Page 1

Table of Contents

1 Introduction

Overview 1–1

Standard Features 1–2

Configuration Overview 1–2

System Requirements 1–2

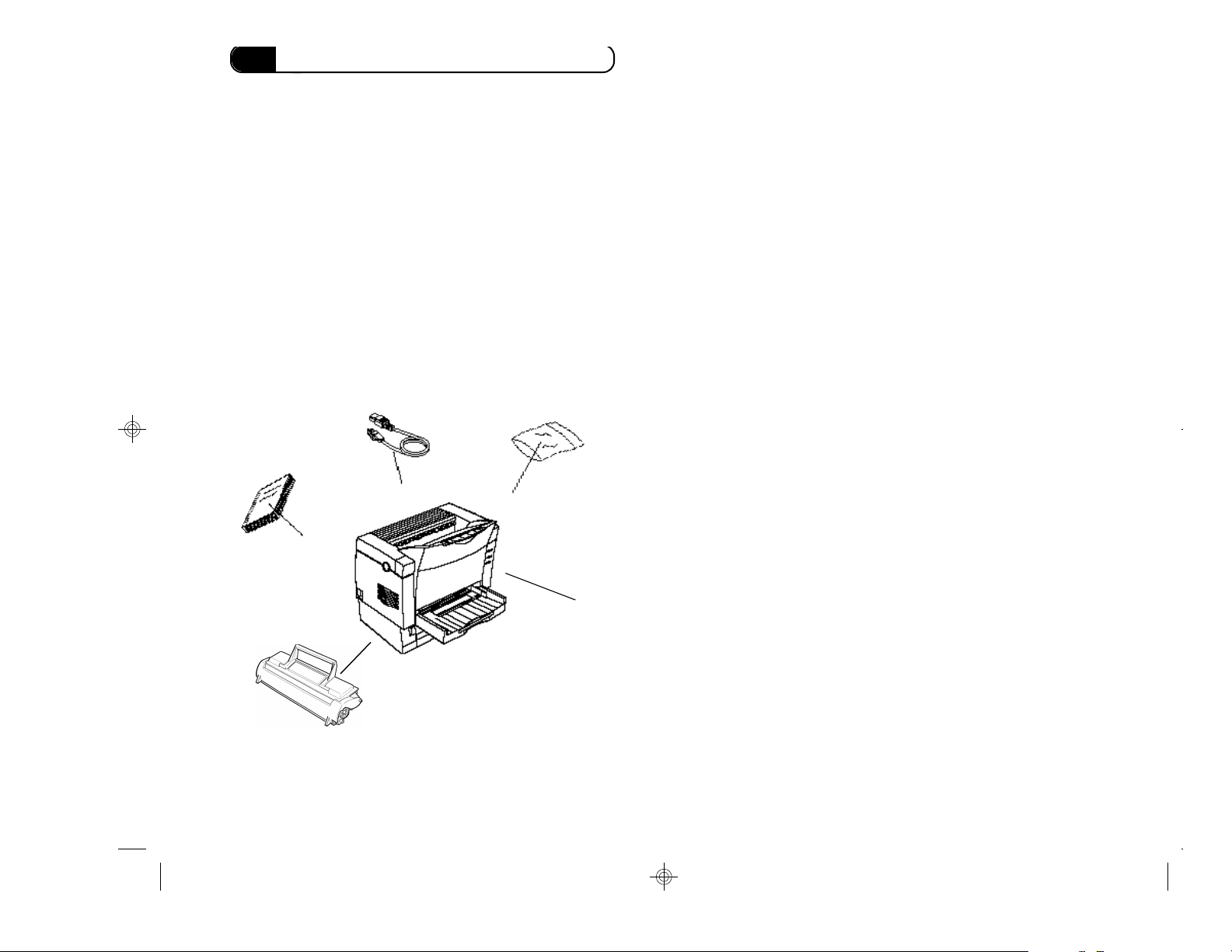

Unpacking the Printer 1–3

Locating the Printer Items 1–3

2 Setting Up and Using the Printer

Overview 2–1

Precautions for Installation 2–2

Installation Site 2–2

Power Source 2–2

Grounding 2–2

Printer Dimensions and Space Requirements 2–3

Operating Environment 2–3

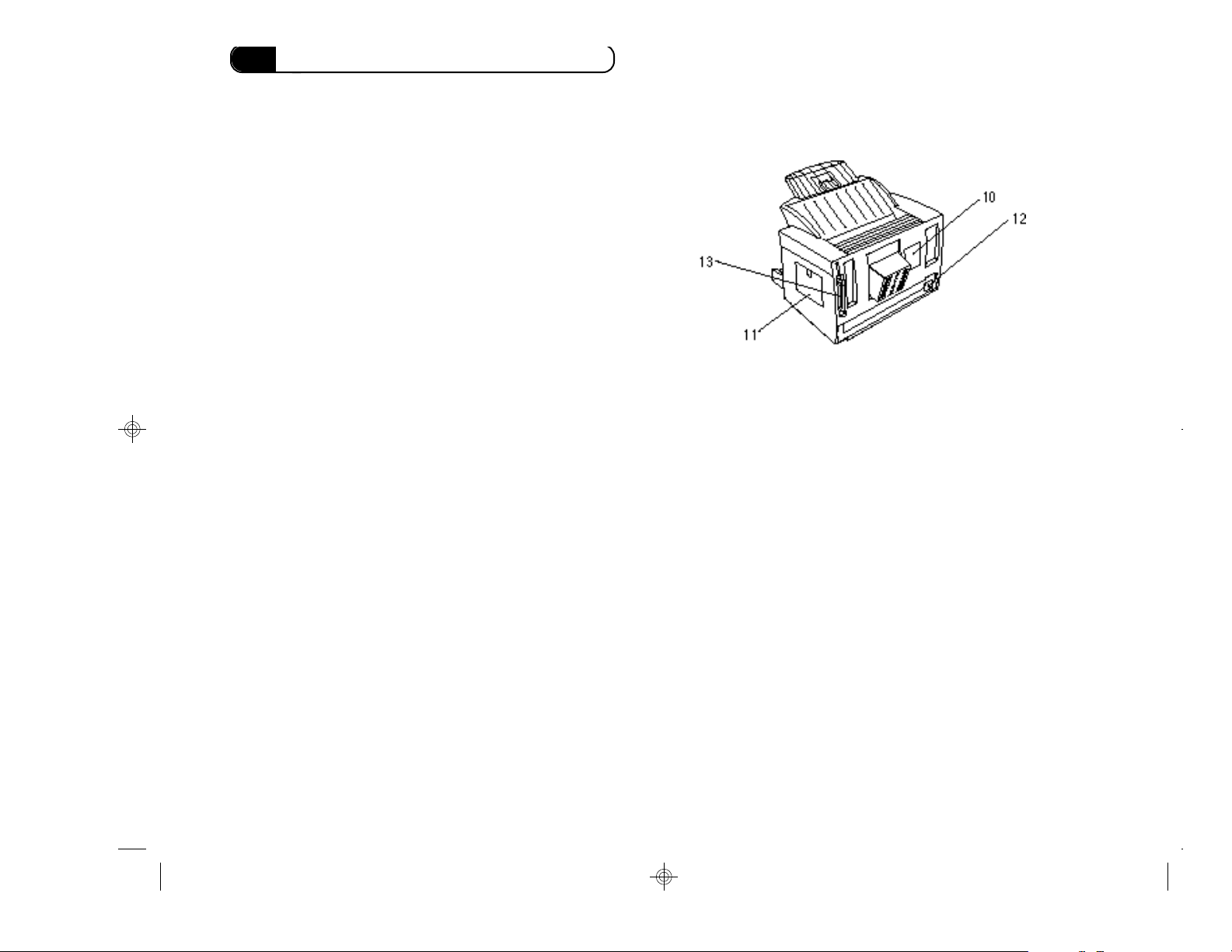

External Printer Parts 2–5

Internal Printer Parts 2–7

Installing the Main Multipurpose Feeder Tray 2–8

Loading Paper 2–8

Loading the Manual Feeder 2–10

Duplex Printing 2–10

Setting Up the Photoconductor Module and

the Toner Module 2–11

Parallel Cable 2–13

Power Cord 2–13

Some Do’s and Don’ts for Using the Printer 2–14

3 Installing the Software

Overview 3–1

SuperScript Software Installation 3–2

Installing the SuperScript Software 3–3

SuperScript Installation Dialogs 3–3

Testing the Installation 3–8

Removing SuperScript Software 3–8

4 SuperScript Console

Overview 4–1

Control Panel 4–2

GDI Setup Window 4–4

Paper 4–4

Advanced Options 4–5

Print Quality 4–5

2Up/4Up 4–6

Form Settings 4–6

Create a Cover/Trailer Page or Overlay file 4–6

Local Queue 4–7

Job Log 4–8

SuperScript Console Menu 4–9

File 4–9

View 4–9

Settings 4–9

Priority 4–9

Local Printer Change 4–10

Network 4–10

Change Name 4–10

i

Page 2

Run 4–10

Help 4–10

Exiting before printing has completed 4–10

Printing from a DOS Application 4–11

5 Monitoring the Printer Status

Overview 5–1

Expanded SuperScript Printer Status Display 5–3

Printer Error Status Messages and Recovery 5–3

Paper Out 5–4

Paper Jam 5–4

Cover Open or Toner Cartridge Missing 5–4

Duplex Printing 5–4

Power Off or Cable Problem 5–4

Engine is Warming Up 5–4

Engine Error 5–4

6 Maintaining the Printer

Overview 6–1

Replacing the Toner Module 6–2

Replacing the Photoconductor Module 6–2

Cleaning the Printer 6–2

Cleaning the Outside 6–3

Cleaning the Transport Roller and

Transfer Unit 6–3

A Troubleshooting

Overview A–1

Maintaining Print Quality A–2

Output Quality A–3

Blank Spots A–4

Solid White Vertical Lines A–5

Incomplete Page A–5

Correcting Paper Jams A–5

Installation Problems A–8

Wrong System or Hardware Configuration A–8

Insufficient Memory A–8

No Printer Port A–8

Insufficient Disk Space A–8

Removing Previously Installed SuperScript

Software A–9

B Frequently Asked Questions

C Printer Options

Overview C–1

250-Sheet Second Hopper C–2

Setting Up the 250-Sheet Hopper C–2

Loading paper on the second tray C–3

Memory Expansion Module (SIMM) C–4

D Selecting Print Media

Overview

Selecting Paper and Media D–2

Care of Printer Supplies D–2

Paper Properties D–3

Print Areas D–3

Media Use Guidelines D–4

Preprinted Forms D–4

Heavy Print Stock D–4

Envelopes D–5

Adhesive Labels D–5

Transparency Film D–6

Media Purchasing Specifications D–7

Printing with Various Media D–9

E Using Fonts

Overview E–1

Fonts in GDI Mode E–2

Fonts in PCL Mode E–3

Installing SuperScript TrueType Fonts E–3

Saving Downloaded Fonts and Macros

(PCL Mode) E–3

ii

Page 3

F Safety Information

Laser Safety F–1

Internal Laser Radiation F–1

