Parkside PDBS 1800 A1 Original Instructions Manual

AIR DRILL PDBS 1800 A1

AIR DRILL

Translation of the original instructions

IAN 315460

DRUCKLUFT-BOHRSCHRAUBER

Originalbetriebsanleitung

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of

the device.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE / NI Translation of t he original instructions Page 1

DE / AT / CH Originalbetriebsanleitung Seite 17

Contents

Introduction ......................................................2

Intended use ................................................................ 2

Features ................................................................... 2

Package contents ............................................................ 2

Technical specifications ....................................................... 3

General safety instructions for compressed-air tools ....................3

Hazards caused by flying parts ................................................. 6

Hazards caused by entanglement ............................................... 7

Hazards during operation ..................................................... 7

Hazards caused by repetitive movements ......................................... 8

Hazards caused by accessories ................................................. 8

Hazards in the workplace ..................................................... 8

Hazards caused by dust and vapours ............................................ 8

Hazards caused by noise ...................................................... 9

Hazards caused by vibrations .................................................. 9

Additional safety instructions for pneumatic machines ............................... 10

Additional safety notices ..................................................... 10

Before use ......................................................11

Lubrication ................................................................11

Refilling oil ................................................................ 11

Connecting to a compressed-air source ..........................................11

Use ............................................................12

Inserting a bit or drill ........................................................12

Switching on and off ........................................................12

Maintenance and cleaning .........................................12

Troubleshooting .................................................13

Disposal ........................................................13

Kompernass Handels GmbH warranty ..............................14

Service ................................................................... 15

Importer .................................................................. 15

Translation of the original Conformity Declaration .....................16

PDBS 1800 A1

GB│IE│NI

│

1 ■

AIR DRILL PDBS 1800 A1

Introduction

Congratulations on the purchase of your new tool.

You have chosen a high-quality product.

The operating instructions are part of this product.

They contain important information about safety,

usage and disposal. Before using the product, please

familiarise yourself with all operating and safety

instructions. Use the product only as described and

for the range of applications specified. Please also

pass these operating instructions on to any future

owner.

Intended use

The tool is suitable for drilling into plastics, wood,

metal and similar materials.

This tool may only be operated with a compressedair supply. The maximum permissible operating

pressure specified on the tool must not be exceeded.

This tool must not be operated with explosive,

flammable or health-damaging gases.

Do not use as a lever, crusher or striking tool.

Any other usage or modification of the tool is

deemed to be improper and carries a significant

risk of accidents. The manufacturer accepts no responsibility for damage(s) resulting from improper

usage. This tool is intended for domestic use only.

