Parkside PBSG 95 A1 User Manual [el]

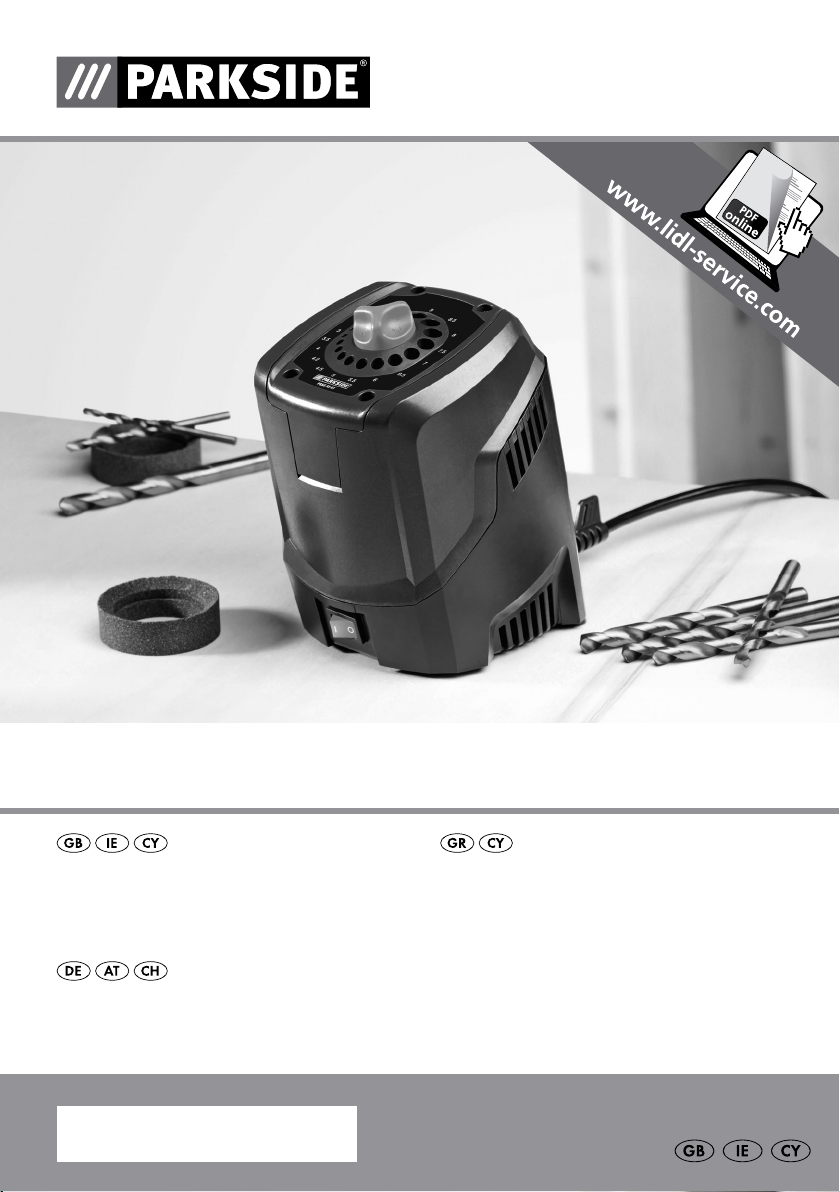

DRILL SHARPENING MACHINE PBSG 95 A1

DRILL SHARPENING MACHINE

Operation and Safety Notes

Translation of original operation manual

BOHRERSCHÄRFGERÄT

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

IAN 72656

ΣΥΣΚΕΥΗ ΑΚΟΝΙΣΜΑΤΟΣ

ΤΡΥΠΑΝΙΩΝ

Υποδείξεις χειρισμού και ασφαλείας

Μετάφραση των αυθεντικών οδηγιών λειτουργίας

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Πριν ξεκινήσετε την ανάγνωση, ανοίξτε τη σελίδα με τις εικόνες και εξοικειωθείτε με όλες τις λειτουργίες της

συσκευής.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE / CY Operation and Safety Notes Page 5

