Perkins Engine 1300 Service Manual

Perkins

Product

Training

1300 Edi Series

Electronic Engine Training

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

Please Note:

zThe Product Training information is distributed for informational purposes only. It is not to be construed as creating or becoming part of Perkins Engines contractual or warranty obligations.

zThe appropriate service literature and ‘Service Bulletins’ available on www.perkins.com should always be the final authority and source of information.

zElectrical Circuits, connections and termination points may change, make sure you have the correct drawings.

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

‘Off Road’ Emissions Legislation

Tier 0

"A" rated engines can be used in regions without Emissions Legislation.

Tier 1

"B" rated engines are suitable for regions with Tier 1/Stage I Emissions Legislation

Tier 2

"C" rated engines are suitable for regions with Tier 2/Stage II Emissions Legislation.

Tier 3

"D" rated engines are suitable for regions with Tier 3/Stage III Emissions Legislation.

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

‘Off Road’ Industrial - Ever Cleaner Engines

|

0.50 |

|

|

|

|

|

|

|

0.45 |

|

|

|

|

|

|

|

0.40 |

|

Tier 3: 56≤kW<75 |

|

|

|

|

|

|

|

|

|

|

1980’s |

|

|

0.35 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PM |

0.30 |

|

Tier 3: 75≤kW<130 |

|

|

|

Particulate Matter |

|

|

|

|

|

|||

(g/kWh) |

|

|

|

|

|

|

(PM) 0.6g/kWh |

|

0.25 |

|

|

|

|

|

|

|

0.20 |

|

Tier 3: 130≤kW<560 |

|

|

|

|

|

|

|

|

|

|

Nitrous Oxide |

|

|

0.15 |

Tier 4B: 56≤kW<560 |

|

|

|

||

|

|

|

|

(NOx) 10.00g/kWh |

|||

|

0.10 |

|

Tier 4A: 56≤kW<130 |

|

|

||

|

Tier 4A: 130≤kW<560 |

|

|

|

|

||

|

|

|

|

|

|

||

|

0.05 |

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

0 |

1 |

2 |

3 |

4 |

5 |

6 |

|

|

|

NOx; NOx + HC (g/kWh) |

|

|

|

|

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

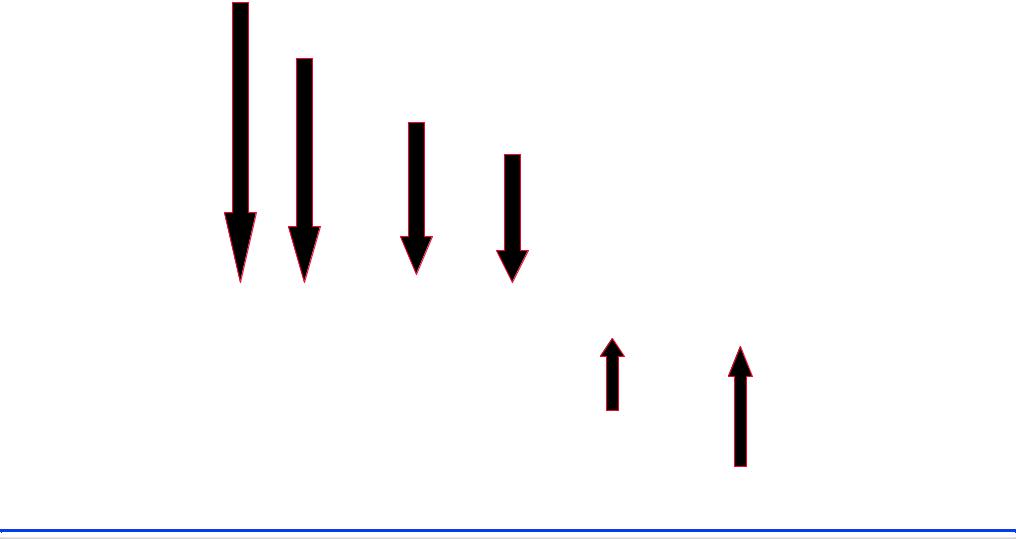

Electronic Engine Benefits

Electronic Engine Management system gives:

zImproved Specific Fuel Consumption (SFC) through precise control of Injection Timing and Duration.

zMachine protection under extreme operating conditions.