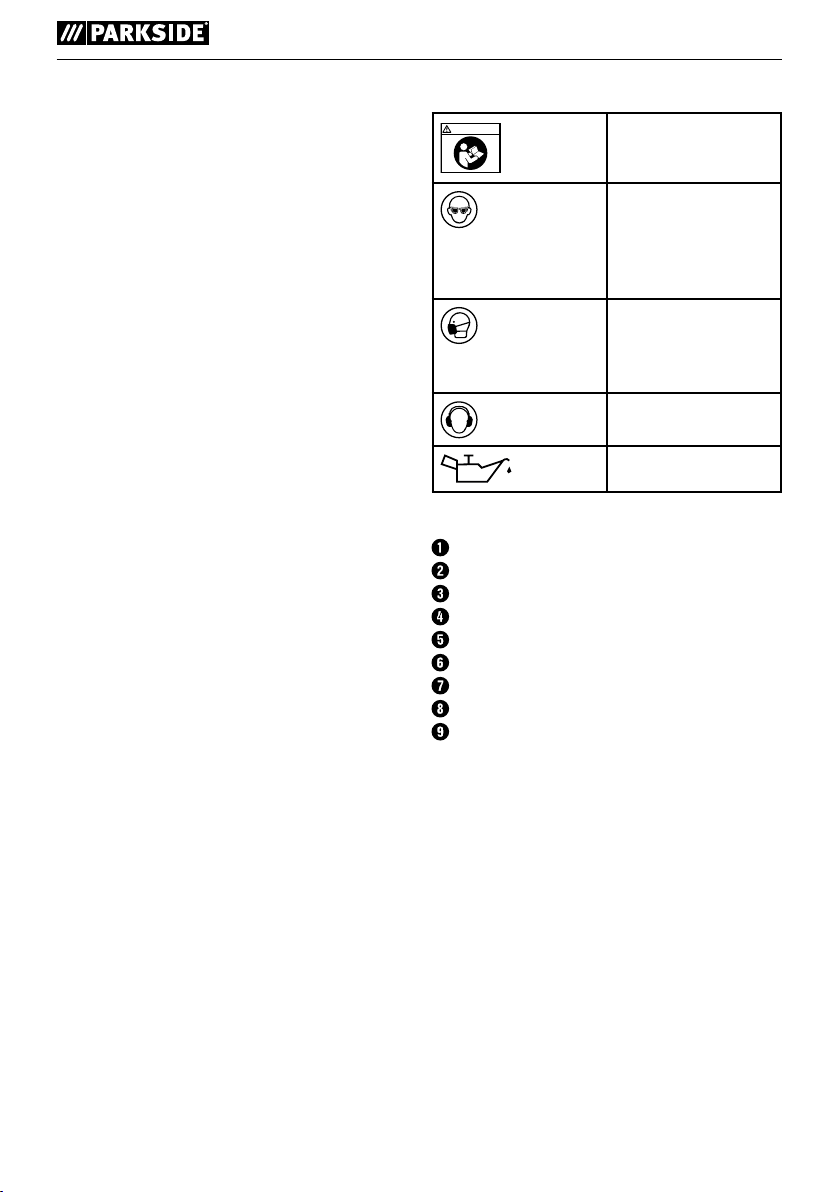

Symbols on the compressed-air tool:

WARNING!

Read the operating

instructions before use.

Always wear eye

protection when

using or servicing

the compressed-air

screwdriver.

Always wear a dust

mask in situations in

which dust is being

generated.

Always wear ear

muffs.

