CNC SYSTEM

OSP-P200M/P200MA

5-AXIS MACHINING FUNCTION

INSTRUCTION MANUAL

(5th Edition)

Pub. No. 5611-E-R4 (ME61-214-R5) Jan. 2011

PART 1 5-AXIS MACHINING FUNCTION

SECTION 1 ACTUAL POSITION DISPLAY...................................................2

SECTION 2 MANUAL FEED FUNCTION ......................................................8

SECTION 3 TOOL CENTER POINT CONTROL .........................................20

SECTION 4 TOOL AXIAL DIRECTION TOOL LENGTH COMPENDSATION ......32

SECTION 5 TOOL SIDE COMPENSATION................................................40

SECTION 6 LEADING EDGE COMPENSATION........................................48

SECTION 7 TOOL ATTITUDE COMMAND FUNCTION .............................60

SECTION 8 TOOL POSTURE COMPENSATION FUNCTION...................72

SECTION 9 ROTARY AXIS PIVOT DISTANCE COMPENSATION

FUNCTION ...............................................................................81

SECTION 10 SLOPE MACHINING FUNCTION 2.........................................88

PART 2 PARAMETERS

SECTION 1 ROTARY AXIS PARAMETERS............................................. 151

PART 3 PROCEDURES FOR MEASURING AND SETTING ROTARY

AXIS CENTER POSITION

SECTION 1 TWO ROTARY AXES ON THE TABLE (ROTARY

C-AXIS/INCLINED A-AXIS)................................................... 158

SECTION 2 TABLE AXIS AND SPINDLE AXIS (ROTARY C-AXIS

ON THE TABLE AND INCLINED A- OR B-AXIS OF THE

SPINDLE) .............................................................................. 167

SECTION 3 TWO SPINDLE AXES

(ROTARY C-AXIS/INCLINED B-AXIS) ................................. 180

SECTION 4 TWO TABLE AXES (ROTARY A-AXIS/INCLINED B-AXIS) . 192

Table of Contents

PART 1 5-AXIS MACHINIG FUNCTION

SECTION 1 ACTUAL POSITION DISPLAY...................................................2

1. Overview .................................................................................................................................. 2

2. ACTUAL POSITION display..................................................................................................... 2

2-1. Display of Various Types of Coordinate Systems ......................................................................... 2

2-2. Display of Status Indicator Lamp................................................................................................... 7

SECTION 2 MANUAL FEED FUNCTION ......................................................8

1. Tool Axial Direction Manual Feed and Perpendicular to the Tool Axial Direction Manual Feed......... 8

1-1. Overview ........................................................................................................................................ 8

1-2. Operation .......................................................................................................................................9

1-3. Screen Display............................................................................................................................. 10

2. Table Coordinate Manual Feed.............................................................................................. 14

2-1. Overview ......................................................................................................................................14

2-2. Operation ..................................................................................................................................... 15

3. Tool Nose Center Manaul Feed.............................................................................................. 16

3-1. Overview ......................................................................................................................................16

3-2. Operation ..................................................................................................................................... 16

4. Other Optional Functions ....................................................................................................... 18

4-1. I-MAP ........................................................................................................................................... 18

4-2. Manual Gauging...........................................................................................................................18

4-3. Interactive Gauging...................................................................................................................... 18

4-4. Manual Angle/Circle Feed ........................................................................................................... 18

5. Alarm List................................................................................................................................ 19

5-1. Alarm A......................................................................................................................................... 19

5-2. Alarm D ........................................................................................................................................19

SECTION 3 TOOL CENTER POINT CONTROL .........................................20

1. Overview ................................................................................................................................ 20

1-1. Definition of the coordinate system for the table having a rotary axis ........................................ 21

2. Program Commands.............................................................................................................. 22

2-1. Command Format........................................................................................................................ 22

2-2. Program Commands in G169 Mode ...........................................................................................25

3. System Variables.................................................................................................................... 27

4. Operation in Zero Setting Screen........................................................................................... 27

5. Operation in Tool Length Offset / Cutter Radius Compensation Screen................................ 27

6. Parameters............................................................................................................................. 28

7. Optional Functions ................................................................................................................. 28

7-1. I-MAP ........................................................................................................................................... 28

7-2. Real 3D Animated Simulation...................................................................................................... 28

7-3. Measurement Cycle..................................................................................................................... 28

7-4. Collision Avoidance System ........................................................................................................ 28

8. Alarm List................................................................................................................................ 29

8-1. Alarm A......................................................................................................................................... 29

8-2. Alarm B......................................................................................................................................... 29

8-3. Alarm D ........................................................................................................................................30

8-4. Error .............................................................................................................................................31

SECTION 4 TOOL AXIAL DIRECTION TOOL LENGTH

COMPENDSATION..................................................................32

1. Overview ................................................................................................................................ 32

2. Program Commands.............................................................................................................. 33

2-1. Command Format........................................................................................................................ 33

2-2. Program Commands in G171 Mode ...........................................................................................34

2-3. Points to be Noted ....................................................................................................................... 35

3. Parameters............................................................................................................................. 36

4. Alarm List................................................................................................................................ 37

4-1. Alarm A......................................................................................................................................... 37

4-2. Alarm B......................................................................................................................................... 38

4-3. Alarm D ........................................................................................................................................39

SECTION 5 TOOL SIDE COMPENSATION................................................40

1. Overview ................................................................................................................................ 40

2. Program Command................................................................................................................ 40

2-1. Command Format........................................................................................................................ 40

2-2. Tool Side Compensation Mode and Other Command Modes .................................................... 41

2-3. Commands during Tool Side Compensation Mode ....................................................................41

3. Tool Movement During the Tool Side Compensation ............................................................. 42

4. Parameter............................................................................................................................... 43

5. Points to be Noted.................................................................................................................. 43

6. Alarm List................................................................................................................................ 44

6-1. Alarm B......................................................................................................................................... 44

SECTION 6 LEADING EDGE COMPENSATION........................................48

1. Overview ................................................................................................................................ 48

2. Program Command................................................................................................................ 49

2-1. Command Format........................................................................................................................ 49

2-2. Movement upon entering the leading edge compensation mode............................................... 49

2-3. Movement during the leading edge compensation is on ............................................................50

2-4. Movement upon exiting the Leading Edge Compensation mode............................................... 51

2-5. Compensation Direction .............................................................................................................. 52

2-6. Functions forbidden while Leading Edge Compensation mode is ON ....................................... 53

2-7. Functions disable leading edge compensation ........................................................................... 54

3. Parameter............................................................................................................................... 55

4. Alarm list................................................................................................................................. 55

SECTION 7 TOOL ATTITUDE COMMAND FUNCTION .............................60

1. Overview................................................................................................................................. 60

2. Program Command................................................................................................................ 61

2-1. Command Format........................................................................................................................ 61

2-2. Parameter .................................................................................................................................... 62

2-3. How to Determine Angle.............................................................................................................. 65

3. Alarm List................................................................................................................................ 69

3-1. Alarm A......................................................................................................................................... 69

3-2. Alarm B......................................................................................................................................... 69

3-3. Alarm D ........................................................................................................................................71

SECTION 8 TOOL POSTURE COMPENSATION FUNCTION...................72

1. Overview................................................................................................................................. 72

2. Procedures............................................................................................................................. 73

2-1. Specification using parameter setting.......................................................................................... 74

3. Alarm List................................................................................................................................ 79

SECTION 9 ROTARY AXIS PIVOT DISTANCE COMPENSATION

FUNCTION ...............................................................................81

1. OVERVIEW............................................................................................................................ 81

2. Parameter Setting .................................................................................................................. 83

2-1. Pivot Distance Compensation .....................................................................................................83

2-1-1. Spindle Center......................................................................................................................... 85

2-1-2. Table Center ............................................................................................................................ 86

SECTION 10 SLOPE MACHINING FUNCTION 2.........................................88

1. Overview ................................................................................................................................ 88

2. Slope Coordinate Conversion Command .............................................................................. 89

2-1. Overview ......................................................................................................................................89

2-2. Program command ......................................................................................................................90

2-2-1. Euler angles ............................................................................................................................ 91

2-2-2. Roll - Pitch - Yaw Angles ......................................................................................................... 92

2-2-3. 3 Points ...................................................................................................................................93

2-2-4. 2 Vectors ................................................................................................................................. 94

2-2-5. Projection ................................................................................................................................ 95

2-2-6. Tool Axis Direction................................................................................................................... 96

2-2-7. Rotary Center Axis .................................................................................................................. 98

2-2-8. X, Y, Z-axis ..............................................................................................................................99

2-2-9. Slope Cancel......................................................................................................................... 100

2-2-10. G codes and mnemonic codes used during slope coordinate conversion ........................101

2-2-11. Upper limit restoration (M52) .............................................................................................. 102

2-2-12. axis command cancel ......................................................................................................... 102

2-2-13. pulse handle override..........................................................................................................102

2-3. Screen display ...........................................................................................................................103

2-3-1. Current position display ........................................................................................................103

2-3-2. Shift amount display.............................................................................................................. 103

2-4. Coordinate conversion in the manual operation mode .............................................................103

2-5. Program example ......................................................................................................................104

2-5-1. Usage example of Euler angle .............................................................................................104

2-5-2. Usage example of 3 points ...................................................................................................105

2-6. Parameter setting.......................................................................................................................106

2-6-1. Slope machining parameter.................................................................................................. 106

2-6-2. NC optional parameter (slope machining function).............................................................. 108

2-7. Alarm List ...................................................................................................................................109

2-7-1. Alarm B .................................................................................................................................. 109

3. Slope Indexing command..................................................................................................... 112

3-1. Overview .................................................................................................................................... 112

3-2. Indexing example for each machine type.................................................................................. 113

3-2-1. Two table axes type .............................................................................................................. 113

3-2-2. Table and spindle type .......................................................................................................... 113

3-2-3. Two spindle axes type........................................................................................................... 114

3-3. Command format (G467)........................................................................................................... 115

3-4. Slope indexing operation and program sample ........................................................................ 115

3-4-1. G467 P0 ................................................................................................................................ 115

3-4-2. G467 P1 ................................................................................................................................ 117

3-5. System variable ......................................................................................................................... 119

3-6. Parameter .................................................................................................................................. 120

3-6-1. Rotary axis indexing range (NC axis)................................................................................... 120

3-6-2. Rotary Axis Indexing Range (Attachment) ...........................................................................122

3-6-3. Rotary Axis Indexing .............................................................................................................124

3-7. How to choose the indexing angle ............................................................................................ 125

3-8. Alarm List ...................................................................................................................................127

3-8-1. Alarm B ....................................................................................................................................................................................127

4. I-MAP function for Slope ...................................................................................................... 128

4-1. Overview ....................................................................................................................................128

4-1-1. Features...................................................................................................................................................................................128

4-2. Loading the slope pattern selection screen............................................................................... 130

4-3. Operation on the slope pattern selection screen....................................................................... 133

4-3-1. Pattern selection ...................................................................................................................133

4-3-2. Data setting ...........................................................................................................................135

4-4. Setting item and program format on screens of “Slope (G469)”...............................................136

4-4-1. Euler Angles ..........................................................................................................................136

4-4-2. Roll - Pitch - Yaw Angles ....................................................................................................... 136

4-4-3. 3 Points .................................................................................................................................137

4-4-4. 2 Vectors ...............................................................................................................................138

4-4-5. Projection .............................................................................................................................. 139

4-4-6. Tool Axial Direction................................................................................................................ 139

4-4-7. Rotary Center Axis ................................................................................................................ 140

4-4-8. XYZ Axis................................................................................................................................140

4-4-9. Slope Cancel......................................................................................................................... 141

4-4-10. Slope Indexing .................................................................................................................... 141

4-4-11. Outline explanation of messages........................................................................................ 142

4-4-12. Supplementary note............................................................................................................ 143

4-5. Setting item and program format on screens of “Slope (G69)”................................................. 144

4-5-1. Slope (G69)...........................................................................................................................144

4-5-2. Slope Cancel (G68) ..............................................................................................................145

4-5-3. Outline explanation of messages .........................................................................................145

4-5-4. Supplementary note.............................................................................................................. 145

4-6. Convert....................................................................................................................................... 146

4-6-1. Conversion example .............................................................................................................146

4-6-2.Supplementary note............................................................................................................... 149

_Toc278589520

PART 2 PARAMETERS

SECTION 1 ROTARY AXIS PARAMETERS............................................. 151

1. ROTARY AXIS PARAMETERS............................................................................................ 151

1-1. Rotary Axis Attribute................................................................................................................... 151

1-2. Rotation Center..........................................................................................................................154

1-3. Pivot Distance Compensation ...................................................................................................156

_Toc278589526

PART 3 PROCEDURES FOR MEASURING AND SETTING ROTARY

AXIS CENTER POSITION

SECTION 1 TWO ROTARY AXES ON THE TABLE (ROTARY

C-AXIS/INCLINED A-AXIS)................................................... 158

1. OVERVIEW.......................................................................................................................... 158

2. MEASURING ROTARY AXIS CENTER POSITION ............................................................ 158

2-1. Measuring the Position of the C-axis Rotation Center.............................................................. 159

2-2. Measuring the Position of the A-axis Rotation Center ..............................................................160

3. SETTING ROTARY AXIS PARAMETERS........................................................................... 162

3-1. Setting Values on the Pivot Distance Compensation Display................................................... 163

3-2. Setting Values on the Rotation Center Display .........................................................................165

SECTION 2 TABLE AXIS AND SPINDLE AXIS

(ROTARY C-AXIS ON THE TABLE AND

INCLINED A- OR B-AXIS OF THE SPINDLE)...................... 167

1. OVERVIEW.......................................................................................................................... 167

2. MEASURING ROTARY AXIS CENTER POSITION ............................................................ 168

2-1. Measuring the Position of the C-axis Rotation Center.............................................................. 169

2-2. Measuring the Position of the A-axis Rotation Center (MILLAC-800VH, etc.) .........................170

2-3. Measuring the Position of the B-axis Rotation Center (MILLAC-1000VH, etc.) .......................172

3. SETTING ROTARY AXIS PARAMETERS........................................................................... 174

3-1. Setting Values on the Pivot Distance Compensation Display................................................... 175

3-2. Setting Values on the Rotation Center Display .........................................................................178

SECTION 3 TWO SPINDLE AXES

(ROTARY C-AXIS/INCLINED B-AXIS) ................................. 180

1. OVERVIEW.......................................................................................................................... 180

2. MEASURING ROTARY AXIS CENTER POSITIONS.......................................................... 180

2-1. Measuring the B-axis Rotation Center Position ........................................................................181

2-2. Measuring the C-axis Rotation Center Position ........................................................................ 184

3. SETTING ROTARY AXIS PARAMETERS ........................................................................... 187

3-1. Setting Values on the Pivot Distance Compensation Display................................................... 188

3-2. Setting Values on the Rotation Center Display .........................................................................190

SECTION 4 TWO TABLE AXES (ROTARY A-AXIS/INCLINED

B-AXIS).................................................................................. 192

1. OVERVIEW.......................................................................................................................... 192

2. MEASURING ROTARY AXIS CENTER POSITION ............................................................ 192

2-1. Measuring the Position of the A-axis Rotation Center ..............................................................193

2-2. Measuring the Position of the B-axis Rotation Center ..............................................................195

3. SETTING ROTARY AXIS SYSTEM PARAMETERS ........................................................... 197

4. SETTING ROTARY AXIS PARAMETERS........................................................................... 198

4-1. Setting Values on the Rotary Axis Attribute Display .................................................................. 199

4-2. Setting Values on the Pivot Distance Compensation Display................................................... 200

4-3. Setting Values on the Rotation Center Display .........................................................................202

PART 1 5-AXIS MACHINING FUNCTION

- 1 -

SECTION 1 ACTUAL POSITION DISPLAY

1. Overview

This manual explains about the displays of coordinate values and status indicators used in the 5-axis

machining functions in the AUTO, MDI, and MANUAL modes.

