Parkside PDEXS 150 A1 User Manual [sv]

Air SAnder PdeXS 150 A1

Air sAnder

Operation and Safety Notes

Translation of original operation manual

TrycklufTsexcenTerslip

Bruksanvisning och säkerhetsanvisningar

Översättning av bruksanvisning i original

drucklufT-exzenTerschleifer

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

pAineilmAkä yTTöinen

epäkeskohiomAkone

Käyttö- ja turvaohjeet

Alkuperäisen käyttöohjeen käännös

TryklufT-ekscenTersliber

Brugs- og sikkerhedsanvisninger

Oversættelse af den originale driftsvejledning

3

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Käännä ennen lukemista kuvallinen sivu esiin ja tutustu seuraavaksi laitteen kaikkiin toimintoihin.

Vik ut bildsidan och ha den till hands när du läser igenom anvisningarna och gör dig bekant med

apparatens / maskinens funktioner.

Før du læser, vend siden med billeder frem og bliv bekendt med alle apparatets funktioner.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE Operation and Safety Notes Page 5

FI Käyttö- ja turvaohjeet Sivu 13

SE Bruksanvisning och säkerhetsanvisningar Sidan 21

DK Brugs- og sikkerhedsanvisninger Side 29

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 37

21

8

7

364

5

C

9

3

11

10

BA

2

9

10

D

Table of contents

Introduction

Proper use ..........................................................................................................................Page 6

Features and equipment ...................................................................................................Page 6

Included items ...................................................................................................................Page 6

Technical data ...................................................................................................................Page 6

Safety advice .............................................................................................................Page 7

Original accessories / tools ..............................................................................................Page 8

Before use

Selecting the Grinding Disc ..............................................................................................Page 9

Changing sanding sheets .................................................................................................Page 9

Dust / Swarf Removal by Suction ..................................................................................................Page 9

Topping up the oil .............................................................................................................Page 9

Preparing for use

Connecting the compressed air source ...........................................................................Page 9

Switching on and off .........................................................................................................Page 9

Advice on use

Sanding surfaces ...............................................................................................................Page 10

Replacing the backing plate .............................................................................................Page 10

Cleaning .........................................................................................................................Page 10

Service centre ...........................................................................................................Page 10

Warranty .......................................................................................................................Page 10

Disposal ..........................................................................................................................Page 11

Declaration of Conformity / Manufacturer........................................Page 11

