Perkins Engine 1100 Service Manual

PERKINS TIER 2 DIESEL

ENGINES

1100 (VK)

H8.00-12.00XM (H170-280HD) [F007, G007];

H13.00-16.00XM (H300-360HD) [E019, F019]; H10.00-12.00XM-12EC (H360HD-EC) [E019, F019]

PART NO. 1541323 |

|

600 SRM 1068 |

|

SAFETY PRECAUTIONS

MAINTENANCE AND REPAIR

•When lifting parts or assemblies, make sure all slings, chains, or cables are correctly fastened, and that the load being lifted is balanced. Make sure the crane, cables, and chains have the capacity to support the weight of the load.

•Do not lift heavy parts by hand, use a lifting mechanism.

•Wear safety glasses.

•DISCONNECT THE BATTERY CONNECTOR before doing any maintenance or repair on electric lift trucks. Disconnect the battery ground cable on internal combustion lift trucks.

•Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT THE LIFT TRUCK ON BLOCKS in the Operating Manual or the Periodic Maintenance section.

•Keep the unit clean and the working area clean and orderly.

•Use the correct tools for the job.

•Keep the tools clean and in good condition.

•Always use HYSTER APPROVED parts when making repairs. Replacement parts must meet or exceed the specifications of the original equipment manufacturer.

•Make sure all nuts, bolts, snap rings, and other fastening devices are removed before using force to remove parts.

•Always fasten a DO NOT OPERATE tag to the controls of the unit when making repairs, or if the unit needs repairs.

•Be sure to follow the WARNING and CAUTION notes in the instructions.

•Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel are flammable. Be sure to follow the necessary safety precautions when handling these fuels and when working on these fuel systems.

•Batteries generate flammable gas when they are being charged. Keep fire and sparks away from the area. Make sure the area is well ventilated.

NOTE: The following symbols and words indicate safety information in this manual:

WARNING

WARNING

Indicates a condition that can cause immediate death or injury!

CAUTION

Indicates a condition that can cause property damage!

Perkins Tier 2 Diesel Engines |

Table of Contents |

TABLE OF CONTENTS |

|

General ................................................................................................................................................................. |

1 |

General Safety Rules....................................................................................................................................... |

1 |

Description ........................................................................................................................................................... |

2 |

Engine Serial Number Codes.......................................................................................................................... |

4 |

Engine Data ..................................................................................................................................................... |

4 |

Engine Removal and Installation ....................................................................................................................... |

5 |

Cylinder Head Assembly Repair ......................................................................................................................... |

5 |

Valve Cover ...................................................................................................................................................... |

5 |

Remove......................................................................................................................................................... |

5 |

Install........................................................................................................................................................... |

6 |

Rocker Arm Assembly ..................................................................................................................................... |

6 |

Remove......................................................................................................................................................... |

6 |

Disassemble ................................................................................................................................................. |

6 |

Inspect.......................................................................................................................................................... |

6 |

Assemble ...................................................................................................................................................... |

6 |

Install........................................................................................................................................................... |

6 |

Valve Clearance Adjustments ......................................................................................................................... |

7 |

Valve Springs ................................................................................................................................................... |

8 |

Cylinder Head Assembly................................................................................................................................. |

9 |

Remove......................................................................................................................................................... |

9 |

Install......................................................................................................................................................... |

11 |

Valves and Valve Springs .............................................................................................................................. |

14 |

Remove....................................................................................................................................................... |

14 |

Inspect........................................................................................................................................................ |

14 |

Install......................................................................................................................................................... |

15 |

Valve Guides .................................................................................................................................................. |

15 |

Inspect........................................................................................................................................................ |

15 |

Remove....................................................................................................................................................... |

15 |

Install......................................................................................................................................................... |

15 |

Cylinder Head and Valve Seats .................................................................................................................... |

16 |

Inspect........................................................................................................................................................ |

16 |

Repair......................................................................................................................................................... |

17 |

New Valve Seats, Install ........................................................................................................................... |

17 |

Piston and Connecting Rod Assemblies Repair ............................................................................................... |

17 |

Rod Bearings.................................................................................................................................................. |

18 |

Remove....................................................................................................................................................... |

18 |

Install......................................................................................................................................................... |

18 |

Piston and Connecting Rod Assembly .......................................................................................................... |

19 |

Service Note............................................................................................................................................... |

19 |

Remove....................................................................................................................................................... |

19 |

Install......................................................................................................................................................... |

20 |

Piston Rings ................................................................................................................................................... |

21 |

Remove....................................................................................................................................................... |

21 |

Inspect........................................................................................................................................................ |

21 |

Install......................................................................................................................................................... |

22 |

Piston and Connecting Rod ........................................................................................................................... |

22 |

Disassemble ............................................................................................................................................... |

22 |

Inspect........................................................................................................................................................ |

22 |

How to Select Correct Replacements ....................................................................................................... |

23 |

Install......................................................................................................................................................... |

24 |

Piston Cooling Jets ........................................................................................................................................ |

24 |

©2004 HYSTER COMPANY |

i |

Table of Contents |

Perkins Tier 2 Diesel Engines |

TABLE OF CONTENTS (Continued) |

|

Remove....................................................................................................................................................... |

24 |

Install......................................................................................................................................................... |

25 |

Crankshaft Assembly Repair ............................................................................................................................ |

25 |

General........................................................................................................................................................... |

25 |

Crankshaft Pulley.......................................................................................................................................... |

26 |

Remove....................................................................................................................................................... |

26 |

Inspect........................................................................................................................................................ |

26 |

Install......................................................................................................................................................... |

26 |

Rear Oil Seal .................................................................................................................................................. |

27 |

Remove....................................................................................................................................................... |

27 |

Install......................................................................................................................................................... |

27 |

Main Bearings................................................................................................................................................ |

28 |

Remove....................................................................................................................................................... |

28 |

Inspect........................................................................................................................................................ |

29 |

Install......................................................................................................................................................... |

29 |

Thrust Washers.............................................................................................................................................. |

29 |

Crankshaft Axial Movement, Check ........................................................................................................ |

29 |

Remove....................................................................................................................................................... |

30 |

Install......................................................................................................................................................... |

30 |

Crankshaft ..................................................................................................................................................... |

31 |

Remove....................................................................................................................................................... |

31 |

Inspect........................................................................................................................................................ |

31 |

Install......................................................................................................................................................... |

32 |

Flywheel ......................................................................................................................................................... |

33 |

Remove....................................................................................................................................................... |

33 |

Ring Gear, Replace .................................................................................................................................... |

33 |

Install......................................................................................................................................................... |

33 |

Flywheel Housing .......................................................................................................................................... |

34 |

Remove....................................................................................................................................................... |

34 |

Install......................................................................................................................................................... |

34 |

Timing Case and Timing Gears Repair ............................................................................................................ |

35 |

General........................................................................................................................................................... |

35 |

Timing Case Cover ........................................................................................................................................ |

35 |

Remove....................................................................................................................................................... |

35 |

Install......................................................................................................................................................... |

36 |

Front Oil Seal................................................................................................................................................. |

36 |

Remove....................................................................................................................................................... |

36 |

Install......................................................................................................................................................... |

36 |

Crankshaft Pulley Wear Sleeve .................................................................................................................... |

37 |

Install......................................................................................................................................................... |

37 |

Idler Gear and Hub ....................................................................................................................................... |

37 |

Remove....................................................................................................................................................... |

37 |

Install......................................................................................................................................................... |

38 |

Air Compressor Drive, Bendix ...................................................................................................................... |

39 |

Disassemble ............................................................................................................................................... |