2. ACTUAL POSITION display

2-1. Display of Various Types of Coordinate Systems

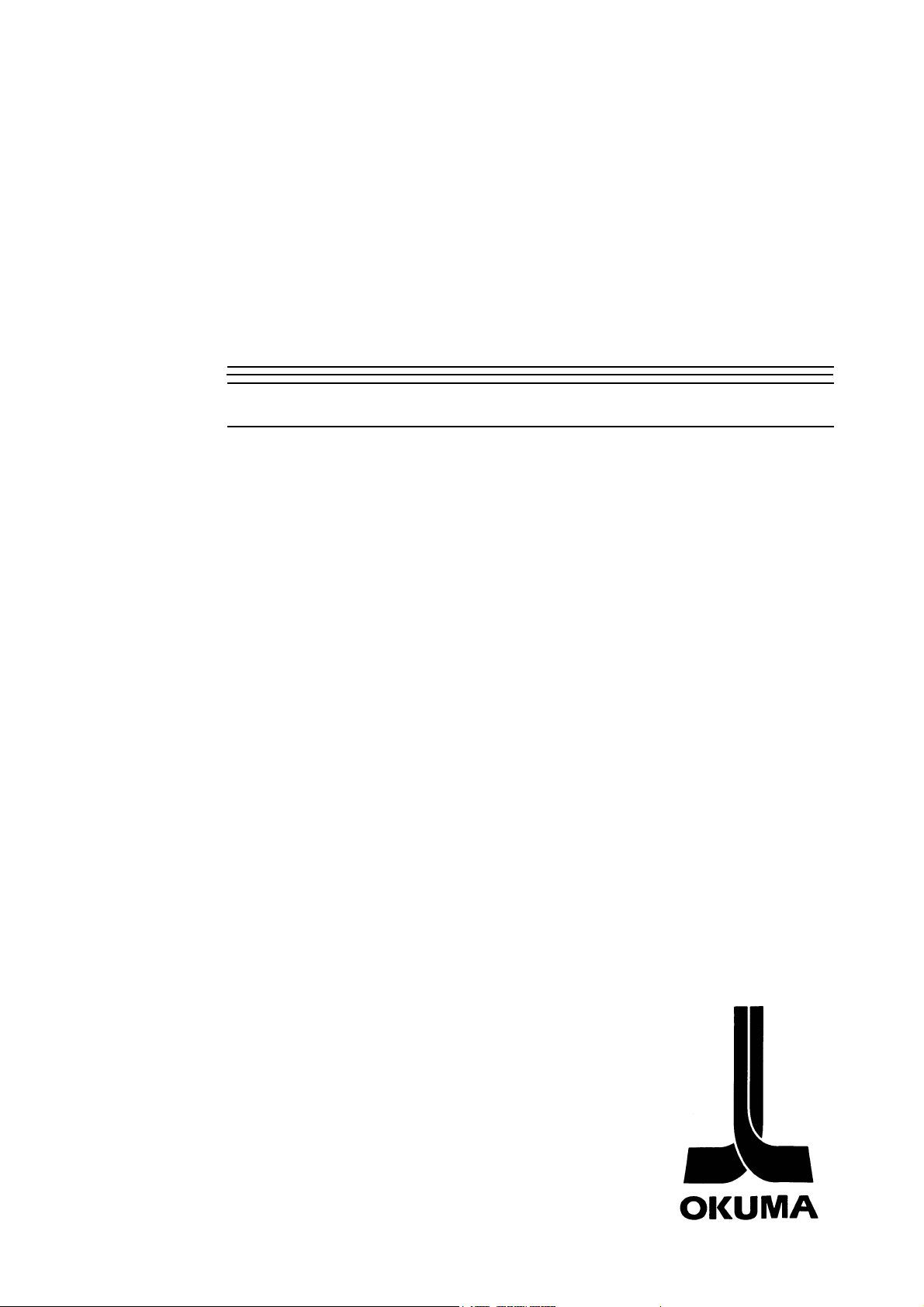

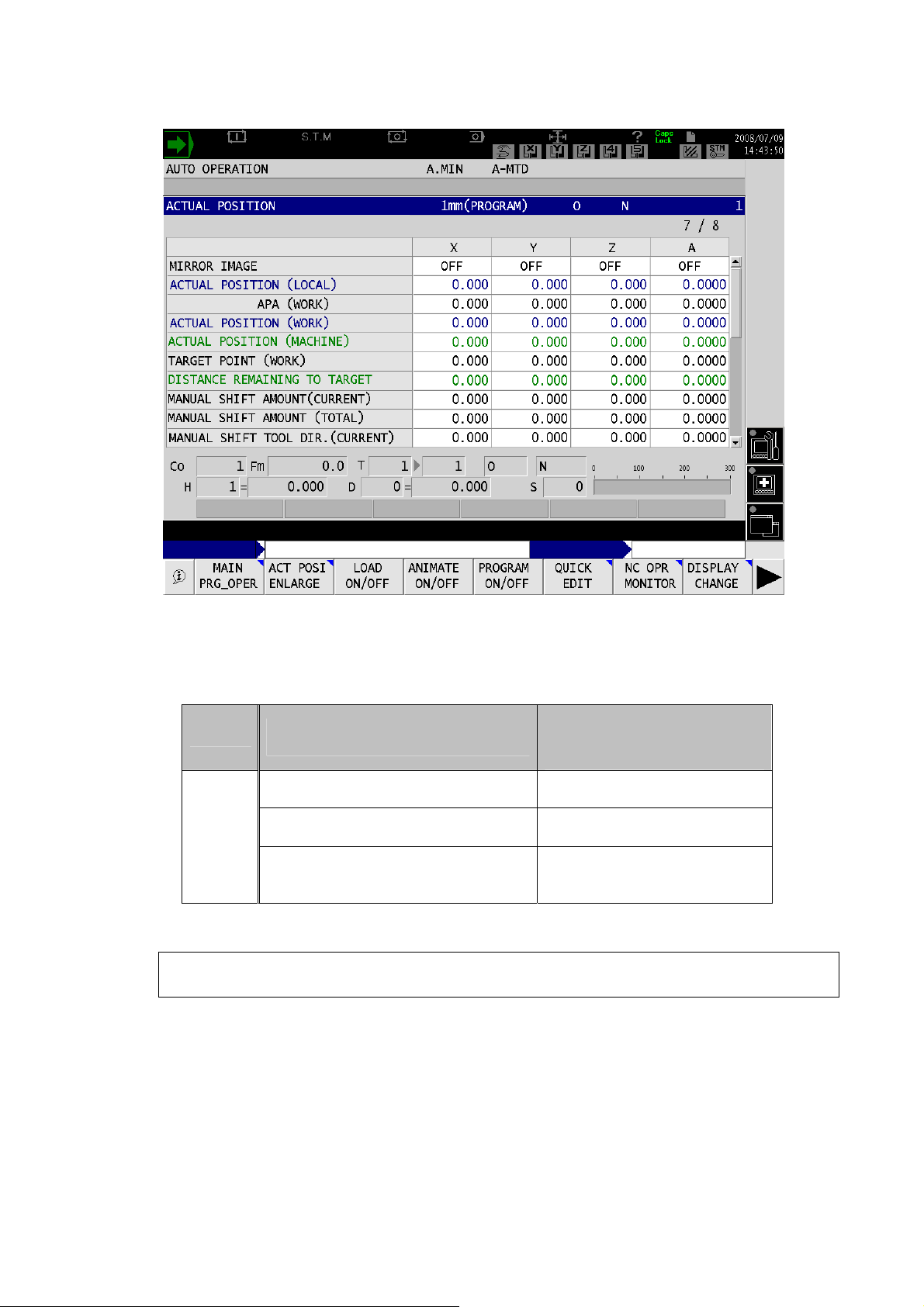

(1) Actual Position Display of Current Coordinate System

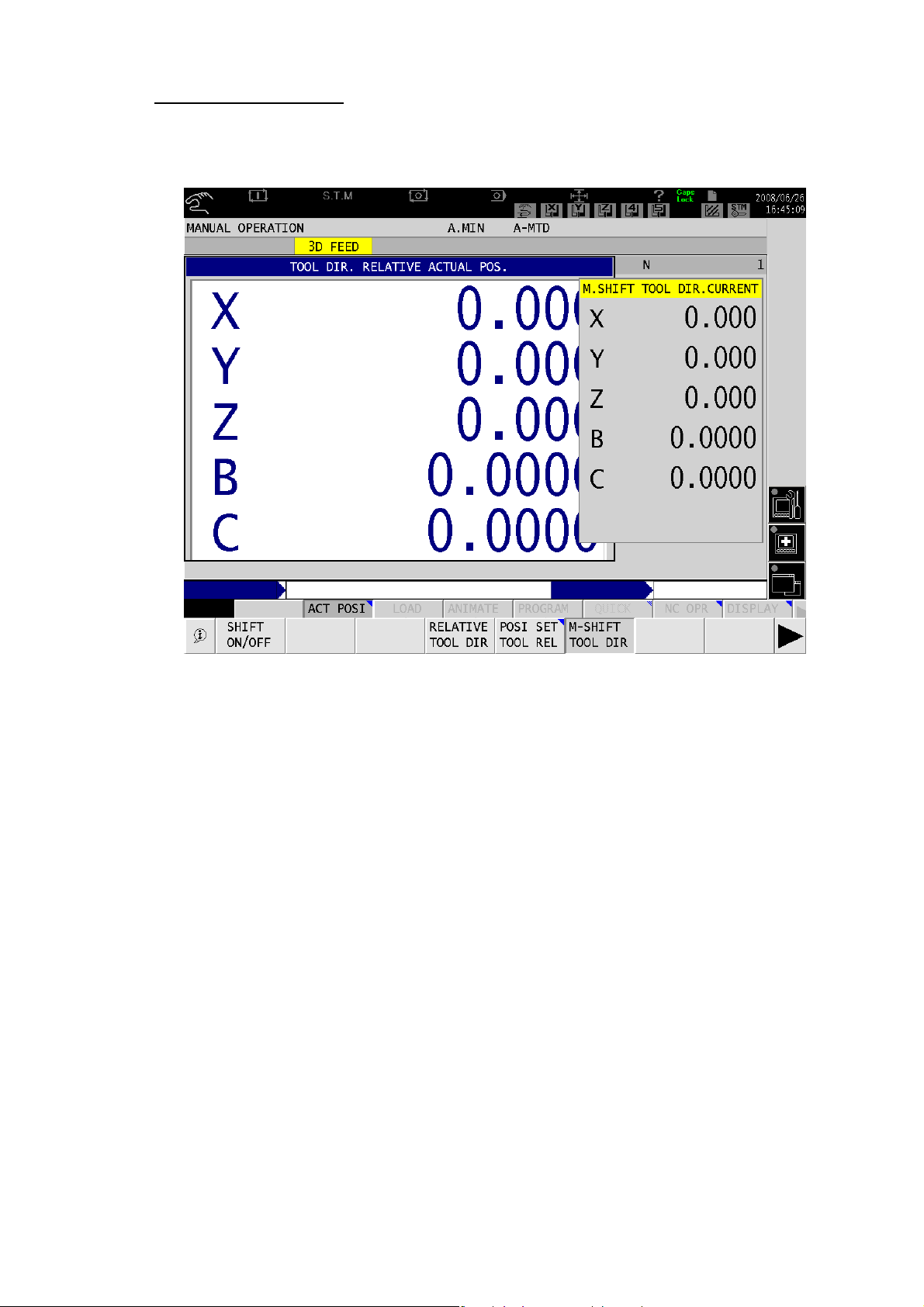

Fig. 1-1 Actual position display screen of current coordinate system

The second page of the actual position display under the operation mode screen shows the coordi-

nate values of the currently selected

The current position display function is available for the following types of coordinate systems:

- Local coordinate system

- Work coordinate system

- Slope coordinate system

- Slope local coordinate system

- Table coordinate system

You can check which coordinate system is currently selected in the comment next to the ACT POSI

and DISTANCE at top of the screen.

coordinate system.

- 2 -

Fig. 1-2 Local coordinate system

Fig. 1-4 Slope coordinate system

Fig. 1-3 Work coordinate system

Fig. 1-5 Slope local coordinate system

Fig. 1-6 Table coordinate system

The display shows the coordinate values of up to 6 axes including linear and rotary axes in one page.

For X, Y, and Z-axes, coordinate system is converted and displayed. For rotary and the additional lin-

ear axes, the current positions of the work coordinate system are to be displayed.

