Parkside PDT 40 B2 User Manual [bg]

PNEUMATIC STAPLER PDT 40 B2

PNEUMATIC STAPLER

Operation and Safety Notes

Translation of original operation manual

ПНЕВМАТИЧЕН ТАКЕР

Инструкции за обслужване и безопасност

Превод на оригиналното ръководство за експлоатация

DRUCKLUFT-TACKER

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

IAN 73782

CAPSATOR CU AER COMPRIMAT

Instrucţiuni de utilizare şi de siguranţă

Traducerea instrucţiunilor de utilizare originale

ΚΑΡΦΩΤΙΚΟ ΑΕΡΟΣ

Υποδείξει χειρισού και ασφαλεία

Μετάφραση των αυθεντικών οδηγιών λειτουργίας

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Înainte de a citi instrucţiunile, priviţi ambele pagini cu imagini şi familiarizaţi-vă cu toate funcţiile aparatului.

Преди да прочетете отворете двете страници с фигурите и след това се запознайте с всички

функции на уреда.

Πριν ξεκινήσετε την ανάγνωση, ανοίξτε τι δυο σελίδε ε τι εικόνε και εξοικειωθείτε ε όλε τι

λειτουργίε τη συσκευή.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

GB / CY Operation and Safety Notes Page 5

RO Instrucţiuni de utilizare şi de siguranţă Pagina 13

BG Инструкции за обслужване и безопасност Страница 21

GR / CY Υποδείξει χειρισού και ασφαλεία Σελίδα 31

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 39

11

10

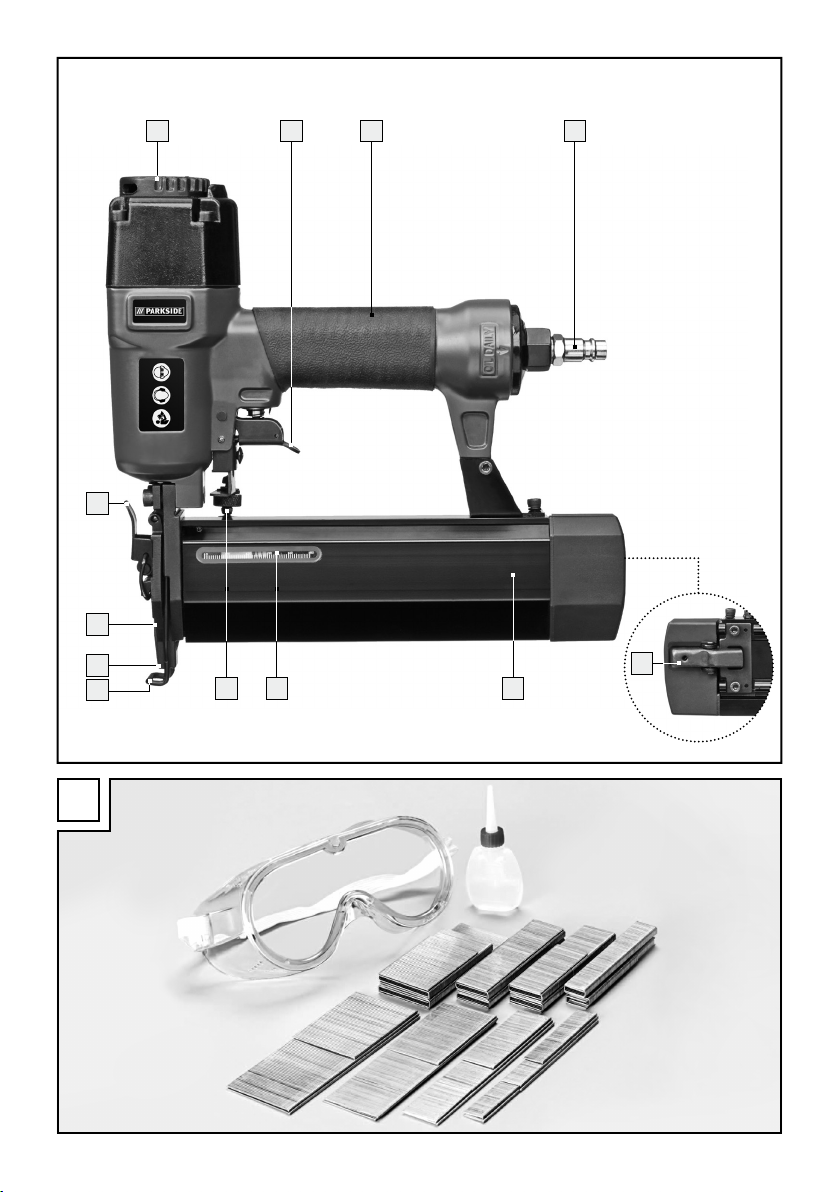

1 2 3 4

A

9

8

7

56

12

B

C

D

Table of contents

Introduction

Intended use ........................................................................................................................................ Page 6