39 |

Assemble .................................................................................................................................................... |

39 |

Fuel Injection Pump Gear ............................................................................................................................. |

40 |

Remove....................................................................................................................................................... |

40 |

Install......................................................................................................................................................... |

41 |

Camshaft Gear............................................................................................................................................... |

41 |

Remove....................................................................................................................................................... |

41 |

ii

Perkins Tier 2 Diesel Engines |

Table of Contents |

TABLE OF CONTENTS (Continued) |

|

Install......................................................................................................................................................... |

42 |

Crankshaft Gear ............................................................................................................................................ |

42 |

Remove....................................................................................................................................................... |

42 |

Install......................................................................................................................................................... |

43 |

Timing Case ................................................................................................................................................... |

43 |

Remove....................................................................................................................................................... |

43 |

Install......................................................................................................................................................... |

43 |

Camshaft and Tappets .................................................................................................................................. |

44 |

Remove....................................................................................................................................................... |

44 |

Install......................................................................................................................................................... |

45 |

Cylinder Block Assembly Repair....................................................................................................................... |

45 |

Description ..................................................................................................................................................... |

45 |

Cylinder Block ............................................................................................................................................... |

45 |

Disassemble ............................................................................................................................................... |

45 |

Inspect........................................................................................................................................................ |

46 |

Assemble .................................................................................................................................................... |

46 |

Cylinder Liner................................................................................................................................................ |

47 |

Inspect........................................................................................................................................................ |

47 |

Cylinder Liner Condition, Check.............................................................................................................. |

47 |

Remove....................................................................................................................................................... |

48 |

Service Liner, Install................................................................................................................................. |

49 |

Partially Finished Liner, Install............................................................................................................... |

50 |

Engine Timing.................................................................................................................................................... |

51 |

Description ..................................................................................................................................................... |

51 |

How to Set Number One Piston to TDC on Compression Stroke ........................................................... |

52 |

How to Set Number One Piston to TDC on Compression Stroke (Alternate Procedure)...................... |

53 |

How to Set Number One Piston to 4 After TDC on Compression Stroke ............................................. |

54 |

Valve Timing, Check.................................................................................................................................. |

55 |

Fuel Injection Pump Timing, Check......................................................................................................... |

56 |

Turbocharger ...................................................................................................................................................... |

56 |

General........................................................................................................................................................... |

56 |

Remove ........................................................................................................................................................... |

56 |

Install ............................................................................................................................................................. |

57 |

Impeller and Compressor Housing, Clean ................................................................................................... |

57 |

Waste-Gate Valve Check ............................................................................................................................... |

58 |

Closed Circuit Breather System (CCB) ........................................................................................................ |

59 |

CCB Assembly, Remove ............................................................................................................................ |

59 |

Closed Circuit Drain Valve, Remove ........................................................................................................ |

59 |

CCB Assembly, Install .............................................................................................................................. |

59 |

Closed Circuit Drain Valve, Install .......................................................................................................... |

59 |

Lubrication System Repair................................................................................................................................ |

60 |

General........................................................................................................................................................... |

60 |

Oil Filter, Replace .......................................................................................................................................... |

60 |

Oil Filter Head............................................................................................................................................... |

60 |

Remove....................................................................................................................................................... |

60 |

Install......................................................................................................................................................... |

60 |

Oil Filter Head Bypass Valve........................................................................................................................ |

61 |

Remove and Install ................................................................................................................................... |

61 |

Oil Sump ........................................................................................................................................................ |

61 |

Remove....................................................................................................................................................... |

61 |

Install......................................................................................................................................................... |

61 |

iii

Table of Contents |

Perkins Tier 2 Diesel Engines |

TABLE OF CONTENTS (Continued) |

|

Oil Pump ........................................................................................................................................................ |

62 |

Remove....................................................................................................................................................... |

62 |

Inspect........................................................................................................................................................ |

62 |

Install......................................................................................................................................................... |

63 |

Relief Valve .................................................................................................................................................... |

64 |

Remove....................................................................................................................................................... |

64 |

Disassemble ............................................................................................................................................... |

64 |

Inspect........................................................................................................................................................ |

64 |

Assemble .................................................................................................................................................... |

64 |

Install......................................................................................................................................................... |

64 |

Idler Gear Shaft, Replace.............................................................................................................................. |

64 |

Remove....................................................................................................................................................... |

65 |

Remove (Alternative) ................................................................................................................................ |

65 |

Install......................................................................................................................................................... |

66 |

Install (Alternative) .................................................................................................................................. |

66 |

Fuel System Repair............................................................................................................................................ |

67 |

Description ..................................................................................................................................................... |

67 |

Fuel Injection Pump ...................................................................................................................................... |

69 |

Remove....................................................................................................................................................... |

69 |

Install......................................................................................................................................................... |

71 |

Fuel System Air Removal.............................................................................................................................. |

72 |

Fuel Filter, Replace ....................................................................................................................................... |

74 |

Fuel Injectors ................................................................................................................................................. |

74 |

Remove....................................................................................................................................................... |

75 |

Inspect........................................................................................................................................................ |

75 |

Install......................................................................................................................................................... |

75 |

Fuel Lift Pump............................................................................................................................................... |

76 |

Remove....................................................................................................................................................... |

76 |

Disassemble ............................................................................................................................................... |

76 |

Assemble .................................................................................................................................................... |

76 |

Install......................................................................................................................................................... |

77 |

Test............................................................................................................................................................. |

77 |

Cooling System Repair ...................................................................................................................................... |

78 |

General........................................................................................................................................................... |

78 |

Thermostat..................................................................................................................................................... |

78 |

Remove....................................................................................................................................................... |

78 |

Install......................................................................................................................................................... |

79 |

Test............................................................................................................................................................. |

79 |

Coolant Pump ................................................................................................................................................ |

79 |

Remove....................................................................................................................................................... |

79 |

Disassemble ............................................................................................................................................... |

80 |

Assemble .................................................................................................................................................... |

82 |

Install......................................................................................................................................................... |

84 |

Fan and Fan Drive ........................................................................................................................................ |

85 |

Remove....................................................................................................................................................... |

85 |

Install......................................................................................................................................................... |

85 |

Oil Cooler ....................................................................................................................................................... |

85 |

Remove....................................................................................................................................................... |

85 |

Disassemble and Assemble....................................................................................................................... |

86 |

Install......................................................................................................................................................... |

86 |

Electrical Equipment Repair............................................................................................................................. |

87 |

iv

Perkins Tier 2 Diesel Engines |

Table of Contents |

TABLE OF CONTENTS (Continued) |

|

Drive Belts ..................................................................................................................................................... |

87 |

Alternator....................................................................................................................................................... |

87 |

Remove....................................................................................................................................................... |

87 |

Install......................................................................................................................................................... |

87 |

Electronic Control Module (ECM) ................................................................................................................ |

88 |

Remove....................................................................................................................................................... |

88 |

Inspect........................................................................................................................................................ |

88 |

Install......................................................................................................................................................... |

88 |

Voltage Load and Protection Module (VLPM).............................................................................................. |

89 |

Remove....................................................................................................................................................... |

89 |

Install......................................................................................................................................................... |

89 |

Engine Speed and Timing Sensor................................................................................................................. |

89 |

Remove....................................................................................................................................................... |

89 |

Install......................................................................................................................................................... |

90 |

Pressure Sensors (Engine Oil and Air Intake)............................................................................................. |

90 |

Remove....................................................................................................................................................... |

90 |

Install......................................................................................................................................................... |

91 |

Temperature Sensor ...................................................................................................................................... |

91 |

Remove....................................................................................................................................................... |