- 3 -

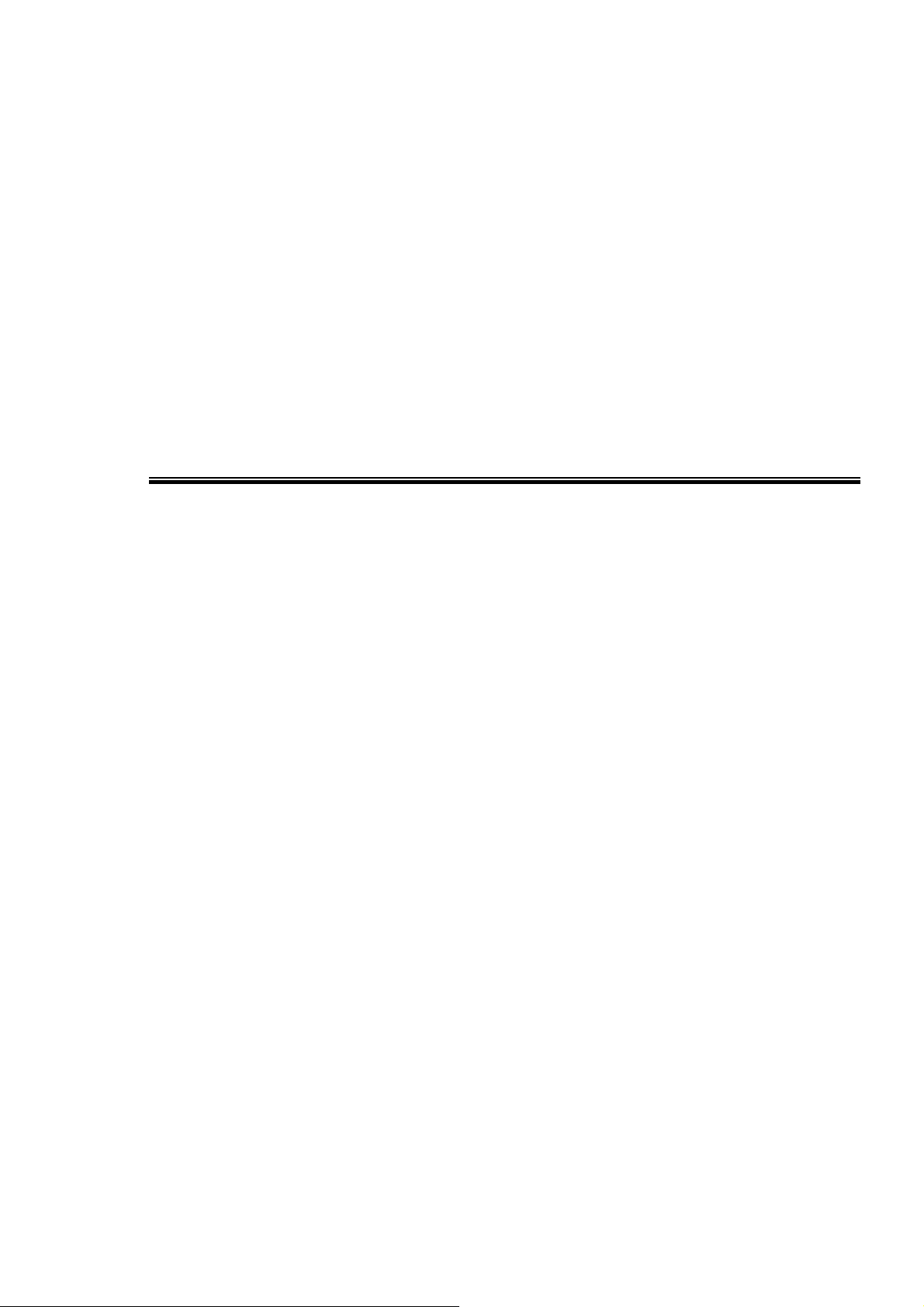

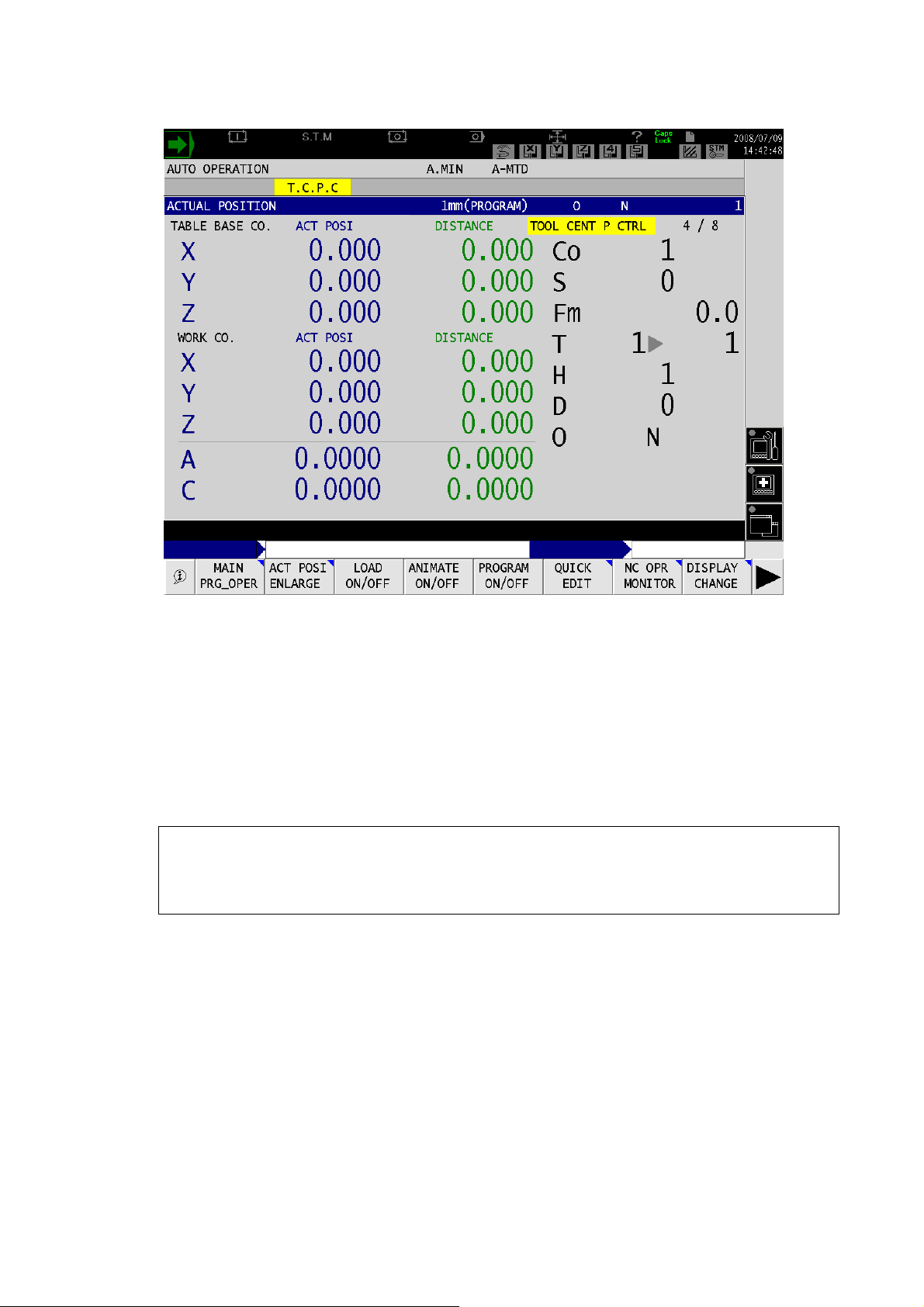

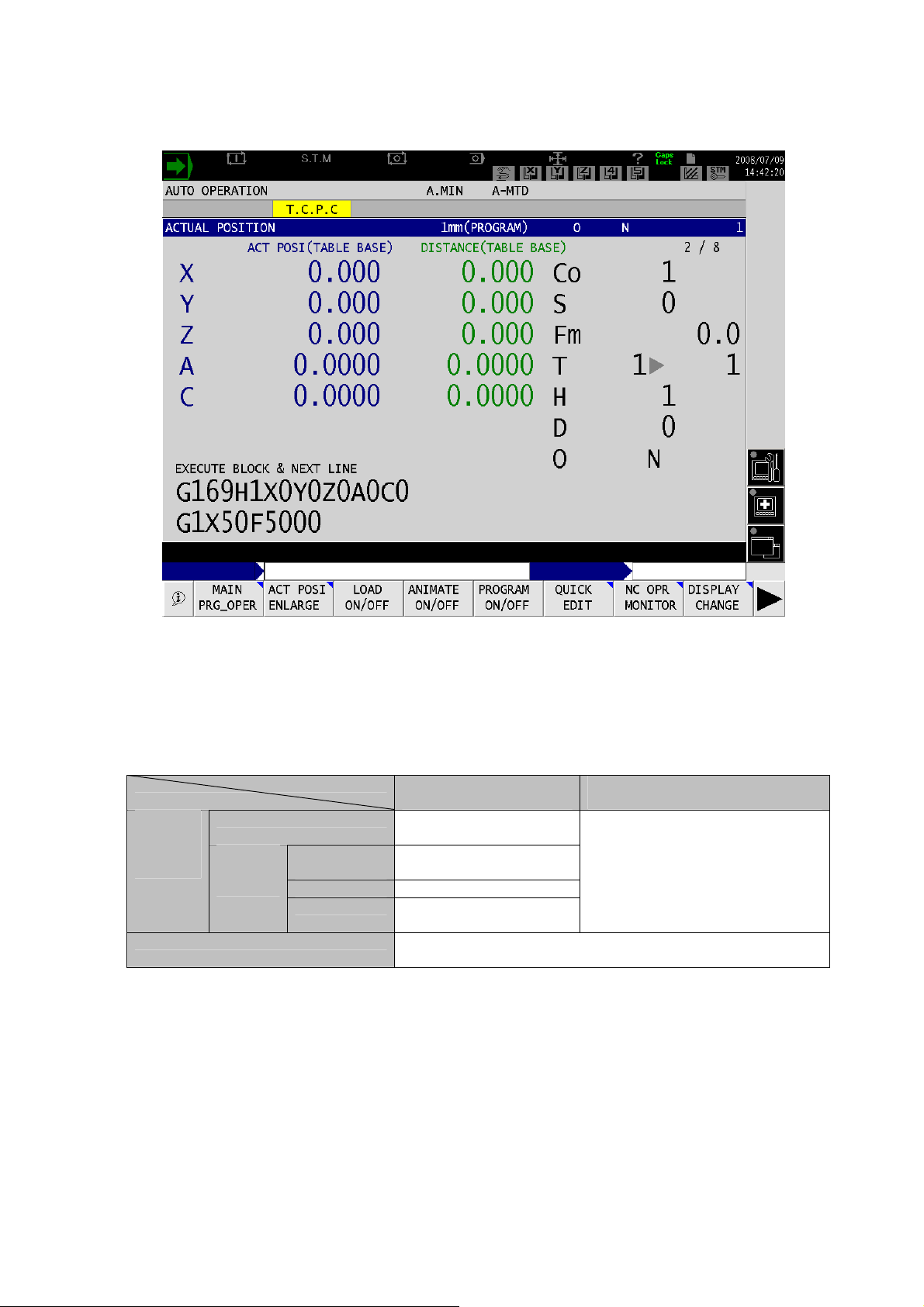

(2) Actual Position of Table Coordinate System

Fig. 1-7 Actual Position of Table Coordinate System

The display shows the coordinate values of the table coordinate system and work coordinate system

in one page. The current position and distance to the target are shown for both coordinate systems.

The rotary axis is only on the Table side and it is shown in the work coordinate system. Indicator

lamp saying T. C. P. C. that indicates that the system is in the tool center point control mode is

shown at the right top, to the left of the page number.

[Supplement]

1) This screen appears when the following conditions are met:

- Tool nose point control, manual feed of tool nose center, or manual feed of table basic coordinate is effective.

- The machine is constructed so that the table has a rotary axis.

- 4 -

(3) Actual Position, APA, Shift Amount, Target Point, and Distance to Target at a Glance

Fig. 1-8 Display Screen for Actual Position of Each Coordinate System, APA, Shift Amount, Target Point, Dis-

tance Remaining to Target, etc.

Following items will be on the display according to the set specification.

Tool Center Point Control

Tool Nose Center Manual Feed

Function

Tool axial direction

manual feed

Table Coordinate Manual Feed

Current Position

(Table Coordinate)

Distance Remaining to Target

(Table Coordinate)

-

Items

MANUAL SHIFT AMOUNT (CURRENT)

MANUAL SHIFT AMOUNT (TOTAL)

RELATIVE ACUTUAL (CURRENT)

POSITION

(TOOL AXIAL DIRECTION)

[Supplement]

1) The above items appear when any of the followings is activated: the tool center point control,

tool axial direction manual feed, tool nose center manual feed, or table coordinate manual feed.

- 5 -

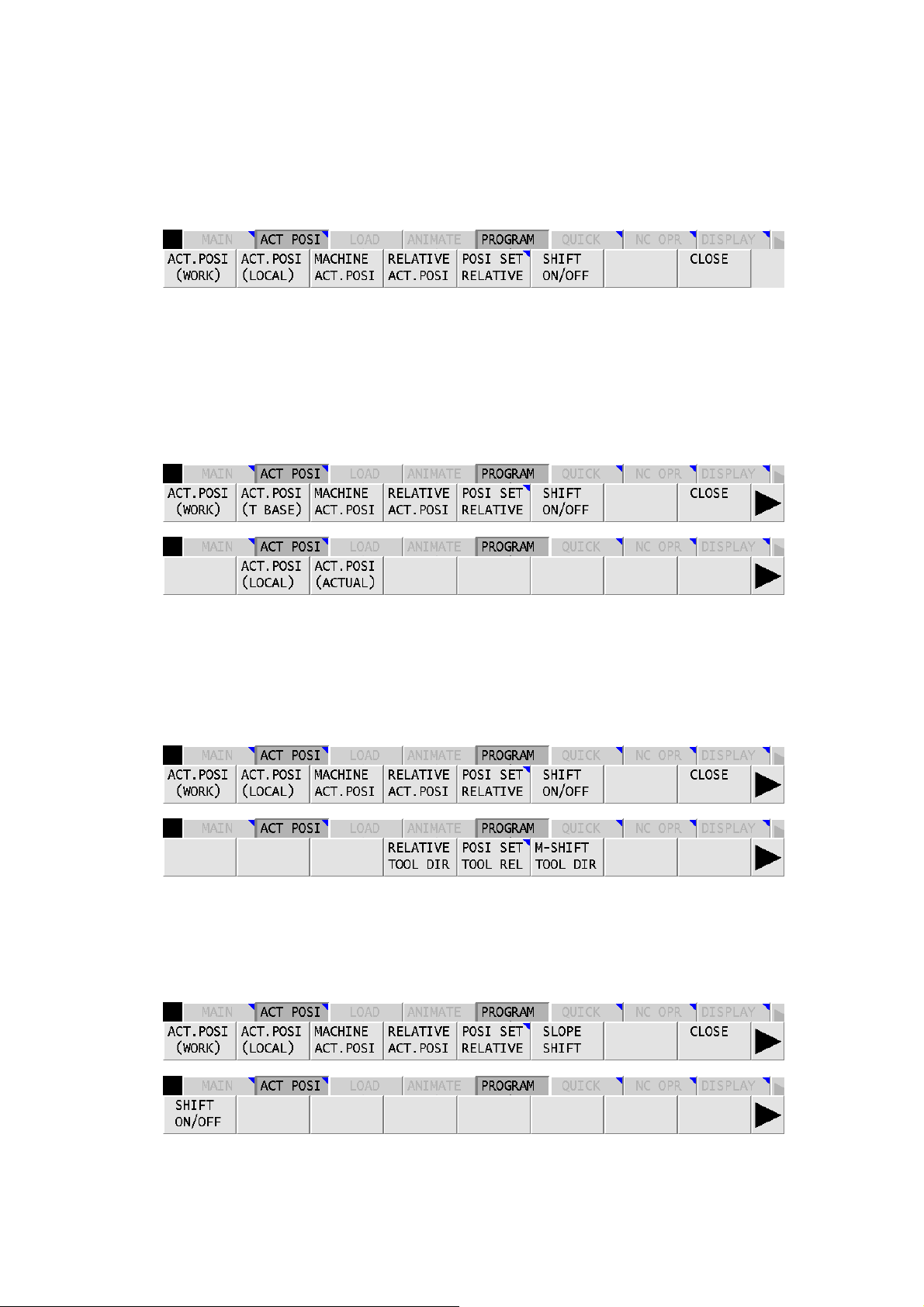

(4) Enlarged Display of Current Position

Press the ACT POSI ENLARGE function under the operation mode to show the pop-up functions

below. Note that pop-up functions differ from the ones for the standard specifications with different

optional specifications.