GR / CY Υποδείξεις χειρισμού και ασφαλείας Σελίδα 13

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 21

1

2

3

4

A

3 3

C

3

5 8 97

E

B

2

5

D

6

F

10

11

Table of contents

Introduction

Proper use ..........................................................................................................................Page 6

Description of parts and features .....................................................................................Page 6

Scope of delivery ..............................................................................................................Page 6

Technical data ...................................................................................................................Page 6

General safety advice

Working safely ..................................................................................................................Page 7

Device-specific safety instructions for drill sharpeners ....................................................Page 8

Original accessories / Attachments ..................................................................................Page 9

Use

Sharpening a drill .............................................................................................................Page 9

Replacing the sharpening stone .......................................................................................Page 10

Maintenance and cleaning .............................................................................Page 10

Service .............................................................................................................................Page 10

Warranty .......................................................................................................................Page 10

Disposal ..........................................................................................................................Page 11

Declaration of Conformity / Manufacturer........................................Page 11

5 GB/IE/CY

Introduction Introduction / General safety advice

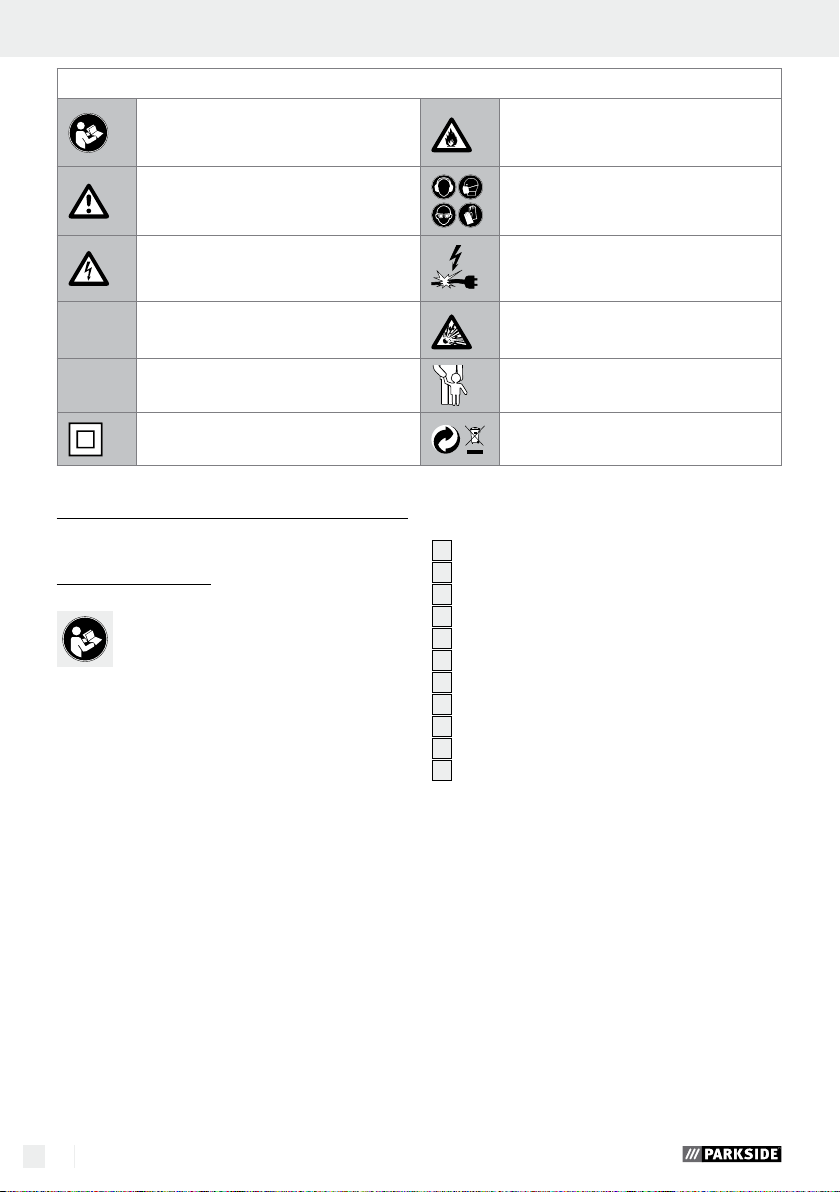

The following pictograms are used in these operating instructions / on the device:

Read instruction manual! Risk of fire!

