Parkside PDAP 75 A1 Original Instructions Manual

IAN 285820

PNEUMATIC AIR POLISHING SET PDAP 75 A1

PNEUMATIC AIR POLISHING SET

Translation of the original instructions

DRUCKLUFT-POLIER-SET

Originalbetriebsanleitung

GB / IE / NI Translation of the original instructions Page 1

DE / AT / CH Originalbetriebsanleitung Seite 13

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of

the device.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

PDAP 75 A1

GB│IE│NI

│

1 ■

Contents

Introduction ......................................................2

Intended use ................................................................ 2

Features ................................................................... 2

Included in delivery .......................................................... 2

Technical data .............................................................. 2

General safety instructions for compressed air tools ....................3

Hazards caused by flying parts ................................................. 4

Hazards caused by entanglement ............................................... 4

Hazards during operation ..................................................... 4

Risks due to repetitive movements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Hazards caused by accessories ................................................. 5

Hazards in the workplace ..................................................... 5

Hazards caused by dust and vapours ............................................ 5

Risks due to noise ............................................................ 6

Risks due to vibrations ........................................................ 6

Additional safety instructions for pneumatic machines ................................ 6

Appliance-specific safety instructions for grinders ................................... 7

Before use .......................................................7

Fitting the connector nipple .................................................... 7

Assembly/disassembly of the polishing disc ....................................... 7

Fitting the polishing attachments ................................................. 7

Lubrication ................................................................. 8

Topping up the oil ........................................................... 8

Connecting to a compressed air source ........................................... 8

Operation .......................................................8

Switching on and off ......................................................... 8

Polishing ................................................................... 8

Maintenance and cleaning ..........................................9

Troubleshooting .................................................10

Disposal ........................................................10

Kompernass Handels GmbH warranty ..............................10

Service ................................................................... 11

Importer .................................................................. 11

Translation of the original Conformity Declaration .....................12

PDAP 75 A1

■ 2 │ GB

│IE│

NI

PNEUMATIC AIR POLISHING

SET PDAP 75 A1

Introduction

Congratulations on the purchase of your new appliance. You have chosen a high-quality product. The

operating instructions are part of this product. They

contain important information about safety, usage

and disposal. Before using the product, please

familiarise yourself with all operating and safety

instructions. Use the product only as described and

for the range of applications specified. Please also

pass these operating instructions on to any future

owner.

Intended use

This compressed air polisher is designed for

polishing various surfaces. Any other usage or

modification of the appliance is deemed to be

improper and carries a significant risk of accidents.

The manufacturer accepts no responsibility for

damage(s) resulting from improper usage. This

appliance is intended for domestic use only.

