DRILL SHARPENER PBSG 55 A1

DRILL SHARPENER

Operation and Safety Notes

Translation of original operation manual

BORRSLIPARE

Bruksanvisning och säkerhetsanvisningar

Översättning av bruksanvisning i original

BOHRERSCHÄRFGERÄT

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

PORANTERIEN TEROITUSLAITE

Käyttö- ja turvaohjeet

Alkuperäisen käyttöohjeen käännös

BORSLIBER

Brugs- og sikkerhedsanvisninger

Oversættelse af den originale driftsvejledning

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Käännä ennen lukemista kuvallinen sivu esiin ja tutustu seuraavaksi laitteen kaikkiin toimintoihin.

Vik ut bildsidan och ha den till hands när du läser igenom anvisningarna och gör dig bekant med

apparatens / maskinens funktioner.

Før du læser, vend siden med billeder frem og bliv bekendt med alle apparatets funktioner.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE Operation and Safety Notes Page 5

FI Käyttö- ja turvaohjeet Sivu 13

SE Bruksanvisning och säkerhetsanvisningar Sidan 21

DK Brugs- og sikkerhedsanvisninger Side 29

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 37

1

2

3

4

A B

3 3

C D

3

2

5

5 8 9

7

E F

6

10

11

Table of contents

Introduction

Proper use ......................................................................................................................Page 6

Description of parts and features .................................................................................Page 6

Scope of delivery ..........................................................................................................Page 6

Technical data ...............................................................................................................Page 6

General safety advice

Working safely ..............................................................................................................Page 7

Device-specific safety instructions for drill sharpeners ................................................Page 8

Original accessories / Attachments ..............................................................................Page 9

Use

Sharpening a drill .........................................................................................................Page 9

Replacing the sharpening stone ...................................................................................Page 9

Maintenance and cleaning .........................................................................Page 10

Service .........................................................................................................................Page 10

Warranty ...................................................................................................................Page 10

Disposal ......................................................................................................................Page 11

Declaration of Conformity / Manufacturer..................................Page 11

