of the |

|

|

|

|

|

one or more of the values for the |

monitored engine |

|

|

|

|

|

engine protection strategy have |

parameters is |

|

|

Flashing |

|

|

been exceeded beyond the level |

outside of the |

On |

Off |

On |

|

that will cause an engine derate. |

acceptable range. |

|

|

|

|

|

|

|

The acceptable |

|

|

|

|

|

|

range has been |

|

|

|

|

|

|

exceeded to |

|

|

|

|

|

|

a level which |

|

|

|

|

|

|

requires a warning |

|

|

|

|

|

|

and an engine |

|

|

|

|

|

|

derate. |

|

|

|

|

Engine |

If both the warning lamp and |

The engine is |

|

|

|

|

shutdown |

the shutdown lamp come on |

either shutdown |

|

|

|

|

(Warning |

during engine operation, and the |

or an engine |

|

|

|

|

and |

diagnostic lamp is flashing, the |

shutdown is |

On |

On |

Flashing |

Off |

shutdown) |

lamps indicate that one or more |

imminent. |

|

of the shutdown values for the |

One or more |

||||

|

|

|

|

|

engine protection strategy has |

monitored engine |

|

|

|

|

|

been exceeded and there is an |

parameters have |

|

|

|

|

|

active event code. |

exceeded the |

|

|

|

|

|

|

limit for an engine |

|

|

|

|

|

|

shutdown. |

|

|

|

|

Diagnostic |

When the diagnostic lamp flashes |

The engine is |

|

|

|

|

(Diagnostic |

during operation of the engine, |

operating but |

|

|

Flashing |

|

only) |

the lamp indicates that an active |

there is one or |

Off |

Off |

Off |

|

diagnostic code (an electrical fault) |

more faults with |

|

|

|

|

|

|

is present. However, the diagnostic |

the electronic |

|

|

|

|

|

code is not serious enough to |

system for the |

|

|

|

|

|

cause a derate or a shutdown. |

engine. |

|

|

|

|

|

|

(continued) |

This document is printed from SPI². Not for RESALE

KENR6201-01 |

|

|

|

|

|

15 |

|

|

|

|

|

|

|

Troubleshooting Section |

|

(Table 4, contd) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Derate |

If the derate lamp comes on |

The engine |

|

|

|

|

|

(Diagnostic |

during engine operation, and |

is operating. |

|

|

|

|

|

and Derate) |

the diagnostic lamp is flashing, |

However, an |

Off |

|

Off |

Flashing |

On |

|

the lamps indicate that an active |

active diagnostic |

|

|

diagnostic code (an electrical fault) |

code is causing |

||||

|

|

|

|

|

|

||

|

|

|

|

|

|

is present. The diagnostic code is |

an engine derate. |

|

|

|

|

|

|

serious enough to cause an engine |

|

|

|

|

|

|

|

derate. |

|

|

|

|

|

|

Engine |

If the shutdown lamp comes on |

The engine is |

|

|

|

|

|

Shutdown |

during engine operation, and the |

either shutdown |

|

|

|

|

|

|

diagnostic lamp is flashing, this |

or an engine |

Off |

|

On |

Flashing |

Off |

|

indicates that an active diagnostic |

shutdown is |

|

|

code (an electrical fault) is present. |

imminent. A |

||||

|

|

|

|

|

|

||

|

|

|

|

|

|

The diagnostic code is serious |

serious diagnostic |

|

|

|

|

|

|

enough to cause the engine to |

code is active. |

|

|

|

|

|

|

shutdown. |

|

|

|

|

|

|

|

|

|

Flash Codes

The “Flash Code” feature is used to flash the two digit code of all active diagnostic and event codes. Refer to the Troubleshooting Guide, “Diagnostic Codes” for the flash code that is related to the diagnostic code or an event.

When a diagnostic code or an event code is active or logged, the diagnostic lamp will flash repeatedly in order to indicate the codes.

Each flash will be on for half a second and off for 300 milliseconds. The “Diagnostic” lamp will remain off for two seconds between each digit of a code. If there is more than one diagnostic code, the “Diagnostic” lamp will go off for five seconds. The lamp will then flash in order to indicate the next code.