91 |

Install......................................................................................................................................................... |

92 |

Starter Motor ................................................................................................................................................. |

92 |

Remove....................................................................................................................................................... |

92 |

Install......................................................................................................................................................... |

92 |

Cold Start Aid ................................................................................................................................................ |

92 |

Air Compressor .................................................................................................................................................. |

92 |

General........................................................................................................................................................... |

92 |

Repair ............................................................................................................................................................. |

93 |

Remove....................................................................................................................................................... |

93 |

Install......................................................................................................................................................... |

93 |

Rotary Exhauster Replacement ........................................................................................................................ |

94 |

Remove ........................................................................................................................................................... |

94 |

Clean .............................................................................................................................................................. |

94 |

Install ............................................................................................................................................................. |

94 |

Engine Specifications......................................................................................................................................... |

95 |

Cylinder Head Assembly............................................................................................................................... |

95 |

Piston and Connecting Rods ......................................................................................................................... |

98 |

Crankshaft Assembly .................................................................................................................................... |

99 |

Crankshaft Overhaul .............................................................................................................................. |

100 |

Timing Case and Drive Assembly............................................................................................................... |

102 |

Engine Block Assembly ............................................................................................................................... |

103 |

Turbocharger................................................................................................................................................ |

104 |

Lubrication System ..................................................................................................................................... |

105 |

Cooling System ............................................................................................................................................ |

107 |

Flywheel and Housing................................................................................................................................. |

107 |

Electrical Equipment................................................................................................................................... |

107 |

Torque Specifications ....................................................................................................................................... |

108 |

Cylinder Head Assembly............................................................................................................................. |

108 |

Piston and Connecting Rod Assemblies ..................................................................................................... |

108 |

Crankshaft Assembly .................................................................................................................................. |

108 |

Timing Case and Drive Assembly............................................................................................................... |

108 |

Turbocharger................................................................................................................................................ |

108 |

v

Table of Contents |

Perkins Tier 2 Diesel Engines |

TABLE OF CONTENTS (Continued) |

|

Lubrication System ..................................................................................................................................... |

108 |

Fuel System ................................................................................................................................................. |

108 |

Cooling System ............................................................................................................................................ |

109 |

Flywheel ....................................................................................................................................................... |

109 |

Auxiliary Equipment................................................................................................................................... |

109 |

Special Torque Specifications .......................................................................................................................... |

109 |

Flywheel and Housing................................................................................................................................. |

109 |

Electrical Equipment................................................................................................................................... |

109 |

Auxiliary Equipment................................................................................................................................... |

109 |

Special Tools ..................................................................................................................................................... |

110 |

Troubleshooting................................................................................................................................................ |

115 |

Turbocharger Troubleshooting ........................................................................................................................ |

117 |

This section is for the following models:

H8.00-12.00XM (H170-280HD) [F007, G007];

H13.00-16.00XM (H300-360HD) [E019, F019];

H10.00-12.00XM-12EC (H360HD-EC) [E019, F019]

vi

600 SRM 1068 |

General |

General

This section has the description and repair instructions for the VK model of the Series 1100 Perkins diesel engine. All VK models are six-cylinder, turbocharged.

GENERAL SAFETY RULES

WARNING

WARNING

Some seals used in this engine are made of synthetic materials called fluoroelastomers

(a commercial name is Viton). These fluoroelastomers can decompose at temperatures greater than 316 C (600

C (600 F) or by burning and cause hydrofluoric acid to form on the surface of the seal or nearby equipment.

F) or by burning and cause hydrofluoric acid to form on the surface of the seal or nearby equipment.

Do not touch gaskets, seals, or O-rings which appear charred or black and sticky after exposure to temperatures greater than 316 C (600

C (600 F) or burning. Contact with this acid can cause severe burns of the skin and eyes. Burns can be delayed several hours after contact.

F) or burning. Contact with this acid can cause severe burns of the skin and eyes. Burns can be delayed several hours after contact.

Do the following procedures to prevent exposure to hydrofluoric acid:

•Wear disposable neoprene or PVC gloves and discard the gloves after use.

•Wash the area with 10 percent calcium hydroxide solution to neutralize any acid and then clean with water.

If burned seal by-product touches the skin or eyes:

•Immediately flush with water for a minimum of 15 minutes.

•Apply 2.5 percent calcium gluconate gel to affected area of skin.

•Get medical help immediately for suspected hydrogen fluoride or hydrofluoric acid burn.

WARNING

WARNING

Disconnect the battery cables before doing any disassembly and repair of the engine or parts of the electrical system. Put a DO NOT OPERATE tag in the operator’s area and on the battery connectors.

Long-term exposure to used engine oil can cause skin irritation or cancer. Wash with detergent and water.

Exhaust from internal combustion engines contains carbon monoxide and other harmful chemicals. Carbon monoxide is a colorless, odorless poison and can cause unconsciousness or death without warning. Long-term exposure to exhaust or chemicals in the exhaust can cause cancer, birth defects, and other reproductive harm. Avoid exposure to engine exhaust.

Do not use diesel engines indoors where soot can accumulate.

If engines are operated in confined spaces, maintain adequate ventilation or vent exhaust to the outside. Do not exceed applicable air contaminant limits.

Follow the inspection and maintenance schedule and procedures in this manual. Do not alter exhaust, ignition, or fuel systems.

CAUTION

CAUTION

Disposal of lubricants and fluids must meet local environmental regulations.

Disposal of batteries must meet local environmental regulations.

The diodes and resistors in the electrical system can be damaged if the following cautions are not followed:

•Do not disconnect the battery when the engine is running. The voltage surge can damage the diodes and resistors.

•Do not disconnect an electric wire before the engine is stopped and the switches are OFF.

•Do not cause a short circuit by connection of the electric wires to the wrong terminals. Make sure a correct identification is made of the wire before it is connected.

•Verify the battery is the correct voltage and polarity before it is connected.

•Do not check for current flow by making a spark because the electronic components can be damaged.

1

Description

CAUTION

CAUTION

When setscrews or studs are fitted into holes which are tapped through the cylinder block, a suitable sealant must be used to prevent leakage.

Micro encapsulated anaerobic sealant (M.E.A.S.) fasteners have been introduced instead of jointing compounds or other sealants when the fasteners are fitted in through holes into oil or coolant passages. The identification of these fasteners, as supplied, is by a red, blue, or other color sealant around the fastener threads.

600 SRM 1068

With M.E.A.S. sealed studs, the sealed end must be fitted into the cylinder head/cylinder block, etc. Ensure that the threaded holes have a 1.59 mm (0.0626 in.), 45 chamfer so that the M.E.A.S. sealant is not removed. If the fasteners have to be removed and fitted again, the threads must be cleaned and a suitable sealant used.

chamfer so that the M.E.A.S. sealant is not removed. If the fasteners have to be removed and fitted again, the threads must be cleaned and a suitable sealant used.

Observe the previous WARNINGS and CAUTIONS before repairing any equipment.