5 GB/IE

Introduction

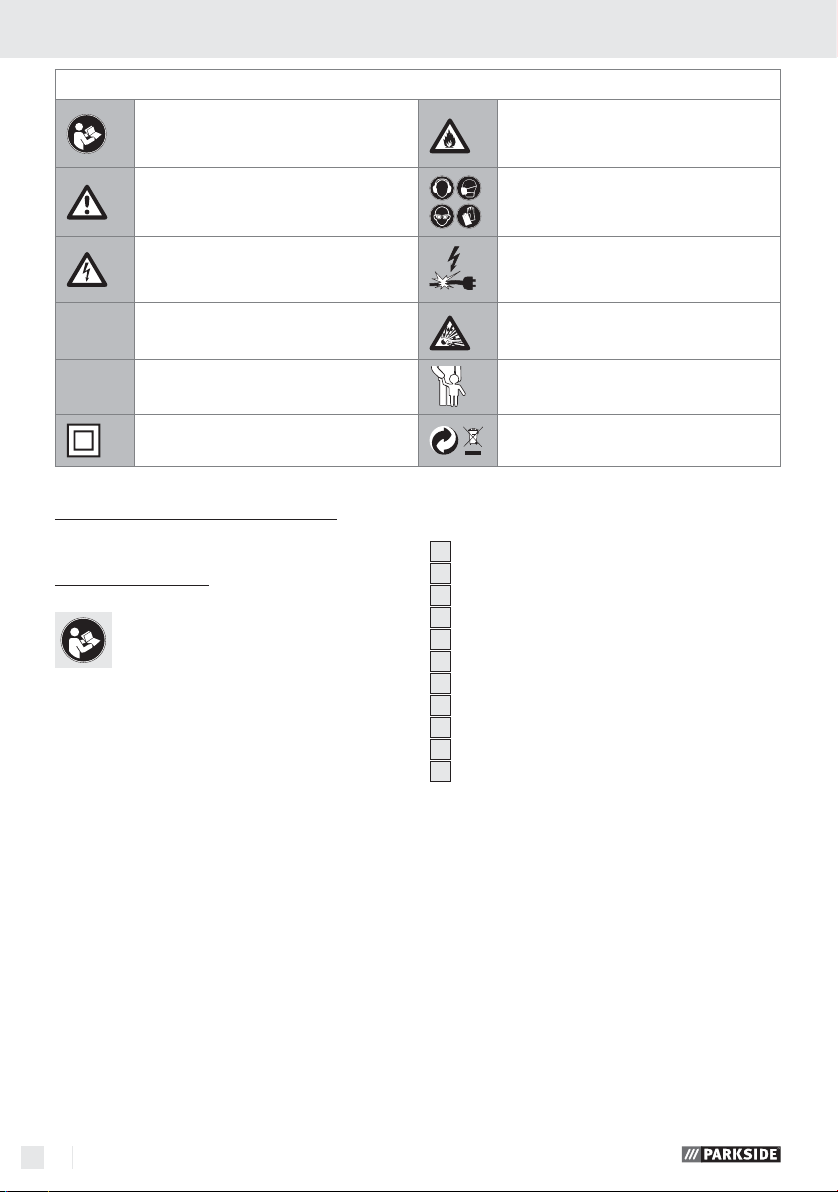

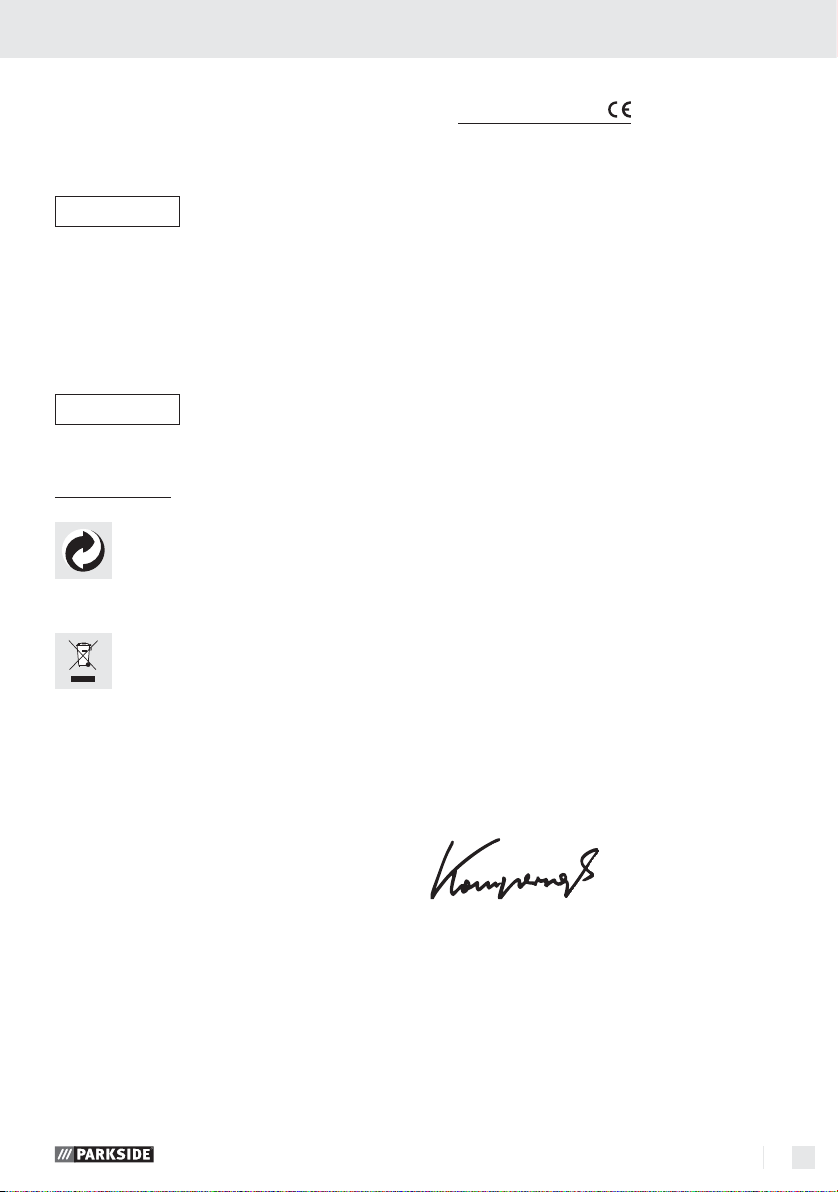

The following pictograms are used in these operating instructions / on the device:

Read instruction manual! Risk of fire!

Wear hearing protection, dust

Observe caution and safety notes!

Caution – electric shock!

Danger to life!

protection mask, protective glasses

and protective gloves.

Risk of loss of life by electric shock

from damaged mains lead or mains

plug!

V

W

Volt (AC) Risk of explosion!

