CNC SYSTEM

OSP-P200L

MACTURN/MULTUS Series

OPERATION MANUAL

(4th Edition)

Pub No. 5262-E-R3 (LE32-114-R4) Feb. 2007

5262-E P-(i)

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The machine is equipped with safety devices which serve to protect personnel and the machine itself from

hazards arising from unforeseen accidents. However, operators must not rely exclusively on these safety

devices: they must also become fully familiar with the safety guidelines presented below to ensure accidentfree operation.

This instruction manual and the warning signs attached to the machine cover only those hazards which

Okuma can predict. Be aware that they do not cover all possible hazards.

1. Precautions Relating to Installation

(1) Please be noted about a primary power supply as follows.

• Do not draw the primary power supply from a distribution panel that also supplies a major

noise source (for example, an electric welder or electric discharge machine) since this

could cause malfunction of the CNC unit.

• If possible, connect the machine to a ground not used by any other equipment. If there is

no choice but to use a common ground, the other equipment must not generate a large

amount of noise (such as an electric welder or electric discharge machine).

(2) Installation Environment

Observe the following points when installing the control enclosure.

• Make sure that the CNC unit will not be subject to direct sunlight.

• Make sure that the control enclosure will not be splashed with chips, water, or oil.

• Make sure that the control enclosure and operation panel are not subject to excessive

vibrations or shock.

• The permissible ambient temperature range for the control enclosure is 5 to 40°C.

• The permissible ambient humidity range for the control enclosure is relative humidity 50%

or less at 40°C (no condensation).

• The maximum altitude at which the control enclosure can be used is 1000 m (3281ft.).

2. Points to Check before Turning on the Power

(1) Close all the doors of the control enclosure and operation panel to prevent the entry of water,

chips, and dust.

(2) Make absolutely sure that there is nobody near the moving parts of the machine, and that there

are no obstacles around the machine, before starting machine operation.

(3) When turning on the power, turn on the main power disconnect switch first, then the CONTROL

ON switch on the operation panel.

5262-E P-(ii)

SAFETY PRECAUTIONS

3. Precautions Relating to Manual/Continuous Operation

(1) Follow the instruction manual during operation.

(2) Do not operate the machine with the front cover, chuck cover, or another protective cover

removed.

(3) Close the front cover before starting the machine.

(4) When machining the initial workpiece, check for machine operations, run the machine under no

load to check for interference among components, cut the workpiece in the single block mode,

and then start continuous operation.

(5) Ensure your safety before rotating the spindle or moving a machine part.

(6) Do not touch chips or workpiece while the spindle is rotating.

(7) Do not stop a rotating part with hand or another means.

(8) Check that the condition of hydraulic chuck jaws as mounted, operating pressure, and maxi-

mum permissible revolving speed.

(9) Check the condition and location of the cutting tool as mounted.

(10) Check the tool offset value.

(11) Check the zero offset value.

(12) Check that the SPINDLE OVERRIDE and FEEDRATE OVERRIDE dials on the NC operation

panel are set to 100%.

(13) When moving the turret, check the software limits for X- and Z-axes or the locations of limit

switch dogs to prevent interference with the chuck and tailstock.

(14) Check the location of the turret.

(15) Check the location of the tailstock.

(16) Cut workpieces with a transmitted power and torque within the permissible range.

(17) Chuck each workpiece firmly.

(18) Check that the coolant nozzle is properly located.

4. Precautions Relating to the ATC

(1) The tool clamps of the magazine, spindle, etc., are designed for reliability, but it is possible that

a tool could be released and fall in the event of an unforeseen accident, exposing you to

danger: do not touch or approach the ATC mechanism during ATC operation.

(2) Always inspect and change tools in the magazine in the manual magazine interrupt mode.

(3) Remove chips adhering to the magazine at appropriate intervals since they can cause

misoperation. Do not use compressed air to remove these chips since it will only push the chips

further in.

(4) If the ATC stops during operation for some reason and it has to be inspected without turning the

power off, do not touch the ATC since it may start moving suddenly.

5262-E P-(iii)

SAFETY PRECAUTIONS

5. On Finishing Work

(1) On finishing work, clean the vicinity of the machine.

(2) Return the ATC, APC and other equipment to the predetermined retraction position.

(3) Always turn off the power to the machine before leaving it.

(4) To turn off the power, turn off the CONTROL ON switch on the operation panel first, then the

main power disconnect switch.

6. Precautions during Maintenance Inspection and When Trouble Occurs

In order to prevent unforeseen accidents, damage to the machine, etc., it is essential to observe the

following points when performing maintenance inspections or during checking when trouble has

occurred.

(1) When trouble occurs, press the emergency stop button on the operation panel to stop the

machine.

(2) Consult the person responsible for maintenance to determine what corrective measures need

to be taken.

(3) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

(4) Use only the specified replacement parts and fuses.

(5) Always turn the power off before starting inspection or changing parts.

(6) When parts are removed during inspection or repair work, always replace them as they were

and secure them properly with their screws, etc.

(7) When carrying out inspections in which measuring instruments are used - for example voltage

checks - make sure the instrument is properly calibrated.

(8) Do not keep combustible materials or metals inside the control enclosure or terminal box.

(9) Check that cables and wires are free of damage: damaged cables and wires will cause current

leakage and electric shocks.

(10) Maintenance inside the Control Enclosure

a. Switch the main power disconnect switch OFF before opening the control enclosure door.

b. Even when the main power disconnect switch is OFF, there may some residual charge in

the MCS drive unit (servo/spindle), and for this reason only service personnel are permitted

to perform any work on this unit. Even then, they must observe the following precautions.

• MCS drive unit (servo/spindle)

The residual voltage discharges two minutes after the main switch is turned OFF.

c. The control enclosure contains the NC unit, and the NC unit has a printed circuit board

whose memory stores the machining programs, parameters, etc. In order to ensure that the

contents of this memory will be retained even when the power is switched off, the memory

is supplied with power by a battery. Depending on how the printed circuit boards are handled, the contents of the memory may be destroyed and for this reason only service personnel should handle these boards.

(11) Periodic Inspection of the Control Enclosure

a. Cleaning the cooling unit

The cooling unit in the door of the control enclosure serves to prevent excessive temperature rise inside the control enclosure and increase the reliability of the NC unit. Inspect the

following points every three months.

• Is the fan motor inside the cooling unit working?

The motor is normal if there is a strong draft from the unit.

• Is the external air inlet blocked?

If it is blocked, clean it with compressed air.

7. General Precautions

5262-E P-(iv)

SAFETY PRECAUTIONS

(1) Keep the vicinity of the machine clean and tidy.

(2) Wear appropriate clothing while working, and follow the instructions of someone with sufficient

training.

(3) Make sure that your clothes and hair cannot become entangled in the machine. Machine opera-

tors must wear safety equipment such as safety shoes and goggles.

(4) Machine operators must read the instruction manual carefully and make sure of the correct pro-

cedure before operating the machine.

(5) Memorize the position of the emergency stop button so that you can press it immediately at any

time and from any position.

(6) Do not access the inside of the control panel, transformer, motor, etc., since they contain high-

voltage terminals and other components which are extremely dangerous.

(7) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

8. Symbols Used in Manual

The following warning indications are used in this manual to draw attention to information of particular importance. Read the instructions marked with these symbols carefully and follow them.

DANGER

indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING

indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION

indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION

5262-E P-(v)

SAFETY PRECAUTIONS

indicates a potentially hazardous situation which, if not avoided, may result in damage to your

property.

SAFETY INSTRUCTIONS

indicates general instructions for safe operation.

5262-E P-(i)

INTRODUCTION

INTRODUCTION

Thank you very much for choosing our CNC system. This numerical control system is a expandable CNC

with various features . Major features of the CNC system are described below.

(1) Compact and highly reliable

The CNC system has become compact and highly reliable because of advanced hardware technology,

including computer boards equipped with high-speed micro processors, I/O link, and servo link. The

‘variable software’ as a technical philosophy of the OSPs supported by a hard disk. Functions may be

added to the CNC system as required after delivery.

