Panasonic NN-ST658W, NN-SD698S, NN-ST678S User Manual

ORDER NO.PHAMOS0801002C3

E1

Microwave Oven

NN-SD698S

NN-ST678S

NN-ST658W

RPH (LATIN AMERICA)

RUH (MEXICO)

© 2008 Panasonic Home Appliances Microwave Oven (Shanghai) Co., Ltd. All rights reserved. Unauthorized copying and distribution is a violation of law.

NN-SD698S / NN-ST678S / NN-ST658W

2

NN-SD698S / NN-ST678S / NN-ST658W

3

NN-SD698S / NN-ST678S / NN-ST658W

CONTENTS

|

Page |

Page |

|

1 SCHEMATIC DIAGRAM |

5 |

5.5. Inverter power supply (U) |

15 |

2 DESCRIPTION OF OPERATING SEQUENCE |

6 |

5.6. Temperature thermistor |

15 |

2.1. Variable power cooking control |

6 |

6 MEASUREMENTS AND ADJUSTMENTS |

16 |

2.2. Inverter power supply circuit |

6 |

6.1. Adjustment of primary latch switch, secondary latch switch |

|

2.3. Inverter defrost |

6 |

and monitor interlock switch. |

16 |

2.4. Sensor cooking |

6 |

6.2. Measurement of microwave output |

16 |

2.5. Sensor reheat |

7 |

7 PROCEDURE FOR MEASURING MICROWAVE ENERGY |

|

2.6. Steam sensor and digital programmer circuit |

7 |

LEAKAGE |

17 |

2.7. Thermistor |

7 |

7.1. Equipment |

17 |

3 CAUTIONS TO BE OBSERVED WHEN TROUBLESHOOTING 8 |

7.2. Procedure for measuring radiation leakage |

17 |

|

3.1. Check the grounding |

8 |

7.3. Record keeping and notification after measurement |

17 |

3.2. Inverter warnings |

8 |

7.4. At least once a year, have the radiation monitor checked |

|

3.3. Part replacement. |

9 |

for calibration by its manufacturer. |

18 |

3.4. When the 20A fuse is blown due to the malfunction of the |

8 TROUBLESHOOTING GUIDE |

19 |

|

monitor interlock switch: |

9 |

8.1. (Troubleshooting) Oven stops operation during cooking |

19 |

3.5. Avoid inserting nails, wire etc. through any holes in the |

8.2. (Troubleshooting) Other problems |

20 |

|

unit during operation. |

9 |