zEasy servicing and fault diagnostics, Electronic Service Tool, (EST)

zExceeds emissions legislation and has a lower noise level.

zBetter engine ‘responsiveness’.

zImproved reliability,engine monitoring and protection.

zFurther cost savings through integration into ‘Genset' design (CAN)

zImproved torque, different torque curves available, torque ‘shaping’

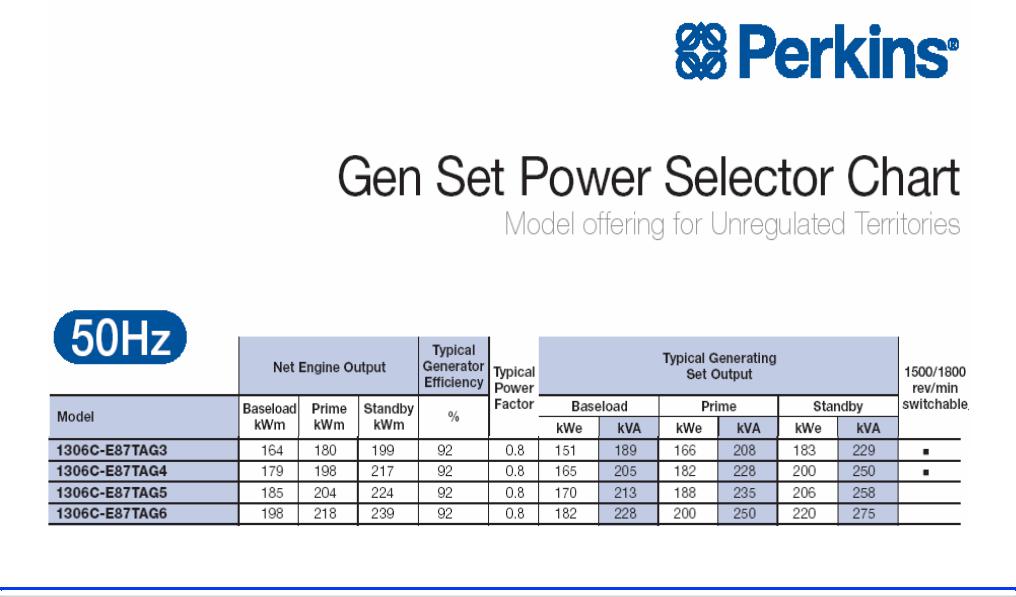

zRating changes available, Base Load, Prime, Standby, 1500/1800

zConfiguration files, gives the customer flexibility, droop, etc

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

z

z

z

Electronics gives control! It needs a good flow of ; Clean Air and Fuel.

Also needs Compression!

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

1300 Edi Series-Industrial Open Power Unit

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

1300 Edi Series-Industrial Open Power Unit

zIOPU 1 -Variable Speed Droop, with analogue throttle and Idle validation switch. (mobile applications)

zIOPU 2 - Variable Speed Isochronous with analogue hand throttle, (no IVS - non Mobile Applications)

zIOPU 3 - Variable Set Speed Isochronous Control.

zIOPU 4 - With Pre-Set Speed Isochronous Control.

z12 Volt and 24 Volt ECM’s available.

If you are not sure of the voltage and markings have been removed check PIN 35 to ground 1.4K Ohms – 12 volts / 2.8K Ohms – 24 volts.

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

1300 Edi Series-Electropack

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

1300 Edi Series-Electropack

z 1500/50 Hertz, can be wired 3 ways,

(auto or manual, (load share) or stand alone, (isochronous)

z 1800/60Hertz, can be wired 3 ways

(auto or manual, (load share) or stand alone, (isochronous)

z 1500/1800 Switchable, can be wired 2 ways

1500 or 1800, Isochronous Only

z 12 Volt and 24 Volt ECM’s available.

If you are not sure of the voltage and the markings have been removed check PIN 35 to ground 1.4K Ohms – 12 volts / 2.8K Ohms – 24 volts.