~

Watts (effective power)

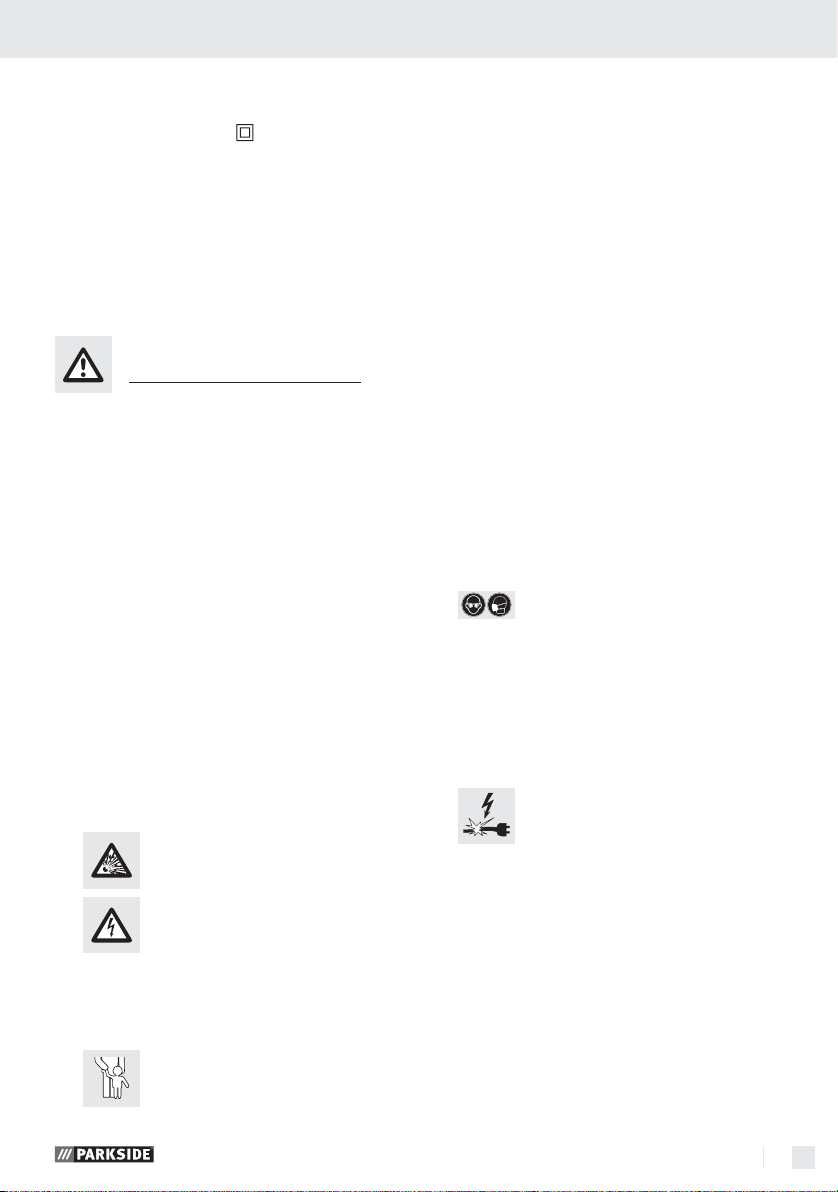

Safety class II

Drill sharpener PBSG 55 A1

Introduction

Please make sure you familiarise your-

self fully with the way the device works

before you use it for the first time and

that you understand how to handle electrical power

tools correctly. To help you do this please read the

accompanying operating instructions. Keep these

instructions in a safe place. If you pass the device

on to anyone else, please ensure that you also pass

on all the documentation.

Proper use

The device is designed to sharpen steel drill bits

according to DIN 338, DIN 340, DIN 345,

DIN 1869 and DIN 1897 (MODEL Type N).

Carbide drill bits must not be milled with this device.

Any other use or modification to the device shall be

considered as improper use and could give rise to

considerable dangers. The manufacturer will not accept liability for loss or damage arising from improper

use. The device is not intended for commercial use.

Keep children away from electrical

power tools!

Dispose packaging and appliance in

an environmentally-friendly way!

Description of parts and features

Rotary switch (“STONE” = Sharpening stone)

1

Sharpening stone cover

2

Sharpening stone cover screw

3

ON / OFF switch

4

Sharpening stone

5

Spring

6

Threaded connection

7

Metal washer

8

Sharpening stone holder

9

Ventilation slots

10

Drill guide

11

Scope of delivery

1 drill sharpener PBSG 55 A1

1 carrying case

16 titanium-coated HSS drills (see Fig. E)

2 spare sharpening stones

1 set of operating instructions

Technical data

Nominal voltage: 230 V~ 50 Hz

Nominal output: 55 W

6 GB/IE

Introduction / General safety advice

Nominal rotation speed: 1500 rpm

For drill bits of diameter: 3 – 10 mm

Protection class:

Noise data:

Refers to A-weighted sound level.

