Parkside PDWE 8 A2 Instructions Manual

AIR FILTER REGULATOR & LUBRICATOR

PDWE 8 A2

GB CY

AIR FILTER REGULATOR &

LUBRICATOR

Operation and Safety Notes

Translation of the original instructions

RO

UNITATE DE REVIZIE PENTRU AER

COMPRIMAT

Indicații de operare și siguranță

Traducerea instrucţiunilor de utilizare originale

GR CY

ΜΟΝΆΔΆ ΣΥΝΤΉΡΉΣΉΣ

ΠΕΠΙΕΣΜΕΝΟΥ ΆΕΡΆ

Υποδείξεις χειρισμού και ασφαλείας

Μετάφραση των αυθεντικών οδηγιών λειτουργίας

RS

PRIPREMNA GRUPA

Prevod originalnog uputstva za upotrebu

BG

ПНЕВМОПОДГОТВЯЩА ГРУПА

Указания за монтаж, работа и безопасност

Превод на оригиналното ръководство

за експлоатация

DE AT CH

DRUCKLUFT WARTUNGSEINHEIT

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

IAN 304723

RS

RO

CYGR

BG

GB CY

Before reading, unfold the page containing the illustrations and familiarise yourself with all

functions of the device.

RS

Pre čitanja rasklopite obe strane sa slikama te se upoznajte sa svim funkcijama uređaja.

RO

Desfaceți înainte să citiți pagina cu ilustrații și apoi familiarizați-vă cu toate funcțiile

aparatului.

BG

Преди да прочетете отворете страницата с фигурите и след това се запознайте с

всички функции на уреда.

GR CY

Πριν ξεκινήσετε την ανάγνωση, ανοίξτε τη σελίδα με τις εικόνες και εξοικειωθείτε με όλες τις

λειτουργίες τηςна уреда.συσκευής.

DE AT CH

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich

anschließend mit allen Funktionen des Gerätes vertraut.

GB / CY Operation and Safety Notes Page 5

RS Prevod originalnog uputstva za upotrebu Stranica 17

RO Instrucţiuni de utilizare şi de siguranţă Pagina 29

BG Инструкции за обслужване и безопасност Страница 41

GR / CY Υποδείξεις χειρισμού και ασφαλείας Σελίδα 55

DE / AT / CH Montage-, Bedienungs- und Sicherheitshinweise Seite 69

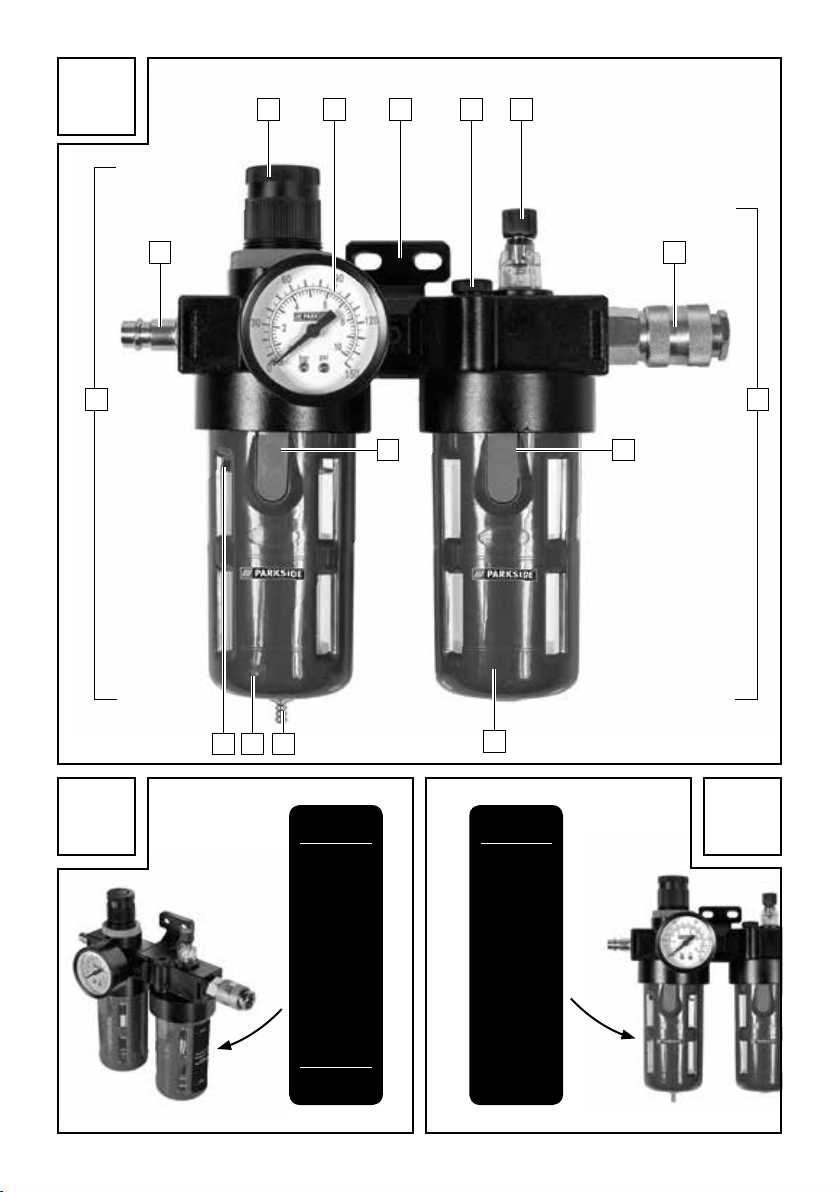

A

3

4 5 6 7

2

1 9

14 13 12

11

8

1010

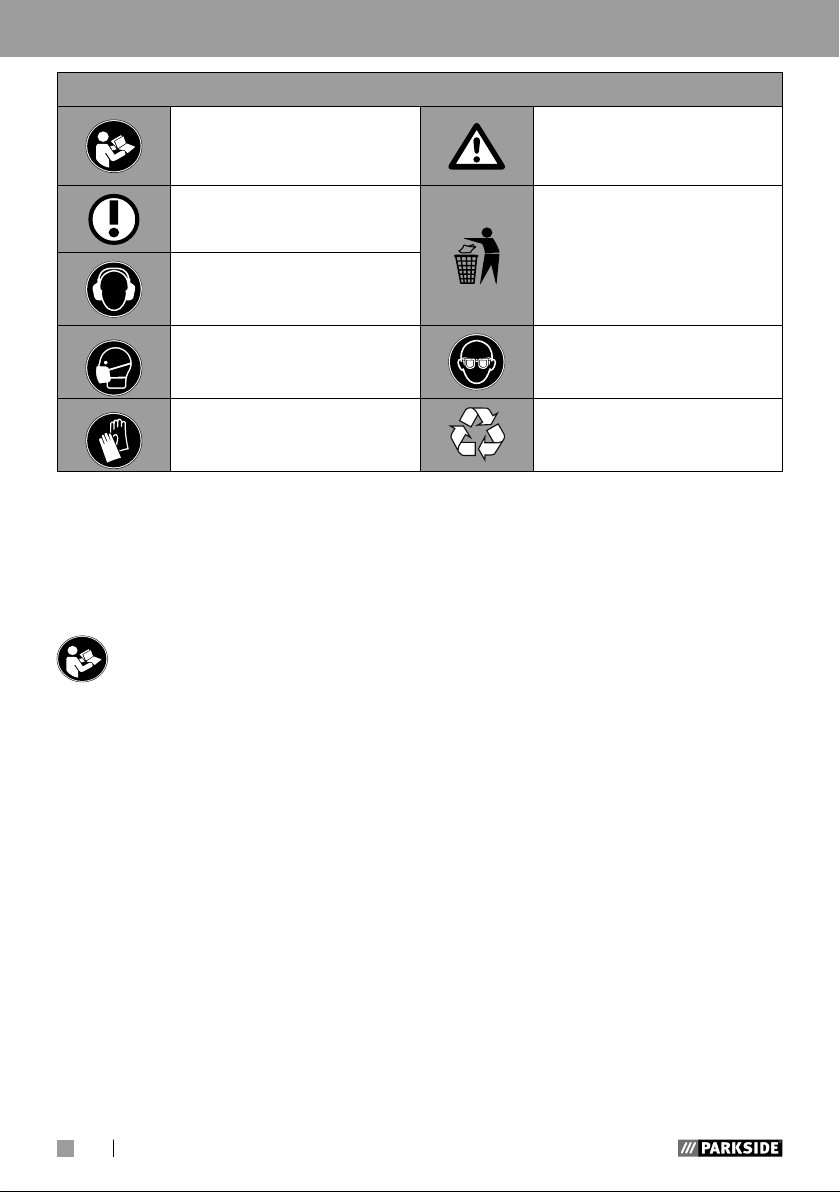

B C

MAX.