Wear hearing protection, dust

Observe caution and safety notes!

Caution–electric shock!

Danger to life!

protection mask, protective glasses

and protective gloves.

Risk of loss of life by electric shock

from damaged mains lead or mains

plug!

V

W

Volt (AC) Risk of explosion!

~

Watts (effective power)

Safety class II

Drill sharpening machine PBSG 95 A1

Q

Introduction

We congratulate you on the purchase of

your new device. You have chosen a

high quality product. The instructions for

use are part of the product. They contain important

information concerning safety, use and disposal.

Before using the product, please familiarise yourself

with all of the safety information and instructions

for use. Only use the unit as described and for the

specified applications. If you pass the product on

to anyone else, please ensure that you also pass

on all the documentation with it.

Q

Proper use

The device is designed to sharpen steel drill bits

according to DIN 338, DIN 340, DIN 345,

DIN 1869 and DIN 1897 (MODEL Type N).

Carbide drill bits must not be milled with this device.

Any other use or modification to the device shall be

considered as improper use and could give rise to

considerable dangers. The manufacturer will not accept liability for loss or damage arising from improper

use. The device is not intended for commercial use.

6 GB/IE/CY

Keep children away from electrical

power tools!

Dispose packaging and appliance in

an environmentally-friendly way!

Q

Description of parts and features

Rotary switch (“STONE” = Sharpening stone)

1

Sharpening stone cover

2

Sharpening stone cover screw

3

ON / OFF switch

4

Sharpening stone

5

Spring

6

Threaded connection

7

Metal washer

8

Sharpening stone holder

9

Ventilation slots

10

Drill guide

11

Q

Scope of delivery

1 drill sharpening machine PBSG 95 A1

1 carrying case

16 titanium-coated HSS drills (see Fig. E)

2 spare sharpening stones

1 set of operating instructions

Q

Technical data

Dimensions: 128 x 173 x 202 mm

(w x h x d)

Weight: 950 g

Nominal voltage: 230–240 V~ 50 Hz

Nominal output: 95 W

Nominal rotation speed: 1350 rpm

For drill bits of diameter: 3–10 mm

Protection class: II /

Noise data:

Refers to A-weighted sound level.

Sound pressure level: 75.3 dB (A)

Sound level: 88.3 dB (A)

Uncertainty K: 3 dB

Values determined in accordance with EN 61029.

General safety advice

CAUTION! In order to protect yourself from

the danger of electric shock, injury or fire when

using electrical power tools, please observe

the following basic safety precautions. Read all

these requirements before you use the electrical

power tool, and keep the safety advice in a

safe place.

Q

Working safely

1. K

eep your working area clean and tid

A disorderly working area can lead to accidents.

2. Be aware of the effects of the

environment.

Do not leave electrical power tools out in the rain.

Do not use electrical power tools in moist or

wet surroundings.

Ensure that your working area is well lit.

Do not use electrical power tools in

areas where there is risk of fire or

explosion.

3.

Avoid touching earthed objects such as pipes,

4. Keep other people at a safe distance.

Protect yourself from electric

shock.

heating radiators, ovens or refrigerators with

parts of your body.

Do not allow other people, in partic-

ular children, to touch the electrical

power tool or the mains lead. Keep

them away from your working area.

5. Store currently unused electrical power

tools in a safe place.

When not being used electrical power tools

should be stored in dry conditions in a high or

enclosed place, out of reach of children.

6. Do not overload your electrical power

tool.

By keeping within the specified working range

of the tool you will work more safely and achieve

a better result.

7. Use the right electrical power tool for

the task.

Do not use low-output devices for heavy tasks.

Do not use an electrical power tool for purposes

for which it was not intended. For example, do

not use a hand operated circular saw for trimming tree branches or cutting logs.

8. Wear suitable clothing.

Do not wear loose-fitting clothing or jewellery.

They could become caught on moving parts.

We recommend that you wear anti-slip footwear

when working outdoors.

If you have long hair, wear a hair net.

9.

y.

Wear protective glasses.

Wear ear protection.

Wear a dust mask if your work generates dust.

10. Attaching the vacuum dust extraction

device.