Sound pressure level: 75.30 dB (A)

Sound level: 85.00 dB (A)

Values determined in accordance with EN 61029.

General safety advice

CAUTION! In order to protect yourself from

the danger of electric shock, injury or fire when

using electrical power tools, please observe

the following basic safety precautions. Read all

these requirements before you use the electrical

power tool, and keep the safety advice in a

safe place.

Working safely

1. K

eep your working area clean and tid

A disorderly working area can lead to accidents.

2. Be aware of the effects of the

environment.

Do not leave electrical power tools out in the rain.

Do not use electrical power tools in moist or

wet surroundings.

Ensure that your working area is well lit.

3.

Avoid touching earthed objects such as pipes,

4. Keep other people at a safe distance.

them away from your working area.

Do not use electrical power tools in

areas where there is risk of fire or

explosion.

Protect yourself from electric

shock.

heating radiators, ovens or refrigerators with

parts of your body.

Do not allow other people, in partic-

ular children, to touch the electrical

power tool or the mains lead. Keep

y.

5. Store currently unused electrical power

tools in a safe place.

When not being used electrical power tools

should be stored in dry conditions in a high or

enclosed place, out of reach of children.

6. Do not overload your electrical power

tool.

By keeping within the specified working range

of the tool you will work more safely and achieve

a better result.

7. Use the right electrical power tool for

the task.

Do not use low-output devices for heavy tasks.

Do not use an electrical power tool for purposes

for which it was not intended. For example, do

not use a hand operated circular saw for trimming tree branches or cutting logs.

8. Wear suitable clothing.

Do not wear loose-fitting clothing or jewellery.

They could become caught on moving parts.

We recommend that you wear anti-slip footwear

when working outdoors.

If you have long hair, wear a hair net.

9.

Wear protective glasses.

Wear a dust mask if your work generates dust.

10. Attaching the vacuum dust extraction

Where there are connection points provided

11.

Do not use the mains lead to pull the plug out

12. Securely support the workpiece.

Use clamps or a vice to grip the workpiece firmly.

13. Avoid placing your body in an

Keep proper footing and balance at all times.

14. Look after your tools carefully.

Keep cutting tools sharp and clean. This way

Use personal protective

equipment.

device.

for vacuum dust extraction please ensure that

the connections are made and used properly.

Do not use the mains lead

for purposes for which it

was not intended.

of the mains socket. Protect the mains lead

from heat, oil and sharp edges.

This is much safer than holding it with your hand.

unnatural position.

you will work more safely and achieve better

results.

7 GB/IE

General safety advice

Follow the advice on tool lubrication and con-

sumables replacement.

Check the condition of the mains lead on your

electrical power tool regularly and have any

damage repaired by a competent specialist.

Check the condition of extension leads regular-

ly and replace them if they are damaged.

Keep handles and hand grips clean, dry and

free of oil and grease.

15. Pull the mains plug out of the mains

socket.

Do this if the electrical power tool is not being

used, before carrying out maintenance tasks

on the electrical power tool and whenever you

are changing inserted tools, e.g. saw blades,

drills or router bits.

16. Make sure that no spanners, keys etc.

are left attached.

Check before switching on that all spanners,

keys and setting tools have been removed.

17. Avoid unintentionally starting up the

device.

Check that the switch is set to OFF on the de-

vice when the mains plug is inserted into the

mains socket.

18. Using an extension lead for working

outdoors.

When working outside, always use an approved

and appropriately labelled extension lead.

19. Remain alert.

Watch what you are doing. Proceed with cau-

tion. Do not use electrical power tools if you

cannot concentrate.

20. Check the electrical power tool for

damage.

Before the electrical power tool is used, carefully

check the safety equipment and any slightly

damaged parts to see that they are still working properly.

Check that all moving parts on the tool are

working properly, can move freely and are not

damaged. All parts must be correctly attached

and fulfil all the requirements necessary to allow

the electrical power tool to operate properly.

Damaged safety equipment and components

must be properly repaired or replaced at a

competent electrical equipment repair centre

8 GB/IE

unless otherwise indicated in the operating instructions.

Damaged switches must be replaced at a

Customer Service Centre.

Never use an electrical power tool that cannot

be switched on and off properly.

21. CAUTION!

The use of inserted tools and accessories other

than those recommended by the manufacturer

could lead to you being injured.

22. Have your electrical power tool

repaired at an electrical equipment

repair specialist.

This electrical power tool complies with the

relevant safety regulations. Repairs may only

be carried out by a specialist electrical repair

centre using original spare parts, otherwise

injury could occur to the user.