Description

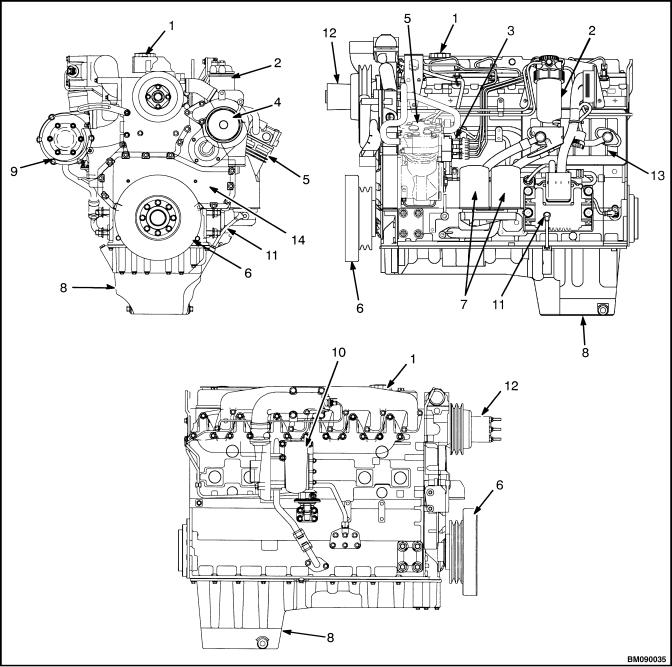

The cylinder head is cast iron and has one inlet valve and one exhaust valve for each cylinder. The valve seats and the valve guides are replaceable. The fuel injectors are in the cylinder head. The overhead valve assembly is actuated by a camshaft inside of the engine block. A gear train, turned by the crankshaft, turns the camshaft, coolant pump, injection pump, and a power-takeoff (PTO) which is available for additional equipment. The hydraulic pump for the steering function or a compressor is normally turned by the PTO. The fuel pump is actuated by the camshaft. See Figure 1.

The crankshaft has seven main bearings. The main bearing in the center of the crankshaft is the thrust bearing and has thrust washers on both sides of the bearing.

The cylinder block is cast iron and has cylinder liners that can be replaced during overhaul.

A Fastram™ combustion chamber in the top of each piston is designed to give an efficient mix of fuel and

air. Each piston has three piston rings (two compression rings and an oil control ring). The top compression ring has a special insert for the groove, to reduce wear. Axial location of the fully floating piston pin is by circlips. The piston pin is off-center to reduce the noise level. A jet for cooling oil to the bottom of the piston is installed.

The cooling fan and the alternator are turned by a drive belt. The cooling fan is not connected to the coolant pump. The coolant pump is turned by the gear for the fuel injection pump in the timing gear case.

The timing, speed adjustment, and quantity of fuel sent to the fuel injectors is controlled electronically by the Electronic Control Module (ECM).

A Bosch VP30 series fuel injection pump is used on all 1100 VK engines. Special tools are needed to repair an injection pump, and they are normally sent to an authorized repair station if repairs are necessary.

2

600 SRM 1068 |

Description |

|

|

|

|

1. |

FILL CAP FOR ENGINE OIL |

8. |

OIL SUMP |

2. |

FUEL FILTER |

9. |

ALTERNATOR |

3. |

FUEL INJECTION PUMP |

10. |

TURBOCHARGER |

4. |

COOLANT PUMP |

11. |

DIPSTICK, ENGINE OIL |

5. |

AIR COMPRESSOR |

12. |

FAN DRIVE |

6. |

VIBRATION DAMPER |

13. |

OIL COOLER |

7. |

OIL FILTERS |

14. |

TIMING CASE |

Figure 1. Engine

3

Description |

600 SRM 1068 |

ENGINE SERIAL NUMBER CODES

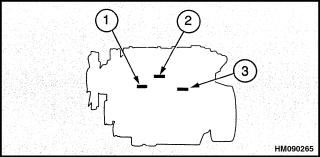

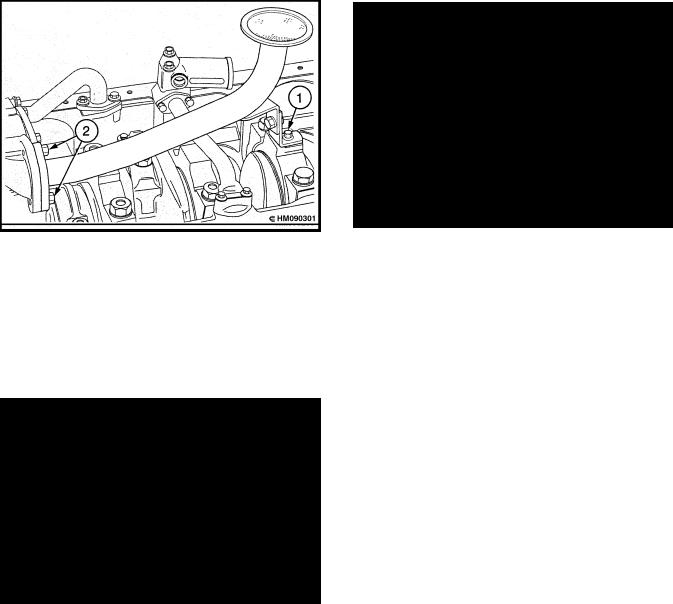

The engine number is on a label on the left side of the engine block. See Figure 2.

|

|

|

1. PART NUMBERS |

2. |

ENGINE SERIAL |

FOR FUEL |

|

NUMBER |

INJECTION PUMP |

3. |

EMISSIONS LABEL |

Figure 2. Serial Number Locations

A typical serial number has the following code:

VK |

U |

090001 |

H |

1 |

2 |

3 |

4 |

where:

1 = Type of engine: VK = 1100

2 = Country of manufacture (U = manufactured in the United Kingdom)

3 = Serial number

4 = Year of manufacture. The letter indicates the year of manufacture. The letters I, O, Q, R, and Z are not used.

If parts or service are required for your engine, the complete engine number must be given to your dealer.

ENGINE DATA

The specifications and tolerance details for engine repair are in a chart at the end of this section.

1100 (VK) |

|

Power rating at 2300 |

|

rpm................................... |

129.5 kW (173.7 bhp) |

Number of cylinders........ |

6 |

Firing order ..................... |

1–5–3–6–2–4 |

Bore and stroke ............... |

100 × 127 mm |

|

(3.937 × 5.000 in.) |

Displacement................... |

6.00 liter (366 in.3) |

Compression ratio ........... |

17.25:1 |

Minimum oil pressure |

|

(at maximum speed |

|

and normal operating |

|

temperature) |

|

Governor speed (no |

|

load) ................................. |

280 kPa (41 psi) |

See the Periodic Maintenance section for your model of lift truck.

Idle Speed ........................ |

725 to 775 rpm |

||||||||

Thermostat |

|

|

|

|

|

|

|

|

|

Begin to open |

80 to 84 |

|

C (176 to 183 |

|

F) |

||||

|

|

||||||||

Fully open |

96 |

|

C (205 |

|

F) |

||||

|

|

||||||||

Valve clearance (hot or cold) |

|||||||||

Inlet ............................. |

0.20 mm (0.008 in.) |

||||||||

Exhaust ....................... |

0.45 mm (0.018 in.) |

||||||||

4

600 SRM 1068 |

Cylinder Head Assembly Repair |

Engine Removal and Installation

See the Frame section for the procedure for removing the engine and transmission. See the Transmission section for the procedure to separate the transmission from the engine.

There can be a variation in the maximum weight of the engine depending upon the components that are attached to it. The following minimum lifting capacity is needed for an engine without coolant, lubricants, or transmission:

1100 (VK) engines |

600 kg (1323 lb) |

Always use a lifting device that provides a vertical lift above the engine lift brackets as shown in Figure 3. Never use a single bracket to lift an engine.

Verify the engine brackets are correctly fastened to the engine. Verify that the valve cover and other components are not damaged by the lifting device. Use a lifting device to lift and move the heavy components of the engine: cylinder block, cylinder head, flywheel housing, flywheel, and crankshaft.

