Perkins Engine 1300EDi Service Manual

TPD1352E, Issue 4

November 2011

User’s

Handbook

1300 Series EDi

WK

WL

WM

WN

WP

WQ

WR

WS

Thispublication iswritten in

PerkinsApproved Clear English

This publication is divided into six chapters:

1General information

2Engine views

3Operation instructions

4Preventive maintenance

5Engine fluids

6Fault diagnosis

The following pages contain a detailed table of contents

ii

1300 Series EDi Models WK to WS

Contents

1 General information

Introduction . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 1 Safety precautions .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 2 How to care for your engine ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 3 Engine preservation ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 4 Parts and service ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 5 Training ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 5 Service literature . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 5 Engine identification ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 6 Engine data . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 8

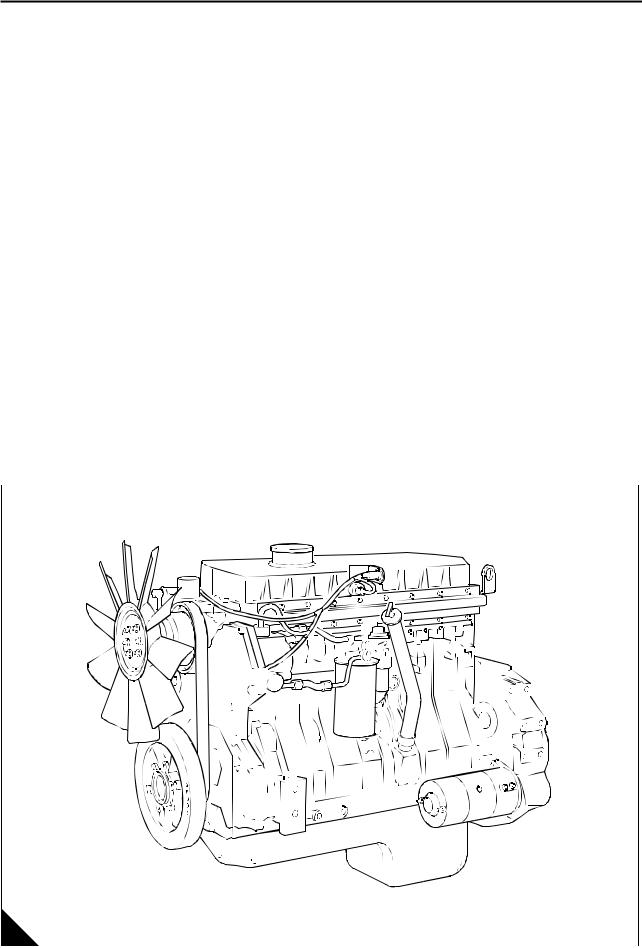

2 Engine views

Introduction . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 11 Location of engine parts .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 11

3 Operation instructions

How to start the engine ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 13 How to start an engine with an ether start system .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 15

How to stop the engine ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 16

Adjustment of engine speed range . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 16 Engine operation at idle speed ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 16

Running-in ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 16 Altitude ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 16

User’s Handbook, TPD 1352E, issue 3 |

iii |

1300 Series EDi Models WK to WS

4 Preventive maintenance

Preventive maintenance periods . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 17

Schedules ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 18

How to drain the cooling system .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 19 How to fill the cooling system .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 20

How to renew the canister of the coolant filter / inhibitor . ... ... ... ... ... ... ... ... ... ... ... ... 21

How to check the drive belt . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 22 How to remove the drive belt ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 22

Fuel pre-filter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 23

How to renew the fuel strainer and the canister of the fuel filter .. ... ... ... ... ... ... ... ... ... 23 How to eliminate air from the fuel system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 24

How to renew the lubricating oil ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 25

How to renew the canister of the lubricating oil filter ... ... ... ... ... ... ... ... ... ... ... ... ... ... 26

Air filter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 27 Restriction indicator . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 27 How to set the valve tip clearances . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 28

5 Engine fluids

Fuel specification . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 29 Lubricating oil specification .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 30 Coolant specification ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 31

6 Fault diagnosis |

|

Problems and possible causes ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... |

33 |

List of possible causes ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... |

34 |

iv |

User’s Handbook, TPD 1352E, issue 3 |

1300 Series EDi Models WK to WS

1

General information

Introduction

The 1300 Series EDi is a family of engines which have an electronic management system. The engines are designed for industrial and agricultural applications from Perkins Engines Limited, a world leader in the design and manufacture of high-performance diesel engines.

