Parkside PDWE 8 A1 Operation And Safety Notes Translation Of The Original Instructions

AIR FILTER REGULATOR AND LUBRICATOR

PDWE 8 A1

GB IE NI

AIR FILTER REGULATOR AND LUBRICATOR

Operation and Safety Notes

Translation of the original instructions

DE

DRUCKLUFT WARTUNGSEINHEIT

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

IAN 292166

DK

TRYKLUFT-SERVICEENHED

Brugs- og sikkerhedsanvisninger

Oversættelse af den originale driftsvejledning

GB

IE

DK

NI

DE

GB IE NI

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of

the device.

DK

Før du læser, vend siden med billeder frem og bliv bekendt med alle apparatets funktioner.

DE

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB/IE/NI Operation and Safety Notes Page 5

DK Brugs- og sikkerhedsanvisninger Side 15

DE Montage-, Bedienungs- und Sicherheitshinweise Seite 25

Table of contents

Table of pictograms used ...............................................................................Seite 6

Introduction ...........................................................................................................Seite 6

Intended use ...............................................................................................................Seite 6

Residual risk ................................................................................................................Seite 6

Parts description ..........................................................................................................Seite 6

Technical specifications ................................................................................................Seite 7

Package contents .........................................................................................................Seite 7

Safety notes ..........................................................................................................Seite 7

Safety notes for using pneumatic devices ..............................................Seite 8

Before starting up ..............................................................................................Seite 9

Installation ............................................................................................................Seite 10

Filling the oil mist unit ...................................................................................................Seite 10

Starting up .............................................................................................................Seite 10

Setting the working pressure ........................................................................................Seite 11

Filter unit ....................................................................................................................Seite 11

Condensate drain via the drain valve .............................................................................Seite 11

Oil mister unit..............................................................................................................Seite 11

Cleaning and maintenance ............................................................................Seite 12

Warranty and service information ............................................................Seite 12

Warranty conditions.....................................................................................................Seite 12

Extent of warranty ........................................................................................................Seite 12

Processing of warranty claims .......................................................................................Seite 13

Environmental notes and

disposal information .........................................................................................Seite 13

Disposal of the

maintenance unit .........................................................................................................Seite 13

GB/IE/NI 5

Table of pictograms used / Introduction

Table of pictograms used

Be Read the operating

instructions!

Note

Dispose of the pneumatic devices

and packaging environmentally

compatibly

Air-driven maintenance unit

PDSP 8 A1

Introduction

Congratulations! You have purchased

one of our high-quality devices. Before

setup or first use, please familiarise

yourself with the product. To do so, please read

through the following operating and safety

instructions carefully. This tool must be set up or

used only by people who have been trained to do

so.

KEEP OUT OF THE REACH OF CHILDREN!

Observe warnings and the safety

instructions!

Wear hearing protection,

respirator / dust mask, goggles,

and protective gloves.

or industrially.

Residual risk

Even if you operate the device according to the

instructions, there will always be residual risks

remaining. The following risks may occur in connection with the build and execution of this pneumatic

maintenance unit:

Danger from beating compressed air hoses.

Danger of falling from compressed air hoses

lying around.

Reduce the residual risk by carefully using the

device as intended and observing all instruction.