5 GB/IE

Introduction

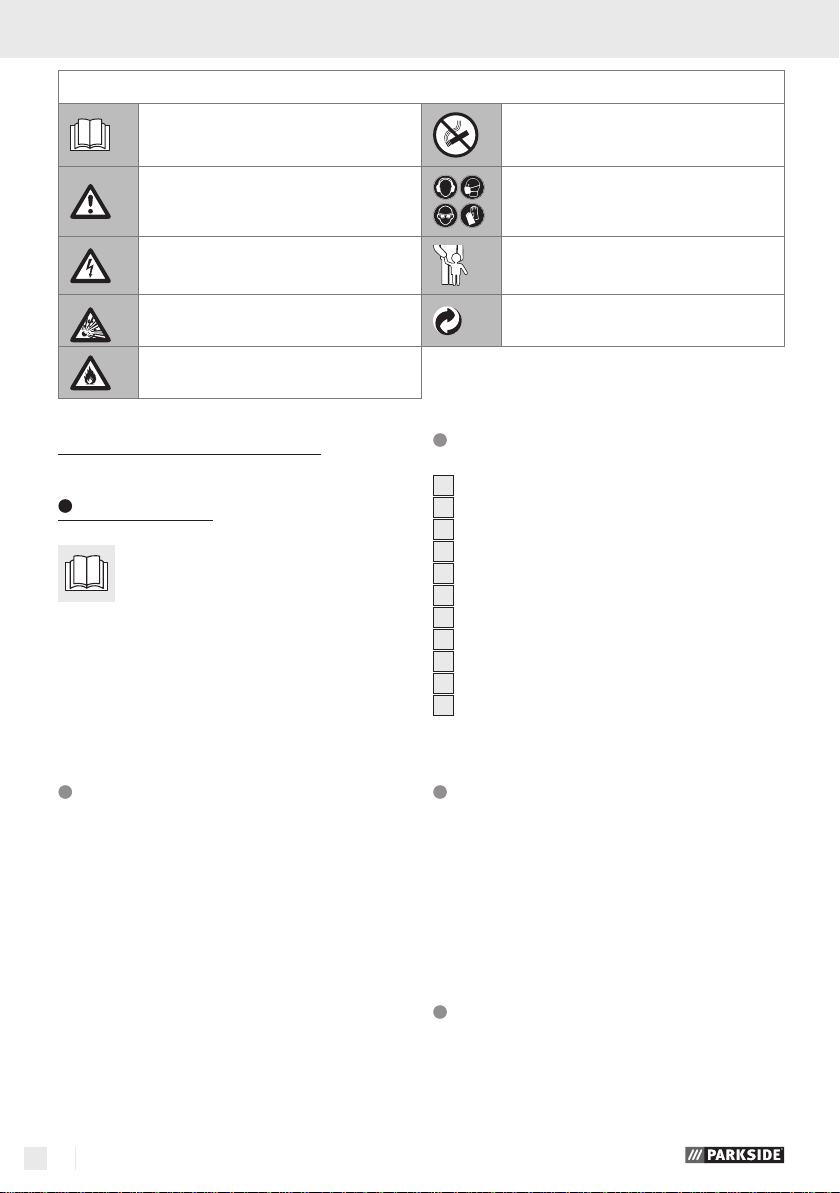

The following pictograms are used in these operating instructions / on the device:

Read instruction manual! No smoking!

Wear hearing protection, dust protection

Observe caution and safety notes!

mask, protective glasses and protective

gloves.

Caution – electric shock!

Danger to life!

Risk of explosion!

Risk of fire!

Air Sander PDEXS 150 A1

Introduction

Please make sure you familiarise yourself fully with the way the air sander

works before you use it for the first time

and that you understand how to handle air sanders

correctly. To help you do this, please read the

accompanying operating instructions. Keep these

instructions in a safe place. If you pass the air sander

on to anyone else, please ensure that you also pass

on all the documentation.

Proper use

Keep children away from the device!

Dispose packaging and appliance in

an environmentally-friendly way!