As an example, an active diagnostic code of “21” is indicated by the “Diagnostic” lamp coming on for 500 ms, then off for 300 ms, then on for 500 ms, then off for 2000 ms, then on for 500 ms and then off.

Illustration 4

Once all codes have been flashed, the “Diagnostic” lamp will go off for a period of 15 seconds before starting the sequence again.

g02048816

Note: Flash codes are always sent in ascending numerical order.

This document is printed from SPI². Not for RESALE

16 |

KENR6201-01 |

Troubleshooting Section |

|

i03805671

Replacing the ECM

NOTICE

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and mandates.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

The engine is equipped with an Electronic Control Module (ECM). The ECM contains no moving parts. Follow the troubleshooting procedures in this manual in order to be sure that replacing the ECM will correct the problem. Verify that the suspect ECM is the cause of the problem.

Note: Ensure that the ECM is receiving power and that the ECM is properly grounded before replacement of the ECM is attempted. Refer to the schematic diagram.

A test ECM can be used in order to determine if the ECM on the engine is faulty. Install a test ECM in place of the suspect ECM. Install the flash file with the correct part number into the test ECM. Program the parameters for the test ECM. The parameters must match the parameters in the suspect ECM. Refer to the following test steps for details. If the test ECM resolves the problem, reconnect the suspect ECM. Verify that the problem returns. If the problem returns, replace the ECM.

Note: If an ECM is intended to be used as a test ECM, “Test ECM Mode” must be selected on the electronic service tool before the engine serial number is entered.

Use the electronic service tool to read the parameters in the suspect ECM. Record the parameters in

the suspect ECM. Install the flash file into the new ECM. After the ECM is installed on the engine, the parameters must be programmed into the new ECM.

Note: When a new ECM is not available, an ECM can be used from an engine that is not in service. The ECM must have the same serial number suffix. Ensure that the replacement ECM and the part number for the flash file match the suspect ECM. Be sure to record the parameters from the replacement ECM. Use the “Copy Configuration ECM Replacement” function in the electronic service tool.

NOTICE

If the flash file and engine application are not matched, engine damage may result.

Perform the following procedure in order to replace the ECM.

1.Connect the electronic service tool to the diagnostic connector.

2.Use the “Copy Configuration ECM Replacement” function from the electronic service tool. If the “Copy Configuration” is successful, proceed to Step 4. If the “Copy Configuration” failed, proceed to Step 3.

Note: Record any Logged Faults and Events for your records.

3.Record the following parameters:

•Record all of the parameters on the “Configuration” screen.

•Record all of the parameters on the “Throttle Configuration” screen.

•Record all of the parameters on the “Mode Configuration” screen.

•Record the serial numbers of the electronic unit injectors. The injector serial numbers are shown on the “Injector Trim Calibration” screen.

Note: If the parameters cannot be read, the parameters must be obtained elsewhere. Some parameters are stamped on the engine information plate, but most parameters must be obtained from the PTMI data on the Perkins intranet.

4.Remove power from the ECM.

5.Remove the ECM. Refer to Disassembly and Assembly, “Electronic Control Module - Remove and Install”.

6.Install the replacement ECM. Refer to Disassembly and Assembly, “Electronic Control Module - Remove and Install”.

7. If the replacement ECM is intended to be used as a test ECM, select “Test ECM Mode” on the

electronic service tool.

This document is printed from SPI². Not for RESALE

KENR6201-01 |

17 |

|

Troubleshooting Section |

8. Download the flash file. |

• Logged |

a.Connect the electronic service tool to the diagnostic connector.

b.Select “WinFlash” from the “Utilities” menu of the electronic service tool.

c.Select the downloaded flash file.

9.If necessary, use the electronic service tool to clear the rating interlock. To clear the rating interlock, enter the factory password when the electronic service tool is first connected. Activating the Test ECM mode will also clear the rating interlock.

10.Use the electronic service tool to program the parameters. Perform the following procedure.

a.If the “Copy Configuration” procedure was successful, use the “Copy Configuration, ECM Replacement” function to load the configuration file into the ECM.

Note: During the following procedure, factory passwords may be required.

b.If the “Copy Configuration” procedure failed, configure the parameters individually. The parameters should match the parameters from step 3.