1) Standard specifications

Fig. 1-9 Function Menu for the Standard Specifications

For TOOL CENTER POINT CONTROL, TOOL NOSE CENTER MANUAL FEED, and TABLE

2)

COORDINATE MANUAL FEED

The [F2] (ACT.POSI (T BASE)) key appears for the function menu of the tool center point control,

tool nose center manual feed, or table coordinate manual feed.

The [F2] (ACT.POSI (LOCAL)) and [F3] (ACT.POSI (ACTUAL)) keys appears in the extended function menu.

Fig. 1-10 Function Menus of Tool Center Point Control, Tool Nose Center Manual Feed, and Table Coor-

dinate Manual Feed

3) For TOOL AXIAL DIRECTION MANUAL FEED

[F4] (RELATIVE TOOL DIR), [F5] (POSI SET TOOL REL), and [F6] (M-SHIFT TOOL DIR) appear

in the extended menu respectively.

Fig. 1-11 Function Menus of Tool Axial Direction Manual Feed

4) For SLOPE MACHINING

The [F6] (SLOPE SHIFT) key appears in the function menu.

The [F1] (SHIFT ON/OFF) key appears in the extended function menu.

Fig. 1-12 Function Menus of Slope Machining

Function menu display differs with different combination of the functions above.

- 6 -

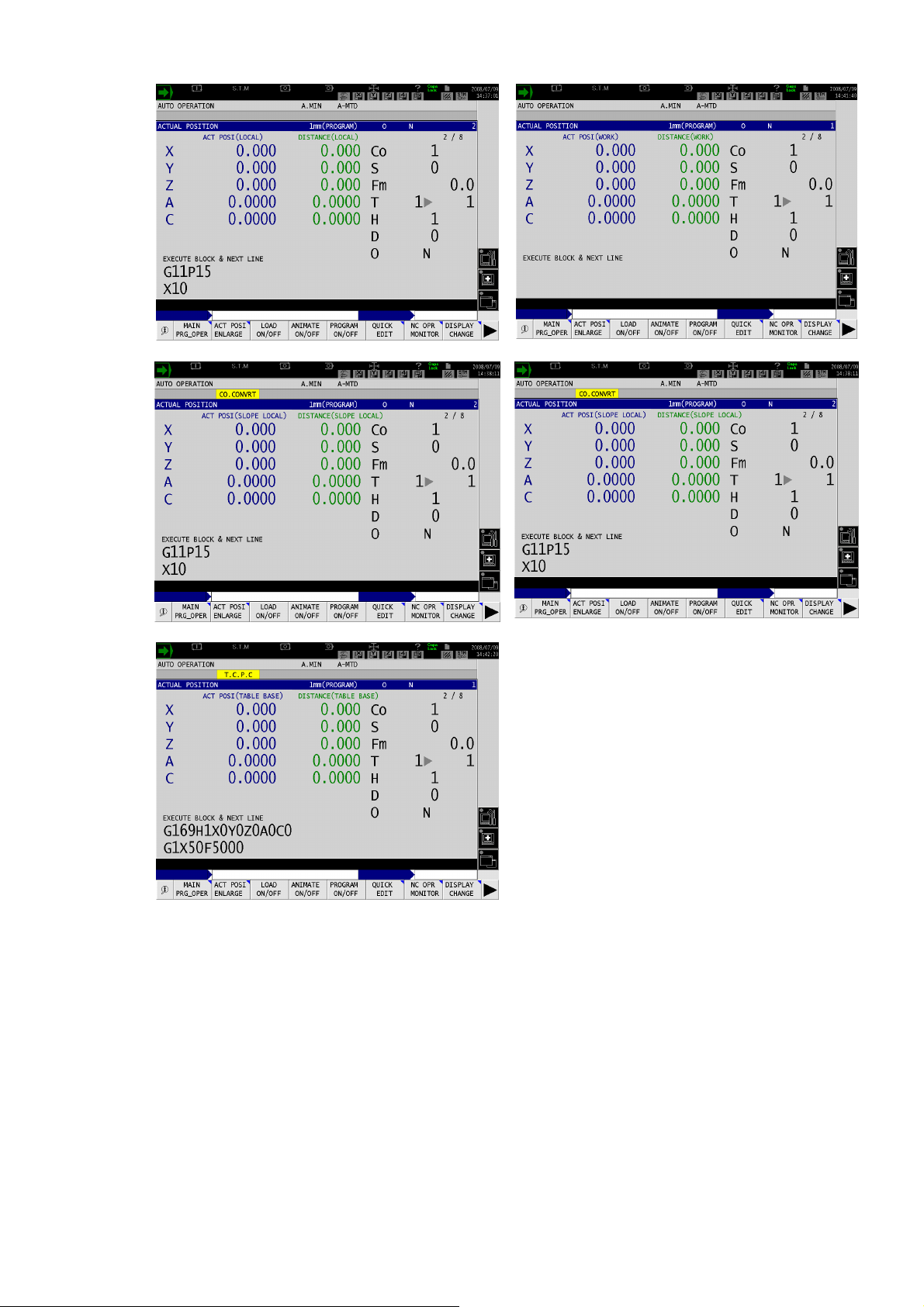

2-2. Display of Status Indicator Lamp

Fig. 1-13 Display of Status Indiactor Lamp

Status indicator lamps available are “CO. CONVET” (slope) for coordinate system is being converted,

“3D FEED” (table coordinate manual feed, tool axial direction manual feed, and tool nose center manual

feed) and “

Manual Interrupt

AUTO,

MDI

operation

mode

Manual operation mode “CO. CONVET” or “3 D FEED” appears according to the setting of

T.C.P.C” that indicates tool center point control is on.

OFF

NC reset status Off

(Nothing on the display)

Program

in progress

During G69

and G469

During G169 T.C.P.C

Others Off

CO. CONVET

(Nothing on the display)

the angle and 3D D FEED switches.

Manual Interrupt

ON

“CO. CONVET” or “3D FEED” appears according to the setting of the

angle and 3D FEED switches.

Note that the status indicator display does not change with ON or OFF status of the pulse override in the

AUTO or MDI operation mode.

- 7 -

SECTION 2 MANUAL FEED FUNCTION

1. Tool Axial Direction Manual Feed and Perpendicular to the Tool Axial Direction

Manual Feed

1-1. Overview

This function is designed for machines with a rotary axis on the spindle side. The function enables manual rapid traverse, manual cutting feed, and manual pulse handle feed of X, Y, and Z-axes when Z-axis is

the tool axial direction. This manual feed function is effective in the index attachments mounted in the

double-column machining center, such as angular attachment, universal attachment, and swivel head.

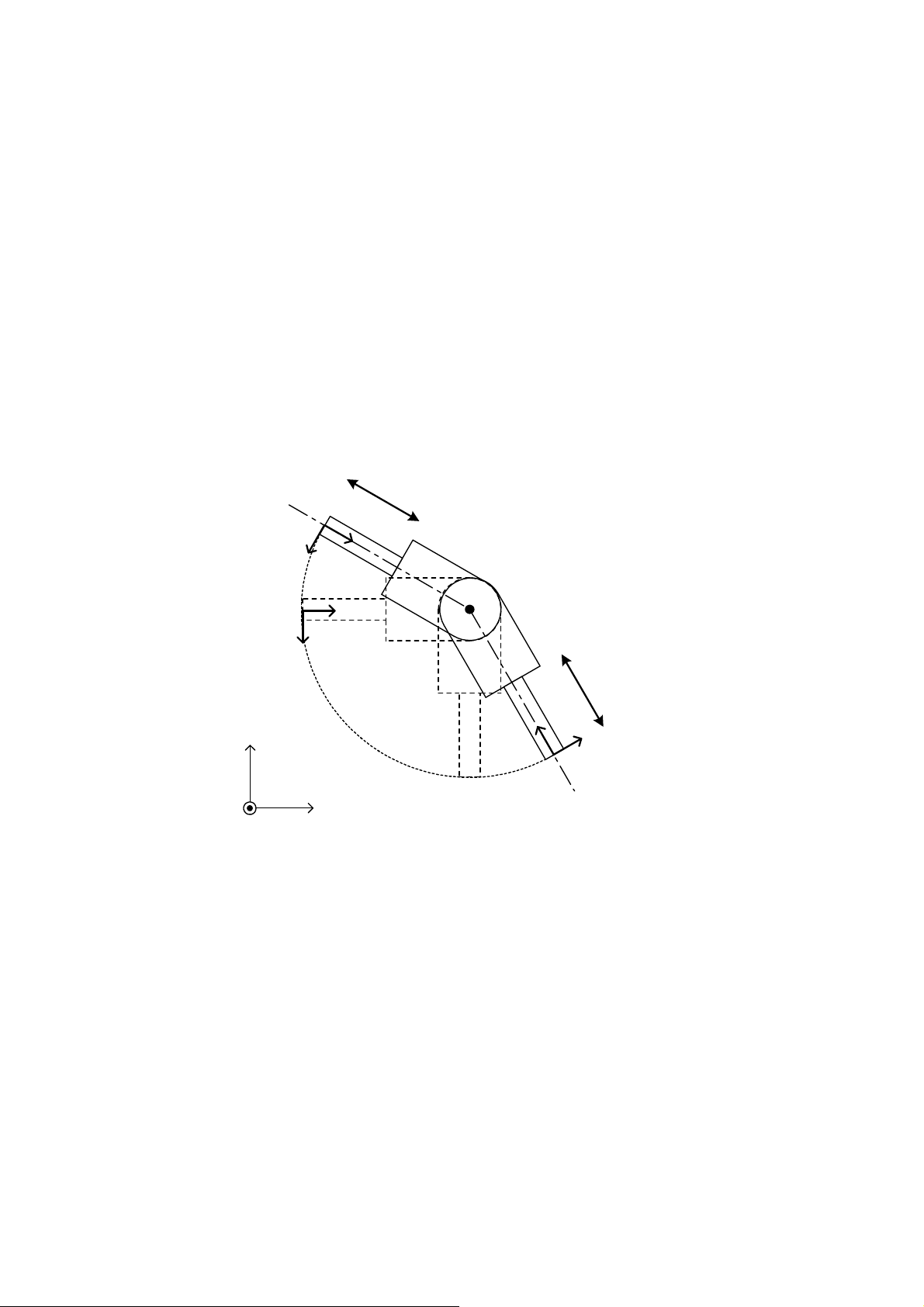

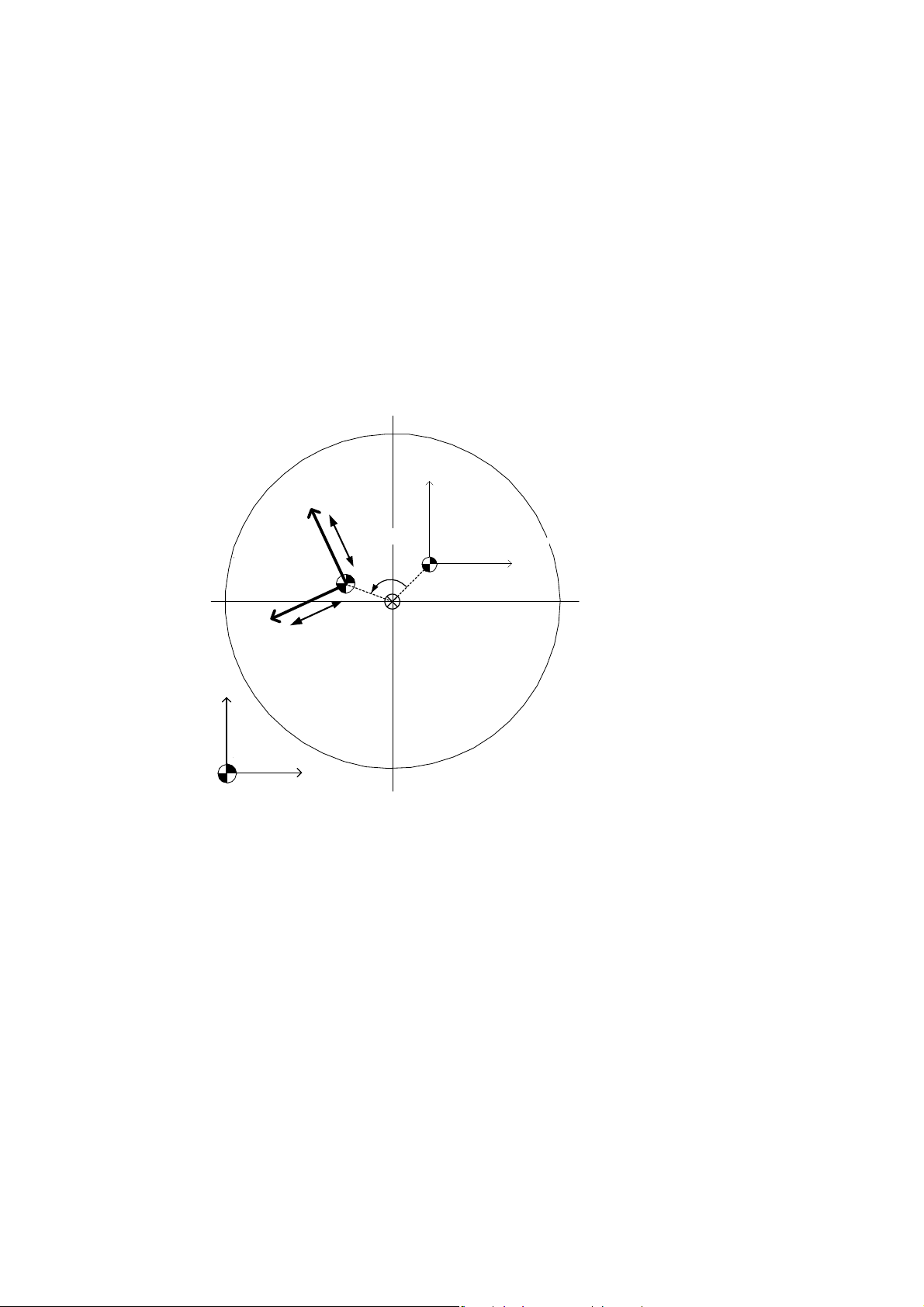

(1) Example of a Machine with A-axis on the Spindle Side

The diagram below shows the relationship between A-axis angle and its feed direction. It is how it appears when you look at the negative direction (-) of the X-axis from the positive (+) direction of the

X-axis. The positive (+) and negative (-) signs are the moving directions when Z-axis is selected for the

tool axial direction manual feed. Moving direction changes with A-axis angle also when Y-axis (the direction perpendicular to the tool spindle) is selected for the tool axial direction manual feed. X-axis is not

dependent on the A-axis angle and it is perpendicular to this document.

