CNC SYSTEMS

OSP-E100L

PROGRAMMING MANUAL

Publication No. 4283-E

CNC SYSTEMS

OSP-E100L

PROGRAMMING MANUAL

(2nd Edition)

Pub. No. 4283-E (LE33-011-R2) Jan. 2000

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The machine is equipped with safety devices which serve to protect personnel and the machine itself

from hazards arising from unforeseen accidents. However, operators must not rely exclusively on these

safety devices: they must also become fully familiar with the safety guidelines presented below to

ensure accident-free operation.

This instruction manual and the warning signs attached to the machine cover only those hazards which

Okuma can predict. Be aware that they do not cover all possible hazards.

1. Precautions Relating to Machine Installation

(1) Install the machine at a site where the following conditions (the conditions for achievement of the

guaranteed accuracy) apply.

• Ambient temperature: 17 to 25°C

4283-E P-(i)

• Ambient humidity: 40% to 75% at 20°C (no condensation)

• Site not subject to direct sunlight or excessive vibration; environment as free of dust, acid,

corrosive gases, and salt spray as possible.

(2) Prepare a primary power supply that complies with the following requirements.

• Voltage: 200 V

• Voltage fluctuation: ±10% max.

• Power supply frequency: 50/60 Hz

• Do not draw the primary power supply from a distribution panel that also supplies a major

noise source (for example, an electric welder or electric discharge machine) since this

could cause malfuntion of the CNC unit.

• If possible, connect the machine to a ground not used by any other equipment. If there is no

choice but to use a common ground, the other equipment must not generate a large

amount of noise (such as an electric welder or electric discharge machine).

(3) Installation Environment

Observe the following points when installing the control enclosure.

• Make sure that the CNC unit will not be subject to direct sunlight.

• Make sure that the control enclosure will not be splashed with chips, water, or oil.

• Make sure that the control enclosure and operation panel are not subject to excessive

vibrations or shock.

• The permissible ambient temperature range for the control enclosure is 0 to 40°C.

• The permissible ambient humidity range for the control enclosure is 30 to 95% (no condensation).

• The maximum altitude at which the control enclosure can be used is 1000 m (3281ft.).

2. Points to Check before Turning on the Power

(1) Close all the doors of the control enclosure and operation panel to prevent the entry of water,

chips, and dust.

(2) Make absolutely sure that there is nobody near the moving parts of the machine, and that there

are no obstacles around the machine, before starting machine operation.

(3) When turning on the power, turn on the main power disconnect switch first, then the CONTROL

ON switch on the operation panel.

3. Precautions Relating to Operation

(1) After turning on the power, carry out inspection and adjustment in accordance with the daily

inspection procedure described in this instruction manual.

(2) Use tools whose dimensions and type are appropriate for the work undertaken and the machine

specifications. Do not use badly worn tools since they can cause accidents.

(3) Do not, for any reason, touch the spindle or tool while spindle indexing is in progress since the

spindle could rotate: this is dangerous.

(4) Check that the workpiece and tool are properly secured.

4283-E P-(ii)

SAFETY PRECAUTIONS

(5) Never touch a workpiece or tool while it is rotating: this is extremely dangerous.

(6) Do not remove chips by hand while machining is in progress since this is dangerous. Always

stop the machine first, then remove the chips with a brush or broom.

(7) Do not operate the machine with any of the safety devices removed. Do not operate the machine

with any of the covers removed unless it is necessary to do so.

(8) Always stop the machine before mounting or removing a tool.

(9) Do not approach or touch any moving part of the machine while it is operating.

(10) Do not touch any switch or button with wet hands. This is extremely dangerous.

(11) Before using any switch or button on the operation panel, check that it is the one intended.

4. Precautions Relating to the ATC

(1) The tool clamps of the magazine, spindle, etc., are designed for reliability, but it is possible that a

tool could be released and fall in the event of an unforeseen accident, exposing you to danger:

do not touch or approach the ATC mechanism during ATC operation.

(2) Always inspect and change tools in the magazine in the manual magazine interrupt mode.

(3) Remove chips adhering to the magazine at appropriate intervals since they can cause misoper-

ation. Do not use compressed air to remove these chips since it will only push the chips further

in.

(4) If the ATC stops during operation for some reason and it has to be inspected without turning the

power off, do not touch the ATC since it may start moving suddenly.

5. On Finishing Work

(1) On finishing work, clean the vicinity of the machine.

(2) Return the ATC, APC and other equipment to the predetermined retraction position.

(3) Always turn off the power to the machine before leaving it.

(4) To turn off the power, turn off the CONTROL ON switch on the operation panel first, then the

main power disconnect switch.

4283-E P-(iii)

SAFETY PRECAUTIONS

6. Precautions during Maintenance Inspection and When Trouble

Occurs

In order to prevent unforeseen accidents, damage to the machine, etc., it is essential to observe the following points when performing maitenance inspections or during checking when trouble has occurred.

(1) When trouble occurs, press the emergency stop button on the operation panel to stop the

machine.

(2) Consult the person responsible for maintenance to determine what corrective measures need to

be taken.

(3) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

(4) Use only the specified replacement parts and fuses.

(5) Always turn the power off before starting inspection or changing parts.

(6) When parts are removed during inspection or repair work, always replace them as they were and

secure them properly with their screws, etc.

(7) When carrying out inspections in which measuring instruments are used - for example voltage

checks - make sure the instrument is properly calibrated.

(8) Do not keep combustible materials or metals inside the control enclosure or terminal box.

(9) Check that cables and wires are free of damage: damaged cables and wires will cause current

leakage and electric shocks.

(10) Maintenance inside the Control Enclosure

(a) Switch the main power disconnect switch OFF before opening the control enclosure door.

(b) Even when the main power disconnect switch is OFF, there may some residual charge in the

MCS drive unit (servo/spindle), and for this reason only service personnel are permitted to

perform any work on this unit. Even then, they must observe the following precautions.

• MCS drive unit (servo/spindle)

The residual voltage discharges two minutes after the main switch is turned OFF.

(c) The control enclosure contains the NC unit, and the NC unit has a printed circuit board whose

memory stores the machining programs, parameters, etc. In order to ensure that the contents

of this memory will be retained even when the power is switched off, the memory is supplied

with power by a battery. Depending on how the printed circuit boards are handled, the contents of the memory may be destroyed and for this reason only service personnel should handle these boards.

(11) Periodic Inspection of the Control Enclosure

(a) Cleaning the cooling unit

The cooling unit in the door of the control enclosure serves to prevent excessive temperature

rise inside the control enclosure and increase the reliability of the NC unit. Inspect the following

points every three months.

• Is the fan motor inside the cooling unit working?

The motor is normal if there is a strong draft from the unit.

• Is the external air inlet blocked?

If it is blocked, clean it with compressed air.

7. General Precautions

(1) Keep the vicinity of the machine clean and tidy.

(2) Wear appropriate clothing while working, and follow the instructions of someone with sufficient

training.

(3) Make sure that your clothes and hair cannot become entangled in the machine. Machine opera-

tors must wear safety equipment such as safety shoes and goggles.

(4) Machine operators must read the instruction manual carefully and make sure of the correct pro-

cedure before operating the machine.

(5) Memorize the position of the emergency stop button so that you can press it immediately at any

time and from any position.

(6) Do not access the inside of the control panel, transformer, motor, etc., since they contain high-

voltage terminals and other components which are extremely dangerous.