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

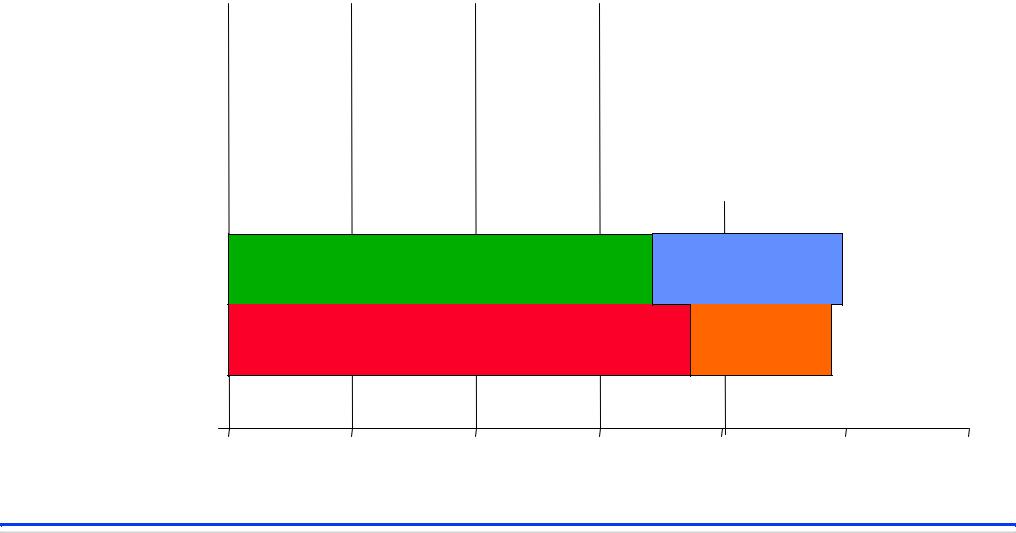

2 Ratings

1306-E87T

1 Rating

6 Ratings

1306-E87TA

4 Ratings

Gen Set Power Range

|

|

149.0 |

- 160.5 kW |

|

|

|

WR4410/WR4411 |

|

|

|

@ 1500 rev/min |

|

|

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

171.5 kW |

|

|

|

WR4412 |

|

|

|

@ |

1800 rev/min |

|

|

|

||

|

|

|

|

|

|

|

|

|

172.0- 246 kW

@1500 rev/min

186.0- 242.5 kW @ 1800 rev/min

WS4413/WS4418

WS4419/WS4422

0 |

50 |

100 |

150 |

200 |

250 |

300 |

Max Gross Standby Ratings

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

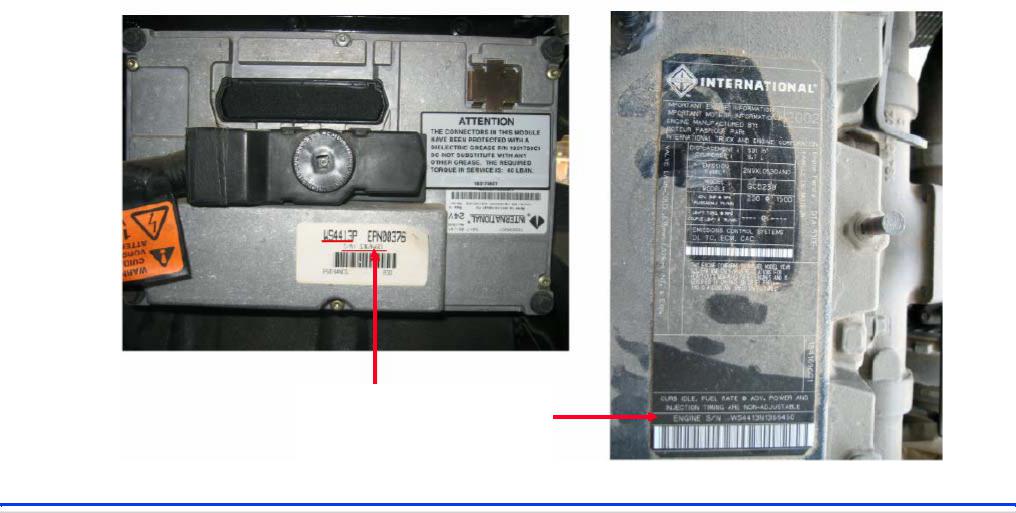

Engine Identification

zEngine Type

Engine Family

Build List Number