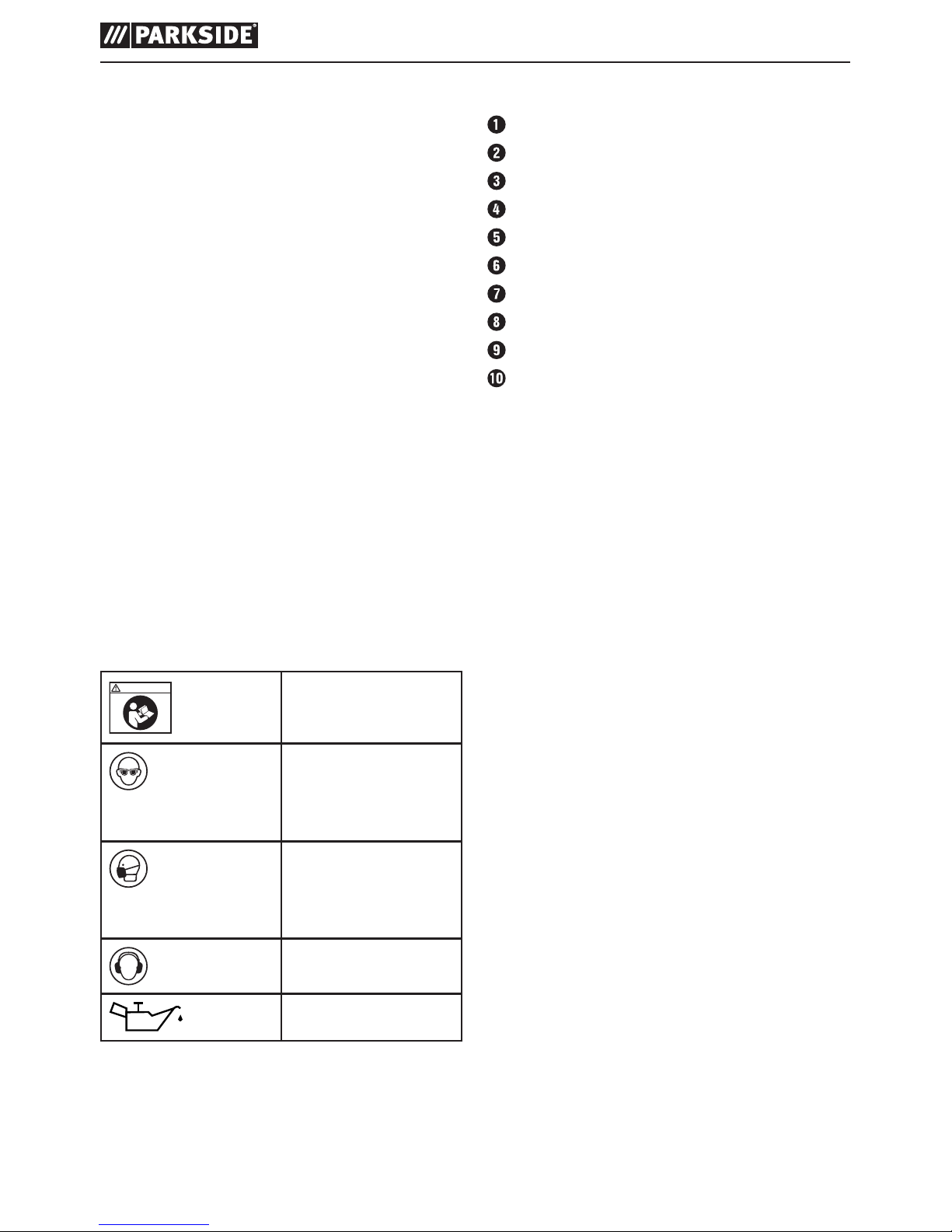

Symbols on the compressed air tool:

WARNING!

Read the operating

instructions before use.

Always wear eye protection when using or

maintaining the compressed air polisher.

Always wear a dust

mask in situations in

which dust is being

generated.

Always wear hearing

protection.