(7) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

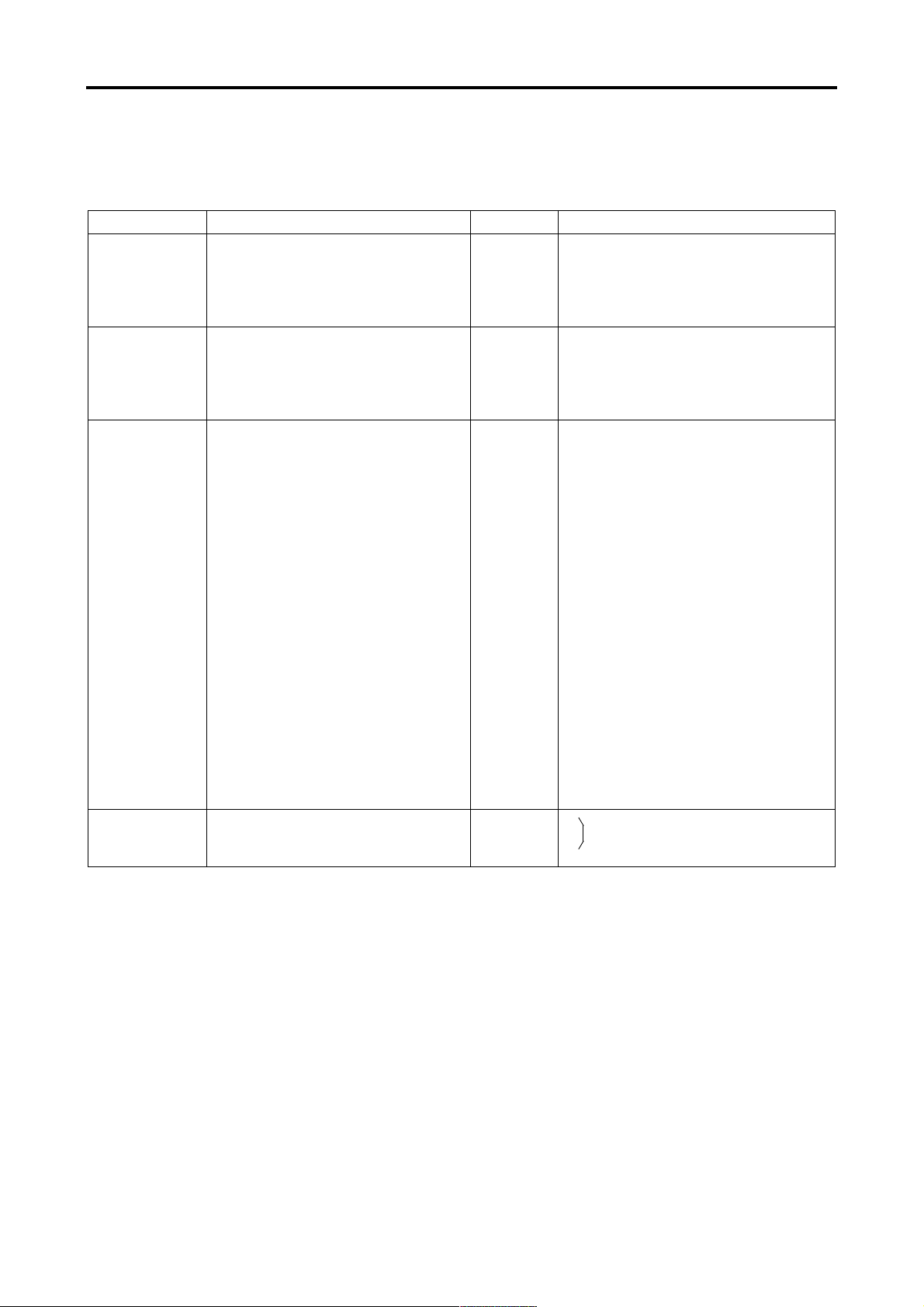

8. Symbols Used in This Manual

4283-E P-(iv)

SAFETY PRECAUTIONS

The following warning indications are used in this manual to draw attention to information of particular

importance. Read the instructions marked with these symbols carefully and follow them.

Indicates an imminent hazard which, if not avoided, will result in death or serious

injury.

Indicates hazards which, if not avoided, could result in death or serious injury.

Indicates hazards which, if not avoided, could result in minor injuries or damage to

devices or equipment.

Indicates precautions relating to operation or use.

INTRODUCTION

INTRODUCTION

Thank you very much for purchasing our numerical control unit OSP-E100L.

Before using this NC unit (hereafter simply called NC), thoroughly read this programming manual

(hereafter called this manual) in order to ensure correct use.

This manual explains how to use and maintain the NC so that it will deliver its full performance and

maintain accuracy over a long term.

You must pay particular attention to the cautions given in this manual, read them carefully, and make

sure you fully understand them before operating the NC.

Display Screens

The NC display screens vary with the selected NC specifications.

The screens shown in this manual, therefore, may not exactly the same with

those displayed on your NC.

4283-E P-(i)

SAFETY PRECAUTIONS

INTRODUCTION

4283-E P-(i)

TABLE OF CONTENTS

TABLE OF CONTENTS

PAGE

SECTION 1 PROGRAM CONFIGURATIONS

1. Program Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. Program Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. Sequence Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Program Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4-1. Word Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4-2. Block Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4-3. Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4-4. Programmable Range of Address Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5. Mathematical Operation Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6. Block Delete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7. Comment Function (CONTROL OUT/IN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8. Program Storage Memory Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9. Two Turrets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

10. Variable Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

11. Determining Feedrate for Cutting along C-Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

11-1. Cutting by Controlling the C-axis Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

11-2. Cutting by Controlling Both C-axis and Z-axis Simultaneously . . . . . . . . . . . . . . . . . . . . . . . 14

11-3. Cutting by Controlling Both C-axis and X-axis Simultaneously . . . . . . . . . . . . . . . . . . . . . . . 15

11-4. Cutting by Simultaneous 3-axis Control of X-, Z-, and C-axis . . . . . . . . . . . . . . . . . . . . . . . . 16

SECTION 2 COORDINATE SYSTEMS AND COMMANDS

1. Coordinate Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-1. Coordinate Systems and Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-2. Encoder Coordinate System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-3. Machine Coordinate System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-4. Program Coordinate System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2. Coordinate Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-1. Controlled Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-2. Commands in Inch System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . 18

4283-E P-(ii)

TABLE OF CONTENTS

2-3. Position of Decimal Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-3-1. Metric System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-3-2. Inch System (Inch/metric switchable specification): . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-4. Absolute and Incremental Commands (G90, G91) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-5. Diametric and Radial Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

SECTION 3 MATH FUNCTIONS

1. Positioning (G00) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2. Linear Interpolation (G01) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3. Circular Interpolation (G02, G03) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4. Automatic Chamfering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-1. C-chamfering (G75) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-2. Rounding (G76) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4-3. Automatic Any-Angle Chamfering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5. Torque Limit and Torque Skip Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5-1. Torque Limit Command (G29) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5-2. Torque Limit Cancel Command (G28) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5-3. Torque Skip Command (G22) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5-4. Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5-5. Program Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SECTION 4 PREPARATORY FUNCTIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1. Dwell (G04) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2. Zero Shift/Max. Spindle Speed Set (G50) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2-1. Zero Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2-2. Max. Spindle Speed Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3. Droop Control (G64, G65) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4. Feed Per Revolution (G95) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5. Feed Per Minute (G94) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6. Constant Speed Control (G96/G97) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

SECTION 5 S, T, AND M FUNCTIONS

1. S Functions (Spindle Functions) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2. SB Code Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3. T Functions (Tool Functions) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4283-E P-(iii)

TABLE OF CONTENTS

4. M Functions (Auxiliary Functions) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5. M-tool Spindle Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5-1. Programming Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5-2. M Codes Used for C-axis Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6. STM Time Over Check Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6-1. Check ON Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6-2. S, T, M Cycle Time Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6-3. Timing Chart Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

SECTION 6 OFFSET FUNCTION

1. Tool Nose Radius Compensation Function (G40, G41, G42) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1-1. General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1-2. Tool Nose Radius Compensation for Turning Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1-3. Compensation Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

1-4. Nose Radius Compensation Commands (G, T Codes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

1-5. Data Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1-6. Buffer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

1-7. Path of Tool Nose “R” Center in Tool Nose Radius Compensation Mode . . . . . . . . . . . . . . . 64

1-8. Tool Nose Radius Compensation Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

1-8-1. G41 and G42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

1-8-2. Behavior on Entering Tool Nose Radius Compensation Mode . . . . . . . . . . . . . . . . . . . 66

1-8-3. Behavior in Tool Nose Radius Compensation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 70

1-8-4. Behavior on Cancelation of the Tool Nose Radius Compensation Mode . . . . . . . . . . . 83

1-8-5. Relieving Tool to Change “S” or “M” Code during Cutting . . . . . . . . . . . . . . . . . . . . . . 86

2. Cutter Radius Compensation Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2-1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

2-2. Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

2-3. Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

SECTION 7 FIXED CYCLES

1. Fixed Cycle Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2. Fixed Thread Cutting Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

2-1. Fixed Thread Cutting Cycle: Longitudinal (G31, G33) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

2-2. Fixed Thread Cutting Cycle: End Face (G32) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3. Non-Fixed Thread Cutting Cycle (G34, G35) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

4. Precautions when Programming Thread Cutting Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4283-E P-(iv)

TABLE OF CONTENTS

5. Thread Cutting Compound Cycle (G71/G72) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

5-1. Longitudinal Thread Cutting Cycle (G71) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

5-2. Program Example for Longitudinal Thread Cutting Compound Fixed Cycle (G71) . . . . . . . .111

5-3. Transverse Thread Cutting Compound Fixed Cycle (G72) . . . . . . . . . . . . . . . . . . . . . . . . . .112