Country of Origin

W P 12345N 654321G

Serial Number

Year of Manufacture

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

Engine Identification

Engine Serial Number

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

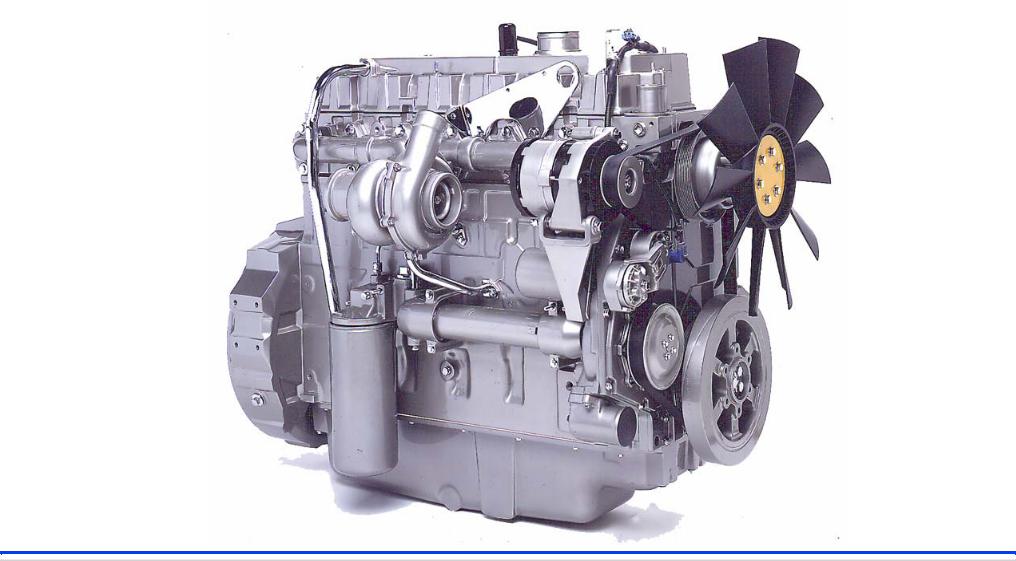

Engine Identification

1306.E87TA

After cooled Turbo charged

8.7 Litre Electronic

6 Cylinder

1300 Series

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

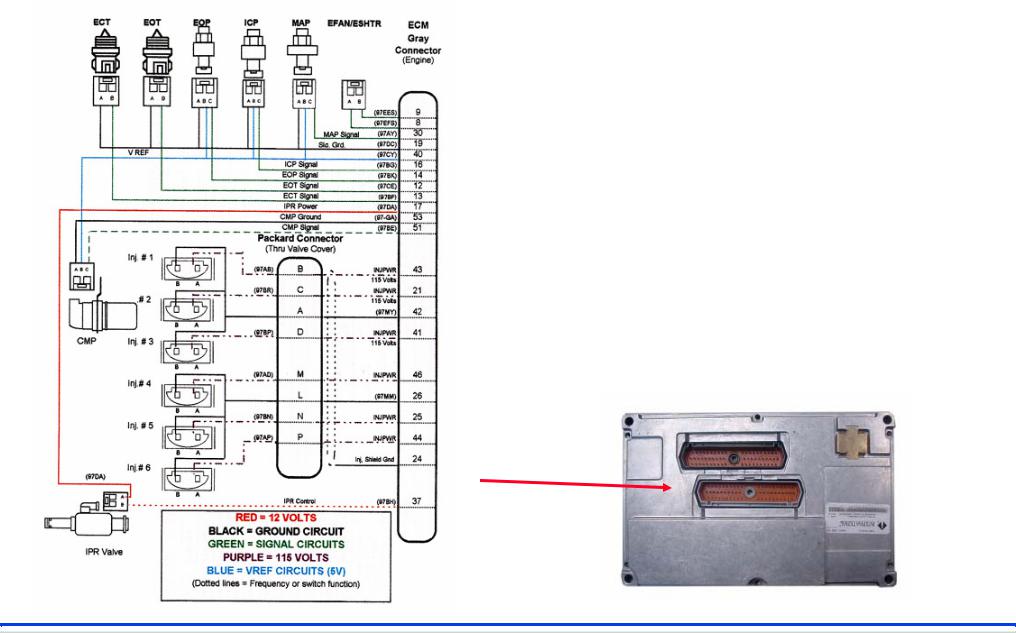

1300 Edi Engine Sensors

On Engine (Gray Connector)

zEngine Coolant Temperature. (ECT)

zEngine Oil Temperature. (EOT)

zManifold Absolute Pressure. (MAP)

zEngine Oil Pressure. (EOP)

zCamshaft Motion Pickup. (CMP)

zInjection Control Pressure (ICP)

z z

Off Engine (Black Connector)