8.3. Troubleshooting of inverter circuit (U) and magnetron |

21 |

3.6. Verification after repair |

9 |

8.4. SIMPLE WAY OF H.V. INVERTER/MAGNETRON |

|

3.7. Sharp edges |

9 |

TROUBLESHOOTING |

22 |

4 DISASSEMBLY AND PARTS REPLACEMENT PROCEDURE 10 |

8.5. H.V.INVERTER BOARD MAIN PARTS LIST |

|

|

4.1. Magnetron |

10 |

(F606Y8M00AP) |

22 |

4.2. Digital programmer circuit (D.P.C) |

10 |

8.6. How to check the semiconductors using an OHM meter 23 |

|

4.3. Low voltage transformer and/or power relays (RY1, RY2) |

9 EXPLODED VIEW AND PARTS LIST |

24 |

|

|

11 |

9.1. EXPLODED VIEW |

24 |

4.4. Fan motor |

11 |

9.2. PARTS LIST |

25 |

4.5. Door assembly |

11 |

9.3. WIRING MATERIALS |

27 |

4.6. Turntable motor |

12 |

9.4. DOOR ASSEMBLY |

28 |

4.7. Steam sensor |

12 |

9.5. ESCUTCHEON BASE ASSEMBLY |

29 |

4.8. Inverter power supply |

13 |

9.6. PACKING AND ACCESSORIES |

32 |

5 COMPONENT TEST PROCEDURE |

14 |

10 DIGITAL PROGRAMMER CIRCUIT |

33 |

5.1. Primary, Secondary Latch Switch interlocks & Power |

|

10.1. NN-SD698S |

33 |

Relay RY1 |

14 |

10.2. NN-ST678S |

35 |

5.2. Monitor Interlock Switch |

14 |

10.3. NN-ST658W |

37 |

5.3. Magnetron |

14 |

10.4. PARTS LIST |

39 |

5.4. key board membrane (Membrane switch assembly) |

14 |

|

|

4

NN-SD698S / NN-ST678S / NN-ST658W

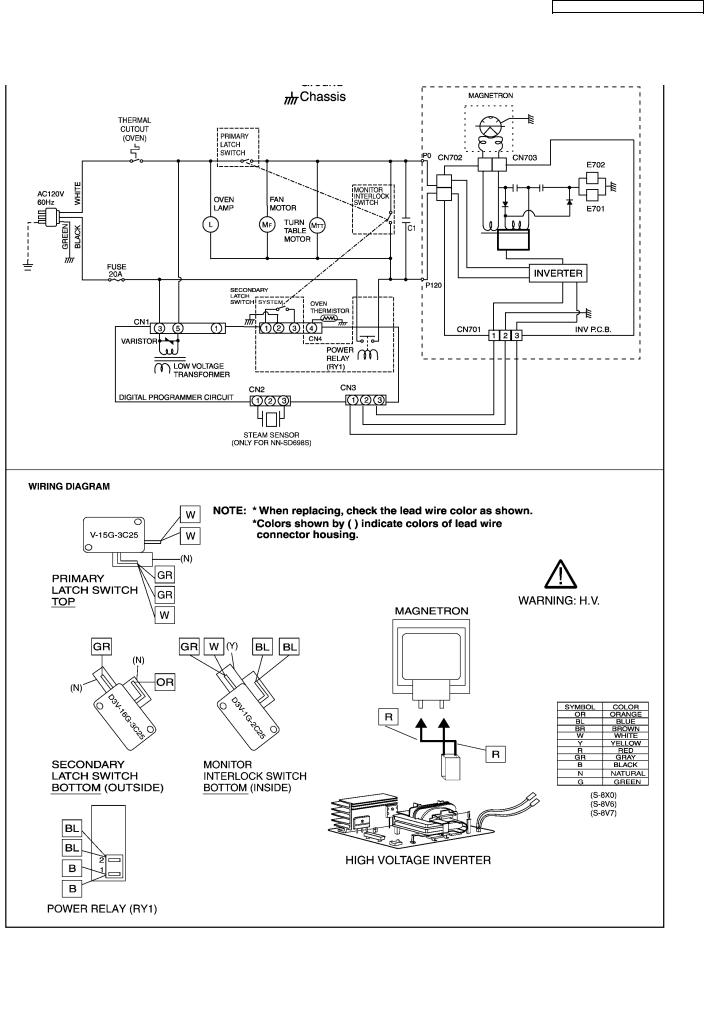

1 SCHEMATIC DIAGRAM

5

NN-SD698S / NN-ST678S / NN-ST658W

2 DESCRIPTION OF OPERATING SEQUENCE

2.1.Variable power cooking control

High Voltage Inverter Power Supply (U) controls output power by the signal from Digital Programmer Circuit (DPC). Power relay always stay on, but PWM (Pulse Width Modulation) signal controls microwave output power.

NOTE:

The ON/OFF time ratio does not correspond with the percentage of microwave power since approximately 2 seconds are required for heating of magnetron filament.