5-4. M Code Specifying Thread Cutting Mode and Infeed Pattern . . . . . . . . . . . . . . . . . . . . . . . .113

5-4-1. M Codes Specifying Thread Cutting Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

5-4-2. M Codes Specifying the Infeed Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

5-4-3. Longitudinal Thread Cutting Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

5-4-4. Transverse Thread Cutting Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

5-5. Multi-thread Thread Cutting Function in Compound Fixed Thread Cutting Cycle . . . . . . . . 125

6. Grooving/Drilling Compound Fixed Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

6-1. Longitudinal Grooving Fixed Cycle (G73) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

6-2. Example Program for Longitudinal Grooving Compound Fixed Cycle (G73) . . . . . . . . . . . 127

6-3. Transverse Grooving/Drilling Fixed Cycle (G74) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

6-4. Example Program for Transverse Grooving/Drilling Fixed Cycle (G74) . . . . . . . . . . . . . . . 129

6-5. Axis Movements in Grooving/Drilling Compound Fixed Cycle . . . . . . . . . . . . . . . . . . . . . . . 129

7. Tapping Compound Fixed Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

7-1. Right-hand Tapping Cycle (G77) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

7-2. Left-hand Tapping Cycle (G78) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

8. Compound Fixed Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

8-1. List of Compound Fixed Cycle Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

8-2. Basic Axis Motions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8-3. Address Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

8-4. M Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

8-5. Drilling Cycle (G181) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

8-6. Boring Cycle (G182) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

8-7. Deep Hole Drilling Cycle (G183) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

8-8. Tapping Cycle (G184) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

8-9. Longitudinal Thread Cutting Cycle (G185) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

8-10. Transverse Thread Cutting Cycle (G186) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

8-11. Longitudinal Straight Thread Cutting (G187) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

8-12. Transverse Straight Thread Cutting (G188) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

8-13. Reaming/Boring Cycle (G189) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

8-14. Key Way Cutting (G190) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

8-15. Synchronized Tapping Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

8-16. Repeat Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

8-17. Tool Relieving Command in Deep-hole Drilling Cycle for Chip Discharge. . . . . . . . . . . . . . 155

4283-E P-(v)

TABLE OF CONTENTS

8-18. Drilling Depth Setting (Only for drilling cycles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

8-19. Selection of Return Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

8-20. M-tool spindle Interlock Release Function (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

8-21. Other Remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

8-22. Program Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

SECTION 8 LATHE AUTO-PROGRAMMING FUNCTION (LAP)

1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

2. G Codes Used to Designate Cutting Mode (G80, G81, G82, G83) . . . . . . . . . . . . . . . . . . . . . . . 166

3. List of Cutting Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

4. Code and Parameter Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

5. Bar Turning Cycle (G85) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

6. Change of Cutting Conditions in Bar Turning Cycle (G84) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

7. Copy Turning Cycle (G86) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

8. Finish Turning Cycle (G87) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

9. Continuous Thread Cutting Cycle (G88) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

10. AP Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

10-1. AP Mode I (Bar Turning) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

10-1-1. Tool Path and Program - Longitudinal Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

10-1-2. Tool Path and Program - Transverse Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

10-1-3. Outline of Bar Turning Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

. . . . . . . . . . . . . . . . . . . 165

10-2. AP Mode II (Copy Turning) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

10-2-1. Tool Path and Program - Longitudinal Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

10-2-2. Tool Path and Program - Transverse Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

10-2-3. Outline of Copy Turning Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

10-3. AP Mode III (Continuous Thread Cutting Cycle) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

10-4. AP Mode IV (High-speed Bar Turning Cycle) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

10-4-1. Tool Path and Program - Longitudinal Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

10-4-2. Tool Path and Program - Transverse Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

10-4-3. Outline of High-speed Bar Turning Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

10-4-4. Precautions when Performing High-speed Bar Turning . . . . . . . . . . . . . . . . . . . . . . . 208

10-4-5. How to Obtain the Infeed Starting Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

10-5. AP Mode V (Bar Copying Cycle) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

10-5-1. Tool Path and Program - Longitudinal Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

10-5-2. Tool Path and Program - Transverse Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

10-5-3. Outline of Bar Copying Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

4283-E P-(vi)

TABLE OF CONTENTS

10-5-4. Precautions when Executing a Bar Copying Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . 221

10-6. Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

11. Application of LAP Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

SECTION 9 CONTOUR GENERATION

1. Contour Generation Programming Function (Face) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

1-1. Function Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

1-2. Programming Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

1-3. Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

1-4. Supplementary Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

2. Contour Generation Programming Function (Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

2-1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

2-2. Programming Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

2-3. Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

SECTION 10 COORDINATE SYSTEM CONVERSION

1. Function Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

2. Conversion Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

3. Program Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

4. Supplementary Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

SECTION 11 PROGRAMMING FOR SIMULTANEOUS 4-AXIS CUTS (2S Model)

1. Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

1-1. Turret Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

1-2. Synchronization Command (P Code) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

1-3. Waiting Synchronization M Code (M100) for Simultaneous Cuts . . . . . . . . . . . . . . . . . . . . 252

2. Programming Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

3. Precautions on Programming Simultaneous 4-axis Cuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

4. Programming Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

4-1. Program Process Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

SECTION 12 MIRROR IMAGE FUNCTION (2-Turret Model)

1. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

2. Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

. . . . . . . . . . . . . . . . . . . . . . . . 260

. . . . 250

3. Programming and Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

4283-E P-(vii)

TABLE OF CONTENTS

3-1. Designating the Turret . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

3-2. Programming Spindle Rotating Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

3-3. Cautions on Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

3-4. Cutting Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

4. Other Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

4-1. Designation of Turrets A and B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

4-2. Sequence Re-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

SECTION 13 USER TASK

1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

2. Types of User Task Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

2-1. Relationship Between Types of Program Files and User Task Functions . . . . . . . . . . . . . . 268

2-2. Comparison of User Task 1 and User Task 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

2-3. Fundamental Functions of User Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

3. User Task 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

3-1. Control Statement Function 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

3-2. Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

3-2-1. Common Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

3-2-2. Local Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

3-2-3. System Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

3-2-4. I/O read variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

3-3. Arithmetic Operation Function 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

4. User Task 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

4-1. Control Functions 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

4-2. I/O Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

4-3. Arithmetic Operation Function 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

5. Supplemental Information on User Task Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

5-1. Sequence Return in Program Using User Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

5-2. Data Types, Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

5-3. Types/Operation Rules of Variables and Evaluation of Their Values . . . . . . . . . . . . . . . . . . 304

6. Examples of User Task Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

SECTION 14 SCHEDULE PROGRAMS

1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

2. PSELECT Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

3. Branch Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

4283-E P-(viii)

TABLE OF CONTENTS

4. Variables Setting Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

5. Schedule Program End Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

6. Program Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

SECTION 15 OTHER FUNCTIONS

1. Automatic Acceleration and Deceleration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

2. Following Error Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

3. Direct Taper Angle Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

4. Barrier Check Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

4-1. General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

4-2. Chuck Barrier and Tailstock Barrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

5. Operation Time Reduction Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

5-1. Spindle Rotation Answer Signal Ignore (M63) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

6. Turret Unclamp Command (for NC Turret Specification) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

APPENDIX

1. EAI/ISO Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

2. G Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

3. Table of Mnemonic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

4. Table of System Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

SECTION 1 PROGRAM CONFIGURATIONS

SECTION 1 PROGRAM CONFIGURATIONS

1. Program Types

For OSP-E100L, three kinds of programs are used: schedule programs, main programs, and subprograms. The

following briefly explains these three kinds of programs.

(1) Schedule Program

When more than one type of workpiece is machined in continuous operation using a bar feeder or other equipment,

multiple main programs are used. A schedule program is used to specify the order in which the main programs are

executed and the number of times the individual main program is executed. Using a schedule program makes it

possible to carry out untended operation easily.

It is not necessary to assign a program name. The END code must be specified at the end of a schedule program.

For details, refer to SECTION 14, “SCHEDULE PROGRAMS”.

(2) Main Program

A main program contains a series of commands to machine one type of workpiece. Subprograms can be called

from a main program to simplify programming.

A main program begins with a program name which begins with address character “O” and ends with M02 or M30.

4283-E P-1

(3) Subprogram

A subprogram can be called from a main program or another subprogram. There are two types of subprograms:

those written and supplied by Okuma (maker subprogram), and those written by the customer (user subprogram).

The program name, which must start with “O”, is required at the beginning of the subprogram. The RTS command

must be specified at the end of the subprogram. For details, refer to SECTION 13, USER TASK FUNCTIONS.

•

Program file format

Main file name: Begins with alphabetic characters (max. 16 characters)

.