Intended use

The air-driven maintenance unit serves to oil the

compressed air for pneumatic tools and at the

same time filters condensation from the compressed

air. Use the products only as described and only

for the specific applications as stated. Keep these

instructions in a safe place. Ensure you hand over

all documentation when passing the product on to

anyone else. Any use that differs to the intended

use as stated above is prohibited and potentially

dangerous. Damage or injury caused by misuse

or disregarding the above warning is not covered

by the warranty or any liability on the part of

the manufacturer. The device was designed for

household use and must not be used commercially

GB/IE/NI6

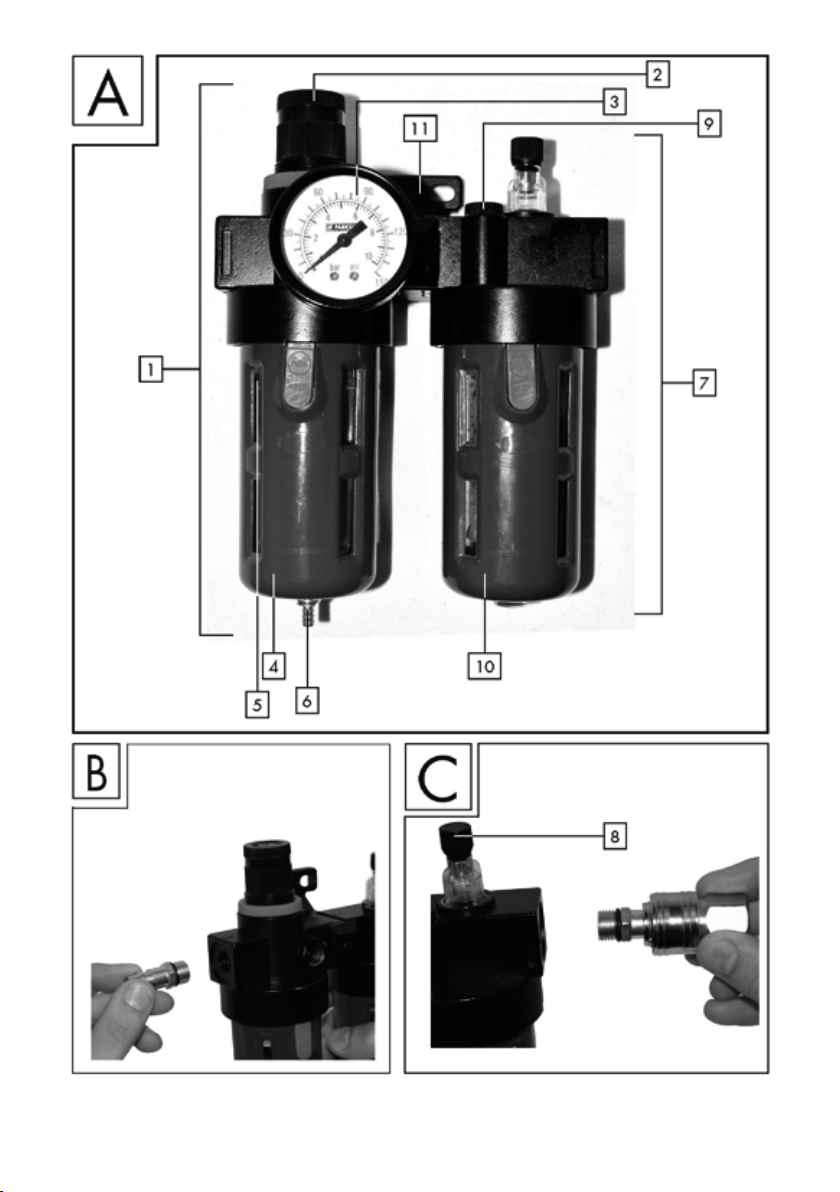

Parts description

After unpacking the product, please check that

the device is in perfect condition. Do not use the

product if it is defective.

1

Filter unit

2

Compressed air controller

3

Compressed air pressure gauge

4

Condensate collection container

5

Filter insert

6

Drain valve

7

Oil mister unit

8

Screw to change the lubrication

9

Oil refilling inlet

10

Container for compressed air oil

11

Holder for wall mounting

Introduction / Safety notes

Technical specifications

Max. working pressure: 8 bar

Oil: Suitable compressor oil

Package contents

1 pneumatic air maintenance unit

Safety notes

Please read the operating instructions

with care and observe the notes

described. Familiarise yourself with

the device, its proper use and the

safety notes based on these operat

-

ing instructions.

The rating plate container all

technical data of this pneumatic

maintenance unit; please learn about

the technical features of this device.

This device can be used by children

16 years and older and also by per

sons with reduced physical, sensory

or mental capacities or a lack of

experience and knowledge if they

are supervised or they have been

instructed with regard to the safe use

of the device and they understand

the dangers it presents. Do not allow

children to play with the product.

Cleaning and user maintenance must

not be performed by children without

supervision.

