Parkside PDBG 125 A1 Operation And Safety Notes

DOPPELBLATTSÄGE

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

TWIN BLADE CIRCULAR SAW

Operation and Safety Notes

Translation of the original instructions

OWIM GmbH & Co. KG

Stiftsbergstraße 1

DE-74167 Neckarsulm

GERMANY

Model No.: HG03284-BS

Version: 11/2017

TWIN BLADE CIRCULAR SAW PDBG 125 A1

IAN 292293IAN 292293

GB / IE / NI Operation and safety notes Page 5

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 17

B

22

23

A B

2120

24

22

9

C D

811

1 2

4

3

18

20

17

19

21

E

4

23

3

F

24

12

A

2 3

789111314 12 10

4

5

6

1

17

1819

16

15

I

G

5

6

H

J

Table of contents

List of pictograms used ......................................................................................................... Page 6

Introduction ............................................................................................................................... Page 6

Intended use .................................................................................................................................. Page 6

Parts description ............................................................................................................................. Page 7

Scope of delivery ........................................................................................................................... Page 7

Technical data ................................................................................................................................ Page 7

Safety warnings ...................................................................................................................... Page 8

General power tool safety warnings .............................................................................................. Page 8

Counter-rotating double blade saw warnings ................................................................................ Page 9

Vibration and noise reduction ........................................................................................................ Page 11

Behaviour in emergency situations ................................................................................................. Page 11

Residual risks .................................................................................................................................. Page 11

Initial use ..................................................................................................................................... Page 12

Unpacking ..................................................................................................................................... Page 12

Accessories .................................................................................................................................... Page 12

Before use .................................................................................................................................. Page 12