(2) NC operation panels

The following types of NC operation panels are offered to improve the user-friendliness.

• Thin color operation panels (horizontal)

• Thin color operation panels (vertical)

One or more of the above types may not be used for some models.

(3) Machining management functions

These functions contribute to the efficient operation of the CNC system and improve the profitability from

small quantity production of multiple items and variable quantity production of variations. Major control

functions are described below.

a. Reduction of setup time

With increase in small-volume production, machining data setting is more frequently needed. The

simplified file operation facilitates such troublesome operation. The documents necessary for setup,

such as work instructions, are displayed on the CNC system to eliminate the necessity of controlling

drawings and further reduce the setup time.

b. Production Status Monitor

The progress and operation status can be checked on a real-time basis on the screen of the CNC

system.

c. Reduction of troubleshooting time

Correct information is quickly available for troubleshooting.

(4) Help functions

When an alarm is raised, press the help key to view the content of the alarm.

This helps take quick action against the alarm.

To operate the CNC system to its maximum performance, thoroughly read and understand this instruction

manual before use.

Keep this instruction manual at hand so that it will be available when you need a help.

Screens

Different screens are used for different models. Therefore, the

screens used on your CNC system may differ from those shown

in this manual.

5262-E P-(i)

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 1 TURRET OPERATION.............................................................................1

1. Overview.................................................................................................................................. 1

2. Turret Indexing Control............................................................................................................ 2

2-1. Turret Index Position ........................................................................................................ 2

2-2. Turret Number Assignment .............................................................................................. 3

2-3. Turret Indexing Turret Control .......................................................................................... 4

3. Turret B-axis Positioning Control.............................................................................................5

3-1. B-axis Positioning ............................................................................................................. 5

3-2. Movable Range of the B-axis ........................................................................................... 5

3-3. Precautions for B-axis positioning control ........................................................................ 6

4. Turret Indexing Commands ..................................................................................................... 7

4-1. Command Systems .......................................................................................................... 7

4-2. Base cutting Position Indexing by Tool Numbers ............................................................. 7

4-3. Vertical Cutting Position Indexing by Tool Numbers ........................................................ 7

4-4. Base cutting Position Indexing by Tool Group Numbers .................................................. 8

4-5. Vertical Cutting Position Indexing by Tool Group Numbers ............................................. 8

4-6. Base cutting Position Indexing by Turret Numbers .......................................................... 8

4-7. Vertical Cutting Position Indexing by Turret Numbers...................................................... 9

4-8. ATC Position Indexing by Turret Numbers ....................................................................... 9

4-9. Independent Direction of the Tool Compensation Number, the Nose R Com-

pensation Number, and the Tool Diameter Compensation Number................................. 9

5. Turret B-axis Positioning Commands .................................................................................... 10

5-1. Command Systems ........................................................................................................ 10

5-2. B-axis Positioning Command in the Same Block as the TL Command.......................... 11

5-3. B-axis Positioning Command in the Same Block as the TG Command ......................... 11

5-4. B-axis Positioning Command in the Same Block as the T Command............................ 12

5-5. Independent Command for Positioning B-axis ............................................................... 12

5-6. Turret Rotary Position Offset Command in B-axis Positioning (G52)............................. 13

5-7. Terms Relevant to Turret Rotary Position Compensation .............................................. 14

6. Manual Turret Indexing Operation ......................................................................................... 15

6-1. Turret Indexing Position.................................................................................................. 15

6-2. H1 Turret ........................................................................................................................ 15

7. Manual B-axis Positioning Operation..................................................................................... 16

7-1. Positioning the B-axis ..................................................................................................... 16

7-2. Canceling B-axis positioning .......................................................................................... 16

7-3. BA Angle Data Display ................................................................................................... 17

8. Manual Slant Feed Function.................................................................................................. 18

8-1. Designating a Slant Feed Direction ................................................................................ 18

8-2. Selecting Slant Feed, Feed Operation ........................................................................... 19

8-3. Caution on Recovering from Manual Intervention .......................................................... 20

8-4. Relationship with the Slant Compound Fixed Cycle Function ........................................ 20

5262-E P-(ii)

TABLE OF CONTENTS

8-5. Others............................................................................................................................. 20

9. Tool Index Function ............................................................................................................... 21

9-1. Relation between Turret Indexing and Tool Indexing ..................................................... 21

9-2. Relation between Tool Indexing and Graphic Display .................................................... 21

9-3. Relation between Tool Index Command and Tool Compensation ................................. 22

9-4. Tool Index Commands ................................................................................................... 22

9-5. Relation between Rotary Tool and Tool Index Commands ............................................ 22

10.Parameter Settings ................................................................................................................ 23

10-1.B-axis User Parameters ................................................................................................ 23

10-2.B-axis System Parameters ............................................................................................ 23

10-3.Turret Position Error Compensation .............................................................................. 23

10-4.B-axis Indexing Angles .................................................................................................. 23

10-5.M-axis Orientation .........................................................................................................24

10-6.System Parameters ....................................................................................................... 24

10-7.Optional Parameters...................................................................................................... 25

10-8.Machine System Parameters ........................................................................................ 25

11.Tool Data Setting ................................................................................................................... 26

11-1.Tool Shape Data............................................................................................................26

11-2.Tool Compensation ....................................................................................................... 27

11-3.Tool Life Management (Special Function)..................................................................... 28

12.Tool Compensation Multi-System Function ........................................................................... 29

12-1.Combinations of Compensation Systems...................................................................... 29

12-2.Tool Compensation Data Structure ............................................................................... 30

12-3.Selecting the TOOL COMPENSATION Screen with the Tool Compensation

Multi-system Function..................................................................................................... 32

12-4.Tool Life Management Tool Information Screen for the Tool Compensation

Multi-system Function..................................................................................................... 32

12-5.System Variables...........................................................................................................33

13.Other Functions ..................................................................................................................... 34

13-1.Tool Compensation Automatic Calculation Function..................................................... 34

13-2.Turret Coolant Interlock ................................................................................................. 34

13-3.Data Input/Output Function ........................................................................................... 35

13-4.Interlock ......................................................................................................................... 37

SECTION 2 ATC OPERATION ..................................................................................38

1. Overview................................................................................................................................ 38

2. Machine Specifications.......................................................................................................... 38

2-1. Outline of the Machine.................................................................................................... 38

2-2. Machine Operation ......................................................................................................... 41

2-3. ATC Operation................................................................................................................ 42

3. ATC Logic Tables .................................................................................................................. 44

3-1. Input Logic Tables ..........................................................................................................44

3-2. Output Logic Tables ....................................................................................................... 45

3-3. Manual Interlock Tables ................................................................................................. 45

5262-E P-(iii)

TABLE OF CONTENTS

4. Manual Operation .................................................................................................................. 46

4-1. Manual Magazine Operation .......................................................................................... 46

4-2. Manual ATC Operation................................................................................................... 55

5. ATC Program Commands ..................................................................................................... 59

5-1. ATC Commands ............................................................................................................. 59

5-2. ATC Macro Commands .................................................................................................. 61

5-3. Others............................................................................................................................. 62

5-4. Example Programs ......................................................................................................... 63

6. Automatic Operation .............................................................................................................. 67

6-1. Sequence Return Procedure .......................................................................................... 67

6-2. Cautions on Using the Program Check/Graphic Scale Automatic Setting Func-

tion while in Machine Lock Status .................................................................................. 69

7. Data Setting ........................................................................................................................... 71

7-1. Magazine Information ..................................................................................................... 71

7-2. Tool Information.............................................................................................................. 74

8. ATC Status Display................................................................................................................ 75

8-1. ATC Status Display Screen ............................................................................................ 75

8-2. Tool Data Display Screen............................................................................................... 77

8-3. Machine Diagnosis Screen............................................................................................. 78

8-4. ATC Input/Output Display Screen .................................................................................. 81

9. Parameter Setting.................................................................................................................. 82

9-1. ATC Tool Change Position and Movable Range............................................................ 82

9-2. Magazine Axis Parameter .............................................................................................. 83

9-3. EC–axis (Tool Change Arm Rotation Axis) Parameter................................................... 84