Inlet Air Temperature. (IAT)

Barometric Pressure. (Baro)

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

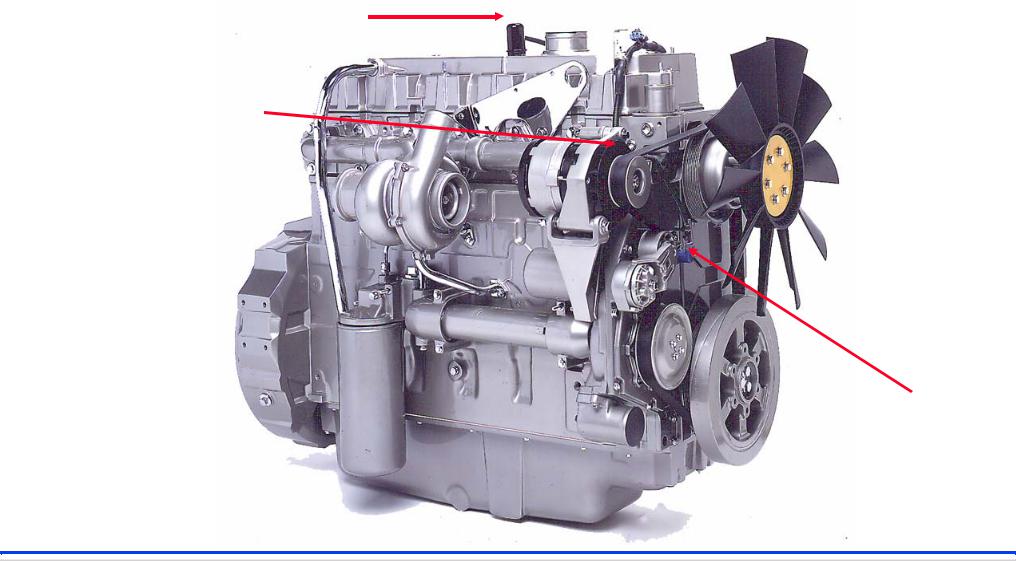

1300 Edi Series Sensor Layout

Manifold Absolute Pressure (MAP)

Engine Coolant

Temperature (ECT)

Camshaft Motion

Pickup (CMP)

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

1300 Edi Series Sensor Layout

Injection Control Pressure

OEM/Customer

Connection

All On-Engine

Connections

Engine Oil Temperature |

Engine Oil |

|

Pressure |

||

|

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

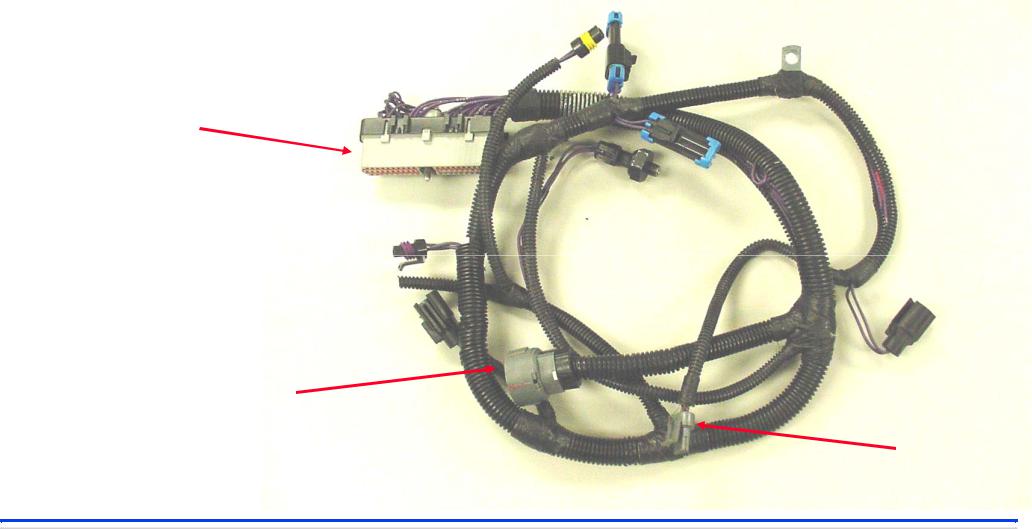

Typical 1300 Edi ‘On Engine’ Wiring Harness

Gray ECM Connector

‘Packard’ 20 pin Injector Plug

Camshaft Motion Pickup Plug

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

‘On Engine’ Connections

(Gray Connector)

zThe injector solenoids are controlled by a 110v DC.pulse.