Features and fittings ............................................................................................................................ Page 6

Included items .....................................................................................................................................Page 6

Technical data ..................................................................................................................................... Page 6

Safety of the fastener driving tool ............................................................................Page 7

Work safety ......................................................................................................................................... Page 8

Additional safety information for compressed air tackers ................................................................ Page 8

Original accessories / tools ................................................................................................................ Page 9

Preparing the product for use

Connecting the compressed air source .............................................................................................Page 9

Loading the magazine ........................................................................................................................ Page 9

Operation .......................................................................................................................................Page 9

Removing jammed fasteners ............................................................................................................... Page 10

Maintenance and cleaning

Maintenance ....................................................................................................................................... Page 10

Cleaning .............................................................................................................................................. Page 11

Service ............................................................................................................................................... Page 11

Warranty ......................................................................................................................................... Page 11

Disposal ............................................................................................................................................ Page 12

Declaration of Conformity / Manufacturer..........................................................Page 12

5 GB/CY

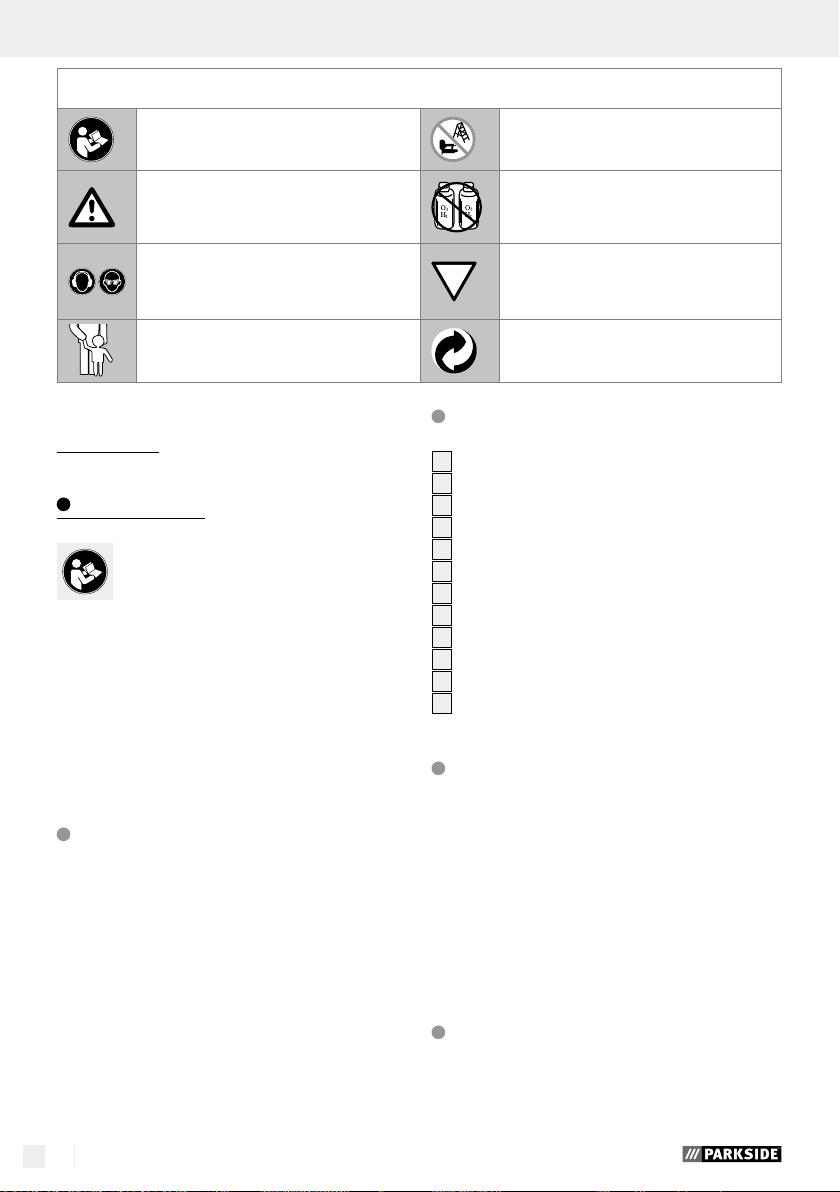

The following pictograms are used in these operating instructions / on the device:

Read instruction manual!

Observe caution and safety notes!

Wear hearing protection

and protective glasses.

Keep children away from electrical

devices!

Pneumatic stapler PDT 40 B2

Introduction

We congratulate you on the purchase of

your new device. You have chosen a high

quality product. The operating instructions

are part of the product. They contain important information concerning safety, use and disposal. Before using the product, familiarise yourself with all

of the operating instructions and safety instructions.

