PACE MBT 250, MBT 220 User manual

1

For any questions regarding the following instructions, contact your local authorized

P ACE dealer or contact P ACE directly at:

Telephone (301) 490-9860, Fax (301) 604-9215

PACE Incorporated

9893 Brewers Court

Laurel MD 20723-1990

MBT 250/220 CALIBRATION KIT

PACE P/N 6993-0133

OPERATION & MAINTENANCE

INSTRUCTIONS

MANUAL NUMBER 5050-0288

REV . A

2

PACE Incorporated retains the right to make changes to specifications contained

herein at any time, without notice.

Contact your local authorized P ACE Distributor or PACE Incorporated to obtain the

latest specifications.

The following are registered trademarks and/or servicemarks of P ACE Incorporated,

Laurel Maryland U.S.A. and may only be used to identify genuine P ACE products or

services:

Cir-Kit, ComForm I, ConducT weez, CRAFT , Dual Path, Flo-D-Sodr, FuseSet,

HotSpot, LapFlo, MBT , MicroChine , Micro Portable, MiniChine, P acenter,

P A CE, P ed-A-V ac, PETS, PRC , PRINT, ResisTweez, SensaTemp, SMR,

Sodr-X-Tractor, StripTweez, SwaPlater, ThermoBand, ThermoPart,

ThermoPik, ThermoJet, ThermoTweez, Thermo-Drive, VisiFilter.

The following are trademarks and/or servicemarks of P ACE Incorporated, Laurel

Maryland U.S.A. and may only be used to identify genuine PACE products or

services:

AdapTip, Arm-Evac, DEXITEST, EK O, HandiPik,PIK-VAC, Pro-Evac,

Redi-Rak, SNAP-V AC , SR-3, SR-4, ST, Tip-Evac.

P ACE Incorporated has provided training on all of its products since 1958 as well as

from:

P ACE Incorporated (301) 490 - 9860

Sales Administration (301) 4983252 Fax

9893 Brewers Court

Laurel MD 20723-1990

©1992 PACE Incorporated, Laurel MD. All rights reserved. Printed in the U.S.A.

advanced technology training in all aspects of hand soldering, rework and

repair.

Additional copies of this manual or other P ACE literature may be obtained

3

INTRODUCTION

The following procedure will allow you to effectively calibrate your MBT 250/220

system to insure accuracy and maintain peak performance.

Perform the following procedure step by step, in sequence, to:

1 . Alter Tip T emperature values.

2 . Alter Tip T emperature Offset values.

3. Determine and/or alter feature status and defaults stored in the system.

4 . Recalibrate the system for accuracy .

