Pace MBT250 Service Manual

1

MANUAL

OPERATION &

MAINTENANCE

MBT 250 SYSTEMS

Use of this manual

The information contained in this manual will provide the user with the knowledge necessary to

properly operate and maintain the PACE MBT 250 systems. When using your new system in

standard soldering/desoldering operations, you can begin operation quickly by performing the

"Set-Up" and "Quick Start - Basic Operation" procedures detailed on pages 13-19 of this manual.

To fully utilize the features of the system, PACE Strongly recommends that the user read and fully

understand the "Operation" and "Calibration" portions of this manual. The use of these features

is especially important when performing operations which require the use of large or specialized

tips. The "Quick Reference" guide is provided as a convenient reference for day-to-day operation

of the system.

If you encounter any difficulty operating your system, call your local authorized PACE dealer or

contact PACE as shown on page iv of this manual.

1

GENERAL INFORMATION

Introduction

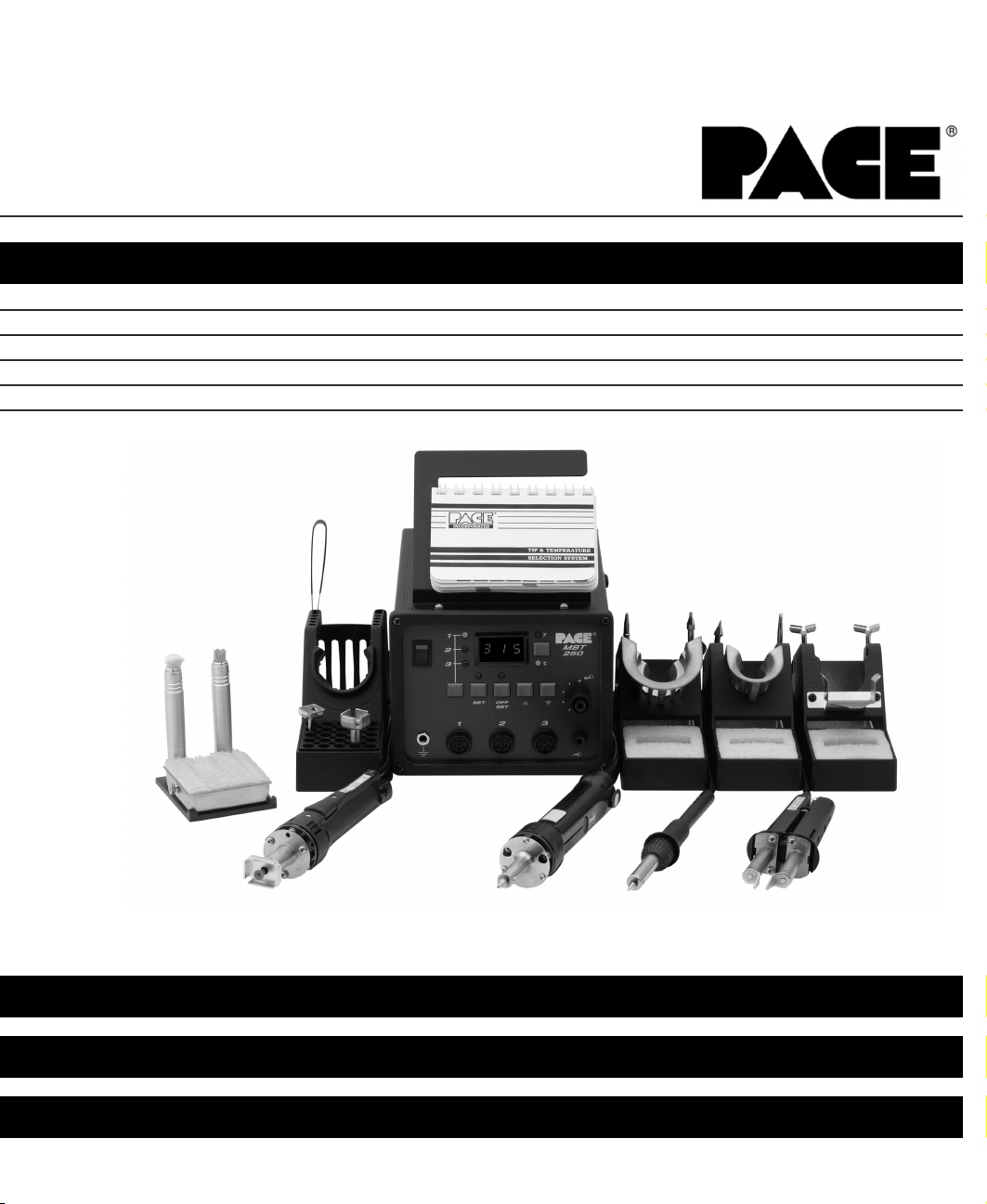

MBT 250 Universal Soldering and Repair Systems provide the user with the power and versatility to remove and

install virtually all SMD and Thru-Hole components. The power source incorporates the highly responsive

SensaTemp (closed-loop) temperature control system which provides up to 182 watts of total power to the three

output channels (see Power Management, Page 12). Microprocessor controlled circuitry allows the user to quickly

configure the system to their requirements and easily recalibrate the system to maintain accuracy and peak

performance. Accessory SensaTemp handpieces (standard & optional) and a wide variety of special use tips,

employing different shapes and sizes, allow the user to remove and replace a wide variety of component

configurations.

Virtually all of today’s specialized handpieces with large SMD tips suffer from a problem in which the actual tip

temperature that the work sees can be more than 55°C (100°F) cooler than the Set Tip Temperature displayed. The

MBT 250 systems feature PACE’s unique Tip & Temperature Selection System with Auto Tip Offset Compensation

which allows the user to Set and Display the True, Correct Tip Temperature for any size and type of tip or

handpiece.

The MBT 250 systems are available in either the 115 VAC, 100 VAC or 230 VAC versions. The 230 VAC version

systems bear the CE Conformity Marking which assures the user that it conforms to all the requirements of council

directive EMC 89/336/EEC. The systems include the power source with a selection of accessories and functional

aids.

PACE uses the following suffix letters on all MBT 250 systems to indicate the specific design configuration.