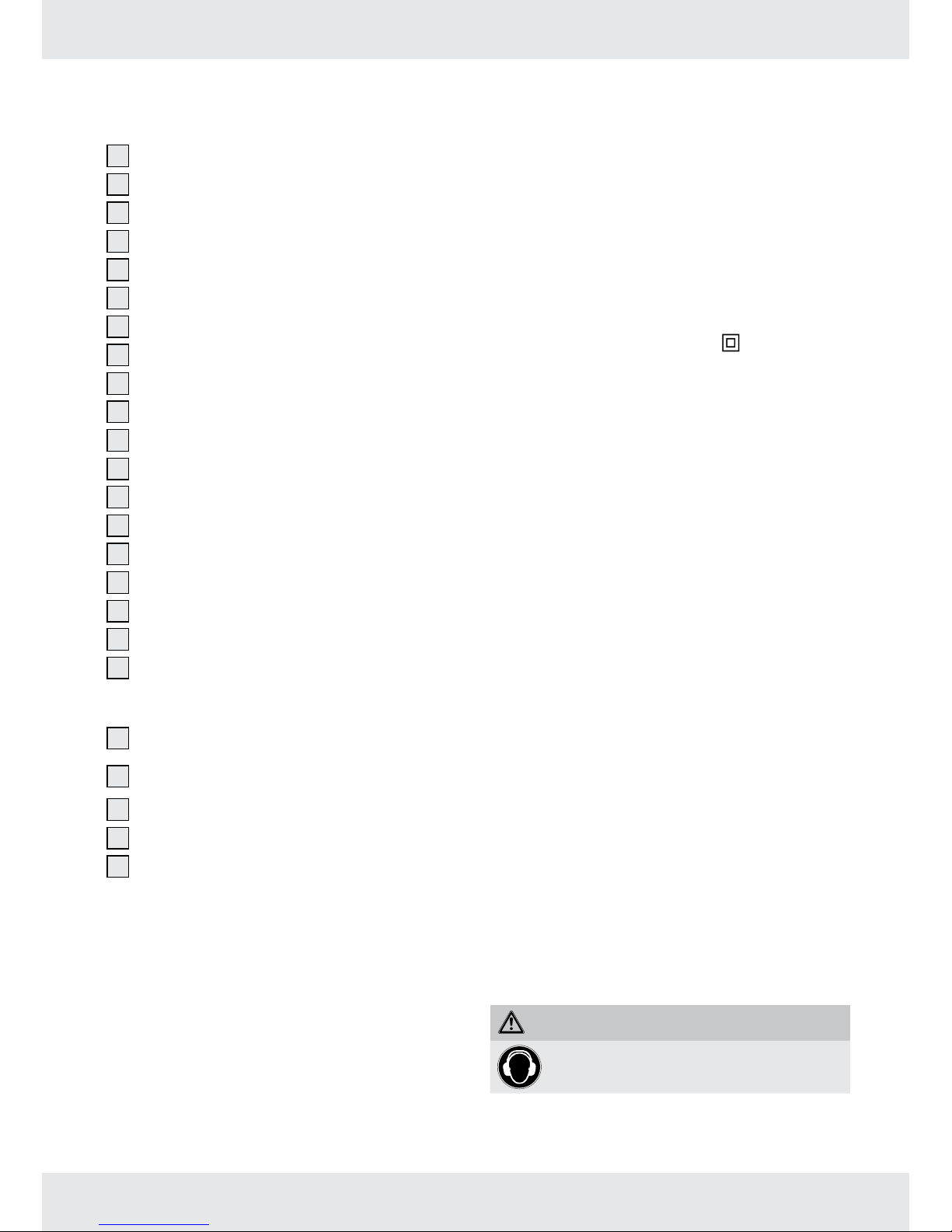

Removing / attaching blades ......................................................................................................... Page 12

Lubrication ..................................................................................................................................... Page 13

Attaching / removing a dust extraction device .............................................................................. Page 13

Operation ................................................................................................................................... Page 13

Cutting guide ................................................................................................................................. Page 13

Switching on and off ...................................................................................................................... Page 13

Cutting ........................................................................................................................................... Page 13

After use ......................................................................................................................................... Page 14

Cleaning and care ................................................................................................................... Page 14

Cleaning ........................................................................................................................................ Page 14

Maintenance .................................................................................................................................. Page 14

Repair ............................................................................................................................................ Page 14

Storage .......................................................................................................................................... Page 14

Transportation ................................................................................................................................ Page 14

Troubleshooting ....................................................................................................................... Page 15

Disposal ....................................................................................................................................... Page 15

Service ......................................................................................................................................... Page 15

Warranty .................................................................................................................................... Page 16

Translation of original

declaration of conformity .................................................................................................... Page 16

5 GB / IE / NI

List of pictograms used:

Read the instruction manual. Wear a dust mask!

Wear protective gloves!

Use in dry indoor rooms only. Wear protective, slip-resistant footwear!

Switch the appliance off disconnect it from

the mains before replacing attachments,

cleaning and when not in use.

Not permitted for wet grinding!

Protection class II (Double insulation) Only permitted for wet cutting!

Alternating current Not permitted for hand-held grinding!

Rotation direction of blade ”A” and ”B”. Not permitted for face grinding!

Suitable for cutting wood.

Do not touch! Blade diameter

Wear hearing protection! Tungsten carbide 32 teeth.

Wear eye protection!

TWIN BLADE CIRCULAR SAW

PDBG 125 A1

Q Introduction

We congratulate you on the purchase of your new

product. You have chosen a high quality product.

The instructions for use are part of the product.

They contain important information concerning

safety, use and disposal. Before using the product,

please familiarise yourself with all of the safety

information and instructions for use. Only use

the product as described and for the specified

applications. If you pass the product on to anyone

else, please ensure that you also pass on all the

documentation with it.

Q Intended use

This twin blade circular saw (hereinafter “product”

or “power tool”) is designed for cross cutting into

firmly supported solid wood (nature timber) and

for cutting chipboard, plywood, aluminum and

copper.

The product is to be used by adults. Children under

the age of 16 may not use the tool except under

supervision.

Any other use or modification of the product are

considered improper use and can result in hazards

such as death, life-threatening injuries and damage.

The manufacturer is not liable for any damages

caused by improper use. The product is not

intended for commercial use or for any other use.