DRUCKLUFTÖL

PNEUMATIC OIL

HUILE

PNEUAMTIQUE

MIN.

MAX.

KONDENSAT

CONDENSATE

CONDENSAT

Table of contents

Table of pictograms used .............................................................................. Page 6

Introduction .......................................................................................................... Page 6

Intended use ............................................................................................................ Page 6

Residual risk ............................................................................................................ Page 6

Parts description ...................................................................................................... Page 7

Technical specifications ........................................................................................... Page 7

Package contents ..................................................................................................... Page 7

Safety notes ......................................................................................................... Page 7

Safety notes for using pneumatic devices ............................................. Page 8

Installation ........................................................................................................... Page 9

Filling the oil mist unit .............................................................................................. Page 10

Starting up ............................................................................................................ Page 10

Setting the working pressure .................................................................................. Page 10

Filter unit .................................................................................................................. Page 11

Condensate drain via the drain valve ..................................................................... Page 11

Oil mister unit .......................................................................................................... Page 11

Troubleshooting .................................................................................................. Page 12

Cleaning and maintenance ........................................................................... Page 12

Warranty and service information ........................................................... Page 12

Warranty conditions ................................................................................................ Page 12

Extent of warranty ................................................................................................... Page 13

Processing of warranty claims ................................................................................. Page 13

Environmental notes and disposal information ................................. Page 13

Disposal of the maintenance unit ............................................................................. Page 13

5GB/CY

Table of pictograms used / Introduction

Table of pictograms used

Read the operating

instructions!

Note!

Use hearing protection!

Use a dust mask! Use a goggles!

Use protective gloves! Made of recycling material.

AIR FILTER REGULATOR &

LUBRICATOR PDWE 8 A2

Introduction

Congratulations! You have purchased

one of our high-quality devices.

Before setup or first use, please

familiarise yourself with the product. To do

so, please read through the following

operating and safety instructions carefully.

This tool must be set up or used only by

people who have been trained to do so.

Observe warnings and the

safety instructions!

Dispose of the pneumatic

devices and packaging environmentally compatibly!

all documentation when passing the product

on to anyone else. Any use that differs to

the intended use as stated above is prohibited and potentially dangerous. Damage

or injury caused by misuse or disregarding

the above warning is not covered by the

warranty or any liability on the part of the

manufacturer. The device was designed for

household use and must not be used commercially or industrially.

Residual risk

KEEP OUT OF THE REACH OF

CHILDREN!

Intended use

The air filter regulator & lubricator serves to

oil the compressed air for pneumatic tools

and at the same time filters condensation

from the compressed air. Use the products

only as described and only for the specific

applications as stated. Keep these instructions in a safe place. Ensure you hand over

6 GB/CY

Even if you operate the device according to

the instructions, there will always be residual

risks remaining. The following risks may

occur in connection with the build and execution of this pneumatic maintenance unit:

Danger from beating compressed air

hoses.

Danger of falling from compressed air

hoses lying around.

Introduction / Safety notes

Reduce the residual risk by carefully using

the device as intended and observing all

instruction.

Parts description

After unpacking the product, please check

that the device is in perfect condition. Do not

use the product if it is defective.

1

Filter unit

2

Barbed fitting

3

Compressed air controller

4

Compressed air pressure gauge

5

Wall bracket

6

Oil refilling inlet

7

Oil gauge plug

8

Quick coupling

9

Oil mister unit

10

Release knob

11

Container for pneumatic oil, oil container

12

Drain valve

13

Condensate collection container

14

Filter insert

Technical specifications

Max. working pressure: 8 bar

Oil: Suitable compressor

oil

Package contents

1 pneumatic air maintenance unit including

connections

Safety notes

Please read the operating

instructions with care and

observe the notes described.

Familiarise yourself with the

device, its proper use and the

safety notes based on these

operating instructions.

The rating plate container all

technical data of this pneumatic maintenance unit; please

learn about the technical features of this device.

This device can be used by

children 16 years and older and also by persons with

reduced physical, sensory or

mental capacities or a lack of

experience and knowledge

if they are supervised or they

have been instructed with

regard to the safe use of the

device and they understand

the dangers it presents. Do

not allow children to play with

the product. Cleaning and

user maintenance must not be

performed by children without

supervision.

In connection with a com-

pressor, the maintenance unit

serves maintenance and care

(e.g. filtering, oiling and regulation) of your pneumatic tools.

The maintenance unit must

only be used with a pneumatic

compressor. When using the

device, observe the maximum

compressed air values of the

connected tools and check

7GB/CY

Safety notes / Safety notes for using pneumatic devices

them several times during use.

This product is only intended

for private use. The maintenance unit must only be used

as intended. Any further, deviating use is forbidden!

Consideration of the safety

note sin the operating instruction and the assembly instructions are also part of intended

use. The manufacturer or

dealer assumes no liability for

any damage caused by non-intended or wrong use.

Only accessories suitable for

this product must be used.

Persons who use the pneumatic maintenance unit and who

may perform maintenance

work are obligated to familiarise themselves with it. They

also must be informed about

potential dangers. The applicable accident prevention provisions must be correctly and

conscientiously observed.

Any changes to the pneumatic

maintenance unit exclude liability of the manufacturer and

any connected damage.

Safety notes for using

pneumatic devices

Important!

Always keep the compressed

air hose firmly in your hands

when releasing a connection.

The lashing backlash of the

compressed air hose may

cause injury.

The compressed air mainte-

nance unit must be installed

before it can be safely taken

into operation. A stable wall

is suitable for installation (with

screw connections).

We recommend only using

the lubricants specified by the

manufacturer.

Never exceed the indicated

maximum pressure values of

the maintenance unit.

The pneumatic maintenance

unit must only be connected to

a compressed air source that

does not exceed the working

pressure of 8 bar.

Do not put the compressed air

lines near any heat, oils, heat

and sharp edges.

The maintenance unit must

only be operated in connection with a pneumatic

compressor. Use of other

compressed air sources, such

as a compressed air cylinder,

is forbidden. There is a danger

of fire and/or explosion.

Make sure that children and

persons with limited physical

or mental capacities are kept

8 GB/CY

Safety notes for using pneumatic devices / Installation

away from the maintenance

unit and the connected compressed air tools.

Only use genuine spare parts

for repairs. Any non-genuine

spare parts may cause severe

damage.

When conducting any main-

tenance, setting and repair

work, always disconnect the

maintenance unit from the

compressed air supply first.

Changes to the maintenance

unit are forbidden.

Use the maintenance unit only

when it is in an impeccable

condition. In doubt, use a specialist's advice.

Have repairs only conducted

by qualified specialists.

User safety

Try out the pneumatic tool

used before every use.

Never use the compressed air

maintenance unit with any higher

operating pressure then indicated

in the technical data. Before you

connect your pneumatic tools to

the pneumatic maintenance unit,

ensure that they are properly and

securely connected.

explosive environment. Avoid

working in environments with substances such as flammable gases, liquids, paint and dust mist.

These substances may inflame

due to very hot surfaces at the

pneumatic unit.

Important note:

Do not use the mainte-

nance unit in connection

with pneumatic devices that

must not use any prepared compressed air (e.g. grease guns,

sand-blasting units, tyre fillers,

etc.).