Oil daily

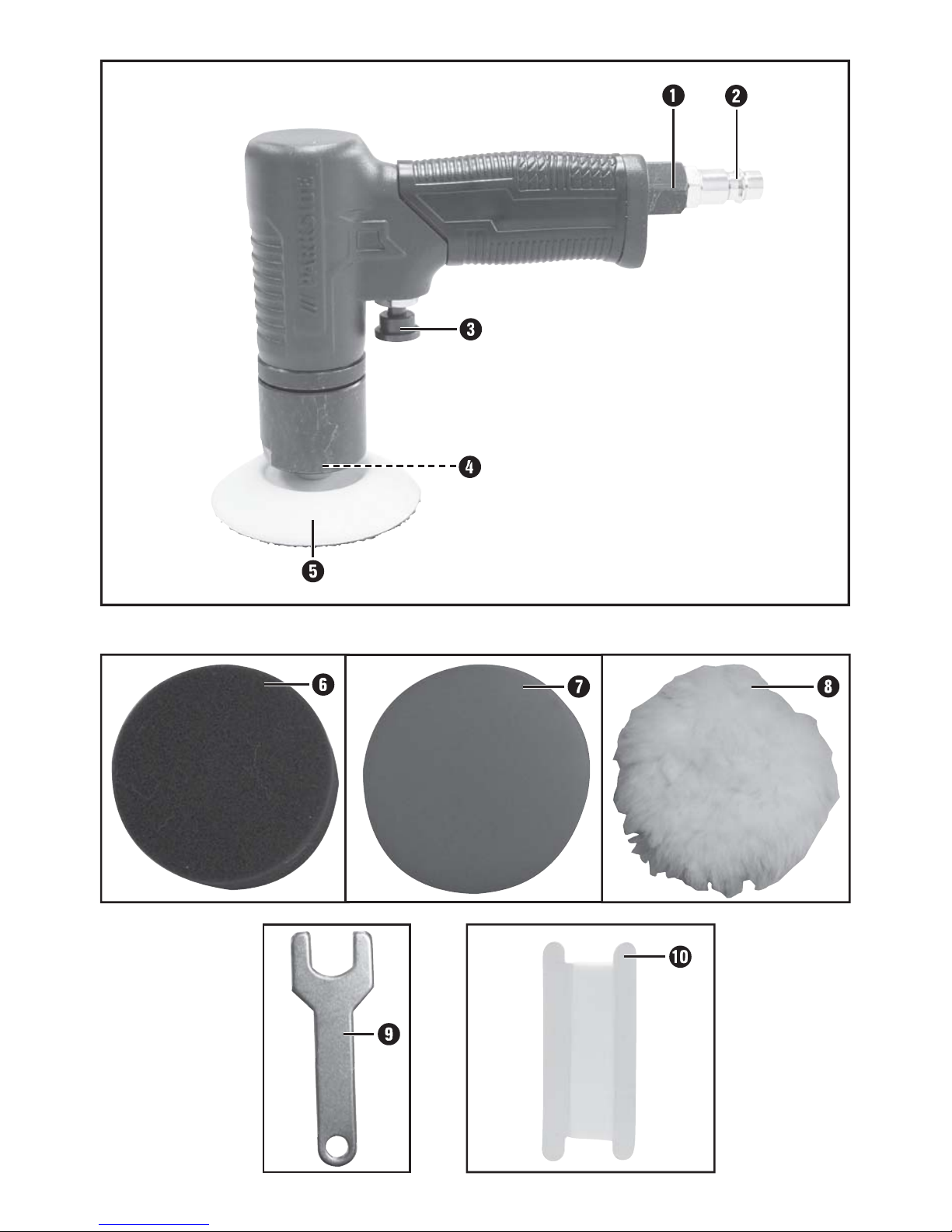

Features

Air inlet

Connector nipple

Trigger

Thread

Polishing disc

Polishing hood black

Polishing hood orange

Fake fur attachment

Assembly spanner

Teflon tape

Included in delivery

1 pneumatic air polishing set PDAP 75 A1

1m Teflon tape

1 polishing disc Ø 75 mm (with Velcro fastener)

1 polishing hood, orange (for pre-polishing)

1 polishing hood, black (for final polishing)

1 fake lambskin

1 connector nipple 6.35 mm (1/4")

1 assembly wrench

1 operating manual

Technical data

Rated frequency: max. 2500 rpm

Rated air pressure: max. 6.3 bar

Grinding disc: Ø 75mm

Weight (without accessories): approx. 740 g

PDAP 75 A1

GB│IE│NI

│

3 ■

Noise emission values:

Noise measurement determined in accordance

with ISO15744:

Sound pressure level: L

pA

= 84.1 dB(A)

Uncertainty: K

pA

= 3 dB

Sound power level: L

WA

= 95.1 dB(A)

Uncertainty: K

WA

= 3 dB

Wear ear protection!

Vibration emission value:

Vibration values determined in accordance with

ISO 28927-3 and EN 12096:

a

h

= 0.25 m/s

2

Uncertainty K = 0.52 m/s

2

WARNING!

► The noise emission levels specified in these

instructions have been measured in accordance with the standardised measuring

procedure specified in ISO 15744 and can

be used to make equipment comparisons.

The noise emission values vary in accordance

with the use of the compressed air tool and

may be higher than the values specified in

these instructions in some cases. It is easy to

underestimate the noise emission load if the

compressed air tool is used regularly in a

certain manner.