Use the product only as described and for the

specified applications. If you pass the product on

to anyone else, please ensure that you also pass

on all the documentation with it.

Intended use

The device is suitable for assembly and repair work.

Any other use or modification to the device shall be

considered as improper use and could give rise to

considerable dangers. We will not accept liability

for loss or damage arising from improper use. The

device is intended for private domestic use only.

Features and fittings

1

Exhaust air aperture (can be rotated)

2

Trigger

3

Handle

6 GB/CY

Do not use the device on scaffolds

or ladders.

Never use hydrogen, oxygen, carbon

dioxide or other bottled gases as an

energy source.

Trigger lock

Dispose of packaging and

device in an environmentally-friendly

way!

4

Threaded nipple 6.35 mm (¼“)

5

Magazine

6

Fill level indicator

7

Knurled screw

8

Trigger lock

9

Mouth

10

Face plate

11

Face plate quick clamp lever

12

Magazine lever

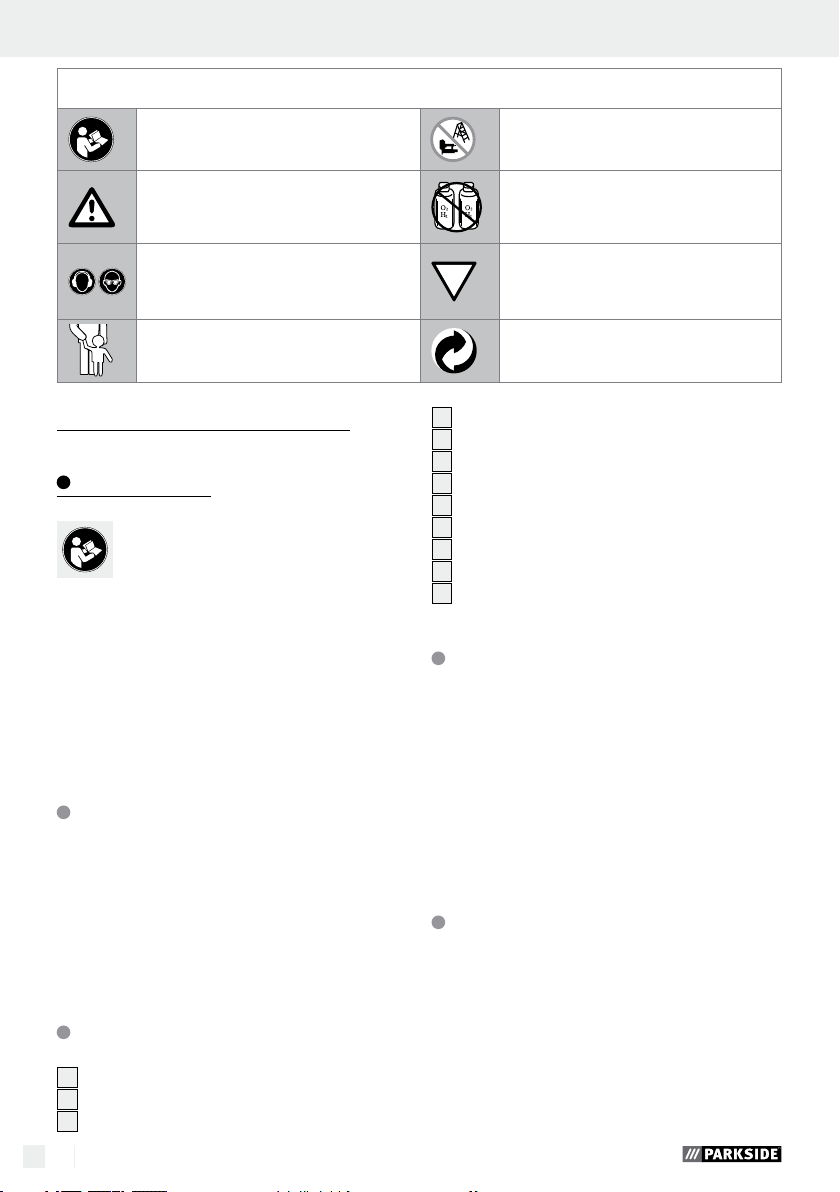

Included items

1 Pneumatic stapler PDT 40 B2

1 Carrying case

1 Special compressed air oil

1 Threaded nipple 6.35 mm (¼“) (pre-assembled)

1 Package nails, 1000 pcs.

1 Package staples, 1000 pcs.

1 Protective glasses

1 Operating instructions

Technical data

Dimensions: 248 x 58 x 246 mm

(L x H x W)

Weight

(without fasteners): 1.513 kg

Trigger type: Compressed air

Maximum permissible

pressure: 8 bar

Introduction / Safety of the fastener driving tool

Recommended pressure

range: 4 to 7.5 bar

Air consumption per

drive in process: approx. 0.13 litre per

driving-in process

Recommended lubricant:

Compressed air special oil

Loading capacity: 100 pcs.