ExtensionMain file name

• Extensions

SDF : Schedule program file

MIN : Main program file

SSB : System subprogram file

SUB : User subprogram file

SECTION 1 PROGRAM CONFIGURATIONS

2. Program Name

With the OSP-E100L, programs are called and executed by designating the program name or program number

assigned to the beginning of individual programs. This simplifies programs.

A program name that contains only numbers is called a program number.

(1) Program Name Designation

• Enter letters of the alphabet (A to Z) or numbers (0 to 9) following address character “O”. Note that no space

is allowed between “O” and a letter of the alphabet or a number. Similarly, no space is allowed between letters of the alphabet and numbers.

• Up to four characters can be used.

• An alphabetic character can only be used in a program name if it begins with an alphabetic character.

Although a program beginning with an alphabetic character can contain a number in it, one that begins with a

number cannot contain an alphabetic character.

4283-E P-2

•

Although all of the four characters may be numeric, program names of the type “OO

cannot be used since this kind of program name is used for system operation, automating functions, etc.

•

A block which contains a program name must not contain other commands.

• A program name may not be used for a schedule program.

• The program name assigned to a subprogram must begin with address character “O”, but this is not manda-

tory for main programs.

• Since program names are handled in units of characters, the following names are judged to be different program names.

• O0123 and O123

•

O00 and O0

•

Do not assign the same name to more than one program, otherwise it will not be possible to select the

intended program.

∗∗∗

∗∗∗

” (

: alphanumeric)

SECTION 1 PROGRAM CONFIGURATIONS

3. Sequence Name

All blocks in a program are assigned a sequence name that begins with address character “N” followed by an

alphanumeric sequence.

Functions such as a sequence search function, a sequence stop function and a branching function can be used for

blocks assigned a sequence name.

A sequence name that contains only numbers is called a sequence number.

(1) Sequence Name Designation

• Enter letters of the alphabet (A to Z) or numbers (0 to 9) following address character “N”.

• Up to five characters can be used.

• Both alphabetic characters and numbers may be used in a sequence name. If an alphabetic character is

used in a sequence name, however, the sequence name must begin with an alphabetic character.

• Sequence numbers may be specified in any order. They can be used however desired, provided there is no

duplication of numbers.

• Since sequence names are handled in units of characters, the following names are judged to be different

sequence names.

• N0123 and N123

4283-E P-3

• N00 and N0

• When a sequence name is used, place a space or a tab after the sequence name.

SECTION 1 PROGRAM CONFIGURATIONS

4. Program Format

4-1. Word Configuration

A word is defined as an address character followed by a group of numeric values, an expression, or a variable

name. If a word consists of an expression or a variable, the address character must be followed by an equal sign

“=”.

Examples:

X-100 Z=100∗SIN[50] Z=V1+V2

Address Numerical

value

Word Word Word

• An address character is one of the alphabetic characters A through Z and defines the meaning of the entry

specified following it. In addition, an extended address character, consisting of two alphabetic characters,

may also be used.

•

Refer to SECTION 13, 3-2. “Variables” for more information on variables.

4-2. Block Configuration

Address Formula Address Variable

4283-E P-4

A group consisting of several words is called a block, and a block expresses a command. Blocks are delimited by

an end of block code.

•

The end of block code differs depending on the selected code system, lSO or EIA:

ISO: “LF”

ElA: “CR”

• A block may contain up to 158 characters.

4-3. Program

A program consists of several blocks.

SECTION 1 PROGRAM CONFIGURATIONS

4-4. Programmable Range of Address Characters

The programmable ranges of numerical values of individual address characters are shown in the following table.

4283-E P-5

Address Function

O Program name 0000 to 9999 same as left

N Sequence name 0000 to 9999 same as left

G Preparatory function 0 to 999 same as left

X, Z

C

I, K

D, U, W, H, L

E ±99999.999 mm/rev ±9999.9999 inch/rev

A, B 0 to 99999.999° 0 to 9999.9999°

F

T Tool number

S

SB

M Miscellaneous function 0 to 511 same as left

QA C-axis revolution 1 to 1999 (rev.) same as left

SA C-axis speed

Coordinate values (linear axis)

Coordinate values

(rotary axis)

Coordinate values of

center of arc

Taper amount and

depth of cut in fixed

thread cutting cycle

Shift amount in grooving cycle

Automatic programming commands

Feedrate per revolution

Feedrate per minute

Dwell time period 0.01 to 9999.99 sec same as left

Spindle speed

M-tool speed

±99999.999 mm ±9999.9999 inch

±359.999 deg. ±359.999 deg.

±99999.999 mm ±9999.9999 inch

0 to 99999.999 mm 0 to 9999.9999 inch

0.001 to 99999.999

mm/rev

0.001 to 99999.999

mm/min

6 digits

4 digits

0 to 9999

0 to 9999

0.001 to 20.000 min

Programmable Range

Metric Inch

0.0001 to 999.9999

inch/rev

0.0001 to 9999.9999

inch/min

same as left

same as left

-1

same as left

Remarks

Alphabetic characters

available

6 digits (with nose R

compensation)

4 digits (without nose R

compensation)

SECTION 1 PROGRAM CONFIGURATIONS

5. Mathematical Operation Functions

Mathematical operation functions are used to convey logical operations, arithmetic operations, and trigonometric

functions. A table of the operation symbols is shown below. Operation functions can be used together with variables to control peripherals or to pass on the results of an operation.

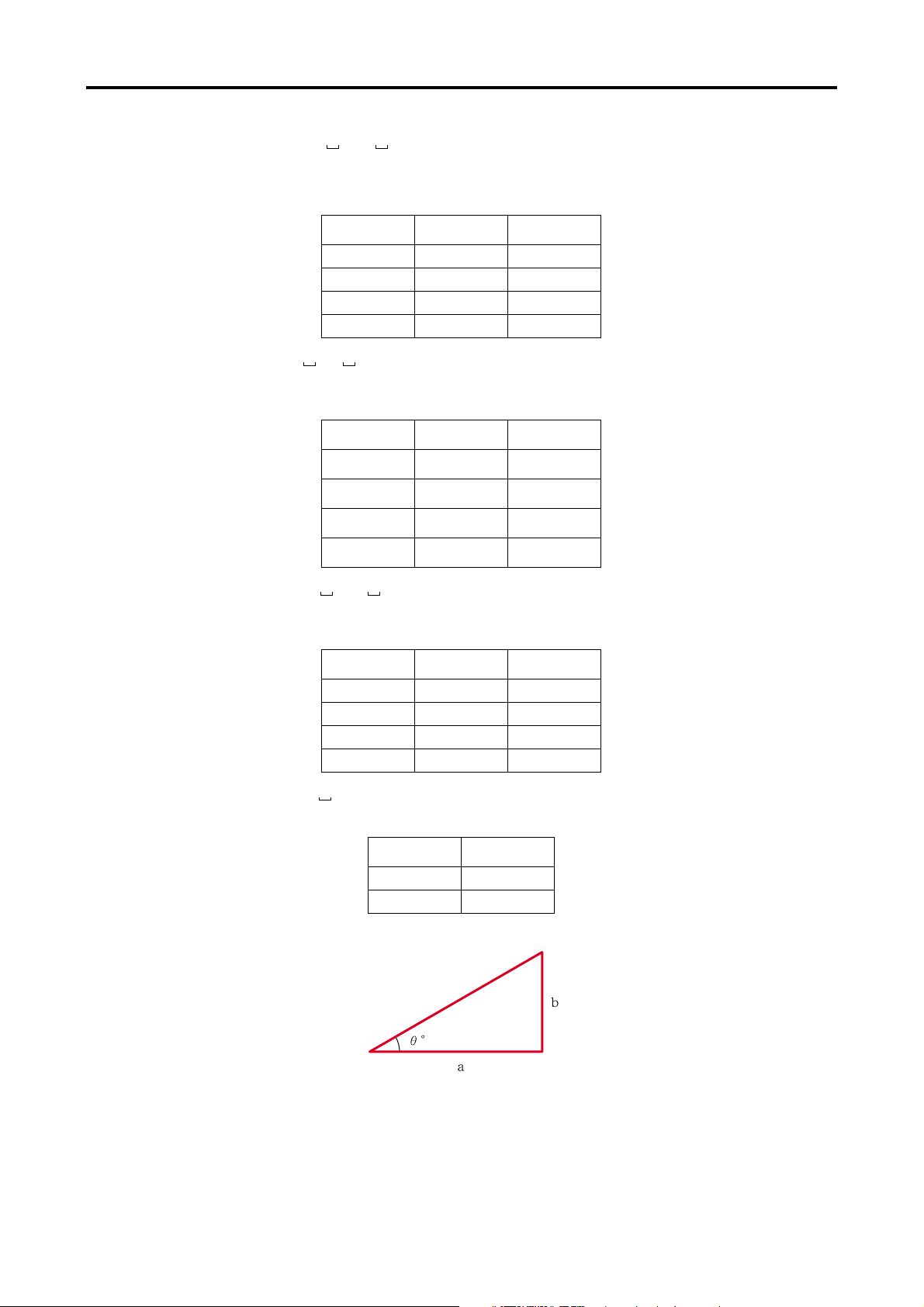

Category Operation Operator Remarks

Exclusive OR EOR 0110 = 1010 EOR 1100 (See *3.)