Variable Power Cooking

POWER SETTING |

OUTPUT |

MANUAL MICROWAVE |

||

|

|

POWER(%) |

DUTY |

|

|

|

APPROX. |

ON(SEC) |

OFF(SEC) |

HIGH |

P10 |

100% |

22 |

0 |

|

P9 |

90% |

22 |

0 |

|

P8 |

80% |

22 |

0 |

MEDIUM-HIGH |

P7 |

70% |

22 |

0 |

MEDIUM |

P6 |

60% |

22 |

0 |

|

P5 |

50% |

22 |

0 |

|

P4 |

40% |

22 |

0 |

MEDIUM-LOW |

P3 |

30% |

22 |

0 |

|

P2 |

20% |

15 |

7 |

|

P1 |

10% |

8 |

14 |

DEFROST |

P3 |

30% |

22 |

0 |

2.2.Inverter power supply circuit

The Inverter Power Supply circuit powered from the line voltage, 120V 60Hz AC input supplies 4,000V DC to the magnetron tube, and functions in place ofthe H.V. transformer, the H.V. capacitor and H.V. diode.

1.The AC input voltage 120V 60Hz is rectified to DC voltage immediately.

2.DC voltage will be supplied to the switching devices called IGBT. These devices are switched ON-OFF by the 20 to 40 kHz PWM (pulse width modulation) signal from the microcomputer in the DPC.

3.This drives the High voltage transformer to increase voltage up to 2,000V AC.

4.Then the half-wave doubler voltage rectifier circuit, consisting of the H.V. diodes and capacitors, generates the necessary 4,000V DC needed for the magnetron.

5.Output power of the magnetron tube is always monitored by the signal output from the current transformer built into the inverter circuit.

6.This signal is fed back to the microcomputer in the DPC to determine operating conditions and output necessary to control PWM signal to the Inverter Power Supply for control of the output power.

2.3.Inverter defrost

When the Auto Control feature is selected and the Start pad is tapped:

1.The digital programer circuit determines the power level and cooking time to complete cooking and indicates the operating state in the display window. Table shows the corresponding cooking times for respective serving by categories.

Inverter Turbo Defrost

SELECTED WEIGHT |

COOKING TIME |

1.0 LB |

5 min.00 sec. |

2.When cooking time in the display window has elapsed, the oven turns off automatically by a control signal from the digital programmer circuit.

2.4.Sensor cooking

Auto sensor cooking without setting a power level or selecting a time. All that is necessary is to select an Auto Sensor Program before starting to cook.

Understanding Auto Sensor Cooking

As the food cooks, a certain amount of steam is produced. If the food is covered, this steam builds up and eventually escapes from the container. In Auto Sensor Cooking, a carefully designed instrument, called the steam sensor element, senses this escape of steam. Then, based upon the Auto Sensor Program selected, the unit will automatically determine the correct power level and the proper length of time it will take to cook the food.

NOTE:

Auto Sensor Cooking is successful with the foods and recipes found in the Auto Sensor Cooking Guide. Because of the vast differences in food composition, items not mentioned in the Cooking Guide should be prepared in the microwave oven using power select and time features. Please consult Variable Power Microwave Cookbook for procedures.

6

Explanation of the Auto Sensor Cooking process

1.During the first 10 second period there is no microwave activity. When calculating the T2 time by using the formula below make sure this 10 seconds is subtracted from the T1 time. In other words, T1 time starts at the end of the 10 second period.

2.T1 time The total amount of time it takes themicrowave oven to switch to T2 time after the 10second period.

3.T2 time When the steam escapes from the cooking container placed in the oven, the steam sensor detects it and the microprocessor calculates the balance of cooking time. This T2 time is then shown in the display and begins counting down.

Balance of cooking time (T2 time)

The balance of cooking time which is called T2time, can be calculated by the following formula.

T2 time (in sec.) = T1 time X K factor

NOTE:

Remember, the T1 time starts after the 10 second period. The coefficient K is programmed into the microprocessor memory and they are listed in the following tables along with the P1 and P2 powers.

NOTE:

When "More" or "Less" pad is selected, the K factor varies resulting in T2 time to be increased or decreased.

Example of calculating the T2 time

Example 1: If the T1 time is measured to be 2 minutes and 40 seconds after the 10 second period, and the Auto program selected is Oatmeal:

T2 = T1 × K

=2 min. and 40 sec. × 0.1

=160sec. × 0.1

=16 sec.