In connection with a compressor, the

maintenance unit serves maintenance

and care (e.g. filtering, oiling and

regulation) of your pneumatic tools.

The maintenance unit must only be

used with a pneumatic compressor.

When using the device, observe the

maximum compressed air values of

the connected tools and check them

several times during use. This product

is only intended for private use. The

maintenance unit must only be used

as intended. Any further, deviating

use is forbidden!

Consideration of the safety note sin

the operating instruction and the

assembly instructions are also part

of intended use. The manufacturer or

dealer assumes no liability for any

damage caused by non-intended or

wrong use.

Only accessories suitable for this

product must be used. Persons who

use the pneumatic maintenance unit

and who may perform maintenance

work are obligated to familiarise

themselves with it. They also must be

informed about potential dangers.

The applicable accident prevention

provisions must be correctly and

conscientiously observed.

GB/IE/NI 7

… / Safety notes for using pneumatic devices

Any changes to the pneumatic

maintenance unit exclude liability of

the manufacturer and any connected

damage.

Safety notes for using

pneumatic devices

Important!

Always keep the compressed air

hose firmly in your hands when

releasing a connection. The lash

ing backlash of the compressed

air hose may cause injury.

The compressed air maintenance

unit must be installed before it can

be safely taken into operation. A

stable wall is suitable for installa

tion (with screw connections).

We recommend only using

the lubricants specified by the

manufacturer.

Never exceed the indicated

maximum pressure values of the

maintenance unit.

The pneumatic maintenance unit

must only be connected to a com

pressed air source that does not

exceed the working pressure of

8 bar.

Do not put the compressed air

lines near any heat, oils, heat and

sharp edges.

The maintenance unit must only

be operated in connection with a

pneumatic compressor.

Use of other compressed air

sources, such as a compressed air

cylinder, is forbidden. There is a

danger of fire and/or explosion.

Make sure that children and

persons with limited physical or

mental capacities are kept away

from the maintenance unit and the

connected compressed air tools.

Only use genuine spare parts for

repairs. Any non-genuine spare

parts may cause severe damage.

When conducting any mainte-

nance, setting and repair work,

always disconnect the mainte

nance unit from the compressed

air supply first.

Changes to the maintenance unit

are forbidden.

Use the maintenance unit only

when it is in an impeccable con

dition. In doubt, use a specialist's

advice.

Have repairs only conducted by

qualified specialists.

User safety

Try out the pneumatic tool

used before every use. Never

use the compressed air maintenance

unit with any higher operating

pressure then indicated in the tech

nical data. Before you connect your

pneumatic tools to the pneumatic

GB/IE/NI8

Safety notes for using pneumatic devices / Before starting up

• Verschrauben Sie den Gewin-

destecknippel (B) manuell mit der

Hand in die abgebildete Position

(E) der Filtereinheit�

Befüllen bzw� Lösen des Behälters die

Wartungseinheit von der Druckluftquel-

le getrennt wurde�

• Entfernen Sie die Verschraubung

des Ölbehälters und befüllen Sie die-

sen mit passendem Kompressoren-Öl

soweit, bis die max� Markierung er-

reicht ist�

• Im Anschluss daran, drehen Sie den

Installation / Inbetriebnahme

maintenance unit, ensure that they

are properly and securely connected.

Forbidden uses

Do not use this maintenance

unit in a potentially explo

sive environment. Avoid working in

environments with substances such

as flammable gases, liquids, paint

and dust mist. These substances may

inflame due to very hot

surfaces at

the pneumatic unit.

Important note:

Do not use the maintenance

unit in connection with

pneumatic devices that must not use

any prepared compressed air

(e.g. grease guns, sand-blasting

units, tyre fillers, etc.).