9-4. EZ–axis (Tool Change Advance/Retraction Rotation Axis) Parameter (MUL-

TUS-B300/B400) ............................................................................................................ 84

9-5. Positioning Point EC (MULTUS-B300/B400).................................................................. 85

9-6. Positioning Point EZ (MULTUS-B300/B400) .................................................................. 85

9-7. Turret Index Angle ..........................................................................................................85

9-8. Magazine Panel Communication Parameter .................................................................. 86

9-9. Setting the Tool Change Arm Rotation Positions Immediately after Installing

the Control Software (MULTUS-B300/B400).................................................................. 87

9-10.Cam Shaft Timing Parameter (Machine System Parameter No.18-1) .......................... 88

9-11.Step Division Parameter................................................................................................ 89

9-12.ATC Tool Change Arm (Machine System Parameter No.18-2)..................................... 90

9-13.Tool Change Arm Torque Limit Parameter (Machine System Parameter

No.18-3).......................................................................................................................... 90

9-14.Tool Change Arm Override 1 (Machine System Parameter No.18-4) ........................... 90

9-15.Tool Change Arm Override 2, 3 (Machine System Parameter No.18-5, 6) ................... 91

10.System Check........................................................................................................................ 92

10-1.System Check Mode Parameters.................................................................................. 92

10-2.ATC Parameters............................................................................................................ 94

10-3.Manual ATC Operation.................................................................................................. 97

11.Others .................................................................................................................................. 100

11-1.G and M Code Macro Functions.................................................................................. 100

5262-E P-(iv)

TABLE OF CONTENTS

11-2.ATC Macro Command Subprograms .......................................................................... 102

11-3.Optical In–process Workpiece Gauging Specification (Optional Specification).............. 108

11-4.At the Occurrence of ATC Failure ............................................................................... 109

SECTION 3 Y-AXIS CONTROL ...............................................................................112

1. OUTLINE Y-AXIS CONTROL.............................................................................................. 112

1-1. OVERVIEW .................................................................................................................. 112

2. OPERATION........................................................................................................................ 113

2-1. MACHINE OPERATION............................................................................................... 113

2-2. MANUAL OPERATION ................................................................................................ 116

2-3. MDI OPERATION......................................................................................................... 118

2-4. AUTOMATIC OPERATION .......................................................................................... 118

2-5. NC OPERATION PANEL DISPLAY ............................................................................. 119

2-6. ADDITIONAL FUNCTIONS .......................................................................................... 121

3. PROGRAMMING................................................................................................................. 130

3-1. OVERVIEW .................................................................................................................. 130

3-2. Y-AXIS CONTROL COMMANDS................................................................................. 130

3-3. Y-AXIS COMPOUND FIXED CYCLES ........................................................................ 134

4. Slant Machining Mode Function .......................................................................................... 145

4-1. Overview....................................................................................................................... 145

4-2. Coordinate System for Slant Machining ....................................................................... 146

4-3. Slant Machining Mode Commands............................................................................... 148

4-4. Functions Usable in Slant Machining Mode ................................................................. 149

4-5. Zero Point Shift Macro Command ................................................................................ 152

4-6. Actual Position Display ................................................................................................. 153

5. DATA OPERATION ............................................................................................................. 154

5-1. DATA OPERATION...................................................................................................... 154

6. PARAMETER ...................................................................................................................... 161

6-1. PARAMETER ............................................................................................................... 161

7. APPENDIX........................................................................................................................... 165

7-1. Y-AXIS MACHINING EXAMPLES (FOR A-TURRET SIDE ONLY).............................. 165

SECTION 4 SUB-SPINDLE OPERATION ...............................................................169

1. Overview.............................................................................................................................. 169

1-1. Overview....................................................................................................................... 169

1-2. Machine Configuration.................................................................................................. 169

1-3. Coordinate System ....................................................................................................... 170

2. Operation Panels................................................................................................................. 171

2-1. Basic Configuration of Operation Panels...................................................................... 171

2-2. Option Panel for Sub-spindle Machines ....................................................................... 172

2-3. Brief Explanation of the Panels .................................................................................... 173

3. Manual Operation ................................................................................................................ 175

3-1. Operations Related to the Spindle 1 (Main Spindle) .................................................... 175

5262-E P-(v)

TABLE OF CONTENTS

3-2. Operations Related to the Spindle 2 (Sub Spindle) ...................................................... 177

3-3. Axis Feed Operation (X–, Z–, C–, and W–axis) ........................................................... 179

3-4. M-TOOL SPINDLE OPERATION ................................................................................. 182

3-5. Other Manual Operations ............................................................................................. 184

4. MDI/Automatic Operation .................................................................................................... 185

4-1. Coordinate System Selection ....................................................................................... 185

4-2. MDI Operation .............................................................................................................. 186

4-3. Automatic Operation..................................................................................................... 186

5. Additional Functions ............................................................................................................ 187

5-1. Workpiece Transfer Function from the Main Spindle to the Sub Spindle ..................... 187

5-2. Z–axis Mirror Image...................................................................................................... 188

5-3. Interlock (for two-saddle models only) .......................................................................... 192

5-4. W-axis Cutting Function (Optional)............................................................................... 193

6. Programming ....................................................................................................................... 195

6-1. Coordinate System ....................................................................................................... 195

6-2. Program Commands .................................................................................................... 197

7. Data Operation .................................................................................................................... 199

7-1. Zero Setting .................................................................................................................. 199

8. Description of Parameters ................................................................................................... 203

8-1. System Parameters ...................................................................................................... 203

8-2. User Parameters .......................................................................................................... 204

8-3. Chuck Parameters........................................................................................................ 205

8-4. Machine System Parameter (Airblow/Coolant)............................................................. 207

8-5. Machine User Parameter (Airblow/Coolant) ................................................................. 210

8-6. Machine User Parameter (Chuck) ................................................................................ 211

8-7. Machine User Parameter (Spindle) .............................................................................. 212

8-8. Machine System Parameter (Spindle).......................................................................... 213

8-9. Machine System Parameter (Door Interlock) ............................................................... 214

8-10.Machine System Parameter (Milling Spindle).............................................................. 215

SECTION 5 MULTI-EDGE TOOL FUNCTION FOR 8-/12-ANGLE INDEX-

ING.......................................................................................................216

1. Overview.............................................................................................................................. 216

2. Function............................................................................................................................... 217

2-1. Tool Management......................................................................................................... 217

2-2. Turret Rotation.............................................................................................................. 218

2-3. Edge Index Command.................................................................................................. 219

2-4. Interlock ........................................................................................................................ 219

3. Tool Data Setting Screen..................................................................................................... 220

3-1. TOOL SHAPE Screen .................................................................................................. 220

3-2. TOOL LIFE MANAGEMENT Screen (for the Machine with Tool Life Manage-

ment FUnction) ............................................................................................................. 221

3-3. GROUP TABLE Screen (for the Machine with Tool Life Management Func-

tion)............................................................................................................................... 223

5262-E P-(vi)

TABLE OF CONTENTS

4. System Variable................................................................................................................... 224

4-1. Internal Tool Number.................................................................................................... 224

4-2. System Variable for Internal Tool Number ................................................................... 225

4-3. System Variable for Tool Group ................................................................................... 226

4-4. System Variable for Turret Number.............................................................................. 226

4-5. System Variables with No Subscript............................................................................. 226

SECTION 6 NC TAILSTOCK (MULTUS-B300/B400) ..............................................227

1. Operation............................................................................................................................. 228

1-1. Setup Operation ........................................................................................................... 228

1-2. Ordinary Operation ....................................................................................................... 228

2. Tailstock Movement............................................................................................................. 229

2-1. Manual Tailstock Movement......................................................................................... 229

2-2. Automatic Tailstock Movement..................................................................................... 229

3. Switching between High/Low Pressure ............................................................................... 230

3-1. Switching between High/Low Pressure Command....................................................... 230

3-2. Operation...................................................................................................................... 230

4. Multiple Sizing Position Command ...................................................................................... 231

4-1. Multiple Sizing Position Command ............................................................................... 231

4-2. Operation...................................................................................................................... 231