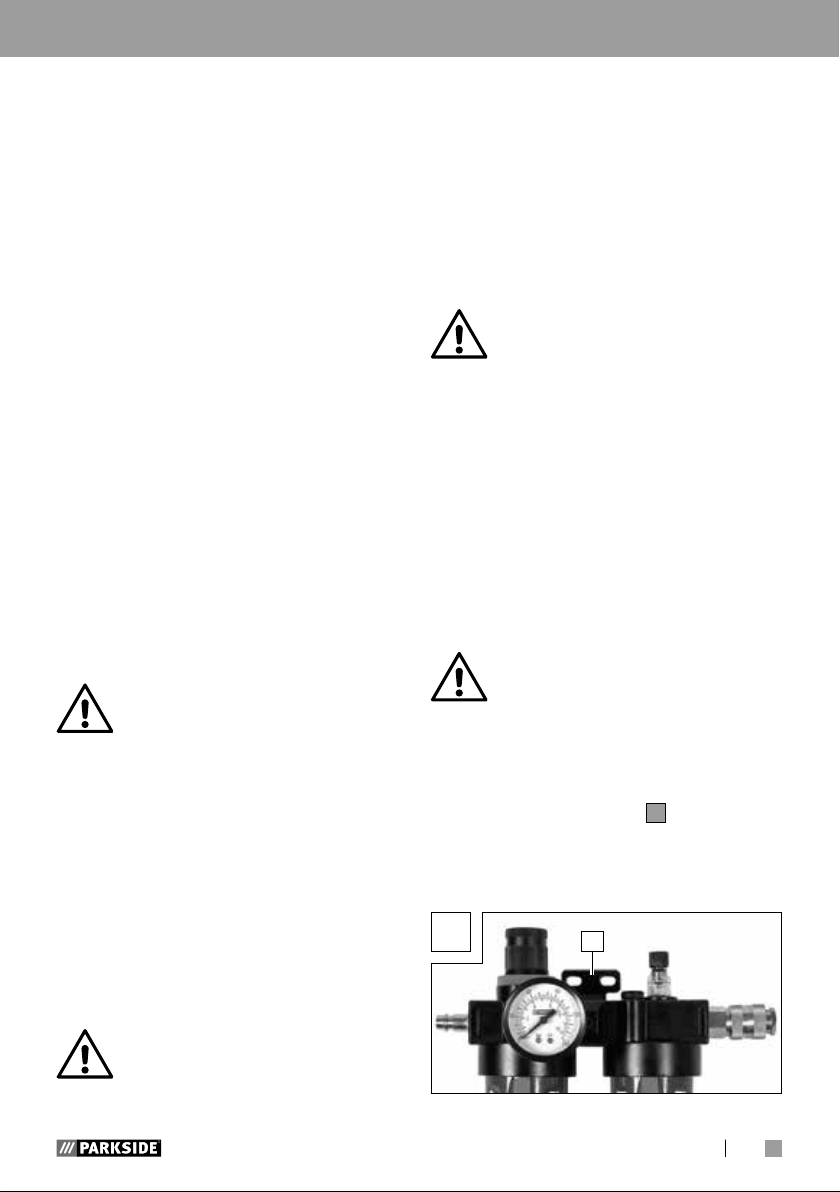

Installation

Attention:

To minimise potential injury or dam-

age, the maintenance unit must be

installed on a suitable wall before first commissioning. Ensure a stable and

assembly of the pneumatic maintenance unit.

Use the attachment unit 5 to mark the

wall for wall installation and for screwing

on with matching connection material

(see Fig. D).

D

5

horizontal

Forbidden uses

Do not use this maintenance unit in a potentially

9GB/CY

Installation / Starting up

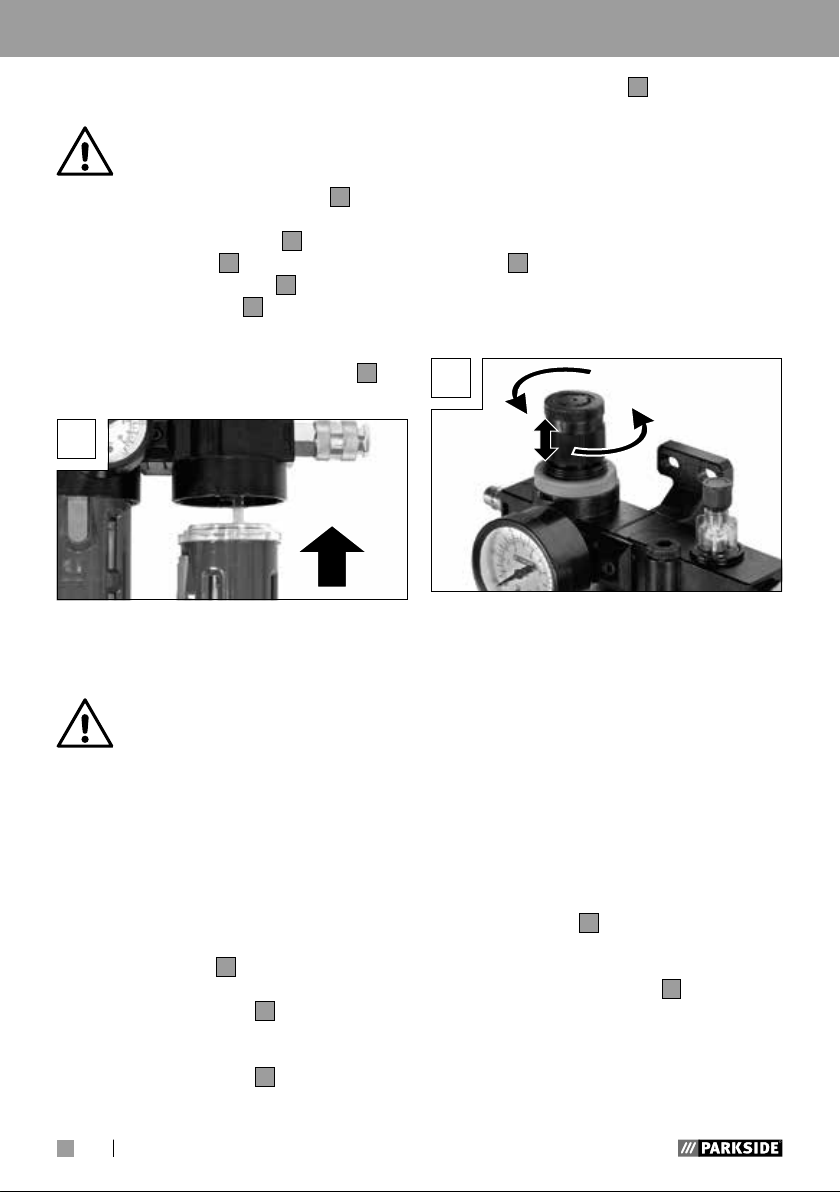

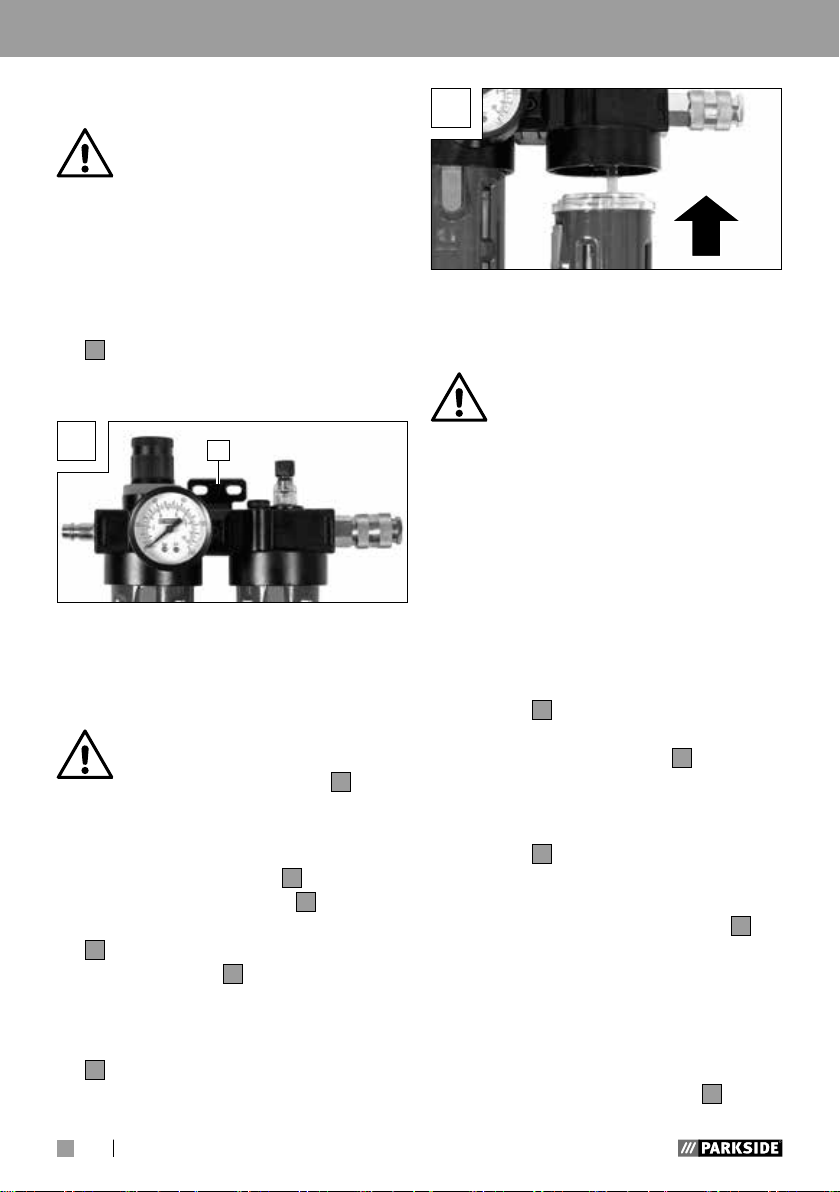

Filling the oil mist unit

Ensure that the maintenance unit

has been separated from the

compressed air source before filling

or releasing the container

Remove the oil container

the release knob

10

and simultaneously

turning the oil container

Fill the oil container

11

using suitable

11

11

by pressing

11

(see Fig. E).