6 GB / IE / NI

Q Parts description

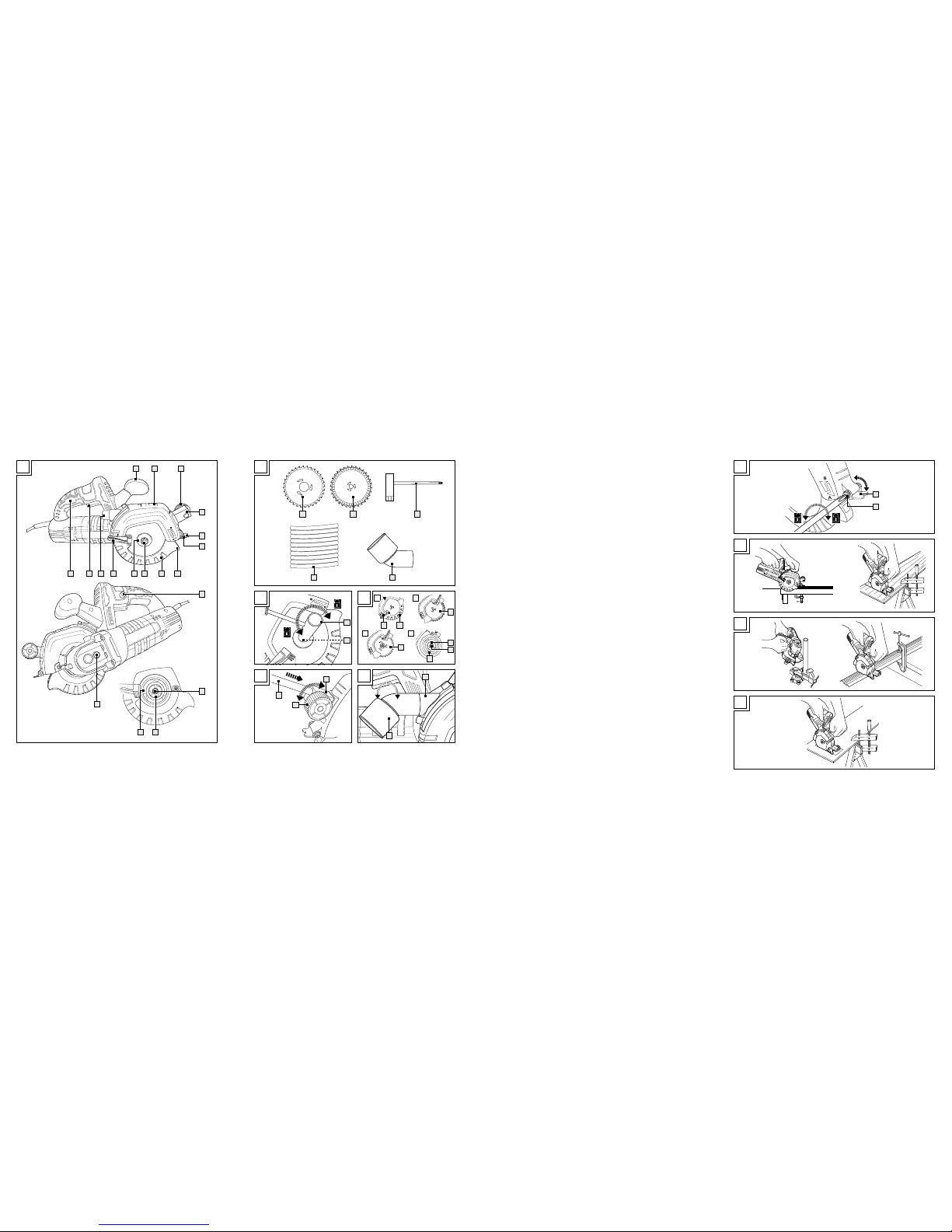

Figure A:

1

Front handle

2

Upper blade guard

3

Wax stick dial

4

Wax stick holder

5

Cutting guide

6

Cutting guide screw

7

Lower blade guard lip

8

Lower blade guard

9

Blade bolt

10

Locking flange

11

Lower blade guard lever

12

Dust extraction outlet

13

On / off switch

14

Rear handle

15

Lock-off button

16

Spindle lock button

17

Spindle

18

Drive flange (outer blade)

19

Drive flange (Inner blade)

Figure B:

20

32-tooth carbide-tipped inner blade

(pre-assembled)

21

32-tooth carbide-tipped outer blade

(pre-assembled)

22

Multi-tool

23

Wax stick (x 10)

24

Dust extraction adaptor

Q Scope of delivery

1 Twin blade circular saw PDBG 125 A1

1 32-tooth carbide-tipped inner blade

(pre-assembled)

1 32-tooth carbide-tipped outer blade

(pre-assembled)