Device-specific safety

instructions for drill

sharpeners

Make sure that the device is switched

off before inserting the mains plug

into the socket.

Always pull the mains plug out before

carry out cleaning or maintenance

work. This is to prevent the device starting up

by accident.

The ventilation openings

tor unit must always be kept clear.

Otherwise there is a risk of the device over

When carrying out work on the device

as well as transporting or storing it,

move the ON / OFF switch

“0” position (off) in order to prevent

it switching itself on by accident.

should always make sure that no-one is at risk

ON / OFF switch

FIRE HAZARD DUE TO FLYNG

SPARKS! Grinding metal will

cause sparks to fly. That is why you

from them and that no combustible materials

are located in the proximity of the area of work.

RISK OF INJURY! Use the

4

to switch the grinder off

in the event of a power failure or when pulling

10

of the mo-

4

to the

heating.

General safety advice / Use

out the mains plug. This prevents the grinder restar

ing by accident, which could cause injury to you.

Never operate the grinder if the power

cable or mains plug is damaged.

Grinding stones must be carefully

stored and handled according to the

manufacturer’s instructions.

Make sure that the grinding tools are

appropriate in line with the instructions

of the manufacturer.

Check the grinding stone before using

it; do not use any broken, cracked or otherwise

damaged goods.

Make sure that a grinding tool is correctly fitted and fastened before using it.

Place the grinder in a safe place and allow it

to run idly for 30 seconds. Stop it immediately if

considerable oscillations occur or if defects are

observed. If this occurs, check the machine to

find out the cause.

Original accessories /

Attachments

Use only the accessories and attachments

detailed in the operating instructions.

The use of inserted tools or accessories other

than those recommended in the operating instructions could lead to you suffering an injury.

t-

Turn the rotary switch 1 in the UP direction

until you hear a grinding noise.

NOTE: The rotary switch

controls the posi-

1

tion of the sharpening stone in the sharpening

head housing and therefore the pressure of the

sharpening stone against the drill. The further

you turn the rotary switch

in the UP di-

1

rection, the greater the pressure. Ensure that

you do not turn the sharpening stone too far up.

Otherwise the sharpening stone could strike

the housing.

Turn the drill under slight pressure loosely and

quickly to and fro between the left and right

stops about 10 times (with small drills about

5 times).