CDRH Regulations F–1

For United States Use Only F–2

FCC Statement F–2

Employer Responsibilities F–2

Minimizing Ozone Exposure F–3

Ozone Emissions F–3

UL Standards for Ozone F–3

EPA Energy Star Computers Award F–3

Technical Specifications F–4

G Glossary

H Technical Support

Assistance Nearby H–1

Help From Within Your Company H–1

Help From Your Dealer H–1

NEC Technical Support H–1

How to Contact NEC H–2

Sending Internet Electronic Mail H–2

Reaching the NEC Bulletin Board System H–3

Reaching NEC on Compuserve H–3

Reaching NEC on America Online H–3

Reaching NEC on AT&T Interchange H–3

Reaching NEC on the World Wide Web H–3

Writing NEC H–3

Ordering Supplies, Printer Options, and

Spare Parts H–3

Support from Your Software Vendor H–4

iii

Page 4

PROPRIETARY NOTICE AND LIABILITY

DISCLAIMER

The information disclosed in this document, including

all designs and related materials, is the valuable

property of NEC Corporation (NEC) and/or its

licensers.NEC and/or its licensers, as appropriate,

reserve all patent, copyright and other proprietary

rights to this document, including all design,

manufacturing, reproduction, use, and sales rights

thereto, except to the extent said rights are expressly

granted to others.

The NEC products discussed in this document are

warranted in accordance with the terms of the

Warranty Statement accompanying each product.

However, actual perfomance of each such product is

dependent upon factors such as system configuration,

customer data, and operator control. Since

implementation by customers of each product may

vary, the suitability of specific product configurations

and applications must be determined by the customer

and is not warranted by NEC.

SuperScript is a trademark of NEC Technologies, Inc.

All other product, brand, or trade names used in this

publication are the trademarks or registered

trademarks of their respective owners.

© NEC Corporation, 1996

© Copyright, WinStyler™/Phase II, 1992-1996

Destiny Technology Corp. Ver. 2.0

© Copyright, WinRefs™/Phase II, 1996

Destiny Technology Corp. Ver. 2.0

© Copyright, DTIR™, 1992-1996

Destiny Technology Corp. Ver. 1.0

© Copyright, LaserAct®/Phase II, 1990-1996

Destiny Technology Corp. Ver. 4.5

© Copyright, PageStyler®/Phase II, 1989-1996

Destiny Technology Corp. Ver. 1.0

© Copyright, 1992, Microsoft Corporation

First Printing — July 1996

To allow for design and specification improvements,

the information in this document is subject to change

at any time, without notice. Reproduction of this

document or portions thereof without prior written

approval of NEC is prohibited.

00 PROPRIET* 96.9.24, 10:39 AM1

Copyright 1994-1996

NEC Corporation

7-1 Shiba 5-Chome, Minato-ku

Tokyo 108-01, Japan

All Rights Reserved

i

Page 5

NEC Corporation

7-1, Shiba 5-chome, Minato-ku,

Tokyo 108-01, Japan

Tel: (03) 3454-1111

Telex: NECTOK J22686

Fax: (03) 3798-1510~1519

NEC (UK) Ltd.

NEC House, 1 Victoria Road

London W3 6UL United Kingdom

Tel: 081-993-8111

Telex: 924213 NECLDN G

Fax: 081-992-7161

NEC Technologies, Inc.

339 North Bernardo Ave.

Mountain View, CA 94043-5223 USA

Tel: 415-528-6000

Fax: 415-528-5700

NEC Europe Ltd.