1 Multi-tool

10 Wax sticks

1 Dust extraction adaptor

1 Operating instructions

Q Technical data

Twin blade circular saw:PDBG 125 A1

Rated voltage, frequency: 230 – 240 V~, 50 Hz

Rated power: 1200 W

No load speed n

0

: 5500 min

-1

Blade diameter Ø: 125 mm

Inner blade arbor size Ø: 28 mm

Outer blade arbor size Ø: 12 mm

Max. blade width: 1.6 mm

Max. cutting depth: 31 mm

Weight (incl. accessories): 3.63 kg

Protection class:

II /

Noise emission value

Noise measurement value determined in

accordance with EN 60745. The A-rated noise

level of the power tool is typically as follows:

Cutting wood

Sound pressure level L

pA

: 96.1 dB(A)

Uncertainty K

pA

: 3 dB

Sound power level L

WA

: 107.1 dB(A)

Uncertainty K

WA

: 3 dB

Cutting metal

Sound pressure level L

pA

: 99.4 dB(A)

Uncertainty K

pA

: 3 dB

Sound power level L

WA

: 110.4 dB(A)

Uncertainty K

WA

: 3 dB

Vibration emission value

Total vibration values (vector total of three directions)

determined in accordance with EN 60745:

Cutting wood

Rear handle

Hand / arm vibration a

h,W

: > 2.5 m/s2 (4.547)

Front handle

Hand / arm vibration a

h,W

: > 2.5 m/s2 (4.675)

Uncertainty K: 1.5 m/s

2

Cutting metal

Rear handle

Hand / arm vibration a

h,M

: > 2.5 m/s2 (5.673)

Front handle

Hand / arm vibration a

h,M

: > 2.5 m/s2 (5.924)

Uncertainty K: 1.5 m/s

2

WARNING!

Wear ear protection!

7 GB / IE / NI

WARNING!

u The vibration level varies in accordance with

the use of the power tool and may be higher

than the value specified in these instructions in

some cases. There is a risk of underestimation

of the vibration load if the power tool is

used regularly in this manner. Try to keep the

vibration loads as low as possible. Measures

to reduce the vibration load are, e.g. wearing

gloves and limiting the working time. Wherein

all states of operation must be included (e.g.

times when the power tool is switched off and

times where the power tool is switched on but

running without load).

NOTE

u The vibration level specified in these

instructions has been measured in

accordance with a standardised measuring

procedure specified in EN 60745 and can

be used to make equipment comparisons. The

specified vibration emission value can also be

used to make an initial exposure estimate.

Safety warnings

Q General power tool safety

warnings

WARNING!

u Read all safety warnings and all

instructions. Failure to follow the warnings

and instructions may result in electric shock,

fire and / or serious injury.

Save all warnings and instructions for

future reference.

The term “power tool” in the warnings refers to

your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work area safety

1. Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

2. Do not operate power tools in

explosive atmospheres, such as in

the presence of flammable liquids,

gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose control.

Electrical safety

1. Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs

with earthed (grounded) power

tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

2. Avoid body contact with earthed or

grounded surfaces, such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock if

your body is earthed or grounded.

3. Do not expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric shock.

4. Do not abuse the cord. Never use

the cord for carrying, pulling or

unplugging the power tool. Keep cord

away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords

increase the risk of electric shock.

5. When operating a power tool

outdoors, use an extension cord

suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of

electric shock.

6. If operating a power tool in a

damp location is unavoidable, use

a residual current device (RCD)

protected supply. Use of an RCD reduces

the risk of electric shock.

Personal safety

1. Stay alert, watch what you are

doing and use common sense when

operating a power tool. Do not use

a power tool while you are tired or

under the influence of drugs, alcohol

or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

2. Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

3. Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and / or

battery pack, picking up or carrying

the tool. Carrying power tools with your

finger on the switch or energising power tools

that have the switch on invites accidents.

8 GB / IE / NI

4. Remove any adjusting key or

wrench before turning the power

tool on. A wrench or a key left attached to

a rotating part of the power tool may result in

personal injury.

5. Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the power tool

in unexpected situations.

6. Dress properly. Do not wear loose

clothing or jewellery. Keep your

hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

7. If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used. Use of

dust collection can reduce dust-related hazards.

Power tool use and care

1. Do not force the power tool. Use

the correct power tool for your

application. The correct power tool will do

the job better and safer at the rate for which it

was designed.

