Parkside PDT 40 D3 Operation And Safety Notes

IAN 109811

PNEUMATIC STAPLER PDT 40 D3

DRUCKLUFT-TACKER

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

PNEUMATSKA KLAMERICA

Upute za posluživanje i za Vašu sigurnost

Prijevod originalnih uputa za uporabu

CAPSATOR CU AER COMPRIMAT

Instrucţiuni de utilizare şi de siguranţă

Traducerea instrucţiunilor de utilizare originale

Пневматичен такер

Инструкции за обслужване и безопасност

Превод на оригиналното ръководство за експлоатация

ΚΑΡΦΩΤΙΚΟ ΑΕΡΟΣ

Υποδείξει χειρισού και ασφαλεία

Μετάφραση των αυθεντικών οδηγιών λειτουργίας

PNEUMATIC STAPLER

Operation and Safety Notes

Translation of the original instructions

GB / CY Operation and Safety Notes Page 5

HR Upute za posluživanje i za Vašu sigurnost Stranica 13

RO Instrucţiuni de utilizare şi de siguranţă Pagina 21

BG Инструкции за обслужване и безопасност Страница 29

GR / CY Υποδείξει χειρισού και ασφαλεία Σελίδα 37

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 45

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Rasklopite prije čitanja obije stranice sa slikama i nakon toga se upoznajte sa svim funkcijama uređaja.

Înainte de a citi instrucţiunile, priviţi ambele pagini cu imagini şi familiarizaţi-vă cu toate funcţiile aparatului.

Преди да прочетете отворете двете страници с фигурите и след това се запознайте с всички

функции на уреда.

Πριν ξεκινήσετε την ανάγνωση, ανοίξτε τι δυο σελίδε ε τι εικόνε και εξοικειωθείτε ε όλε τι

λειτουργίε τη συσκευή.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

A

3 41 2

6789

12

11

10

5

b

D

E

c

5 GB/CY

Table of contents

Introduction

Intended use ........................................................................................................................................ Page 6

Features and fittings ............................................................................................................................ Page 6

Included items .....................................................................................................................................Page 6

Technical data ..................................................................................................................................... Page 6

Safety of the fastener driving tool

Work safety ......................................................................................................................................... Page 7

Additional safety information for compressed air tackers ................................................................ Page 8

Original accessories / tools ................................................................................................................Page 9

Preparing the product for use

Connecting the compressed air source .............................................................................................Page 9

Loading the magazine ........................................................................................................................ Page 9

Operation .......................................................................................................................................Page 9

Removing jammed fasteners ...............................................................................................................Page 10

Maintenance and cleaning

User maintenance ...............................................................................................................................Page 10

Cleaning ..............................................................................................................................................Page 10

Service ...............................................................................................................................................Page 10

Warranty ......................................................................................................................................... Page 11

Disposal ............................................................................................................................................ Page 11

6 GB/CY

Introduction

Pneumatic stapler PDT 40 D3

Introduction

We congratulate you on the purchase of your new

device. You have chosen a high quality product. The

operating instructions are part of the product. They

contain important information concerning safety,

use and disposal. Before using the product, familiarise yourself with all of the operating instructions

and safety instructions. Use the product only as described and for the specified applications. If you

pass the product on to anyone else, please ensure

that you also pass on all the documentation with it.

Intended use

The device is suitable for assembly and repair work.

Any other use or modification to the device shall be

considered as improper use and could give rise to

considerable dangers. We will not accept liability

for loss or damage arising from improper use. The

device is intended for private domestic use only.