NEC House, 1 Victoria Road

London W3 6UL United Kingdom

Tel: 081-993-8111

Fax: 081-992-7161

NEC Deutschland GmbH

Steinheilstraße 4-6,

D-85737 Ismaning, Deutschland

P.O. Box 1430

Tel: 089/96274-0

Fax: 089/96274-500

NEC France S.A.

56 Rue De Hautes Pâtures

92024 Nanterre Cedex, France

Tel: 1-4649-4649

Telex: NEC PARI 610880F

Fax: 1-4769-9595

NEC Scandinavia AB

Karlsbodavägen 20,

Box 20057-161 20 Bromma, Sweden

Tel: 8-635-9200

Telex: 10339 NECBSS S

Fax: 8-635-9350

NEC Ibérica S. A.

Miniparc 1, Edificio A, Calle Azalea 1,

28109EI Soto de la Moraleja,

Alcobendas, Madrid, Spain

Tel: 1-650-1313

Fax: 1-650-1967

NEC Italia S. R. L.

Viale Leonardo Da Vinci 97 Trezzano Sul

Naviglio Milano, Italy

Tel: 2-484-151

Fax: 2-484-00875

ii

00 PROPRIET* 96.9.24, 10:40 AM2

Page 6

NEC Australia Pty. Ltd.

20 Rodborough Road, Frenchs Forest,

N.S.W. 2086, Australia (P. O. Box 500)

Tel: 2-930-2000

Telex: NECSYD AA 27411

Fax: 2-930-2020

NEC (Thailand) Ltd.

19th Floor, Asoke Tower Building.

219/63-65 Sukhumvit 21 Road,

Bangkok 10110, Thailand

Tel: 2-259-1192~8

Telex: 22102 NECTHAI TH

Fax: 2-259-1199~1201

NEC Singapore Pte., Ltd.

1 Maritime Square #12-10, World Trade Centre,

Singapore 0409, Singapore

Tel: 278-1818

Telex: NECSIN RS55874

Fax: 271-7188 or 271-7288

NEC Hong Kong Ltd.

11F, Tower B, Mandarin Plaza,

14 Science Museum Road,

Tsimshatsui East, Kowloon, Hong Kong

Tel: 3690335

Telex: 50041 NECBS HX

Fax: 7245733

NEC Taiwan Ltd.

12F, No. 37, Section 3, Min-Chuan East Road,

Taipei, Taiwan R. O. C.

Tel: 02-515-0000

Fax: 02-515-2255

NEC Sales (Malaysia) Sdn. Bhd.

13th Floor, Bangunan Arab-Malaysian

Letter Box No. 13C 55,

Jalan Raja Chulan

50200 Kuala Lumpur, Malaysia

Tel: 3-238-7788

Telex: NECSEL MA20309

Fax: 3-238-7312

00 PROPRIET* 96.9.24, 10:40 AM3

iii

Page 7

Chapter 1: Introduction

1

Introduction

Overview

This chapter describes the standard features of the

SuperScript 660plus printer. It has the details about

• Unpacking the printer

• System requirements for the printer

• General information about Easy and Custom

installation

02 Ch.1 Intro 96.9.24, 10:48 AM1

1—1

Page 8

Chapter 1: Introduction

This guide provides installation and operating

instructions for the NEC SuperScript 660plus.

The NEC SuperScript 660plus was developed

especially for users of Windows 95, Windows 3.1 and

Windows for Workgroups. The software supports GDI

and PCL emulation modes.

Standard Features

NEC SuperScript 660plus is a printing solution

developed for Windows 95, Windows 3.1 and

Windows for Workgroups that provides complete

Windows-based printing.

This new SuperScript 660plus provides the following

features:

• Full Compatibility with Windows 95, Windows 3.1,

and Windows for Workgroups

• Software emulation for HP LaserJet (PCL 5e

Emulation)

Configuration Overview

The SuperScript 660plus program provides Easy

Installation and Custom Installation options that you

can select based on how you intend to use the printer:

Easy Installation

• GDI mode only

Custom Installation (full featured)

• GDI and PCL

For Easy Installation you can use the CD-ROM or

floppy disks. For Custom Installation, you must use the

CD-ROM.

System Requirements

The minimum free disk space required is 40MB. This

matches the Microsoft general recommendation that

users maintain 40MB of free disk space at all times

when running Windows, for best performance.

1—2

02 Ch.1 Intro 96.9.24, 10:49 AM2

• Because of SuperScript’s high speed interface, it is

important to use a properly manufactured parallel

Page 9

Chapter 1: Introduction

• Photoconductor module

• Power cord

• Parallel printer cable

• Packing material

Note: Save this Users Guide, the box, and all

packing materials in case the printer needs to be

repacked.

cable. A poor quality parallel cable may affect your

output. A long cable may also cause print

problems. For best results use the 6 foot length

cable supplied with your SuperScript 660plus

printer.

• A 1.4 MB floppy drive or CD-ROM drive is also

required.

• Microsoft Windows 95, Windows 3.1, or Windows

for Workgroups 3.11.