1. |

ENGINE LIFT BRACKETS |

|

|

|

Figure 3. Lifting an Engine |

Cylinder Head Assembly Repair |

||

VALVE COVER |

Legend for Figure 4 |

|

|

VALVE COVER |

|

|

1. |

|

|

2. |

OIL FILLER CAP SEAL |

|

3. |

OIL SEPARATOR ASSEMBLY SEAL |

|

4. |

VALVE COVER GASKET |

|

5. |

CAPSCREW ASSEMBLY |

|

Remove |

|

|

1. |

Disconnect the breather pipe. |

|

2. |

Remove the capscrews and sealing washers from |

|

|

the valve cover. See Figure 4. |

|

3. |

Lift the valve cover and gasket from the cylinder |

|

|

head. The valve cover gasket fits between the |

|

|

valve cover and the induction manifold. |

|

|

|

Figure 4. Valve Cover

5

Cylinder Head Assembly Repair

Install

1.Check the condition of the valve cover gasket, bolts, and seal washers. Replace components as necessary. Verify that the surfaces are clean.

2.Install the valve cover and gasket on the cylinder head. See Figure 4.

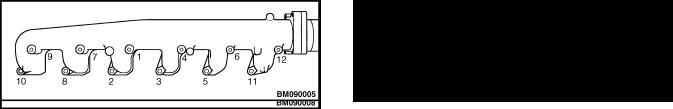

3.Install the valve cover bolts. Torque to 9 N•m (80 lbf in) in sequence shown in Figure 5.

Figure 5. Valve Cover Torque Sequence

4. Connect the breather pipe.

ROCKER ARM ASSEMBLY

Remove

1.Remove the valve cover.

2.Loosen the nuts evenly that fasten the brackets for the rocker arm shafts to the cylinder head. Loosen the brackets at each end of the cylinder head first and loosen the brackets in sequence towards the center. Remove the nuts and washers when the pressure is removed from the rocker arms. Lift the rocker arm assembly from the cylinder head.

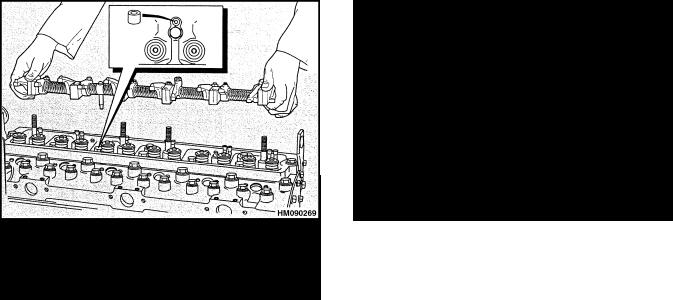

3.Remove the rubber seal from the oil supply connection or the hole for the oil supply in the cylinder head. See Figure 6.

Disassemble

1.Remove the clips from both ends of the rocker arm shaft. Verify that the ends of the rocker arm shaft are not damaged. Loosen the location screw for the oil supply connection.

2.Make a note of the position of each component on the rocker arm shaft so that they can be assembled correctly. Remove the components from the rocker arm shaft.

600 SRM 1068

Figure 6. Rubber Seal Location

Inspect

Clean and inspect all the components for wear and damage. Check the clearance of the rocker arms on the rocker arm shaft. If the clearance is greater than 0.09 mm (0.0035 in.), install a new rocker arm, or install a new rocker arm shaft if it is worn.

Assemble

1.Verify that the lubrication holes in the rocker arms and the rocker arm shaft are open and clean.

2.Lubricate the components with clean engine oil as they are assembled on the rocker arm shaft. Verify the components are assembled in the correct order. See Figure 7. Verify that the location screw for the oil supply connection is fitted correctly in the rocker arm shaft and torqued to 4 N•m (35 lbf in). Install the clips at the ends of the rocker arm shaft.

Install

1.Verify that the rocker arm assembly is clean and dry.

2.Install a new rubber seal in the hole for the oil supply in the cylinder head. See Figure 6.

3.Check that the push rods fit correctly in the sockets for the tappets. Install the rocker arm assembly over the four studs, insert the oil supply connection into the oil supply hole in the cylinder head.

6

600 SRM 1068 |

Cylinder Head Assembly Repair |

|

|

|

|

|

|

|

Figure 7. Rocker Arm Assembly

CAUTION

CAUTION

Loosen any tappet adjustment screws that may tighten during the following procedure.

4.Verify that the alignment of the rocker arms and the push rods is correct. Install the nuts and washers on the studs that hold the brackets for the rocker arm shafts to the cylinder head. Tighten the nuts evenly. Begin tightening the nuts at the center of the rocker arm shaft and tighten in sequence towards the ends of the shaft. The final torque on the nuts is 75 N•m (55 lbf ft).

5. Check and adjust valve tip clearances. See Valve |

Figure 8. Valve Clearance Adjustment |

|

Clearance Adjustments. |

||

|

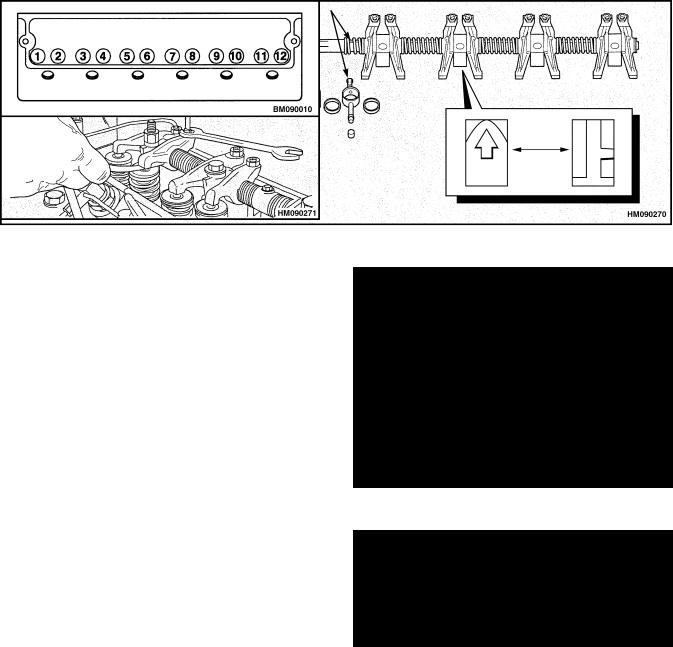

VALVE CLEARANCE ADJUSTMENTS

The valve clearance is measured between the top of the valve stem and the rocker arm as shown in Fig- ure 8.

Valve clearance (hot or cold)

Inlet |

0.20 mm (0.008 in.) |

Exhaust |

0.45 mm (0.018 in.) |

Number one cylinder is at the front of the engine. The inlet valve is the first valve in the sequence. See Figure 9.

1.Turn the crankshaft in the normal direction of rotation until the inlet valve of number six cylinder has just opened and the exhaust valve of the same cylinder has not fully closed. Check the clearances of the valves of number one cylinder and adjust them as necessary.

Figure 9. Valve Positions

NOTE: The torque for the locking nut is 27 N•m (21 lbf ft).

2.Turn the crankshaft in the normal direction of rotation until the inlet valve of number two cylinder has just opened and the exhaust valve of the same cylinder has not fully closed. Check the valve clearances on number five cylinder and adjust them as necessary.

7

Cylinder Head Assembly Repair |

600 SRM 1068 |

3.Turn the crankshaft in the normal direction of rotation until the inlet valve of number four cylinder has just opened and the exhaust valve of the same cylinder has not fully closed. Check the valve clearances on number three cylinder and adjust them as necessary.