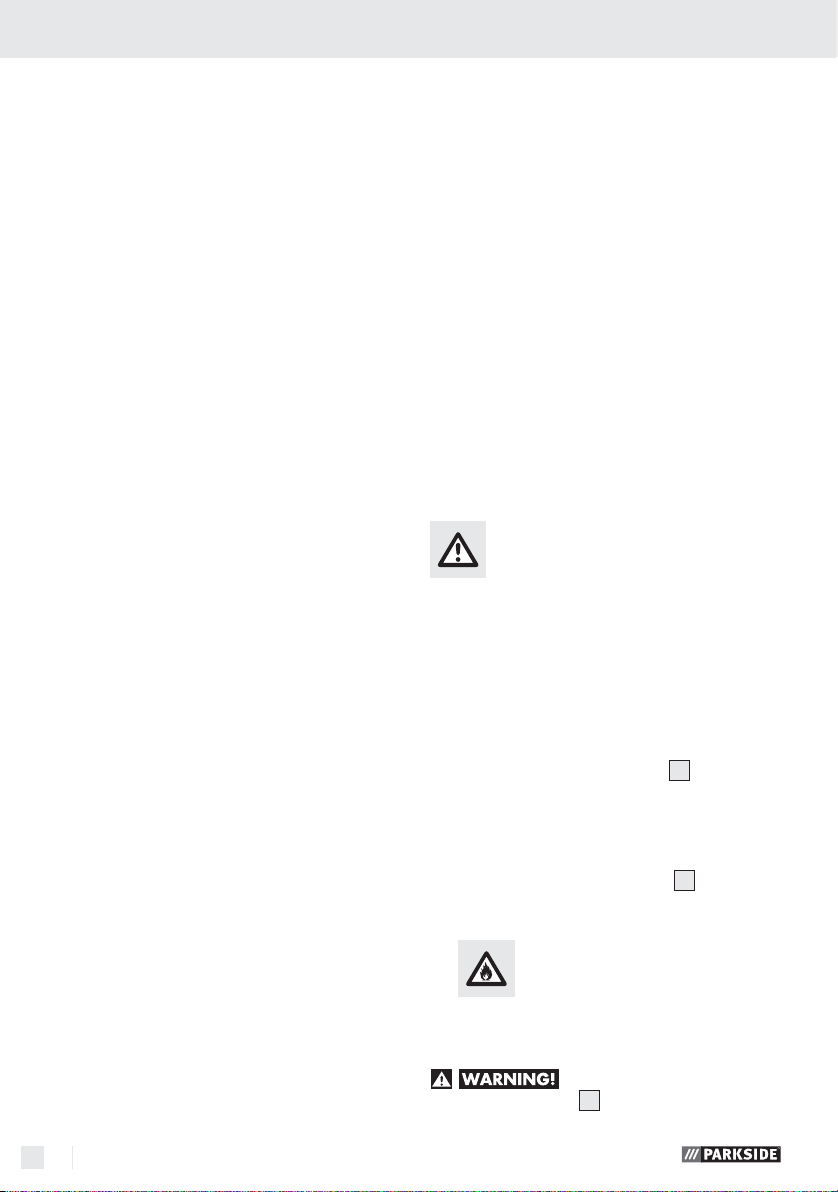

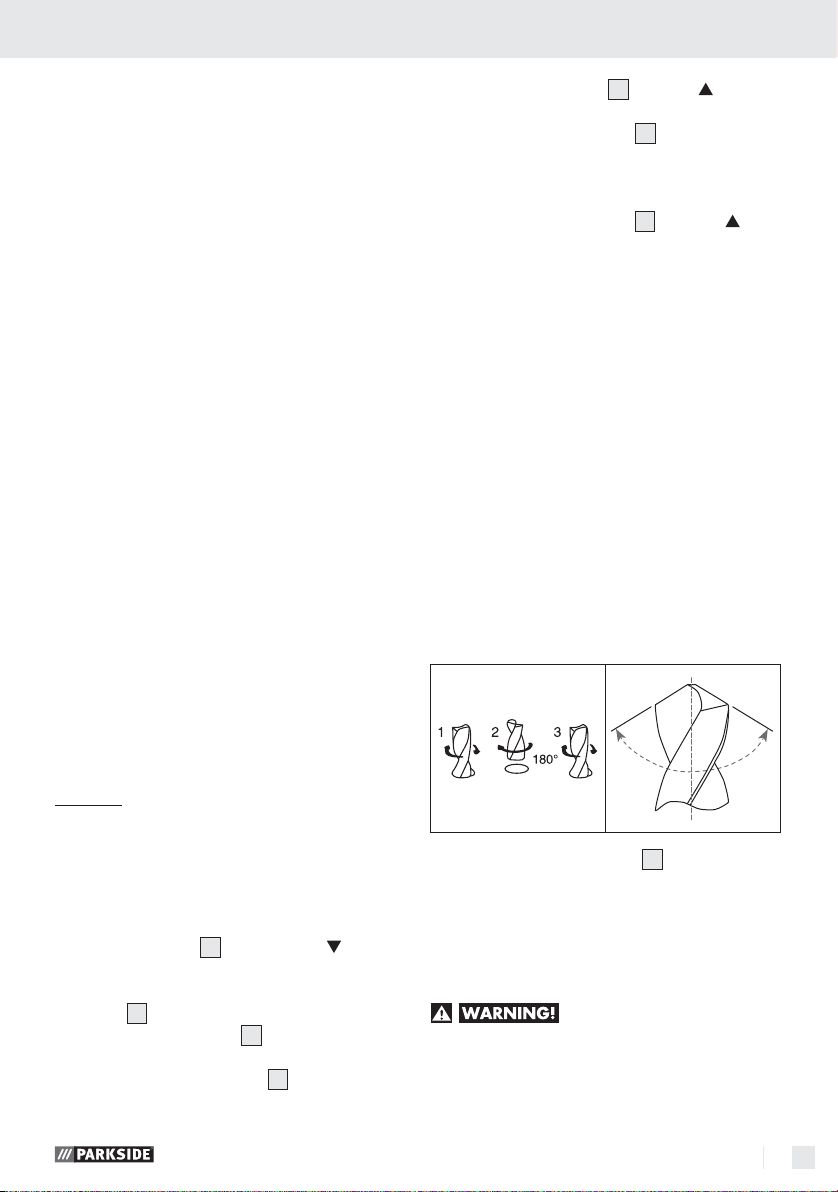

Pull the drill out, turn it through 180° (horizon

and insert it again until it meets the sharpening

stone.

If necessary repeat whole process until both

cutting edges of the drill are sharp. Control the

grinding operation so that the angle between

the main and transverse cutting edges for a

standard drill is 130°. Both cutting edges (b)

must have the same angle to the drill axis (a)

and be the same length so that the drill runs

concentrically (see following figures).

(a)

tally)

(b)(b)

Use

Sharpening a drill

NOTE: Badly damaged drills should first be coarsely

sharpened on a sharpening block.