-

+

A-120°

Z

Y

Z

A-90°

Y

Z

+

Z

-

Y

A+30°

A0°

X

The multiple rotary axes on the spindle side also move in the tool axial direction and the direction perpendicular to the tool axial direction according to their indexed angle.

Y

Fig. 2-1 (Spindle side) A-axis Angle and Manual Feed Direction

- 8 -

1-2. Operation

(1) MANUAL Operation Mode

Turn on the 3D FEED switch, select the axis out of X, Y, or Z-axis with the MANUAL FEED AXIS

SELECTION key on the machine panel or with the manual pulse handle axis selection switch, and

move the axis in the tool axial direction or direction perpendicular to it.

* The 3D FEED switch is displayed as “3D” on the operation panel depending on models. Regard the

description of 3D FEED below as 3D in that case.

(2) AUTO/MDI Operation Mode

- Pulse Handle Override

If the pulse handle override and the 3D FEED ON/OFF switch are both turned on, “4337

Alarm-D Tool nose center man-feed func is invalid” will appear. While this alarm is ON, it is still

possible to manually feed the axis in the tool axial direction or in the direction perpendicular to it.

However, note that “1336 Alarm-A The manual shift remains. Be warned axis move.” will be

raised if G169 or G171 mode is ON.

- Manual Interrupt

Manual feed in the tool axial direction and the direction perpendicular to it are possible while

manual interrupt mode is ON. However, if the shift amount (total) remains (≠0) when the manual

interruption is turned off in G169/G171 mode, “1336 Alarm-A The manual shift remains. Be

warned axis move” appears. Make sure to set the shift amount (total) to zero manually or with a

sequence restart switch before you exit the manual interrupt mode. (For details, see “TOOL

CENTER POINT CONTROL” and “TOOL AXIAL DIRECTION TOOL LENGTH

COMPENSATION” in this manual)

[CAUTION]

If the machine has rotary axes on the spindle and table sides, the axial movement of X, Y, and

Z-axes fed with the 3D FEED switch differs according to the NC optional parameter bit settings

below. Turn the parameter bit OFF to enable the tool axial manual feed and perpendicular to

the tool axial direction manual feed.

NC Optional Parameter Bit

No. bit Description

Specifies the coordinate system which will be

selected when the three fundamental axes are

78 6

fed manually after the 3D FEED switch is turned

on on the machine with a rotary axis on the spindle side and table side respectively.

Selects the

table base coordinate system.

Selects the

tool axis

coordinate

system.

Initial

status

- 9 -

1-3. Screen Display

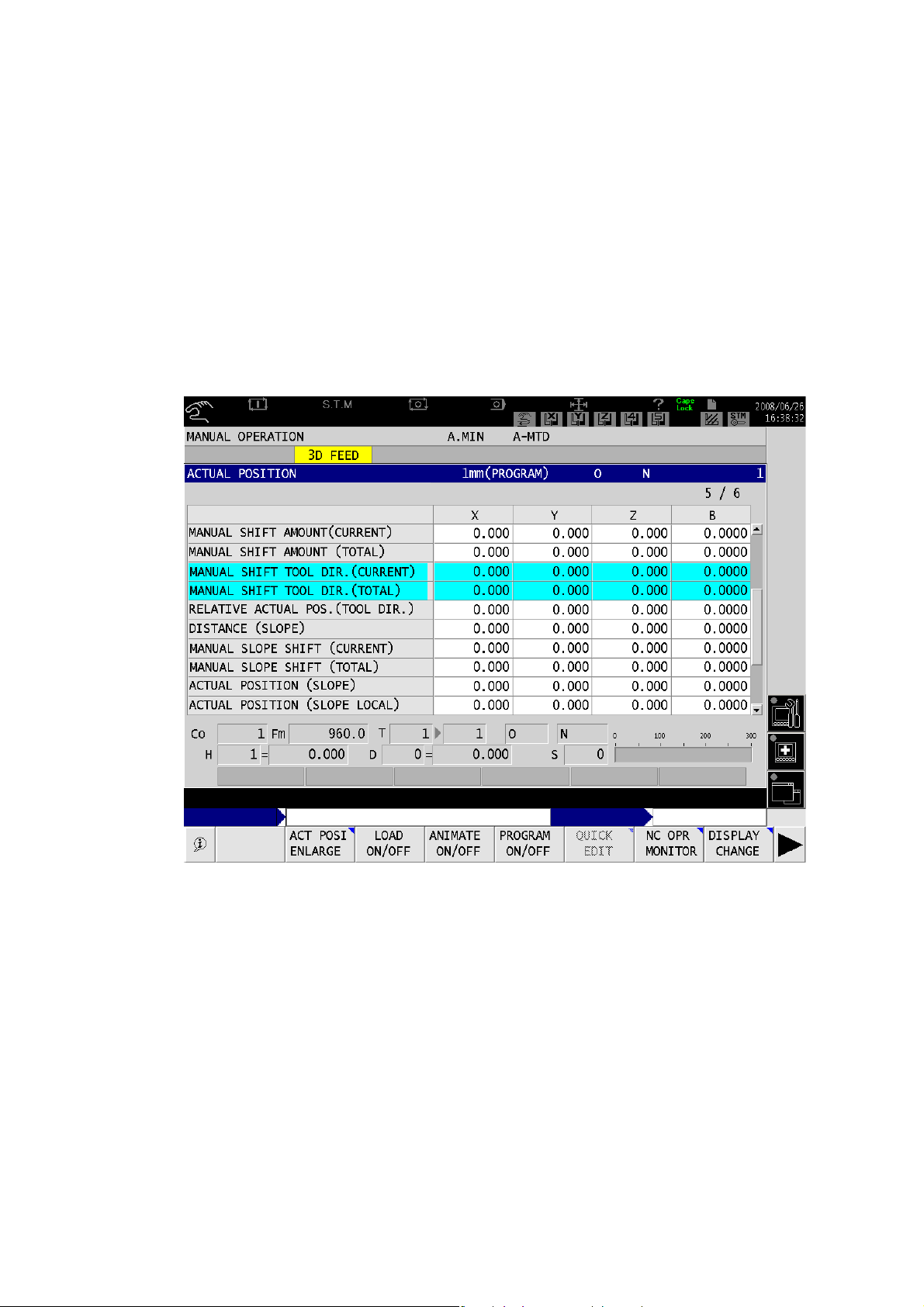

(1) ACTUAL (CURRENT) Position, APA, Shift amount, Traget position, and Distance remaining to the

target at a Glance

Feed the page of the ACTUAL (CURRENT) POSITION screen under the operation screen to see the informa-

tion on the following items:

- MANUAL SHIFT AMOUNT (CURRENT)

- MANUAL SHIFT AMOUNT (TOTAL)

- RELATIVE CURRENT POSITION (TOOL AXIAL DIRECTION)

MANUAL SHIFT AMOUNT (CURRENT) and MANUAL SHIFT AMOUNT (TOTAL) will be highlighted in

blue when you turn the manual operation mode or manual interrupt ON and the feed in the tool axial direction and the direction perpendicular to it become valid.

When manual feed in the tool axial direction and the direction perpendicular to it are valid:

Fig. 2-2

- 10 -

When manual feed in the tool axial direction and the direction perpendicular to it are valid

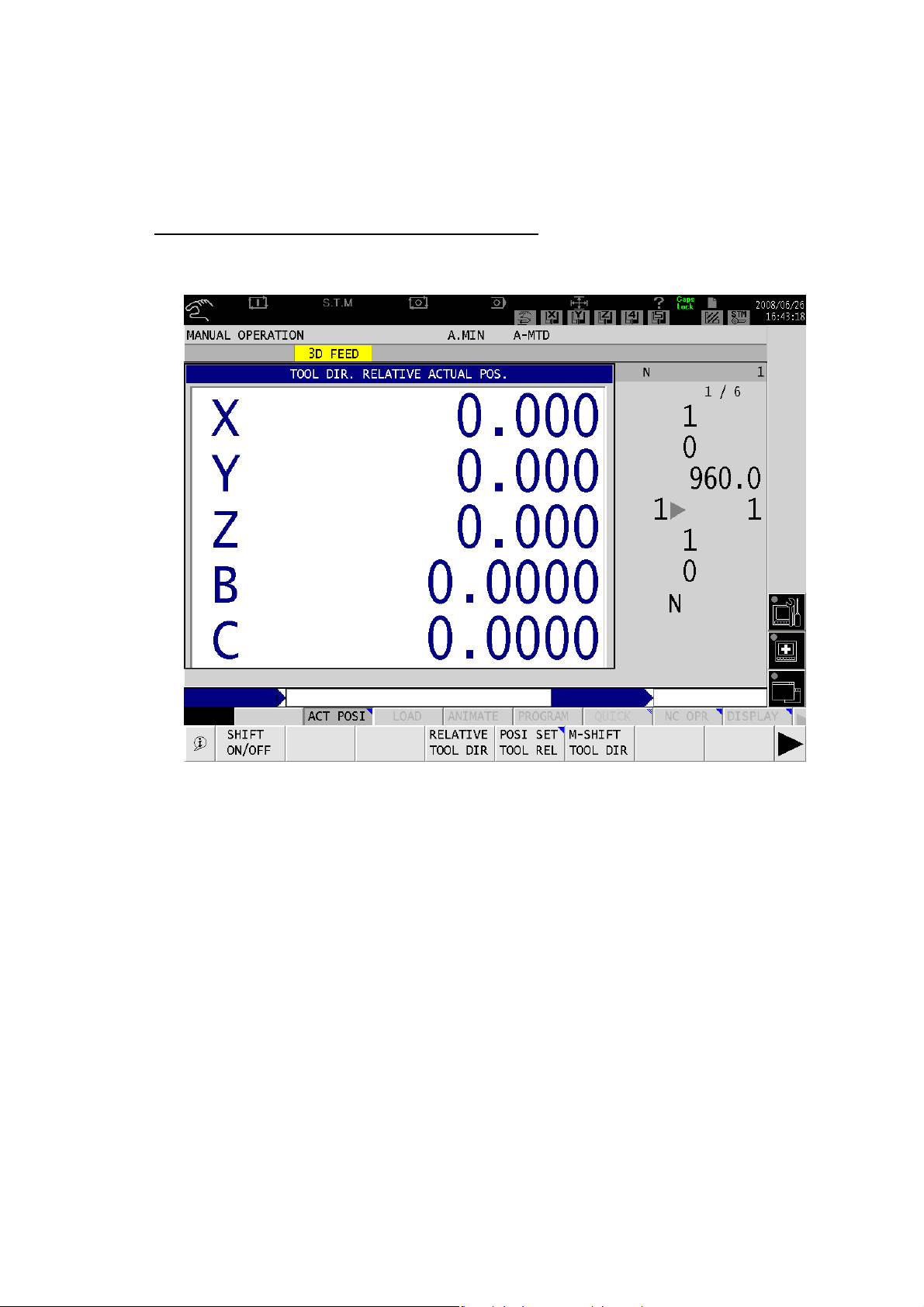

(2) Enlarged Current Position Window

Following function keys will appear in the pop-up function opened by [F2] (ACT POSI ENLARGE) under the

operation mode screen.

- TOOL DIRECTION RELATIVE ACTUAL (CURRENT) POSITION

- POSITION SET (TOOL)

- TOOL SHIFT ON/OFF

Tool Direction Relative Actual (Current) Position Function

Press the TOOL DIR. RELATIVE ACTUAL POS. function key to open the TOOL DIRECTION

RELATIVE ACTUAL POSITION window. Meanwhile, [F5] (POSI SET TOOL REL).

Fig. 2-3 TOOL DIR. RELATIVE ACTUAL POS. Screen

The window shows the RELATIVE ACTUAL POSITION of the coordinate system whose Z-axis is

the spindle axis. Set the zero point for this coordinate system in the POSITION SET window. Press

the POSITION SET function key to open the window.

- 11 -

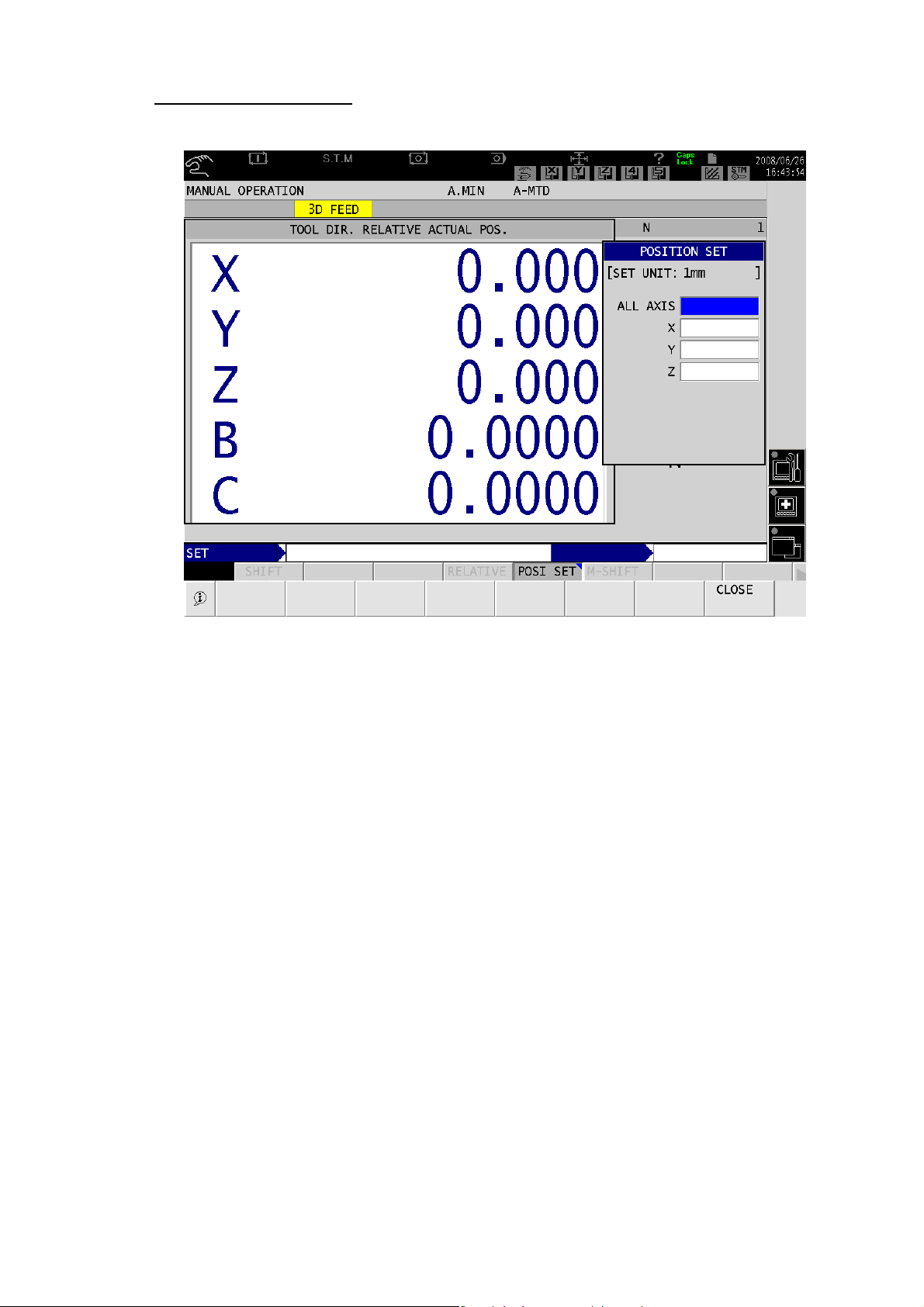

Position Set (Tool) Function

Press the [F5] (POSI SET TOOL REL) key to open the “POSITION SET” window.