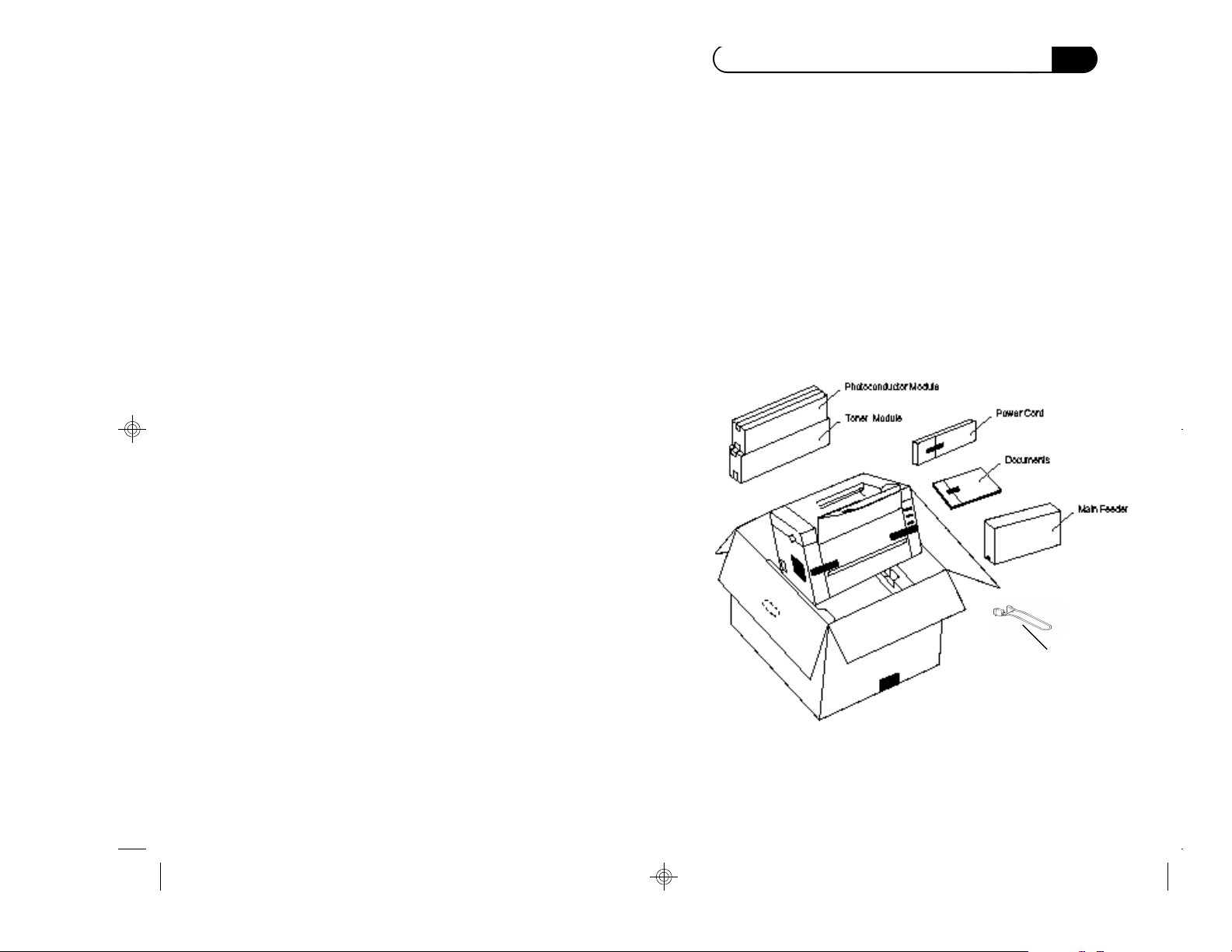

Unpacking the Printer

Follow these steps to set up your SuperScript printer.

1. Open the box and take out the documents the

software diskettes, the toner module, the

photoconductor module, the main feeder, the

parallel printer cable, and the power cord.

2. Lift out the printer together with the packing

materials and set on a flat, sturdy surface.

Locating the Printer Items

Locate the following items:

• NEC SuperScript 660plus Printer

• SuperScript 660plus software kit

• User’s Guide

• Quick Installation Guide

• Main feeder

• Toner module

02 Ch.1 Intro 96.9.24, 10:49 AM3

Parallel Printer Cable

1—3

Page 10

Chapter 2: Setting Up and Using the Printer

Overview

This chapter gives you the information you need when

you set up your printer, load paper, and begin

printing. The chapter has information about

• Choosing an appropriate place for the printer

• Power sources and grounding the printer

• All internal and external printer parts

• How to install the main feeder tray

• How to load paper in the manual feeder

• How to print on both sides of the page

• How to install the photoconductor and toner

modules

• How to connect the printer cable and power cord

2

Setting Up and Using the Printer

03 Ch.2 Setting Up 96.9.24, 11:04 AM1

2—1

Page 11

Chapter 2: Setting Up and Using the Printer

Precautions for Installation

Installation Site

To ensure a long life for the printer, it is important to

select an appropriate installation site. Choose a site that

meets the following requirements:

• A well-ventilated place.

• An area that will not generate ammonia or other

organic gases.

• A power outlet is nearby, so that the power cord

can be plugged in and unplugged easily.

• An area free from direct sunlight.

• A place that is out of the direct air stream of an air

conditioner, heater, or ventilator and is not subject

to very high or very low temperature or humidity.

• A stable and level location not subject to undue

vibration.

• A place free from anything that could obstruct the

printer’s heat exhaust duct.

• There are no curtains or other fabrics nearby that

could catch fire.

• There is no possibility of being splashed with

water, coffee, or any other liquid.

• The area is dust-free.

Power Source

The power source voltage requirements are as follows.

• Voltage fluctuation: 110 V 60 Hz

• Frequency fluctuation: Within ±0.3% 110V 60 Hz

Observe the following precautions when establishing

the power source for your printer:

• Use a power source with little voltage and

frequency fluctuation.

• Use an outlet with the specified voltage capacity

only.

• Be sure to insert the power cord all the way into

the outlet. The outlet should be located near the

printer and be easily accessible, so that the power

cord can be unplugged immediately when

necessary.

• Be sure that outlet is visible, and not hidden

behind the printer or any other office equipment.

• If any other electrical equipment uses the same

outlet, make sure that the capacity of the outlet is

not exceeded.

• If an extension cord is needed, use one with a

capacity greater than the power consumption of

the printer. A cord that falls short of the capacity

requirements could cause a fire.

• Never connect any other appliances or machines

by means of a multiple socket to the outlet you use

for the printer.

Grounding

Always ground the printer to prevent electrical shocks

in the case of electrical leakage. If you are unable to

make grounding connections consult your NEC

Technical Support at 1-800-632-4650 (toll free).

03 Ch.2 Setting Up 96.9.24, 11:05 AM2

2—2

Page 12

Chapter 2: Setting Up and Using the Printer

Connect the grounding wire to

• The outlet’s ground terminal

• A grounding contact that complies with local

electrical standards.

Caution! Never connect the grounding wire to a gas

pipe, to the grounding wire for a telephone, or to a

water pipe.