PROCEDURE

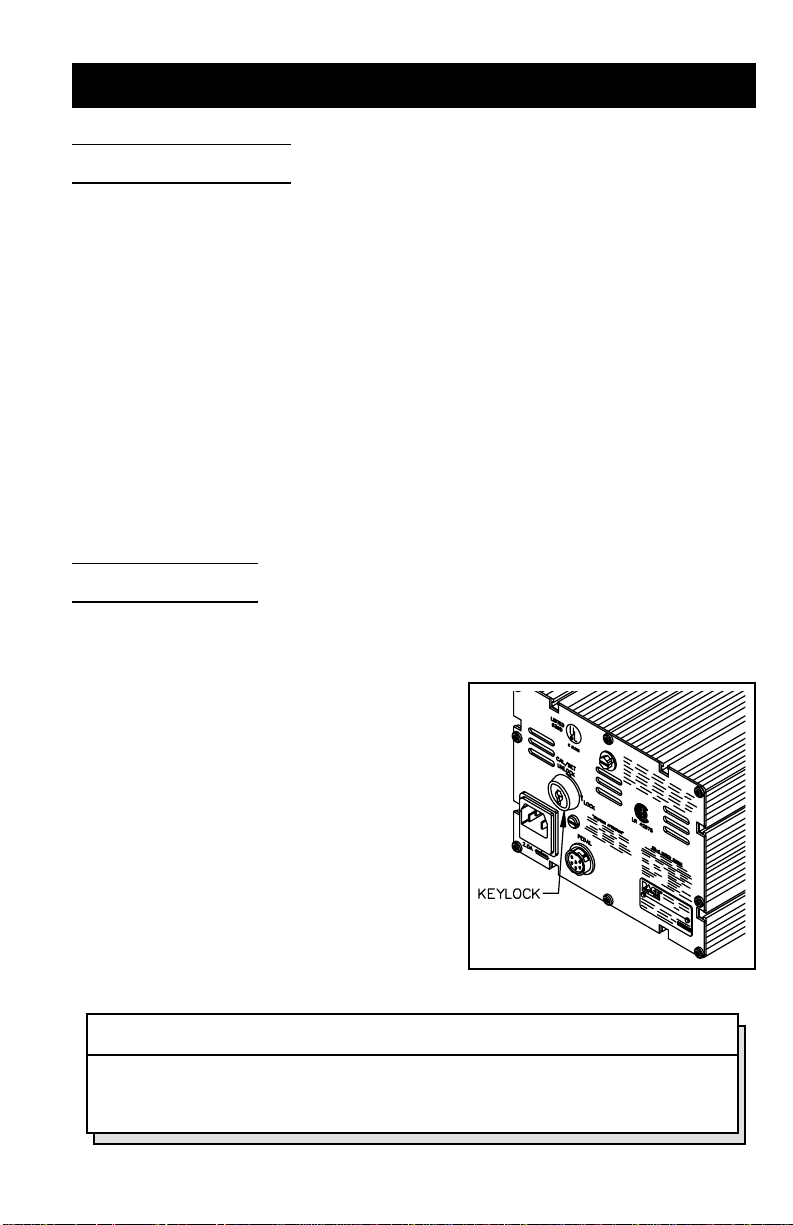

KEYLOCK OPTION

1 . An optional KeyLock feature is available

from P ACE which prevents unauthorized

alteration of stored data or calibration of

the system. Check the rear panel of the

system power source. If the KeyLock

feature is present there will be a KeyLock

switch located in the upper left portion of

the panel. Use the key to turn the switch

to the “Unlock” position. If the feature is

not present, there will be a round plastic

filler plug present at that location.

NOTE

The KeyLoc k switch must be turned to the “UNLOCK” position to alter any

of the data stored in memory or to recalibrate the system.

ENTERING CALIBRATION MODE

4

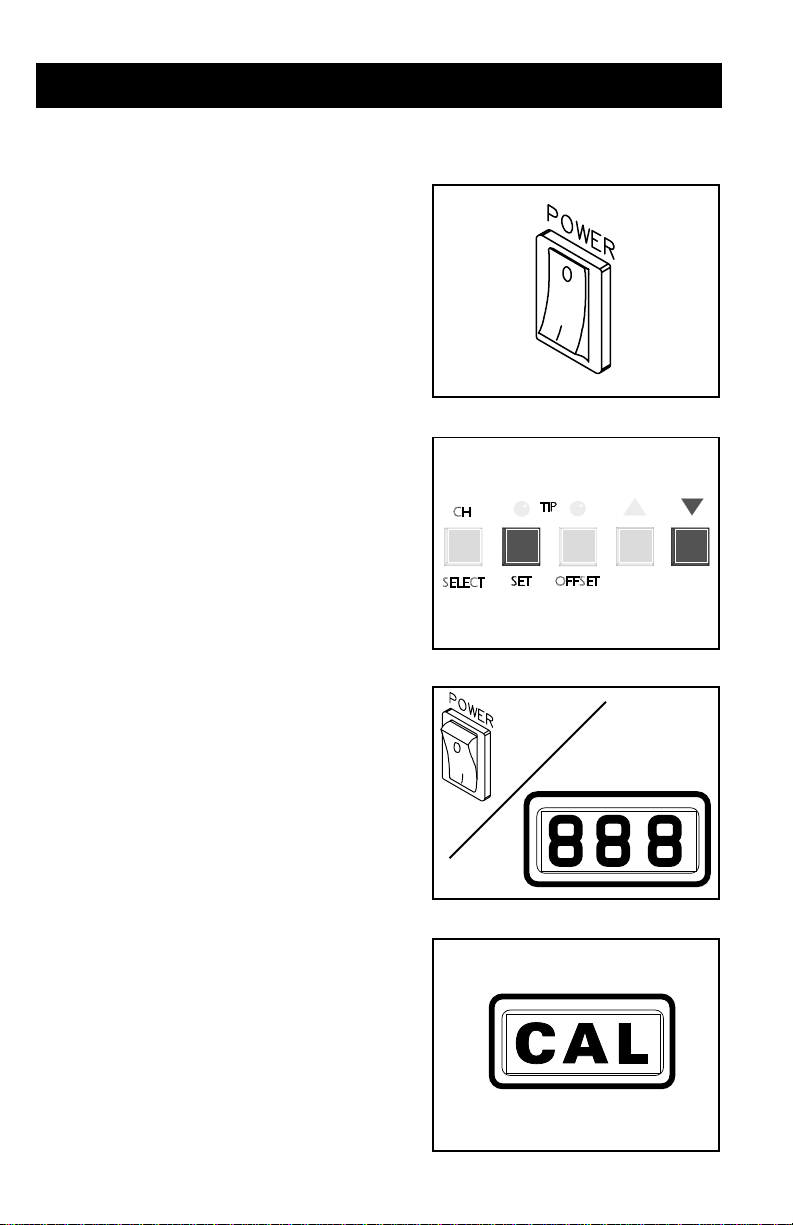

2. Place POWER Switch in the “OFF” (0)

position.

3. Press and hold the Tip Temperature Set

and Scroll Down Keys.

4. Place POWER Switch in the “ON” (1)

position. All of the system LEDs will light.

The T emperature Display will read “888”

and change to read “1-X”.

5 . Release the Tip T emperature Set and Scroll

Down Keys. The T emperature Display will

now read “CAL” and only the three

Channel LEDs will remain lit signifying

that the system is now in the Calibration

Mode.

°F/°C READOUT DEFAULT

6. Press and release the Tip Temperature Set

Loading...

Loading...