S - Soldering (PS-90)

D - Desoldering (SX-80)

T - Thermotweez (TT-65)

J - ThermoJet (TJ-70)

P - ThermoPic (TP-65)

2

GENERAL INFORMATION

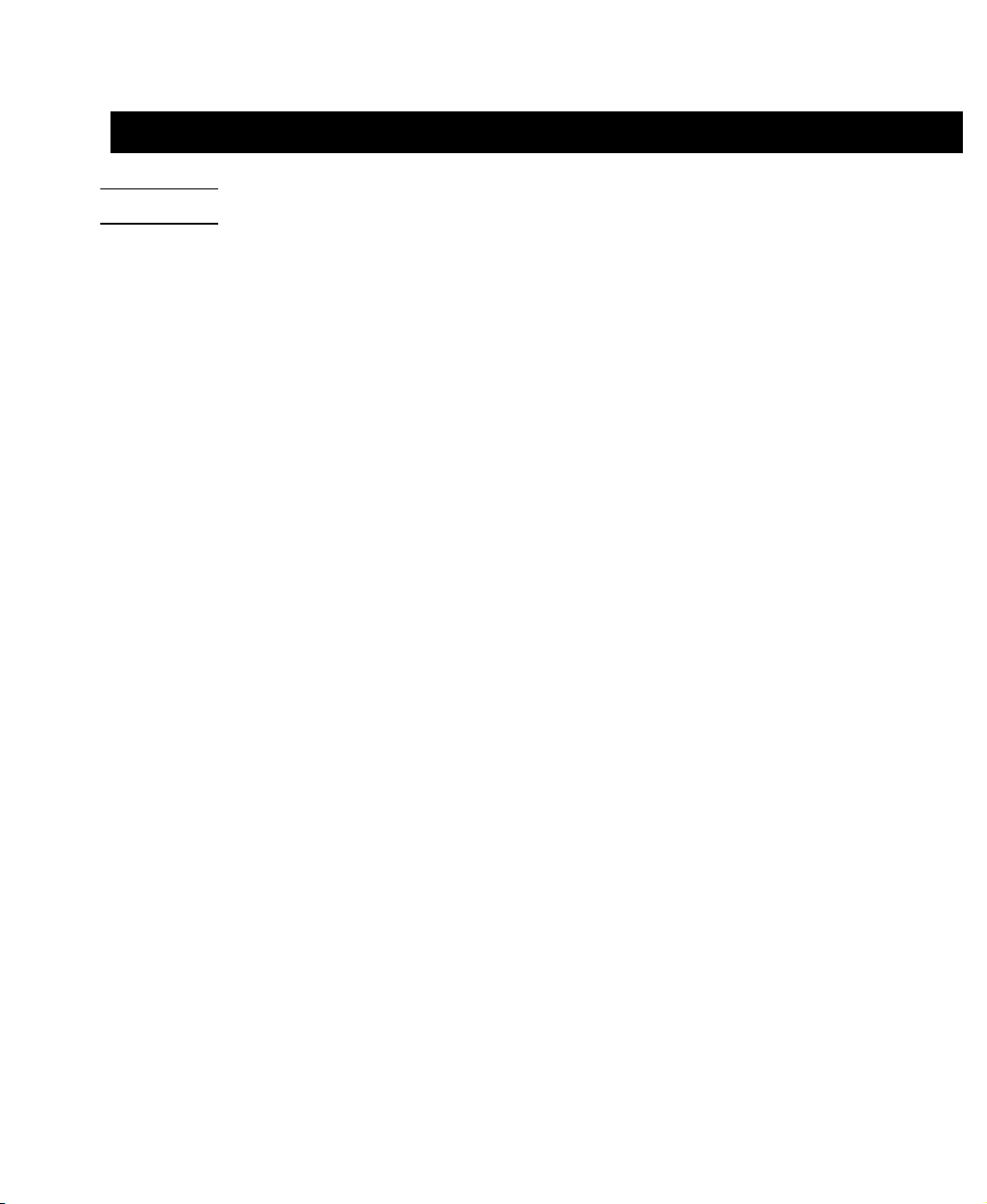

System Configurations

MBT 250-SD

MBT 250-SDPT

MBT 250E-SD Soft Ground

MBT 250E-SD

MBT 250E-SDPT

MBT 250E-SDPT Soft Ground

8007-0203

8007-0204

8007-0204-01

8007-0206

8007-0207

8007-0207-1

3

Power Source, 115 VAC, 60 Hz

X

X

Power Source, 230 VAC 50 Hz

X

X

X

X

PS-90 Soldering Iron

X

X

X

X

X

X

SX-80 Sodr-X-Tractor

X

X

X

X

X

X

TP-65 ThermoPic Handpiece

X

X

X

TT-65 ThermoTweez Handpiece

X

X

X

PS-90 Tip and Tool Stand

X

X

X

X

X

X

SX-80 Tip and Tool Stand

X

X

X

X

X

X

Tip Maintenance Station

X

X

X

X

X

X

Pace Tip & Tempurature Selection System Kit

X

X

X

X

X

X

System Part Number

GENERAL INFORMATION

SPECIFICATIONS

POWER REQUIREMENTS

MBT 250 - Version operates on 97-127 VAC, 50/60 Hz.

185 Watts, 1.6 Amp max, 100% Duty Cycle, Motor on.

MBT 250E - Version operates on 196-253 VAC, 50 Hz.

212 Watts, 0.92 Amp max, 100% Duty Cycle, Motor on.

PHYSICAL PARAMETERS

Size: 13.5 cm H x 16.5 cm W x 26 cm D (5.3"H x 6.5"W x 10.25"D)

Weight: 4.5 Kg. (10 Lbs.)

VACUUM AND AIR (motor operated systems)

Measurements at front panel AUTO SNAP-VAC and CONTROLLABLE PRESSURE Ports.

Vacuum Rise Time: Evacuates 33 cc (2 cubic inch) volume

to 25 cm Hg. (10 in. Hg.) in 150 ms.

Vacuum: 51 cm Hg. (20 in. Hg.) (nominal)

Pressure: .48 Bar (7 P.S.I.) (nominal MAXIMUM setting)

Air Flow: 9 SLPM (0.32 SCFM)MAXIMUM

TEMPERATURE SPECIFICATIONS

Tip Temperature Range: 38°C to 482°C (100°F to 900°F) nominal (see note).

Digital Readout Resolution: ±1° (°C or °F)

Tip Temperature Stability: ±1.1°C (2°F) at Idle from Set Tip Temperature.

4

GENERAL INFORMATION

EOS/ESD

Tip-To-Ground Resistance: Less than 5 ohms (except on Soft Ground Systems).

AC Leakage: Less than 2 millivolts RMS from 50Hz to 500Hz

(except on Soft Ground Systems).