(110 Volt DC is a dangerous voltage)

zPressure Sensors and Cam Motion Pickup require 5 volt dc.

zThe Injection Pressure Regulator Valve requires a Pulse Width Modulated (PWM) signal.

All ‘On Engine’

Connections

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

1300 Edi Series ‘On Engine’ Wiring Harness

zThe Harness is protected by a plastic tubing.

zIt is mechanically fixed to the engine via clips, to keep the harness secure and away from potential damage.

zAll connectors are ‘keyed’ to ensure correct orientation.

zMake sure all seals are correctly positioned. Blanking plugs must be fitted on any unused pins, to prevent any liquid ingress.

(SPECIAL PowerPart grease is recommended for ECM Plug)

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

1300 Edi Series ‘On Engine’ Wiring Harness

zWe have a very ‘Fault Tolerant’ extremely reliable system. Inevitably after many years service, faults may occur.

zTraditionally, if the problem is ‘Electrical’, wiring / connectors are most likely to be the cause.

zShorts / open circuits / high resistance connections, can be caused by any combination of corrosion / abrasion / burning / vibration / fatigue and ‘liquid ingress’.

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

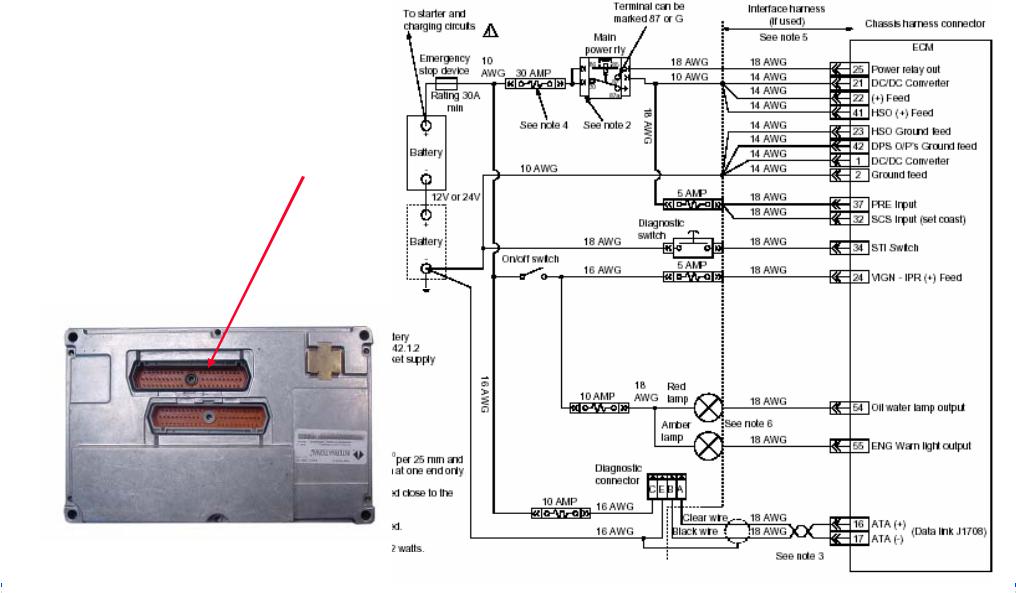

OEM/Customer Typical Connections

(Black Connector)

All OEM/Customer

Connections

|

|

|

|

|

|

|

|

|

Product Training Sept 2004 |

|

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

|

OEM/Customer side, Connections

zAll Battery Positive and Negative connections to the ECM, should be connected to prevent Voltage drop.

zIt is important that ECM power cables be connected directly to battery Positive and Negative –

zCorrect cable sizes and fuses, should be always be used.

zMake sure of the current rating of the power relay contacts.

zProtect against ‘back EMF’ by installing a diode across relay

zInstall 6 pin Deutsch Diagnostic Connector, for Communications.