Category |

P1 |

P2 |

K Factor |

|

Power |

Power |

Standard |

Oatmeal |

HIGH |

HIGH |

0.1 |

NN-SD698S / NN-ST678S / NN-ST658W

2.5.Sensor reheat

Auto Sensor Reheat is a quick and easy way to reheat refrigerated and room temperature foods.

Simply press the reheat pad. There is no need to select power level and cooking time.

NOTE:

The Auto Sensor Reheat process is same as Auto Sensor Cooking process.

Category |

P1 |

P2 |

K Factor |

|

Power |

Power |

Standard |

Sensor Reheat |

HIGH |

MEDIUM |

0.3 |

2.6.Steam sensor and digital programmer circuit

In order to determine if the steam sensor function of the digital programmer circuit is working, do the following test.

1.Place a water load (150 cc) in the oven.

2.Tap Sensor Reheat pad.

3.Tap Start pad.

4.Steam Sensor detects steam about 1.5 to 4 minutes after the Start pad is tapped.

5.T1 time cooking automatically switches to remaining time for cooking (T2).

6.The remaining cooking time (T2) appears in display window. If the following cooking time appears, Steam Sensor function is normal.

T1 TIME |

T2 TIME (Remainingcooking time) |

1 Min. 30 Sec. ~ 4 Min. |

27 Sec. ~ 1Min.12 Sec. |

2.7.Thermistor

The thermistor which fixed on magnetron detects magnetron temperature and make power down when the temperature becomes abnormal high. A normal thermistor´s resistance values for temperature ranges between 75-85 degree F is from 37kΩ to 57kΩ.

7

NN-SD698S / NN-ST678S / NN-ST658W

3CAUTIONS TO BE OBSERVED WHEN TROUBLESHOOTING

Unlike many other appliances, the microwave oven is a high voltage, high current device. It is free from danger in ordinary use, though extreme care should be taken during repair.

CAUTION

CAUTION

Servicemen should remove their watches and rings whenever working close to or replacing the magnetron.

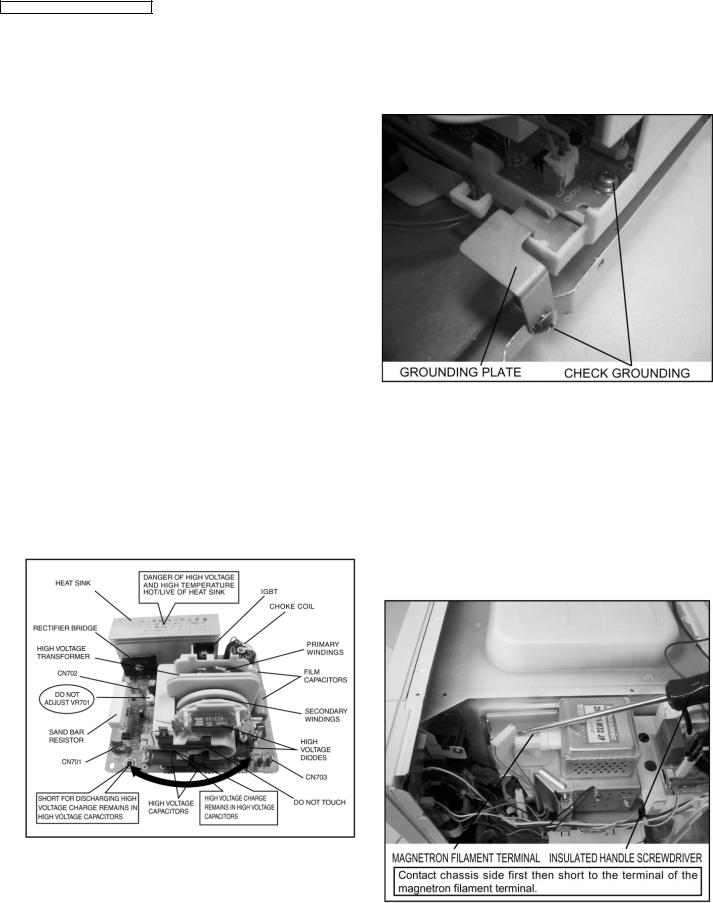

3.1.Check the grounding

Do not operate on a two wire extension cord. The microwave oven is designed to be grounded when used. It is imperative, therefore, to ensure the appliance is properly grounded before beginning repair work.