Features and equipment

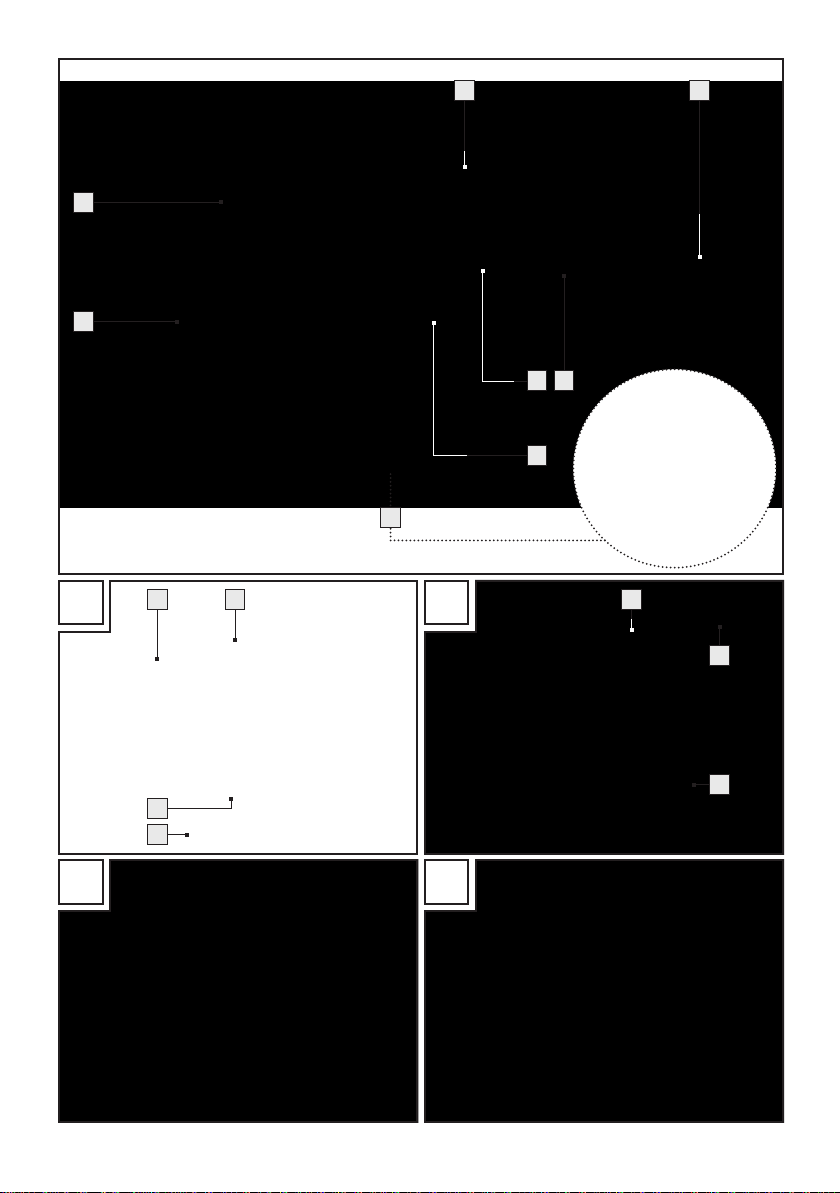

1

Trigger / operator’s lever

2

Connection for dust extraction

3

Plug nipple ¼"

4

Compressed air connection (for plug nipple ¼")

5

Speed control

6

Backing plate with hook and loop fastener,

7

Collar

8

Housing

9

Exhaust air hose

10

Dust bag

11

Open-ended spanner (22 mm) for replacing

the backing plate

Included items

The air sander is suitable for sanding, polishing

and preparation of various surfaces. Any other use

or modification to the device shall be considered as

improper use and could give rise to considerable

risk of accident. We will not accept liability for loss

or damage arising from improper use. The device is

intended for private domestic use only.

6 GB/IE

1 Air Sander PDEXS 150 A1

1 Exhaust air hose

1 Plug nipple ¼"

1 Dust bag

1 Open-ended spanner (22 mm)

1 Operating instructions

Technical data

Max. working pressure: 6.3 bar

Air requirement: approx. 330 l / min

Sanding disc ø: 150 mm

Introduction / Safety advice

Speed: 10500 min

-1

Sanding stroke: 5 mm

Sound pressure level: 89 dB(A)

Sound power level: 100 dB(A)

Uncertainty K: 2.5 dB

Wear ear protection!

Vibration emission value = 6.8 m / s

Uncertainty K = 1.5 m / s

2

2

Values determined in accordance with EN 28662-1;

EN ISO 8662-8

Safety advice

Read all the safety advice

and instructions. Even minor failures to observe

the safety advice and instructions could lead to severe injury.

Keep all the safety advice and instructions

in a safe place for future reference.

Check the device for damage before

bringing it into use. Do not use the device

if you discover any defects.

can cause you to lose control of the device.

Ensure that the power tool

electric power as it is not insulated.

The power tool is not generally insulated for

coming into contact with electric cables;

Wear protective gloves. Failure

Keep your hands, hair and clothing

away from the moving end of the

power tool. Failure to observe this advice

risks drawing in and trapping and could result

in injury.

Keep children and other people

away while you are operatin

t

he sandblasting gun. Distractio

ns

does not come into contact in

any way with sources of

to observe this advice could result

in cutting injury!

g

For your own safety, wear

suitable personal protective

equipment.

Wear an approved dust

mask / protective hood!

Wear protective glasses!

RISK OF EXPLOSION! Do not

use the air sander

containing gases,

or gas-operated water heat

in environments

open flames, fires

ers.

NO SMOKING!

Work in adequately ventilated spaces

only.

Never use oxygen or other combusti

gas as the energy source.

Never exceed the maximum working air

pressure of 6.3 bar.

Ensure that the compressed air supply

hose cannot wave around in an uncontrolled manner. Failure to observe this

advice could result in injury.

Do not use grinding wheels or cutting

discs.

Check that the maximum operating

speed of the machine tool attachment

(backing plate, sanding belt, fibre

grinding disc etc.) is higher than the

specified speed of the power tool.

Self-adhesive sanding sheets must

be attached concentrically on to the

backing plate.

Release the trigger / operator‘s lever

if there is an interruption in the mains

power supply.

Use only the lubricant (pneumatic oil)

recommended by the manufacturer.

Never touch the rotating parts while

the device is operating. Failure to observe

this advice could result in injury.

RECOIL FORCES! High

working pressures can give rise to recoil forces

that under certain conditions can result in

danger from continuous loading.

ble

7 GB/IE

Safety advice

DANGER OF INJURY! Disconnect the device

from the com

pressed air source before carrying

out any repairs or maintenance of the device

or moving it to another location.

Take precautions to ensure that other

people are not contaminated (dust

generation).

Do not remove rating plates or labels - they

are safety-relevant parts of the device.