Logical

operation

Arithmetic

operation

Trigonometric

functions, etc.

Brackets

Logical OR OR 1110 = 1010 OR 1100

Logical AND AND 1000 = 1010 AND 1100

Negation NOT 1010 = NOT 0101

Addition + 8 = 5 + 3

Subtraction - 2 = 5 - 3

Multiplication ∗ 15 = 5 ∗ 3

Division / (slash) 3 = 15/5

Sine SIN 0.5 = SIN [30] (See *4.)

Cosine COS 0.5 = COS [60]

Tangent TAN 1 = TAN [45]

Arctangent (1) ATAN 45 = ATAN [1] (value range: -90° to 90°)

Arctangent (2) ATAN2 30 = ATAN 2 [1,(Square root 3)] (See *1.)

Square root SQRT 4 = SQRT [16]

Absolute value ABS 3 = ABS [-3]

Decimal to binary conversion BIN 25 = BIN [$25]

($ represents a hexadecimal number.)

Binary to decimal conversion BCD $25 = BCD [25]

Integer implementation (rounding) ROUND 128 = ROUND [1.2763 x 102]

Integer implementation (truncation) FIX 127 = FIX [1.2763 x 102]

Integer implementation (raising) FUP 128 = FUP [1.2763 x 102]

Unit integer implementation (rounding) DROUND 13.265 = DROUND [13.26462] (See *2.)

Unit integer implementation (truncation) DFlX 13.264 = DFlX [13.26462] (See *2.)

Unit integer implementation (raising) DFUP 13.265 = DFUP [13.26462] (See *2.)

Remainder MOD 2 = MOD [17, 5]

Opening bracket [ Determines the priority of an operaClosing bracket ]

tion. (Operations inside the bracket

are performed first.)

4283-E P-6

∗

1. The value of ATAN2 [b, a] is an argument (range: -180° to 180°) of the point that is expressed by coordinate

values (a, b).

∗2. In this example, the setting unit is mm.

∗3. Blanks must be placed before and after the logical operation symbols (EOR, OR, AND, NOT).

∗4. Numbers after function operation symbols (SIN, COS, TAN, etc.) must be enclosed in brackets “[ ]”. ( “a”, “b”,

and “c” are used to indicate the contents of the corresponding bits.)

(1) Logical Operations

• Exclusive OR (EOR) c = a EOR b

If the two corresponding values agree, EOR outputs 0.

If the two values do not agree, EOR outputs 1.

• Logical OR (OR) c = a OR b

If both corresponding values are 0, OR outputs 0.

If not, OR outputs 1.

4283-E P-7

SECTION 1 PROGRAM CONFIGURATIONS

abc

000

011

101

110

abc

000

011

101

111

• Logical AND (AND) c = a AND b

If both corresponding values are 1, AND outputs 1.

If not, AND outputs 0.

abc

000

010

100

111

• Negation (NOT) b = NOT a

NOT inverts the value (from 0 to 1, and 1 to 0).

ab

01

10

• Arc tangent (1) (ATAN)

θ = ATAN [b/a]

• Arc tangent (2) (ATAN2)

θ = ATAN2 [b/a]

• Integer implementation (ROUND, FIX, FUP)

Converts a specified value into an integer by rounding off, truncating, or raising the number at the first place

to the right of the decimal point.

(in units of microns)

SECTION 1 PROGRAM CONFIGURATIONS

6. Block Delete

[Function]

This function allows the operator to specify whether specific blocks are executed or ignored in automatic mode

operation.

Blocks preceded by “/” are ignored during automatic mode operation if the BLOCK DELETE switch on the machine

operation panel is set on. If the switch is off, the blocks are executed normally.

When the block skip function is activated, the entire block is ignored.

[Notes]

•

The slash “/” code must be placed at either the start of a block or immediately after a sequence name (number). If it is placed in another position in a block, it will cause an alarm.

• The slash “/” may not be contained in the program name block.

• Blocks which contain a “/” code are also subject to the sequence search function, regardless of the BLOCK

DELETE switch position.

• The block delete function is not possible during SINGLE BLOCK mode. The succeeding block is executed,

and then the operation stops.

4283-E P-8

SECTION 1 PROGRAM CONFIGURATIONS

7. Comment Function (CONTROL OUT/IN)

A program may be made easier to understand by using comments in parentheses.

• Comments must be parenthesized to distinguish them from general operation information.

• Comments are also subject to TV and TH checks.

Example:

N100 G00 X200 (FIRST STEP)

Comment

4283-E P-9

SECTION 1 PROGRAM CONFIGURATIONS

8. Program Storage Memory Capacity

The NC uses memory to store machining programs. The memory capacity is selectable depending on the size of

the machining program. For execution, a program is transferred from the memory to the operation buffer (RAM).

The capacity of the operation buffer is indicated by one program capacity.

If the size of the program to be executed is large, it is necessary to expand the one program capacity. The one program capacity can be selected from 320 m (1049.92 ft), 640 m (2099.84 ft.), 1280 m (4199.68 ft.), to expand program storage capacity.

4283-E P-10

SECTION 1 PROGRAM CONFIGURATIONS

9. Two Turrets

With flat bed type machines, there are models which have two turrets mounted on a saddle. Since both turrets are

mounted in the same saddle in this configuration, it is not possible to control them independently. For such

machines, the turret should be selected first when making a part program.

In the two-turret specification machines, the front and rear turrets are called turret A and turret B, respectively, and

the turrets are selected by specifying the following G codes.

Selection of turret A : G13

Selection of turret B : G14

Although the numerically controlled axes are the X- and Z-axis only, since the machine has only one saddle, program zero is set for turrets A and B independently.

It should also be noted that the X-axis direction of coordinate systems is reversed between turrets A and B.

X-axis

Z-axis

4283-E P-11

X-axis

Z-axis

SECTION 1 PROGRAM CONFIGURATIONS

10. Variable Limits

On execution of a command that specifies axis movement to a target point beyond the variable limit in the positive

direction, the specified target point is replaced with the variable limit in the positive direction.

For commands specifying axis movement to a target point beyond the variable limit in the negative direction, axis

movement is not executed and an alarm occurs.