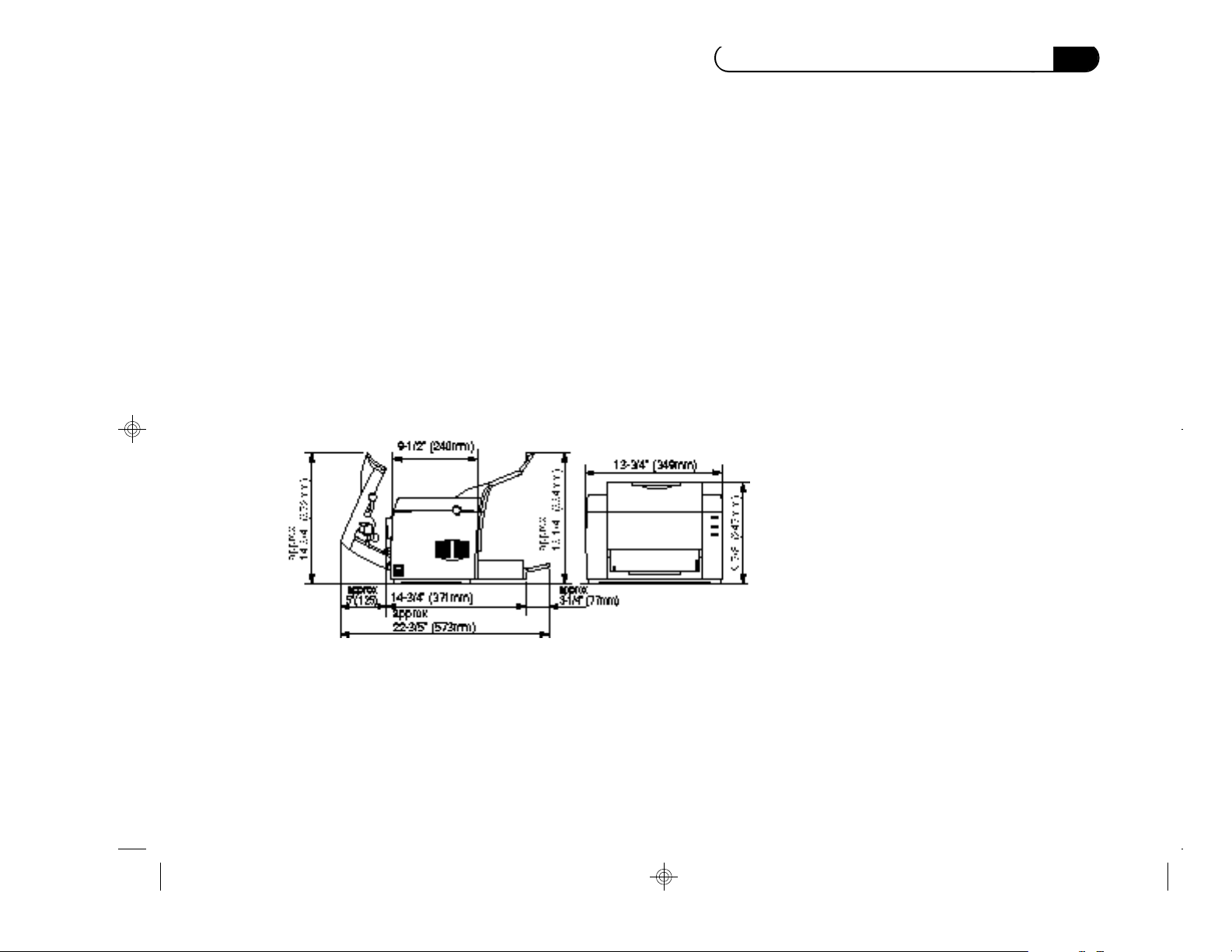

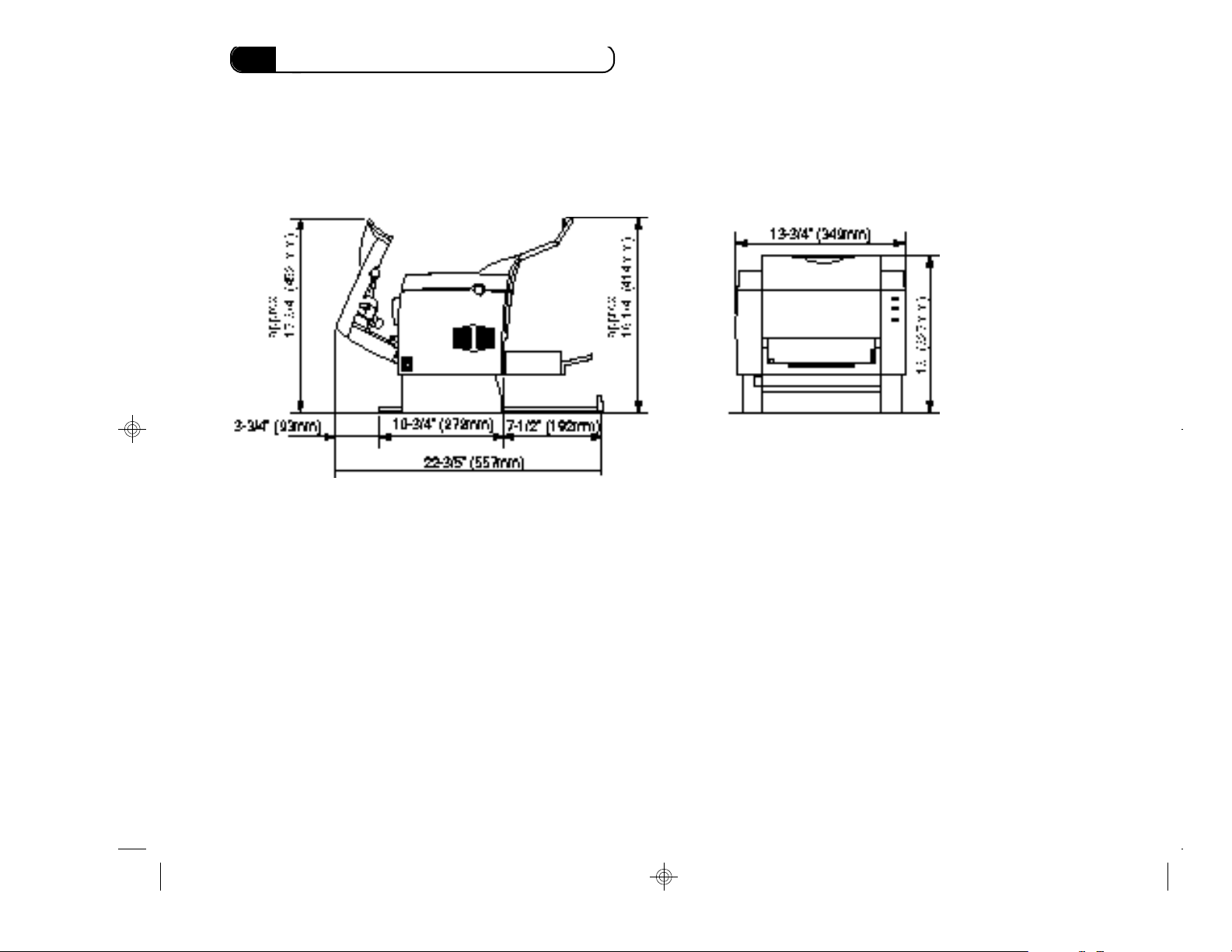

Printer Dimensions and Space Requirements

To ensure easy printer operation, supply replacement,

and service maintenance, adhere to the recommended

space requirements detailed below.

Operating Environment

The operating environmental requirements of the

printer are as follows:

Temperature: 50°F to 90.5°F (10°C to 32.5°C) with a

fluctuation of 10°per hour

Humidity: 20% to 80% RH with a fluctuation of

20% per hour

SuperScript 660plus with the optional

03 Ch.2 Setting Up 96.9.24, 11:05 AM3

2—3

Page 13

Chapter 2: Setting Up and Using the Printer

250 sheet hopper mounted

Note: Because of the NEC SuperScript 660plus high

speed interface, it is important that you use the parallel

cable that is included with your SuperScript 660plus

printer. Using a poor quality parallel cable can affect your

output.