3.2.Inverter warnings

WARNING HIGH VOLTAGE AND HIGHTEMPERATURE (HOT/LIVE) OF THE INVERTERPOWER SUPPLY (U)

WARNING HIGH VOLTAGE AND HIGHTEMPERATURE (HOT/LIVE) OF THE INVERTERPOWER SUPPLY (U)

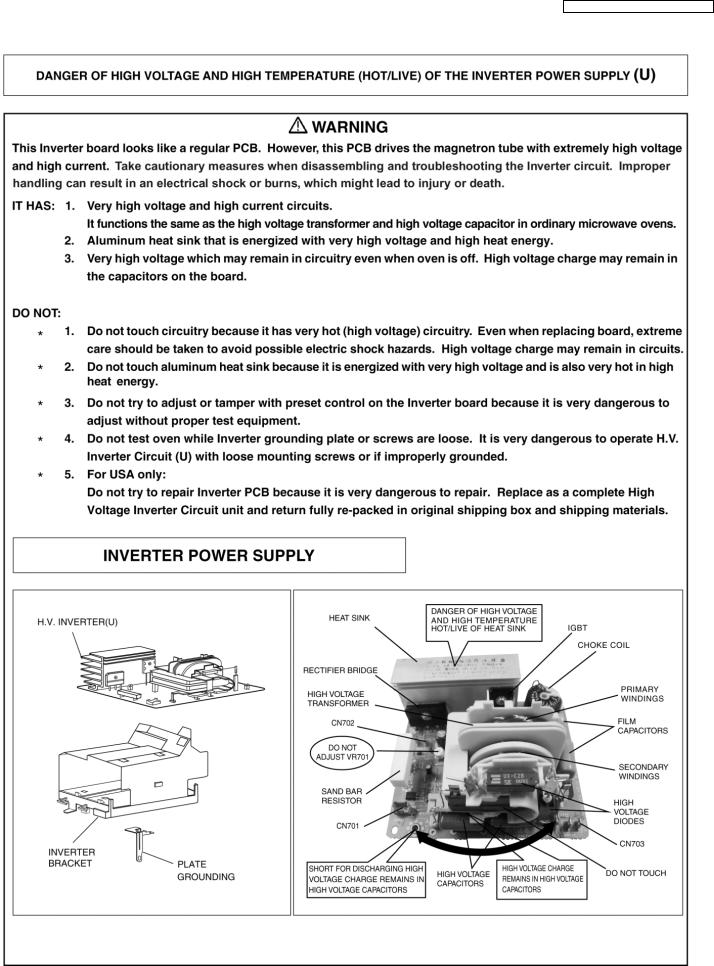

The High Voltage Inverter Power Supply generates very high voltage and current for the magnetron tube. Though it is free from danger in ordinary use, extreme care should be taken during repair.

The aluminum heat sink is also energized with high voltage (HOT), do not touch when the AC input terminals are energized. The power device Collector is directly connected to the aluminum heat sink.

The aluminum heat sink may be HOT due to heat energy, therefore, extreme care should be taken during servicing.

H.V. Inverter warning

WARNING FOR INVERTER POWER SUPPLY (U) GROUNDING

WARNING FOR INVERTER POWER SUPPLY (U) GROUNDING

Check the High Voltage Inverter Power Supply circuit grounding. The high voltage inverter power supply circuit board must have a proper chassis ground. The inverter grounding plate must be connected to the chassis. If the inverter board is not grounded it will expose the user to very high voltages and cause extreme DANGER! Be sure that the inverter circuit is properly grounded via the inverter grounding plate.