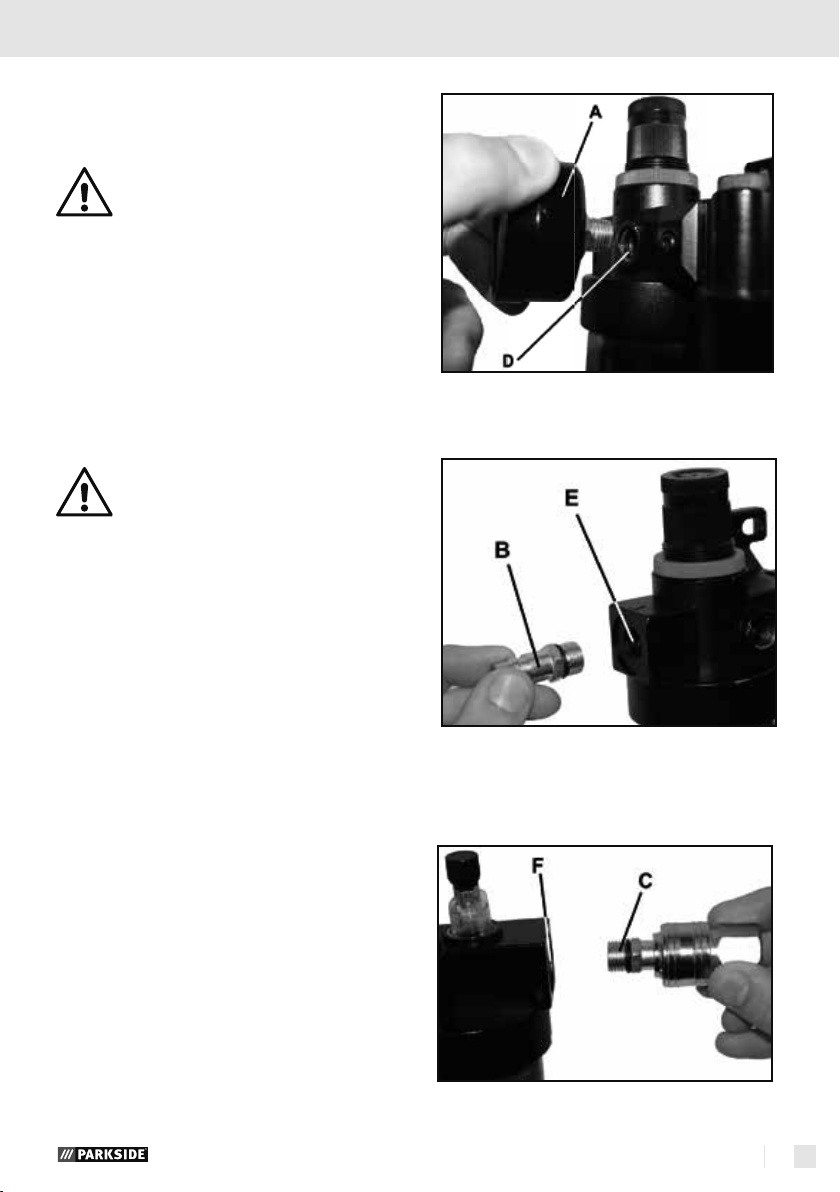

Screw the threaded barbed fitting (B) manually

in the illustrated position (E) of the filter unit.

Before starting up

Connect the pressure gage and the connection

pieces

Wind the Teflon band (not enclosed) around

the threads of the pressure gauge(A), the

threaded barbed fitting (B) (not enclosed) and

the quick coupling (C) (not enclosed).

Subsequently screw the pressure gauge (A)

manually in the illustrated position (D) of the

filter unit.

Screw the quick-coupling (C) manually in the

illustrated position (F) of the oil-mist unit.

GB/IE/NI 9

Installation

Achtung:

Zur Minimierung von potenti-

ell auftretenden Verletzungen

oder Schäden ist es erforder-

lich, die Wartungseinheit vor der ers-

ten Inbetriebnahme an einer geeigne-

ten Wand zu montieren� Achten Sie

auf eine stabile und horizontale Mon-

tage der Druckluft Wartungseinheit�

• Benutzen Sie zur Wandmontage

die Befestigungseinheit zur Markierung

an der Wand und zur Verschraubung

mit passendem Verbindungsmaterial�

Befüllen bzw� Lösen des Behälters die

Wartungseinheit von der Druckluftquel-

le getrennt wurde�

• Entfernen Sie die Verschraubung

des Ölbehälters und befüllen Sie die-

sen mit passendem Kompressoren-Öl

soweit, bis die max� Markierung er-

reicht ist�

• Im Anschluss daran, drehen Sie den

Behälter nur manuell (ohne Werkzeug)