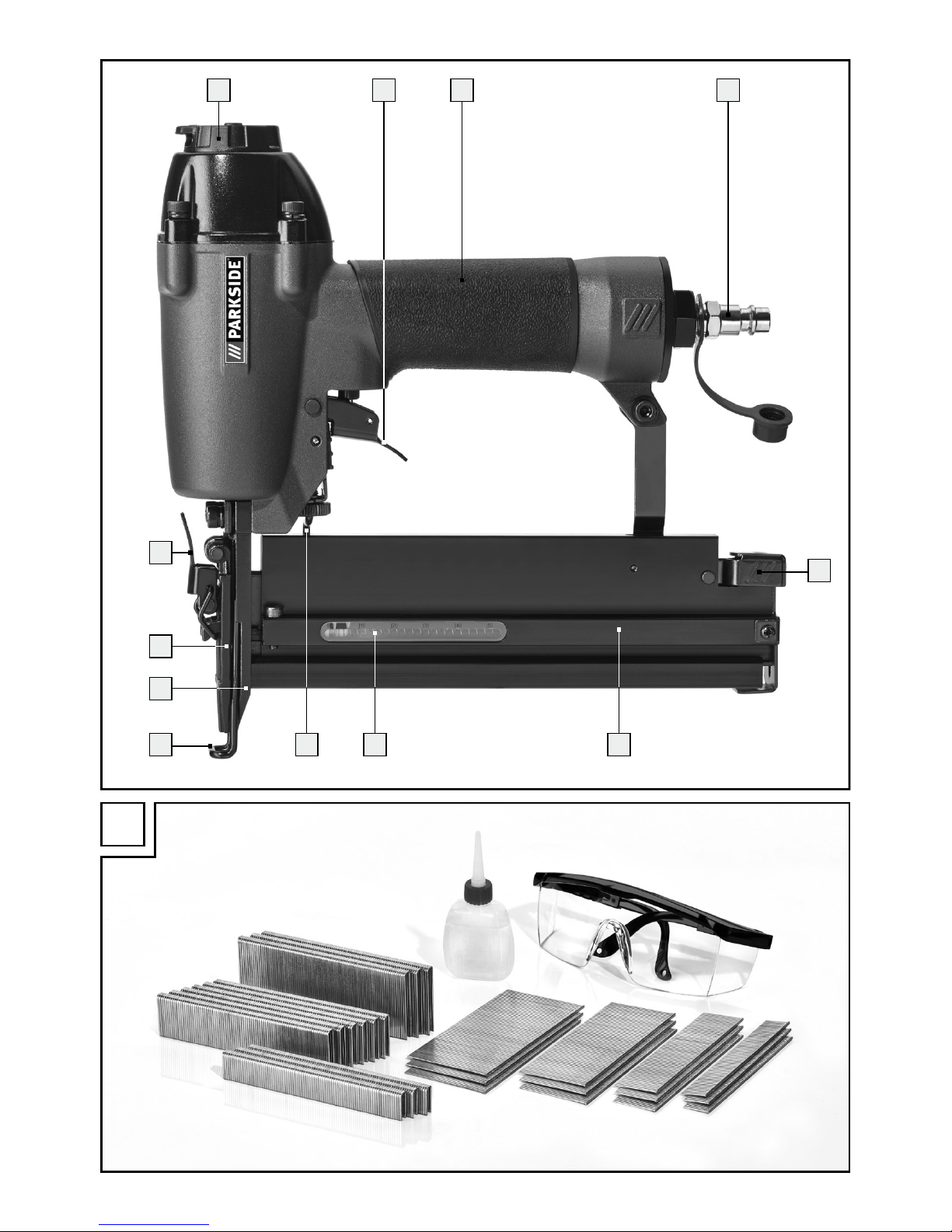

Features and fittings

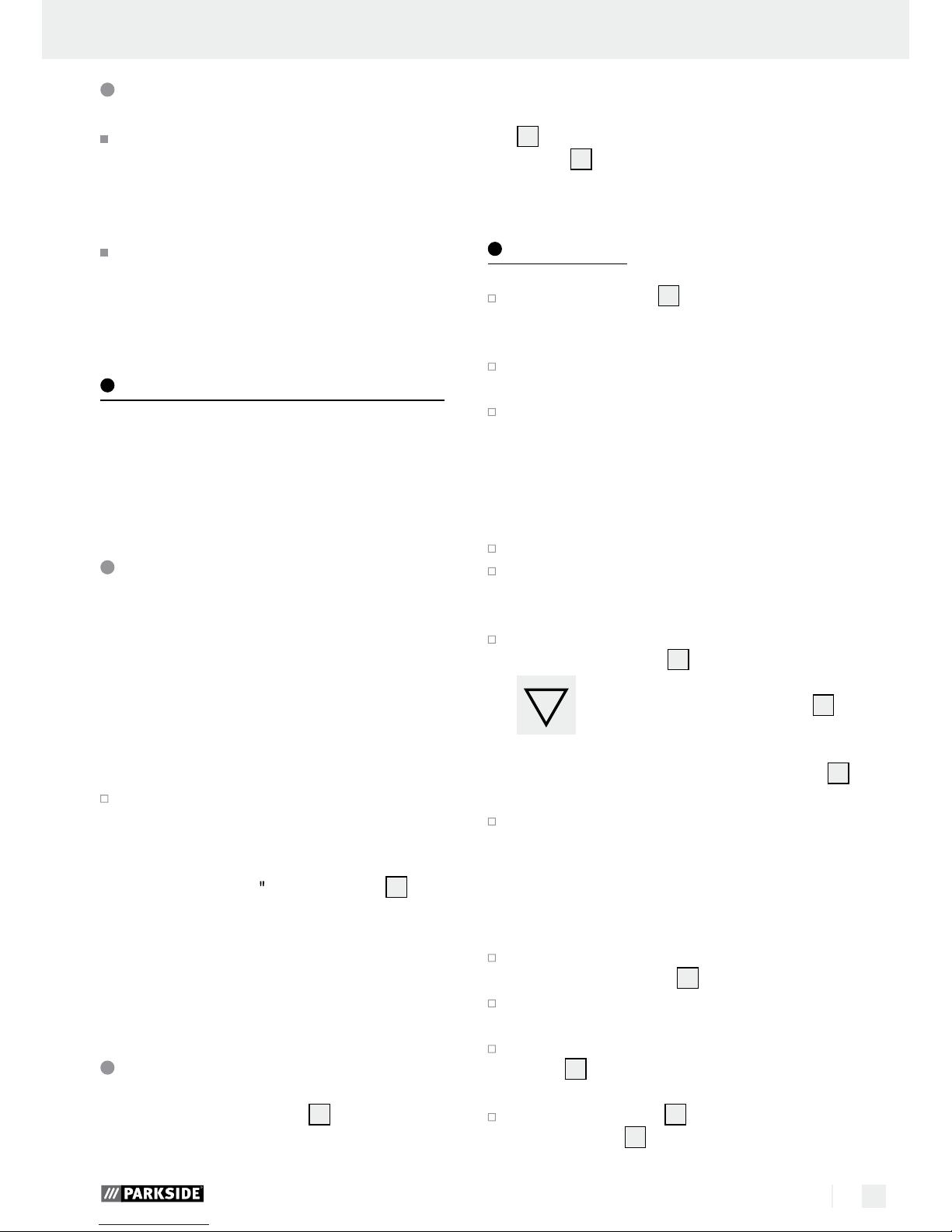

1

Exhaust air aperture (can be rotated)

2

Trigger

3

Handle

4

Threaded nipple 6.35 mm (¼ )

5

Magazine lever

6

Magazine

7

Fill level indicator

8

Knurled screw

9

Trigger lock

10

Mouth

11

Face plate

12

Face plate quick clamp lever

Included items

1 Pneumatic stapler PDT 40 D3

1 Carrying case

1 Special compressed air oil

1 Threaded nipple 6.35 mm (¼ ) (pre-assembled)

1 Package nails, 1000 pcs.

1 Package staples, 1000 pcs.

1 Protective glasses

1 Operating instructions

Technical data

Dimensions: 297 x 280 x 71 mm

(L x H x W)

Weight

(without fasteners): 1181 g

Trigger type: Compressed air

Maximum permissible

pressure: 8 bar

Recommended pressure

range: 4 to 7 bar

Air consumption per

drive in process: approx. 0.09 litre per

driving-in process

Recommended lubricant:

Compressed air special oil

Loading capacity: 100 pcs.