4-3. Sequence Restoration (operation starting from the halfway of the program) ............... 231

5. Preparatory Operation .........................................................................................................232

5-1. Setting the Sizing Position............................................................................................ 232

5-2. No-load Torque Measurement...................................................................................... 233

6. Parameters .......................................................................................................................... 234

6-1. NC Tailstock User Parameter....................................................................................... 234

6-2. NC Tailstock System Parameter .................................................................................. 238

7. Interlock ............................................................................................................................... 240

SECTION 7 OTHER FUNCTIONS...........................................................................243

1. Description of Other Functions ............................................................................................ 243

1-1. Override for Internal Arc Cutting................................................................................... 243

1-2. Helical Cutting Function (Optional)............................................................................... 245

SECTION 8 APPENDIX...........................................................................................246

1. Logic Tables ........................................................................................................................ 246

2. ATC Input/Output Bit Tables................................................................................................ 269

3. List of Data Formats ............................................................................................................ 283

3-1. Tool data setting (T) ..................................................................................................... 283

3-2. Zero point data setting (0) ............................................................................................ 284

3-3. Parameter setting (P) ................................................................................................... 285

5262-E P-(i)

CONTENTS

CONTENTS

SECTION 1 TURRET OPERATION

SECTION 2 ATC OPERATION

SECTION 3 Y-AXIS CONTROL

SECTION 4 SUB-SPINDLE OPERATION

SECTION 5 MULTI-EDGE TOOL FUNCTION FOR 8-/12-ANGLE INDEX-

ING

SECTION 6 NC TAILSTOCK (MULTUS-B300/B400)

SECTION 7 OTHER FUNCTIONS

SECTION 8 APPENDIX

SECTION 1 TURRET OPERATION

1. Overview

This section describes the functions and operations of the turrets installed in MACTURN and MULTUS series.

MACTURN and MULTUS series can move its saddle in three directions X-axis, Y-axis, and Z-axis.

The turret rotates around the Y-axis.

The turret indexing function is available in two modes: “B-axis 1° indexing” by 1°, and “B-axis 1/

1000° indexing” by 0.001°. However, only “B-axis 1/1000° indexing” is available in MULTUS series.

B-axis indexing type

1° indexing 1/1000° indexing

MACTURN 250/350/550 Available Available

MULTUS B300/B400 Not available Available

5262-E P-1

SECTION 1 TURRET OPERATION

2. Turret Indexing Control

Since the turret of MACTURN and MULTUS series rotates around the Y-axis, a single tool can be

used on the front or on a side according to the direction the turret is indexed.

2-1. Turret Index Position

(1) Base cutting position

One of the basic indexing operations of the turret for MACTURN and MULTUS series machines

is “base cutting position” indexing. The base cutting position means the state the tool attached

faces the Z-axis direction. When a second spindle is equipped, the turret indexing position is

180 degrees shifted from the base cutting position.

(2) Vertical cutting position

The “vertical cutting position” is the state the B-axis is shifted 90 degrees from the base cutting

position in the positive direction. In this position, the tool attached faces the X-axis direction.

(3) ATC position

MACTURN and MULTUS series are generally equipped with an ATC. To mount a tool to the turret using an ATC, the saddle must be moved to the position where the tool can be replaced, and

the turret must be indexed to the ATC position in advance. On MACTURN and MULTUS series

machines, the ATC position and the turret indexing angle to the base cutting position are the

same.

Although physical turret indexing is the same, the control mode may be different.

5262-E P-2

SECTION 1 TURRET OPERATION

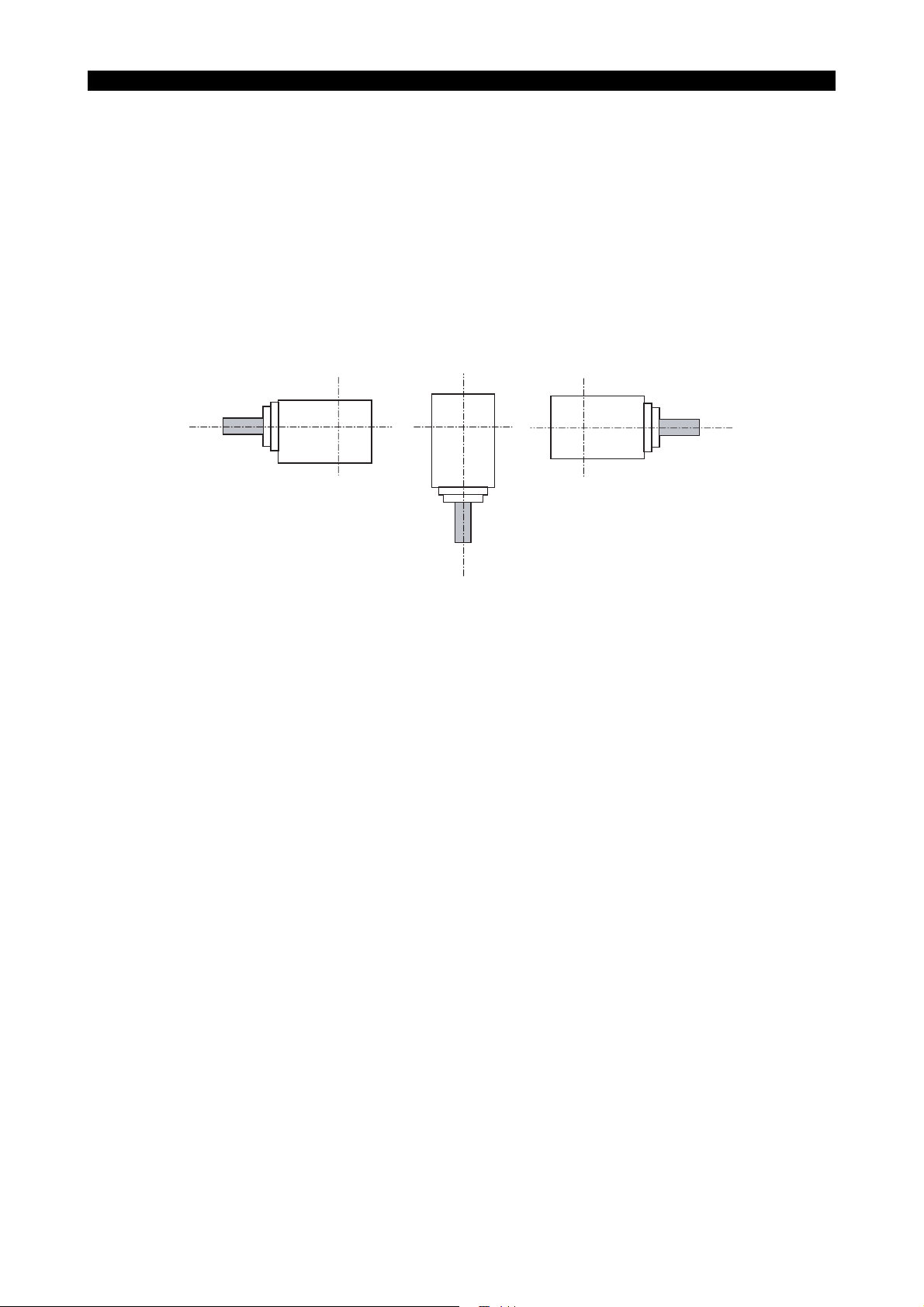

• H1 turret

First spindle

base cutting

position

Second spindle

base cutting

position

Vertical cutting position

LE32114R0400300030001

2-2. Turret Number Assignment

A general turret, for example an octagonal turret, is indexed with index numbers 1 to 8. The turret for

MACTURN and MULTUS series machines, on the other hand, can use a single tool in two different

indexing positions, which means both the H1 turrets are internally controlled as square turrets in the

NC.

With a regular turret indexing command (such as T0100 and T0300), the turret number NC has

internally assigned will be indexed to the base cutting position.

H1 turret numbers

Although only one tool can be attached to the H1 turret, turret numbers 1 to 3 are assigned to it. The

turret can, therefore, be indexed as shown below with a T command, but to which direction the tool

will be faced will generally be directed.