ENVIRONMENTAL REQUIREMENTS

Ambient Operating Temperature: 0°C to 50°C (32°F to 120°F)

Storage Temperature: -40°C to 100°C (-40°F to 212°F)

Capabilities

All capabilities are dependent upon the use of the appropriate Functional Accessories or Work Aids (refer to Basic

Operation section). Available SensaTemp handpieces and their associated assembly and repair functions are listed

below. An Operations and Maintenance Manual is provided separately with each handpiece which describes the

applications and recommended procedures for that particular tool.

PS-90 Soldering Iron - Provides a wide range of SMD and thru-hole installation and removal capability as well as

unsurpassed thermal performance on heavy, multilayer thru-hole assemblies at safe, lower working temperatures.

A wide variety of 3/16" shank, quick change thru-hole and SMD tips (for chip components, SOTs, SOICs and

other components) are available.

SX-80 Sodr-X-Tractor handpiece - Air handpiece ideal for thru-hole desoldering on extra high mass multilayer

boards. Also ideal for removal of TSOP & TQFP surface mount components and for “Flo” desoldering during

surface mount land preparation.

TT-65 ThermoTweez handpiece - Performs removal of PLCC (J Leaded), LCCC (leadless) and other surface mount

devices.

TP-65 ThermoPik handpiece - Air handpiece performs removal of Flat Pack, QFP & PQFP surface mount devices.

DTP-80 Dual ThermoPik handpiece - Air handpiece performs removal of large Flat Pack, QFP, PQFP & BGA surface

mount devices.

TJ-70 Mini ThermoJet handpiece - Air handpiece. Focused hot air reflow handpiece used for installation of all

types of surface mount devices.

5

NOTE

Actual minimum and maximum Operating Tip Temperatures may vary

depending on handpiece & tip selection.