Perkins approved assembly and quality standards, together with the latest technology, have been applied to the manufacture of your engine to give you reliable and economic power.

Note: To ensure that you use the relevant information for your specific engine type, refer to "Engine identification" on page 6.

Danger is indicated in the text by two methods:

Warning! This indicates that there is a possible danger to the person. Caution: This indicates that there is a possible danger to the engine.

Note: Is used where the information is important, but there is not a danger.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

W251/1 |

||||||||||||||||||||||||||||||||||||||||

User’s Handbook, TPD 1352E, issue 4 |

1 |

1 |

1300 Series EDi Models WK to WS |

Safety precautions |

|

These safety precautions are important.

You must refer also to the local regulations in the country of use. Some items only apply to specific applications.

zOnly use these engines in the type of application for which they have been designed.

zDo not change the specification of the engine.

zDo not smoke when you put fuel in the tank.

zClean away fuel which has been spilt. Material which has been contaminated by fuel must be moved to a safe place.

zDo not put fuel in the tank while the engine runs (unless it is absolutely necessary).

zDo not clean, add lubricating oil, or adjust the engine while it runs (unless you have had the correct training; even then extreme caution must be used to prevent injury).

zDo not make adjustments that you do not understand.

zEnsure that the engine does not run in a location where it can cause a concentration of toxic emissions.

zOther persons must be kept at a safe distance while the engine or auxiliary equipment is in operation.

zDo not permit loose clothing or long hair near moving parts.

zKeep away from moving parts during engine operation.

Warning! Some moving parts cannot be seen clearly while the engine runs.

zDo not operate the engine if a safety guard has been removed.

zDo not remove the filler cap or any component of the cooling system while the engine is hot and while the coolant is under pressure, because dangerous hot coolant can be discharged.

zDo not use salt water or any other coolant which can cause corrosion in the closed coolant circuit.

zDo not allow sparks or fire near the batteries (especially when the batteries are on charge) because the gases from the electrolyte are highly flammable. The battery fluid is dangerous to the skin and especially to the eyes.

zDisconnect the battery terminals before a repair is made to the electrical system.

zOnly one person must control the engine.

zEnsure that the engine is operated only from the control panel or from the operator's position. Discard used lubricating oil in a safe place to prevent contamination.

zEnsure that the control lever of the transmission drive is in the "out-of-drive" position before the engine is started.

zThe combustible material of some components of the engine (for example certain seals) can become extremely dangerous if it is burned. Never allow this burnt material to come into contact with the skin or with the eyes.

zDiesel fuel and lubricating oil (especially used lubricating oil) can damage the skin of certain persons. Protect your hands with gloves or a special solution to protect the skin.

zDo not wear clothing which is contaminated by lubricating oil. Do not put material which is contaminated with oil into the pockets of clothing.

zDiscard used lubricating oil in accordance with local regulations to prevent contamination.

zUse extreme care if emergency repairs must be made in adverse conditions.

Continued

2 |

User’s Handbook, TPD 1352E, issue 4 |

1300 Series EDi Models WK to WS |

1 |

zAlways use a safety cage to protect the operator when a component is to be pressure tested in a container of water. Fit safety wires to secure the plugs which seal the hose connections of a component which is to be pressure tested.

zDo not allow compressed air to contact your skin. If compressed air enters your skin, obtain medical help immediately.

zTurbochargers operate at high speed and at high temperatures. Keep fingers, tools and debris away from the inlet and outlet ports of the turbocharger and prevent contact with hot surfaces.

zThe fuel injector units of this engine are controlled electronically by a pulse of 110 volts.

zThe fuel injector units are actuated by high-pressure engine lubricating oil. Do not remove any component of the high-pressure system while the engine oil is under pressure, because dangerous oil can be discharged.

zFit only genuine Perkins parts.

How to care for your engine

This handbook has been written to assist you to maintain and operate your engine correctly.

To obtain the best performance and the longest life from your engine, you must ensure that the maintenance operations are done at the intervals indicated in Chapter 4, Preventive maintenance. If the engine works in a very dusty environment or other adverse conditions, certain maintenance intervals will have to be reduced.

Renew the filter canisters and lubricating oil regularly in order to ensure that the inside of your engine remains clean.

Ensure that all adjustments and repairs are done by personnel who have had the correct training. Perkins distributors have this type of personnel available. You can also obtain parts and service from your Perkins distributor.

The terms "left side" and "right side" apply when the engine is seen from the flywheel end.