2. Do not use the power tool if the

switch does not turn it on and off. Any

power tool that cannot be controlled with the

switch is dangerous and must be repaired.

3. Disconnect the plug from the

power source and / or the battery

pack from the power tool before

making any adjustments, changing

accessories, or storing power tools.

Such preventive safety measures reduce the

risk of starting the power tool accidentally.

4. Store idle power tools out of the

reach of children and do not allow

persons unfamiliar with the power

tool or these instructions to operate

the power tool. Power tools are

dangerous in the hands of untrained users.

5. Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any

other condition that may affect the

power tool’s operation. If damaged,

have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

6. Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

7. Use the power tool, accessories

and tool bits etc. in accordance

with these instructions, taking into

account the working conditions and

the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Service

1. Have your power tool serviced by

a qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

Q Counter-rotating double blade

saw warnings

Safety instructions for all saws – Cutting

procedures

1. DANGER! Keep hands away from

cutting area and the blade. Keep your

second hand on auxiliary handle, or

motor housing. If both hands are holding

the saw, they cannot be cut by the blade.

2. Do not reach underneath the

workpiece. The guard cannot protect you

from the blade below the workpiece.

3. Adjust the cutting depth to the

thickness of the workpiece. Less than a

full tooth of the blade teeth should be visible

below the workpiece.

4. Never hold piece being cut in your

hands or across your leg. Secure the

workpiece to a stable platform. It is

important to support the work properly to

minimise body exposure, blade binding, or

loss of control.

5. Hold the power tool by insulated

gripping surfaces only, when

performing an operation where

the cutting tool may contact hidden

wiring or its own cord. Contact with

a “live” wire will also make exposed metal

parts of the power tool “live” and could give

the operator an electric shock.

6. When ripping, always use a rip fence

or straight edge guide. This improves

the accuracy of cut and reduces the chance

of blade binding.

7. Always use saw blades with correct

size and shape (diamond versus

round) of arbour holes. Blades that do

not match the mounting hardware of the saw

will run eccentrically, causing loss of control.

9 GB / IE / NI

8. Never use damaged or incorrect

blade washers or bolts. The blade

washers and bolt were specially designed

for your saw, for optimum performance and

safety of operation.

Further safety instructions for all saws –

Kickback causes and related warnings

¢ A kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing

an uncontrolled saw to lift up and out of the

workpiece toward the operator;

¢ when the blade is pinched or bound tightly

by the kerf closing down, the blade stalls and

the motor reaction drives the unit rapidly back

toward the operator;

¢ if the blade becomes twisted or misaligned

in the cut, the teeth at the back edge of the

blade can dig into the top surface of the

wood causing the blade to climb out of the

kerf and jump back toward the operator.

Kickback is the result of saw misuse and / or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below.

1. Maintain a firm grip with both hands

on the saw and position your arms

to resist kickback forces. Position

your body to either side of the blade,

but not in line with the blade. Kickback

could cause the saw to jump backwards,

but kickback forces can be controlled by the

operator, if proper precautions are taken.

2. When blade is binding, or when

interrupting a cut for any reason,

release the trigger and hold the

saw motionless in the material

until the blade comes to a complete

stop. Never attempt to remove

the saw from the work or pull the

saw backwards while the blade is

in motion or kickback may occur.

Investigate and take corrective actions to

eliminate the cause of blade binding.

3. When restarting a saw in the

workpiece, centre the saw blade in

the kerf and check that saw teeth

are not engaged into the material.

If saw blade is binding, it may walk up or

kickback from the workpiece as the saw is

restarted.

4. Support large panels to minimise the

risk of blade pinching and kickback.

Large panels tend to sag under their own

weight. Supports must be placed under the

panel on both sides, near the line of cut and

near the edge of the panel.

5. Do not use dull or damaged blades.

Unsharpened or improperly set blades

produce narrow kerf causing excessive

friction, blade binding and kickback.

6. Blade depth and bevel adjusting

locking levers must be tight and

secure before making cut. If blade

adjustment shifts while cutting, it may cause

binding and kickback.

7. Use extra caution when sawing into

existing walls or other blind areas.

The protruding blade may cut objects that can

cause kickback.

Safety instructions for circular saws with

inner pendulum guard - Lower guard

function

1. Check lower guard for proper

closing before each use. Do not

operate the saw if lower guard does

not move freely and close instantly.