Nail lengths: 15 mm, 20 mm

25 mm, 30 mm,

32 mm, 35 mm,

38 mm, 40 mm,

45 mm, 50 mm,

Staple lengths: 10–40 mm

Staple width: 5.7 mm

Recommended

Hose diameter: ∅ 9 mm

Compressed air quality: Cleaned, oil-misted

and condensate-free

Noise and vibration data:

Measured values for noise are determined in accordance with EN 12549:1999, EN ISO 4871.

The A-weighted sound pressure level of the device

is typically 112.6 dB(A). The sound power level of

the device is 80 dB(A). Uncertainty K = 2.5 dB.

L

wa

: 125.6 dB(A)

L

pa

(at the work station): 114.3 dB(A)

L

pc

: 115.9 dB(A)

These values are characteristic values referenced to

the device and do not reflect noise development at

the work location. Noise development at the work

7 GB/CY

Introduction / Safety of the fastener driving tool

location depends e.g. on the work environment, the

workpiece, the workpiece support and the number

of fastener driving processes.

In correspondence with conditions at the work location, individual noise reduction measures may need

to be carried out, such as placing the workpiece on

a noise-suppressing surface, clamping or covering

to prevent workpiece vibration and adjusting to the

minimum pressure required by the work process. In

certain cases, wearing personal hearing protection

is require.

Wear hearing protection!

Vibration values in accordance with

ISO 8662-11:1999:

Vibration emission value a

h,W

= 15.0 m / s

2

Uncertainty K = 0.29 m / s

2

Mechanical impact (vibration)

The vibration value for the fastener driving device was

determined in accordance with ISO 8662-11:1999 —

Hand-held portable power tools – Measurement of

vibrations at the handle — Fastener driving tools

(see technical data). The value is referenced to the

device and does not represent the influence on the

hand-arm system when the device is used. Influence

on the hand-arm system when using the device depends on e.g. gripping force, pressing force, working direction, air pressure set, the workpiece and its

position.

Safety of the fastener

driving tool

Please read

all the safety information and

instructions. Failure to comply with

the safety instructions and instructions can result in

severe injuries and / or damage to property.

PLEASE RETAIN ALL SAFETY INFORMATION

AND INSTRUCTIONS FOR FUTURE REFERENCE.

Each time before starting work, check

for flawless functioning of the safety

and triggering devices as well as the

firm fit of all bolts and nuts.

Do not conduct any improper manipu-

lation of the fastener driving tool.

Do not dismount or block any part of

the fastener driving tool, such a trigger lock.

Do not conduct any „emergency re-

pairs“ with unsuitable materials.

The fastener driving tool must be reg-

ularly and properly maintained as

specified by the manufacturer.

Prevent anything that would weaken

or damage the device, e.g. by:

– stamping or engraving,

– alterations not permitted by the

manufacturer,

– guiding on templates made of hard

material, e.g. steel,

– permitting to fall onto or slide across

the floor,

– using as a hammer,

– every type of external force.

Always securely fasten staple guns to supports,

e.g. work table. Brackets used for this purpose

must always be designed so as to protect the

staple gun from damage, rotation or shifting.

Work safety

Never point a fastener driving tool that

is ready to use directly at yourself,

other persons or animals.

During work, hold the fastener driving

tool so that head and body can not be

injured by possible kickback due to a

fault in the power supply or from hard

places in the workpiece.

Never trigger the fastener driving tool

into empty space. Following this instruction

will prevent danger due to uncontrolled flying

fasteners and overloading the device.

Before transporting, disconnect the

fastener driving tool from the compressed air network, particularly when

using ladders or are moving with an

unaccustomed body posture.

8 GB/CY

At the workplace, only carry the fas-

tener driving tool by its grip and never

with the trigger actuated.

Pay attention to workplace conditions.

Fasteners may strike completely through thin

workpieces or slide off corners or edges to

cause a danger to persons.

Use suitable personal protection equip-

ment, e.g. hearing and eye protection.

Wearing personal protective devices such as

dust mask, non-slip safety shoes, safety helmet

or hearing protectors, depending on the type

of fastener driving tool and its application, reduces the risk of injuries.

Additional safety information

for compressed air tackers

RISK OF INJURY! Never

exceed the maximum permissible operating

pressure of 8 bar. Use a pressure reducer to

adjust the operating pressure.

RISK OF INJURY! Never

use oxygen or other flammable gases as ener-

gy source.

Keep your working area clean and

well lit. Untidy or poorly lit working areas

can lead to accidents.

Keep children and other individuals

away from the fastener driving tool

during use. Distractions can cause you to

lose control of the device.

Remain alert at all times, watch what

you are doing and always proceed with

caution when working with a fastener

driving tool. Do not use any fastener

driving tool if you are tired or under the

influence of drugs, alcohol or medica

tion.

One moment of carelessness when using the fastener driving tool may result in serious injuries.

Avoid placing your body in an unnat-

ural position. Keep proper footing

and balance at all times. By doing this you

will be in a better position to control the fastener driving tool in unforeseen circumstances.

Before any repair and maintenance work or

transport, remove the device from the compressed air source.

RISK OF INJURY! Do not use the device on

scaffolds or ladders.

Never use hydrogen, oxygen, carbon

dioxide or other bottled gasses to

power this tool as doing so may result in an explosion and thus may cause severe

injuries.

RISK OF INJURY! Do not use the device if

the trigger lock

9

is damaged or has been

removed. Otherwise injuries may result.