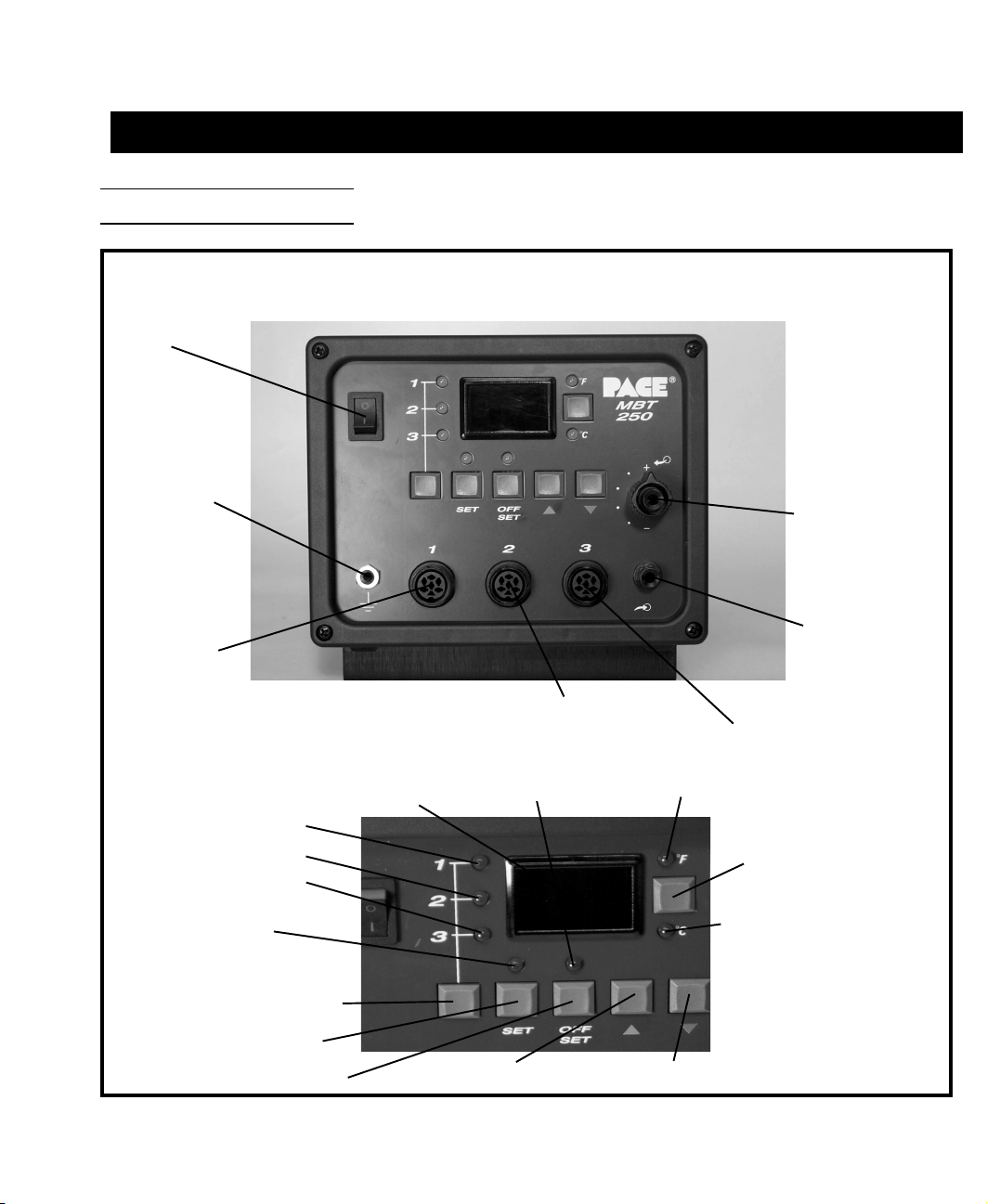

GENERAL INFORMATION

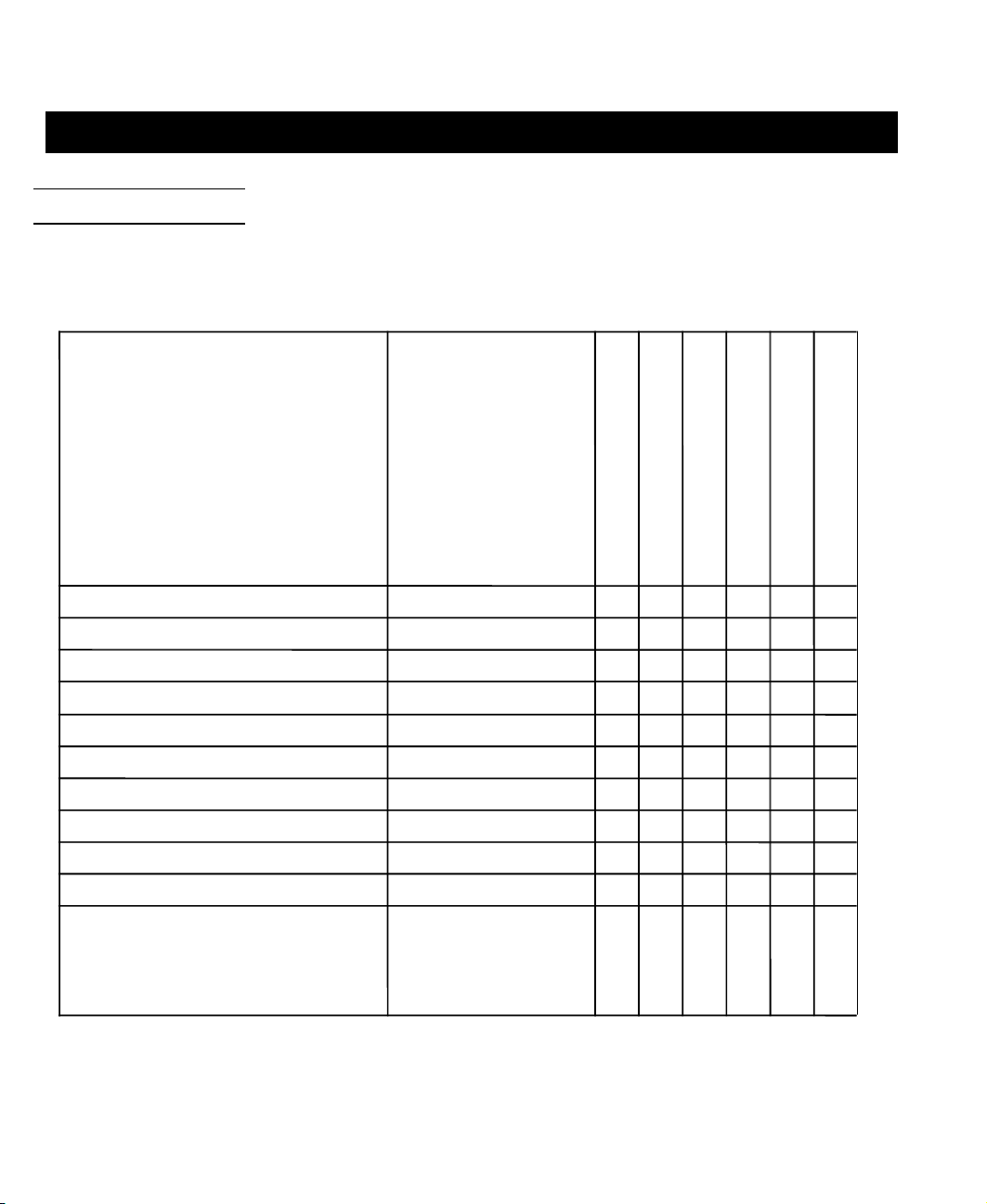

Parts Identification

Listed below is a description of the system power source parts. Use Figures 1 & 2 as a guide.

1. CH 1 POWER RECEPTACLE - Provides power, tip ground, sensing circuitry and finger switch connection

from MBT system to handpiece connected to Channel 1 (CH 1).

2. CH 2 POWER RECEPTACLE - Provides power, tip ground, sensing circuitry and finger switch connection

from MBT system to handpiece connected to Channel 2 (CH 2).

3. CH 3 POWER RECEPTACLE - Provides power, tip ground, sensing circuitry and finger switch connection

from MBT system to handpiece connected to Channel 3 (CH 3).

4. POWER SWITCH - Turns system ON ("1") and OFF ("0"); controls input power to the system.

5. AUTO SNAP-VAC PORT - Quick connect fitting provides quick-rise vacuum for Sodr-X-Tractor,

ThermoPik and Dual ThermoPik handpieces. Vacuum is present when handpiece finger switch or optional

foot pedal is actuated. Vacuum ceases 1.2 seconds after switch (or foot pedal) released.

6. CONTROLLABLE PRESSURE PORT - Quick connect fitting with adjustable valve which provides

variable air flow for Mini ThermoJet handpiece (in Hot Jet Mode) and Sodr-X-Tractor handpiece. Air

pressure is present when handpiece finger switch or optional foot pedal is actuated. Air pressure ceases

1.2 seconds after switch (or foot pedal) is released.

7. DIGITAL READOUT - Provides a three digit display of the Current Channel (channel with illuminated LED;

CH 1, CH 2 or CH 3 ) temperature information. This includes: Operating Tip Temperature in Temperature

Display Mode (normal operation), Tip Offset Constant in Tip Offset Mode, Set Tip Temperature in Tip Set

Mode and other information in Calibration (CAL) Mode.

8. °F /°C KEY - Selects °F or °C display of Set and Operating Tip Temperatures and Tip Offset Constants.

9. °F LED - Illuminates when Set\ Operating Tip Temperatures and Tip Offset Constants are displayed in °F.

10. °C LED - Illuminates when Set\ Operating Tip Temperatures and Tip Offset Constants are displayed in °C.

11. CH 1 LED - Illuminates when Channel 1 (CH 1) is the “Current Channel” i.e., the channel (with connected

handpiece\tip) whose temperature information is displayed on the digital readout.

12. CH 2 LED - Illuminates when Channel 2 (CH 2) is the “Current Channel” i.e., the channel (with connected

handpiece\tip) whose temperature information is displayed on the digital readout.

13. CH 3 LED - Illuminates when Channel 3 (CH 3) is the “Current Channel” i.e., the channel (with connected

handpiece\tip) whose temperature information is displayed on the digital readout.

14. CH SELECT KEY - Selects the Current Channel (among "Active Channels" i.e., those with a connected

handpiece).

15. TIP SET KEY - Allows the operator to adjust the Set Tip Temperature for the handpiece\tip combination

connected to the Current Channel. Places the system in the Tip Set Mode.