Where there are connection points provided

for vacuum dust extraction please ensure that

the connections are made and used properly.

11.

Do not use the mains lead to pull the plug out

of the mains socket. Protect the mains lead

from heat, oil and sharp edges.

12. Securely support the workpiece.

Use clamps or a vice to grip the workpiece firmly.

This is much safer than holding it with your hand.

Use personal protective

equipment.

Do not use the mains lead

for purposes for which it

was not intended.

7 GB/IE/CY

13. Avoid placing your body in an

unnatural position.

Keep proper footing and balance at all times.

14. Look after your tools carefully.

Keep cutting tools sharp and clean. This way

you will work more safely and achieve better

results.

Follow the advice on tool lubrication and con-

sumables replacement.

Check the condition of the mains lead on your

electrical power tool regularly and have any

damage repaired by a competent specialist.

Check the condition of extension leads regular-

ly and replace them if they are damaged.

Keep handles and hand grips clean, dry and

free of oil and grease.

15. Pull the mains plug out of the mains

socket.

Do this if the electrical power tool is not being

used, before carrying out maintenance tasks

on the electrical power tool and whenever you

are changing inserted tools, e.g. saw blades,

drills or router bits.

16. Make sure that no spanners, keys etc.

are left attached.

Check before switching on that all spanners,

keys and setting tools have been removed.

17. Avoid unintentionally starting up the

device.

Check that the switch is set to OFF on the de-

vice when the mains plug is inserted into the

mains socket.

18. Using an extension lead for working

outdoors.

When working outside, always use an approved

and appropriately labelled extension lead.

19. Remain alert.

Watch what you are doing. Proceed with cau-

tion. Do not use electrical power tools if you

cannot concentrate.

20. Check the electrical power tool for

damage.

Before the electrical power tool is used, carefully

check the safety equipment and any slightly

damaged parts to see that they are still working properly.

Check that all moving parts on the tool are

working properly, can move freely and are not

8 GB/IE/CY

damaged. All parts must be correctly attached

and fulfil all the requirements necessary to allow

the electrical power tool to operate properly.

Damaged safety equipment and components

must be properly repaired or replaced at a

competent electrical equipment repair centre

unless otherwise indicated in the operating instructions.

Damaged switches must be replaced at a

Customer Service Centre.

Never use an electrical power tool that cannot

be switched on and off properly.

21. CAUTION!

The use of inserted tools and accessories other

than those recommended by the manufacturer

could lead to you being injured.

22. Have your electrical power tool

repaired at an electrical equipment

repair specialist.

This electrical power tool complies with the

relevant safety regulations. Repairs may only

be carried out by a specialist electrical repair

centre using original spare parts, otherwise

injury could occur to the user.