Grounding of the inverter circuit board

WARNING DISCHARGE THE HIGH VOLATGE CAPACITORS

WARNING DISCHARGE THE HIGH VOLATGE CAPACITORS

For about 30 seconds after the oven is turned off, an electric charge remains in the high voltage capacitors of the Inverter Power Supply circuit board.

When replacing or checking parts, remove the power plug from the outlet and short the inverter output terminal of the magnetron filament terminals to the chassis ground with an insulated handle screwdriver to discharge. Please be sure to contact the chassis ground side first and then short to the output terminal.

8

Discharging the high voltage capacitors  WARNING

WARNING

There is high voltage present with high current capabilities in the circuits of the primary and secondary windings, choke coil and heat sinkof the inverter. It is extremely dangerous to work on or near these circuits with the oven energized. DO NOT measure the voltage in the high voltage circuit including the filament voltage of the magnetron.

WARNING

WARNING

Never touch any circuit wiring with your hand or with an insulated tool during operation.

3.3.Part replacement.

When troubleshooting any part or component is to be replaced, always ensure that the power cord is unplugged from the wall outlet.

3.4.When the 20A fuse is blown due to the malfunction of the monitor interlock switch:

WARNING

WARNING

When the 20A 120V fuse is blown due to the malfunction of the monitor interlock switch, replace all of the components (primary latch switch, monitor interlock switch and power relay RY1).

1.This is mandatory. Refer to “measurements and adjustments” for the location of these switches.

2.When replacing the fuse, confirm that it has the appropriate rating for these models.

3.When replacing faulty switches, be sure the mounting tabs are not bent, broken or deficient in their ability to hold the switches.

3.5.Avoid inserting nails, wire etc. through any holes in the unit during operation.

Never insert a wire, nail or any other metal object through the lamp holes on the cavity or any holes or gaps, because such objects may work as an antenna and cause microwave leakage.

NN-SD698S / NN-ST678S / NN-ST658W

3.6.Verification after repair

1.After repair or replacement of parts, make sure that the screws of the oven, etc. are neither loosen or missing. Microwave energy might leak if screws are not properly tightened.

2.Make sure that all electrical connections are tight before inserting the plug into the wall outlet.

3.Check for microwave energy leakage. (Refer to procedure for measuring microwave energy leakage).

CAUTION OF MICROWAVE RADIATION LEAKAGE

USE CAUTION NOT TO BECOME EXPOSED TO RADIATION FROM THE MICROWAVE MAGNETRON OR OTHER PARTS CONDUCTING MICROWAVE ENERGY.

IMPORTANT NOTICE

1.The following components have potentials above 2000V while the appliance is operated.

•Magnetron

•High voltage transformer (Located on inverter (U))

•High voltage diodes (Located on inverter (U))

•High voltage capacitors (Located on inverter (U)) Pay special attention to these areas.

2.When the appliance is operated with the door hinges or

magnetron installed incorrectly, the microwave leakage can exceed more than 5mW/cm2. After repair or exchange, it is very important to check if the magnetron and the door hinges are correctly installed.

3.7.Sharp edges

CAUTION

CAUTION

Please use caution when disassembling or reassembling internal parts. Some exposed edges may be sharp to the touch and can cause injury if not handled with care.

9

NN-SD698S / NN-ST678S / NN-ST658W

4DISASSEMBLY AND PARTS REPLACEMENT PROCEDURE

4.1.Magnetron

1.Discharge high voltage charge.

2.Remove 1 screw holding air guide A on the oven cavity.

3.Remove 1 screw holding air guide A on the magnetron.

4.Remove 1 screw holding air guide B.

5.Remove 1 screw holding themistor.

6.Disconnect 2 high voltage lead wires from magnetron filament terminals.

7.Remove 4 screws holding the magnetron.

NOTE:

After replacement of the magnetron, tighten mounting screws properly in an x pattern, making sure there is no gap between the waveguide and the magnetron to prevent microwave leakage.

CAUTION

When replacing the magnetron, be sure the antenna gasket is in place.