Active Code – An active diagnostic code indicates that an active fault has been detected by the control system. Active codes require immediate attention.

Always service active codes prior to servicing logged codes.

Logged Code – Every generated code is stored in the permanent memory of the ECM. The codes are logged for 100 operating hours unless a code is cleared by use of the electronic service tool.

Event Code – An event code is generated by the detection of an abnormal engine operating condition. For example, an event code will be generated if the oil pressure is too low. In this case, the event code indicates the symptom of a fault.

Logged codes may not indicate that a repair is needed. The fault may have been temporary. The fault may have been resolved since the logging of the code. If the system is powered, it is possible to generate an active diagnostic code whenever a

component is disconnected. When the component is reconnected, the code is no longer active. Logged codes may be useful to help troubleshoot intermittent faults. Logged codes can also be used to review the performance of the engine and the electronic system.

i03473503

Perform the “Fuel System Verification Test”.

11. Check for logged diagnostic codes. Factory passwords are required to clear logged events.

i03538621

Self-Diagnostics

The Electronic Control Module (ECM) has the ability to detect faults in the electronic system and with engine operation. A self-diagnostic check is also performed whenever power is applied to the ECM.

When a fault is detected, a code is generated. An alarm may also be generated. There are two types of codes:

•Diagnostic codes

•Event codes

Diagnostic Code – When a fault in the electronic system is detected, the ECM generates a diagnostic code. This indicates the specific fault in the circuitry.

Diagnostic codes can have two different states:

Sensors and Electrical

Connectors

The Electronic Control Module (ECM) and the sensors are located on the left side of the engine. Refer to Figure 5.

• Active

This document is printed from SPI². Not for RESALE

18 |

KENR6201-01 |

Troubleshooting Section |

|

|

|

Illustration 5 |

|

|

g01811780 |

|

|

|

|

||

Sensor locations |

|

|

|

|

(1) Coolant Temperature Sensor |

(4) Fuel Rail Pressure Sensor |

(7) |

Primary Speed/Timing Sensor |

|

(2) |

Intake Manifold Temperature Sensor |

(5) Electronic Control Module (ECM) |

(8) |

Secondary Speed/Timing Sensor |

(3) |

Intake Manifold Pressure Sensor |

(6) Oil Pressure Sensor |

(9) |

Solenoid for the Fuel Rail Pump |

Note: If equipped, the wastegate regulator is installed on the right side of the engine.