2—4

03 Ch.2 Setting Up 96.9.24, 11:05 AM4

Page 14

Chapter 2: Setting Up and Using the Printer

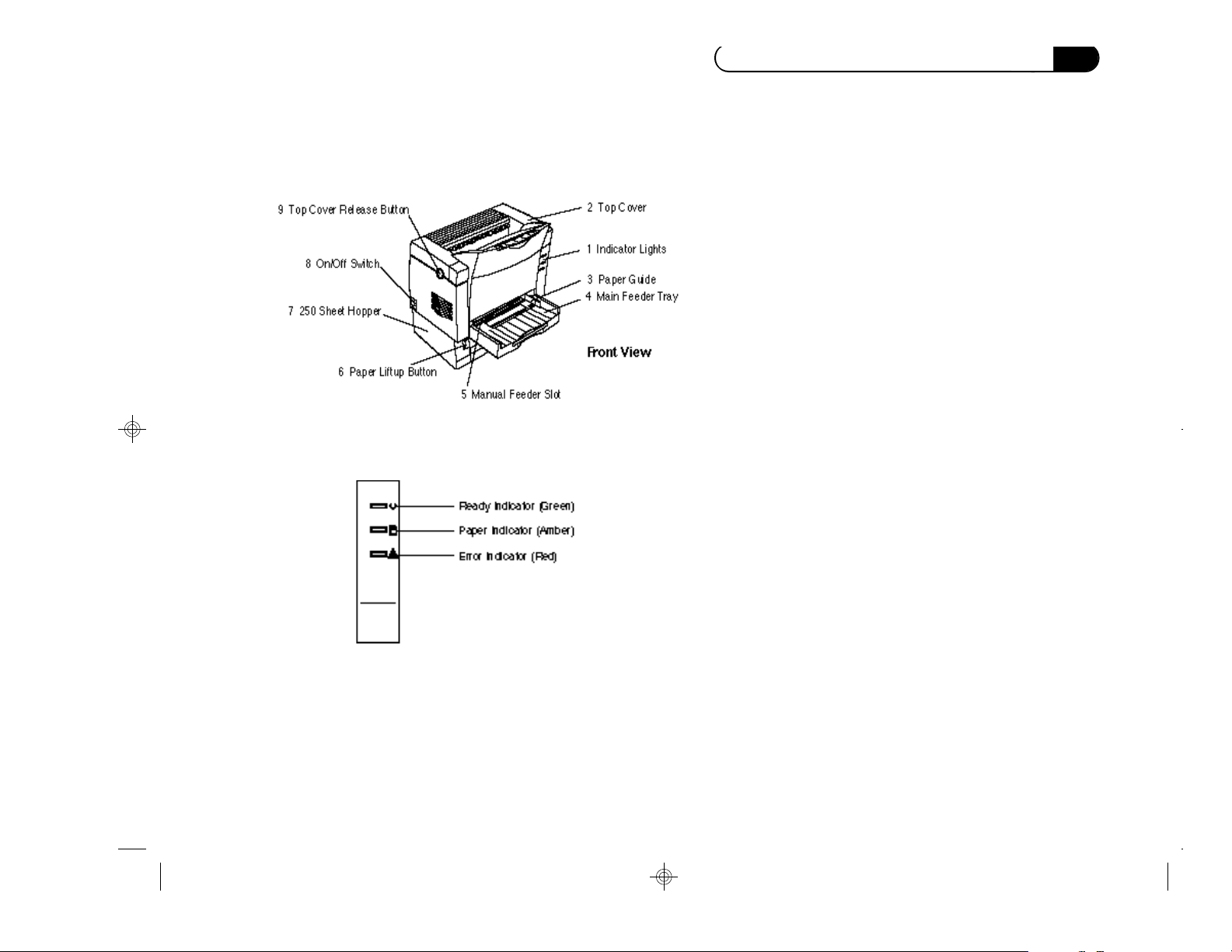

• Ready Indicator light – the upper light shows that

the printer is ready (steady green), warming up,

processing a job (rapid blink), or in power saving

mode (slow blink).

• Paper Indicator Light – the middle light shows

that the printer detects that the paper tray is empty

(steady amber), or that you are using the manual

feed (blinking).

• If you have the second hopper installed, “Pick

Miss” will appear on your screen if the paper did

not feed.

• Error Indicator – the lower light shows that the

printer detects that the cover is open, that there is

no toner module, no photoconductor module, or

that there is a paper jam (steady red), or that there

is a data error (blinking).

All indicators light when the printer is turned on, or

when there is a printer hardware error.

2. Top Cover (and output tray) – provides access to

the inside of the printer and, when printing, serves

as an output tray. It stacks the printed sheets with

the printed side facing down.

Maximum capacity: 100 sheets. (17 lb. paper)

3. Paper Guide – slides to the size of the paper.

(Main Feeder)

External Printer Parts

The following is an external view of the printer and its

parts.

1. Indicator Lights – three LED lights that indicate the

operating status of the printer.

03 Ch.2 Setting Up 96.9.24, 11:06 AM5

2—5

Page 15

Chapter 2: Setting Up and Using the Printer

4. Main (multipurpose) Feeder – holds up to

150 sheets of paper.

5. Manual Feeder Slot – you insert a sheet of

paper or an envelope manually into this slot

in the manual feed print mode.

6. Paper Liftup Button – used when loading

paper in the (optional) 250 sheet hopper.

7. 250 Sheet Hopper (optional) – when fitted to

the printer, and used with the multipurpose

paper tray, permits printing up to 400 pages.

8. On/Off Switch

9. Top Cover Release Button – press to swing

the top cover up.

10. Model Number – indicates the model

number and the serial number of your

printer. You enter these numbers on your

warranty registration.

11. Memory Cover – provides access to the inside of

the printer, to the optional memory expansion

module. The printer’s memory can be expanded by

adding a Single Inline Memory Module (SIMM),

available from your local dealer.

2—6

03 Ch.2 Setting Up 96.9.24, 11:07 AM6

12. Power Plug – the printer’s power cord is inserted

here.

13. Parallel Port – provides the connection to the

computer’s Centronics-type parallel interface

connector.

Page 16

Chapter 2: Setting Up and Using the Printer

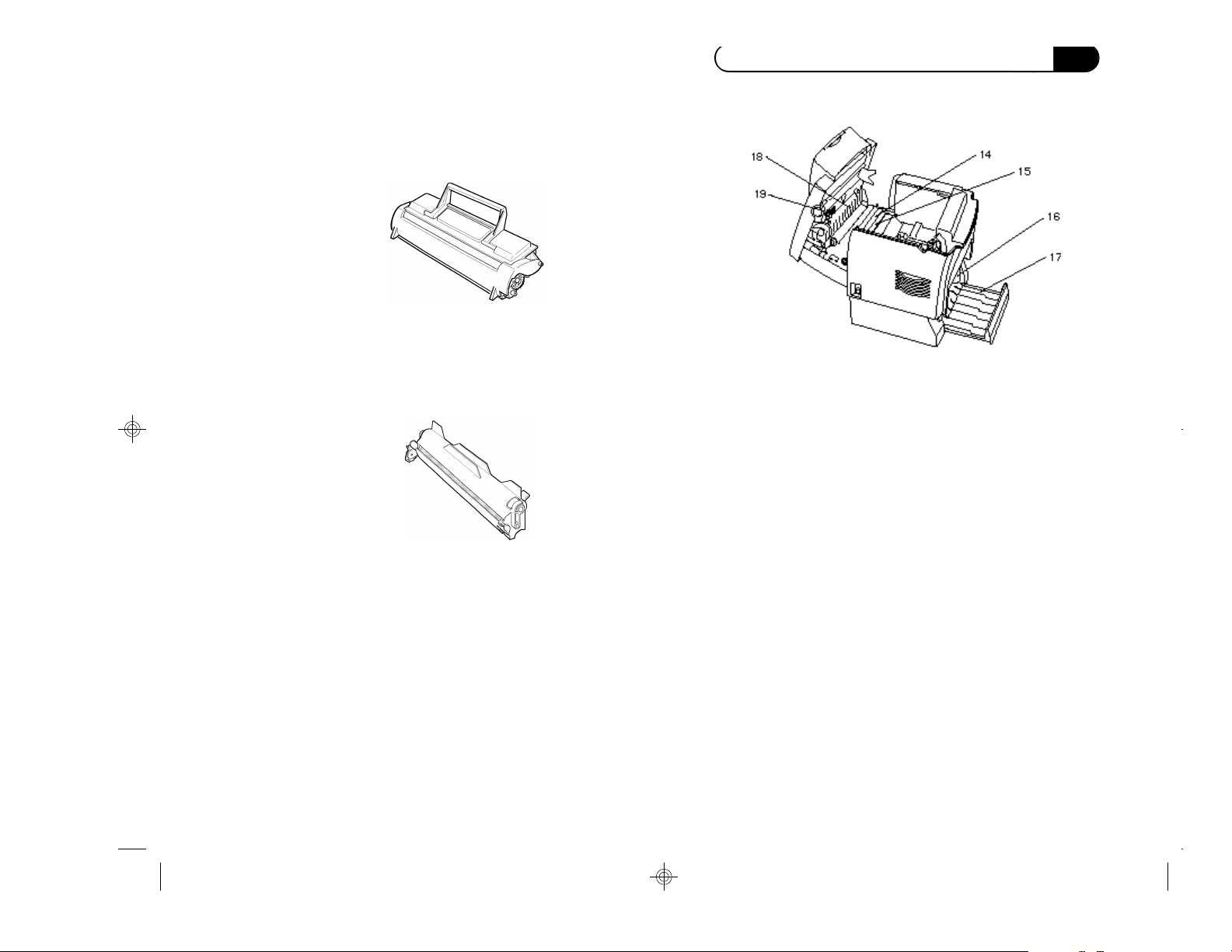

Internal Printer Parts

Toner Module – contains the toner used in the printing

process, which you can replace when the toner runs

out. (Approximately 3,000 pages at 5% coverage.)