mit der Hand fest�

Inbetriebnahme

Verbinden Sie die Druckluft

Wartungseinheit mit der Druck-

luftquelle

Achten Sie darauf, dass die

angeschlossene Druckluftlei-

tung sauber und ölfrei ist, um

die Druckluft Wartungseinheit auch

Installation / Inbetriebnahme

Installation / Inbetriebnahme

Before starting up/ Installation / Starting up

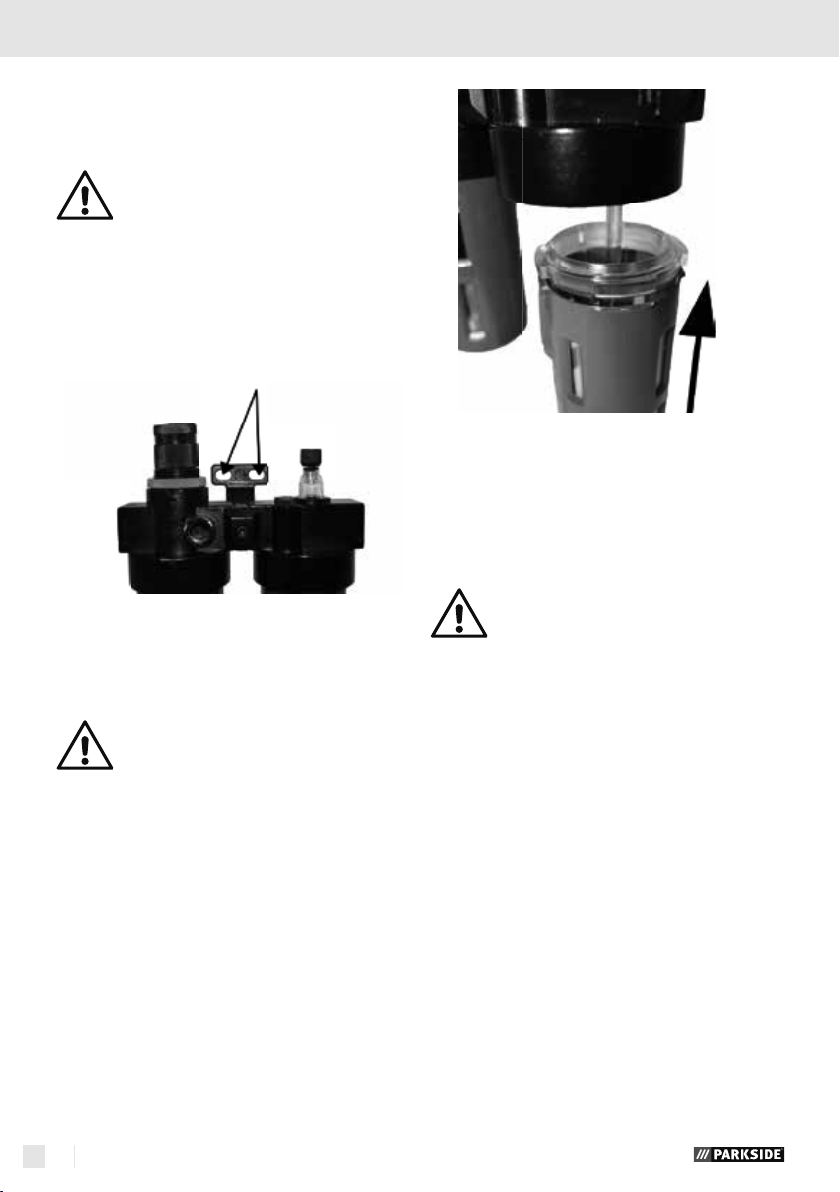

Installation

Attention:

To minimise potential injury or damage,

the maintenance unit must be installed on

a suitable wall before first commissioning. Ensure a stable and

pneumatic maintenance unit.