6

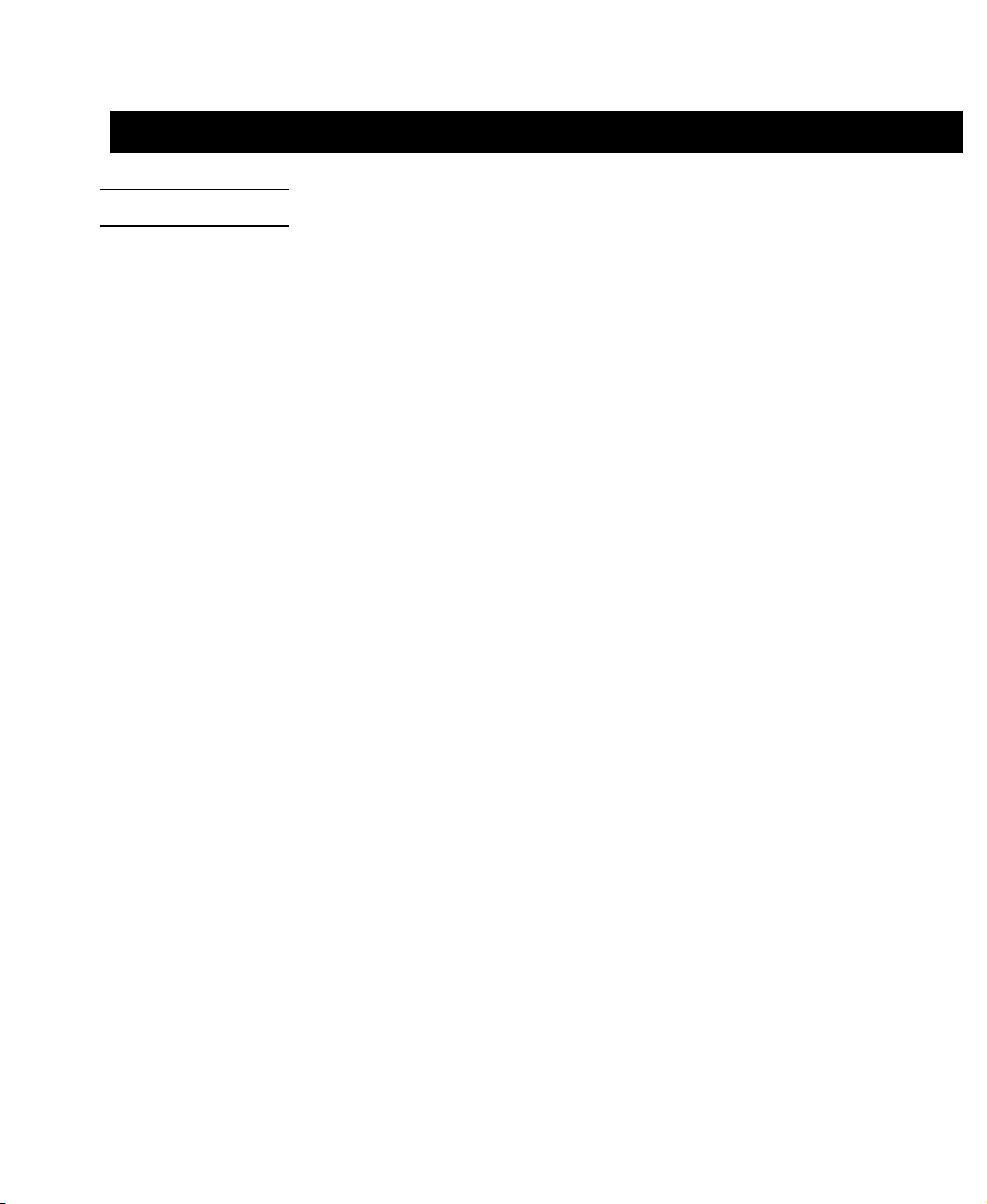

GENERAL INFORMATION

16. TIP SET LED - Flashes when TIP SET Key is pressed indicating that the system is in Tip Set Mode.

17. TIP OFFSET KEY - Allows the operator to adjust the Tip Offset Constant for the handpiece connected to

the Current Channel. Places the system in the Tip Offset Mode.

18. TIP OFFSET LED - Flashes when TIP OFFSET Key is pressed indicating that the system is in Tip Offset

Mode. Remains illuminated (not flashing) in Temperature Display Mode (normal operating mode) when a

Tip Offset Constant of greater than "3" for °C ("6" for °F) is entered.

19. SCROLL UP KEY - Increases the Set Tip Temperature (in Tip Set Mode) and the Tip Offset Constant (in

Tip Offset Mode) in one, then ten degree increments. Also used in “CAL” (Calibration) Mode.

20. SCROLL DOWN KEY - Decreases the Set Tip Temperature (in Tip Set Mode) and the Tip Offset Constant

(in Tip Offset Mode) in one then ten degree increments. Also used in “CAL” (Calibration) Mode.

21. EARTH GROUND RECEPTACLE - provides positive earth ground to which a ground cable can be

connected from the workpiece or work surface as part of a static control program.

22 . TIP & TEMPERATURE SELECTION SYSTEM CHART HOLDER - Holds PACE’s Tip & Temperature

Selection System Charts which enable the operator to accurately set and display the true, correct operating

tip temperature for any handpiece\tip configuration.

23. AC POWER RECEPTACLE / FUSE HOLDER - Receptacle for providing power to the system from AC

outlet through power cord. Also location of Fuse (F1) which protects system from overcurrent conditions.

24. CAL / SET KEY LOCK (optional) - In the "LOCK" position, Set Tip Temperatures and Tip Offset

Constants cannot be changed. In addition, the system cannot be put into "CAL" Mode. In the

"UNLOCK" position, all system functions operate normally.

25. FOOT PEDAL RECEPTACLE - Input for Foot Pedal (optional) which actuates vacuum or pressure to the

air-operated handpieces.

26. AIR HOSE FITTING ("V" systems only) - Fitting for connection of house air supply to power source air

venturi assembly.

26. FUSE - Provides overload protection for system.

7

GENERAL INFORMATION

Figure 1. Parts Identification, Front View

Parts Identification (Con't)