This document is printed from SPI². Not for RESALE

KENR6201-01 |

19 |

|

Troubleshooting Section |

|

|

Illustration 6 |

g01811835 |

|

Detailed views of the sensor locations

This document is printed from SPI². Not for RESALE

20 |

KENR6201-01 |

Troubleshooting Section |

|

Table 5 |

|

|

|

Connector |

Function |

|

|

P1 |

Machine Harness to ECM Connector (64 Pin Connector) |

|

|

P2 |

Engine Harness to ECM Connector (64 Pin Connector) |

|

|

P532 |

Fuel Rail Pump Solenoid Connector (2 Pin Connector) |

|

|

P402 |

Secondary Speed/Timing Sensor (2 Pin Connector) |

|

|

P401 |

Primary Speed/Timing Sensor (2 Pin Connector) |

|

|

P201 |

Engine Oil Pressure Sensor (3 Pin Connector) |

|

|

P228 |

Fuel Rail Pressure Sensor (3 Pin Connector) |

|

|

P200 |

Intake Manifold Pressure Sensor (3 Pin Connector) |

|

|

P103 |

Intake Manifold Temperature Sensor (2 Pin Connector) |

|

|

P100 |

Coolant Temperature Sensor (2 Pin Connector) |

|

|

J23 |

Diagnostic Connector (if equipped) |

|

|

P691/J691 |

Electronic Unit Injectors for No. 1 and No. 2 Cylinders (4 Pin |

|

Connector) |

P692/J692 |

Electronic Unit Injectors for No. 3 and No. 4 Cylinders (4 Pin |

|

Connector) |

P693/J693 |

Electronic Unit Injectors for No. 5 and No. 6 Cylinders (4 Pin |

|

Connector) |

P511 |

Wastegate regulator (if equipped) (2 Pin Connector) |

|

|

This document is printed from SPI². Not for RESALE

KENR6201-01 |

21 |

|

Troubleshooting Section |

|

|

Illustration 7 |

|

|

|

|

g01808033 |

|

|

|

|

|

|

||

(1) Electronic Unit Injector |

(6) |

Primary Speed/Timing Sensor |

(11) Coolant Temperature Sensor |

|||

(2) |

Solenoid for the Fuel Rail Pump |

(7) Intake Manifold Pressure Sensor |

(12) |

Diagnostic Connector (if equipped) |

||

(3) |

Wastegate Regulator (if equipped) |

(8) |

Fuel Rail Pressure Sensor |

(13) |

Electronic Control Module (ECM) |

|

(4) |

Secondary Speed/Timing Sensor |

(9) |

Engine Oil Pressure Sensor |

|

|

|

(5) Fuel Rail Pump |

(10) Intake Manifold Temperature Sensor |

|

|

|||

|

|

|

i03805830 |

Table 6 |

|

|

Engine Wiring Information

Harness Wire Identification

Perkins identifies all wires with eleven solid colors. The circuit number is stamped on the wire at a 25 mm (1 inch) spacing. Table 6 lists the wire colors and the color codes.

Color Codes for the Harness Wire

Color Code |

Color |

Color Code |

Color |

|

|

|

|

BK |

Black |

BU |

Blue |

|

|

|

|

BR |

Brown |

PU |

Purple |

|

|

|

|

RD |

Red |

GY |

Gray |

|

|

|

|

OR |

Orange |

WH |

White |

|

|

|

|

YL |

Yellow |

PK |

Pink |

|

|

|

|

GN |

Green |

|

|

|

|

|

|

This document is printed from SPI². Not for RESALE

22 |

KENR6201-01 |

Troubleshooting Section |

|

For example, a wire identification of F730-OR on the schematic would signify an orange wire with the circuit number F730. F730-OR identifies the power supply for the oil pressure sensor.

Note: Always replace a harness wire with the same gauge of wire and with the same color code.

This document is printed from SPI². Not for RESALE

KENR6201-01 |

23 |

|

Troubleshooting Section |

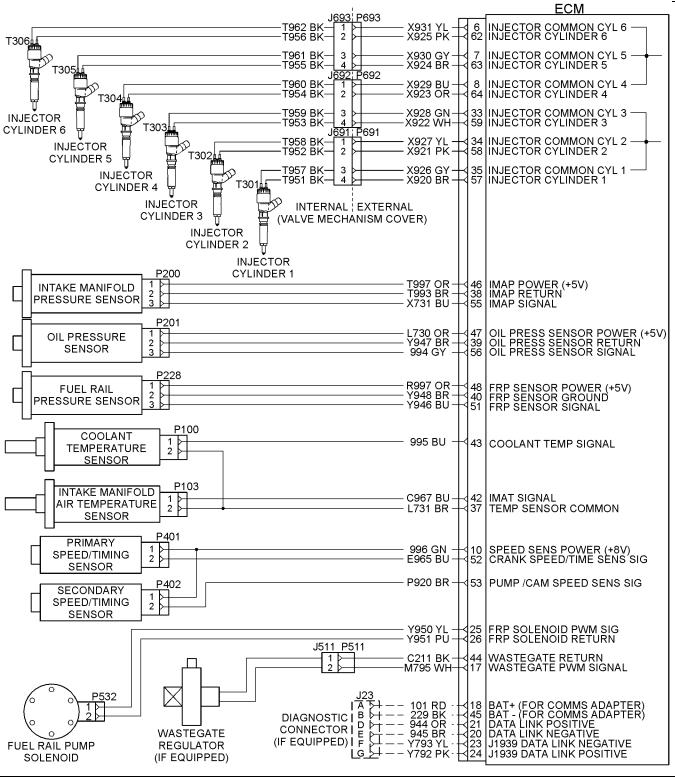

Schematic Diagrams

Illustration 8 |

g01782875 |

|

Schematic Diagram for the Engine Harness

This document is printed from SPI². Not for RESALE

24 |

KENR6201-01 |

Troubleshooting Section |

|

|

|

Illustration 9

Schematic Diagram for a Typical Application

i03434106

ECM Harness Connector Terminals

The Electronic Control Module (ECM) uses connectors that have 64 terminals to interface to the wiring harness.