Use the attachment unit to mark the wall for

wall installation and for screwing on with

matching connection material.

horizontal assembly of the

Filling the oil mist unit

Ensure that the maintenance unit has

been separated from the compressed air

source before filling or releasing the

container.

Remove the screws of the oil container and fill

it with the matching compressor oil until the

max. mark has been reached.

Subsequently tighten the container only

manually (without tools).

Starting up

Connect the pneumatic maintenance unit

to the compressed air source

Ensure that the connected compressed air

line is clean and oil-free in order to

properly use the compressed air

maintenance unit. Further ensure that the pneumatic

system is depressurised. To minimise pressure loss,

it is beneficial if the compressed air lines are kept

as short as possible.

First, turn counter-clockwise to set the com-

pressed air controller to the lowest possible

level. The desired settings will be assumed by

pushing down the compressed air controller.

Connect the compressed air supply line of the

tool to be connected to the right side (output) of

the maintenance unit (see figure on the right). A

triangle "" on the surface of the device indicates the flow direction of the compressed air.

Connect the compressed air supply of the

compressed air source on the left (input) of the

maintenance unit (directly at the input, the surface has a triangle "", that indicates the flow

direction of the compressed air).

GB/IE/NI10

mierung von Druckverlusten, ist es vor-

teilhaft, die Druckluftleitungen mög-

lichst kurz zu halten�

• Stellen Sie zuerst durch Drehen ge-

gen den Uhrzeigersinn, den Druckluft-

regler auf die niedrig möglichste Stufe

ein� Die gewünschten Einstellungen

werden übernommen, indem Sie den

Druckluftregler nach unten drücken�

• Schließen Sie die Druckluftzuleitung

des anzuschließenden Werkzeuges

auf der rechten Seite (Ausgang) der

Wartungseinheit an (siehe Bild rechts)�

Ein Dreieck „ “ auf der Oberfläche

des Gerätes zeigt die Fließrichtung der

Druckluft an�

• Schließen Sie die Druckluftzuleitung

der Druckluftquelle auf der linken Seite

(Eingang) der Wartungseinheit an (di-

rekt am Eingang befindet sich auf der

Oberfläche ein Dreieck „ “, welches

die Fließrichtung der Druckluft angibt)�

Druck erzeugt�

• Einstellen des Arbeitsdrucks

Nach Verknüpfung der Wartungsein-

heit mit einer Druckluftquelle (siehe

oben), können Sie den gewünschten

Betriebsdruck mittels des Druckreglers

einstellen�

• Durch drehen gegen den Uhrzei-

gersinn wird der Druck reduziert und

durch drehen im Uhrzeiger sind wird

der Druck erhöht�

• Entnehmen Sie den eingestellten

Druck an der Manometeranzeige�

Hinweis: Achten Sie darauf,

dass der maximal mögliche

Betriebsdruck der Wartungs-

einheit und des eingesetzten Druckluft-

werkzeugs nicht überschritten wird�

• Filtereinheit

Die Filtereinheit ist mit dem Druckregler

verknüpft� Der maximale Arbeitsdruck

beträgt 8 bar und der Betriebsdruck

ist von 0,5 bis 8 bar regulierbar� Die

Filtereinheit wird zum Filtern von Kon-

densat eingesetzt und speichert das

Kondensat im Filterbehälter�

Den Füllstand des Kondensats können

Sie durch die transparenten Sichtflä-

chen überprüfen� Das gespeicherte

Kondensat kann über das Ablassventil

abgelassen werden�

• Kondensatablass mittels des

Inbetriebnahme

dung der Filtereinheit ohne montierten

Behälter ist untersagt�

• Um das gespeicherte Kondensat

aus dem Behälter zu entleeren, ver-

wenden Sie einen entsprechenden

Behälter� Durch leichte Betätigung des

Ablassventils (6), öffnet sich dieses und

das Kondensat kann abgelassen wer-

den�

zu steigern�

• Das integrierte Schauglas ermög-

licht einen ständigen Überblick auf die

gefilterte Druckluft�

• Um Öl nachzufüllen, drehen Sie

die Schraube (B) mit einem geeigneten

Inbusschlüssel ab� Befüllen Sie den Be-

hälter mittels eines passenden Trichters

und drehen Sie die Schraube danach

wieder mit dem Schlüssel fest�

Fehlererkennung und Behebung

Fehler Ursachen Lösung

Die Schmie-

rung ist nicht

ausreichend

Öldurchlass-

schraube

ist zu fest in

Richtung („-“)