Power

Switch

Earth

Ground

Receptacle

CH1

Power

Receptacle

Controllable

Pressure

Port

AUTO

SNAP-VAC

Port

CH3

Power

Receptacle

CH2

Power

Receptacle

Digital

Readout

Tip Offset

LED

°F LED

°F / °C KEY

CH1 LED

CH2 LED

CH3 LED

Tip Set

LED

CH Select Key

Tip Set Key

Tip Offset Key Scroll Up Key Scroll Down Key

°C LED

8

GENERAL INFORMATION

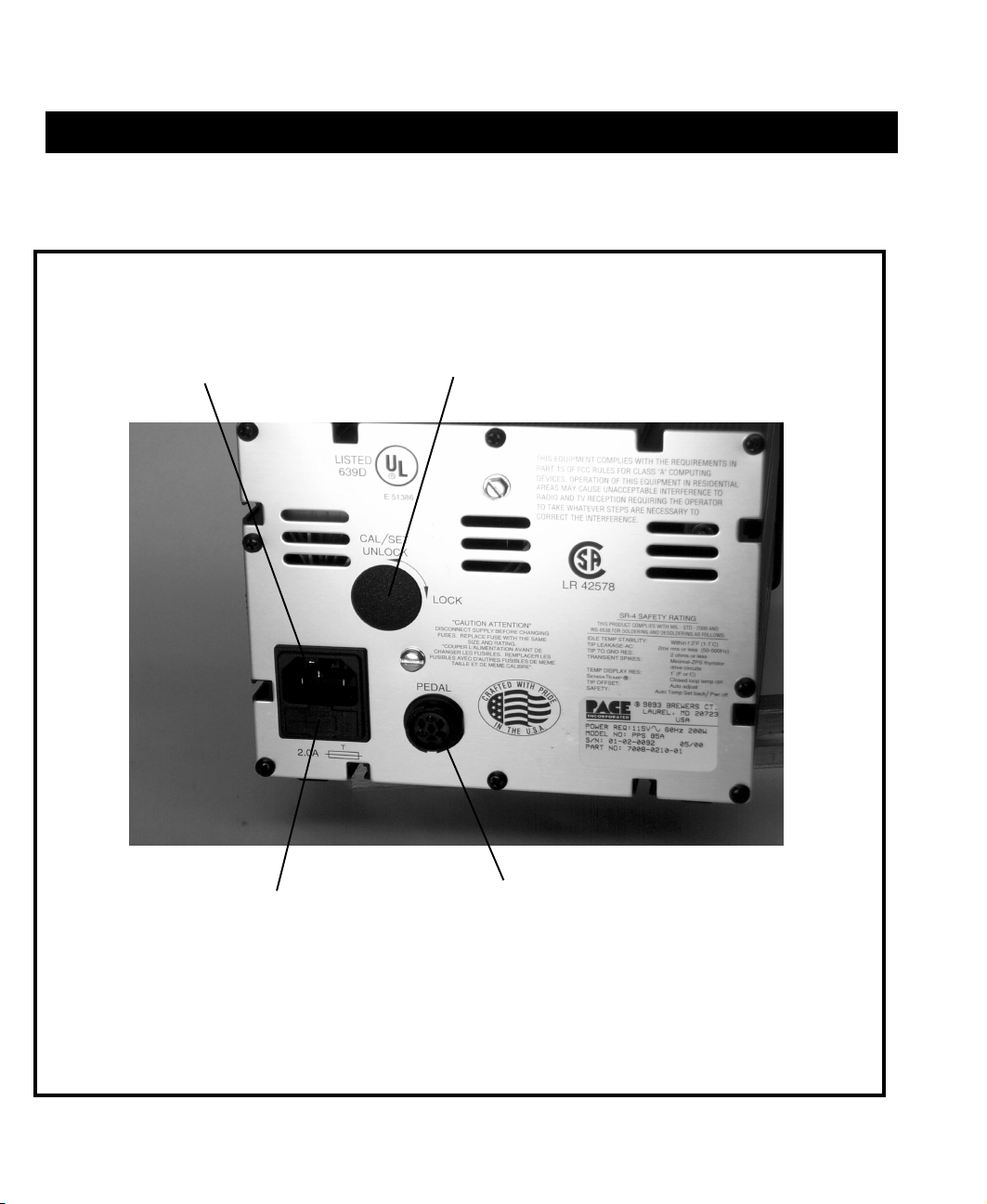

10

Figure 2. Parts Identification, Rear View

CAL/SET

Key Lock

(Optional)

AC Power

Receptacle/

Fuse Holder

Fuse

Foot

Pedal

Receptacle

9

GENERAL INFORMATION

11

Power Management

IMPORTANT

POWER MANAGEMENT NOTE

The MBT 250 systems will perform nominally when using any combination of handpieces with a total of 197

Watts or less. When using 2 TT-65 ThermoTweez or DTP-80 Dual ThermoPik handpieces on the system, PACE

recommends that the operator leave the third Power Receptacle vacant to insure optimum performance.

MAX. POWER

1. PS-90 Soldering Iron .............................................................................. 51 Watts

2. SX-80 Sodr-X-Tractor handpiece (air handpiece) ................................. 48 Watts

3. TT-65 ThermoTweez handpiece ............................................................74 Watts (37 Watts each heater)

4. TJ-70 Mini ThermoJet handpiece (air handpiece) ................................. 75 Watts

5. TP-65 ThermoPik handpiece (air handpiece) ......................................... 43 Watts

6. DTP-80 Dual ThermoPik handpiece ...................................................... 74 Watts (37 Watts each heater)

NOTE

Although 2 air handpieces can be powered up and idle at set temperature

simultaneously, only one may have its air hose attached to the unit and operate

at a time. In addition, any other combination of handpieces with a total of 197

Watts or less will perform nominally (add the Wattage designations on the heater

flange(s) of each handpiece to calculate total Watts). For example, you may want

to have two or more PS-90 Soldering Irons with different tips powered up at one

time for convenience.

PACE recommends the purchase of a ST series system power source which can be used in conjunction

with the MBT 250 system. For example, you may want to power a TJ-70 Mini ThermoJet, PS-90 Soldering

Iron and a SX-80 Sodr-X-Tractor handpiece on your MBT 250, and power a TT-65 ThermoTweez handpiece

on your ST-TT system to suit your particular application.

If you require assistance in the use of this product, contact your local authorized PACE dealer or

PACE directly as shown on page iv of this manual.

10

GENERAL INFORMATION

12

The purpose of this "SAFETY" section is to inform users of the heading guidelines used in this manual to indicate

special Notes, Cautions, Warnings or Dangers. Also included are recommended precautions which must be

observed when operating or servicing this product.

Heading Guidelines

PACE adheres to the following Heading Guidelines (based on OSHA guidelines) when listing special information or

precautions to be taken. Especially important are all procedures and practices which, if not strictly observed, could

result in injury or loss of life.

These "NOTES", "CAUTIONS","WARNINGS" and "DANGERS" are inserted in this manual whenever deemed

necessary. They appear in a blocked off form with double outline and a shaded background to highlight the

information as shown below.

NOTE

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

NOTE

Used to indicate a statement of company recommendation or policy. The message may relate directly or indirectly

to the safety of personnel or protection of property. NOTE is not associated directly with a hazard or hazardous

situation and is not used in place of "CAUTION", "WARNING" or "DANGER".