.

compressor oil until the max. mark has

been reached (see Fig. B).

Subsequently tighten the container

11

only manually (without tools).

E

Starting up

Ensure that the connected compressed air line is clean and oil-free

in order to properly use the

compressed air maintenance unit. Further

ensure that the pneumatic system is depressurised. To minimise pressure loss, it is

beneficial if the compressed air lines are

kept as short as possible.

Connect the pneumatic maintenance unit

to the compressed air source

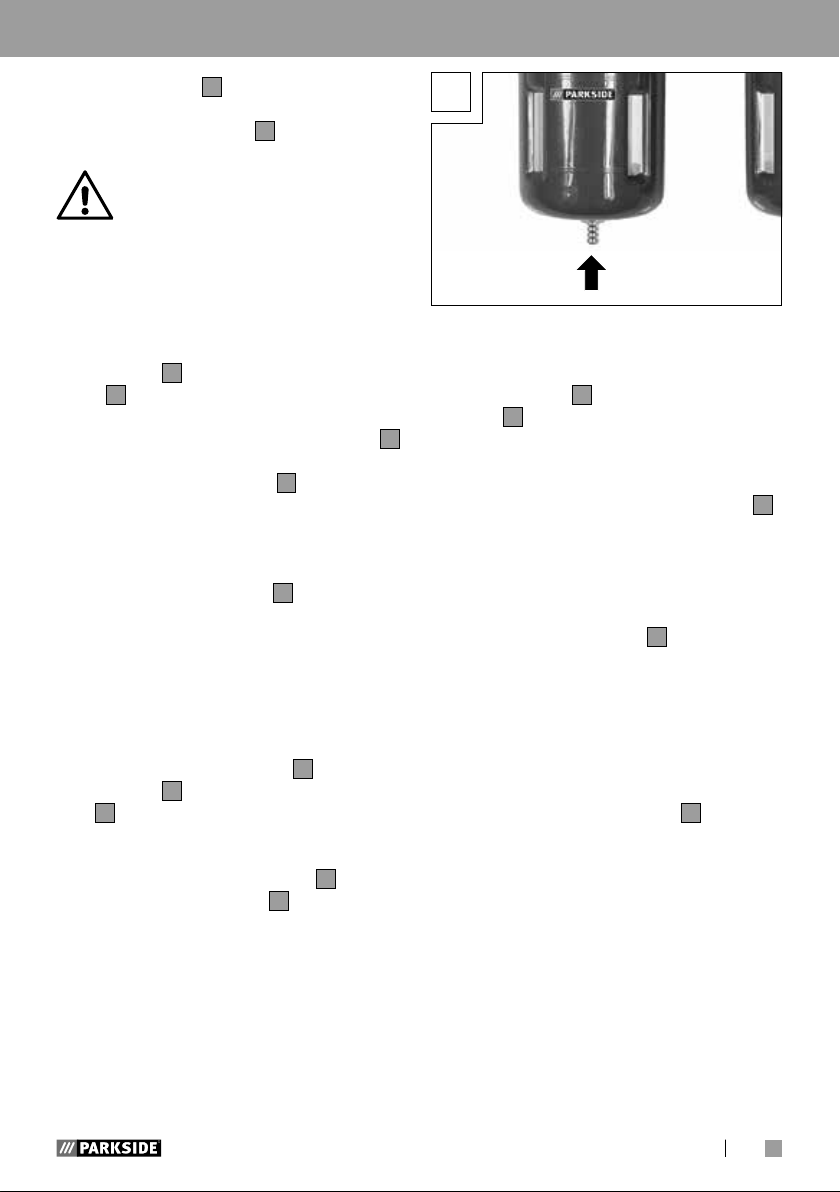

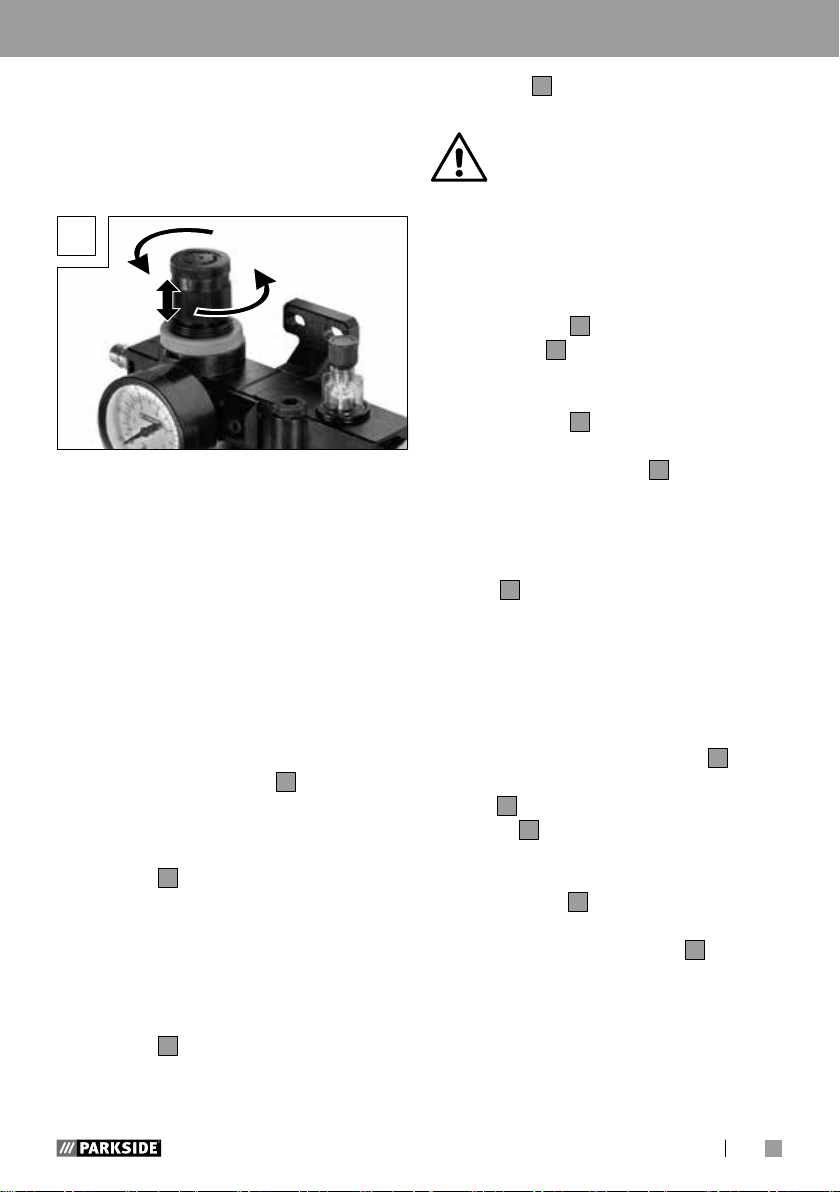

First release the lock by mpulling the

pressure regular

Turn counter-clockwise to set the com-

pressed air controller

possible level. The desired settings will

be assumed by pushing down the compressed air controller

Connect the compressed air supply line

3

upwards. (see Fig. F)

3

to the lowest

3

.

at the quick coupling 8 of the tool to

be connected to the right side (output) of

the maintenance unit (see figure on the

right). A triangle "" on the surface of

the device indicates the flow direction of

the compressed air.

Connect the compressed air supply of

the compressed air source at the barbed

2

fitting

on the left (input) of the maintenance unit (directly at the input, the

surface has a triangle "", that indicates

the flow direction of the compressed air).

F

Before commissioning of the mainte-

nance unit, check the compressed air

flow direction with the mark " " on the

surface. If the setting is not correct, the

pressure generated will not be correct.