Nail lengths: 15 mm, 20 mm

25 mm, 30 mm,

32 mm, 35 mm,

38 mm, 40 mm,

45 mm, 50 mm,

Staple lengths: 10–40 mm

Staple width: 5.7 mm

Recommended

Hose diameter: ∅ 9 mm

Compressed air quality: Cleaned, oil-misted

and condensate-free

Noise and vibration data:

Measured values for noise are determined in accordance with EN 12549:1999, EN ISO 4871.

The A-weighted sound pressure level of the device is

typically 90.6 dB (A). Uncertainty K = 3 dB. The

sound level while working can exceed 103.6 dB (A).

These values are characteristic values referenced to

the device and do not reflect noise development at

the work location. Noise development at the work

location depends e.g. on the work environment, the

workpiece, the workpiece support and the number

of fastener driving processes.

In correspondence with conditions at the work location, individual noise reduction measures may need

to be carried out, such as placing the workpiece on

a noise-suppressing surface, clamping or covering

to prevent workpiece vibration and adjusting to the

minimum pressure required by the work process. In

certain cases, wearing personal hearing protection

is require.

Wear hearing protection!

Vibration values in accordance with

ISO 8662-11:1999:

Vibration emission value a

Uncertainty K = 1.5 m / s

= 12.380 m / s

h,D

2

2

Mechanical impact (vibration)

The vibration value for the fastener driving device was

determined in accordance with ISO 8662-11:1999 —

Hand-held portable power tools – Measurement of

vibrations at the handle — Fastener driving tools

(see technical data). The value is referenced to the

device and does not represent the influence on the

hand-arm system when the device is used. Influence

on the hand-arm system when using the device depends on e.g. gripping force, pressing force, working direction, air pressure set, the workpiece and its

position.

Safety of the fastener

driving tool

Please read all the safety

information and instructions. Failure to com-

ply with the safety instructions and instructions can

result in severe injuries and / or damage to pro

PLEASE RETAIN ALL SAFETY INFORMATION

AND INSTRUCTIONS FOR FUTURE REFERENCE.

Each time before starting work, check

for flawless functioning of the safety

and triggering devices as well as the

firm fit of all bolts and nuts.

Do not conduct any improper manipu-

lation of the fastener driving tool.

Do not dismount or block any part of

the fastener driving tool, such a trigger lock.

Do not conduct any „emergency re-

pairs“ with unsuitable materials.

The fastener driving tool must be reg-

ularly and properly maintained as

specified by the manufacturer.

Prevent anything that would weaken

or damage the device, e.g. by:

– stamping or engraving,

perty.

7 GB/CY

– alterations not permitted by the

manufacturer,

– guiding on templates made of hard

material, e.g. steel,

– permitting to fall onto or slide across

the floor,

– using as a hammer,

– every type of external force.

Work safety

Never point a fastener driving tool that

is ready to use directly at yourself,

other persons or animals.

During work, hold the fastener driving

tool so that head and body can not be

injured by possible kickback due to a

fault in the power supply or from hard

places in the workpiece.

Never trigger the fastener driving tool

into empty space. Following this instruction

will prevent danger due to uncontrolled flying

fasteners and overloading the device.

Before transporting, disconnect the

fastener driving tool from the compressed air network, particularly when

using ladders or are moving with an

unaccustomed body posture.

At the workplace, only carry the fas-

tener driving tool by its grip and never

with the trigger actuated.

Pay attention to workplace conditions.

Fasteners may strike completely through thin

workpieces or slide off corners or edges to

cause a danger to persons.

Use suitable personal protec-

tion equipment, e.g. hearing

and eye protection. Wearing personal

protective devices such as dust mask, non-slip

safety shoes, safety helmet or hearing protectors,

depending on the type of fastener driving tool

and its application, reduces the risk of injuries.

Additional safety

information for

compressed air tackers

RISK OF INJURY! Never

exceed the maximum permissible operating

pressure of 8 bar. Use a pressure reducer to

adjust the operating pressure.

RISK OF INJURY! Never

use oxygen or other flammable gases as en-

ergy source.

Keep your working area clean and

well lit. Untidy or poorly lit working areas

can lead to accidents.

Keep children and other indi-

viduals away from the fastener driving tool during use.

Distractions can cause you to lose control of

the device.

Remain alert at all times, watch what

you are doing and always proceed

with caution when working with a

fastener driving tool. Do not use any

fastener driving tool if you are tired

or under the influence of drugs, alcohol

or medication. One moment of carelessness

when using the fastener driving tool may result

in serious injuries.

Avoid placing your body in an unnat-

ural position. Keep proper footing

and balance at all times. By doing this you

will be in a better position to control the fastener driving tool in unforeseen circumstances.

Before any repair and maintenance work or

transport, remove the device from the compressed air source.