When loosening the hose coupling, hold the

hose firmly in your hand to prevent injuries

caused by a rebounding hose.

Be absolutely certain to use a ¼ threaded

nipple and a quick-release coupling for the

compressed air connection.

Never place your hands near the mouth when

the device is ready to operate. Otherwise injuries may result.

Pay attention to damage. Check the de-

vice for damage before bringing it into use. If

the device exhibits defects, it must not be operated under any circumstances.

Do not use any pointed objects. Never

insert pointed and / or metal objects into the

inside of the device.

Only connect the air-powered staple gun to

lines which are guaranteed not to exceed the

maximum operating pressure by more than

10 %, e.g. with a pressure control valve in the

compressed air line (pressure regulator) with

downstream or built-in pressure limiting valve.

When using the air-powered staple gun be sure

not to exceed the max. pressure.

Only operate the air-powered staple gun at the

pressure required for the respective operation

to prevent needlessly high noise levels, inc

reased

wear and malfunctions this causes.

FIRE AND EXPLOSION

HAZARD! Never pressurise the air-powered

staple gun with oxygen or flammable gasses.

Safety of the fastener driving tool

9 GB/CY

Original accessories / tools

Use only the accessories and attachment

s

detailed in the operating instructions.

The use of fasteners or other accessories other

than those recommended in the operating instructions could lead to you suffering an injury.

Always have your air-powered tool

repaired by a professional using only

original spare parts. This will ensure the

air-powered tool remains safe.

Preparing the product for use

NOTE: always wear the protective goggles supplied

before putting the tool into operation. Remove the

protective film from the protective goggles before

using for the first time.

Connecting the compressed

air source

NOTE: The compressed air tacker must only be

operated with cleaned, oil-misted compressed air

and must not exceed the maximum operating pressure of 8 bar. The compressor must be fitted with a

pressure reducer in order to regulate the operating

pressure.

Connect the device to a suitable compressed

air source.

1. To do so, press the compressed air hose quickrelease coupling (not included in the scope of

delivery) on the ¼

threaded nipple 4 of the

compressed air tacker.

Locking is automatic.

2. Connect the other end of the compressed air

hose to the (filter) pressure reducer on the compressor.

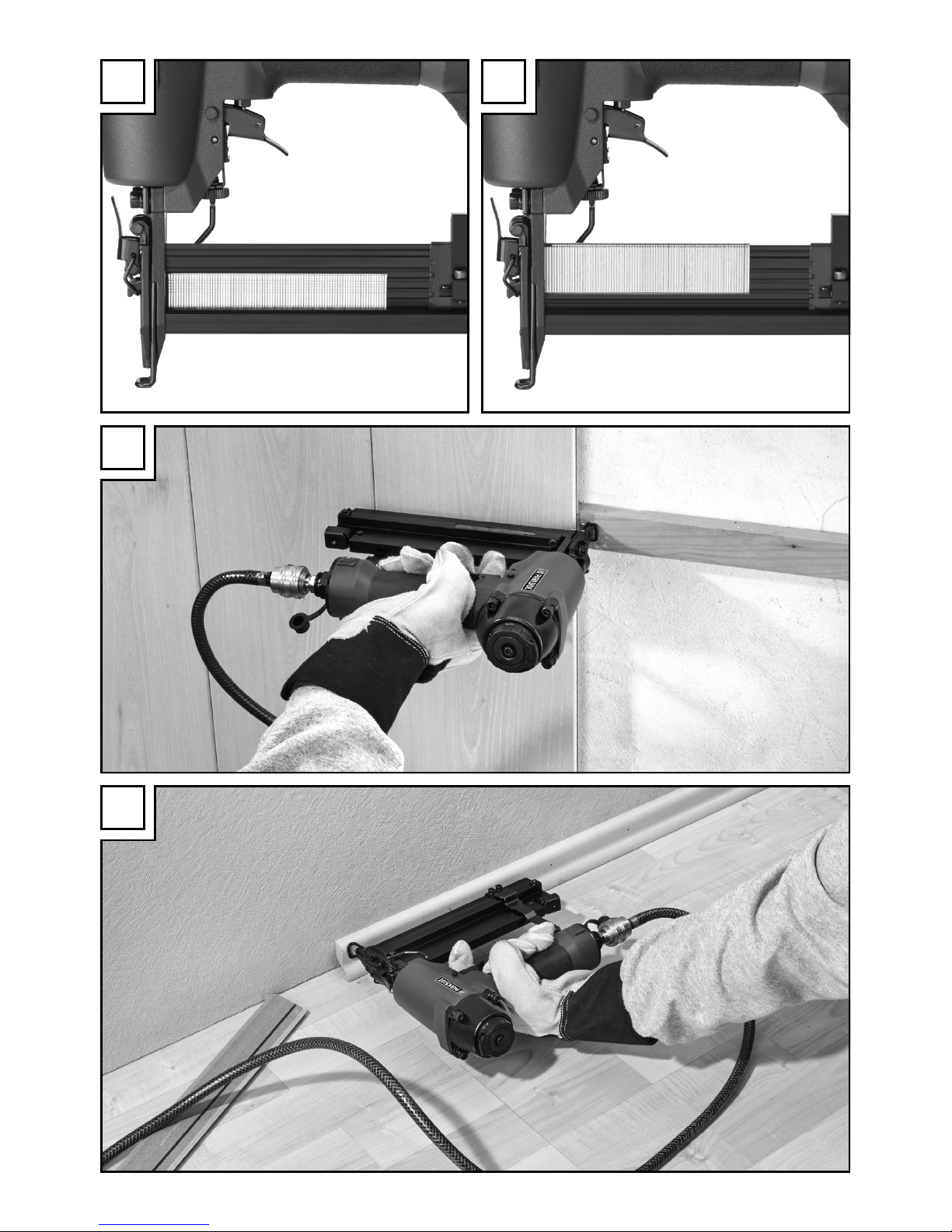

Loading the magazine

1. Press the magazine lever 5 and pull the magazine cover back to its stop position.

2. Insert the corresponding fastener (nails, see

Fig. B or staples, see Fig. C) into the magazine

6

. The tacks must be put on the rail of the ma-

gazine

6

.