Setting the working

pressure

After linking the maintenance unit to a

compressed air source (see above), you can

set the desired operating pressure with the

pressure controller

First release the lock by pulling the

compressed air controller

(see Fig. F)

Turning counter-clockwise reduces the

pressure, and turning clockwise increases the pressure.

Read the set pressure at the pressure

3

.

3

upwards.

10 GB/CY

Starting up

gauge display 4.

Lock the setting by pressing the com-

pressed air controller

3

downwards.

Note:

Ensure that the maximum possible

operating pressure of the maintenance unit and the pneumatic tool is

not exceeded.

Filter unit

The filter unit 1 is linked to the pressure con-

3

troller

. The maximum working pressure

is 8 bar and the operating pressure can be

adjusted from 0.5 to 8 bar. The filter unit

1

is used to filter condensate and stores the

condensate in the filter tank

13

.

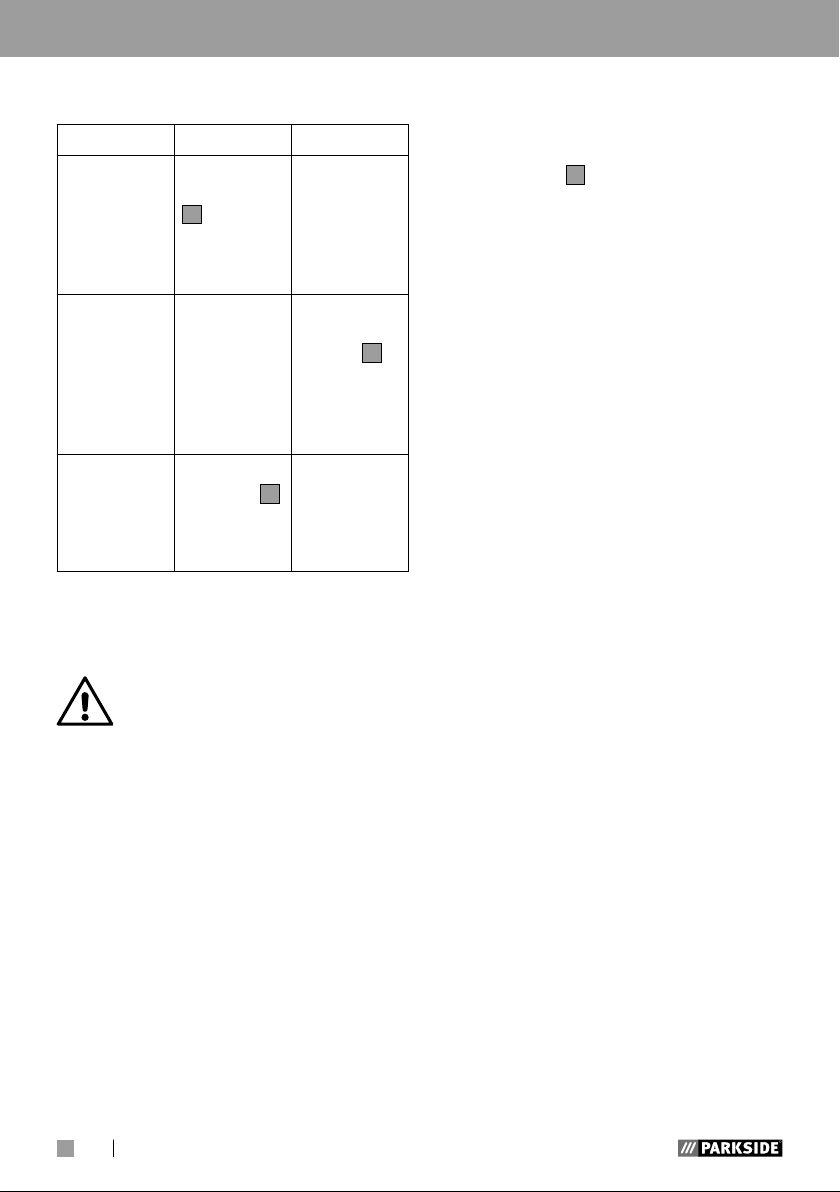

You can check the condensate fill level

through the transparent sight windows (see

Fig. C). The stored condensate can be

drained via the drain valve

12

.

Condensate drain via the

drain valve

Ensure horizontal installation of the maintenance unit so that the condensate can be

stored horizontally in the tank

The filter unit

13

tank

1

installed.

must not be used without the

Use a matching tank in order to drain the

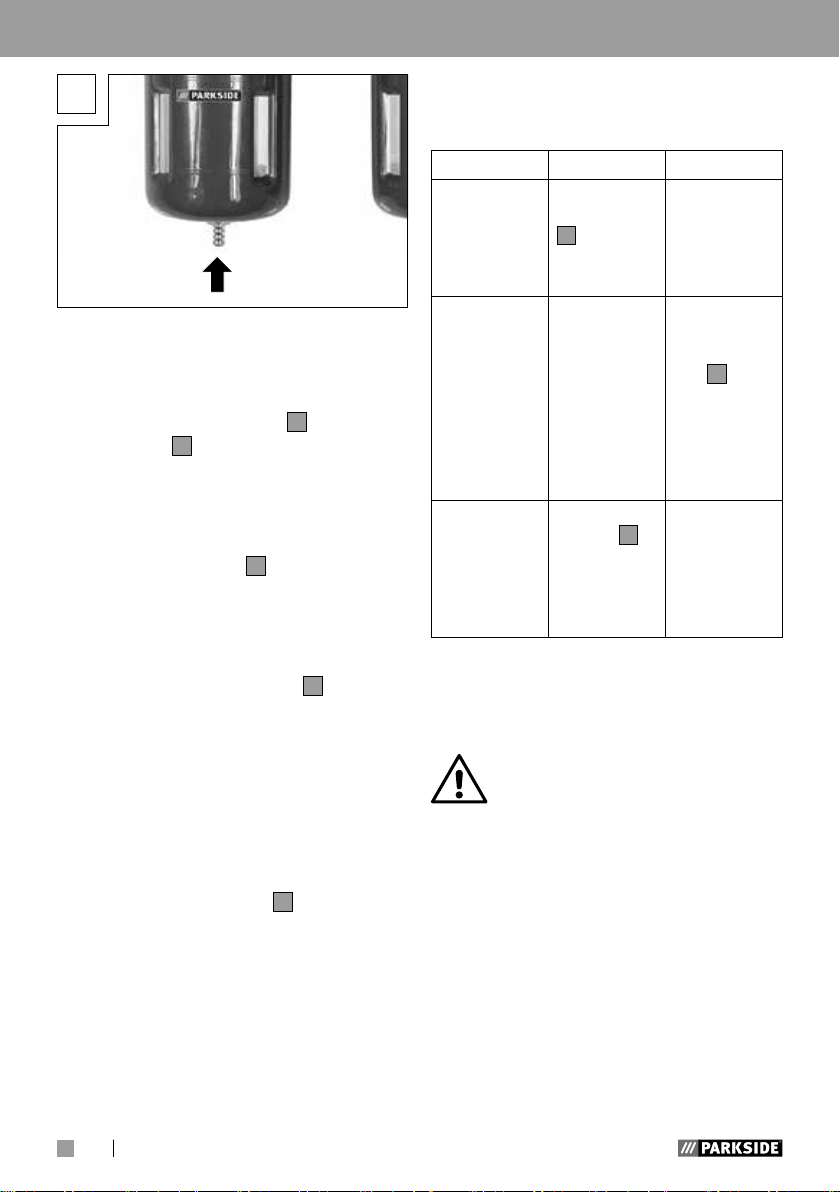

stored condensate from the tank

against the drain valve

(see Fig. G), this causes it to open and

thus, the condensate flows into the

container.

13

as well.

13

12

from below

. Press

G

Oil mister unit

The oil mister unit 9 is connected to the

filter unit

filtered compressed air that is transported

towards the compressed air tool.

You can check the fill level of the oil tank

(integrated into the oil mister unit) through

the transparent sight windows. Use only

matching oil for this maintenance unit (see

above).

Turn the oil drain screw

The integrated sight window permits

To top up oil, turn the screw

1

. It has the function of oiling the

7

that is installed on the sight glass clockwise ("–"),

in order to reduce the required volume

of oil. Turn it counter-clockwise ("+") to

increase the volume of oil.

continuous overview of the filtered compressed air.

6

with a suitable socket wrench. Fill the

tank with a matching hopper and tighten

the screw again with the wrench.

down

11

11GB/CY

Troubleshooting / Cleaning and maintenance / Warranty and service ...