5262-E P-3

SECTION 1 TURRET OPERATION

T1

T3

T2

LE32114R0400300040001

2-3. Turret Indexing Turret Control

The H1 turret cannot make a full turn because of the structure of the turret, and moves like a turret

within a specific range as shown below.

In a machine with a turret indexing single-direction positioning function (*) for turret control, an error

will occur if an overshoot in a single direction is in the turret indexing prohibition range.

* Such a machine positions the B-axis from the B-axis negative direction to the positive direction,

irrespective of the position of the target point. With a command of positioning to a smaller angle

than the current one, the B-axis will move to -10 degrees and then in the positive direction to

the target point.

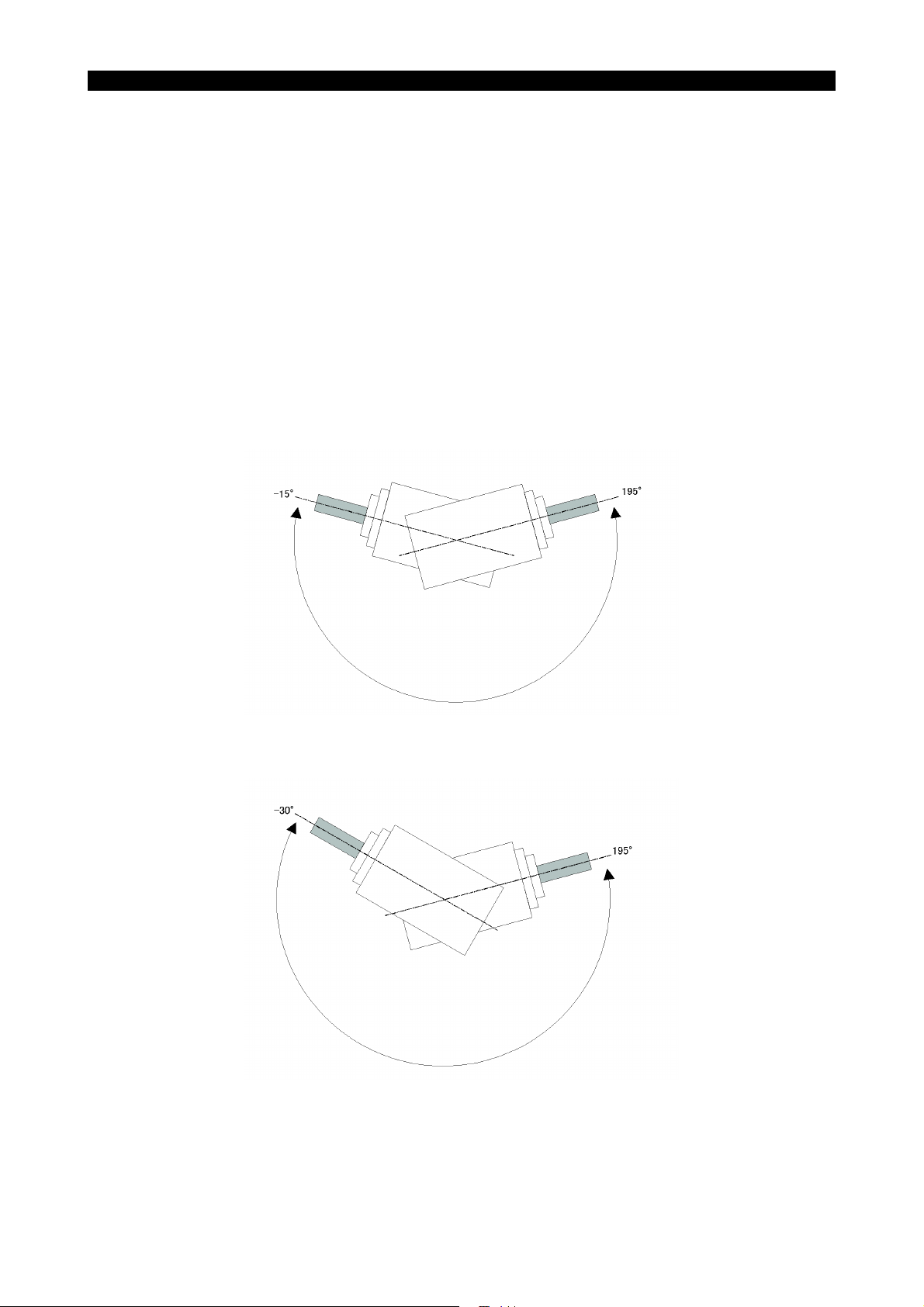

H1 turret

The MACTURN series can rotate the H1 turret between -15° and +195° and MULTUS series

machine can rotate between -30° and +195° with the base cutting position set at 0°.

It will be indexed in the order of T1 → T2 → T3 → T2 → T1 → T2... with the manual turret swing button.

5262-E P-4

SECTION 1 TURRET OPERATION

LE32114R0400300050001

LE32114R0400300050002

3. Turret B-axis Positioning Control

When “B-axis one-degree indexing mode” or “B-axis 1/1000-degree pitch indexing mode” is

selected, the B-axis can be positioned to any set angle. This B-axis positioning control function is

available for machining inclined faces.

3-1. B-axis Positioning

The B-axis can be positioned with only an MDI command or program command. To perform manual

operation with the B-axis positioned, the B-axis must be positioned in advance by MDI operation.

For specific B-axis positioning commands, see 5. “Turret B-axis Positioning Commands”.

3-2. Movable Range of the B-axis

In B-axis positioning, the angular reference for the B-axis angle command is different depending on

the turret Indexed state. Basically, the increment in the B-axis angle from the turret indexing position

as the reference is directed.

Depending on the turret indexing position, an error will occur if he B-axis positioning angle is out of

the movable range.

Set the movable range with the mechanical system parameters “turret boundary angle” and “turret

angle range.”

5262-E P-5

SECTION 1 TURRET OPERATION

H1 turret

Assuming that the indexed angle of the B-axis with T1 as the base cutting position is 0.000°, the Baxis positioning command range for MACTURN series is between -30° and +195° and MULTUS

series is -30° and +195°.

LE32114R0400300080001

LE32114R0400300080002

3-3. Precautions for B-axis positioning control

(1) The B-axis positioning data just after software installation is 0 degrees.

(2) Issue a B-axis angle data command in the “BA=” format.

(3) A B-axis positioning command must be set in the same block as a turret indexing command.

(4) “BA = 0” will be considered directed when only a turret indexing command is issued.

(5) After the operation mode is switched from automatic or MFI operation to manual operation, the

angle data for the B-axis positioning command remains valid. The B-axis angle data is backed

up in real time and will be retained even after the power is turned OFF.

(6) The B-axis positioning angle data is displayed as current position data. However, if there is a

difference of more than 0.5 degrees between the directed B-axis position and the angle of the

B-axis actually positioned, the current position will be displayed as “.” In this case, the

current position will be displayed in the normal manner by swinging the turret again.

(7) The direction of the B-axis coordinates generally depends on the direction of the Y-axis coordi-

nates. MACTURN and MULTUS series machines, however, always treat the counterclockwise

direction as the B-axis positive direction. This direction will not be affected by Y-axis mirror

images that will be described later. On machines equipped with a sub-spindle, the clockwise

direction viewed from the turret is the B-axis positive direction when the coordinate system for

the second spindle mode is selected.

5262-E P-6

SECTION 1 TURRET OPERATION

4. Turret Indexing Commands

A wide variety of directing methods are available for turret indexing according to the purpose.

First understand the outline of the command systems, and see details of the directing methods.