Fig. 2-4 POSITION SET Window

When you start the manual interrupt, you can check the distance remaining to the target when you

feed the axis in the tool axial direction by setting the relative current position of the tool axial direction

zero in this window.

If the input data were recognized as numeric data, “Error 5343 Numerical data” will occur.

If the input data were out of the valid numeric data range, “Error 5209 Input data overflow” will occur.

Relative positions will be set for X, Y, and Z-axes when a value is given for ALL AXIS. Values used

for the relative positions for the tool axial direction, the normal relative positions, and the current position of the slope relative position will not be shared.

- 12 -

Tool Shift ON/OFF Function

Press the function key to open the M.SHIFT TOOL DIR. CURRENT window. Turn the manual operation

mode or manual interrupt ON. The title on top of the window turns yellow if the manual feed in the tool

axial direction or the direction perpendicular to it is valid.

Fig. 2-5 M. SHIFT TOOL DIR. CURRENT Window

- 13 -

Y

2. Table Coordinate Manual Feed

2-1. Overview

Table coordinate manual feed function is designed for machines with a rotary axis on the table side. The

function enables manual rapid traverse, manual cutting feed, and manual pulse handle feed of X, Y, and

Z-axes for the datum coordinate system of the tilted table or the rotary table.

This function is intended for the NC rotary axis (min. input increment: 0.001° or 0.0001°).

(1) Example of a Machine with C-axis on the Table Side

Following diagram shows the relationship between C-axis angle and its moving direction. It is how it

appears when you look at the negative direction (-) of the Z-axis from the positive (+) direction of the

Z-axis. Table Coordinate System rotates according to the C-axis’s indexed angle. In the example below,

both X- and Y-axes move simultaneously if you attempt to move the X- or Y-axis of the table coordinate

system. Z-axis is independent from the C-axis angle and it is perpendicular to this document.

Y

X

+

X-axis

Operation

テーブル基準

Table

Coordinate

座標系

System

Y

+

Y

X軸操作

-

作

-axis

操

軸

Operation

-

Work Coordinate-

ワーク座標系原点

System

C軸旋回中心

Center of C-axis Rotary

X

Y

Machine

機械座標系

Coordinate System

X

Fig. 2-6 Table Side C-axis Angle and Manual Feed Direction

For machines with multiple rotary axes on the table side, their axial movements are to be according to the

table coordinate system determined by their indexed angles.

- 14 -

2-2. Operation

(1) MANUAL Operation Mode

Turn 3D FEED switch ON and select the desired axis out of X, Y, and Z-axis with the manual feed axis selection key on the machine operation panel or manual pulse handle axis selection switch. The selected axis

will move based on the table coordinate system in manual rapid traverse, manual cutting feed, or manual

pulse handle feed.

(2) AUTO/MDI Operation Mode

Table coordinate manual feed moves in the AUTO/MDI operation mode as follows.

- Pulse Handle Override

If the pulse handle override and the 3D FEED ON/OFF switch are both turned on, “4337

Alarm-D Tool nose center man-feed func is invalid” will appear. While this alarm is ON, it is still

possible to feed the axes in table coordinate manual feed. However, note that “1336 Alarm-A

The manual shift remains. Be warned axis move.” will be raised if G169 or G171 mode is ON.

- Manual Interrupt

Manual feed in the table coordinate is possible while manual interrupt mode is ON. However, if

the shift amount remains (≠0) when the manual interruption is turned off in G169/G171 mode,

“1336 Alarm-A The manual shift remains Be warned axis move” appears. Make sure to set the

shift amount (total) to zero manually or with a sequence restart switch before you exit the manual interrupt mode. (For details, see “TOOL CENTER POINT CONTROL” and “TOOL AXIAL

DIRECTION TOOL LENGTH COMPENSATION” in this manual.)

[CAUTION]

If the machine has rotary axes on the spindle and table sides, the axial movement of X, Y, and

Z-axes fed with the 3D FEED switch differs according to the NC optional parameter bit settings

below. Turn the parameter bit ON to enable the table coordinate manual feed.

NC Optional Parameter Bit

No. bit

Specifies the coordinate system which will be

selected when the three fundamental axes are

78 6

fed manually after the 3D FEED switch is turned

on on the machine with a rotary axis on the spindle side and table side respectively.

Description

Selects the

table base coordinate system.

Selects the

tool axis

coordinate

system.

Initial

status

- 15 -

3. Tool Nose Center Manaul Feed

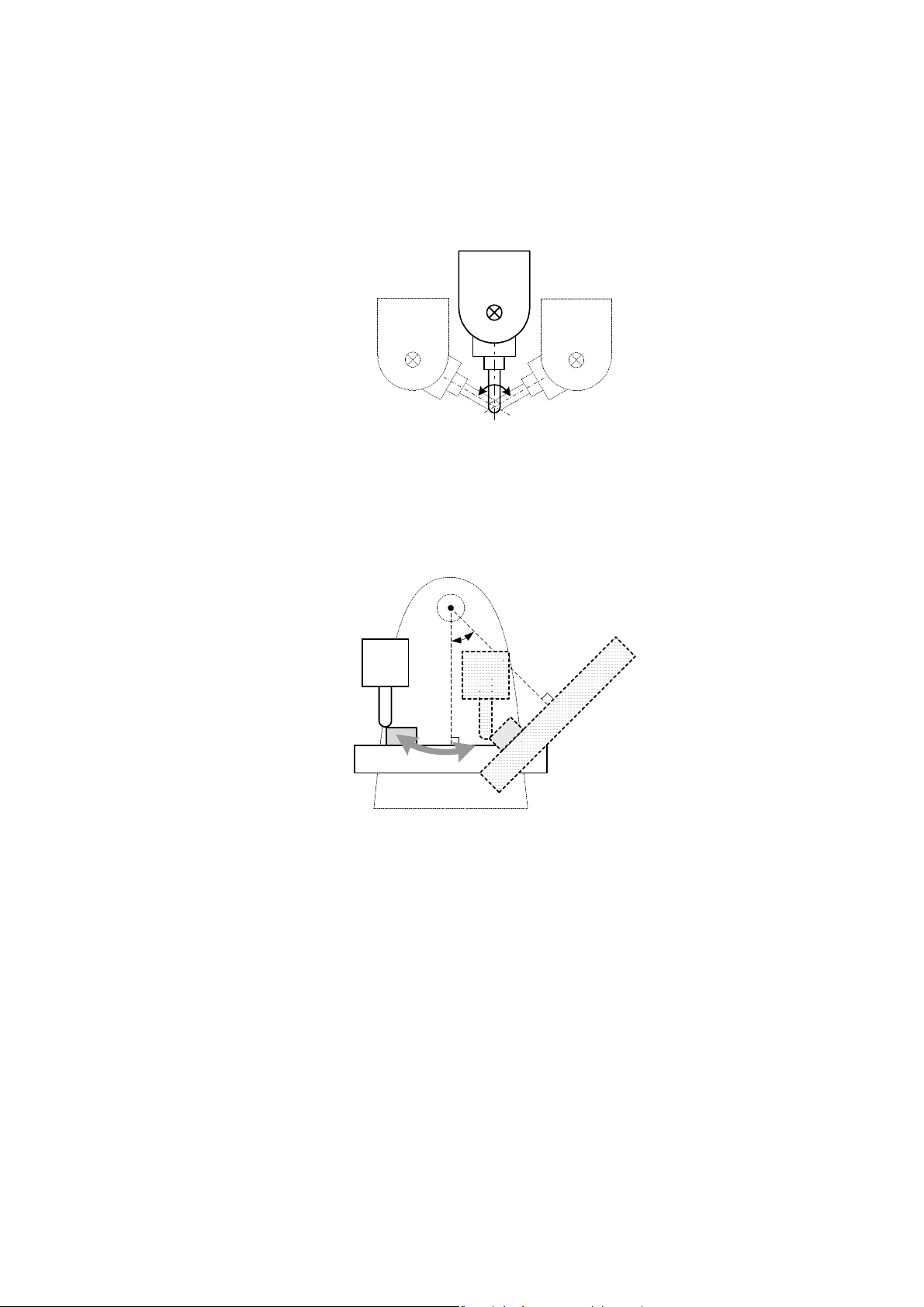

3-1. Overview

Tool nose center manual feed function is designed for machines with rotary axes on the spindle and table

sides. The function enables the spindle or table rotate around the tool nose center.

(1) Rotary axis on the spindle side

Spindle rotates around the tool nose center.

Fig. 2-7 Movement of the tool nose center manual feed

(with the rotary axis on the spindle side)

(2) Rotary axis on the table side

Table rotates keeping the tool nose center position seen from the table (work). The tool appears tilting

around tool nose center if you see the tool by reference to the table (work).

Fig. 2-8 Movement of the tool nose center manual feed

(with the rotary axis on the table side)

3-2. Operation

(1) MANUAL Operation Mode

Turn 3D FEED switch ON and select the desired axis out of A, B, and C-axis with the manual feed axis selection key on the machine operation panel or manual pulse handle axis selection switch. The selected axis

will rotate around on the tool nose center in manual rapid traverse, manual cutting feed, or manual pulse

handle feed.

(2) AUTO/MDI Operation Mode

Tool nose center manual feed

moves in the AUTO/MDI operation mode as follows.

- Pulse Handle Override

If the pulse handle override and the 3D FEED ON/OFF switch are both turned on, “4337 Alarm-D

Tool nose center man-feed func is invalid” will appear. While this alarm is ON, manual pulse handle

would not work.

- 16 -

- Manual Interrupt

Manual feed in the table coordinate is possible while manual interrupt mode is ON. However, if the

shift amount remains (≠0) when the manual interruption is turned off in G169/G171 mode, the

“1336 Alarm-A The manual shift remains. Be warned axis move” appears. Make sure to set the

shift amount (total) to zero manually or with a sequence restart switch before you exit the manual

interrupt mode. (For details, see “TOOL CENTER POINT CONTROL” and “TOOL AXIAL

DIRECTION TOOL LENGTH COMPENSATION” in this manual.)

[CAUTION]

■ Tool Length Compensation

If the machine has a rotary axis on the spindle side, the system finds the tool nose position based on

the distance from the center of the rotation of the rotary axis to the spindle nose and the tool length

compensation amount. The found point will be the center of the tool nose center feed movement.

Therefore, make sure that proper tool compensation number is selected for the spindle tool even in

the manual operation. Tool compensation numbers can be specified in the program command (H) in

the AUTO or MDI operation. The number selected there will be kept even after the mode is switched

to manual mode.

■ Stroke End Limit

Linear axes are to move along with the rotary axis in the tool nose center manual feed. When a linear

axis is about to reach the stroke end limit, it stops in the limit vicinity and the rotary axis movement

also stops.

■ Speed Limit

If rotary radius is large in the tool nose center manual feed, the linear axes travel distance becomes

longer. If the rotary axis feedrate is high, the linear axis feedrate also becomes high. To avoid the

linear axis feedrate to be too fast, the rotary axis feedrate limit is controlled based on the rotary radius and the linear axis feedrate limit. In some cases, the rotary axis feedrate limit determined here

may be lower than the feedrate set by the command.

- 17 -

4. Other Optional Functions

4-1. I-MAP

By using the CAL key for the I-MAP PLAYBACK function, it is possible to acquire the actual position of

the currently selected work coordinate system. With the machine having rotary axes on the table, the

current position in the table coordinate system is acquired when manual axis feed in the table coordinate system is effective or the G169 mode is selected with the program command.

4-2. Manual Gauging

Note that axis feed will be tool axial direction manual feed/table coordinate manual feed/tool nose

center manual feed if the 3D FEED switch is ON during manual gauging.

4-3. Interactive Gauging

If the +SINGLE, -SINGLE, or AUTO switch on the operation panel is ON, tool length gauging skip or

work gauging skip will NOT depend on the 3D FEED switch ON/OFF status. Turn on the 3D FEED

switch for manually moving the probe close to the work in the tool axial direction manual feed, table

coordinate manual feed, or tool nose center manual feed.

4-4. Manual Angle/Circle Feed

3D FEED function is not supported for manual angle/circle feed.

- 18 -

5. Alarm List

5-1. Alarm A

1336 The manual shift remains. Be warned axis move.

The shift amount exists in G169 mode or G171 mode.

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

None

[Measures to Take]

1: Cancel the shift amount (total).

2: Change the alarm level to warning by setting data at the NC optional parameter (bit) No.78 bit4.

[Related Specifications]

Tool center point control, Tool axial direction tool length compensation

5-2. Alarm D

4337Tool nose center man-feed func is invalid

Both 3D axis feed switch and pulse handle override were turned on in automatic or MDI operation.

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

None

[Measures to Take]

1: Turn off the 3D axis feed switch or pulse handle override.

[Related Specifications]

Tool nose center manual feed

4338 The manual shift remains. Be warned axis move.

The shift amount exists in G169 mode or G171 mode.

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

None

[Measures to Take]

1: Cancel the shift amount (sum).

[Related Specifications]

Tool nose control, tool length offset in tool axis direction

- 19 -

SECTION 3 TOOL CENTER POINT CONTROL

1. Overview

This function is applicable to the 5-axis machining center having three linear axes X, Y, and Z and

two rotary axes. The function controls the movements of each axis by adding the tool length offset

amount so that the tool center point moves along the workpiece through the tool path specified by

the axis movement commands. It also controls the feedrate of each axis so that tool center point

moves along the workpiece at the specified feedrate.