4.Turn the crankshaft in the normal direction of rotation until the inlet valve of number one cylinder has just opened and the exhaust valve of the same cylinder has not fully closed. Check the valve clearances on number six cylinder and adjust them as necessary.

5.Turn the crankshaft in the normal direction of rotation until the inlet valve of number five cylinder has just opened and the exhaust valve of the same cylinder has not fully closed. Check the valve clearances on number two cylinder and adjust them as necessary.

6.Turn the crankshaft in the normal direction of rotation until the inlet valve of number three cylinder has just opened and the exhaust valve of the same cylinder has not fully closed. Check the valve clearances on number four cylinder and adjust them as necessary.

NOTE: After valve adjustments, lubricate the rocker assembly with clean engine oil.

VALVE SPRINGS

NOTE: This procedure is normally for changing the valve springs of a single cylinder while the cylinder head is still installed on the engine. If the valves and springs must be removed from the cylinder head for repairs, see the procedures under Valves and Valve Springs, later in this section.

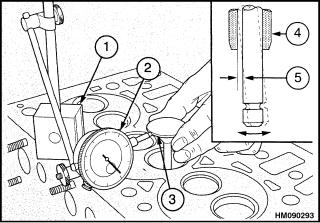

Special Tools: Valve spring compressor Stud adapter

Setscrew adapter

1.Remove the valve cover.

2.Turn the crankshaft in the normal direction of rotation until the piston for the cylinder is at top dead center (TDC). The inlet valve will just open and the exhaust valve will not be fully closed when the cylinder is at TDC.

3.Remove the rocker arm assembly.

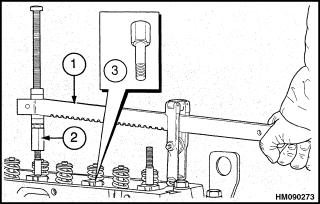

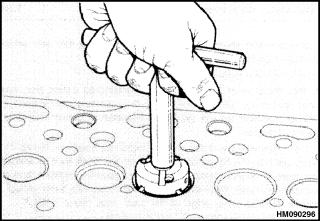

4.Install the spring compressor and the adapter. See Figure 10.

|

|

|

1. |

VALVE SPRING |

3. SETSCREW |

|

COMPRESSOR |

ADAPTER |

2. |

STUD ADAPTER |

|

Figure 10. Valve Spring Compressor

5.Compress the valve springs and remove the retainers. Verify the valve springs are compressed parallel to the valve stems, or the valve stems can be damaged.

NOTE: Do not turn the crankshaft while the valve springs are removed.

6.Release the valve spring compressor and remove the retainer cap and valve springs.

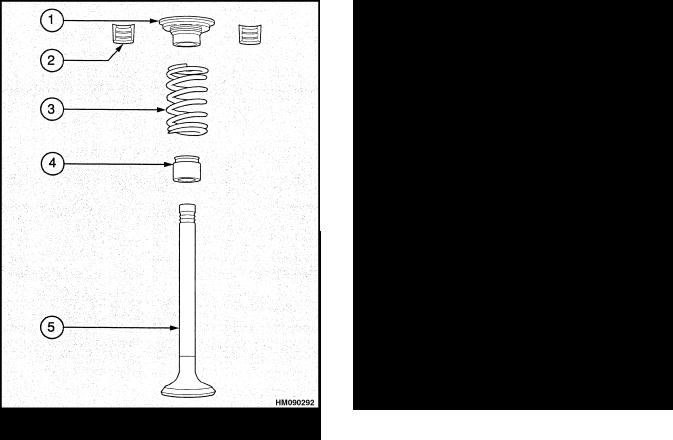

NOTE: The outer diameter of the exhaust valve guide is 1 mm (0.039 in.) larger than the inlet valve guide. To prevent leakage past the inlet valve stem it is important that the larger exhaust valve seal is not fitted into the inlet guide. The seals are color coded.

7.Install new valve stem seals on the valve guides. Verify that the brown seal is installed on the exhaust valve and the green seal on the inlet valves.

8.Install the new valve springs. The springs can be fitted with either end toward the cylinder head.

9.Install the retainer cap.

10.Use the valve spring compressor to compress the valve springs and install the retainers. Remove the valve spring compressor.

11.Install the rocker arm assembly.

12.Check the valve clearances. See Valve Clearance Adjustments.

13.Install the valve cover.

8

600 SRM 1068

NOTE: Valve springs can be changed in two cylinders at a time.

When the piston in cylinder one is at TDC, the piston in cylinder six is also at TDC. When the piston in cylinder two is at TDC, the piston in cylinder five is also at TDC. When the piston in cylinder three is at TDC, the piston in cylinder four is also at TDC.

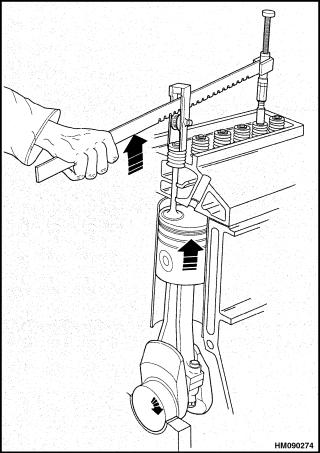

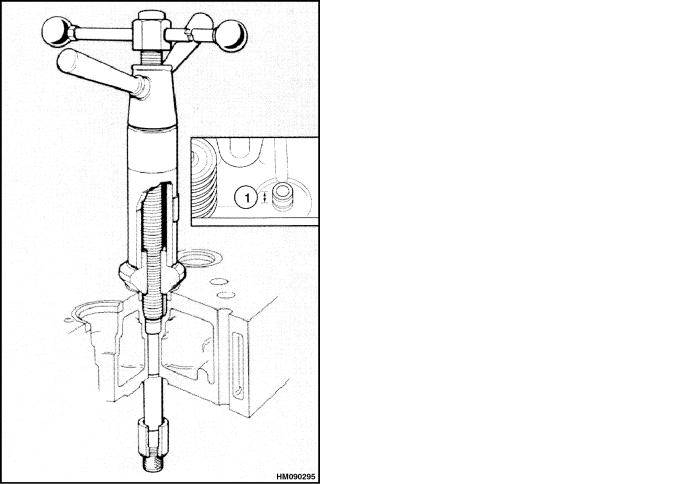

If the rocker arm assembly was removed before TDC was found, install the valve spring compressor and compress the valve springs to open the valve. Turn the crankshaft by hand in the normal direction until the piston touches the valve. Continue to turn the crankshaft and, at the same time, release the pressure on the valve spring compressor until the piston is at TDC. See Figure 11.

Figure 11. Find TDC With Valve Spring

Compressor

Cylinder Head Assembly Repair

CYLINDER HEAD ASSEMBLY

Remove

1.If the engine is still in the lift truck, do the following procedures:

a.Disconnect the battery terminals.

b.Drain the cooling system.

c.Disconnect the sender unit for the coolant temperature gauge.

2.If equipped, remove closed circuit breather unit.

3.Remove the Machine Interface Connector (MIC) connection from the mounting bracket if the mounting bracket is attached to the cylinder head.

4.Remove the air intake hose.

5.Remove the fuel line between the cold start aid in the induction manifold and the fuel filter. Disconnect the electrical connection and electrical connectors from sensors.

6.Disconnect all connections to the turbocharger and remove turbocharger. See Turbocharger, Re- move.

7.Remove the induction manifold capscrews.

8.Remove the induction manifold and gasket from the cylinder head. Discard the gasket.

9.Remove exhaust manifold fasteners and the exhaust manifold.

10.Remove the low pressure fuel lines between the fuel injection pump and the fuel filter. Remove the fuel filter bracket and the fuel filters.