Oil daily

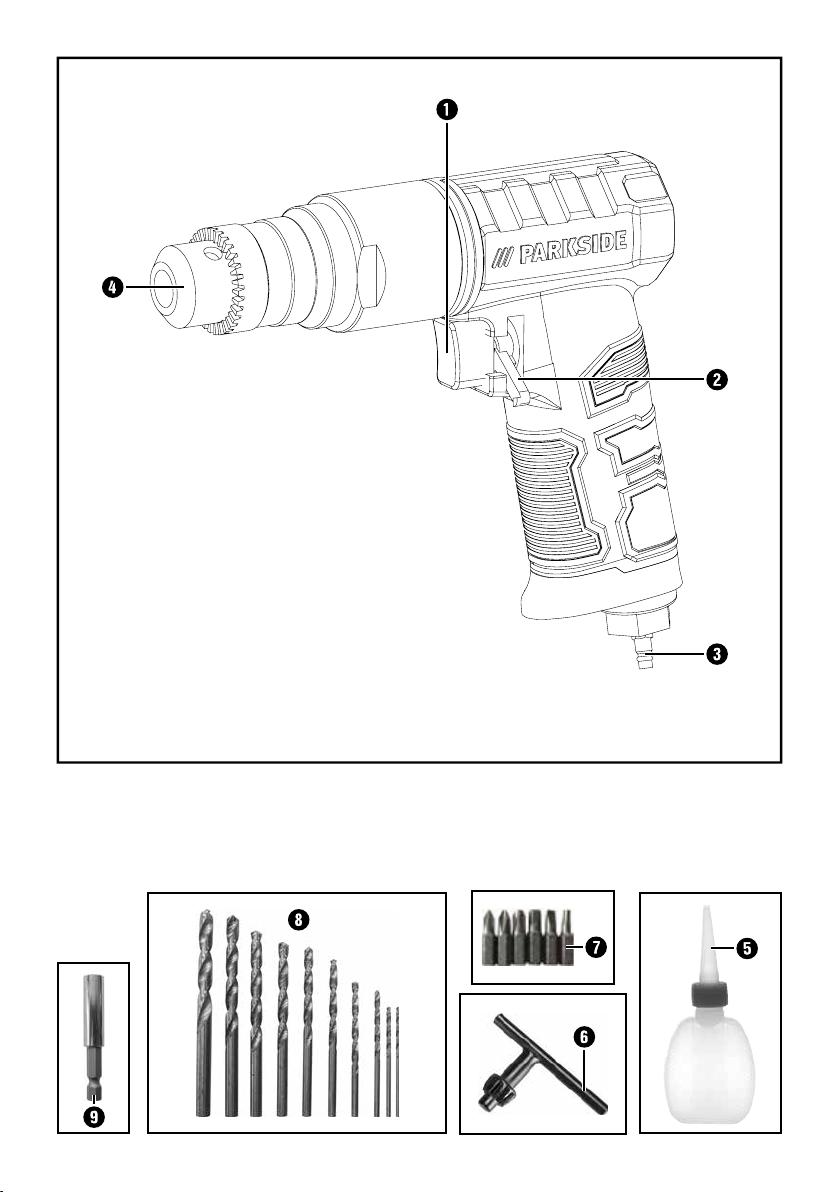

Features

Trigger

Rotation direction switch

Connector nipple

Wheel-rim chuck

Oil bottle

Wrench

Bits

Drill bits

Bit extension

Package contents

1 air drill PDBS 1800 A1

1 wrench

1 oil bottle

1 connector nipple 6.35 mm (1/4") pre-assembled

10 drill bits

6 bits

1 bit extension

1 carrying case

1 set of operating instructions

■ 2 │ GB

│IE│

NI

PDBS 1800 A1

Technical specifications

Rated air pressure: max. 6.8 bar

Air consumption: 720 l/min

Max. rotation speed: max. 1800 rpm

Tool fitting: max. Ø 10 mm

(wheel-rim chuck)

Noise emission values:

Noise measurement determined in accordance

with ISO15744:

Sound pressure level: L

Uncertainty: K

Sound power level: L

Uncertainty: K

Wear hearing protection!

Vibration emission value:

Vibration values determined in accordance with

ISO 28927-5 and EN 12096:

a

= 0.98 m/s

h

2

Uncertainty K = 0.59 m/s

WARNING!

► The noise emission levels specified in these

instructions have been measured in accordance with the standardised measuring

procedure specified in ISO 15744 and can

be used to make equipment comparisons.

The noise emission values vary in accordance

with the use of the compressed-air tool and

may be higher than the values specified in

these instructions in some cases. It is easy to

underestimate the noise emission load if the

compressed-air tool is used regularly in a

certain manner.

NOTE

► For an accurate estimate of the noise emission

load during a certain working period, the

times during which the tool is switched off or

is running but not actually being used must

also be taken into consideration. This can

significantly reduce the noise emission load

over the total working period.

= 87.9 dB (A)

pA

= 3 dB

pA

= 98.9 dB (A)

WA

= 3 dB

WA

2

WARNING!

General safety instructions for compressed-air

tools

WARNING!

► Read all safety warnings and all instructions.

Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious

injury.

NOTE

► The terms “compressed-air tool" or "tool" used

in the following text refer to the compressed-air

tools specified in these operating instructions.

Save all warnings and instructions for future

reference.

■ The user must evaluate the specific risks that

may arise due to different kinds of use.

■ Please ensure that you have read and under-

stood the safety instructions before fitting,

operating, repairing, servicing or replacing

any accessories and before working near the

compressed-air tool. Failure to do this can result

in serious bodily injury.

■ The compressed-air tool should only be set up,

adjusted or used by adequately qualified and

trained operators.

■ The compressed-air tool may not be modified.

Modifications can reduce the effectiveness of

the safety measures and increase the risks for

the operator.

■ Never use damaged compressed-air tools.

Maintain compressed-air tools with care. Check

regularly whether moving parts function correctly

and do not jam; check whether any parts are

broken or damaged to an extent that the compressed-air tool will no longer operate correctly.

Check signs and labels for completeness and

readability. If damaged, have parts repaired

or replaced before using the compressed-air

tool. Many accidents are caused by poorly

maintained compressed-air tools.

PDBS 1800 A1

GB│IE│NI

│

3 ■

■ This tool is not intended for use by persons

(including children) with limited physical,

physiological or intellectual abilities or lack

of experience and/or knowledge, unless they

are supervised by a person who is responsible

for their safety, or receive instructions from this

person on how to use the tool.

■ Do not allow children to play with the tool.

WARNING – RISK OF INJURY!

► Disconnect the compressed-air supply before

carrying out maintenance work.

■ RISK OF EXPLOSION! Never use gasoline or

other flammable liquids to clean the compressedair tool! Sparks can ignite vapours remaining

in the compressed-air tool and lead to an

explosion of the compressed air tool. Do not

operate the compressed-air tool in explosive

atmospheres or environments with flammable

liquids, gases or dust. Do not work with any

materials that are or could become inflammable

or explosive.