If you are inexperienced in the use of this type

of device, you should seek out information or

training to learn how to handle it safely.

Always use a quick-release coupler to

connect this device to a compressor.

When emptying the dust bag, take

care not to send any sanding dust into

the air. Do not inhale the sanding dust.

Always disconnect this device from the

compressed air supply before you:

- Replace a sanding sheet or backing

plate

- Rectify malfunctions or

- If the device is defective

Protect the device and in particular

the compressed air connection and

operating controls from dust and dirt.

CAUTION! DANGER OF FIRE!

Ensure that the material being

ground and the grinder itself

do not overheat. Always empty the dust

container before taking a break from work.

Grinding dust in the dust sack, microfilter, paper

sack (or in the filter sack or filter of the vacuum

cleaner) can ignite automatically under unfavour-able conditions such as flying sparks when

metal is being ground. There is a par-ticular

hazard if the grinding dust is mixed with paint

or polyurethane residues or other chemical

substances and the material being ground is hot

after being worked on for a prolonged period.

TOXIC VAPOURS! The work-

ing of materials that can produce harmful / tox-

ic dusts presents a health risk for the operator

and for people located in the close vicinity.

When working for extended periods

on wood and, in particular, materials

that produce dusts that are hazardous

8 GB/IE

to health, connect the appliance to an

appropriate external suction device.

Do not soak materials or surfaces to

be worked with liquids containing

solvents.

Avoid sanding lead-based paints or

other materials that are hazardous to

health.

Material containing asbestos may not

be worked. Asbestos is considered to be a

carcinogen.

Avoid contact with the moving sand-

ing sheet.

Use the appliance only with a sanding

sheet in place.

The appliance must always be kept

clean, dry and free of oil or grease.

Keep your workplace clean. Material

mixtures are particularly dangerous. Light metal

dust can burn or explode.

Secure the workpiece. A workpiece held

in a clamp or vice is kept more securely in place

than one held by your hand.

Never support yourself by placing your

hands near or in front of the device or

the workpiece surface. A slip can result

in injury.

Ensure that flying sparks do not endan-

ger the safety of other people. Remove

combustible materials from your working area.

Flying sparks are often created while you are

abrading metals.

Introduce the appliance to the work

piece with it switched on. On task com-

pletion, lift the appliance from the work piece

and then switch it off.

Permit the switched off appliance to

come to a complete standstill before

putting it down.

Original accessories / tools

Use only the accessories detailed in the

operating instructions. The use of inserted

tools or accessories other than those recommended in the operating instructions could lead

to you suffering an injury.

Before use / Preparing for use

Before use

Selecting the Grinding Disc

Metal Removal and Surface:

The rate of metal removal and the surface quality

are determined by the grain size of the grinding disc.

lease note that corresponding grinding discs

with different grain sizes should be used for

processing different materials.

Changing sanding sheets

The air sander is fitted with a hook and loop fastening,

which allows for quick and easy replacement of

sanding discs.

Lift the grinding disc at the side and pull it off

from the backing pad

6

in order to remove it.

Note: Before securing a new sanding sheet, re-

move all dust and dirt from the sander plate

6

.

Ensure that the openings in the sanding sheet

concur with the boreholes of the sanding plate 6.

Dust / Swarf Removal by Suction

You may ensure this in any of the

following ways:

Connect a service unit with an oiler to the

compressor.

Install a line oiler in the compressed air line or

at the compressed air device.

Put approx. 3–5 drops of pneumatic oil by

hand into the plug nipple

3

every 15 minutes

of operation.

Preparing for use

Connecting the compressed

air source

Note: The air sander must be operated using

cleaned and condensate-free compressed air only

and its maximum allowable working

6.3 bar at the device must not be exceed

Note: The compressed air source must be fitted

a (filter) pressure reducer so that the air pressure can

be regulated.

Connect the plug nipple 3 by a quick-release

coupler to the compressed air supply.

pressure of

ed.

with

Please note the “Safety instructions” section.

Using the internal vacuum extraction

with dust collection device (see Fig. B):

Push the exhaust air hose 9 fully on to the

connection for dust extraction

ing of the dust bag

exhaust air hose

10

9

and fasten the dust bag 10

2

. Put the open-

over the free end of the

firmly in position.

Note: Empty the dust bag

10

in good time and

regularly to ensure optimum dust extraction. To

do this open the zip fastener on the underside

of the dust bag

10

.