RISK OF INJURY! Do not use the

device on scaffolds or ladders.

Never use hydrogen, oxygen, car-

bon dioxide or other bottled gasses

to power this tool as doing so may

result in an explosion and thus may cause severe injuries.

RISK OF INJURY! Do not use the device if

the trigger lock

removed. Otherwise injuries may result.

8

is damaged or has been

8 GB/CY

Safety of the fastener driving tool / Preparing the product for use / Operation

When loosening the hose coupling, hold the

hose firmly in your hand to prevent injuries

caused by a rebounding hose.

Be absolutely certain to use a ¼‘„ threaded

nipple and a quick-release coupling for the

compressed air connection.

Never place your hands near the mouth when

the device is ready to operate. Otherwise injuries may result.

Pay attention to damage. Check the de-

vice for damage before bringing it into use. If

the device exhibits defects, it must not be operated under any circumstances.

Do not use any pointed objects. Never

insert pointed and / or metal objects into the

inside of the device.

Original accessories / tools

Use only the accessories and attachment

detailed in the operating instructions.

The use of fasteners or other accessories other

than those recommended in the operating instructions could lead to you suffering an injury.

Preparing the product for use

1. To do so, press the compressed air hose quickrelease coupling (not included in the scope of

delivery) on the ¼“ threaded nipple

compressed air tacker.

Locking is automatic.

2. Connect the other end of the compressed air

hose to the (filter) pressure reducer on the compressor.

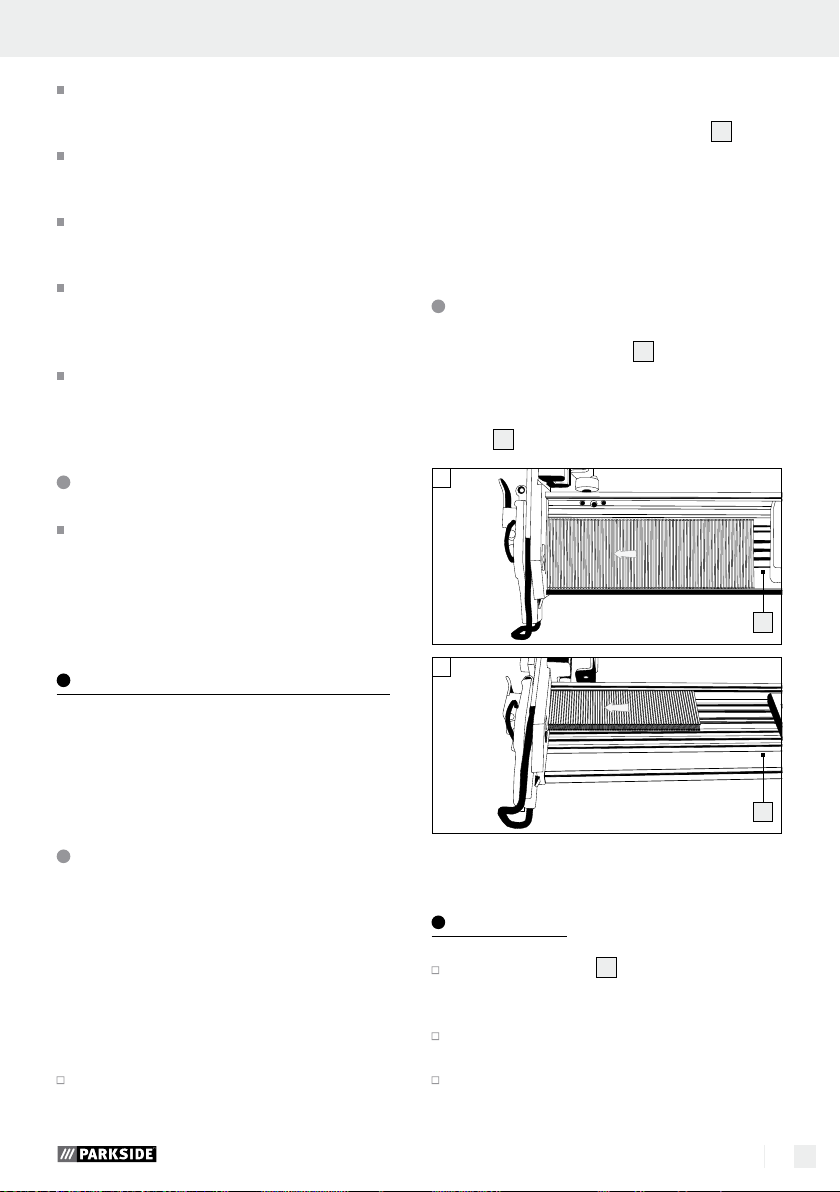

Loading the magazine

1. Press the magazine lever 12 and pull the magazine cover back to its stop position.

2. Insert the corresponding fastener (nails, see

Fig. 01 or staples, see Fig. 02) into the maga-

5

zine

.