4283-E P-12

SECTION 1 PROGRAM CONFIGURATIONS

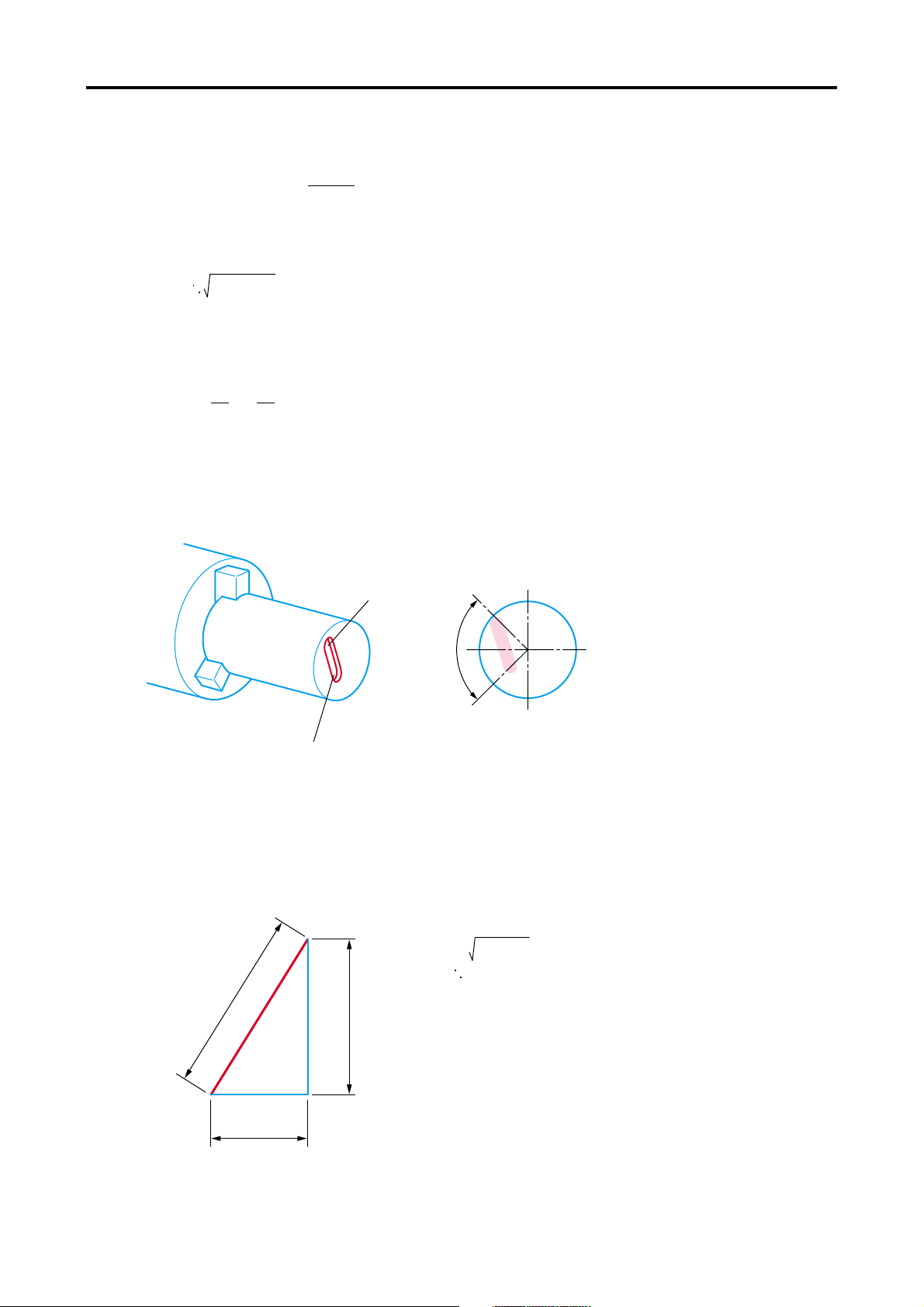

11. Determining Feedrate for Cutting along C-Axis

11-1. Cutting by Controlling the C-axis Only

Although it is possible to machine a workpiece by controlling the C-axis, tool movement distance in unit time (one

minute) differs according to the diameter of the position to be machined because the feedrate is specified in units of

deg/min. This must be taken into consideration when making a program.

[Memo]

To match the unit of the C-axis feed command with the X- and/or Z-axis command, the feedrate command (F)

should be calculated by converting 360° into 500 mm. This conversion should also be carried out when only a Caxis command is given.

Example:

90°

200φ

50φ

4283-E P-13

B

90°

A

Axis movement distance along slot A: ⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅π × 50/4 = 39 mm

Axis movement distance along slot B: ⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅π × 200/4 = 156 mm

Therefore, if cutting is carried out at a feedrate of 100 mm per minute,

the feedrate (deg/min) of the C-axis is calculated as follows:

Along slot A(deg/min)⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅100/39 × 90 = 230

Along slot B(deg/min)⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅100/156 × 90 = 58

Convert the unit of feed from "deg/min" into "mm/min".

Slot A: (mm/min)⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅230/360 × 500 = 320 (F320)

Slot B: (mm/min)⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅58/360 × 500 = 80 (F80)

SECTION 1 PROGRAM CONFIGURATIONS

11-2. Cutting by Controlling Both C-axis and Z-axis Simultaneously

Example:

A

4283-E P-14

90°

Point A coordinate value X = 80

Z = 100

C = 120

B

Point B coordinate value

X = 80

Z = 50

C = 210

When cutting the spiral from A to B with a two-flute end mill under the following cutting conditions, calculate the feedrate of C-axis as explained below:

Cutting conditions: Feed per tooth 0.05 mm

M-tool speed 400 min-1 {rpm}

1) Calculate the distance between A and B.

A development of the diagram above is indicated below.

L2

90˚

L1

The distance, L

L

1 = 80 × π ×

The distance, L

L

2 = 63

1, along the circumference is:

90

= 63 (mm)

360

2, between A and B is:

2

+ 502 = 80 (mm)

C

50 mm

2) Calculate the cutting time, T, on the basis of the cutting conditions indicated above to feed the axes along the

slot.

2

T=

(Feed per tooth) x (Number of teeth) x (min-1 (rpm))

=

80

0.05 × 2 × 400

L

= 2 (min)

SECTION 1 PROGRAM CONFIGURATIONS

3) Inside the computer, the distance L3 between A and B is calculated in the following manner.

X-axis travel = 50 mm

C-axis travel = 90° ×

500mm

360°

= 125mm

(conversion based on 360° = 500 mm)

Therefore, the distance between A and B is calculated as below:

2

L

3 = 50

135 (mm)

+ 125

2

4) The feedrate to be specified in the program is approximately calculated as below:

3

135

L

F =

= = 67.5

T

2

Specify F67.5 in the program.

11-3. Cutting by Controlling Both C-axis and X-axis Simultaneously

Example:

4283-E P-15

A

90°

Point A coordinate value X = 80

B

•

The cutting conditions are the same as used in 11-2. “Cutting by Controlling Both C-axis and Z-axis Simulta-

Point B coordinate value

neously”.

1) Calculate the distance between A and B.

The distance, L

between A and B is:

2

A

402+20

2

L

2

=

= 44.7 mm

L

2

40

Z = 100

C = 120

X = 40

Z = 100

C = 210

B

20

4283-E P-16

SECTION 1 PROGRAM CONFIGURATIONS

2) Calculate the cutting time, T, on the basis of the cutting conditions indicated above to feed the axes along the

slot.

2

360°

L

=125 mm

T=

(Feed per tooth) x (Number of teeth) x (min-1 (rpm))

44.7

0.05 × 2 × 400

=

1.12 min

3) Inside the computer, the distance L3 between A and B is calculated in the following manner.

X-axis travel = 40 mm

C-axis travel = 90° ×

500 mm

(conversion based on 360° = 500 mm)

Therefore, the distance between A and B is calculated as below:

2

L

3 = 40

+ 125

2

= 131.2 mm

4) The feedrate to be specified in the program is approximately calculated as below:

L

131.2

3

F =

= = 117

T

1.12

Specify F117 in the program.

11-4. Cutting by Simultaneous 3-axis Control of X-, Z-, and C-axis

Example:

A

90°

B

Point A coordinate value X = 80

Z = 50

C = 120

Point B coordinate value

X = 40

Z = 100

C = 210

• When cutting a slot on a cone as indicated above, simultaneous 3-axis control of the X-, Z-, and C-axis

becomes necessary. The feedrate to be programmed should be calculated in the following manner. Note

that the example below assumes the same cutting conditions as in 11-2. “Cutting by Controlling Both C-axis

and X-axis Simultaneously”.

4283-E P-17

SECTION 1 PROGRAM CONFIGURATIONS

1) First, consider the development of the slot on the C-axis and X-axis. In this case, calculation of the feedrate is

possible in the same manner as in 12-3. “Cutting by Controlling Both C-axis and X-axis Simultaneously” .

The C and X-axis travel component, L

L3 = 402+ 20

2

= 44.7 mm

2

, is:

2) Calculate the actual distance between A and B from L

A

4

L

L

2

Z-axis travel

3) Calculate the cutting time T for distance L

4

T=

(Feed per tooth) x (Number of teeth) x (min-1 (rpm))

=

67.1

0.05 × 2 × 400

L

:

4

= 1.68 min

calculated in (1).

2

L4 =

= 67.1

B

44.72 + 50

2

4) Inside the computer, distance L

between A and B is calculated in the following manner.

5

X-axis travel = 40 mm

Z-axis travel = 50 mm

C-axis travel

= 90 ´

500 mm

365

= 125 mm

(conversion based on 360 = 500 mm)

C

L

5

Z

L5 =

402+502+125

= 140.4 mm

2

X

5) The feedrate to be specified in the program is approximately calculated as below:

L

140.4

5

F =

= = 83.6

T

1.68

Specify F83.6 in the program.

SECTION 2 COORDINATE SYSTEMS AND COMMANDS

SECTION 2 COORDINATE SYSTEMS AND

COMMANDS

1. Coordinate Systems

1-1. Coordinate Systems and Values

To move the tool to a target position, the reference coordinate system must be set first to define the target position,

and the target position is defined by coordinate values in the set coordinate system. There are the three types of

coordinate system indicated below. A program coordinate system is used for programming.

• Encoder coordinate system

• Machine coordinate system

• Program coordinate system

1-2. Encoder Coordinate System

An encoder is used to detect the position of a numerically controlled axis. The encoder coordinate system is established based on the position data output by the encoder.