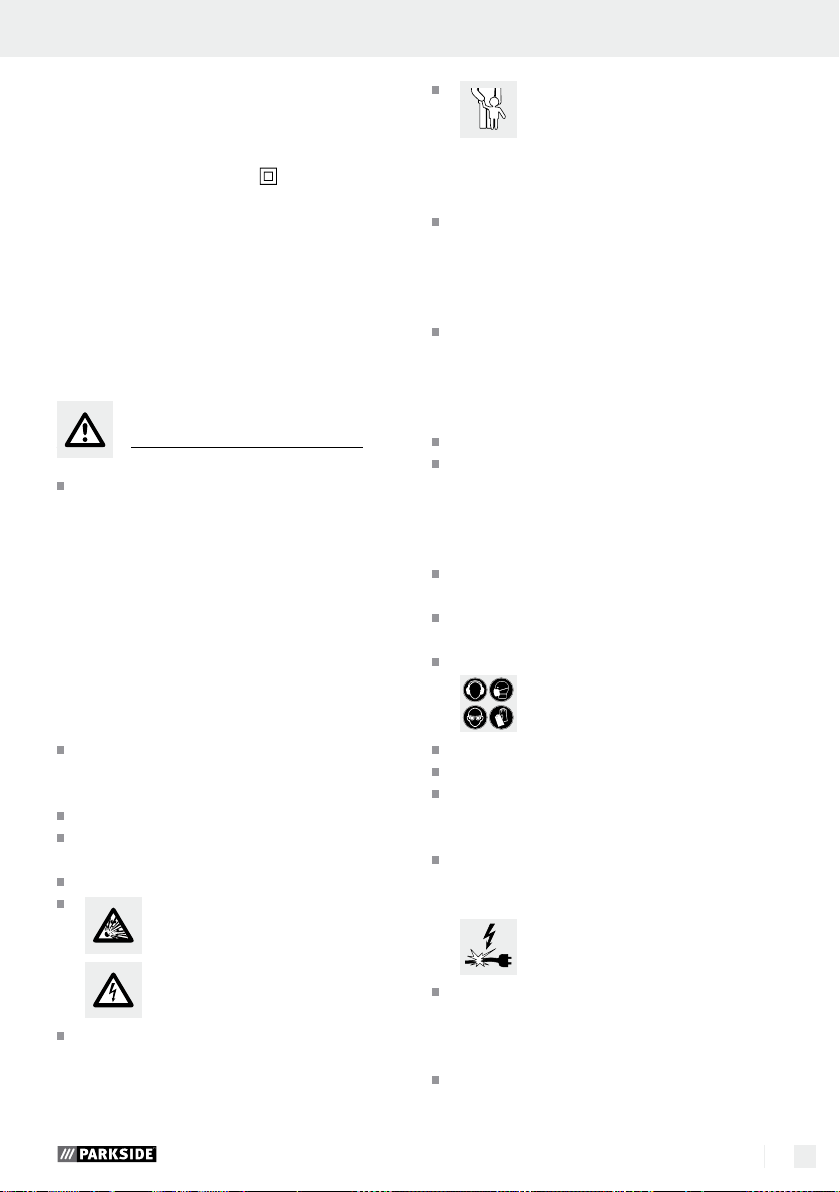

Device-specific safety

instructions for drill

sharpeners

Make sure that the device is switched

off before inserting the mains plug

into the socket.

Always pull the mains plug out before

carry out cleaning or maintenance

work. This is to prevent the device starting up

by accident.

10

The ventilation openings

tor unit must always be kept clear.

Otherwise there is a risk of the device over

When carrying out work on the device

as well as transporting or storing it,

move the ON / OFF switch

“0” position (off) in order to prevent

it switching itself on by accident.

FIRE HAZARD DUE TO FLYNG

SPARKS! Grinding metal will

cause sparks to fly. That is why you

of the mo-

heating.

4

to the

General safety advice / UseGeneral safety advice

should always make sure that no-one is at risk

from them and that no combustible materials

are located in the proximity of the area of work.

RISK OF INJURY! Use the

ON / OFF switch

4

to switch the grinder off

in the event of a power failure or when pulling

out the mains plug. This prevents the grinder restar

ing by accident, which could cause injury to you.

Never operate the grinder if the power

cable or mains plug is damaged.

Grinding stones must be carefully

stored and handled according to the

manufacturer’s instructions.

Make sure that the grinding tools are

appropriate in line with the instructions

of the manufacturer.

Check the grinding stone before using

it; do not use any broken, cracked or otherwise

damaged goods.

Make sure that a grinding tool is correctly fitted and fastened before using it.

Place the grinder in a safe place and allow it

to run idly for 30 seconds. Stop it immediately if

considerable oscillations occur or if defects are

observed. If this occurs, check the machine to

find out the cause.

Q

Original accessories /

Attachments

Use only the accessories and attachments

detailed in the operating instructions.

The use of inserted tools or accessories other

than those recommended in the operating instructions could lead to you suffering an injury.

Insert the drill into the smallest suitable drill

guide

(Ø) of each drill guide

on the drill sharpener. The exact size

11

is shown by the ad-

11

jacent lettering (3 to 10).

Press the ON / OFF switch 4 into position “I”

to switch on the device.

t-

Turn the rotary switch 1 in the UP direction

until you hear a grinding noise.

NOTE: The rotary switch

controls the posi-

1

tion of the sharpening stone in the sharpening

head housing and therefore the pressure of the

sharpening stone against the drill. The further

you turn the rotary switch 1 in the UP direction

the greater the pressure. Ensure that you do not

turn the sharpening stone too far up. Otherwise

the sharpening stone could strike the housing.