Never clamp or tie the lower guard

into the open position. If saw is

accidentally dropped, lower guard may be

bent. Raise the lower guard with the retracting

handle and make sure it moves freely and

does not touch the blade or any other part, in

all angles and depths of cut.

2. Check the operation of the lower

guard spring. If the guard and the

spring are not operating properly,

they must be serviced before use.

Lower guard may operate sluggishly due to

damaged parts, gummy deposits, or a build-up

of debris.

3. Lower guard may be retracted

manually only for special cuts such

as “plunge cuts” and “compound

cuts”. Raise lower guard by retracting

handle and as soon as blade enters the

material, the lower guard must be released.

For all other sawing, the lower guard should

operate automatically.

4. Always observe that the lower

guard is covering the blade before

placing saw down on bench or floor.

An unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in

its path. Be aware of the time it takes for the

blade to stop after switch is released.

10 GB / IE / NI

Additional circular saw safety warnings

¢ If the supply cord is damaged, it must be

re-placed by a special cord or assembly

available from the manufacturer or its service

agent.

¢ Do not use any grinding discs.

¢ Use only blades with diameters

corresponding to the label on the product.

¢ When cutting wood or other materials which

may create dusts that are hazardous to

health, always connect a suitable, certified

vacuum extractor device.

¢ Wear a dust mask when cutting wood.

¢ Use only the recommended blades.

¢ Always wear ear protectors.

¢ Do not allow the teeth of the blade to

overheat.

¢ When cutting plastic, avoid melting the

plastic.

Saw blade safety warnings

¢ Only use saw blades if you have knowledge

of how to use and handle them.

¢ Pay attention to the maximum rotational

speed. The maximum rotational speed marked

on the saw blade shall not be exceeded.

¢ Do not use working saw blades which are

cracked. Scrap of saw blades which bodies

are cracked. Repairing is not permitted.

¢ Clamping surfaces shall be cleaned to

remove dirt, grease, oil and water.

¢ Do not use loose rings or sleeves to «make

up» bore sizes on saw blades.

¢ Ensure that fixed reduction rings for securing

the accessory have the same diameter and at

least 1/3 of the cutting diameter.

¢ Ensure fixed rings are parallel to each other.

¢ Handle saw blades with care. Store them in

the original packaging or in special boxes.

Wear gloves for handling and to reduce

injuries.

¢ Ensure all guards are correctly fixed before

using saw blades.

¢ Before use, make sure that the saw blade

complies with the technical requirements of

the product and is correctly fixed.

¢ Use the supplied saw blade only for cutting of

wood, never for metal.

¢ A longer period of use may lead to

overheating of the blade tips. Therefore take

breaks of approx. 15 minutes on a regular

basis to let the blade tips cool down.

Q Vibration and noise reduction

To reduce the impact of noise and vibration

emission, limit the time of operation, use lowvibration and low-noise operating modes as well

as wear personal protective equipment.

Take the following points into account to minimise

the vibration and noise exposure risks:

¢ Only use the product as intended by its

design and these instructions.

¢ Ensure that the product is in good condition

and well maintained.

¢ Use correct attachments for the product and

ensure they are in good condition.

¢ Keep tight grip on the handles / grip surface.

¢ Maintain this product in accordance with

these instructions and keep it well lubricated

(where appropriate).

¢ Plan your work schedule to spread any high

vibration tool use across a longer period of

time.

Q Behaviour in emergency

situations

Familiarise yourself with the use of this product by

means of this instruction manual. Memorise the

safety warnings and follow them to the letter. This

will help to prevent risks and hazards.

¢ Always be alert when using this product, so

that you can recognise and handle risks early.

Fast intervention can prevent serious injury

and damage to property.

¢ Switch the product off and disconnect it from

the mains if there are malfunctions. Have the

product checked by a qualified professional

and repaired, if necessary, before you

operate it again.

Q Residual risks

Even if you are operating this product in

accordance with all the safety requirements,

potential risks of injury and damage remain. The

following dangers can arise in connection with the

structure and design of this product:

¢ Health defects resulting from vibration

emission if the product is being used over

long periods of time or not adequately

managed and properly maintained.

¢ Injuries and damage to property due to

broken cutting attachments or the sudden

impact of hidden objects during use.

¢ Danger of injury and property damage

caused by flying objects.

11 GB / IE / NI

Loading...

Loading...