Warning! Read the "Safety precautions" on page 2 and remember them. They are given for your protection and must be applied at all times.

User’s Handbook, TPD 1352E, issue 4 |

3 |

1 |

1300 Series EDi Models WK to WS |

Engine preservation |

|

Introduction

The recommendations indicated below are designed to prevent damage to the engine when it is withdrawn from service for a prolonged period. Use these procedures after the engine is withdrawn from service.

Procedure

Caution: The procedure for this engine is different to the procedure for other Perkins engines, because of the design of the fuel injection units.

1Completely clean the outside of the engine.

2Operate the engine until it is warm. Stop the engine and drain the lubricating oil from the sump. Ensure that the oil gallery of the high-pressure lubrication system is drained.

Caution: If the gallery is not drained, the engine cylinders will be filled with engine lubricating oil when the fuel injector units are removed.

3 Drain the fuel supply gallery, fitted to the cylinder head.

Caution: If the gallery is not drained, the engine cylinders will be filled with fuel when the fuel injector units are removed.

4Renew the canister of the lubricating oil filter, see "How to renew the canister of the lubricating oil filter" on page 26.

5Fill the sump to the full mark on the dipstick with new and clean lubricating oil. Use a correct preservative fluid instead of the lubricating oil. If a preservative fluid is used, this must be drained and the lubricating oil sump must be filled to the correct level with normal lubricating oil at the end of the storage period.

6Drain the coolant circuit, see "How to drain the cooling system" on page 19. In order to protect the cooling system against corrosion, fill it with an approved antifreeze mixture because this gives protection against corrosion.

Caution: If protection against frost is not necessary and a corrosion inhibitor is to be used, it is recommended that you consult the Technical Service Department, Perkins Engines Company Limited, Peterborough.

7Connect the battery, eliminate air from the fuel system. Operate the engine for a short period in order to circulate the lubricating oil and the coolant in the engine. Then correct leakages of fuel, lubricating oil or air.

8Disconnect the battery. Then put the battery into safe storage in a fully charged condition. Before the battery is put into storage, protect its terminals against corrosion.

9Remove the air filter. Then, if necessary, remove the pipe(s) installed between the air filter and the turbocharger. Seal the air inlet to the turbocharger with waterproof tape.

Continued

4 |

User’s Handbook, TPD 1352E, issue 4 |

1300 Series EDi Models WK to WS |

1 |

10Remove the exhaust pipe. Seal the manifold or the turbocharger with waterproof tape.

11Clean the engine breather pipe and seal the end of the pipe.

12When a preservative fuel is to be used, drain the fuel system and fill it with the preservative fuel. If preservative fuel is not used, the system can be completely filled with normal fuel but the fuel must be drained and discarded at the end of the storage period together with the fuel filter canister.

13Remove the drive belts and put them into storage.

14Seal the vent pipe of the fuel tank or the fuel filler cap with waterproof tape.

Every month, the crankshaft must be rotated in order to change the spring loading on the valve train. Rotate the crankshaft more than 180 degrees. Visibly check for damage or corrosion to the engine.

If the engine protection is done correctly according to the above recommendations, no corrosion damage will normally occur. Perkins are not responsible for damage which may occur when an engine is in storage after a period in service.

Parts and service

If problems occur with your engine or with the components fitted onto it, your Perkins distributor can make the necessary repairs and will ensure that only the correct parts are fitted and that the work is done correctly.

Training

Local training for the correct operation, service and overhaul of engines is available at certain Perkins distributors. If special training is necessary, your Perkins distributor can advise you how to obtain it at the Perkins Customer Training Department, Peterborough, or other main centres.

Service literature

Workshop manuals, installation drawings and other service publications are available from your Perkins distributor at a nominal cost.

User’s Handbook, TPD 1352E, issue 4 |

5 |

1 |

1300 Series EDi Models WK to WS |

Engine identification |

|

The 1300 Series EDi engines consist of a range of six cylinder in-line engines which are turbocharged or turbocharged/intercooled. The engines have an electronic management system.