■ Use the tool only in the fields of application for

which it was designed!

■ Do not force the tool.

■ Never use hydrogen, oxygen, carbon dioxide

or other gas in bottles as sources of energy for

this tool, as this can lead to an explosion and

consequently serious injuries.

■ Maintain and clean the tool on a regular basis

as specified (see Section "Maintenance and

cleaning").

■ Check the tool for any possible defects before

use. Ensure that the tool is in good working

condition before every use.

■ Remain alert at all times! Unexpected move-

ments of the tool can cause dangers.

■ Do not overreach. Keep proper footing and bal-

ance at all times. This provides for better control

over the compressed-air tool in unexpected

situations.

■ Do not use the tool if its switch is defective. Any

tool that cannot be switched on or off is dangerous and must be repaired.

■ Keep compressed-air tools that are not being

used out of the reach of children. Do not allow

persons unfamiliar with the tool or these instructions to operate the tool. Compressed-air tools

are dangerous in the hands of inexperienced

users.

■ Treat the tool with care. Check whether moving

parts function correctly and do not jam; check

whether any parts are broken or damaged to

an extent that the tool will no longer operate

correctly. If damaged, have the tool repaired

before use. Many accidents are caused by

poorly maintained tools.

■ Switch off the tool when not in use.

■ Use personal protective equipment. Always

wear eye protection. Wearing protective equipment such as a dust mask, non-slip safety shoes,

a helmet or hearing protection depending on

the type and use of the compressed-air tool

reduces the risk of personal injuries.

■ Check all connections and supply lines. All

maintenance units, couplings and hoses must

correspond to the tool parameters in terms of

pressure and air flow. If the pressure is too low,

the function of the tool will be compromised

and if the pressure is too high, this can cause

property damage and personal injury.

■ 4 │ GB

│IE│

NI

PDBS 1800 A1

■ Protect the hoses against kinking, constriction,

solvents and sharp edges. Keep hoses away

from heat, oil and rotating parts.

■ Ensure that the hose clamps are always tight-

ened firmly. Loose or damaged hose clamps

can allow air to escape in an uncontrolled

manner.

■ Replace a damaged hose immediately. A de-

fective supply line can cause a compressed-air

hose to thrash about and cause personal injury.

■ If the power cable of this tool is damaged, it

must be replaced by the manufacturer or its customer service or by a similarly qualified person

in order to avoid hazards.

■ Do not use the tool if you are tired or under the

influence of drugs, alcohol or medication.

A moment of inattention when operating the

tool can result in serious personal injury.

■ Do not breathe in the exhaust air directly. Avoid

getting exhaust air in your eyes. The exhaust air

from the compressed-air tool can contain water,

oil, metal particles or dirt from the compressor.

This can cause damage to health.

WARNING!

► BE CAREFUL WHEN PUTTING DOWN THE

TOOL! Always put the tool down in such a

way that it does not lie on the trigger. Under

certain circumstances, this might cause an

accidental activation of the tool, which in turn

might lead to hazards.

■ Only suitable accessories may be used.

You can purchase these from the manufacturer.

Accessories other than original equipment can

cause hazards.

■ Use only filtered and regulated compressed

air. Dust, caustic fumes and/or moisture can

damage the motor of a compressed-air tool.

■ The hose must be designed for a pressure of at

least 6.8 bar or 125 psi, corresponding to at

least 150% of the maximum pressure generated

in the system.

■ The tool and the supply hose must be fitted

with a hose coupling that allows the pressure of

the coupling hose to be dispersed completely

during disconnection.

■ DANGER! Avoid contact with an energised line!

This tool is not insulated against electric shock.

WARNING – RISK OF INJURY!

► Under certain circumstances, high working

pressures can cause kickback to occur. This

can cause hazards due to the continuous

loading.

■ If you are inexperienced with the tool, seek

training in how to use it safely.

WARNING – RISK OF INJURY!

► RISK OF PUNCTURE WOUNDS! Do not

treat an injection wound as a simple cut.

A high-pressure jet can inject toxins into the

body and cause serious injuries. In the event

of an injection into the skin, seek medical

assistance immediately.

■ The compressed-air tool must not be modified in

any way without the manufacturer's approval.

■ Use the compressed-air tool only with the speci-

fied pressure (6.8 bar).

■ The compressed-air tool must always be discon-

nected from the air supply after use and for as

long as it is not in use.