Fully lower the sharpening stone. To do this turn

the rotary switch

in the DOWN direction

1

as far as it will go.

Insert the drill into the smallest suitable drill

guide

(Ø) of each drill guide

on the drill sharpener. The exact size

11

is shown by the ad-

11

jacent lettering (3 to 10).

Press the ON / OFF switch

into position “I”

4

to switch on the device.

Press the ON / OFF switch 4 into position “0”

to switch off the device.

Replacing the

sharpening stone

RISK OF INJURY! Before you

carry out any work on the device, always pull the

mains plug out of the mains socket. Replace the

sharpening stone if it is worn out or damaged

(deteriorating, irregular sharpening performance,

9 GB/IE

Use / Maintenance and cleaning / Service / Warranty

broken stone). A Phillips screwdriver is required for

this step.

Screw the four screws

head cover

and remove the cover 2, refer

2

out of the sharpening

3

to Fig. A.

Take out the sharpening stone

Clamp the sharpening stone

lease the threaded connection

the sharpening stone

stone holder

9

on to the sharpening

5

, using a 20 mm open spanner,

.

5

in a vice. Re-

5

, which holds

7

see Fig. B.

NOTE! LEFT-HAND THREAD - TO RELEASE

TURN IT CLOCKWISE!

Remove the metal washer

.

8

Mount the new sharpening stone, with its flat-

tened edge facing downwards, on to the

sharpening holder

washer

.

8

Clamp the sharpening stone

and tighten the threaded connection

and reinsert the metal

9

again in a vice

5

7

using

a 20 mm open spanner.

NOTE! LEFT-HAND THREAD - TO TIGHTE

N

TURN IT ANTICLOCKWISE!

Ensure that the spring

is inserted into the

6

device in accordance with Fig. D and insert the

sharpening stone back into the device. Turn the

sharpening stone until it goes precisely back

into place, as shown in Fig. A, otherwise the

sharpening stone cover

Place the sharpening stone cover

cannot be fitted.

2

back in

2

position and screw it in place with the four

screws

Maintenance and cleaning

.

3

Apart from replacing the sharpening stone, the drill

sharpener is maintenance-free.

Regularly clean the device straight after using it.

To clean the casing, use a dry cloth; on no

account should you use any petrol, solvents or

cleaning agents.

Never open the devices. Any

repairs or replacements should only be carried

out by the service centre or an electrician.

Service

Have your device repaired

at the service centre or by qualified

specialist personnel using original

manufacturer parts only. This will ensure

that your device remains safe to use.

If the plug or lead needs

to be replaced, always have the

replacement carried out by the manufacturer or its service centre. This will

ensure that your device remains safe to use.

Warranty

The warranty for this appliance is for 3

years from the date of purchase. The appliance has been manufactured with care

and meticulously examined before delivery. Please retain your receipt as proof

of purchase. In the event of a warranty

claim, please make contact by telephone

with our Service Department. Only in this

way can a post-free despatch for your

goods be assured.

The warranty covers only claims for material and

maufacturing defects, but not for transport damage,

for wearing parts or for damage to fragile components, e.g. buttons or batteries. This product is for private use only and is not intended for commercial use.

The warranty is void in the case of abusive and improper handling, use of force and internal tampering not carried out by our authorized service branch.

Your statutory rights are not restricted in any way

by this warranty.

The warranty period will not be extended by repairs

made unter warranty. This applies also to replaced

and repaired parts. Any damage and defects extant

on purchase must be reported immediately after

unpacking the appliance, at the latest, two days after

the purchase date. Repairs made after the expiration

of the warranty period are subject to payment.

10 GB/IE

Warranty / Disposal / Declaration of Conformity / Manufacturer

GB

Service Great Britain

Tel.: 0871 5000 720

(0,10 GBP / Min.)

e-mail: kompernass@lidl.gb

IAN 61094

IE

Service Ireland

Tel: 1890 930 034

(0,08 EUR / Min. (peak)

0,06 EUR / Min. (off peak))

e-mail: kompernass@lidl.ie

IAN 61094

Disposal

The packaging is wholly composed of

environmentally-friendly materials that

can be disposed of at a local recycling

centre.

Do not dispose of electrical

power tools with the household

rubbish!