g02047353

Illustration 10 |

g01784773 |

|

|

Layout of the Connector Pins (view from the rear) |

|

This document is printed from SPI². Not for RESALE

KENR6201-01 |

25 |

|

Troubleshooting Section |

Removal and Installation of the

Harness Connector Terminals

Terminal Removal

Table 7

3.Insert the removal tool into the hole that is adjacent to the terminal in order to release the locking device.

Note: Make sure that the tool stays perpendicular to the face of the connector.

Required Tools

Part Number |

Part Description |

Qty |

|

|

|

27610285 |

Removal Tool |

1 |

|

|

|

|

|

|

Illustration 11 |

g01784793 |

|

|

Removal of Terminal Position Assurance Components |

|

1.Remove the connector from the ECM. Refer to Disassembly and Assembly, “Electronic Control Module - Remove and Install”.

2.Use a screwdriver that has a flat blade (1) to remove the two terminal position assurance components (2) from the connector (3).

Note: Do not use the removal tool to remove the terminal position assurance components.

4.Hold the tool in position and gently pull the wire in order to remove the terminal from the rear of the connector (3).

5.Remove the removal tool from the face of the connector (3).

Note: If a terminal must be replaced, part number 28170085 must be used.

Terminal Insertion

1.Push the terminal into the rear of the connector (3) until the terminal engages with the locking device.

2.Gently pull on the wire in order to make sure that the terminal is retained by the locking device.

3.Install the two terminal position assurance components (2) into the sides of the connector (3).

4.Connect the connector to the ECM. Refer to Disassembly and Assembly, “Electronic Control Module - Remove and Install”.

Illustration 12 |

g01784822 |

|

Removal Tool

This document is printed from SPI². Not for RESALE

26 |

KENR6201-01 |

Troubleshooting Section |

|

Programming Parameters

i02415216

Programming Parameters

The electronic service tool can be used to view certain parameters that can affect the operation of the engine. The electronic service tool can also be used to change certain parameters. The parameters are stored in the Electronic Control Module (ECM). Some of the parameters are protected from unauthorized changes by passwords. Parameters that can be changed have a tattletale number. The tattletale number shows if a parameter has been changed.

Note: “Test ECM Mode” can only be activated if the engine serial number has not already been programmed during normal operation of the ECM. If the engine serial number is programmed and the ECM is not in “Test ECM Mode”, the ECM can never be used as a test ECM.

6.Use the “Copy Configuration” feature on the electronic service tool to program the test ECM.

Note: If the “ECM Replacement” feature can not be used, program the test ECM with the values from the “Customer Specified Parameters Worksheet” and the values from the System Configuration Parameters.

7.Program the engine serial number into the test ECM.

i03434204

Test ECM Mode

“Test ECM Mode” is a feature in the software that can be used to help troubleshoot an engine that may have a fault in the Electronic Control Module (ECM). This feature allows a standard ECM to be used as a test ECM. This feature eliminates the need to stock a test ECM.

1. Search for the latest flash file for the engine.

Note: If a newer software version is available for the engine, install the newest software on the suspect ECM. If the new software does not rectify the fault, continue with this procedure.

2.Use the “Copy Configuration” feature on the electronic service tool to copy the parameters from the suspect ECM.

Note: The “Test ECM Mode” must be activated before the engine serial number is programmed into the ECM.

8. Verify that the test ECM rectifies the fault.

When the “Test ECM Mode” is activated, an internal timer sets a 24 hour clock. This clock will count down only while the ECM is powered and the keyswitch

is in the ON position. After the ECM has counted down the 24 hour period, the ECM will exit the “Test ECM Mode”. The parameters and the engine serial number will be set.

If the test ECM rectifies the fault, the engine can be released while the “Test ECM Mode” is still active.

Once an ECM has been activated in the “Test ECM Mode”, the ECM will stay in the “Test ECM Mode” until the timer times out. If the ECM is used as a test ECM for more than one engine, the “Test ECM Mode” must be reactivated. Anytime prior to the “Test ECM Mode” timing out, the ECM can be reset to 24 hours.