Topping up the oil

In order for the air sander to have a long service life,

there must always be enough pneumatic oil in the

device.

Switching on and off

Note: Always switch on the air sander before

bringing it into contact with the workpiece material.

Switching on the air sander:

Press the operator’s lever 1 fully down

(see Fig. C).

Set the speed using the speed control 5.

Switching off the air sander:

Release the operator’s lever 1.

After you finish work, disconnect the device

from the compressed air source.

Note: First disconnect the hose from the com-

pressed air source (compressor) and only then

disconnect the compressed air supply hose

from the device. This will ensure that the compressed air supply hose does not wave around

in an uncontrolled manner.

9 GB/IE

Advice on use / Cleaning / Service centre / Warranty

Advice on use

Wait until the device has come to a standstill

before you put it down.

Sanding surfaces

Switch the air sander on and bring the whole

of its sanding area into contact with the surface

to be abraded. Move it using even pressure to

and fro over the workpiece (see Fig. D).

Note: The sanding output and appearance are

largely dependent on the choice of sanding

sheet and the pressure applied. A sanding sheet

must be free of defects to produce a good

sanding output.

Ensure that you use an even pressure. Excessive

pressure does not produce a higher sanding output, it just increases the wear on the sanding

A sanding sheet previously used on metal must

not be used on other materials.

Replacing the backing plate

RISK OF INJURY! Always

disconnect the device from the compressed air

source before you replace the backing plate

Push the open-ended spanner 11 between the

backing plate

6

and collar 7.

Release the backing plate 6 by turning the

plate anticlockwise and holding the open-ended

spanner

11

still against this movement.

Screw on a new backing plate 6 clockwise

until tight while holding the open-ended span-

11

ner

still against this movement.

sheet.

6

Cleaning

RISK OF INJURY! Always

disconnect the device from the compressed air

source before you clean it.

Clean the air sander after you have finished

using it.

Store the air sander in dry enclosed rooms only.

Use a dry cloth to clean the device. Under no

circumstances should you use petrol, solvent or

cleaners which attack plastic.

Keep the ventilation openings clear at all times.

Remove dust clinging to the sander

with a brush.

Service centre

Have your air sander

repaired only by qualified specialist

personnel using original manufacturer

parts. This will ensure that the air sander

remains safe to use.

Warranty

The warranty for this appliance is for 3

years from the date of purchase. The ap-

.

pliance has been manufactured with care

and meticulously examined before delivery. Please retain your receipt as proof

of purchase. In the event of a warranty

claim, please make contact by telephone

with our Service Department. Only in this

way can a post-free despatch for your

goods be assured.

10 GB/IE

The warranty covers only claims for material and

maufacturing defects, but not for transport damage,

for wearing parts or for damage to fragile components, e.g. buttons or batteries. This product is for priva

te use only and is not intended for commercial use.

Warranty / Disposal / Declaration of Conformity / Manufacturer

The warranty is void in the case of abusive and improper handling, use of force and internal tampering not carried out by our authorized service branch.

Your statutory rights are not restricted in any way

by this warranty.

The warranty period will not be extended by repairs

made unter warranty. This applies also to replaced

and repaired parts. Any damage and defects extant

on purchase must be reported immediately after

unpacking the appliance, at the latest, two days after

the purchase date. Repairs made after the expiration

of the warranty period are subject to payment.

GB

Service Great Britain

Tel.: 0871 5000 720

(0,10 GBP / Min.)

e-mail: kompernass@lidl.gb

IAN 64578

IE

Service Ireland

Tel: 1890 930 034

(0,08 EUR / Min. (peak)

0,06 EUR / Min. (off peak))

e-mail: kompernass@lidl.ie

Declaration of Conformity /

Manufacturer

We, Kompernaß GmbH, the person responsible for

documents: Mr Semi Uguzlu, Burgstr. 21, D-44867

Bochum, Germany, hereby declare that this product

complies with the following standards, normative

documents and EU directives:

Machinery Directive

(2006 / 42 / EC)

Applicable harmonized standards

DIN EN 792-8:2009

(EN 792-8:2001+A1:2008)

Type / Device description:

Air Sander PDEXS 150 A1

Date of manufacture (DOM): 06 - 2011

Serial number: IAN 64578

Bochum, 30.06.2011

IAN 64578

Disposal

The packaging is wholly composed of

environmentally-friendly materials that

can be disposed of at a local recycling

centre.

Do not dispose of the device with your

household rubbish!