zInstall warning lamps, Amber/Red and Diagnostics push button

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

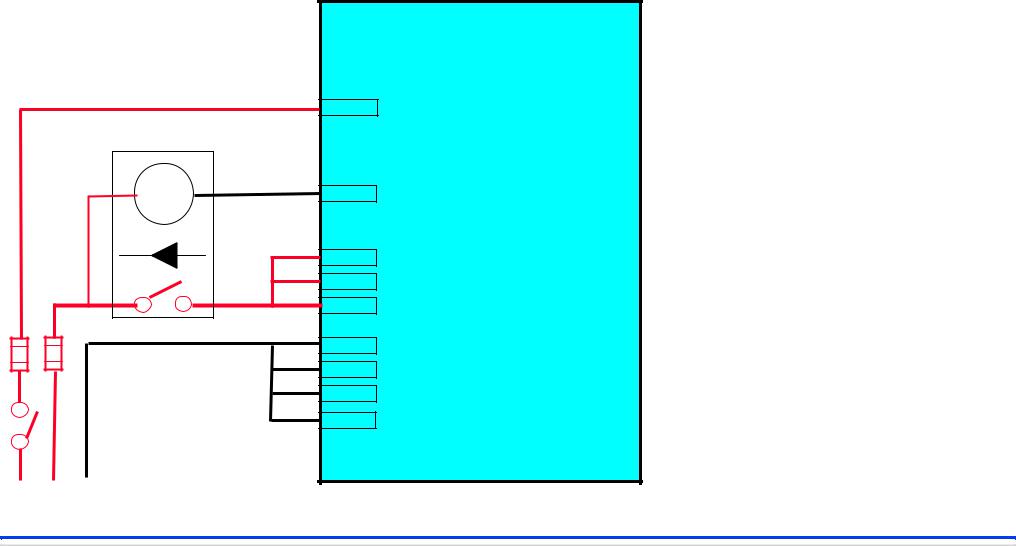

Minimum Connections, to run a 1300 Series

Customer Connections |

|

|

|

CONTROL |

|||

|

|

|

|

|

|

|

E C M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+-

ECM Power Supply,

12/24 v

Note.

We do suggest that a connection is made to Service Tool to allow Communication with The ECM via the ATA

For Example 16 ATA + 17 ATA - + on pin C

- on pin E

Alternative:

SAE J1939. 18 CAN Screen

19 CAN High +

20 CAN Low –

(minimal information)