Note: If the “ECM Replacement” feature cannot be used, record the programmed values into the “Customer Specified Parameters Worksheet”. Also record the system configuration parameters.

i03434261

Factory Passwords

3.Disconnect the suspect ECM. Temporarily connect the test ECM to the engine. Do not mount the test ECM on the engine.

4.Flash program the test ECM with the newest software that is available.

5.Start the “Test ECM Mode” on the electronic service tool. Access the feature through the “Service” menu. The electronic service tool will display the status of the test ECM and the hours that are remaining for the “Test ECM Mode”.

NOTICE

Operating the engine with a flash file not designed for that engine will damage the engine. Be sure the flash file is correct for your engine.

Note: Factory passwords are provided only to Perkins dealers.

Factory passwords are required to perform each of the following functions:

This document is printed from SPI². Not for RESALE

KENR6201-01 |

27 |

|

Troubleshooting Section |

•Program a new Electronic Control Module (ECM).

When an ECM is replaced, the system configuration parameters must be programmed into the new ECM. A new ECM will allow these parameters to be programmed once without factory passwords. After the initial programming, some parameters are protected by factory passwords.

•Rerate the engine.

This may require changing the interlock code, which is protected by factory passwords.

•Clear engine events and certain diagnostic codes.

Most engine events require factory passwords in order to clear the code from ECM memory. Clear these codes only when you are certain that a fault has been rectified. For example, the E362-1 Engine Overspeed requires the use of factory passwords in order to clear the code from ECM memory.

Since factory passwords contain alphabetic characters, the electronic service tool must be used to perform these functions. In order to obtain factory passwords, proceed as if you already have the password. If factory passwords are needed, the electronic service tool will request the factory passwords and the electronic service tool will display the information that is required to obtain the passwords.

i03807230

Flash Programming

Flash Programming – A method of loading a flash file into the Electronic Control Module (ECM)

The electronic service tool can be utilized to program a flash file into the ECM. The programming transfers the flash file from the PC to the ECM.

Flash Programming a Flash File

1. Obtain the part number for the new flash file.

Note: If you do not have the part number for the flash file, use “PTMI” on the Perkins Intranet.

Note: You must have the engine serial number in order to search for the part number for the flash file.

2.Connect the electronic service tool to the service tool connector.

3.Turn the keyswitch to the ON position. Do not start the engine.

4.Select “WinFlash” from the “Utilities” menu on the electronic service tool.

Note: If “WinFlash” will not communicate with the ECM, refer to Troubleshooting, “Electronic Service Tool Will Not Communicate with ECM”.

5.Program the flash file into the ECM.

a.Select the engine ECM under the “Detected ECMs”.

b.Press the “Browse” button in order to select the part number of the flash file that will be programmed into the ECM.

c.When the correct flash file is selected, press the “Open” button.

d.Verify that the “File Values” match the application. If the “File Values” do not match the application, search for the correct flash file.

e.When the correct flash file is selected, press the “Begin Flash” button.

f.The electronic service tool will indicate when programming has been successfully completed.

6.Start the engine and check for proper operation.

7.Access the “Configuration” screen under the “Service” menu in order to determine the parameters that require programming. Look under the “Tattletale” column. All of the parameters should have a tattletale of 1 or more. If a parameter has a tattletale of 0, program that parameter.

“WinFlash” Error Messages

If you receive any error messages during programming, click on the “Cancel” button in order to stop the process. Access the information about the “ECM Summary” under the “Information” menu. Ensure that you are programming the correct flash file for your engine.

i03818309

Injector Trim File

The electronic service tool is used to load the injector trim files into the Electronic Control Module (ECM).

The injector trim files must be loaded into the ECM if any of the following conditions occur:

• An electronic unit injector is replaced.

This document is printed from SPI². Not for RESALE

28 |

KENR6201-01 |

Troubleshooting Section |

|

•The ECM is replaced.

•Diagnostic code 268-2 is active.

•Electronic unit injectors are exchanged between cylinders.

Exchanging Electronic Unit Injectors