11.Remove the high pressure fuel lines. Use a separate wrench to prevent movement of the outlets of the fuel injection pump when the fuel lines are disconnected. Put plugs in the open ports of the fuel injection pump.

12.Remove the fuel injectors from the cylinder head. Keep the fuel injectors clean and prevent damage to the nozzles.

13.If an air compressor is installed, remove the coolant pipe between the cylinder head and the compressor. Remove the coolant pipe between the bypass connection and the compressor.

9

Cylinder Head Assembly Repair

14.Loosen the hose clamp and remove the coolant bypass hose from the cylinder head. Remove the capscrews and remove the coolant bypass connection and the hose.

15.Disconnect the coolant temperature sender.

16.Remove the valve cover. See Valve Cover, Re- move.

600 SRM 1068

17.Remove the rocker arm assembly. See Rocker Arm Assembly, Remove.

18.Remove the push rods.

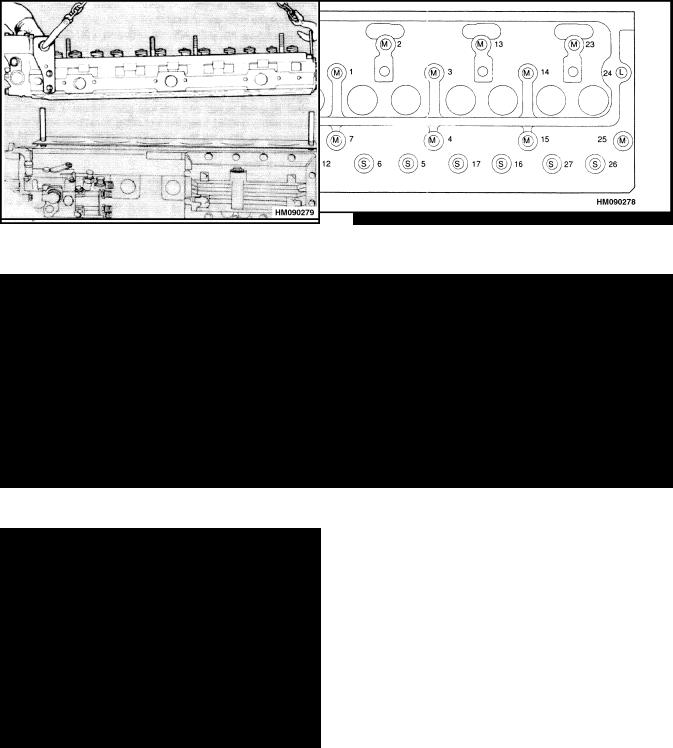

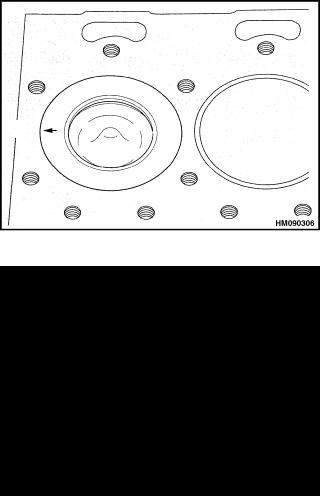

19.Loosen the capscrews for the cylinder head evenly in a reverse sequence from the sequence shown in Figure 12.

Figure 12. Cylinder Head Tightening Sequence

20.Lift the cylinder head from the engine block. Do not use a pry bar between the cylinder head and the engine block, that can cause damage to the gasket surfaces. See Figure 13.

Figure 13. Cylinder Head Removal

21.Inspect the capscrews for the cylinder head with a straightedge. See Figure 14. Check that the capscrews are straight and do not have distortion. If there is a reduction in the diameter of the

thread that has not been in engagement with the cylinder block, the capscrew must be discarded.

1.STRAIGHTEDGE

2.CAPSCREW MUST BE STRAIGHT AND WITHOUT DISTORTION

3.THREADS MUST BE IN GOOD CONDITION AND NOT HAVE A REDUCED DIAMETER

Figure 14. Capscrews Inspection

10

600 SRM 1068

Install

Special Tools: |

Angle gauge to tighten the |

|

capscrews for the cylinder head |

1.Verify the surfaces of the cylinder head and the top of the engine block are clean. Verify that there is no dirt or objects in the cylinders.

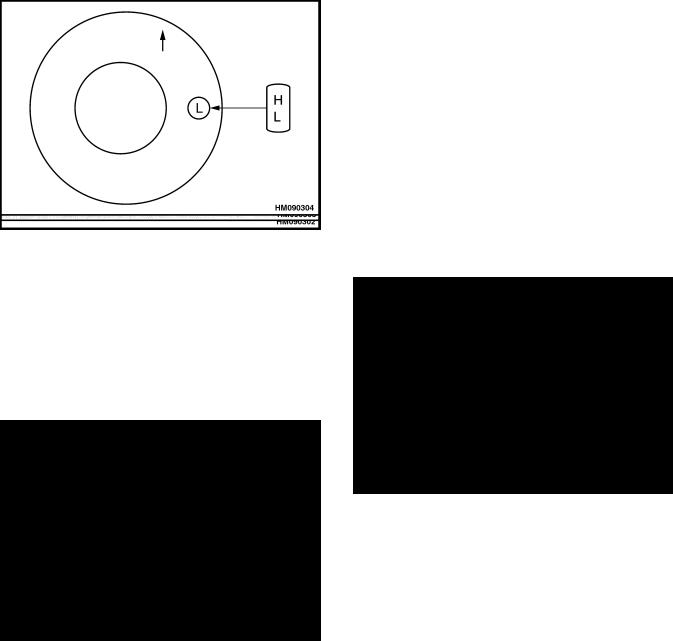

2.Install the gasket for the cylinder head as shown in Figure 15. Verify the TOP FRONT is in the correct position. Do not use any gasket sealant on any of the surfaces.

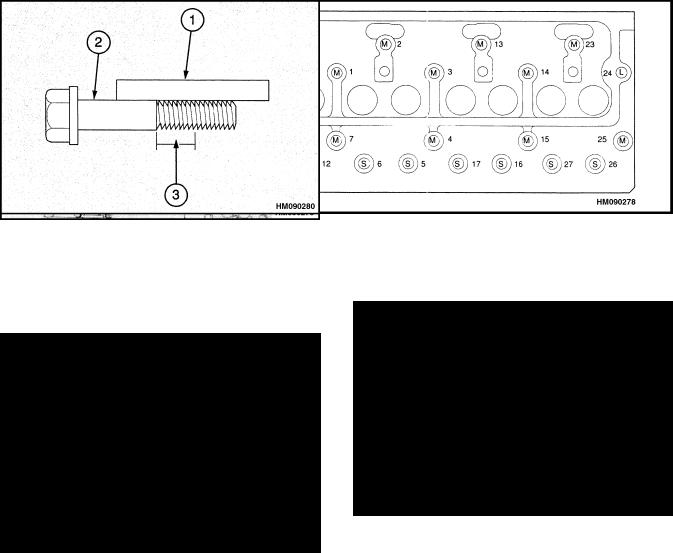

3.Use two 1/2 UNF studs in positions 25 and 30. See Figure 16. Lower the cylinder head into position on the engine block. See Figure 17.

Cylinder Head Assembly Repair

Figure 15. Head Gasket Position

Figure 16. Cylinder Head Tightening Sequence

CAUTION

CAUTION

There are three lengths of capscrews. S = short, M = medium, L = long. Figure 16 shows their positions in the engine. Verify that the capscrews are installed in the correct positions.