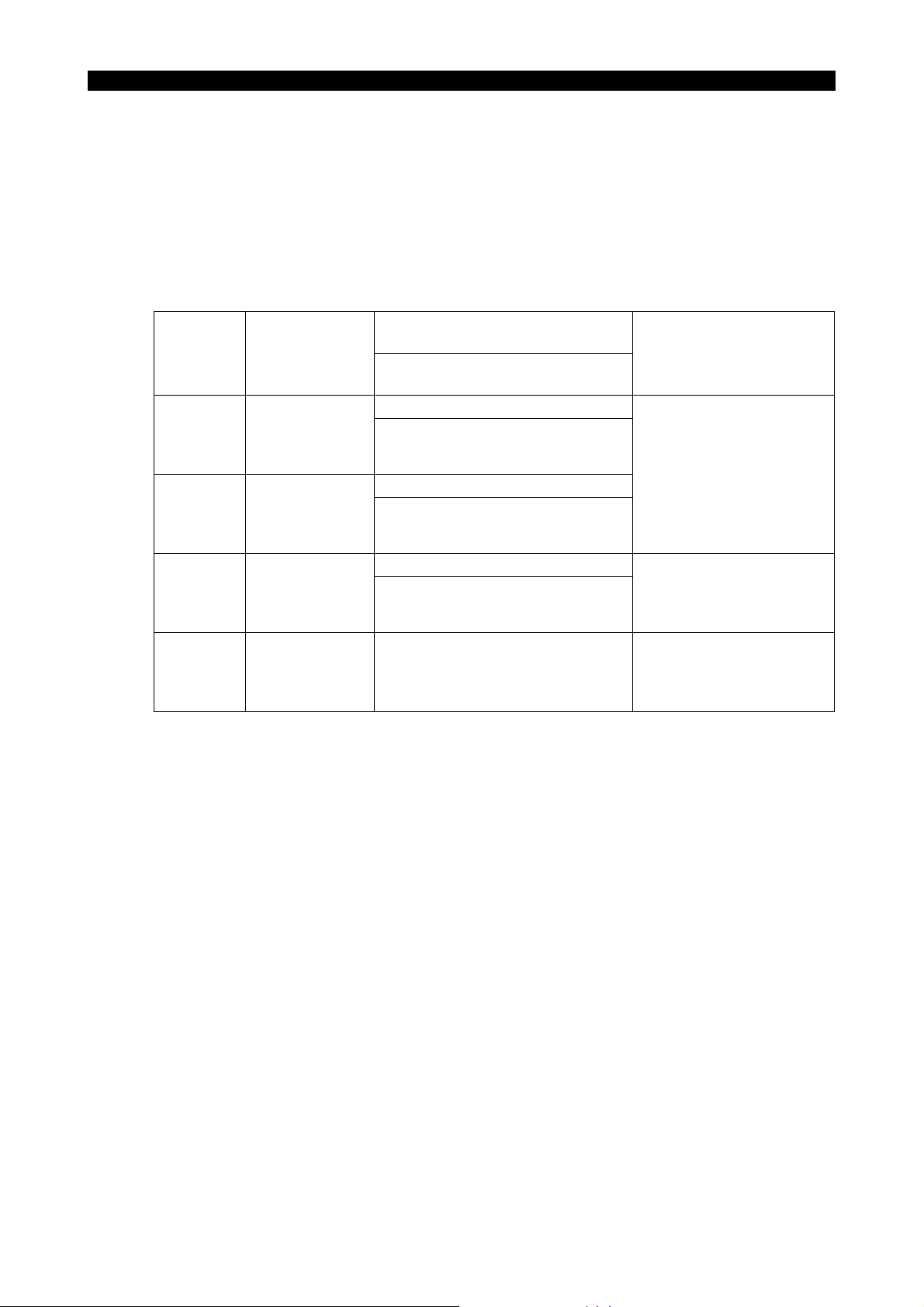

4-1. Command Systems

Command

TL

TG

T

TC

Directing turret indexing with the tool

number as an argument.

Directing turret indexing with the tool

group number as an argument.

Directing turret indexing with the turret number as an argument.

Indexing the turret to the ATC position with the turret number as an

argument.

Purpose

5262-E P-7

SECTION 1 TURRET OPERATION

Base cutting

position indexing

Vertical cutting

position indexing

TL=rr t t oo BT=0

TL=rr t t oo BT=1

TG=gg BT=0

TG=gg BT=1

Trr t t oo TP=0 The TP command must exist

Trr t t oo TP=1

TC=nn

The BT command must exist

in the same block as the TL

or TG command.

in the same block as the T

command.

Remarks

rr: Nose R compensation number

tt: Tool number

oo: Tool compensation number

nn: Turret number

4-2. Base cutting Position Indexing by Tool Numbers

TL = r r t t oo BT = 0

TL = t t tooo BT = 0Number of tool life control sets: 200

This command indexes the tool of the number specified in [tt] to the base cutting position.

• Commands for BT = 0 can be omitted.

• With regard to 200 tool life control sets, specify a tool number in [ttt] and a tool compensation

number in [ooo]. The same number as the tool compensation number will be selected as the

nose R compensation number.

4-3. Vertical Cutting Position Indexing by Tool Numbers

TL = r r t t oo BT = 1

TL = t t tooo BT = 1Number of tool life control sets: 200

This command indexes the tool of the number specified in [ttt] to the vertical cutting position.

• With regard to 200 tool life control sets, specify a tool number in [ttt] and a tool compensation

number in [ooo]. The same number as the tool compensation number will be selected as the

nose R compensation number.

SECTION 1 TURRET OPERATION

4-4. Base cutting Position Indexing by Tool Group Numbers

TG = gg BT = 0

TG = ggg BT = 0 Number of tool life control sets: 200

This command indexes the tool of the tool group number specified in [gg] to the base cutting position.

• Commands for BT = 0 can be omitted.

• With regard to 200 tool life control sets, specify a tool group number in [ggg].

• Specify an offset group with OG = [1/2/3].

• The same number as the tool compensation number will be selected as the nose R compensa-

tion number.

4-5. Vertical Cutting Position Indexing by Tool Group Numbers

TG = gg BT = 1

TG = ggg BT = 1 Number of tool life control sets: 200

5262-E P-8

This command indexes the tool of the tool group number specified in [gg] to the vertical cutting position.

• With regard to 200 tool life control sets, specify a tool group number in [ggg].

• Specify an offset group with OG = [1/2/3].

• The same number as the tool compensation number will be selected as the nose R compensa-

tion number.

4-6. Base cutting Position Indexing by Turret Numbers

T r r n n oo TP = 0

T n n ooo TP = 0 Number of tool life control sets: 200

This command indexes the turret of the number specified in [tt] to the base cutting position and

begins cutting with the tool attached in the base cutting position.

• With regard to 200 tool life control sets, specify a tool compensation number in [ooo]. The same

number as the tool compensation number will be selected as the nose R compensation number.

[Supplement]

Although TP = 0 can be omitted, a simple turret indexing command will be set in this case. T2 can

be directed.

5262-E P-9

SECTION 1 TURRET OPERATION

4-7. Vertical Cutting Position Indexing by Turret Numbers

T r r n n oo TP =1

T n n ooo TP = 1

This command indexes the turret of the number specified in [tt] to the base cutting position and

begins cutting with the tool attached in the vertical cutting position.

• With regard to 200 tool life control sets, specify a tool compensation number in [ooo]. The same

number as the tool compensation number will be selected as the nose R compensation number.

4-8. ATC Position Indexing by Turret Numbers

TC = 1 H1 turret

This command indexes the turret of the number specified to the ATC position.

4-9. Independent Direction of the Tool Compensation Number, the

Nose R Compensation Number, and the Tool Diameter Compensation Number

In general, the tool compensation number, nose R compensation number or tool diameter compensation number is specified by setting the compensation number together with a turret indexing command. However, by using this function, these compensation numbers can independently be set

without using a turret indexing command.

[Command format]

OF = oo

OF = ooo Number of tool life control sets: 200

This command can change the currently valid tool compensation number or nose R compensation

number.

• An error will occur if the OF command is set in the same block as the T, TL, and OG commands.

• The compensation number with the OF command will be valid for all of the tool offset number,

the nose R compensation number, and the tool diameter compensation number.

5. Turret B-axis Positioning Commands

A wide variety of directing methods are available for turret positioning according to the purpose

when the B-axis one-degree indexing function or B-axis 1/1000-degree indexing function is

selected.

First understand the outline of the command systems, and see details of the directing methods.

5-1. Command Systems

Positioning from

Command Purpose

Performing posi-

TL

TG

T

Indepen-

dent

tioning simultaneously with the

TL command.

Performing positioning simultaneously with the

TG command.