Troubleshooting

Faults Causes Solution

The lubrication is not

sufficient

The operating pressure

of the compressed air

is too low.

The oil passage screw

7

it tightened too far

in direction

("–").

The compressed air

volume is

too low, i.e.

below the

minimum fill

level.

The pressure

controller

is tightened

too far

(see above).

Increase

lubrication

(see above).

Pour more

oil into the

oil tank

Observe the

maximum fill

level.

Increase the

pressure

3

(see above).

Cleaning and maintenance

11

and the connections with a moist cloth at

regular intervals.

Drain the pneumatic maintenance unit's

tank at regular intervals. For this, press in

the metal pin

condensate drain (see Fig. G). Note that

the pneumatic maintenance unit must be

depressurised for safety.

12

at the bottom and let the

Warranty and service infor-

mation

.

Warranty from Creative Marketing

Consulting GmbH

Dear Customer, The warranty for this device

is 3 years from the date of purchase. In the

event of product defects, you have legal

rights against the retailer of this product.

Your statutory rights are not affected in any

way by our warranty conditions, which are

described below.

Warranty conditions

Note:

The pneumatic maintenance unit

must be regularly serviced and overhauled for proper function and for compliance with the safety requirements. Improper

and wrong operation may cause failures

and damage to the device.

Never use any sharp and/or scraping

cleaning agents or solvents. They may

damage the plastic parts of the pneumatic maintenance unit.

Make sure that no water can enter inside

the oiler.

Ensure that the housing and the inside of

the pneumatic maintenance unit remains

dust- and dirt-free. For this, regularly rub

the pneumatic maintenance unit with a

clean cloth.

Clean the pneumatic maintenance unit

12 GB/CY

The warranty period begins on the date of

purchase. Please retain the original sales

receipt. This document is required as your

proof of purchase. Should this product show

any defect in materials or manufacture within

3 years from the date of purchase, we will

repair or replace it – at our discretion – free

of charge. To claim against this warranty,

you must present the defective device and

your purchase receipt within the 3-year period, and include a brief written description

of the nature of the defect and the date it

occurred. If the defect is covered by our warranty, we will repair and return your product

or send you a replacement.

The original warranty period is not extended

when a device is repair or replaced.

... / Environmental notes and disposal information

Extent of warranty

The device has been manufactured according to strict quality guidelines and meticulously examined before delivery. The warranty applies to material and manufacturing

defects only. This warranty does not extend

to product parts which are subject to normal

wear and tear and can thus be regarded as

consumable parts, or for damages to fragile

parts, e.g. switches, rechargeable batteries,

or parts made from glass. This warranty is

voided if the product becomes damaged or

is improperly used or maintained. For proper

use of the product, all of the instructions

given in the operating instructions must be

followed precisely. If the operating instructions advise you or warn you against certain

uses or actions, these must be avoided in all

circumstances. The product is for consumer

use only and is not intended for commercial

or trade use. The warranty becomes void in

the event of misuse and improper use, use

of force, and any work on the device that

has not been carried out by our authorised

service branch.

Note

If you visit www.lidl-service.com,

you can download this manual

and many other manuals, product

videos and software.

How to contact us:

GB / CY

Name: C. M. C. GmbH

Website: www.cmc-creative.de

E-mail: service.gb@cmc-creative.de

Phone: 0-808-189-0652

Registered office: Germany

IAN 304723

Please note that the following address is not

a service address. Please first contact the

service point given above.

Address:

C. M. C. GmbH

Katharina-Loth-Str. 15

D-66386 St. Ingbert

GERMANY

Processing of warranty

claims

Please follow the instructions below to ensure

quick processing of your claim: Please

retain your proof of purchase and quote the

product number (e.g. the IAN 12345) in all

correspondence. The product number can be

found on the type plate, an engraving, the

cover page of your instructions (bottom left),

or the sticker on the back or bottom. In the

event of malfunctions or other defects, please

first contact our service department below by

phone or email. If your product is found to

be defective, you can then send your product with proof of purchase (till receipt) and a

statement describing what the fault involves

and when it occurred free of charge to the

service address given.

Environmental notes and

disposal information

Always recycle the device, accessories and packaging in an environmentally-friendly manner.

Do not dispose of pneumatic devices in

household waste! Devices that are no longer

functional should be recycled wherever possible. Ask your local stockist for advice.

Disposal of the

maintenance unit

Dispose of the maintenance unit according

to the provisions applicable in your country.

13GB/CY

Environmental notes and disposal information

If the maintenance unit can no longer be

used, return it to a collection point of your

municipality/quarter. This ensures that it

will be professionally recycled and avoids

negative effects on the environment.

14 GB/CY

15GB/CY

16 GB/CY

Sadržaj

Tabela simbola ............................................................................................... Stranica 18

Uvod .................................................................................................................. Stranica 18

Primerena upotreba ........................................................................................ Stranica 18

Ostale opasnosti ............................................................................................. Stranica 18

Opis delova ..................................................................................................... Stranica 19

Tehnički podaci................................................................................................Stranica 19

Sadržaj isporuke ............................................................................................. Stranica 19

Sigurnosne napomene ................................................................................ Stranica 19

Sigurnosne napomene za upotrebu

pneumatskih uređaja.................................................................................... Stranica 20

Montaža .......................................................................................................... Stranica 22

Punjenje jedinice za raspršivanje ulja ............................................................. Stranica 22

Upotreba .......................................................................................................... Stranica 22

Podešavanje radnog pritiska .......................................................................... Stranica 23

Filterska jedinica ............................................................................................. Stranica 23

Ispuštanje kondenzata pomoću ispusnog ventila............................................ Stranica 23

Jedinica za raspršivanje ulja ........................................................................... Stranica 24

Otkrivanje i otklanjanje kvarova................................................................ Stranica 24

Čišćenje i održavanje ................................................................................... Stranica 24

Napomene o garanciji i servisiranju ........................................................ Stranica 25

Uslovi garancije ............................................................................................... Stranica 25

Obim garancije ................................................................................................ Stranica 25

Obrada garantnih zahteva............................................................................... Stranica 25

Zaštita životne sredine i odlaganje .......................................................... Stranica 26

Odlaganje pripremne grupe ............................................................................ Stranica 26

Garancija i garantni list ............................................................................... Stranica 27

17RS

Tabela simbola / Uvod

Tabela simbola

Pročitajte uputstvo za

upotrebu!

Napomena!

Koristite zaštitu za uši!

Koristite masku protiv

prašine!

Koristite zaštitne rukavice!

PRIPREMNA GRUPA PDWE 8 A2

Uvod

Čestitamo! Odabrali ste kvalitetan

uređaj iz naše kuće. Upoznajte se

s proizvodom pre prve upotrebe.

Pažljivo pročitajte ovo uputstvo i sigurnosne

napomene. Ovaj uređaj smeju da

upotrebljavaju samo obučena lica.

Pridržavajte se sigurnosnih

napomena!

Pneumatske uređaje

i ambalažu odlažite na

ekološki prihvatiljiv način.

Koristite zaštitne naočare!

Proizvedeno od recikliranog

materijala.

Zabranjena je i može biti potencijalno

opasna svaka primena koja odstupa

od primerene upotrebe. Šteta nastala

nepridržavanjem uputstava ili pogrešnom

upotrebom proizvoda nije pokrivena

garancijom i za nju odgovornost ne može

snositi proizvođač. Uređaj je dizajniran

za kućnu upotrebu i ne sme se koristiti za

komercijalne ili industrijske namene.

DRŽATI DALJE OD DOMAŠAJA DECE!

Primerena upotreba

Pripremna grupa služi za podmazivanje

komprimovanog vazduha za pneumatski

alat i istovremeno uklanja kondenzat iz

komprimovanog vazduha. Koristite proizvod

samo onako kako je opisano i samo za

navedene oblasti primene. Sačuvajte ovo

uputstvo.

Prilikom ustupanja proizvoda drugom

licu predajte i sve propratne dokumente.

18 RS

Ostale opasnosti

Postoje druge opasnosti čak i kada uređaj

koristite primereno. U vezi sa konstrukcijom

i projektovanjem ove pripremne grupe može

doći do sledećih opasnosti:

Opasnost usled „nemirnog“

pneumatskog creva.

Opasnost od pada usled pneumatskih

creva koja leže okolo.

Svedite ostale opasnosti na najmanju meru

pažljivim i primerenim korišćenjem uređaja

Uvod / Sigurnosne napomene

i poštovanjem uputstava.