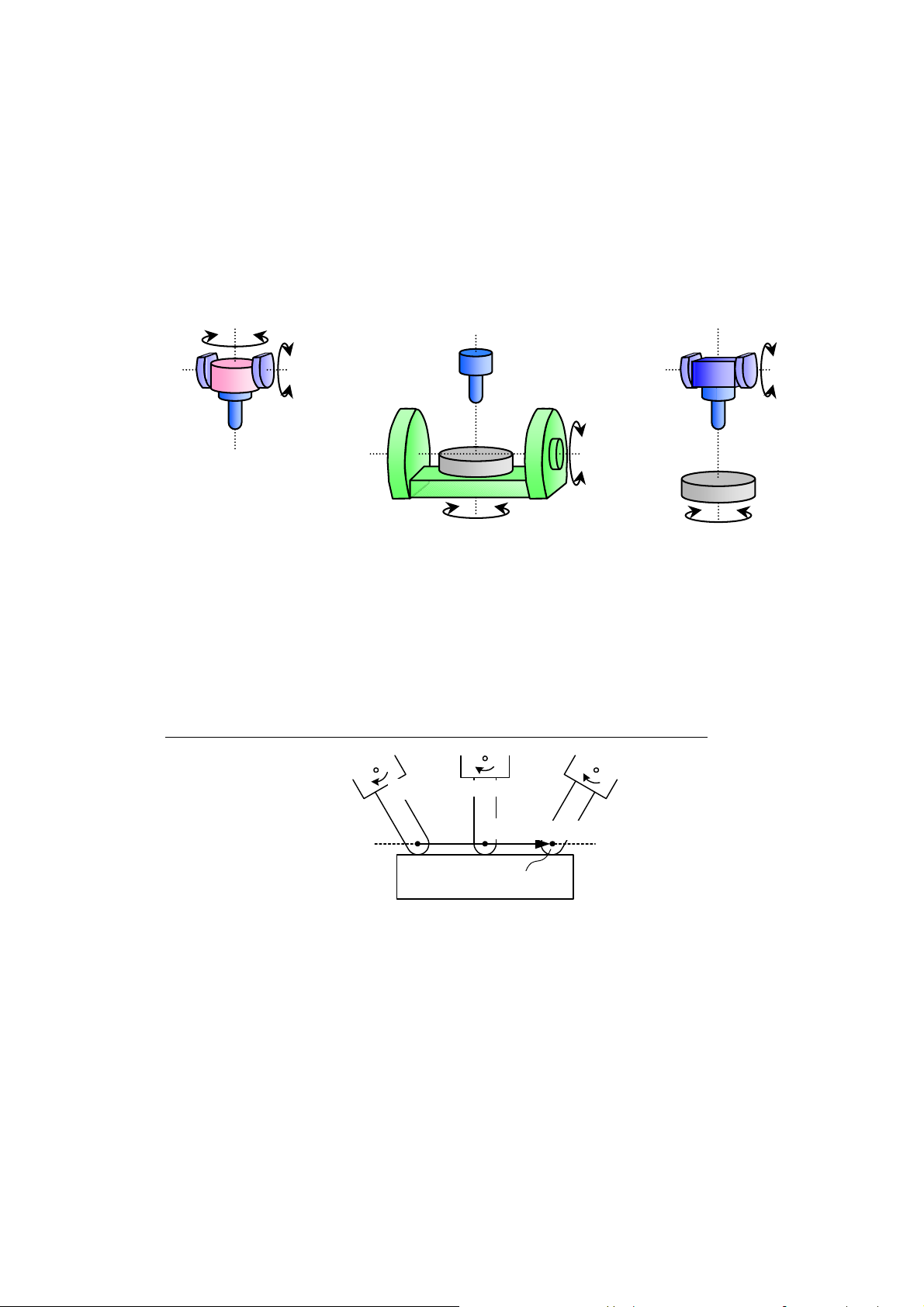

The rotary axis configuration of 5-axis machining center can be classified into the following three

cases: the spindle has two rotary axes, the table has two rotary axes, and the spindle and the table

have one rotary axis.

Spindle having

two rotary axes

Fig. 3-1 Rotary axis configuration in relation with the tool center point control

Table having two

rotary axes

One rotary axis each for spin-

dle and table

The commands G00 (positioning), G01 (linear interpolation), and G02/G03 (circular interpolation)

can be used in the tool center point control mode.

If the rotary axis command and the linear axis command are simultaneously specified to the rotary

axis on the spindle side with G01 (linear interpolation), the machine behaves as follows.

When the X-axis and B-axis commands are specified simultaneously with G01

B-axis movement

B軸動作

X-axis movement

X軸動作

指令点

Command point

Fig. 3-2 Movement with the rotary axis on the spindle side

- 20 -

A

If the rotary axis command and the linear axis command are simultaneously specified to the rotary

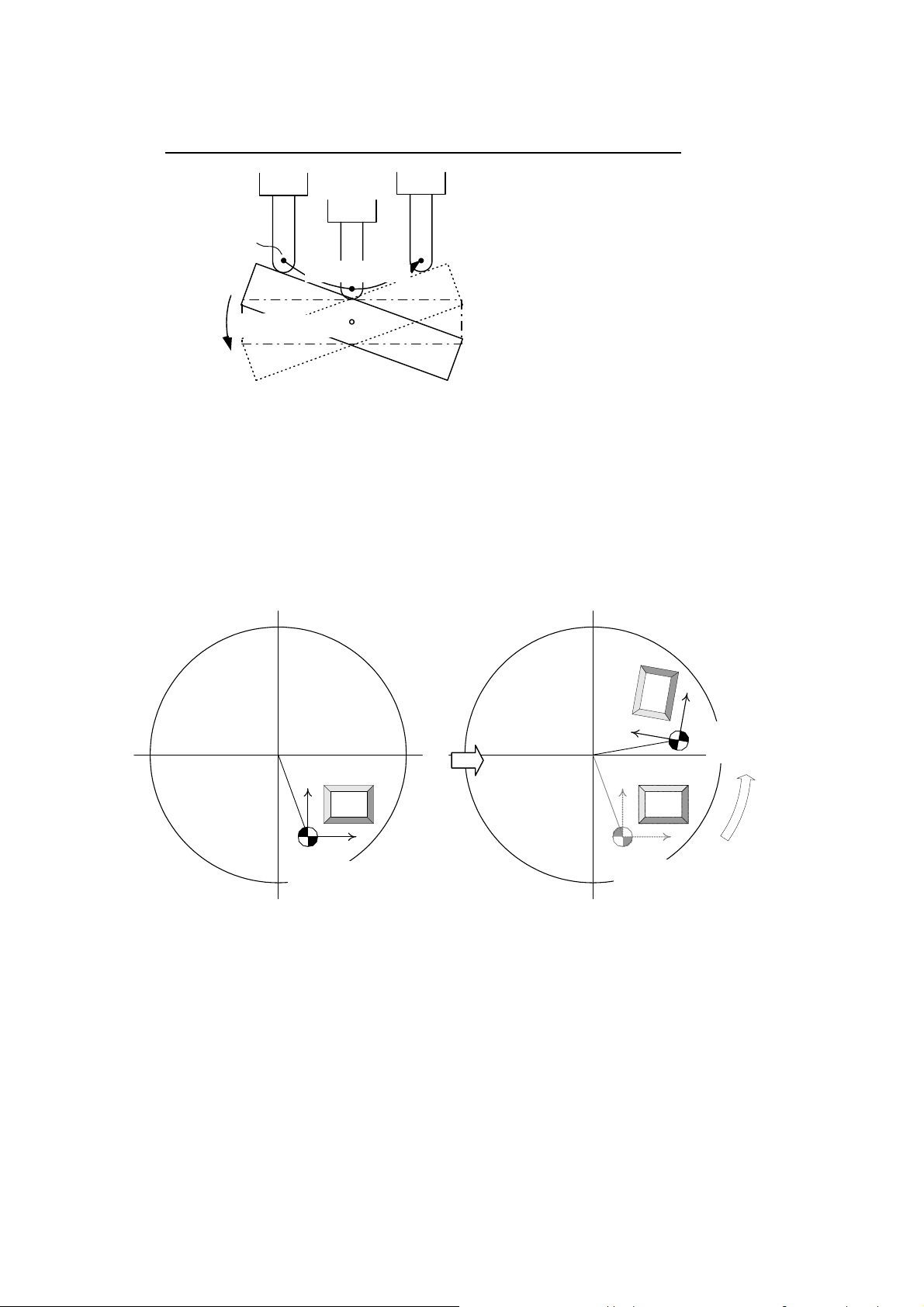

axis on the table side with G01 (linear interpolation), the machine behaves as follows.

When Y-axis and A-axis commands are specified simultaneously with G01

Command point

指令点

A軸動作

-axis movement

Y軸動作

Y-axis movement

The tool center point path viewed from table

(work) is linear.

Fig. 3-3 Movement with the rotary axis on the table side

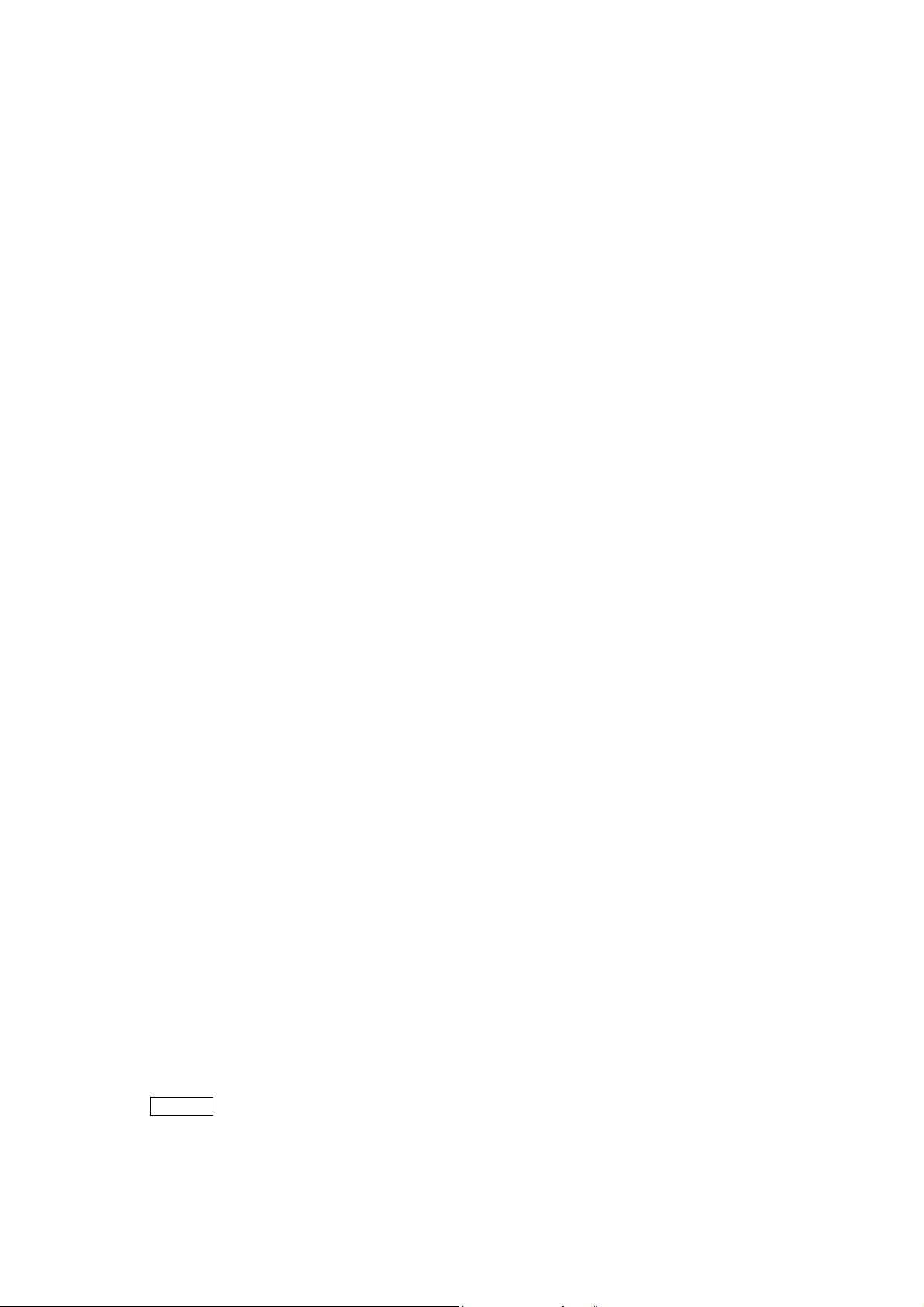

1-1. Definition of the coordinate system for the table having a rotary axis

When the table side rotary axis is rotated, the work installed on the table will also rotate. But if the

coordinate system fixed to the table is defined, the coordinate system for the table (work) does not

move even if the table rotates. Such a coordinate system is called “Table-based coordinate system.” This coordinate system is based on the work coordinate system for the table located in “0°”

position (0° in the machine coordinate system). In the tool center point control, program commands

are issued to this table-based coordinate system.

Table-based

coordinate sys-

Work

Work coordinate system

Work coordinate system

tem

Original state

The coordinate system rotates as the table rotes.

=> Table-based coordinate system

Fig. 3-4 Table-based coodinate system

For the machine with a spindle having two rotary axes, the table based coordinate system is the

same with the work coordinate system because the table does not rotate.

- 21 -

2. Program Commands

2-1. Command Format

G169 P_H_.................................. Tool center point control mode ON

P_

:

G170 P_ ..................................... Tool center point control mode OFF

P: Position Commands (for X, Y, Z, A, B, and C)

The A, B, and C commands are used to specify the inclination of the tool with regard to

the work in the position (end of block) specified with X, Y, Z command. Specify the rotary

axis provided for the machine among A, B, and C. Then, specify the angle of currently

selected work coordinate system.

The X, Y, and Z commands are used to specify the tool nose position in the currently selected work coordinate system (table-based coordinate system for the rotary axis on the

table). If the rotary axis is on the spindle, the machine controls the axes so that the inclined tool nose position is equal to the specified position.

H: Tool length offset number (1 to the number of offset data sets)

The feed mode when the G169 command is specified shall be G00 or G01. Axis feed mode in the

G169 block is the feed mode specified when the G169 command is specified. Axis in this block is

also fed under the tool center point control.

In G169 mode, the machine interpolates the rotary axis movement, and controls the linear axis

movement so that the tool nose path seen from the work match the path in the specified feed

mode and that the feedrate of the tool center point with regard to the work is equal to the specified feedrate.

- The position commands are omissible.

- If the tool length offset number is omitted, the currently selected tool length offset number will

be automatically adopted.

- If a position command and a tool length offset number are specified in the G169 block, the tool

nose will be positioned in a position which the tool length offset value is added by the feed

mode selected at that time (G00 or G01). An alarm occurs if the feed mode is not G00 or G01.