NOTE

► For an accurate estimate of the noise emission

load during a certain working period, the

times during which the appliance is switched

off or is running but not actually being used

must also be taken into consideration. This

can significantly reduce the noise emission

load over the total working period.

WARNING!

General safety instructions for compressed

air tools

WARNING!

► For multiple hazards: Please ensure that you

have read and understood the safety instructions before adjusting, operating, repairing,

maintaining or replacement of accessories on

the polisher as well as before working in the

vicinity of the machine. Failure to do this can

result in serious bodily injury.

■ The sander or the polisher should only be ad-

justed, set or used by adequately qualified and

trained operators.

■ This sander or this polisher may not be modi-

fied. Modifications can reduce the effectiveness

of the safety measures and increase the risks for

the operator.

■ The safety instructions should not be lost –

give them to the operator.

■ Never use damaged sanders or polishers.

■ The appliance must be inspected regularly to

ensure that it is labelled with the required rated

values and markings given in this manual. The

user must contact the manufacturer to obtain

replacement labels if necessary.

PDAP 75 A1

■ 4 │ GB

│IE│

NI

Hazards caused by flying parts

■ If a workpiece or accessory or even part of the

machine tool itself breaks, parts can be flung

out at high speeds.

■ When operating the sander or the polisher or

when exchanging accessories on the appliance,

always wear eye protection. The degree of necessary protection must be evaluated separately

for each individual task.

■ Wear a safety helmet if working above head

height. In this case, the risks for others should

also be assessed.

■ You must ensure that the workpiece has been

securely fixed.

Hazards caused by entanglement

■ Suffocation, scalping and/or cut wounds

can occur if loose clothing, jewellery, necklaces,

hair or gloves are not kept away from the

machine and its accessories.

Hazards during operation

■ When using the machine, the operator's hands

can be subject to hazards such as cuts, grazing

and heat. Wear suitable gloves to protect your

hands.

■ The operator and maintenance personnel must

be physically capable of handling the size,

mass and power of the machine.

■ Hold the machine correctly: be ready to coun-

teract any normal or sudden movements - have

both hands ready.

■ Ensure that your body is balanced and that you

have a secure standing position.

■ Release the start/stop control in case of a

disruption to the electricity supply.

■ Use only the lubricants recommended by the

manufacturer.

■ Suitable safety goggles must be worn; wearing

protective gloves and safety clothing is recommended.

■ Check the grinding disc before every use. Do

not use if this is cracked, broken or has been

dropped.

■ Avoid direct contact with the movable grinding

disc, to avoid squashing or cutting your hands

or other parts of the body. Always wear suitable gloves to protect your hands.

■ Never use the machine without an abrasive

attachment.

■ There is a risk of electrostatic discharge if the

machine is used on plastic and other non-conductive materials.

■ Dust and vapours created by the grinding and

sanding can cause a potentially explosive atmosphere. Always use a dust extraction or suppression system suitable for the material being

worked.

Risks due to repetitive movements

■ When using a sander or polisher to perform

work-related activities, operators may experience uncomfortable sensations in their hands

and arms, as well as in the neck and shoulders

or other parts of the body.

■ When using a sander or a polisher, the opera-

tor should adopt a comfortable posture whilst

ensuring a secure hold and avoiding awkward

postures or positions in which it is difficult to

maintain balance. The operator should change

positions during the course of long-lasting tasks.

This can be helpful in the prevention of discomfort and fatigue.

PDAP 75 A1

GB│IE│NI

│

5 ■

■ If the operator notices symptoms such as persis-

tent or recurring illness, discomfort, throbbing,

pain, tingling, burning or stiffness, these indications should not be ignored.

In this case, the operator should consult a suitably qualified physician.

Hazards caused by accessories

■ Disconnect the sander or the polisher from the

power before changing the tools or accessories.

■ Avoid direct contact with the machine tool during

and after use, since this can have heated up or

have become sharp.

■ Use only tools for sanders and polishers which

have been approved by the manufacturer of the

sander and polisher.

■ Cutting discs and machines for cutting may not

be used.