Opis delova

Proverite da li je proizvod u besprekornom

stanju odmah nakon otpakivanja. Nemojte

koristiti proizvod koji je u kvaru.

1

Filterska jedinica

2

Nasadna spojnica

3

Regulator komprimovanog vazduha

4

Manomater komprimovanog vazduha

5

Zidni nosač

6

Otvor za dolivanje ulja

7

Čep za dovod ulja

8

Brza spojka

9

Jedinica za raspršivanje ulja

10

Dugme za oslobađanje

11

Rezervoar za ulje komprimovanog

vazduha

12

Ispusni ventil

13

Rezervoar za kondenzat

14

Uložak ltera

Tehnički podaci

Najveći radni pritisak 8 bara

Ulje: odgovarajuće ulje

za kompresore

Sadržaj isporuke

1 pripremna grupa uključujući priključke

Sigurnosne napomene

Pažljivo pročitajte uputstvo

za upotrebu i pridržavajte

se napomena. Upoznajte

se s uređajem, njegovom

pravilnom upotrebom

i sigurnosnim napomenama

prema ovom uputstvu.

Na natpisnoj pločici navedeni

su tehnički podaci ove

pripremne grupe. Upoznajte

se s tehničkim podacima ovog

uređaja.

Ovaj proizvod smeju da

koriste deca starija od

16 godina i osobe sa

smanjenim zičkim, čulnim

ili mentalnim sposobnostima

odnosno nedovoljnim

iskustvom i znanjem ako su

pod nadzorom ili su podučena

o bezbednoj upotrebi uređaja

i razumeju opasnosti koje

iz toga proističu. Deca se

ne smeju igrati uređajem.

Čišćenje i održavanje ne

smeju obavljati deca bez

nadzora odraslih.

U spoju s kompresorom

pripremna grupa služi za

održavanje i negu (npr.

ltriranje, podmazivanje

i regulaciju) vašeg

pneumatskog alata.

Pripremna grupa sme

19RS

... / Sigurnosne napomene za upotrebu pneumatskih uređaja

se koristiti isključivo s

kompresorom za vazduh.

Vodite računa o najvećim

vrednostima komprimovanog

vazduha za priključeni

pneumatski alat pri upotrebi

uređaja i proveravajte ih

više puta u toku korišćenja.

Ovaj proizvod je predviđen

isključivo za privatnu

upotrebu. Pripremna grupa

sme se koristiti samo u skladu

s namenom. Zabranjena je

svaka druga upotreba koja

odstupa od predviđene!

Sastavni deo primerene

upotrebe takođe predstavlja

poštovanje sigurnosnih

napomena navedenih

u uputstvu kao i uputstva

za montažu. Proizvođač

i prodavac ne snose

odgovornost za štetu nastalu

neprimerenom ili pogrešnom

upotrebom.

Sme se koristiti samo pribor

pogodan za ovaj proizvod.

Lica koja koriste pripremnu

ili vrše radove na održavanju

dužna su da se upoznaju

s uređajem. Osim toga moraju

biti informisana o mogućim

opasnostima. Potrebno

je tačno i savesno se

pridržavati važećih propisa za

sprečavanje nezgoda na radu.

Za izmene na pripremnoj

grupi i štetu nastalu na takav

način proizvođač ne snosi

odgovornost.

Sigurnosne napomene

za upotrebu pneumatskih

uređaja

Važno!

Uvek čvrsto rukama držite

pneumatsko crevo prilikom

otpuštanja priključka.

Trzaj pneumatskog creva

može da dovede do povrede.

Potrebno je montirati

pripremnu grup pre upotrebe.

Za montažu je potreban

stabilan zid (za ksiranje

vijcima).

Preporučuje se upotreba

maziva koja je odredio

proizvođač.

Nikada ne prekoračujte

navedene najveće vrednosti

pritiska pripremne grupe .

Pripremna grupa sme

se priključiti na izvor

komprimovanog vazduha koji

ne premašuje radni pritisak od

8 bara.

Ne postavljajte vodove

komprimovanog vazduha

u blizini toplote, ulja i oštrih

ivica.

Pripremna grupa sme se

20 RS

Sigurnosne napomene za upotrebu pneumatskih uređaja... / Sigurnosne napomene za upotrebu pneumatskih uređaja

koristiti samo u spoju s

kompresorom za vazduh.

Zabranjena je upotreba

drugih izvora komprimovanog

vazduha, npr. boce s

komprimovanim vazduhom.

Postoji opasnost od požara

odnosno eksplozije.

Decu i osobe sa smanjenim

zičkim i psihičkim

sposobnostima uvek udaljite

od pneumatskih jedinica za

održavanje i priključenog

pneumatskog alata.

Koristite samo originalne

rezervne delove pri popravci.

Neoriginalni rezervni delovi

mogu da prouzrokuju ozbiljna

oštećenja.

Pri obavljanju radova na

održavanju, podešavanju ili

popravci uvek prvo isključite

pripremnu grupu sa dovoda

komprimovanog vazduha.

Nije dozvoljeno vršiti izmene

na pripremnoj grupi.

Pripremnu grupu koristite

samo ako se nalazi u

besprekornom stanju. Ako

postoji sumnja, posavetujte se

sa stručnjakom pre upotrebe

motalice.

Popravku sme da vrši samo

kvalikovano stručno lice.

Bezbednost korisnika

Pre svake upotrebe

testirajte pneumatski

alat. Ni u kom slučaju nemojte

koristiti pripremnu grupu pri

većem radnom pritisku od onog

koji je propisan tehničkom

dokumentacijom. Uverite se

da je pneumatski alat pravilno

i sigurno priključen pre nego

što ga povežete s jedinicom za

održavanje.

Zabranjene oblasti

primene

Nemojte koristiti ovu

pripremnu grupu u okruženju

gde postoji opasnost od

eksplozije. Izbegavajte rad u

okruženjima u kojima se nalaze

supstance poput zapaljivih

gasova i tečnosti, raspršene boje

ili prašine. Ove supstance mogu

se zapaliti

zbog vrelih površina

na pneumatskom uređaju.

Važna napomena:

Nemojte koristiti

pripremnu grupu u spoju

s pneumatskim uređajima

koji ne smeju da se napajaju

pripremljenim komprimovanim

vazduhom (npr. prese za mast,

uređaji za mlazno peskarenje,

uređaji za naduvavanje

pneumatika itd.).

21RS

Montaža / Upotreba

Montaža

Pažnja: Da bi se mogućnost

nastanka povreda ili štete svela

na najmanju meru potrebno je

montirati pripremnu grupu na podesni zid

pre upotrebe. Vodite računa da pripremna

grupa bude montirana stabilno i

horizontalno.

E

Za montažu na zid koristite zidni nosač

5

kako biste obeležili mesto na zidu

i pričvrstili ga odgovarajućim materijalom

za ksiranje. (videti sliku D)

D

5

Punjenje jedinice za

raspršivanje ulja

Vodite računa da je pripremna

grupa isključena s dovoda

komprimovanog vazduha

punjenja odnosno uklanjanja

rezervoara za ulje.

Skinite rezervoar za ulje

na dugme za oslobađanje

i istovremenim odvrtanjem rezervoara

11

za ulje (videti sliku E). Napunite

rezervoar za ulje

uljem za kompresore dok ne dostignete

oznaku maksimalno (videti sliku B).

Zatim rezervoar za ulje čvrsto zavrnite

11

rukom (bez upotrebe alata).

11

odgovarajućim

11

pritiskom

10

11

pre

Upotreba

Vodite računa da priključeni vod

komprimovanog vazduha bude čist

i bez ulja kako biste mogli pravilno

da koristite pripremnu grupu. Takođe vodite

računa da sistem komprimovanog vazduha

bude oslobođen pritiska. Da bi se gubici

pritiska sveli na najmanju meru, savetuje se

da vodovi komprimovanog vazduha budu što

kraći.

Povezivanje pripremne grupe s izvorom

komprimovanog vazduha.

Najpre otpustite ustavni mehanizam

povlačenjam regulatora komprimovanog

vazduha

Postavite regulator komprimovanog

vazduha na najniži stepen

okretanjem suprotno smeru kazaljke.

Željene postavke se primenjuju

pritiskom na regulator komprimovanog

vazduha

Priključite dovod komprimovanog

vazduha pneumatskog alata koji

želite da povežete na brzu spojku

(na desnoj strani – izlaz) pripremne

grupe. Troguao „“ na spoljnoj strani

uređaja pokazuje smer toka

komprimovanog vazduha.