4. |

Lubricate the capscrews with a thin coat of oil |

|

and install them into their holes in the cylinder |

|

head. When the cylinder head and gasket are |

|

held in position, remove the two studs and install |

|

the two capscrews in those positions. |

5. |

Evenly tighten the capscrews in the sequence |

Figure 17. Cylinder Head Installation |

shown in Figure 16. The final torque on the cap- |

screws is 110 N•m (81 lbf ft). |

11

Cylinder Head Assembly Repair

6.Verify all of the capscrews are tightened to the correct torque described in Step 5. The capscrews must be further tightened in the sequence shown in Figure 16 according to the following procedure:

a.The short capscrews (S) must be tightened an additional 150 (2.5 flats).

(2.5 flats).

b.The medium capscrews (M) must be tightened an additional 180 (3.0 flats).

(3.0 flats).

c.The long capscrews (L) must be tightened an additional 210 (3.5 flats).

(3.5 flats).

NOTE: A special tool shown in Figure 18 can be used for this procedure to measure the tightening angles. If an angle gauge is not available, make a mark in a line with one of the corners of the capscrew. See Figure 19. Make another mark at the correct angle (counterclockwise) on the edge of the flange of the cylinder head for each capscrew and according to the length of each capscrew. Tighten each capscrew in the correct sequence until the two marks are aligned.

7.Install the push rods in the engine. Verify that the end of each push rod fits correctly in the tappet socket.

Figure 18. Angle Gauge

Figure 19. Tighten Cylinder Head Capscrews

600 SRM 1068

8.Install the rocker arm assembly per Rocker Arm Assembly, Installl.

9.Adjust the valve clearances per Valve Clearance Adjustments.

10.Install the fuel injectors per Fuel Injectors, In- stall.

11.Install the high pressure fuel lines between the fuel injection pump and the fuel injectors. Use a separate wrench to prevent movement of the outlets of the fuel injection pump when the fuel lines are connected. Tighten the connection nuts to 27.5 N•m (20 lbf ft).

12.Install the fuel filter and bracket. Install the lowpressure fuel lines between the fuel filter and the fuel injection pump.

13.If equipped, reinstall the MIC to the MIC mounting bracket.

14.Install the coolant bypass connection. Tighten the capscrews and the hose clamp.

15.If an air compressor is installed on the engine, install the coolant pipe between the cylinder head and the compressor. Install the pipe between the coolant bypass and the compressor.

NOTE: Do not use sealant compound on gaskets of the manifold.

16.Verify the exhaust manifold gaskets and gasket surfaces are clean and not damaged.

17.Place the temporary studs in the cylinder head.

a.For two-piece exhaust manifolds, place temporary studs in positions 4, 8, 11, and 15 of the cylinder head. See Figure 20.

Figure 20. Two-Piece Exhaust Manifold

Tightening Sequence

12

600 SRM 1068 |

Cylinder Head Assembly Repair |

b.For three-piece exhaust manifolds, place temporary studs in positions 2, 5, 14, and 17 of the cylinder head. See Figure 21.

Figure 21. Three-Piece Exhaust Manifold

Tightening Sequence

18.Place the exhaust manifold gaskets in position over the studs. Verify the gaskets are in the correct position.

19.Reassemble the sections of the exhaust manifold and place in position over the temporary studs.

20.Insert the capscrews into all positions that do not have temporary studs and torque to 12.5 N•m (9 lbf ft).

21.Remove temporary studs and insert remaining capscrews and torque to 12.5 N•m (9 lbf ft).

22.Torque the capscrews again in sequence to 12.5 N•m (9 lbf ft). See Figure 20 and Figure 21.

CAUTION

CAUTION

Before the inlet manifold capscrews are installed again, any loose M.E.A.S in the cylinder head holes must be removed to allow the manifold to be fully tightened.

Do not scratch or damage the flange faces of the inlet manifold.

NOTE: The capscrews that retain the manifold to the cylinder head have M.E.A.S applied to the threads. If the capscrews are removed and installed again, the threads must be cleaned and POWERPART threadlock sealant used.

23.Place a new induction manifold gasket into position on the cylinder head.

24.Place the induction manifold in position on the cylinder head.

25.Install the induction manifold capscrews and torque in sequence to 22 N•m (16 lbf ft). See Figure 22.

Figure 22. Induction Manifold Tightening

Sequence

26.Install the fuel line between the fuel filter and the cold start aid. If the engine is in the lift truck, install the electrical connection to the cold start aid.

27.Install the air intake hose.

28.Install the turbocharger. See Turbocharger, In- stall.

29.Install the closed circuit breather assembly if previously removed.

30.Install the fuel lines between the fuel filter and the fuel injection pump.

31.If the engine is still in the lift truck, do the following procedures:

a.Connect the sender unit for the coolant temperature gauge.

b.Connect the hoses for the coolant system. Fill the cooling system.

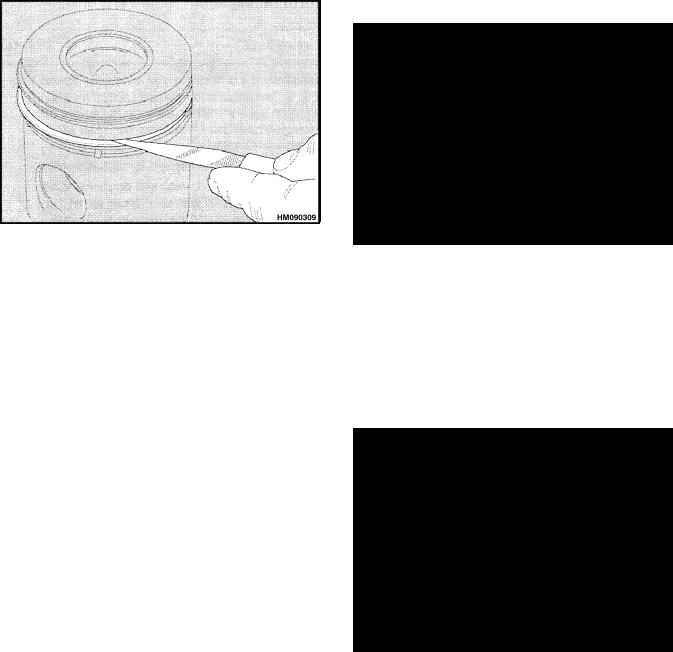

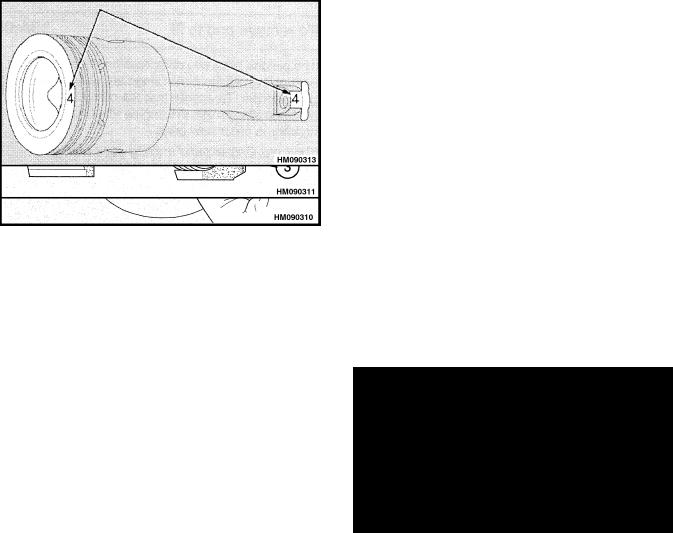

c.Connect the battery terminals.