zugedreht�

Steigern Sie

die Schmie-

rung (siehe

oben)�

Die Druck-

luftölmen-

ge ist zu

Gießen Sie

mehr Öl in

den Ölbehäl-

Reinigung und Wartung

Before commissioning of the maintenance unit,

check the compressed air flow direction with

the mark "" on the surface. If the setting is

not correct, the pressure generated will not be

correct.

Setting the working

pressure

After linking the maintenance unit to a compressed

air source (see above), you can set the desired

operating pressure with the pressure controller.

Turning counter-clockwise reduces the pressure,

and turning clockwise increases the pressure.

Read the set pressure at the pressure gauge

display.

Note:

Ensure that the maximum possible operating pressure of the maintenance unit and

the pneumatic tool is not exceeded.

Filter unit

The filter unit is linked to the pressure controller.

The maximum working pressure is 8 bar and the

operating pressure can be adjusted from 0.5 to

8 bar. The filter unit is used to filter condensate and

stores the condensate in the filter tank.

You can check the condensate fill level through the

Starting up

transparent sight windows. The stored condensate

can be drained via the drain valve.

Condensate drain via the

drain valve

Ensure horizontal installation of the maintenance

unit so that the condensate can be stored horizontally in the tank as well. The filter unit must not be

used without the tank installed.

Use a matching tank in order to drain the

stored condensate from the tank. Slight operation of the drain valve (6) opens it and lets the

condensate drain.

Oil mister unit

The oil mister unit is connected to the filter unit. It

has the function of oiling the filtered compressed air

that is transported towards the compressed air tool.

You can check the fill level of the oil tank

(integrated into the oil mister unit) through the

transparent sight windows. Use only matching oil

for this maintenance unit (see above).