01

s

02

4

of the

5

NOTE: always wear the protective goggles supplied before putting the tool into operation. Remove

the protective film from the protective goggles before

using for the first time.

Connecting the compressed

air source

NOTE: The compressed air tacker must only be

operated with cleaned, oil-misted compressed air

and must not exceed the maximum operating pressure of 8 bar. The compressor must be fitted with a

pressure reducer in order to regulate the operating

pressure.

Connect the device to a suitable compressed

air source.

5

3. Slide the magazine cover forwards until it locks.

Operation

Load the magazine 5 of the compressed air

tacker as described in the chapter “Loading the

magazine“.

Use the pressure reducer to set the correct

operating pressure.

Ensure that the permissible operating pressure

of 8 bar at the device is never exceeded.

Operating pressure that is too high does not

9 GB/CY

provide any performance increase, but only increases compressed air consumption and ac-

celerates wear on the device.

Switch on the compressor.

Allow the compressor to run once long enough

until maximum tank pressure is reached and the

device is switched off.

Place the compressed air tacker on the workpiece

and press the trigger

2

.

NOTE: The compressed air tacker

is equipped with a trigger lock

8

The fastener will only leave the device

when the mouth of the compressed air tacker is

pressed against the workpiece and the trigger

is actuated.

Check that the fastener has been driven in cor-

responding to the work requirements.

– If the fastener is protruding, increase the air

pressure in 0.5 bar increments.

– If the fastener is too deep, decrease the air

pressure in 0.5 bar increments.

As an alternative, you can accelerate the work

by keeping the trigger

2

depressed.

Set the compressed air tacker against the work-

piece.

Press the device against the workpiece until the

9

mouth

touches it. The fastener will leave the

device.

As long as the trigger 2 is kept depressed, each

time the mouth

9

touches the workpiece one

fastener will leave the device.

Another alternative is to keep the mouth

9

pressed against the workpiece.

Each time the trigger 2 is actuated, a fastener

will leave the device.

NOTE: Fine adjustment with the knurled screw

is possible.

Turn the knurled screw 7 downwards in order

to drive the fastener more deeply into the workpiece.

Turn the knurled screw 7 upwards in order to

drive the fastener less deeply into the workpiece.

Turn the exhaust air aperture 1 to guide the

exhaust airflow in the desired direction.

After finishing work, disconnect the device from

the compressor.

Removing jammed fasteners

If a staple or nail gets jammed in the magazine

slot, immediately disconnect the compressed

air supply.

Open the magazine 5 as described in the

.

chapter “Loading the magazine“.

Open the face plate 10 by pulling the face

plate quick clamping lever

2

of the trigger lock

11

in the direction

8

.

Remove the jammed fastener.

Close the face plate 10 by pulling the face

plate quick clamping lever

of the exhaust air aperture

11

in the direction

1

.

Close the magazine 5 of the compressed air

tacker as described in the chapter “Loading the

magazine“.

Maintenance and cleaning

RISK OF INJURY! Be absolutely certain to

disconnect the device from the compressed air

source before cleaning or maintaining it.

Maintenance

Lubrication with oil mister

NOTE: As a treatment stage after the pressure re-

ducer, an oil mister provides continuous and opti

lubrication of the compressed air tacker. An oil mister gives off fine drops of oil into the airflow and so

guarantees regular lubrication.

7

Install the oil mister after the (filter) pressure re-

ducer. To do so, insert the nipple of the oil mister into the quick-release coupling of the (filter)

pressure reducer.

Then connect the compressed air device to the

quick-release coupling provided for it.

mum

10 GB/CY

Maintenance and cleaning / Service / Warranty

Manual lubrication

NOTE: If you do not have an oil mister, lubricate the

device each time after driving about 5000 fasteners.

Apply 1–2 drops of special compressed air oil

into the threaded nipple

4

of the compressed

air tacker.

Then press the trigger 2 several times.

ATTENTION: Be certain not to use too much

oil; otherwise oil could leave the mouth with the

fastener and potentially damage the workpiece.

Cleaning

Do not use any sharp objects to clean the de-

vice. Do not allow any liquids to enter the device. Otherwise the device could be damaged.

Clean the device regularly, preferably always

immediately after finishing work.

Use a dry cloth to clean the housing. Under no

circumstances should you use petrol, solvent or

cleaners which attack plastic.

After each use, pack the compressed air tacker

in the carrying case it was delivered with to

protect it from dirt.

Service

Have your fastener

driving tool repaired only by qualified

specialist personnel using original manufacturer parts only. This will ensure that

your fastener driving tool remains safe to use.

way can a post-free despatch for your

goods be assured.