3. Slide the magazine cover forwards until it locks.

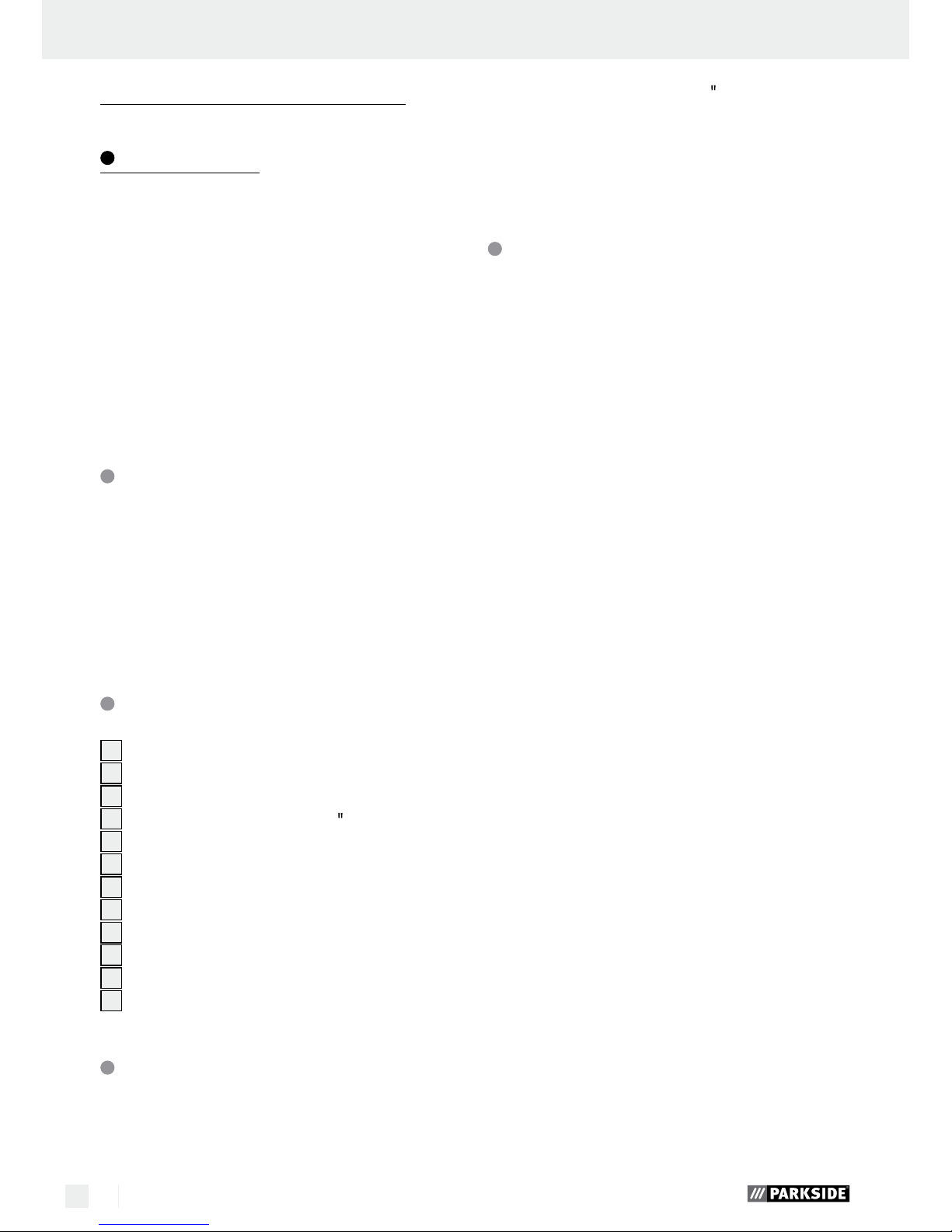

Operation

Load the magazine 6 of the compressed air

tacker as described in the chapter “Loading the

magazine“.

Use the pressure reducer to set the correct

operating pressure.

Ensure that the permissible operating pressure

of 8 bar at the device is never exceeded.

Operating pressure that is too high does not

provide any performance increase, but only increases compressed air consumption and accelerates wear on the device.

Switch on the compressor.

Allow the compressor to run once long enough

until maximum tank pressure is reached and the

device is switched off.

Place the compressed air tacker on the workpiece

and press the trigger

2

.

NOTE: The compressed air tacker

is equipped with a trigger lock

9

.

The fastener will only

leave the device

when the mouth of the compressed air tacker is

pressed against the workpiece and the trigger 2

is actuated.

Check that the fastener has been driven in cor-

responding to the work requirements.

– If the fastener is protruding, increase the air

pressure in 0.5 bar increments.

– If the fastener is too deep, decrease the air

pressure in 0.5 bar increments.

As an alternative, you can accelerate the work

by keeping the trigger

2

depressed.

Set the compressed air tacker against the work-

piece.

Press the device against the workpiece until the

mouth

10

touches it. The fastener will leave the

device.

As long as the trigger 2 is kept depressed, each

time the mouth

10

touches the workpiece one

fastener will leave the device.

Safety of the fastener driving tool / Preparing the product for use / Operation

10 GB/CY

Another alternative is to keep the mouth

10

pressed against the workpiece.

Each time the trigger 2 is actuated, a fastener

will leave the device.

NOTE: Fine adjustment with the knurled screw

8

is possible.

Turn the knurled screw 8 downwards in order

to drive the fastener more deeply into the workpiece.