■ The compressed-air tool must not be used if it is

not airtight or if it requires repair.

■ Never connect the compressed-air tool with a

compressed-air hose that exceeds a pressure

of 6.8 bar.

PDBS 1800 A1

GB│IE│NI

│

5 ■

■ Keep work area clean and well lit. Cluttered or

dark areas invite accidents. This enables better

control of the tool in unexpected situations.

WARNING!

► Have your tool serviced by qualified trained

personnel using only original spare parts.

This ensures that the safety of the tool is

maintained.

■ Keep children and other persons away from the

tool during operation. Distractions can cause

you to lose control.

■ Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

■ Put the trigger and the tool away in the case of

an unexpected stoppage of the compressor.

■ Wherever possible, use a condensate separator

or drain the condensate (water) from the hoses

and tubing regularly before and during the use

of the compressed-air tools.

■ NOTICE! An undersized compressed-air system

will reduce the efficiency of your tool.

■ Please ensure that you have read and under-

stood the safety instructions regarding multiple

hazards before installation, operation, repair,

service and replacement of any accessories

and before work near the automatic screwdriver.

Otherwise, there is a risk of serious physical

injuries.

■ The automatic screwdriver should only be

fitted, adjusted or used by qualified and trained

operators.

■ The automatic screwdriver may not be modified.

Modifications can reduce the effectiveness of

the safety measures and increase the risks for

the operator.

■ Do not lose the safety instructions – hand them

to the operator.

■ Never use a damaged machine on screwed

joints.

■ The machines must be serviced regularly to

check whether the rated values and markings

required in the present part of ISO 11148 are

appended legibly on the machine. The employee/operator must contact the manufacturer to

obtain replacement stickers for labelling if this is

necessary.

Hazards caused by flying parts

■ If a workpiece or one of the accessory parts or

even the machine tool itself breaks, parts can

be thrown off at high speeds.

■ Always wear impact-resistant safety goggles

during operation, when replacing accessory

parts or during repair or maintenance work.

The level of the required protection must be

evaluated separately for each individual task.

■ The wrench must be removed before drilling

begins.

■ Ensure that the workpiece has been securely

fixed in place.

■ Check regularly that the rotation speed of

the compressed-air tool is not higher than the

specified rotation speed appended on the

compressed-air tool. These rotation speed tests

must be conducted without any accessory tools

attached.

■ Ensure that sparks and fragments created

during work do not constitute a hazard.

■ Separate the compressed-air tool from the

compressed-air supply before replacing the

attachment or accessories or before you adjust

the settings, service or clean the tool.

■ Ensure that no dangers are created for other

persons either.

■ 6 │ GB

│IE│

NI

PDBS 1800 A1

Hazards caused by entanglement

■ Hazards caused by entanglement can result

in suffocation, scalping and/or cut wounds if

loose clothing, personal jewellery, necklaces,

hair or gloves are not kept away from the

machine and its accessories.

■ Gloves can get caught in the rotating drive,

which can lead to injuries or fractures of the

fingers.

■ Rubber or metal-reinforced gloves can become

entangled easily in rotating drive fittings and

extensions.

■ Never wear loose-fitting gloves or gloves with

cut-off or worn-out glove fingers.

■ Never hold onto the drive, the fitting or the drive

extension.

■ Keep your hands away from the rotating drive.

■ Dress properly. Do not wear loose clothing

or jewellery. Keep hair, clothing and gloves

away from the compressed-air tool and moving

parts. Loose clothes, jewellery or long hair can

be caught in moving parts. There is a risk of

personal injury.

■ Always wear impact-resistant safety goggles

during operation, repair or maintenance work

and when replacing accessory parts on the

drill or thread cutter. The level of the required

protection must be evaluated separately for

each individual task.

Hazards during operation

■ When using the machine, the operator's hands

may be exposed to risks such as crushing, striking, cutting, abrasion and heat. Wear suitable

gloves to protect your hands.

■ Avoid contact with the rotating shaft and the

accessory tool to prevent cuts on your hands

and other body parts.

■ The operator and maintenance personnel must

be physically capable of handling the size,

weight and power of the machine.

■ Hold the machine correctly: be ready to counter-

act any normal or sudden movements – keep

both hands ready.

■ Ensure that your body is balanced and that you

have stable footing.

■ Keep proper footing and balance at all times.

■ High reaction torques can occur in the event

of a jam/blockage, which can be caused by

excessive loads working on the drill, jamming of

the drill in the work material being processed or

by the drill cutting through the material.