Priključite dovod komprimovanog

vazduha sa izvora komprimovanog

vazduha na nasadnu spojnicu

3

naviše. (videti sliku F)

3

naniže.

3

8

2

22 RS

Upotreba

(na levoj strani – ulaz) pripremne grupe.

Direktno na ulazu na spoljnoj strani

nalazi se trougao „“ koji pokazuje

smer toka komprimovanog vazduha.

F

Pre upotrebe pripremne grupe proverite

smer toka komprimovanog vazduha

pomoću oznake „“ na spoljnoj strani.

U slučaju pogrešnog podešavanja ne

proizvodi se dovoljan pritisak.

Podešavanje radnog pritiska

vazduha

3

naniže.

Napomena:

Vodite računa da ne prekoračite

najveći mogući radni pritisak

pripremne grupe i pneumatskog alata koji

koristite.

Filterska jedinica

Filterska jedinica 1povezana je

s regulatorom

Najveći radni pritisak iznosi 8 bara i može

se podešavati u rasponu od 0,5 do 8 bara.

Filterska jedinica

kondenzata i prikuplja kondenzat

u rezervoaru za kondenzat

Nivo kondenzata može se proveriti pomoću

prozirnih kontrolnih površina (videti sliku C).

Prikupljeni kondenzat može se ispustiti

pomoću

3

komprimovanog vazduha.

1

služi za izdvajanje

12

ispusnog ventila.

13

.

Ispuštanje kondenzata

pomoću ispusnog ventila

Po priključivanju pripremne grupe na izvor

komprimovanog vazduha možete da

podesite željeni radni pritisak pomoću

regulatora komprimovanog

3

vazduha.

Najpre otpustite ustavni mehanizam

povlačenjem regulatora komprimovanog

vazduha

3

naviše (videti sliku F).

Okretanjem regulatora suprotno

smeru kazaljke pritisak se smanjuje.

Okretanjem regulatora u smeru kazaljke

pritisak se povećava.

Podešavanje pritiska očitajte

na manometru komprimovanog

vazduha

4

.

Zakočite željeno podešavanje

pritiskanjem regulatora komprimovanog

Vodite računa da pneumatska jedinica za

održavanje bude montirana horizontalno

kako bi se kondenzat horizontalno

13

prikupljao u rezervoaru. Upotreba lterske

jedinice

kondenzat

1

bez montiranog rezerovara za

13

nije dozvoljena.

Da biste ispraznili nakupljeni kondenzat

iz rezervoara 13za kondenzat, koristite

odgovarajuću posudu. Pritisnite ispusni

ventil s donje strane nagore

12

(videti

sliku G) koji će se otvoriti, a kondenzat

će iscuriti u posudu.

23RS

Upotreba / Otkrivanje i otklanjanje kvarova / Čišćenje i održavanje

G

Jedinica za raspršivanje ulja

Jedinica za raspršivanje ulja 9povezana

je s lterskom

podmazivanje ltriranog komprimovanog

vazduha koji se transportuje u smeru

pneumatskog alata.

Nivo rezervoara za ulje

u jedinicu za raspršivanje ulja) može se

proveriti pomoću prozirnih kontrolnih

površina. Koristite samo odgovarajuće ulje

za ovu pripremnu grupu (videti gore).

Okrenite čep za dovod ulja

na kontrolno okno u smeru kazaljke („–“)

kako biste smanjili potrebnu količinu

ulja. Okrenite ga suprotno smeru

kazaljke („+“) da povećate količinu ulja.

Ugrađeno kontrolno okno omogućuje

stalan nadzor ltriranog komprimovanog

vazduha.

Da biste dopunili ulje, okrenite čep

otvora za dolivanje ulja

odgovarajućeg inbus ključa. Napunite

rezervoar korišćenjem odgovarajućeg

levka, a zatim ponovo čvrsto zategnite

čep pomoću ključa.

1

jedinicom. Njena uloga je

11

(ugrađen

7

montiran

6

pomoću

Otkrivanje i otklanjanje

kvarova

Kvar Uzroci Rešenje

3

Povećajte

količinu ulja.

Dospite još

ulja

u rezervoar

11

.

ulja

Vodite

računa

o maksima lnom nivou

ulja.

Povećajte

pritisak.

Nedovoljno

podma zivanje.

Radni

pritisak

kompr imovanog

vazduha je

preslab.

Čep za

dovod ulja je

7

previše

zavrnut u

smeru („–“).

Količina ulja

za kompri movani

vazduh je

premala

odnosno

ispod

minimalnog

nivoa.

Regulator

pritiska

je previše

zavrnut.

Čišćenje i održavanje

Napomena:

Da bi se obezbedio besprekoran

rad i pridržavanje sigurnosnih

zahteva, potrebno je redovno održavati

pripremnu grupu. Nepravilna i pogrešna

upotreba može za posledicu imati kvarove i

štetu na uređaju.

Nemojte koristiti jaka ni abrazivna

sredstva za čišćenje ili rastvarače.

Ona mogu da oštete plastične delove

pripremne grupe.

Vodite računa da voda ne dospe

u unutrašnjost mazalice.

Vodite računa da kućište i unutrašnjost

24 RS

Čišćenje i održavanje / Napomene o garanciji i servisiranju

pripremne grupe uvek budu čisti.

Redovno brišite pneumatsku jedinicu za

održavanje čistom krpom.

Redovno čistite pripremnu grupu i

priključke vlažnom krpom.

Redovno praznite rezervoar pripremne

grupe. Pritisnite ispusni ventil

sliku G) s donje strane naviše. U svrhu

bezbednosti vodite računa da pripremna

grupa bude oslobođena pritiska.

12

(videti

Napomene o garanciji

i servisiranju

Garancija preduzeća

Creative Marketing & Consulting GmbH

Poštovani korisniče, na ovaj uređaj imate

trogodišnju garanciju od dana kupovine.

Ako proizvod ima nedostataka, sleduju Vam

zakonom zagarantovana prava u odnosu

na prodavca. Vaša zakonska prava nisu

ograničena dole navedenom garancijom.

Uslovi garancije

Garantni rok počinje danom kupovine.

Molimo Vas da dobro čuvate skalni isečak.

On je potreban kao dokaz o kupovini. Ako

se u roku od tri godine od dana kupovine

na proizvodu pojavi materijalni ili proizvodni

nedostatak, Vaš proizvod će po našoj

proceni ili besplatno biti popravljen ili

zamenjen novim. Da biste ostvarili ovo

pravo po garanciji, potrebno je da priložite

pokvareni uređaj i dokaz o kupovini (skalni

isečak) uz kratak opis nedostatka i naznaku

vremena njegovog nastanka. Ako je kvar

pokriven našom garancijom, vratićemo

Vam popravljen proizvod ili dati nov. Nakon

popravke ili zamene proizvoda ne počinje

novi garantni rok.

Obim garancije

Ovaj uređaj je proizveden u skladu sa

strogim standardima kvaliteta i pažljivo

ispitan pre isporuke.

Garancija važi za materijalne i proizvodne

greške. Ova garancija ne pokriva delove

proizvoda koji podležu uobičajenom

habanju i shodno tome se smatraju

potrošnim delovima niti oštećenja lomljivih

delova, npr. prekidači, baterije ili delovi

izrađeni od stakla.

Garancija ne važi za proizvod koji je

oštećen nepravilnom upotrebom ili

održavanjem. Za pravilnu upotrebu

proizvoda potrebno je strogo se pridržavati

svih uputstava navedenih u priručniku.

Izbegavajte upotrebu i rukovanje koji se

ne savetuju u priručniku ili na koje se

u priručniku upozorava.

Proizvod je namenjen isključivo za kućnu

upotrebu, ne i za komercijalnu. Garancija

ne važi u slučaju neprimerene i nepravilne

upotrebe, nasilne upotrebe ili intervencija

koje nije obavio ovlašćeni servis.

Obrada garantnih zahteva

Kako bismo obezbedili brzu obradu

Vašeg zahteva, pridržavajte se sledećih

napomena: Za sve upite molimo Vas da

pripremite skalni isečak i broj artikla (npr.

IAN 12345) kao dokaz kupovine. Broj artikla

nalazi se na natpisnoj pločici, gravuri,

naslovnoj strani uputstva (dole levo) ili

na nalepnici na zadnjoj ili donjoj strani. U

slučaju funkcionalnih ili drugih nedostataka,

obratite se najpre dole navedenom servisu

25RS

Loading...

Loading...