In this handbook, the different engine types are indicated by their code letters, which are the first two letters of the engine number as indicated in table 1.

|

|

|

|

Table 1 |

Code letters |

Capacity |

|

Aspiration system |

|

Litre |

|

in3 |

||

|

|

|

||

WK |

7,6 |

|

466 |

Turbocharged |

|

|

|

|

|

WL |

7,6 |

|

466 |

Turbocharged / intercooled |

|

|

|

|

|

WM |

8,6 |

|

531 |

Turbocharged |

|

|

|

|

|

WN |

8,6 |

|

531 |

Turbocharged / intercooled |

|

|

|

|

|

WP |

7,6 |

|

466 |

Turbocharged |

|

|

|

|

|

WQ |

7,6 |

|

466 |

Turbocharged / intercooled |

|

|

|

|

|

WR |

8,6 |

|

531 |

Turbocharged |

|

|

|

|

|

WS |

8,6 |

|

531 |

Turbocharged / intercooled |

|

|

|

|

|

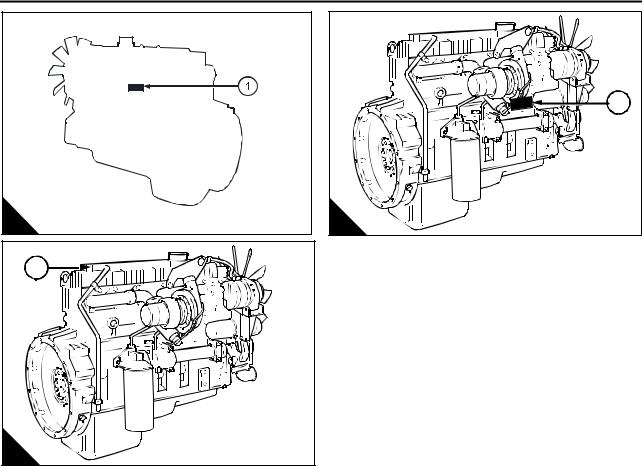

The engine number is stamped on the left side of the cylinder block (A1) on the earliest engines, behind the high pressure pump. On later engines, the engine number is located at position (B1). On the current engine, the identification plate is located on the top cover of the engine (C1).

An example of an engine number is WP1296N1234567. The components of the engine number are as follows: WP = Type code letters

1296 = Build list number N = Built in the USA

1234567 = Engine serial number

Certain engines built after 4th January 2010 use a different engine number format. An example of the engine number in the different engine format is WGBF1296N12345U.

The components of the engine number are as follows: W = Engine series

G = Application B = Engine type

F = Number of cylinders 1296 = Build list number N = Built in the USA

123456U = Engine serial number

If you need parts, service or information for your engine, you must give the complete engine number to your Perkins distributor.

6 |

User’s Handbook, TPD 1352E, issue 4 |

1300 Series EDi Models WK to WS |

|

|

1 |

|

|

|

1 |

A |

W002 |

B |

PW250/1 |

1 |

|

|

|

C

User’s Handbook, TPD 1352E, issue 4 |

7 |

1 |

1300 Series EDi Models WK to WS |

Engine data |

|

Number of cylinders ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..6 Cylinder arrangement ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. In line Cycle .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..Four stroke Induction system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Turbocharged or Turbocharged/intercooled Combustion system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Direct injection

Nominal bore:

- WK and WL.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 109,2 mm (4.301 in) - WM, WN, WP, WQ, WR and WS. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 116,6 mm (4.590 in)

Stroke:

- WK, WL , WP and WQ ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 118,9 mm (4.681 in) - WM, WN, WR and WS. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 135,9 mm (5.350 in) Compression ratio.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..16.5:1

Cubic capacity:

- WK, WL , WP and WQ. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 7,64 litres (466.4 in3)

- WM, WN, WR and WS. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 8,71 litres (531.0 in3) Firing order. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..1, 5, 3, 6, 2, 4

Valve tip clearances (cold):

- Inlet and exhaust . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,64 mm (0.025 in) Lubricating oil pressure (minimum):

- Idle ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..137 kPa (20 lbf in2) 1,4 kgf/cm2 - maximum engine speed and normal engine temperature ... ... ... ... ... ... ... ..276 kPa (40 lbf/in2) 2,8 kgf/cm2 Capacity of a typical lubricating oil sump (1):

- Without filter canister ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 22,7 litres (40.0 UK pints) 24 US quarts - With filter canister ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 28,3 litres (49.9 UK pints) 28 US quarts Typical coolant capacity (engine only) ... ... ... ... ... ... ... ... ... ... ... .. 12,8 litres (22.5 UK pints) 13,5 US quarts Direction of rotation ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . Clockwise from the front

(1) The capacity of the sump may vary according to the application. Fill to the "Full" mark on the dipstick. Do not exceed the "Full" mark.

8 |

User’s Handbook, TPD 1352E, issue 4 |

Loading...

Loading...