Turn the drill under slight pressure loosely and

quickly to and fro between the left and right

stops about 10 times (with small drills about 5

times).

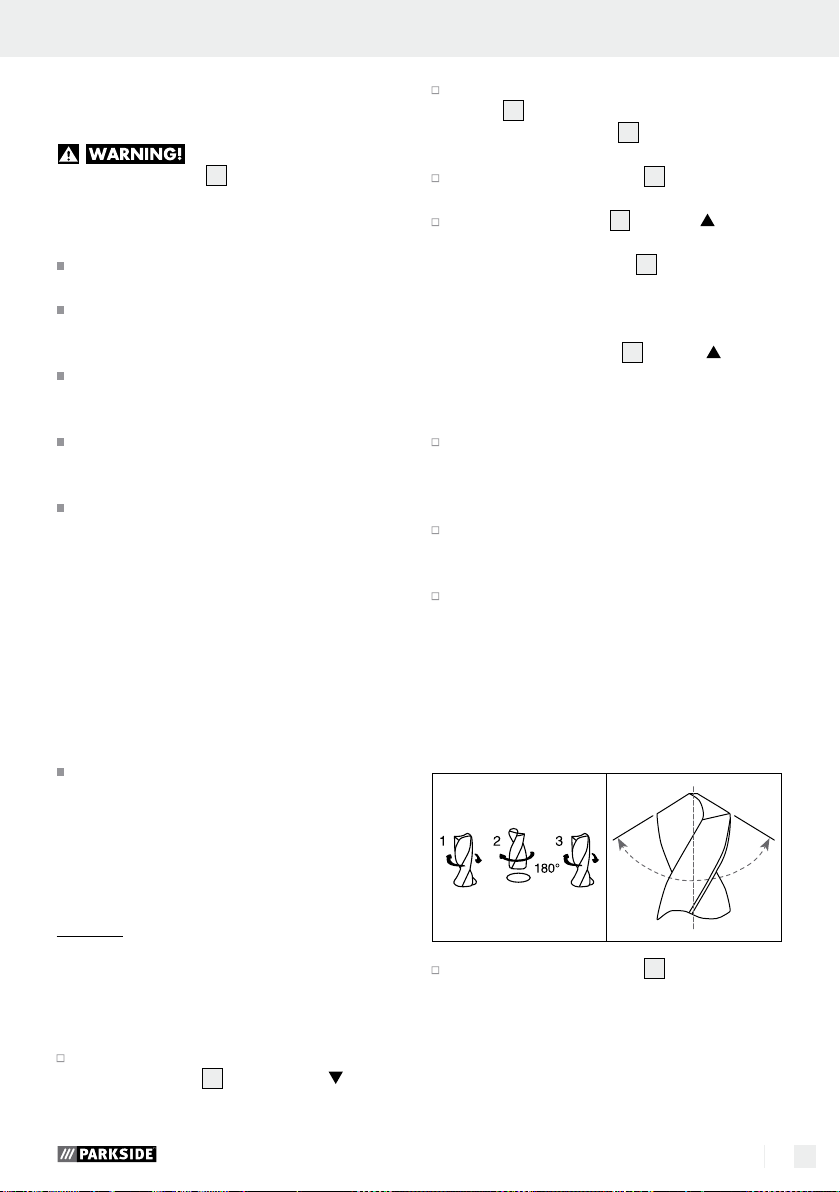

Pull the drill out, turn it through 180° (horizon

and insert it again until it meets the sharpening

stone.

If necessary repeat whole process until both

cutting edges of the drill are sharp. Control the

grinding operation so that the angle between

the main and transverse cutting edges for a

standard drill is 130°. Both cutting edges (b)

must have the same angle to the drill axis (a)

and be the same length so that the drill runs

concentrically (see following figures).

,

tally)

(b)(b)

(a)

Q

Use

Q

Sharpening a drill

NOTE: Badly damaged drills should first be coarsely

sharpened on a sharpening block.

Fully lower the sharpening stone. To do this turn

the rotary switch

in the DOWN direction

1

as far as it will go.

Press the ON / OFF switch 4 into position “0”

to switch off the device.

9 GB/IE/CY

Loading...

Loading...