- The tool length offset number will not be cleared by NC reset.

- The tool length offset number will be backed up when the power gets shut off. The backed up

number will be automatically selected when the power is supplied again.

- If the G169 command is specified when the tool length offset number is 0 (H0), an alarm will

result.

- HA, HB, and HC are treated as an H command.

- If the work zero number is “0” (work coordinate system = machine coordinate system), the machine controls the axis on an assumption that there is a table coordinate system in the position

where the machine coordinate system is rotated by the angle of the table rotary axis.

- G169 command can be specified in G91 (incremental command) mode. However, immediately

after specifying G169, specify the axis movement command to all the axes in G90 (absolute

command) mode.

Notes

Immediately after specifying the G169 command, specify the axis movement command to all

the axes (five axes) simultaneously in the G90 (absolute command) mode in order to establish

the position in the work (-based) coordinate system.

- 22 -

Example: A- and C-axes are rotary axes.

G169X0.Y0.Z500.A0.C0.H1

:

or

G169H1

X0.Y0.Z500.A0.C0.

:

Before performing tool center point control with the G169 command, specify the rotary axis

unclamp command.

A-axis unclamp: M11

B-axis unclamp: M21

C-axis unclamp: M27

Also when performing machining that involves rotary axis movement with the Super-NURBS

control mode ON, specify the rotary axis unclamp command in the same way.

At the end of machining under the tool center point control or the Super-NURBS control, cancel

the rotary axis unclamp command.

A-axis unclamp cancel: M10

B-axis unclamp cancel: M20

C-axis unclamp cancel: M26

* Some machine models use the commands other than what are described above. For the ro-

tary axis clamp/unclamp command, refer to the instruction manual separately issued for

each machine model.

If there remains shift amount (≠ 0) when G169 is specified, the shift amount will be canceled.

In this same way, if there remains the shift amount (≠ 0) when G170 is specified, the shift

amount will be canceled.

Pulse handle override

- Manual tool center point feed does not work with pulse handle override.

If the pulse handle override and 3D axis feed ON/OFF switch are both turned on, “4337

Alarm-D Tool nose center man-feed func is invalid” will appear on the display. While this alarm

is ON, the rotary axis movement by pulse handle is disabled.

- If manual feed in tool axis direction by pulse handle override or manual feed in table-based

coordinate system is attempted in G169 mode, the “1336 Alarm-A The manual shift remains.

Be warned axis move” will occur. Furthermore, the pulse input with the 3D FEED switch OFF

causes the alarm A.

Manual interruption

- In the manual interruption mode, manual feed in tool axis direction, manual feed in table coordinate system, and manual feed of tool nose center are all possible.

However, if there remains the shift amount (≠ 0) when the manual interruption in G169 mode is

turned off, the “1336 Alarm-A The manual shift remains. Be warned axis move” will occur.

- 23 -

y

y

The alarm A caused by the above-mentioned pulse handle override or manual interruption can

be changed to the alarm D by turning on the NC optional parameter (bit) No.78 bit 4. However,

even when the rotary axis is moved by the program command in G169 mode when there remains a shift amount, the shift direction will not change.

B-axis position after rotation

Not the position used for rotation

around the shift start point

Shifted in Z direc-

B-axis rotated in

G169 mode after

shift input

B-axis rotated

in G169 mode

tion by manual

feed in tool axis

direction

Programmed

tool path

Programmed

tool path

Fig. 3-5 In case of the spindle rotary axis rotated by the program commands in G169 mode when there

remains a shift amount.

Tool nose

position after

C-axis rotation

X

Table-based coordinate s

stem

Program command

position

Y

X

Table-based coordinate s

stem

Tool nose position

after shifting

Shifted in X direction

by feed in work-based

coordinate system

Not the position on the line

extended from swing radius

C-axis rotated in

G169 mode after

shift input

C-axis

rotation in

G169

mode

Y

X

Y

Fig. 3-6 In case of the table rotary axis rotated by the program commands in G169 mode when there

remains a shift amount.

- 24 -

2-2. Program Commands in G169 Mode

The other G codes and mnemonic commands that can be specified in G169 mode are as follows.

Specifiable G codes and mnemonic commands

- G00 (Positioning)

The tool nose always moves linearly regardless of whether the linear interpolation at rapid

traverse is effective or not.

When this command block includes rotary axis movement, movement beyond the travel end

limit causes an alarm A. Special operation outside the travel limit is impossible.

- G60 (Unidirectional positioning)

This command can be specified, but it operates as G00 and does not perform unidirectional

positioning.

- G01 (Linear interpolation)

The tool nose moves linearly so that the tool path determined according to the workpiece

shape.

- G02/G03 (Circular interpolation)

These G codes are usable for circular interpolation and helical cutting. If a rotary axis command is specified with any of these codes simultaneously, an alarm B occurs.

3D circular interpolation command cannot be specified.

- G04 (Dwell)

- G11 (Parallel / Rotational shift of a coordinate system)

Converts the table (-based) coordinate system into the local coordinate system.

- G15/G16 (Work coordinate system selection)

Immediately after specifying this command, specify the first axis movement command to all the

axes (5 axes) in G90 mode in order to define the coordinate values.

- G17/G18/G19 (Plane selection)

Selects a plane from the table (-based) coordinate system.

- G22 (Programmable limit)

Checks the travel limit in the work coordinate system.

- G51 (Enlargement and reduction of geometry)

Geometry is enlarged or reduced in the table (-based) coordinate system.

- G61 (Exact stop mode)

- G09 (Exact stop, one shot)

- G90/G91 (Absolute / incremental commands)

- G94 (Feed per minute)

- G131 (Super-NURBS control mode ON)

- MITCAN (Manual shift amount cancel)

- CALL (Sub program call)

- IF/GOTO (Branching command)

- Coordinates calculation function

Coordinates are calculated in the table (-based) coordinate system.

- Area machining function

This command is regarded as the command in the table (-based) coordinate system.

- G code macro

- MSG

- COPY/COPYE (Copy function)

Copies the figure in the table (-based) coordinate system.

- 25 -

The following commands cause an alarm if specified in the G169 mode.

- M6 (Tool change command)

- G30 (Home position command)

- G41/G42 (Cutter radius compensation)

- G45/G46 (Tool side offset)

- G47 (Leading edge offset)

- G54 to G59 (Tool length offset)

(with the rotary axis on the spindle side)

- G69, G469 (Setting a slope coordinate system)

- G467 (Slope indexing)

- Fixed cycles

- G171 (Tool length offset in tool axis direction ON)

Alarm occurs also in the following cases.

- The tool length offset number cannot be changed with H command in G169 mode. An alarm B

occurs if attempted.

- Tool change command cannot be specified in G169 mode. It causes an alarm B.

- Alarm B occurs if the G169 command is specified during the search by the upgraded sequence

restart function.

- Alarm B occurs if data setting in the system variables VTOFH and VZOF* is specified in G169

mode.

- 26 -

3. System Variables

Under the tool center point control mode, no data can be entered in the following system variables. The alarm occurs if such a command is issued.

VZOF* (*: axis name) .................Work zero

VTOFH .......................................Tool length offset data

2213 Alarm-B Program bad direct: system variable

Code: 1 The command for writing work zero was issued in the tool center point con-

trol mode (G169).

2 The command for writing tool length offset data was issued in the tool cen-

ter point control mode (G169).

4. Operation in Zero Setting Screen

In the tool center point control mode, it is impossible to change the offset value (by SET, ADD, CAL

function) of the currently selected work zero number.

Error 5285 Set impossible

Code: 3 Attempt was made to change the currently selected work zero offset in the

tool center point control mode.

5. Operation in Tool Length Offset / Cutter Radius Compensation Screen

In the tool center point control mode, it is impossible to change the tool length offset value (by SET,

ADD, CAL function) of the currently selected tool length offset number.

Error 5285 Set impossible

Code: 4 Attempt was made to change the currently selected tool length offset value

in the tool center point control mode (G169).

- 27 -

6. Parameters

Before using this function, it is necessary to set the ROTARY AXIS PARAMETER in the parameter set-

ting mode. The default values have been set at the factory. For details, see “ROTARY AXIS

PARAMETERS” in this manual.

There are the following parameters in addition to the above.

NC optional parameter (bit)

No. bit Description

The initial statuses have been factory set. For

details, refer to the ROTARY AXIS

4

PARAMETER INSTRUCTION MANUAL.

78

Specifies the coordinate system which will be

selected when the three fundamental axes are

fed manually after the 3D FEED switch is

6

turned on on the machine with a rotary axis on

the spindle side and table side respectively.

Selects the

alarm D.

Selects the

table base

coordinate

system.

Selects the

alarm A.

Selects the

tool axis

coordinate

system.

7. Optional Functions

7-1. I-MAP

By using the CAL key for the I-MAP PLAYBACK function, it is possible to acquire the current position

of the currently selected table-based coordinate system. With the machine having rotary axes on the

table, the current position in the table coordinate system is acquired when manual axis feed in the ta-

ble coordinate system is effective or the G169 mode is selected with the program command.

7-2. Real 3D Animated Simulation

The real 3D animated simulation is not compatible with the tool center point control function.

Initial status

7-3. Measurement Cycle

The tool center point control mode must be turned off (by G170) when executing the measurement cy-

cles such as automatic tool length offset or the automatic measurement.

7-4. Collision Avoidance System

The interference check function of the collision avoidance system is not compatible with the tool cen-

ter point control. (For details, refer to the “COLLISION AVOIDANCE SYSTEM INSTRUCTION

MANUAL -Basic/Tutorial-” and “COLLISION AVOIDANCE SYSTEM INSTRUCTION MANUAL

-Additional Functions-”.)

- 28 -

8. Alarm List

8-1. Alarm A

1336 The manual shift remains. Be warned axis move.

The shift amount exists in G169 mode or G171 mode.

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

None

[Measures to Take]

1: Cancel the shift amount (total).

2: Change the alarm level to warning (Alarm-D) by setting data at the NC optional parameter (bit)

No.78 bit4.

[Related Specifications]

Tool center point control, Tool axial direction tool length compensation

8-2. Alarm B

2213 Program bad direct: System variable

[Code]

1: The workpiece zero command is specified during the tool center point control mode (G169).

2: The tool length offset data command is specified during the tool center point control mode

(G169).

[Measures to Take]

Check the system variable.

2263 Data word: G code

[Character-string]

None

[Code]

133: The tool nose control mode (G169) was specified during the 3D coordinate conversion

(G469).

134: The 3D

trol mode (G169).

161: The slope indexing command (G467) was specified during the tool nose control mode

(G169).

[Probable Faulty Locations]

G code in

[Measures to Take]

Correct the program error which is specified by the alarm code displayed.

2644 Data word: G code (5-axis machining function)

[Character]

None

[Code]

1: The rotary axis is removed when G169 or G171 command is specified.

2: G169 or G171 command was specified in the tool length offset mode.

3: G169 or G171 command was specified with “0” set as the tool length offset number.

4: G169 command was specified during parallel or rotation shift (by G11, COPY).

5: G169 command was specified when expansion or reduction of the geometry is ON (G51).

6: G169 command was specified in the mirror image mode.

coordinate conversion command (G469) was specified during the tool nose con-

the NC program

- 29 -

7: G169 command was specified during axial name designation (G14).

8: G169 was specified during the fixed cycle.

9: G169 was specified in the cutter radius compensation mode.

A: G169 was specified in the 3D tool offset mode.

B: G169 was specified during tool groove cutting, spindle path control, or turning cut mode.

C: G169 was specified in a mode other than G00 and G01.

D: G169 was specified in the feed-per-revolution mode or inverse time feed mode (G95, G93).

E: G169 was specified in the cylindrical side machining mode (G175).

F: G169 was specified in the 2nd tool length offset mode (G189).

10: G169 was specified in the slope coordinate system mode (G69).

11: G169 was specified in the projection drawing designation command mode (G256).

12: G169 was specified in the attachment rotation offset mode (G181 to 185).

13: G169 was specified during tool length offset in tool axis direction (G171).

101: Any angle chamfering command (G246, 249) was specified in G169 mode.

102: Tool length offset ON (G54 to G59) was specified in G169 or 171 mode.

103: An “H” command was specified in G169 mode.

104: Skip command (G31) was specified in G169 mode.

105: A fixed cycle was specified in G169 mode.

106: Tool change M code was specified in G169 mode.

107: A rotary axis (including the multi-rotation type and the limited type) was specified as a circular

interpolation command in G169 mode.

108: Work coordinate system setting command (G92) was specified in G169 mode.

109: Home position command (G30) was specified in G169 mode.

10A: Slope coordinate system mode ON (G69) was specified in G169 mode.

10B Thread cutting command (G33) was specified in G169 mode.

10C: 3D circular interpolation command (G2, G3, G172, or G173) was specified in G169 mode.

10D: Projection drawing designation command (G256) was specified in G169 mode.

10E: NURBS curve interpolation command (NURBS) was specified in G169 mode.

10F: Cutter radius compensation ON (G41, G42) was specified in G169 mode.

110: The 3D tool offset ON (G44) was specified in G169 mode.

111: Feed-per-revolution or inverse time feed (G95, G93) was specified in G169 mode.

112: Axis name designation command (G14) was specified in G169 mode.

113: Cylindrical side machining ON command (G175) was specified in G169 mode.

114: The 2nd tool length offset ON command (G189) was specified in G169 mode.

115: Attachment rotation offset command (G181-G185) was specified in G169 mode.

116: Tool groove cutting, spindle path control, or turning cut was specified in G169 mode.

118: Tool length offset in tool axis direction (G171) was specified in G169 mode.

119: Mirror image (G62) was specified in G169 mode.

[Probable Faulty Locations]

Part program

[The measure against disposal]

Review the part program.

8-3. Alarm D

4337 Tool nose center man-feed func is invalid

Both 3D axis feed switch and pulse handle override were turned on in automatic or MDI operation.

[Character-string]

None

- 30 -

[Code]

None

[Probable Faulty Locations]

None

[Measures to Take]

Turn off the 3D axis feed switch or pulse handle override.

[Related Specifications]

Tool nose center manual feed

4338 The manual shift remains. Be warned axis move.

The shift amount exists in G169 mode or G171 mode.

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

None

[Measures to Take]

Cancel the shift amount (total).

[Related Specifications]

Tool center point control, Tool axis direction tool length offset

8-4. Error

5285 Set impossible

[Code]

3: Changing the workpiece zero offset under execution is attempted during the tool center point

control mode.

4: Changing the tool length offset value under execution is attempted during the tool center point

control mode (G169).

- 31 -

SECTION 4 TOOL AXIAL DIRECTION TOOL LENGTH COMPENDSATION

1. Overview

Tool length compensation (G54-G59) is usually done on each axis (X, Y, Z, U, V, or W axis) (Fig.

1 shows the compensation in Z-axis direction). However, if the tool direction is not parallel to the