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

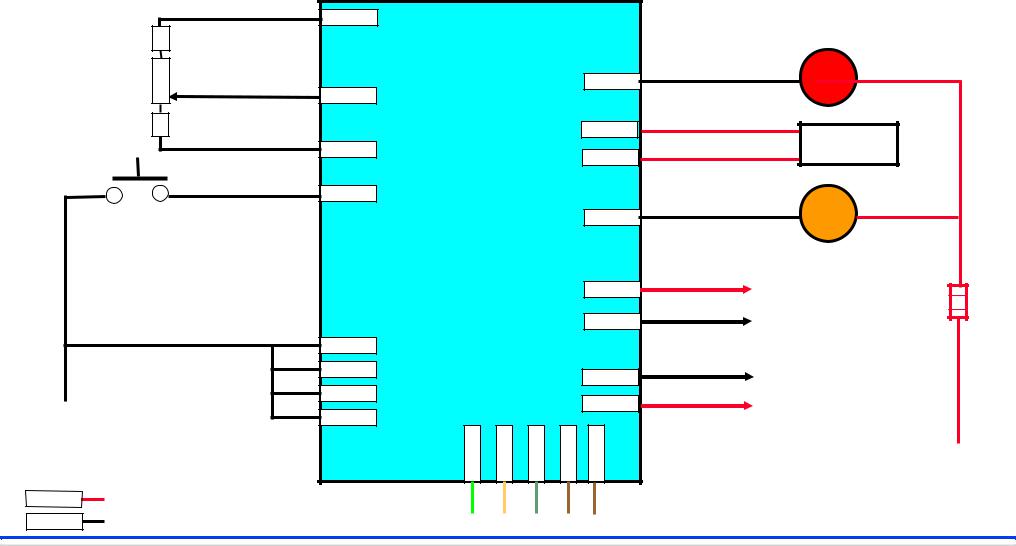

Some Typical Connections - 1300 Series ECM

INPUTS |

|

|

OUTPUTS |

|

CONTROL |

Red Lamp |

|

Analogue |

E C M |

||

Speed Adjust |

|

|

|

Diagnostics |

|

|

IPR Valve |

|

Amber Lamp |

||

|

|

||

|

|

+ |

5 volt Pressure |

|

|

|

|

|

|

- |

Sensors |

|

|

|

|

- |

|

- |

110 volt |

|

|

||

|

|

Injectors 3 |

|

ECM Power Supply, |

|

+ |

|

|

|

||

12/24 v |

|

|

+ |

|

|

|

|

+

-

Communications Adapter

12/24 v

ATA J1939-CAN

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

Connectors

zAlways use high quality connectors. (Gold/Nickel Plated)

zKeep connections to a minimum.

zMake sure all rubber seals are correctly fitted.

zRemember…

‘BAD’ CONNECTIONS CAUSE RESISTANCE!

RESISTANCE CAUSES VOLTAGE DROP!

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

Effects of ‘Bad’ (Resistance) Connections

‘P’ Plug |

‘J’ Jack |

24v dc |

Possible ‘Bad’ Connections |

Lamp 24v dc |

Has the same effect as….Resistances in circuit

1 volt |

2 volt |

Don’t forget all connections!

24v dc |

Resistors |

Lamp 19.9v dc |

Don’t forget all connections!

0.1 volt |

1 volt |

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

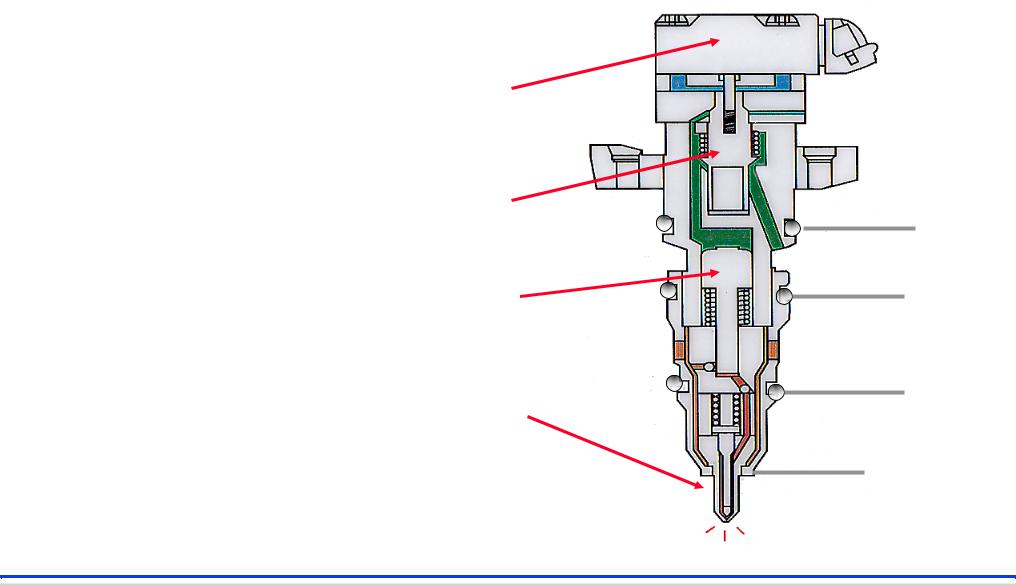

HYDRAULICALLY ACTUATED

ELECTRONICALLY CONTROLLED

UNIT

INJECTION

zHEUI is the fuel system used in place of the mechanical high pressure fuel injection pump and nozzles

zHydraulically actuated using High Pressure Engine lubrication oil as power medium

zInjection controlled by an 110 volt electrical solenoid

zSolenoid controlled by Electronic Control Module (ECM)

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

H.E.U.I. Injector

110 volt Solenoid

Enables control of: |

Poppet Valve |

||

|

|

||

z |

Injection Pressure |

High Pressure |

|

Engine Oil |

|||

z |

Injection Rate |

Intensifier Piston |

|

Fuel |

|||

z |

Injection Timing |

Injection Nozzle |

|

Coolant |

|||

|

|

||

Product Training Sept 2004 |

@Perkins |

Proprietary Information of Perkins Engines Company Limited 2004 - All Rights Reserved |

|

Loading...

Loading...