CAUTION

Used to indicate a hazardous situation which may result in minor or moderate injury. May also be used to alert

personnel to conditions, procedures and practices which, if not observed, could result in damage to or destruction

of the product or other equipment.

WARNING

Used to define additional information that if not closely followed might result in serious damage to equipment and

represent a potential for serious personnel injury.

DANGER

Defines additional information that if not closely followed might result in severe personnel injury or death. Danger

is not used for property damage unless personal injury risk is present.

11

SAFETY

13

Precautions

The following are general safety precautions which personnel must understand and follow when using or servicing

this product. These precautions may or may not be included elsewhere in this manual.

CAUTIONS

1. Handpiece heaters and installed tips are hot when handpiece is powered on. DO NOT touch either the

heater or tip. Severe burns may result! Always store handpiece in the appropriate Tip & Tool Stand

when not in use.

2. Always use this system in a well ventilated area. A fume extraction system such as those available from

PACE are highly recommended to help protect personnel from solder flux fumes.

3. Exercise proper precautions when using materials (e.g., solder paste). Refer to the Material Safety Data

Sheet (MSDS) supplied with each chemical and adhere to all safety precautions recommended by the

manufacturer.

NOTES

Refer to the MBT 250, Service Manual (P/N 5050-0352) whenever service is required.

To insure continued peak performance, use genuine PACE replacement parts.

12

SAFETY

14

Safety Guidelines, English Language

The following are safety precautions which personnel must understand and follow when using or servicing this

product.

1. POTENTIAL SHOCK HAZARD - Repair procedures on PACE products should be performed by

Qualified Service Personnel only. Line voltage parts may be exposed when the equipment is

disassembled. Service personnel must avoid contact with these parts when troubleshooting the

product.

2. To prevent personnel injury, adhere to safety guidelines in accordance with OSHA and other applicable

safety standards.

3. SensaTemp handpiece heaters and installed tips are hot when the handpiece is powered on and for a

period of time after power off. DO NOT touch either the heater or the tip. Severe burns may result.

4. PACE Tip & Tool Stands and handpiece cubbies are designed specifically for use with the associated

handpiece and houses it in a manner which protects the user from accidental burns. Always store the

handpiece in its holder. Be sure to place the handpiece in its holder after use and allow to cool before

storing.

5. Always use PACE systems in a well ventilated area. A fume extraction system such as those available

from PACE are highly recommended to help protect personnel from solder flux fumes.

6. Exercise proper precautions when using chemicals (e.g., solder paste). Refer to the Material Safety Data

Sheet (MSDS) supplied with each chemical and adhere to all safety precautions recommended by the

manufacturer.

Sicherheit Korrekturlinien, Deutsche Sprache

Die nachfolgenden Sicherheitsvorschriften sollten vom Bedien- un Servicepersonal verstanden und befolgt

werden.

1. Entladung spannungsfuehrender Teile - Reparaturen an PACE Produkten sollten nur von qualifizierten

Personal durchgefuehrt werden. Spannungsfuehrende Teile koennen sich bei gezogenen Netzstecker

entladen. Servicepersonal muss den Kontakt dieser Teile vermeiden.

2. Um moegliche Gefahren fuer Personen auszuschliessen, muessen alle Sicherheitsvorschriften in

Uebereinstimmung mit OSHA und anderen anwendbaren Sicherheitsstandards eingehalten werden.

13

SAFETY

15

3. Angeschlossene SensaTemp Heizelemente von Handwerkzeugen und installierte Loetspitzen sind

heiss wenn das System eingeschaltet ist oder erst vor kurzer Zeit ausgeschaltet wurde. Heizelement

und Loetspitze nicht beruehren. Verbrennungsgefahr.

4. PACE Tip & Tool und andere Handwerkzeugablagen sind so konstruiert, dass ein versehentliches

Beruehren des dazugehoerendes Handwerkzeuges vermieden wird. Bewahren Sie das Handwerkzeug

nach Gebrauch stets in der Ablage auf. Bevor das Handwerkzeug an einem anderen Ort gelagert werden

muss, lassen Sie es in der Werkzeugablage vollstaendig abkuehlen.

5. Benutze PACE Systeme nur in gut beluefteten Raeumen. Ein Loetrauchabsaugsystem, wie es z.B. von

PACE erhaeltlich ist, hilft Bedienpersonen von den Gefahren von Loetrauch zu schuetzen.

6. Wenn Chemikalien (z.B.: Lotpaste) verwendet werden, muessen alle die in den Sicherheitsdatenblaettern

des Herstellers ausgewiesenen Sicherheitsvorschriften eingehalten werden.

SICHERHEITDIRECTIVES DE SÉCURITÉ,

Les précautions suivantes, sont celles que le personnel doit comprendre et suivre lorsqu'il utilise, effectue la

maintenance ou se sert d'un produit PACE.

1. Danger potentiel de choc èlectrique - Les procédures de réparation sur les produits PACE doivent être

effectuées seulement par du personnel qualifié. Des parties de l'équipement désassemblées peuvent

être sous tension. Le personnel de maintenance doit éviter tout contact avec ces parties en réparant le

produit.

2. Pour prévenir tout préjudice, le personnel adhère au guide de sécurité en accord avec OSHA

(équivalent à des normes françaises de sécurité) et d'autres standards de sécurité applicable.

3. La mise sous tension des outils SensaTemp comporte des éléments chauffants (buse). Ces derniers,

gardent la chaleur même après la mise hors tension pendant un certain temps. Ne pas toucher les

parties chaudes aux extrémités des outils. Des brûlures sévères peuvent en résulter.

4. Les outils PACE et leurs pannes ainsi que le support sont dessinés de manière spécifique afin de

protéger l'utilisateur/opérateur de brûlures accidentelles. Reposer toujours les outils après chaque

utilisation dans leurs étuis/supports afin de permettre leur refroidissement.

5. Utiliser toujours les stations Pace dans unlieu bien ventilé. Des extracteurs de fumée Pace sont

hautement recommandés pour protéger votre personnel des vapeurs de soudure/flux.

6. Prenez les mesures nécessaires quand vous utilisez des produits (ex: solder paste) chimiques. Reportez-

vous au document (fiche technique/sécurité) du fabricant fourni avec chaque produit. Respectez toutes

les procédures de sécurité recommandées par le constructeur.

Directives de Sécurité, Française Langue

14

SAFETY

16

Misure di Sicurezza, Italiana Lingua

Le seguenti instruzioni sono misure di sicurezza che il personale deve comprendere e seguire quando utilizza o

ripara I prodotti PACE.