Declaration of Conformity /

Manufacturer

We, Kompernaß GmbH, the person responsible for

documents: Mr Felix Becker, Burgstr. 21, D-44867

Bochum, Germany, hereby declare that this product

complies with the following standards, normative

documents and EU directives:

Machinery Directive

(2006 / 42 / EC)

EU Low Voltage Directive

(2006 / 95 / EC)

Electromagnetic Compatibility

(2004 / 108 / EC)

Applicable harmonized standards

EN 61029-1:2009

EN ISO 12100-2/A1:2009

EN 55014-1:2006

EN 55014-2/A2:2008

EN 61000-3-2:2006

EN 61000-3-3:2008

Type / Device description:

Drill sharpener PBSG 55 A1

In accordance with European Directive 2002 / 96 / E

(covering waste electrical and electronic equipment)

and its transposition into national legislation, worn

out electrical power tools must be collected separately

and taken for environmentally compatible recycling.

Contact your local refuse disposal authority for

more details of how to dispose of your worn out

electrical devices.

Date of manufacture (DOM): 03 - 2011

C

Serial number: IAN 61094

Bochum, 31.03.2011

Hans Kompernaß

- Managing Director -

We reserve the right to make technical modifications in the course of further development.

11 GB/IE

12

Sisällysluettelo

Aluksi

Ohjeidenmukainen käyttö .............................................................................................Sivu 14

Osien kuvaus .................................................................................................................. Sivu 14

Toimitukseen kuuluu ....................................................................................................... Sivu 14

Tekniset tiedot .................................................................................................................Sivu 14

Yleiset turvallisuusohjeet

Turvallinen työskentely ................................................................................................... Sivu 15

Poranterien teroituslaitteiden laitekohtaiset turvallisuusohjeet ..................................... Sivu 16

Alkuperäisvarusteet ja -varaosat ...................................................................................Sivu 17

Käyttöönotto

Poranterän hionta ........................................................................................................... Sivu 17

Hiomalaikan vaihto ........................................................................................................Sivu 17

Huolto ja puhdistus ............................................................................................Sivu 18

Huolto............................................................................................................................Sivu 18

Takuu ............................................................................................................................. Sivu 18

Hävittäminen .......................................................................................................... Sivu 18

Vaatimustenmukaisuusvakuutus / Valmistaja ...........................Sivu 19

13 FI

Yleistä

Tässä käyttöohjeessa / laitteessa käytetään seuraavia kuvakkeita:

Lue käyttöohje! Palonvaara!

Käytä aina laitteella työskennellessäsi

Huomioi varoitus- ja turvaohjeet!

Varo sähköiskua!

Hengenvaara!

suojalaseja, kuulo- ja hengityssuojaimia

sekä asianmukaisia työkäsineitä.

Viallisen verkkojohdon tai pistokkeen

käyttöön liittyvän sähköiskun aiheuttama hengenvaara!

V

W

Voltti (Vaihtojännite) Räjähdysvaara!

~

Watti (vaikutusteho) Pidä lapset loitolla sähkötyökalusta!

Suojausluokka II

Poranterien teroituslaite

PBSG 55 A1

Aluksi

Tutustu ennen käyttöönottoa laitteeseen,

sen käyttöohjeisiin ja sähkölaitteita kos-

keviin yleisiin turvallisuusohjeisiin. Lue

tämä käyttöopas huolella. Säilytä käyttöopas huolellisesti. Saatat myöhemmin tarvita sen tietoja. Jos

luovut laitteesta, anna uudelle omistajalle myös

kaikki laitteen asiakirjat.

Ohjeidenmukainen käyttö

Laite on tarkoitettu DIN 338, DIN 340, DIN 345,

DIN 1869 ja DIN 1897 (versio tyyppi N) mukaisten

teräksisten poranterien teroitukseen. Kovametelliporanteriä ei saa hioa. Laitteen ohjeidenvastainen käyttö,

samoin kuin muuntelu, saattaa kasvattaa tapaturmien

riskiä. Valmistaja ei vastaa ohjeidenvastaisesta

käytöstä aiheutuneista vahingoista. Laitetta ei ole

tarkoitettu ammattikäyttöön.

Hävitä pakkaus ja laite

ympäristöystävällisesti!

Osien kuvaus

Vääntökytkin („STONE“ = hiomalaikka)

1

Hiomalaikan suojus

2

Hiomalaikan suojuksen ruuvi

3

PÄÄLLE- / POIS-kytkin

4

Hiomalaikka

5

Jousi

6

Ruuviliitos

7

Metallirengas

8

Hiomalaikan pidike

9

Tuuletusrako

10

Poranohjaus

11

Toimitukseen kuuluu

1 poranterien teroituslaite PBSG 55 A1

1 kantolaukku

16 titaanipinnoitettua HSS-poranterää (katso kuva E)

2 varahiomakiveä

1 käyttöohje

Tekniset tiedot

14 FI

Nimellisjännite: 230 V~ 50 Hz

Nimellisteho: 55 W

Loading...

Loading...