Contact your local refuse disposal authority for

more details of how to dispose of your worn out

electrical devices.

Semi Uguzlu

- Quality Manager -

We reserve the right to make technical modifications

in the course of product development.

11 GB/IE

12

Sisällysluettelo

Johdanto

Määräystenmukainen käyttö ............................................................................................Sivu 14

Varustus .............................................................................................................................Sivu 14

Toimitukseen kuuluu ..........................................................................................................Sivu 14

Tekniset tiedot ....................................................................................................................Sivu 14

Turvallisuusohjeet ..................................................................................................Sivu 15

Alkuperäiset tarvikkeet / lisälaitteet ..................................................................................Sivu 16

Ennen laitteen käyttöönottoa

Hiomalaikan valitseminen .................................................................................................Sivu 16

Hiomalevyn vaihtaminen ..................................................................................................Sivu 17

Pölyn- / las tujen imu ..........................................................................................................Sivu 17

Öljyn lisääminen ...............................................................................................................Sivu 17

Käyttöönotto

Paineilmalähteen liittäminen .............................................................................................Sivu 17

Päälle- ja poiskytkentä ......................................................................................................Sivu 17

Työohjeet.......................................................................................................................Sivu 17

Pintojen hionta ...................................................................................................................Sivu 18

Hiomalautasen vaihto .......................................................................................................Sivu 18

Puhdistus .......................................................................................................................Sivu 18

Huolto...............................................................................................................................Sivu 18

Takuu ................................................................................................................................Sivu 18

Hävittäminen .............................................................................................................Sivu 19

Vaatimustenmukaisuusvakuutus /

Valmistaja .....................................Sivu 19

13 FI

Johdanto

Tässä käyttöohjeessa / laitteessa käytetään seuraavia kuvakkeita:

Lue käyttöohje! Tupakointi kielletty!

Pidä ja kuulonsuojainta, hengitys- /

Huomioi varoitus- ja turvaohjeet!

Varo sähköiskua! Hengenvaara! Pidä lapset loitolla laitteesta!

pölysuojanaamaria, suojalaseja ja

suojakäsineitä.

Räjähdysvaara!

Tulipalovaara!

Paineilmakäyttöinen epäkeskohiomakone PDEXS 150 A1

Johdanto

Tutustu ennen ensimmäistä käyttöönottoa

paineilma-epäkeskohiomakoneen toimin-

toihin ja ota selvää paineilma-epäkeskohiomakoneen oikeasta käsittelystä. Lue tätä varten

seuraava käyttöohje tarkkaavaisesti läpi. Säilytä tämä

käyttöohje huolellisesti. Anna kaikki dokumentit mukaan seuraavalle käyttäjälle, jos luovutat paineilmaepäkeskohiomakoneen edelleen.

Määräystenmukainen käyttö

Paineilma-epäkeskohiomakone soveltuu hiontaan,

kiillottamiseen sekä erilaisten pintojen käsittelyyn.

Kaikki muunlainen käyttö tai muutosten teko laitteeseen on määräystenvastaista ja voi aiheuttaa huomattavia tapaturmavaaroja. Emme ota mitään vastuuta

määräystenvastaisesta käytöstä aiheutuneista vahingoista. Laite on tarkoitettu ainoastaan yksityiskäyttöön.

Varustus

1

Laukaisin / käyttövipu

2

Pölynimurin liitäntä

3

Liitinnippa ¼"

14 FI

Hävitä pakkaus ja laite

ympäristöystävällisesti!

4

Paineilmaliitäntä (liitinnippa ¼")

5

Nopeudensäädin

6

Hiomalautanen tarrakiinnityksellä

7

Mansetti

8

Kotelo

9

Poistoilmaletku

10

Pölypussi

11

Kiintoavain SW 22 hiomalautasen vaihtoon

Toimitukseen kuuluu

1 paineilmakäyttöinen epäkeskohiomakone

PDEXS 150 A1

1 poistoilmaletku

1 liitinnippa ¼"

1 pölypussi

1 kiintoavain (22 mm)

1 käyttöohje

Tekniset tiedot

Max. työpaine: 6,3 bar

Ilmantarve: n. 330 l / min

Hiomalautanen-ø: 150 mm

Kierrosluku: 10500 r / min

Työisku: 5 mm

Äänenpainetaso: 89 dB(A)

Äänitehotaso: 100 dB(A)

Epävarmuus K: 2,5 dB

Loading...

Loading...