Photoconductor Module – contains the

electrophotographic (EP) drum. Handle with the

utmost care. (Estimated life 20,000 pages)

14. Transport Roller – moves the paper through the

printer.

15. Transfer Unit (discharge plate) – a high voltage

plate that attracts the toner to the paper.

16. Paper Guide (for the 250 sheet hopper) – changes

the guide position to the size of the paper.

17. 250 Sheet Hopper (Optional) – when fitted to the

printer, and used with the multipurpose paper

tray, permits printing up to 400 pages.

18. Fuser Unit – fixes the toner image on the paper.

19. Transfer Unit Cleaner – used to clean the transfer

unit.

03 Ch.2 Setting Up 96.9.24, 11:07 AM7

2—7

Page 17

Chapter 2: Setting Up and Using the Printer

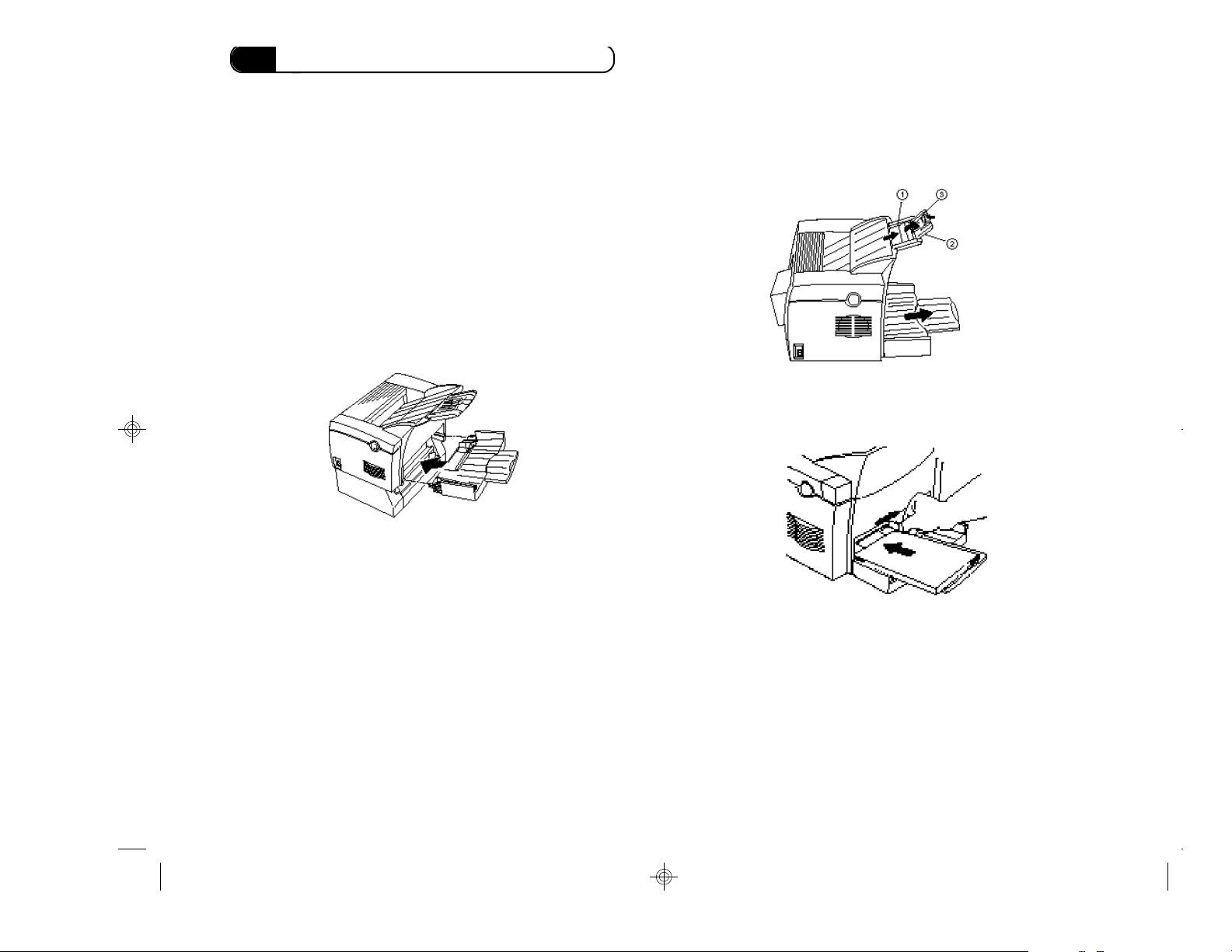

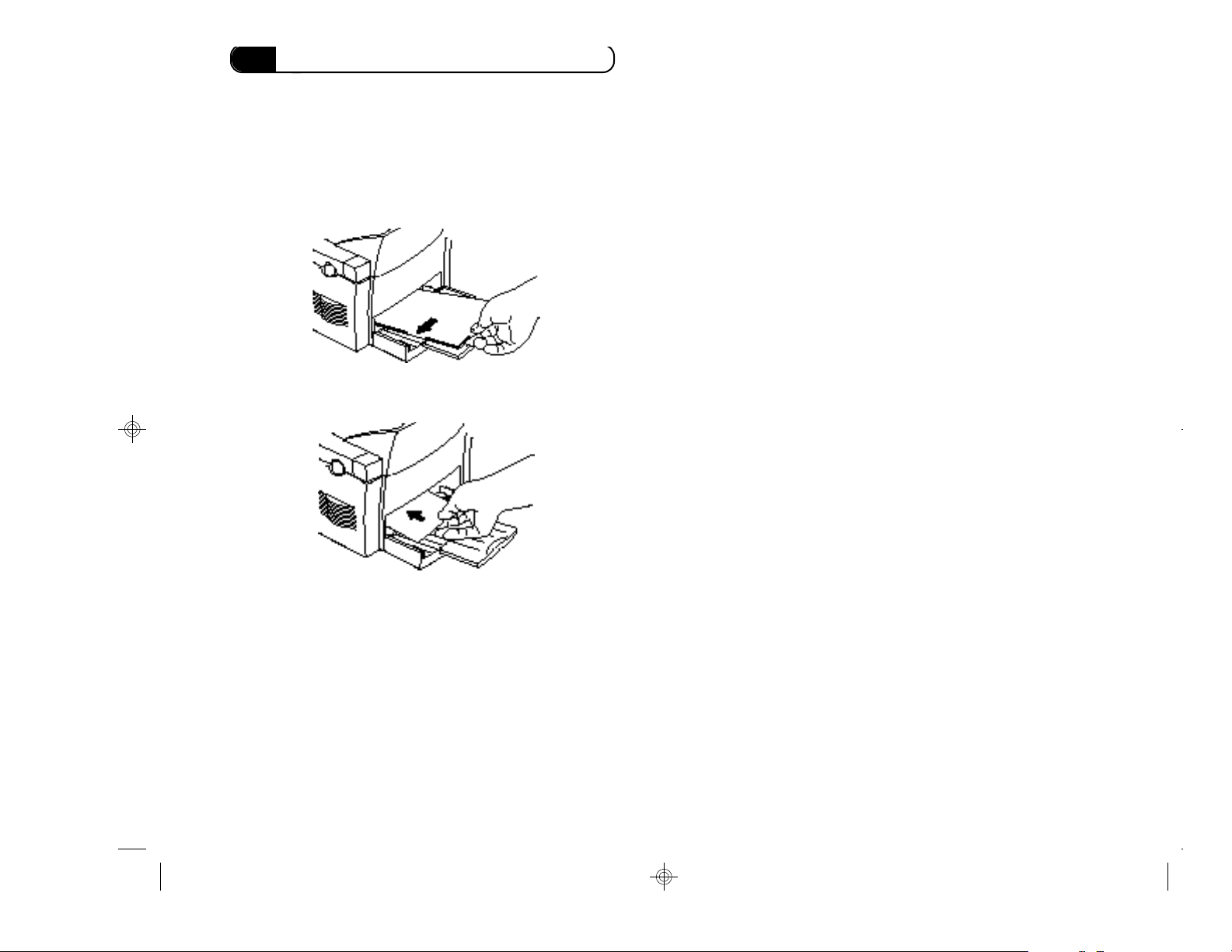

Installing the Main (Multipurpose) Feeder Tray

Referring to the figure of the external printer parts,

attach the multipurpose tray as follows:

1. Hold the multipurpose tray with both hands.

2. Carefully set the tray into the printer at an upward

angle.

3. Once the tray is completely inserted, gently press

down to lock the tray into place. Be sure it is

pressed down fully.

Raise the stopper e when using a letter-size or A4

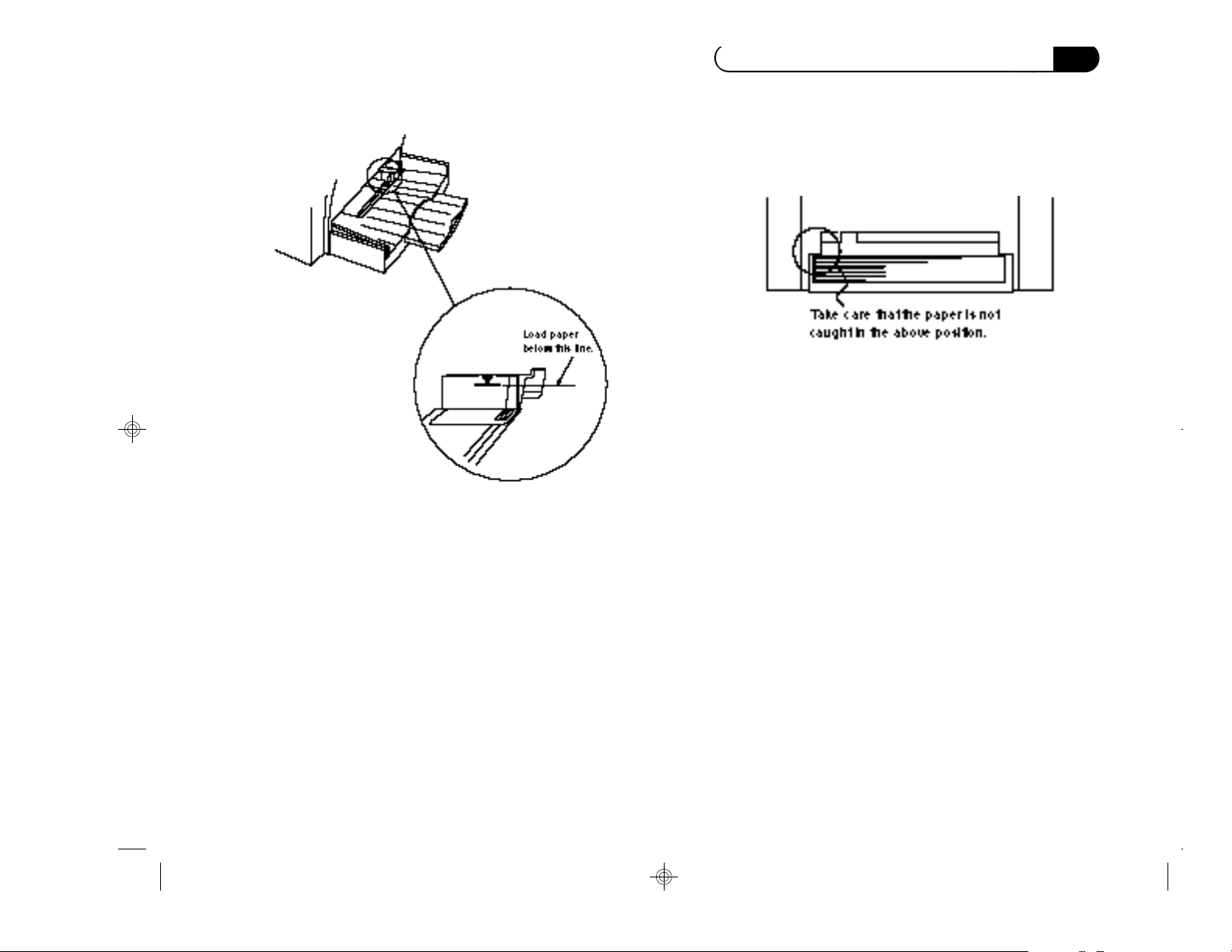

size paper.

2. Load a stack of paper evenly into multipurpose

tray. Adjust the paper guide to fit snugly against

side of the paper:

Loading Paper

A maximum of 150 sheets (17 lb. paper) can be loaded

into the tray at once.

1. Pull out the extension piece of the multipurpose

tray.

Pull out the larger extension guide q, then fold out