Turn the knurled screw 8 upwards in order to

drive the fastener less deeply into the workpiece.

Turn the exhaust air aperture 1 to guide the

exhaust airflow in the desired direction.

After finishing work, disconnect the device from

the compressor.

Removing jammed fasteners

If a staple or nail gets jammed in the magazine

slot, immediately disconnect the compressed

air supply.

Open the magazine 6 as described in the

chapter “Loading the magazine“.

Open the face plate 11 by pulling the face

plate quick clamping lever

12

in the direction

of the trigger lock

9

.

Remove the jammed fastener.

Close the face plate 11 by pulling the face

plate quick clamping lever

12

in the direction

of the exhaust air aperture

1

.

Close the magazine 6 of the compressed air

tacker as described in the chapter “Loading the

magazine“.

Maintenance and cleaning

RISK OF INJURY! Be absolutely certain to

disconnect the device from the compressed air

source before cleaning or maintaining it.

User maintenance

Lubrication with oil mister

NOTE: As a treatment stage after the pressure re-

ducer, an oil mister provides continuous and opti

mum

lubrication of the compressed air tacker. An oil mister gives off fine drops of oil into the airflow and so

guarantees regular lubrication.

Install the oil mister after the (filter) pressure re-

ducer. To do so, insert the nipple of the oil mister

into the quick-release coupling of the (filter)

pressure reducer.

Then connect the compressed air device to the

quick-release coupling provided for it.

Manual lubrication

NOTE: If you do not have an oil mister, lubricate the

device each time after driving about 5000 fasteners.

Apply 1–2 drops of special compressed air oil

into the threaded nipple

4

of the compressed

air tacker.

Then press the trigger 2 several times.

ATTENTION: Be certain not to use too much

oil; otherwise oil could leave the mouth with the

fastener and potentially damage the workpiece.

Cleaning

Do not use any sharp objects to clean the device.

Do not allow any liquids to enter the device.

Otherwise the device could be damaged.

Clean the device regularly, preferably always

immediately after finishing work.

Use a dry cloth to clean the housing. Under no

circumstances should you use petrol, solvent or

cleaners which attack plastic.

After each use, pack the compressed air tacker

in the carrying case it was delivered with to

protect it from dirt.

Service

Should problems arise whilst operating your ROWI

Electronics product, please proceed as follows:

Operation / Maintenance and cleaning / Service

11 GB/CY

1. Contact us

You may contact the ROWI Electronics Service

Team at:

ROWI Electronics GmbH

Augartenstr. 3

76698 Ubstadt-Weiher

service@rowi-electronics.de

Service hotline: +49 (0) 7253 9460-40

IAN 109811

Please have your receipt and the item number (e.g.

IAN 12345) ready as your proof of purchase when

enquiring about your product.

Most problems can be resolved with the skilled

technical support of our Service Team.

2. Should an inspection or repair by the

ROWI Electronics Service Center be

required, please proceed as follows:

– Pack product

Pack the product in the original packaging.

Ensure it is adequately padded and protected

from impact. Transport damage is not covered

by the warranty.

– Include receipt

The sales receipt must be included. Repairs

under warranty can only be processed with

the sales receipt.

– Send product

Only send the product to the above address

after contacting the ROWI Electronics Service

Center.

Warranty

ROWI Electronics extends a 36 months warranty from

the date of purchase to the owner of this product.

During this period, the ROWI Electronics Service

Center will repair defects in material or manufacturing detected on the product free of charge.

This warranty does not cover problems not resulting

from defcts in material or manufacturing, e.g.

– Transport damage of any type

– Defects due to incorrect installation

– Defects due to improper use

– Defects due to improper handling

– Defects due to incorrect repairs or repairs

attempted by persons and / or companies

not authorised by ROWI Electronics

– Normal wear and tear from operation

– Cleaning components

– Adaptation to different national, technical or

safety requirements if the product is used in

a country for which it was not designed and

manufactured.

We further assume no warranty for products where

the serial number has been forged, altered or re

moved.

The warranty will also be void when installing parts

not approved by ROWI Electronics GmbH into the

product.

The warranty does not cover claims beyond free

repair of the defect, e.g. claims for damages.

Disposal

The packaging is made entirely of recyclable materials which you can dispose

of at your local recycling facilities.

Do not dispose of the product with

household rubbish!

Contact your local refuse disposal authority for

more details of how to dispose of your worn out

electrical devices.

Service / Warranty / Disposal

12

13 HR

Popis sadržaja

Uvod

Namjena ........................................................................................................................................ Stranica 14

Oprema ......................................................................................................................................... Stranica 14

Opseg isporuke ............................................................................................................................. Stranica 14

Tehnički podaci ............................................................................................................................. Stranica 14

Sigurnost uređaja za zabijanje

Sigurnost kod rada ....................................................................................................................... Stranica 15

Dodatne sigurnosne upute za pneumatsku klamericu ................................................................ Stranica 16

Originalni pribor / dodatni uređaji............................................................................................... Stranica 17

Stavljanje u pogon

Priključivanje izvora pneumatskog zraka .................................................................................... Stranica 17

Punjenje spremnika ....................................................................................................................... Stranica 17

Rukovanje ................................................................................................................................ Stranica 17

Otklanjanje ukliještene spojnice ................................................................................................... Stranica 18

Održavanje i čišćenje

Tekuće održavanje obnaša korisnik ............................................................................................ Stranica 18

Čišćenje ......................................................................................................................................... Stranica 18

Servis ............................................................................................................................................ Stranica 19

Jamstvo ...................................................................................................................................... Stranica 19

Zbrinjavanje ........................................................................................................................... Stranica 20

14 HR

Uvod

Pneumatska klamerica PDT 40 D3

Uvod

Čestitamo Vam na kupnji novog uređaja. Ovom

kupnjom odlučili ste se za visokokvalitetan proizvod.