4.2.Digital programmer circuit (D.P.C)

CAUTION:

CAUTION:

Be sure to ground any static electric charge built up in your body before handling the DPC.

1.Disconnect all connectors from D.P.C.

2.Remove 1 grounding screw.

3.Remove 1 screw holding escutcheon base and slide the escutcheon base upward slightly.

4.Remove all screws holding D.P.C. board on escutcheon base.

5.Separate D.P.C board from tabs on the escutcheon base and remove D.P.C board.

To replace membrane key board

6.Use tools such as kinfe etc. to lift the edge of escutcheon sheet and peel off escutcheon sheet & key board membrane completely from escutcheon base.

NOTE:

1.The membrane key board is attached to the escutcheon base with double faced adhesive tape. Therefore, applying hot air such as using a hair dryer is recommended for smoother removal.

2.When installing the new key board membrane, make sure that the surface of escutcheon base is clean to prevent a malfunction or shorted contacts.

10

4.3.Low voltage transformer and/or power relays (RY1, RY2)

CAUTION:

CAUTION:

Be sure to ground any static electric charge built up in your body before handling the DPC.

1.Replace D.P.C. board.

(A)Using solder wick or a desoldering tool and 30W soldering iron carefully remove all solder from the terminal pins of the low voltage transformer and/or power relays.

CAUTION:

CAUTION:

Do not use a soldering iron or desoldering tool of more than 30 watts on D.P.C. contacts.

(B) With all the terminal pins cleaned and separated from D.P.C. contacts, remove the defective transformer/power relays, Replace components making sure all terminal pins are inserted completely resolder all terminal contacts carefully.

4.4.Fan motor

1.Disconnect 2 lead wires from fan motor terminals.

2.Remove 2 screws at location on oven attaching orifice assembly.

3.Remove orifice assembly from oven assembly.

4.Remove fan blade from the fan motor shaft by pulling it straight out.

5.Remove 2 screws holding fan motor to orifice.

NN-SD698S / NN-ST678S / NN-ST658W

4.5.Door assembly

1.Remove door C from door E by carefully pulling outward, starting from upper right hand corner using a flat blade screwdriver.

2.Separate door E from tabs on door A and remove door A.

3.Open Door E at the opening angle of approximately

10°(Note: The door cannot be removed if the opening angle is greater than 10°).

4.Remove the door E from its hinges by pushing the door E upward and out.

5.Remove door screen B from door A.

6.Remove door key and door key spring.

7.Replace other components.

To re-install components:

1.Place the door’s lower hinge pin into the bottom hinge hole.

2.Use your left index finger to support the door’s lower hinge pin while guiding the door’s upper hinge pin into the top hinge hole.

3.Lower your finger to seat the door onto the hinges.

NOTE:

Adjust so that the upper portion of the door will touch firmly to the oven cavity front plate, without pushing the door. If the door assembly is not mounted properly, microwave power may leak from the clearance between the door and oven.

NOTE:

Always perform the microwave leakage measurement test after installation and adjustment of door assembly.

11

NN-SD698S / NN-ST678S / NN-ST658W

4.6.Turntable motor

1.Remove the motor cover by breaking off at the 8 spots indicated by arrows with a cutter or the like.

NOTE:

NOTE:

After removing the motor cover, be sure that cut portions are properly trimmed or bent to the inside so that no sharp edges will be exposed to outside.

2.Disconnect 2 lead wires connected to the turntable motor.

3.Remove the turntable motor by removing screw.

NOTE:

NOTE:

After reinstalling the new turntable motor and reconnecting the 2 lead wires, reinstall the motor cover by rotating it around 180, tucking the 2 tabs under the base in the 2 provided slots, then screw the single tab to the base using a 4mm × 6mm screw.

4.7.Steam sensor

1.Disconnect connector CN2 from digital programmer circuit board.

2.Disengage catch hooks on sensor cover C from orifice.

3.Remove steam sensor from orifice.

NOTE:

NOTE:

When installing the steam sensor, make sure that the direction of steam sensor is as shown in figure.

12

Loading...

Loading...