Performing positioning simultaneously with the

T command.

Independently

performing positioning.

TL=rr t t oo BT=0 BA=[angle] G52

TL=rr t t oo BT=1 BA=[angle] G52

TG=gg BT=0 BA=[angle] G52

TG=gg BT=1 BA=[angle] G52

Trr t t oo TP=0 BA=[angle] G52

Trr t t oo TP=1 BA=[angle] G52

BA=[angle] G52

base cutting position

Positioning from

vertical cutting position

5262-E P-10

SECTION 1 TURRET OPERATION

Remarks

Available for only the H1

turret.

Angle from the base cutting

position.

rr: Nose R compensation number

tt: Tool number

oo: Tool compensation number

angle: B-axis positioning angle directed value

G52: Edge offset calculated value at B-axis positioning

5262-E P-11

SECTION 1 TURRET OPERATION

5-2. B-axis Positioning Command in the Same Block as the TL Com-

mand

TL = r r t t oo BT = [0/1] BA = [angle] G52

TL = t t t ooo BT = [0/1] BA = [angle] G52 Number of tool life control sets: 200

This command indexes the tool of the number specified in [tt] to the cutting position specified with

BT and relatively positions it to the position equal to the angle data specified with BA from the indexing position.

• Commands for BT = 0 can be omitted.

• With regard to 200 tool life control sets, specify a tool number in [ttt] and a tool compensation

number in [ooo].

The same number as the tool compensation number will be selected as the nose R compensation number.

• The minimum setting unit of BA depends on the indexing function.

Minimum command unit = 1 degree B-axis one-degree pitch indexing function

Minimum command unit = 0.001 degree B-axis 1/1000-degree pitch indexing function

5-3. B-axis Positioning Command in the Same Block as the TG Com-

mand

TG = gg BT = [1/0] BA = [angle] G52

TL = ggg BT = [1/0] BA = [angle] G52 Number of tool life control sets: 200

This command indexes the tool of the tool group number specified in [tt] to the cutting position specified with BT and relatively positions it to the position equal to the angle data specified with BA from

the indexing position.

• Commands for BT = 0 can be omitted.

• With regard to 200 tool life control sets, specify a tool number in [ggg].

• Specify an offset group with OG = [1/2/3].

• The same number as the tool compensation number will be selected as the nose R compensa-

tion number.

• The minimum setting unit of BA depends on the indexing function.

Minimum command unit = 1 degree B-axis one-degree pitch indexing function

Minimum command unit = 0.001 degree B-axis 1/1000-degree pitch indexing function

5262-E P-12

SECTION 1 TURRET OPERATION

5-4. B-axis Positioning Command in the Same Block as the T Com-

mand

T r r n n oo TP = [1/0] BA = [angle] G52

T n n ooo TP = [1/0] BA = [angle] G52 Number of tool life control sets: 200

This command indexes the turret of the number specified in [tt] to the base cutting position and relatively positions it to the position equal to the angle data specified with BA from the indexing position.

• With regard to 200 tool life control sets, specify a tool compensation number in [ooo]. The same

number as the tool compensation number will be selected as the nose R compensation number.

[Supplement]

Although TP = 0 can be omitted, a simple turret indexing command will be set in this case, and

positioning with the BA command will be performed from the base cutting position.

5-5. Independent Command for Positioning B-axis

The BA command can independently be directed.

In this case, however, the same positioning as that with the following command will internally take

place. The tool offset, nose radius compensation, and tool diameter compensation numbers will be

all cleared, and they must be reset when they need to be reset.

LE32114R0400300250001

5262-E P-13

SECTION 1 TURRET OPERATION

5-6. Turret Rotary Position Offset Command in B-axis Positioning

(G52)

When performing machining by issuing the BA command after locating the turret in a specified position, regular tool offset is no more effective. The tool edge position must be offset by dividing the

edge position into the X direction component and the Z direction component using the turret rotation

axis as the center.

The T, TL, and OG commands are used to index the turret, but they do not perform tool offset when

the B-axis is located in cutting position. To calculate the edge position when the BA command is

executed, execute the G52 command. By doing this, the edge position will be internally calculated

using various parameters such as turret center offset, edge position offset, turret number, and tool

offset, allowing you to set correct offset positions.

LE32114R0400300260001

SECTION 1 TURRET OPERATION

5-7. Terms Relevant to Turret Rotary Position Compensation

Positions indicated by the terms relevant to turret rotary position compensation

5262-E P-14

LE32114R0400300270001

LE32114R0400300270002

(1) Okuma reference point

The offset reference point is factory-set at the point where the motor rotary axis intersects with

the motor end face when the B-axis angle is set to 0°.

(2) Turret center offset

The positional relation between the Okuma reference point and the turret rotation center can be

set. Normally, this offset is already set before a machine is shipped. This value affects the calculation of the turret rotary position offset command.

(3) Edge position offset

The offset from the Okuma reference point to the user reference point set by a user can be set.

6. Manual Turret Indexing Operation

Although the turret for MACTURN and MULTUS series machines is the H1 turret in appearance, it is

internally controlled so that 90-degree indexing is possible. For turrets that are not designed to continuously swing due to the structure of the turret, turret control is performed instead.

6-1. Turret Indexing Position

There are three turret indexing positions: the base cutting position, the vertical cutting position, and

the ATC position.

On MACTURN and MULTUS series machines, the base cutting position and the ATC position are

identical, but because the purpose of operation is different between them, for which purpose indexing will be performed must be selected with “turret indexing” on the ATC operation panel.

6-2. H1 Turret

The H1 turret cannot continuously swing. For this reason, the order of indexing to the cutting position is as shown below. Additionally, since only one tool can be attached to the turret, the turret does

not operate even if the turret swing button is pressed after the tool has been indexed to the ATC

position as long as “ATC position” indexing is selected.

5262-E P-15

SECTION 1 TURRET OPERATION

6-2-1. Indexing the turret to the cutting position

The turret is indexed in the order shown below. However, when the B-axis positioning command (BA

command) is set, the axis will be positioned to the position offset by the angle.

6-2-2. Indexing the turret to the ATC position

T1 is indexed directly to the ATC position, irrespective of the indexed state of the turret. However, by

clicking the turret button in the state of T3, the turret suspends swinging in the state of T2. Holding

down the button indexes the turret directly to the ATC position.

6-2-3. Turret swing conditions

LE32114R0400300310001

• Either the X-axis or Z-axis is positioned on the positive variable limit.

• On a machine equipped with a sub-spindle, the X-axis is positioned on the positive variable

limit.

• The saddle is positioned in the ATC tool replacement position.

The turret can swing when any one of the above conditions is met.

7. Manual B-axis Positioning Operation

When the “B-axis one-degree pitch indexing” function or “B-axis 1/1000-degree pitch indexing” function is selected, the turret swing can be not only positioned but also positioned as the B-axis. This

section describes B-axis positioning.

Since only the difference between one-degree pitch indexing function and 1/1000-degree pitch

indexing is the minimum command unit, note that only the command values must be replaced with

the appropriate ones when reading the text.

7-1. Positioning the B-axis

The B-axis cannot be positioned in manual operation. To position it in a specific position, executed

the BA command in advance in MDI operation mode or automatic operation mode. Once the BA

command has been executed, it remains valid until the next command is executed. It will be kept

stored even if the machine is reset or the power is turned OFF.

The issued BA command pairs up with a turret number. To index the turret for which the BA command has been executed when the turret swing button is pressed in manual operation mode, the

turret will be positioned to the position the BA command is reflected.

B-axis positioning described above cannot be performed until “cutting position” is selected for turret

indexing on the ATC operation panel.

5262-E P-16

SECTION 1 TURRET OPERATION

7-2. Canceling B-axis positioning

To cancel B-axis positioning in manual turret indexing, index the turret to the base cutting position or

vertical cutting position in MDI operation mode or automatic operation mode. When no BA command is attached, [BA = 0] is considered in the NC directed and the B-axis angle data is deemed

cleared.

7-3. BA Angle Data Display

The BA data after B-axis positioning will be displayed as [BA] of the current position. When the Baxis one-degree pitch indexing function is used, decimals are not displayed. If there is a difference

between the BA command and the actual B-axis positioning angle, **** (asterisks) will be displayed.