Uputa za uporabu je sastavni dio ovog proizvoda.

Ona sadrži važne upute o sigurnosti, uporabi i

uklanjanju otpada. Prije upotrebe proizvoda upoznajte se sa svim njegovim uputama za korištenje i

sigurnosnim uputama. Koristite ovaj proizvod u

skladu s navedenim uputama te u navedene svrhe.

Ukoliko proizvod dajete nekoj drugoj osobi, predajte toj osobi također i sve upute.

Namjena

Ovaj uređaj je prikladan za radove kod montaže i

popravka. Svako drugo korištenje ili izmjena na

uređaju tretira se kao nepropisano i krije znatne

opasnosti od nesreća. Ne preuzimamo nikakvu

odgovornost za štete nastale od nenamjenske uporabe. Uređaj je isključivo namijenjen u privatne svrhe.

Oprema

1

blenda za odlazni zrak (može se okretati)

2

okidač

3

drška

4

navojni utikač-spojnica 6,35 mm (¼ )

5

poluga spremnika

6

spremnik

7

pokazivač stanja punjenja

8

nazubljeni vijak

9

okidni osigurač

10

grlo

11

prednja ploča

12

brzo stezna poluga prednje ploče

Opseg isporuke

1 pneumatska klamerica PDT 40 D3

1 kofer za nošenje

1 specijalno ulje kod komprimiranog zraka

1 navojni utikač-spojnica, 6,35 mm (¼ )

(već montirano)

1 paket čavla, 1000 kom.

1 paket spajalica, 1000 kom.

1 zaštitne naočale

1 upute za korištenje

Tehnički podaci

Dimenzije: 297 x 280 x 71 mm

(Š x V x D)

Težina (bez pribora): 1181 g

Vrsta okidača: komprimirani zrak

Maksimalni dozvoljeni tlak: 8 bara

Preporučeno područje tlaka: 4 do 7 bara

Potrošnja zraka po jedinici

zabijanja: cca. 0,09 l po jedinici

zabijanja

Preporučeno mazivo: specijalno ulje kod

komprimiranog zraka

Kapacitet punjenja: 100 kom.

Dužina čavla: 15 mm, 20 mm,

25 mm, 30 mm,

32 mm, 35 mm,

38 mm, 40 mm,

45 mm, 50 mm

Dužina spajalica: 10–40 mm

Širina spajalica: 5,7 mm

Preporučamo

promjer crijeva: ∅ 9 mm

Kvaliteta komprimiranog

zraka: očišćen, raspršeno

ulje i bez kondenzata

Informacija o buci i vibraciji:

Mjerne vrijednosti utvrđene u sukladnosti sa smjernicom EN 12549:1999, EN ISO 4871. Procjenjena

razine zvučnog pritisaka-A stroja iznosi karakteristično

112,6 dB(A). Razina buke iznosi 80 dB(A). Nesigurnost K = 2,5 dB.

L

wa

: 125,6 dB(A)

L

pa

(na radnom mjestu): 114,3 dB(A)

L

pc

: 115,9 dB(A)

Ove vrijednosti su specifičnosti uređaja, i ne izražavaju

buku na mjestu uporabe. Buka na mjestu uporabe,

ovisi npr. o okolini radnog mjesta, komadu koji se

15 HR

Uvod / Sigurnost uređaja za zabijanje

obrađiva, podlozi na kojij se obrađiva i broju zabijanja.

Ovisno o radnom prostoru i obliku dijela koji se

obrađiva potrebno je provesti individualne mjere

smanjenja buke, kao npr. postavljanje komada na

podlogu koja ublažuje zvuk, sprečavanje vibracija

radnih komada pomoću stezanja ili pokrivanja,

podešavanje najniže potrebnog tlaka za radnu

operaciju. U posebnim slučajevima je potrebno

nošenje osobnih štitnika za sluh.

Nosite štitnike za uši!

Ukupne vrijednosti vibracije prema ISO

8662-11:1999:

Vrijednost emisije vibracije a

h,W

= 15,0 m / s

2

Nesigurnost K = 0,29 m / s

2

Mehanički udarci (vibracija)

Za uređaj zabijanja utvrđena je karakteristična vibracijska vrijednost na temelju smjernice ISO 866211:1999 - ručno držani motorni alati - mjerenje vibracije na drški - uređaji za zabijanje (vidi tehnički

podaci). Vrijednost je specifični parametar za uređaj

i ne predstavlja djelovanje na sustav šake i ruke pri

primjeni uređaja. Djelovanje na sustav šake i ruke

kod primjene uređaja, ovisi npr. o snazi hvatanja,

snazi pritiskivanja, smjeru obrade, namještenom tlaku, dijelu koji se obrađiva, podlozi na kojoj leži dio

za obrađivanje.

Sigurnost uređaja za zabijanje

Pročitajte

upute za sigurnost i ostale upute. Propusti zbog nepridržavanja

sigurnosnih i drugih uputa mogu prouzročiti teške

ozljede i / ili materijalnu štetu.

SVE SIGURNOSNE UPUTE I OSTALE UPUTE

SAČUVAJTE ZA BUDUĆU UPORABU.

Provjerite prije svakog početka rada

na ispravno funkcioniranje sigurnosnih i okidnih naprava, kao i sve vijke i

matice da li čvrsto stoje.

Nemojte izvoditi nikakve nepravilne

manipulacije na uređaju za zabijanje.

Nemojte demontirati ili blokirati dije-

love uređaja za zabijanje, kao npr.

okidnog osigurača.

Ne vršite nikakve „hitne popravke“ s

neprikladnim sredstvima.

Uređaj za zabijanje se mora redovito

o

državati, prema uputama proizvođaća.