■ Prevent unintentional starting. If the air supply is

interrupted, switch off the compressed-air tool

using the On/Off switch.

■ When aids are needed to absorb the reaction

torque, we recommend using a suspension unit

wherever possible. If this is not possible, side

handles for machines with a straight grip and

machines with pistol grip are recommended.

We recommend always using aids to absorb

the torque if it is higher than 4 Nm on machines

with straight grips, and higher than 10 Nm on

machines with a pistol grip, and higher than

60 Nm on offset screwdrivers.

■ Release the start/stop control in case of a

disruption to the electricity supply.

■ Use only the lubricants recommended by the

manufacturer.

■ Fingers might be crushed in nut wrenches with

an open pan head.

■ Keep your hands away from the rotating collet

chuck and the rotating drill.

■ Do not use the tool in confined spaces and en-

sure that your hands are not crushed between

the machine and the work piece, especially

when removing screws.

■ Safety goggles must be worn. The wearing of

protective gloves and safety clothing is recommended.

■ Use personal protective equipment. Always wear

eye protection. Wearing personal protective

equipment such as protective gloves, non-slip

safety shoes or hearing protection, depending on

the type and use of the tool reduces the risk of

personal injuries and it is recommended.

PDBS 1800 A1

GB│IE│NI

│

7 ■

■ The permissible speed of the accessory tool

used must be at least as high as the maximum

speed specified for the compressed-air tool. Accessories which rotate faster than the maximum

permissible rate can break and throw pieces

into the air.

■ Wear a safety helmet for overhead work.

■ The tool will run on after the compressed-air

tool has been switched off.

■ Ensure that no hazard is caused by sparks cre-

ated during use. Explosive or flammable dusts

can be generated when processing certain

materials. There is a risk of explosion or fire.

Hazards caused by repetitive movements

■ Users of an automatic screwdriver may experi-

ence unpleasant sensations in their hands, arms,

shoulders, neck area or other body parts while

working with the tools.

■ Assume a comfortable position when working

with this machine, pay attention to safe footing

and avoid unfavourable positions or such that

make it difficult to keep your balance. During

work over longer periods, the operator should

change posture to avoid discomfort and fatigue.

■ If the operator notices symptoms such as

persistent discomfort, throbbing, pain, tingling,

burning or stiffness, these warning indications

should not be ignored. The operator should

consult a qualified medical doctor.

Hazards caused by accessories

■ Disconnect the machine from the energy supply

before changing the machine tool or accessory.

■ Do not touch fittings or accessories during

the striking process because this can increase

the risk of cuts, burns or injuries caused by

vibrations.

■ Avoid direct contact with the accessory tool

during and after use because it may be hot or

have sharp edges.

■ Use only accessories and supplies of the sizes

and types recommended by the manufacturer

of machines for screw connections; do not

use any other types or sizes of accessories or

consumable materials.

■ Use only impact fittings that are in good work-

ing order because any defects in the handles

and accessories can cause these to break and

be ejected when used with impact wrenches.

■ The permissible speed of the accessory tool

used must be at least as high as the maximum

speed specified for the compressed-air tool. Accessories which rotate faster than the maximum

permissible rate can break and throw pieces

into the air.

Hazards in the workplace

■ Slipping, tripping up and falling are the main

causes of injuries in the workplace. Pay attention to surfaces that may have become slippery

from the use of the machine and also be aware

of tripping hazards caused by air or hydraulic

hoses.

■ Proceed with caution in unknown surroundings.

Hidden hazards caused by power or other

supply lines may be present.

■ This compressed-air tool is not suitable for use

in explosive atmospheres and is not insulated

against contact with power sources.

■ Ensure that there are no electric mains, gas

pipes, etc. that might result in a hazard if damaged by using the machine.

■ Make sure (e.g. by using a metal detector) that

there are no hidden power, water or gas lines in

the location where you are working.

Hazards caused by dust and vapours

■ The dusts and vapours produced by using the

machines for screw connections can be hazardous to health (e.g. cause cancer, birth defects,

asthma and/or dermatitis); it is essential to

carry out a risk assessment in respect of these

risks and to implement corresponding regulatory mechanisms.

■ The risk assessment should include the dust

caused by using the machine and any existing

dust that may be raised at the same time.

■ 8 │ GB

│IE│

NI

PDBS 1800 A1

Loading...

Loading...