5262-E P-17

SECTION 1 TURRET OPERATION

LE32114R0400300370001

8. Manual Slant Feed Function

It is possible to feed the saddle in slanted directions (X-axis - Z-axis contouring) by manual pulse

handle feed or JOG feed.

8-1. Designating a Slant Feed Direction

Set in “SLANT FEED ANGLE” on the PARAMETER/B-AXIS USER PARAMETER screen the angle

at which manual slant feed will be performed

Procedure :

1 Select parameter setting mode.

2 Using [DISPLAY CHANGE], [ITEM], etc., have the “B-AXIS USER PARAMETER” screen dis-

played.

3 Move the cursor to “SLANT FEED ANGLE,” and set specific angle data.

5262-E P-18

SECTION 1 TURRET OPERATION

LE32114R0400300390001

5262-E P-19

Z

SECTION 1 TURRET OPERATION

For control, set to what degrees the coordinate system formed by Z-X will be rotated around the Yaxis.

The axis selection key (X/Z) for manual operation mode can select the axis to the coordinate system

after rotation.

X

Z'

Slant feed

rotation angle

LE32114R0400300390002

8-2. Selecting Slant Feed, Feed Operation

To perform slant feed by manual operation, the “SLANT FEED” key on the auxiliary operation panel

to select slant feed mode. During slant feed selection, the LED on the panel remains lit.

During slant feed selection, the X-axis feed key and the Z-axis feed key are available, or pulse hand

X-axis/Y-axis selection becomes valid for the X’-axis and the Z’-axis. Other operations relating to the

Y-axis and the C-axis are the same as the regular operations.

[Supplement]

• If two or more of the X-axis, Y-axis, Z-axis, and C-axis JOG keys on the operation panel are

pressed at the same time when the “SLANT FEED” LED is lit, none of all of the feed axes will

move.

• Slant feed can be selected only in “manual operation mode or manual intervention mode” and

“Y-axis control mode.”

(1) Manual slant feed speed, slant feed distance

Manual slant feed using the JOG keys is performed at the X-axis or Z-axis manual feed unit rate

set in the axis data file, whichever is slower. The manual feed acceleration unit rate increases or

decreases with the manual feed acceleration unit rate for the axis whose manual feed unit rate

has been adopted.

The feed distance in pulse handle feed is the travel distance in the manual slant feed direction

designated by the pulse handle.

During slant feed selection, the Y-axis command is a radius value command as Y-axis control

mode is selected.

(2) Control when the axis has reached the variable limit

The X-axis or Z-axis setting position is valid as the variable limit even during manual slant feed

selection. When either the X-axis or Z-axis, which is in manual slant feed in the X’-axis or Z’axis, has reached the variable limit, all axis feed operations will stop, and the X’-axis or Z’-axis

will not move in the direction beyond the variable limit.

5262-E P-20

SECTION 1 TURRET OPERATION

8-3. Caution on Recovering from Manual Intervention

[Supplement]

If slant feed is performed and the SEQUENCE RETURN key is pressed during manual intervention, the X-axis and the Y-axis independently travel to the sequence restart position and will not

linearly move back in the slant feed direction. Each axis returns at the manual feed speed. Before

pressing the SEQUENCE RESTART key, move the axes closer to the return position in advance

to minimize the axis travel distance to return.

8-4. Relationship with the Slant Compound Fixed Cycle Function

The slant angle command value, which is issued simultaneously with the slant machining mode ON

command (G127), is automatically set in “SLANT FEED ANGLE” on the B-AXIS USER PARAMETER screen. Before manually using the slant feed function, confirm that the feed angle set in

“SLANT FEED ANGLE” is the appropriate value.

8-5. Others

Since the turret B-axis positioning angle and the coordinate conversion angle around the Y-axis

specified in “SLANT FEED ANGLE” are independently handled, pay attention to both angle data

when drilling a slant face.

SECTION 1 TURRET OPERATION

9. Tool Index Function

The H1 turret for MACTURN and MULTUS series machines has the same attachment structure for

both cutting tools and rotary tools. The edge of even a cutting tool can be set at any desired angle by

means of an M-axis indexing function. Making effective use of this structure and turning the edge

180 degrees make it possible to use tool for other purposes. The tool index function is intended to

index a tool and select its data.

9-1. Relation between Turret Indexing and Tool Indexing

5262-E P-21

First spindle base position

Position A

First spindle base position

Position B

First spindle vertical position A

Second spindle vertical position B

First spindle vertical position B

Second spindle base position

Second spindle base position

Position B

Second spindle vertical position A

9-2. Relation between Tool Indexing and Graphic Display

The tool index function changes the graphic display based on the preset tool shape data each time

the tool direction is changed 180°.

If you set the tool shape data with its angle set at 0°, the graphic display changes when the tool is

indexed.

Position A

LE32114R0400300450001

5262-E P-22

SECTION 1 TURRET OPERATION

9-3. Relation between Tool Index Command and Tool Compensation

When a tool index command is specified, the graphic display of the tool shape changes automatically. However, the tool compensation data is not changed. It is, therefore, necessary to specify the

tool compensation data again after indexing the tool.

Description below is the mechanism of a machine equipped with a “tool compensation multi-system

function.”

A machine equipped with a tool compensation multi-system function has a tool compensation data

table for each of the base position, the vertical position and positions A/B (a machine having a subspindle has eight data tables in all). Upon execution of a tool index command, the tool offset, nose R

compensation, and nose R compensation direction numbers switch to those shown in the opposite

position table. That is, each compensation number remains unchanged, but the compensation values specified by these compensation numbers are changed as the table itself is changed.

Position A

Tool offset

Nose R

compensation

Nose R

direction

For example, when the dot-meshed compensation of No. 2 is selected in position A, the compensation switches to No. 2 in the table under Position B upon execution of tool indexing. Since the tables

are independent, the compensation values are different between them.

No.1 No.1

No.2 No.2

No.3 No.3

:

No.1 No.1

No.2 No.2

No.3 No.3

:

No.1 No.1

No.2 No.2

No.3 No.3

:

9-4. Tool Index Commands

(1) M codes

The following M codes are used to index an M-tool spindle:

M602: Command for indexing the M-tool spindle at 0° position and clamping it.

M603: Command for indexing the M-tool spindle at 180° position and clamping it.

Position B

:

:

:

LE32114R0400300470001

9-5. Relation between Rotary Tool and Tool Index Commands

The tool index command can be specified even if a rotary tool is mounted.

Since the rotary tool can be used for turning as well as milling, it is necessary to specify the tool

index command according to the purpose of use.

As described in 9-3. “Relation between Tool Index Command and Tool Compensation”, if the tool offset multi-system is provided, the tool offset table changes upon designation of a tool index command even when using a rotary tool for milling.

Set the tool offset data used only for milling in position A, and after specifying the tool index command, return the tool to position A before performing milling.

10. Parameter Settings

10-1. B-axis User Parameters

(1) Slant feed angle

This parameter sets the Z-X coordinate turning angle in manual slant feed of the saddle.

Setting unit : 1°

Setting range : -359.999° to 359.999°

Initial value : 0.000°

(2) Tool edge offset

This parameter sets the offset from the Okuma reference point to the user reference point set

by a user. When the edge offset is changed, the tool offset must be reset.

Setting unit : 1 mm

Setting range : -9999.999 to 9999.999

Initial value : 0.000

10-2. B-axis System Parameters

5262-E P-23

SECTION 1 TURRET OPERATION

(1) Turret center offset

The positional relation between the Okuma reference point and the turret rotation center can be

set. Normally, this offset is already set before a machine is shipped.

Setting unit : 1 mm

Setting range : -9999.999 to 9999.999

Initial value : 0.000

10-3. Turret Position Error Compensation

Turret position error compensation in the reference cutting position is the same as general turret

position error compensation. However, turret position error compensation in the vertical cutting position becomes valid only when the “B-axis one-degree pitch indexing function” and the “B-axis 1/

1000-degree pitch indexing function” are not provided.