The position data directly output from the encoder is not displayed on the screen, and this coordinate system may

be disregarded in daily operation.

4283-E P-18

1-3. Machine Coordinate System

The reference point in the machine is referred to as the machine zero and the coordinate system which has its origin at the machine zero is called the machine coordinate system. The machine zero is set for each individual

machine using system parameters and it is not necessary to change the setting after the installation of the

machine.

If “0” is set for the encoder zero point offset (system parameter), the machine coordinate system agrees with the

encoder coordinate system.

1-4. Program Coordinate System

The coordinate system used as the reference for program commands is called the program coordinate system.

The position of the origin of the program coordinate system varies according to the kind of workpieces to be

machined and the origin is set at the required position by setting the zero offset data. The program coordinate system used for machining a specific kind of workpiece is thus defined based on the set origin.

Although the origin of a program coordinate system (program zero) can be set at any position, it is usually set on

the centerline of a workpiece for the X-axis and at the left end face of workpiece for the Z-axis.

4283-E P-19

SECTION 2 COORDINATE SYSTEMS AND COMMANDS

Zd

Zm Zp

Z

1 Z2

Machine coordinate

system

Machine zero

Zero point of encoder

Program zero

Program coordinate

system

Xp

X2

Xm

X1

Xd

Xd, Zd : Output value of position encoder

(0: Zero point of position encoder)

Xm, Zm : Coordinate values in the machine coordinate system

(0: Machine zero)

Xp, Zp : Coordinate values in the program coordinate system

(0: Program zero)

X1, Z1 : Offset amount of position encoder

X1, Z1 : Offset amount of position encoder

2. Coordinate Commands

2-1. Controlled Axis

• The following table lists the addresses necessary for axis control.

Address Contents

X

Linear axis

Z

Rotary axis C Rotary axis in a plane orthogonal to Z-axis

• A command used to move an axis consists of an axis address, a direction of movement, and a target point.

For the designation of a target point, two different methods are available: absolute commands and incremental commands. With absolute commands, the target point is specified using the coordinate values in the program coordinate system and with incremental commands the target point is defined by relative movement

distance in reference to the actual position.

For details of absolute and incremental commands, refer to 2-4. “Absolute and Incremental commands”.

• The basic coordinate system is a right-hand orthogonal coordinate system that is fixed on a workpiece.

4283-E P-20

SECTION 2 COORDINATE SYSTEMS AND COMMANDS

Controlled axis in the direction parallel to the

workpiece end face

Controlled axis in the direction parallel to the

workpiece longitudinal direction.

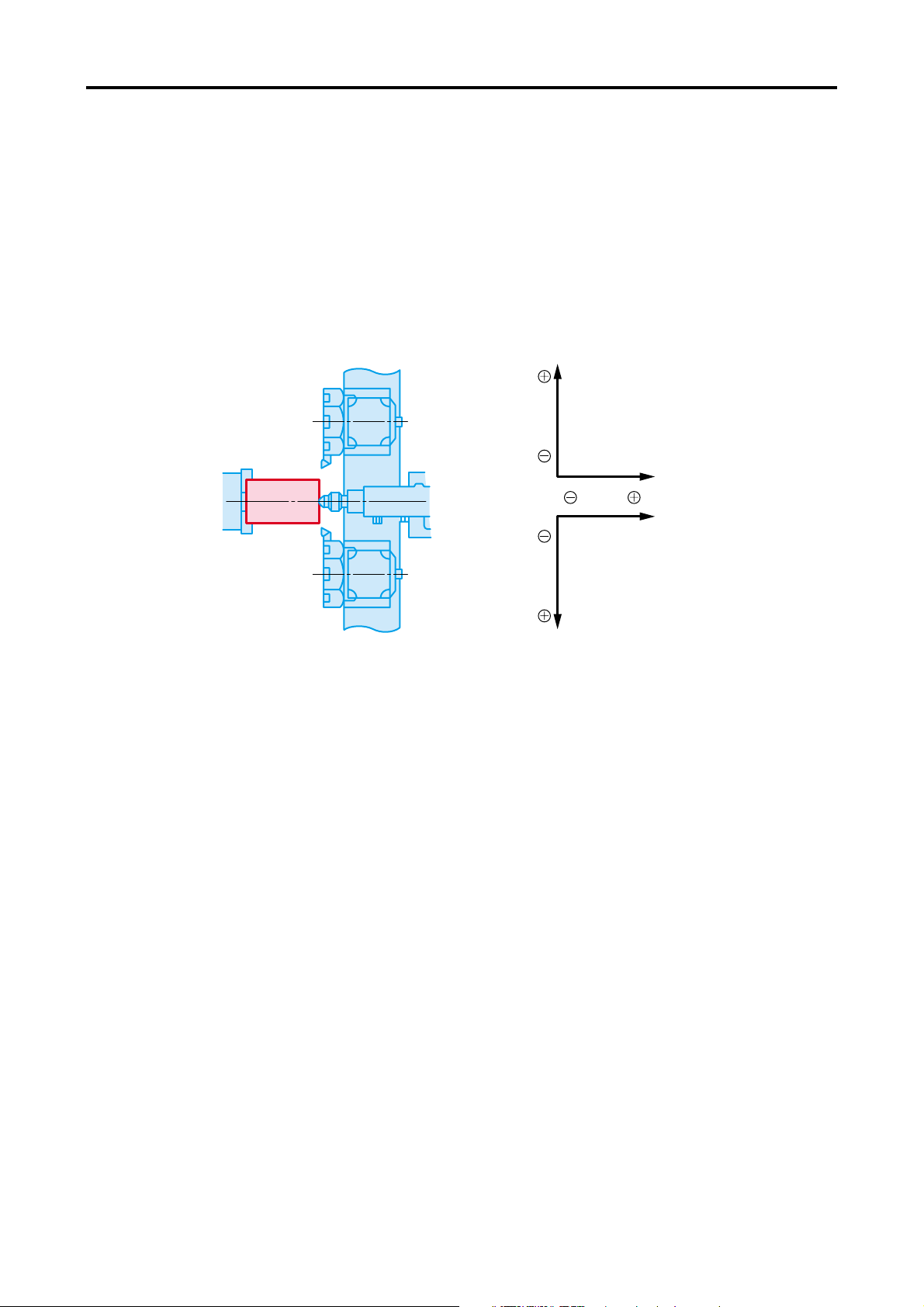

(1) Single-saddle NC lathe

Directions of turret motion:

(2) Single-saddle NC lathe (flat bed)

X-axis

Z-axis

Infeed direction .... X-axis

Longitudinal direction ... Z-axis

Z-axis

Directions of turret motion:

X-axis

Infeed direction .... X-axis

Longitudinal direction ... Z-axis

(3) Two-saddle NC lathe

4283-E P-21

SECTION 2 COORDINATE SYSTEMS AND COMMANDS

X-axis

+

Turret A (upper turret)

-

-

-

Turret B (lower turret)