Izbjegavajte svako slabljenje i oštećenje

uređaja, npr. zbog:

– udara ili graviranja,

– mjere remontiranja, koje nisu

dozvoljene od strane proizvođača,

– vođenja uz šablone, koje su načinjene

od tvrdog materijala, npr. čelika,

– padanja ili guranja po podu,

– upotrebe kao čekića,

– svake vrste djelovanja sile.

Učvrstite takere na nosače, npr. radni stol, tako

da uvijek stoje sigurno. Držači koje rabite za

učvršćivanje moraju biti takvi da štite taker od

oštećenja, zakretanja ili pomjeranja.

Sigurnost kod rada

Ne usmjeravajte nikada uređaj za zabi-

janje prema sebi ili na druge osobe.

Držite uređaj za zabijanje pri radu

tako, da glava i tijelo ne mogu bili

ozlijeđeni, kod eventualnog udarca

unatrag zbog kvara napajanja ili od

tvrdih dijelova na komadu u obradi.

Ne pokrečite nikada uređaj za nabi-

janje u otvorenom prostoru. Na taj način

možete izbjeći opasnost od slobodno letećieg

pribora za klamanje i iscrpljivanja uređaja.

Za transport mora se uređaj za zabi-

janje odvojiti od voda komprimiranog

zraka, osobito ako koristite ljestve ili

se krečete u neobičnom položaju.

Nosite uređaj za zabijanje na radnom

mjestu samo na drški, a ne s aktiviranim okidačem.

Obratite pozornost na mogućnosti na

radnom mjestu. Spajalice i čavli mogu

eventualno prodrijeti kroz tanke komade ili

16 HR

Sigurnost uređaja za zabijanje

pasti kada se radi na rubovima ili na uglovima

komada i pri tome ugrožavati ljude.

Koristite za Vašu osobnu zaštitu pri-

kladna zaštitna sredstva za tijelo, kao

npr. štitnike za uši i zaštitu za oči. Kori-

štenje osobne zaštitne opreme, kao maske za

prašinu, zaštitne cipele, zaštitne kacige ili štitnika

za uši, je ovisno o vrsti i uporabi električnog

alata, smanjuje rizik od ozljeda.

Dodatne sigurnosne upute za

pneumatsku klamericu

OPASNOST PO ŽIVOT!

Ne prekoračujte nikada radni tlak od maksi-

malno 8 bara. Za namještanje radnog tlaka

koristite reduktora tlaka.

OPASNOST PO ŽIVOT!

Ne koristite nikada kisik ili druge gorive plinove

kao izvor energije.

Vodite uvijek računa o tome, da Vaše

radno mjesto bude čisto i dobro osvjetljeno. Nered i ne osvjetljeno područje rada,

može uzrokovati nezgode.

Držite djecu i druge osobe tijekom

korištenja podalje od uređaja. Kod

nepažnje, mogli bi izgubiti kontrolu nad

uređajem.

Budite uvijek pozorni, vodite računa

o tome što radite i razumno pristupajte radu sa uređajem za zabijanje. Ne

upotrebljavajte uređaj za zabijanje

ako ste umorni ili pod utjecajem droga, alkohola ili lijekova. Jedan trenutak

nepažnje za vrijeme korištenja uređaja za

zabijanje, može uzrokovati teške ozljede.

Pazite na ispravno držanje tijela. Vo-

dite računa o tome da sigurno stojite

na tlu i održavate vlastitu ravnotežu.

Na taj način možete boje kontrolirati uređaj

za zabijanje u neočekivanim situacijama.

Prije popravaka i radova održavanja kao i

prije transporta, odstranite uređaj od izvora

komprimiranog zraka.

OPASNOST OD OZLJEDA! Ne koristite

uređaj kada se nalazite na platformama ili

ljestvama.

Ne upotrebljavajte nikada vodik, ki-

sik, ugljični dioksid ili drugi plin u

bocama kao izvor energije za ovaj

alat, jer to može dovesti do eksplozije i na taj

način do teških ozljeda.

OPASNOST OD OZLJEDA! Ne stavljajte

uređaj u pogon ako je okidni osigurač 9 ošteć

en

ili ako je odvojen. Inače prijeti opasnost od

ozljeda.

Pri otpuštanju cijevne spojke, držite cijev čvrsto

u ruci, kako bi izbjegli ozljede od cijevi u slučaju

iznenadnog udarca unatrag.

Koristite za priključak komprimiranog zraka

obavezno navojnu utikač-spojnicu od ¼

i jed-

nu brzu spojnicu.

Nikada ne dolazite sa svojim rukama u blizinu

grla, dok je uređaj spreman za rad. Inače prijeti opasnost od ozljeda.

Pazite na oštećenja. Prije stavljanja u po-

gon, provjerite uređaj na moguća oštećenja.

Ukoliko uređaj sadrži manjkavosti, nesmije ga

se ni u kojem slučaju stavljati u pogon.

Ne koristite nikakve oštre predmete.

Ne uvlačite nikakve šiljate i/ili metalne predmete u unutrašnjost uređaja.

Taker na pneumatski pogon smije se priključiti

samo na vodove kod kojih je osigurano da ne

može doći do premašivanja maksimalno dopuštenog tlaka za više od 10 %, npr. pomoću

ventila za kontrolu tlaka, koji se nalazi u pneumatskom vodu (reduktor tlaka), s začelno spojenim ili ugrađenim ventilom za ograničenje

tlaka.

Kod rabljenja takera na pneumatski pogon,

pazite da se ne premaši maks. tlak.

Pneumatski taker smije raditi samo pod tlakom

predviđenim za određenu radnu operaciju,

kako bi se izbjegla nepotrebno visoka razina

buke, pojačano trošenje i smetnje koje nastaju

usljed toga.

POSTOJI OPASNOST

OD POŽARA I EKSPLOZIJE! Pneumatski

taker ne smije nikada raditi s pogonom na kisik

ili zapaljive plinove pod tlakom.

Loading...

Loading...