■ Check whether the maximum operating speed

of the tool (stitched buffs, abrasive belts, fibre

discs, etc.) is higher than that of the machine;

■ Self-adhesive grinding discs must be applied

concentrically on the mounting plate.

Hazards in the workplace

■ Slipping, tripping up and falling are the main

causes of injuries in the workplace. Take note

of surfaces which could have become slippery

through use of the machine, and also any tripping hazards caused by air or hydraulic hoses.

■ These sanders and polishers are not suitable for

use in explosive environments and are not insulated against contact with power sources.

■ Do not operate the appliance in the vicinity of

electric mains, gas pipelines etc. which could

pose a hazard if damaged by the machine.

Hazards caused by dust and vapours

■ The dust and vapours produced by using sand-

ers and polishers can be hazardous to health

(e.g. cause cancer, birth defects, asthma and/

or dermatitis); it is essential to carry out a risk

assessment in respect of these risks and to implement corresponding regulatory mechanisms.

■ The risk assessment should include all dust

caused by the use of the machine and the existing dust that may be kicked up at the same

time.

■ The sander or polisher is to be operated and

maintained in accordance with the recommendations contained in this manual to keep the

release of dust and vapours to a minimum.

■ The exhaust air should be routed so that the

raising of dust in already dusty environments is

kept to a minimum.

■ If dusts or vapours are created, the main prior-

ity must be to control these at the site of their

release.

■ All inserts or accessories of the machine in-

tended for collecting, extracting or suppressing

airborne dust or vapours or should be used and

serviced in accordance with the manufacturer’s

instructions.

■ Consumables/machine tools should be se-

lected, maintained and replaced in accordance

with the recommendations in this guide in order

to avoid unnecessary intensification of dust or

vapour production.

■ Use a dust mask as per the instructions provided

by your employer or as required by health and

safety regulations.

PDAP 75 A1

■ 6 │ GB

│IE│

NI

Risks due to noise

■ Excessive noise levels in conjunction with insuf-

ficient hearing protection may lead to permanent

hearing damage, hearing loss and other problems, such as tinnitus (ringing, buzzing, whistling

or humming in your ears). It is essential that

a risk assessment is carried out with respect

to these risks and that appropriate regulatory

mechanisms are implemented.

■ Suitable regulatory mechanisms include meas-

ures such as the use of insulation materials

to avoid ringing noise occurring on the workpieces.

■ Use ear protection as per the instructions

provided by your employer or as required by

health and safety regulations.

■ The sander or polisher is to be operated and

maintained in accordance with the recommendations contained in this manual to reduce any

unnecessary increase of the noise levels.

■ Consumables/machine tools should be se-

lected, maintained and replaced in accordance

with the recommendations in this guide in order

to avoid unnecessary increase of the noise

levels.

■ If the sander or polisher is equipped with a

silencer, always ensure that this in its place and

is operational while the machine is in operation.

Risks due to vibrations

■ Vibrations can damage the nerves and cause

malfunctions to the blood circulation in the

hands and arms.

■ When working in a cold environment, wear

warm clothing and keep your hands warm and

dry.

■ If you notice numbness, tingling or pain in your

fingers or hands or notice that the skin of your

fingers or hands has become pale, stop working with the sander or the polisher, inform your

employer and consult a doctor.

■ The sander or polisher is to be operated and

maintained in accordance with the recommendations contained in this manual to reduce any

unnecessary increase of the vibrations.

■ Hold the machine securely but not too firmly

while maintaining the necessary hand-reaction

force, as the vibration risk generally increases

the harder the machine is held.

Additional safety instructions for

pneumatic machines

■ Compressed air can cause serious injury.

– Ensure that the air supply is switched off,

the hose is not under pressure, that the air

supply has been shut off and that the

machine is disconnected from the air supply

when not in use, and also before exchanging accessories or carrying out repairs.

– Never aim the airflow towards yourself

or any other person.

■ Thrashing hoses can cause serious injury. There-

fore, always check that the hoses and their fixings are not damaged or have not come loose.

Loading...

Loading...