The warranty covers only claims for material and

maufacturing defects, but not for transport damage,

for wearing parts or for damage to fragile components, e.g. buttons or batteries. This product is for private use only and is not intended for commercial use.

The warranty is void in the case of abusive and improper handling, use of force and internal tampering not carried out by our authorized service branch.

Your statutory rights are not restricted in any way

by this warranty.

The warranty period will not be extended by repairs

made unter warranty. This applies also to replaced

and repaired parts. Any damage and defects extant

on purchase must be reported immediately after

unpacking the appliance, at the latest, two days after

the purchase date. Repairs made after the expiration

of the warranty period are subject to payment.

GB

Service Great Britain

Tel.: 0871 5000 720

(0,10 GBP / Min.)

e-mail: kompernass@lidl.co.uk

IAN 73782

CY

Service Cyprus

Tel.: 8009 4409

e-mail: kompernass@lidl.com.cy

Warranty

The warranty for this appliance is for 3

years from the date of purchase. The appliance has been manufactured with care

and meticulously examined before delivery. Please retain your receipt as proof

of purchase. In the event of a warranty

claim, please make contact by telephone

with our Service Department. Only in this

IAN 73782

11 GB/CY

Disposal

The packaging is made entirely of recyclable materials which you can dispose

of at your local recycling facilities.

Do not dispose of the product with household rubbish!

Contact your local refuse disposal authority for

more details of how to dispose of your worn out

electrical devices.

Declaration of Conformity /

Manufacturer

We, Kompernaß GmbH, Burgstr. 21, D-44867

Bochum, Germany, hereby declare that this product

complies with the following EU directives:

Machinery Directive

(2006 / 42 / EC)

Applicable harmonised standards:

EN 792-13 / A1:2008

Type / Description of product:

Pneumatic stapler PDT 40 B2

Date of manufacture (DOM): 05–2012

Serial number: IAN 73782

Bochum, 31.05.2012

12 GB/CY

Semi Uguzlu

- Quality Manager -

We reserve the right to make technical modifications

in the course of product development.

Cuprins

Introducere

Utilizare conform destinaţiei ........................................................................................................... Pagina 14

Dotare .............................................................................................................................................. Pagina 14

Pachet de livrare ............................................................................................................................. Pagina 14

Date tehnice .................................................................................................................................... Pagina 14

Siguranţa aparatului ......................................................................................................... Pagina 15

Siguranţa muncii .............................................................................................................................. Pagina 16

Indicaţii de siguranţă complementare pentru capsatorul pneumatic ........................................... Pagina 16

Accesorii originale / - aparate auxiliare ........................................................................................ Pagina 17

Punere în funcţiune

Racordarea sursei de aer comprimat ............................................................................................ Pagina 17

Alimentarea magaziei .................................................................................................................... Pagina 17

Utilizare

Scoaterea capselor blocate ........................................................................................................... Pagina 18

Curăţare şi întreţinere

Întreţinere ......................................................................................................................................... Pagina 19

Curăţare ........................................................................................................................................... Pagina 19

Service ........................................................................................................................................... Pagina 19

Garanţie ....................................................................................................................................... Pagina 19

Eliminarea ca deşeu ........................................................................................................... Pagina 20

Declaraţia de conformitate / Producător .......................................................... Pagina 20

13 RO

În acest manual de utilizare sunt folosite / următoarele pictograme pe aparat:

Citiţi manualul de utilizare! Nu folosiţi aparatul pe schele sau scări.

Respectaţi indicaţiile de avertizare

şi siguranţă!

Purtaţi căşti antizgomot şi ochelari

de protecţie.

Nu lăsaţi aparatul electric la

îndemâna copiilor!

Capsator cu aer comprimat

PDT 40 B2

Introducere

Vă felicităm pentru achiziţionarea noului

dumneavoastră aparat. Aţi ales un produs

de înaltă calitate. Manualul de utilizare

reprezintă o parte integrantă a acestui produs. Acesta

conţine informaţii importante referitoare la siguranţă,

la utilizare şi la eliminarea ca deşeu. Înainte de utilizarea acestui produs, familiarizaţi-vă mai întâi cu

instrucţiunile de utilizare şi de siguranţă. Folosiţi

produsul numai în modul descris şi numai în domeniile de utilizare indicate. Predaţi toate documentele

aferente în cazul în care înstrăinaţi produsul.

Nu folosiţi niciodată hidrogen, oxigen,

dioxid de carbon sau alte gaze în butelii ca sursă de energie.

Mecanism anti-declanşare

Înlăturaţi ambalajul şi aparatul în

mod ecologic!