1. EVENTUALI RISCHI DI SHOCK ELETTRICO- Si consiglia di far eseguire le operazioni di riparazione

dei prodotti PACE, da un servizio di personale qualificato. Quando la stazione non é assemblata le parti

sottoposte alla tensione di linea potrebbero essere scoperte. Il personale deve evitare il contatto con

queste parti durante manutenzione del prodotto.

2. Per evitare eventuali pericoli al personale, attenersi alle norme di sicurezza previste dalla guida, in conformitá

all’OSHA e agli altri Standard di Sicurezza applicabili.

3. Le resistenze PACE Sensatemp e le punte installate sono calde quando la stazione é accesa e per un

periodo successivo allo spegnimento. Non toccare la resistenza e la punta. Puó comportare gravi

ustioni.

4. I supporti PACE sono specificamente costruiti insieme alla corrispondente impugnatura e progettati per

un uso che protegge gli utenti da ustioni accidentali. Mettere sempre l’impugnatura nel propio supporto

dopo l’utilizzo e lasciarla raffredare prima di riporla.

5. Utilizzare sempre I stazioni PACE in una zona be aerata per proteggere il personale dai fumi. É fortemente

raccomandato un sistema di aspirazione (dei fumi) come quello disposta dalla PACE.

6. Usare precauzioni quando si utilizzano sotanze chimiche (es. Pasta di stagno). Fare riferimento al

Material Safety Data Sheet (MSDS) fornita con ogni sostanza chimica e seguire tutte le misure di

sicurezza raccomandate dal fabbricante.

15

SAFETY

17

2. Para evitar danos pessoais, siga as normas de segurança OSHA ou outras normas aplicáveis.

3. Resistencias de aquecimento dos ferros e as pontas instaladas estão quentesquando o ferro está

alimentado, e mesmo durante algum tempo após ser desligado. NUNCA TOCAR nem na resistencia de

aquecimento nem na ponta. Pode resultar em queimaduras severas.

4. Os suportes para pontas e ferros da PACE, foram concebidos para uso especifico, e para proteger o

operador de queimaduras acidentais. Coloque sempre os ferros nos respectivos suportes. Tenha a

certeza de colocar sempre o ferro no respectivo suporte após cada utilização e deixe-o arrefecer antes de

o guardar.

5. Utilize sempre os sistemas da PACE em locais bem ventilados. Um Sistema de extracção de fumos, como os

Sistemas disponiveis na PACE, são altamente recomendados para a protecção dos utilizadores contra os fumos

produzidos pela solda e fluxo.

6. Tenha precauções apropriadas ao utilizar produtos quimicos (ex. pasta de soldar). Lêr sempre atentamente os

normas de segurança fornecidas com cada produto químico e siga sempre todas as precauções de segurança

recomendadas pelo fabricante.

Guias de Consulta de Seguridad, Espãnol Lenguaje

Lo siguiente es precauciones de seguridad que el personal debe entender y debe seguir al usar o reparar productos

de PACE.

1. RIESGO de SHOCK POTENCIAL - Los procedimientos de la Reparación en productos de PACE sólo

deben ser realizados por Personal de Servicio Calificado. Pueden exponerse partes de voltaje de línea

cuando el equipo se desmonta. El personal de servicio debe evitar contacto con estas partes al arreglar el

producto.

2. Para prevenir lesión del personal, adhiera a las reglas de seguridad de acuerdo con OSHA y otras

normas de seguridad aplicables.

16

Guidelines de Segurança, Portuguese Lingua

Segeum-se precauções de segurança que os operadores devem compreender e seguir ao utilizar ou reparar

produtos PACE.

1. Perigo de choque eléctrico - Os procedimentos de reparação em produtos PACE, devem ser apenas

efectuados por pessoal qualificado. Linhas de alimentação podem ficar expostas ao desmontar o

equipamento. Pessoal de reparação deve evitar o contacto com essas partes ao reparar o produto.

SAFETY

18

3. Las herramientas SensaTemp tienen sus calentadores y las puntas instaladas calientes cuando la

herramienta esta encendida y por un periodo de tiempo después de apagar el equipo. No toque el

calentador o la punta. Las quemaduras severas pueden resultar.

4. El Soporte de punta y Herramienta PACE se diseñan específicamente para el uso con las herramientas

asociadas y las almacena de una manera que protege al usuario de las quemaduras accidentales.

Siempre guarde la herramienta en su soporte. Esté seguro de poner la herramienta en su soporte

después del uso y permita que la herramienta enfríe antes de guardar.

5. Siempre use sistemas de PACE en una área bien ventilada. Un sistema de extraccíon de humo como

esos disponibles de PACE se recomiendan para ayudar a protejer al personal contra los humos de flujo

de soldadura.

6. Ejercicie las precauciones apropiadas al usar químicos (ej., pasta de la soldadura). Refiérase a la Hoja de Datos de

Seguridad de Material (MSDS) proporcionadó con cada químico y adhiere a todas las precauciones de seguridad

recomendadas por el fabricante.

Säkerhetsföreskrifter, Svenska

Följande säkerhetsföreskrifter måste förstås och följas av personal som använder eller utför service på PACE

produkter.

1. RISK FÖR STRÖMSTÖT - Service / Reparation av PACE produkter får endast utföras av aktoriserad

service personal. Strömförande delar kan kommas åt när produkten är isärplockad. Iaktag aksamhet när

felsökning görs för att undvika strömstötar.

2. För att undvika personskada rekommenderas att OSHA eller andra liknande arbetssäkerhets standarder

följs.

3. SensaTemp verktygselement och installerade spetsar är heta när strömmen är påslagen och en tid efter

att strömmen slagits av. RÖR EJ element eller spets. Risk för brännskador!

4. PACE Spets och Verktygshållare är speciellt utformade för att passa PACE respektive verktyg så att

risken för brännskador kan undvikas. När verktyget ej används bör det alltid förvaras i sin hållare.

5. Tillse att ventilationen är god där PACE System används. Ett lödröksutsug system som t.ex. PACE

tillhandahåller rekommenderas för att skydda användaren för giftig lödrök.

6. Tillse att gällande säkerhetsföreskrifter följs vid användning av kemikalier, t.ex. lodpasta.Se

säkerhetsdatabladen som medföljer kemikalierna och följ de rekommenderade säkerhetsföreskrifterna

från respektive tillverkare. Säkerhetsföreskrifter, Svenska

17

SAFETY

Loading...

Loading...