+

X-axis

Z-axis

+

Z-axis

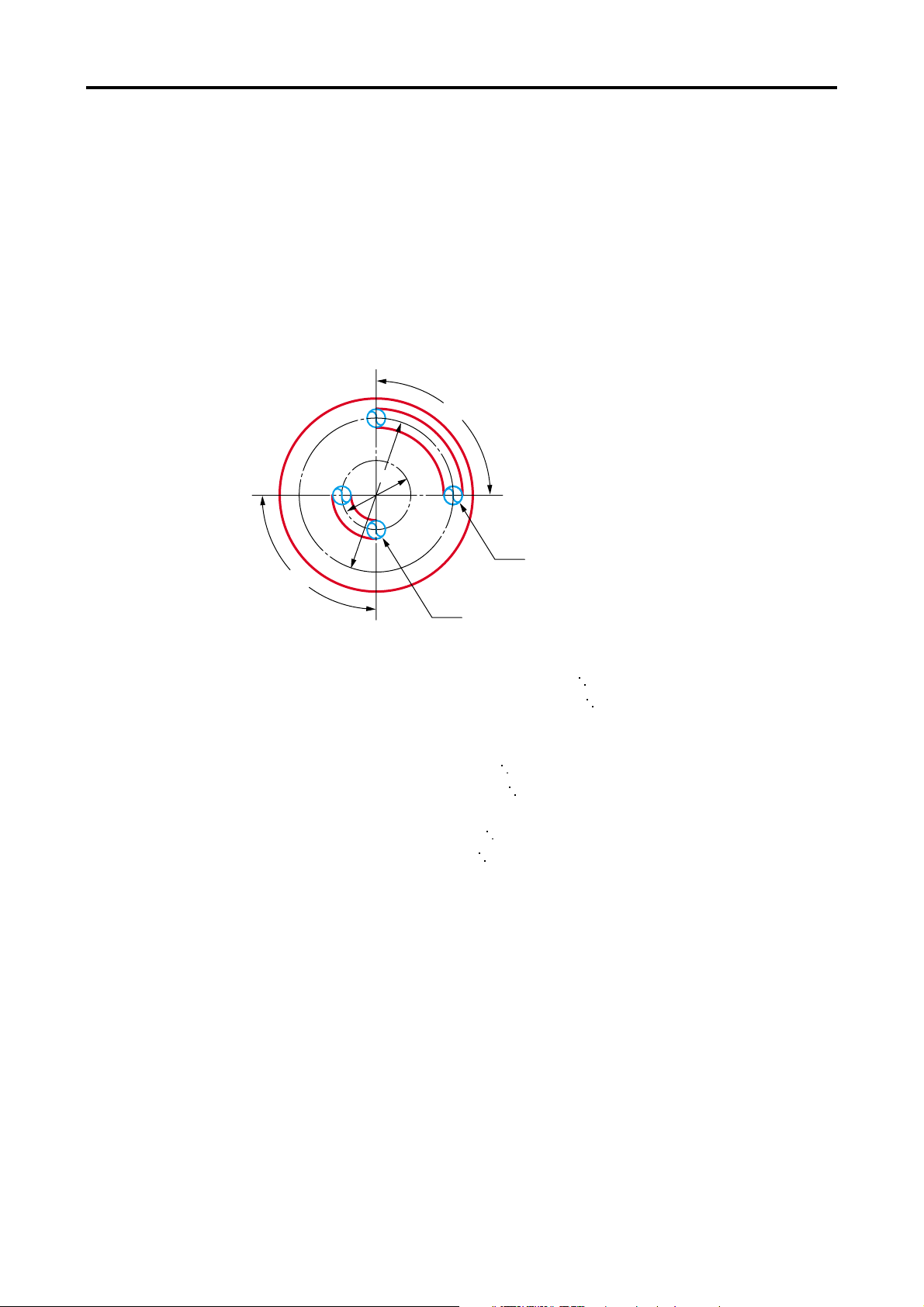

(4) C-axis coordinate system

Negative direction

M16 M15

C90˚

(Viewed from tailstock)

Directions of turret motion:

C90˚

C180˚

Positive direction

C270˚

Chuck

Infeed

direction

Longitudinal

direction

X-axis

Z-axis

Rightward rotation is defined as positive direction of C-axis movement and is commanded by M15.

M16 is used to specify C-axis movement in the negative direction.

2-2. Commands in Inch System

If the inch/metric switchable specification is selected, it is possible to specify dimensions in the inch unit system.

Even if dimensions are specified in the inch system values in a part program, the NC processes the data on the

basis of metric system values. The unit system to be selected for data input is determined according to the setting

of an NC optional parameter (UNIT). The actual unit system for data input can be checked on the NC optional

parameter (UNIT) screen.

NOTICE

In the conversion from the inch system data to the metric system data, used for internal processing by

the NC, real data values below the minimum input unit are rounded off. Integer data values are truncated.

SECTION 2 COORDINATE SYSTEMS AND COMMANDS

2-3. Position of Decimal Point

It is possible to select the unit system of the place of a decimal point. Units of the data available with the control

are shown below and the unit to be employed can be selected by entering a proper parameter data. Once the unit

system of the command data is established, it applies to all numerical data to be entered, such as MDI operation

and zero offset data.

2-3-1. Metric System

• 1 µm

•

10 µm

• 1 mm

2-3-2. Inch System (Inch/metric switchable specification):

• 1/10000 inch

• 1 inch

Unit Data Table (Value for data “1”)

4283-E P-22

Dimension

Length:

X, Z, I, K, D, H, L,

U, W

Feed (/rev):

F, E

Feed (/min):

A, B, C

Angle:

A, B, C

Time:

F, E

Spindle

-1

{rpm}:

min

S

Surface speed:

S

Metric System Inch System

1 µm 10 µm 1 mm 1/10000 inch 1 inch

0.001 (mm) 0.1 (mm) 1 (mm) 0.0001 (inch) 1 (inch)

0.001 (mm/rev) 0.01 (mm/rev) 1 (mm/rev) 0.0001 (inch/rev) 1 (inch/rev)

0.1 (mm/min) 1 (mm/min) 1 (mm/min) 0.01 (inch/min) 1 (inch/min)

0.001 (°) 0.01 (°) 1 (°) 0.001 (°) 1 (°)

0.01 (sec) 0.1 (sec) 1 (sec) 0.01 (sec) 1 (sec)

1 (min-1 {rpm}) 1 (min-1 {rpm}) 1 (min-1 {rpm}) 1 (min-1 {rpm}) 1 (min-1 {rpm})

1 (m/min) 1 (m/min) 1 (m/min) 1 (feet/min) 1 (feet/min)

SECTION 2 COORDINATE SYSTEMS AND COMMANDS

Example 1: 1 mm unit system

Commanding:

• 0.001 mm movement of X-axis X0.001

• 10 mm movement of X-axis X10

• 100.00 mm movement of X-axis X100.01

• Feedrate of 0.23456 mm/rev. F0.23456

The following commands are all handed as X1 mm:

X1

X1.0

X1.00

X1.000

Example 2: 10 mm unit system

Commanding:

• 0.001 mm movement of X-axis X0.1

• 10 mm movement of X-axis X1000

• 100.010 mm movement of X-axis X10001

• Feedrate of 0.23456 mm/rev. F23.456

Example 3: 1 mm unit system

Commanding:

• 0.001 mm movement of X-axis X0.1

• 10 mm movement of X-axis X10000

• 100.010 mm movement of X-axis X100010

• Feedrate of 0.23456 mm/rev. F234.56

4283-E P-23

[Supplement]

For F words, numerical data smaller than the selected unit system is effective if it consists of up to eight digits.

F1.2345678 ⋅⋅⋅⋅⋅⋅⋅⋅⋅⋅Acceptable

F100.000001⋅⋅⋅⋅⋅⋅⋅⋅⋅Alarm (9 digits)

SECTION 2 COORDINATE SYSTEMS AND COMMANDS

2-4. Absolute and Incremental Commands (G90, G91)

The amount of axis movement can be expressed by either absolute commands or incremental commands.

1) Absolute commands

Designated with G90

Commanded values are coordinate values in the program coordinate system.

When the control is reset, it is in the G90 mode.

2) Incremental commands

Designated with G91

Commanded values are the travel from the actual position to the target position.

Example:

(Positioning from point (1) to point (2)):

Absolute

(2)

X100 Z50

X

100

25

G00 X50 Z150 (1)

X100 Z50 (2)

Incremental

G00 X50 Z150 (1)

*G91 X50 Z-100 (2)

*Designate dimensional differences between points (2) and (1).

4283-E P-24

(1)

X50 Z150

NOTICE

1) In incremental programming, the X word should be expressed as a diameter.

2) It is not permissible to specify both G90 and G91 in the same block.

2-5. Diametric and Radial Commands

In a turning operation, the workpiece is rotated while being is machined. Due to the nature of the turning operation,

the tool cuts a circle with a radius equivalent to the distance from the center of rotation to the tool nose position. In

a program, X-axis commands specify the diameter of the circle to be cut. If a command of “X100” is specified, for

example, the actual position data displayed on the screen is “100” and the workpiece is machined to a cylinder of

100-mm diameter.

In compound operations, commands in the X-axis direction are specified as diametric values too, although this type

of operation is not a turning operation. In the coordinate conversion mode, however, the radial values (actual

length in an orthogonal coordinate system) must be specified for both X- and Y-axis commands.

SECTION 3 MATH FUNCTIONS

SECTION 3 MATH FUNCTIONS

1. Positioning (G00)

[Function]

Each axis moves independently from the actual position to the target position at its own rapid feedrate. At the start

and end of axis movement, it is automatically accelerated and decelerated.

[Programming format]

G00 X__ Z__ C__

X/Z/C : Indicates the target position for positioning operation.

[Details]

• In G00 mode positioning, execution of the commands in the next block begins only after the positioning at the

target position given in the current block is completed.

• Non-linear interpolation mode:

The axes move independently of each other at a rapid feedrate. Therefore, the resultant tool path is not

always a straight line.

4283-E P-25

NOTICE

X

Actual position

The rapid feedrates of each axis are set by the machine specifications.

Target position

Z

SECTION 3 MATH FUNCTIONS

2. Linear Interpolation (G01)

[Function]