Dotare

1

Capac pentru aerul evacuat (rotativ)

2

Trăgaci

3

Mâner

4

Niplu cu filet 6,35 mm (¼“)

5

Magazie

6

Indicator pentru nivelul de alimentare

7

Şurub cu cap striat

8

Mecanism anti-declanşare

9

Ieşire

10

Placă frontală

11

Manetă de armare rapidă placă frontală

12

Manetă magazie

Pachet de livrare

Utilizare conform destinaţiei

Acest aparat poate fi folosit pentru lucrări de montaj şi de reparaţii. Orice altă utilizare sau modificare

a aparatului este considerată neconformă cu destinaţia şi reprezintă pericole de accidente grave. Pentru daunele cauzate de o utilizare neconformă cu

destinaţia nu preluăm responsabilitatea. Aparatul

este prevăzut numai pentru uzul privat.

14 RO

1 capsator cu aer comprimat PDT 40 B2

1 cutie de transport

1 ulei special pentru echipamente pneumatice

1 niplu cu filet 6,35 mm (¼“) (montat în prealabil)

1 cutie de cuie, 1000 buc.

1 cutie de capse, 1000 buc.

1 pereche ochelari de protecţie

1 manual de utilizare

Date tehnice

Dimensiuni: 248 x 58 x 246 mm

(l x H x A)

Introducere / Siguranţa aparatuluiIntroducere

Greutate

(fără piesele de introdus): 1,513 kg

Tip de declanşare: aer comprimat

Presiune maximă admisă: 8 bari

Domeniu de presiune

recomandat: 4 până la 7,5 bari

Consum de aer pentru

fiecare procedură de

introducere: aprox. 0,13 l per

procedură de introducere

Lubrifiant recomandat: ulei special pentru echi-

pamente pneumatice

Capacitate de alimentare: 100 buc.

Lungimi cuie: 15 mm, 20 mm,

25 mm, 30 mm,

32 mm, 35 mm,

38 mm, 40 mm,

45 mm, 50 mm

Lungime capse: 10–40 mm

Lăţime capse: 5,7 mm

Diametru recomandat

al furtunului: ∅ 9 mm

Calitatea aerului

comprimat: curăţat, cu ceaţă de ulei

şi fără condens

Informaţii privind emisiile de zgomot şi

vibraţii:

Valori de măsurare determinate conform

EN 12549:1999, EN ISO 4871. Nivelul de zgomot

evaluat cu A al aparatului măsoară în mod tipic

90,6 dB (A). Nesiguranţă K = 3 dB. În timpul lucrului, nivelul de zgomot poate depăşi 103,6 dB (A).

Aceste valori sunt caracteristici referitoare la aparat

şi nu redau nivelul zgomotului produs la locul de

utilizare. Nivelul de zgomot produs la locul de utilizare depinde de exemplu de mediul de lucru, de

obiectul de prelucrat, de suprafaţa pe care se află

obiectul de prelucrat, de numărul de proceduri de

introducere.

În funcţie de condiţiile de la locul de muncă şi realizarea obiectului de prelucrat trebuie luate, după caz,

măsuri individuale pentru reducerea zgomotului, cum

ar fi suporturi de amortizare a zgomotului, împiedicarea vibrării obiectului de prelucrat şi fixare sau

acoperire, reglarea celei mai mici presiuni

necesare pentru procedura de lucru respectivă. În

cazuri speciale este necesară purtarea căştilor antizgomot.

Purtaţi căşti de protecţie!

Valorile totale ale vibraţiilor conform

ISO 8662-11:1999:

Valoarea de emisie vibraţii a

Nesiguranţă K = 1,5 m / s

2

= 12,380 m / s

h,D

2

Şocuri mecanice (vibraţii)

Pentru aparat s-a determinat o caracteristică de

vi

braţii conform ISO 8662-11:1999 — echipam

ente

acţionate cu motor, ţinute în mână — măsurarea oscilaţiilor mecanice la mâner — aparate de introducere

(consultaţi datele tehnice). Valoarea este o caracteristică referitoare la aparat şi nu redă efectul asupra

sistemului mână-braţ în timpul utilizării aparatului.

Efectul asupra sistemului mână-braţ în timpul utilizării

aparatului depinde de exemplu de forţa de prindere,

forţa de presare, direcţia de lucru, presiunea reglată

a aerului, obiectul de prelucrat, suportul obiectului

de prelucrat.

Siguranţa aparatului

Citiţi toate indicaţiile

de siguranţă şi instrucţiunile. Nerespectarea

indicaţiilor de siguranţă şi instrucţiunilor poate cauza accidente grave şi / sau daune materiale.

PĂSTRAŢI TOATE INSTRUCŢIUNILE ŞI INDICAŢIILE DE SIGURANŢĂ PENTRU CONSULTAREA

ULTERIOARĂ.

Înainte de a începe lucrările verificaţi

întotdeauna dacă dispozitivele de siguranţă şi de declanşare funcţionează

corect şi dacă toate şuruburile şi piuliţele sunt strânse.

Nu realizaţi modificări ale aparatului

care nu corespund prescripţiilor.

15 RO

Loading...

Loading...