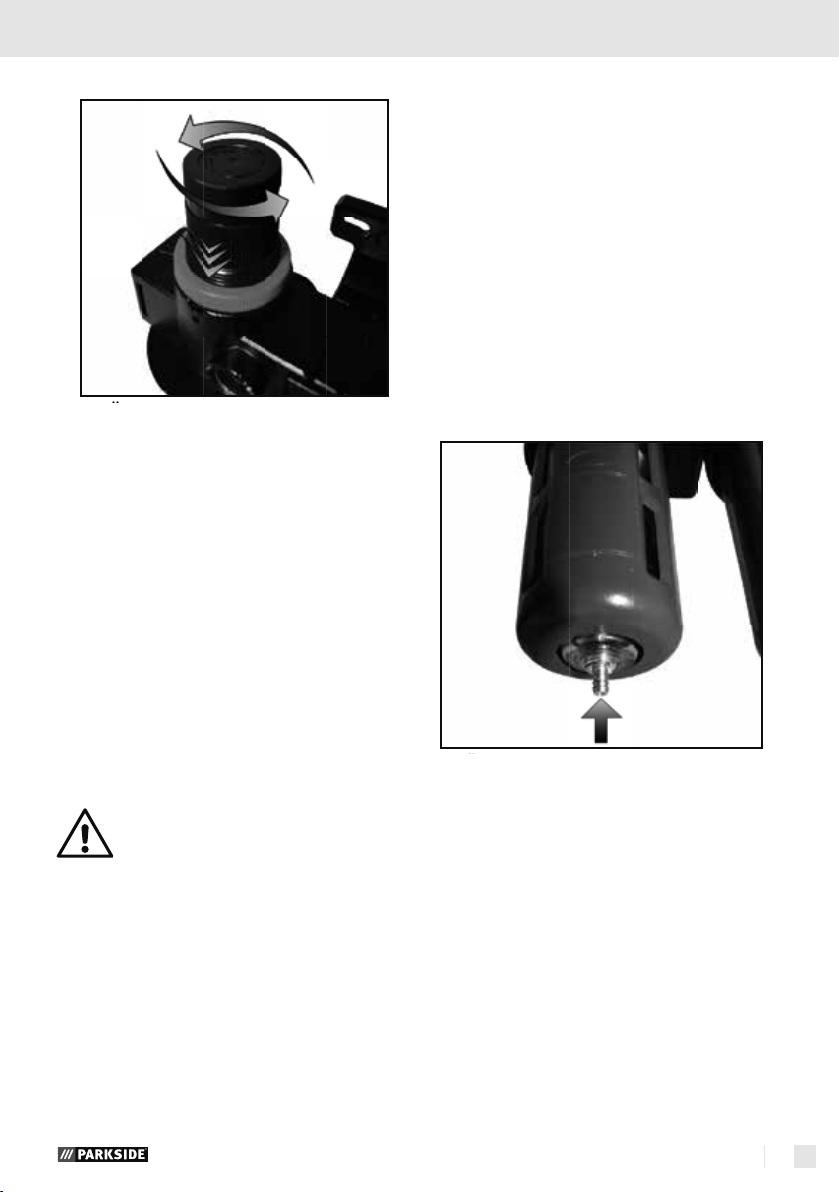

Turn the oil drain screw (A) that is installed

on the sight glass clockwise ("–"), in order

to reduce the required volume of oil. Turn it

counter-clockwise ("+") to increase the volume

GB/IE/NI 11

... / Cleaning and maintenance / Warranty and service information

of oil.

The integrated sight window permits continuous

overview of the filtered compressed air.

To top up oil, turn the screw (B) down with

a suitable socket wrench. Fill the tank with a

matching hopper and tighten the screw again

with the wrench.

Troubleshooting

Faults Causes Solution

The lubrication

is not sufficient

The operating

pressure of the

compressed

air is too low.

The oil passage screw it

tightened too

far in direction

("–").

The compressed air

volume is too

low, i.e. below

the minimum

fill level.

The pressure

controller

is tightened

too far

(see above).

Increase

lubrication

(see above).

Pour more oil

into the oil

tank. Observe

the maximum

fill level.

Increase the

pressure

(see above).

Cleaning and maintenance

Note:

The pneumatic maintenance unit must be

regularly serviced and overhauled for

proper function and for compliance with the safety

requirements. Improper and wrong operation may

cause failures and damage to the device.

Never use any sharp and/or scraping cleaning

agents or solvents. They may damage the plastic parts of the pneumatic maintenance unit.

Make sure that no water can enter inside the

oiler.

Ensure that the housing and the inside of the

pneumatic maintenance unit remains dust- and

dirt-free. For this, regularly rub the pneumatic

maintenance unit with a clean cloth.

Clean the pneumatic maintenance unit and the

connections with a moist cloth at regular intervals.

Drain the pneumatic maintenance unit's tank

at regular intervals. For this, press in the metal

pin at the bottom and let the condensate drain.

Note that the pneumatic maintenance unit must

be depressurised for safety.

Warranty and service

information

Warranty from Creative Marketing

Consulting GmbH

Dear Customer,

The warranty for this device is 3 years from the

date of purchase. In the event of product defects,

you have legal rights against the retailer of this

product. Your statutory rights are not affected in

any way by our warranty conditions, which are

described below.

Warranty conditions

The warranty period begins on the date of purchase. Please retain the original sales receipt. This

document is required as your proof of purchase.

Should this product show any defect in materials

or manufacture within 3 years from the date of

purchase, we will repair or replace it – at our

discretion – free of charge. To claim against this

warranty, you must present the defective device

and your purchase receipt within the 3-year period,

and include a brief written description of the nature

of the defect and the date it occurred. If the defect

is covered by our warranty, we will repair and

return your product or send you a replacement.

The original warranty period is not extended when

a device is repair or replaced.

Extent of warranty

The device has been manufactured according to

strict quality guidelines and meticulously examined

GB/IE/NI12

Loading...

Loading...