the smaller extension guide w for paper out tray.

2—8

03 Ch.2 Setting Up 96.9.24, 11:08 AM8

Page 18

Chapter 2: Setting Up and Using the Printer

Note: Do not load additional paper until all the paper

in the tray has fed through the printer.

Take care not to overload the tray. Do not add paper

while resetting the printer.

03 Ch.2 Setting Up 96.9.24, 11:08 AM9

2—9

Page 19

Chapter 2: Setting Up and Using the Printer

Loading the Manual Feeder

1. With the side to be printed facing up, press the

edge of the paper against the left side in the

manual feeding slot.

2. Insert one sheet of paper until it stops.

the slot at a time. Insert envelopes face up with the

narrow end first, and the flap to the right. Refer to

the paper path sticker in the accessory kit for a

small diagram showing you how to insert paper

and envelopes.

Duplex Printing

When printing on both sides of the paper (manually),

observe the following:

• Papers are not fed from the main feeder tray. Use

the manual feeder slot instead.

• Be sure the temperature is between 59°F to 77° F

(15° to 25°C) and the humidity is between 20 to 70%

• Be sure the image density of the text on the first

printed side does not exceed a black to white ratio

of 5%.

• Use paper 24 lbs. or heavier.

Insert only one sheet of paper or one envelope into

2—10

03 Ch.2 Setting Up 96.9.24, 11:08 AM10

• Use paper right after being unwrapped.

Page 20

Chapter 2: Setting Up and Using the Printer

3. Install the photoconductor in the printer, aligning

the guides with the slits inside the printer frame.

Press it down firmly.

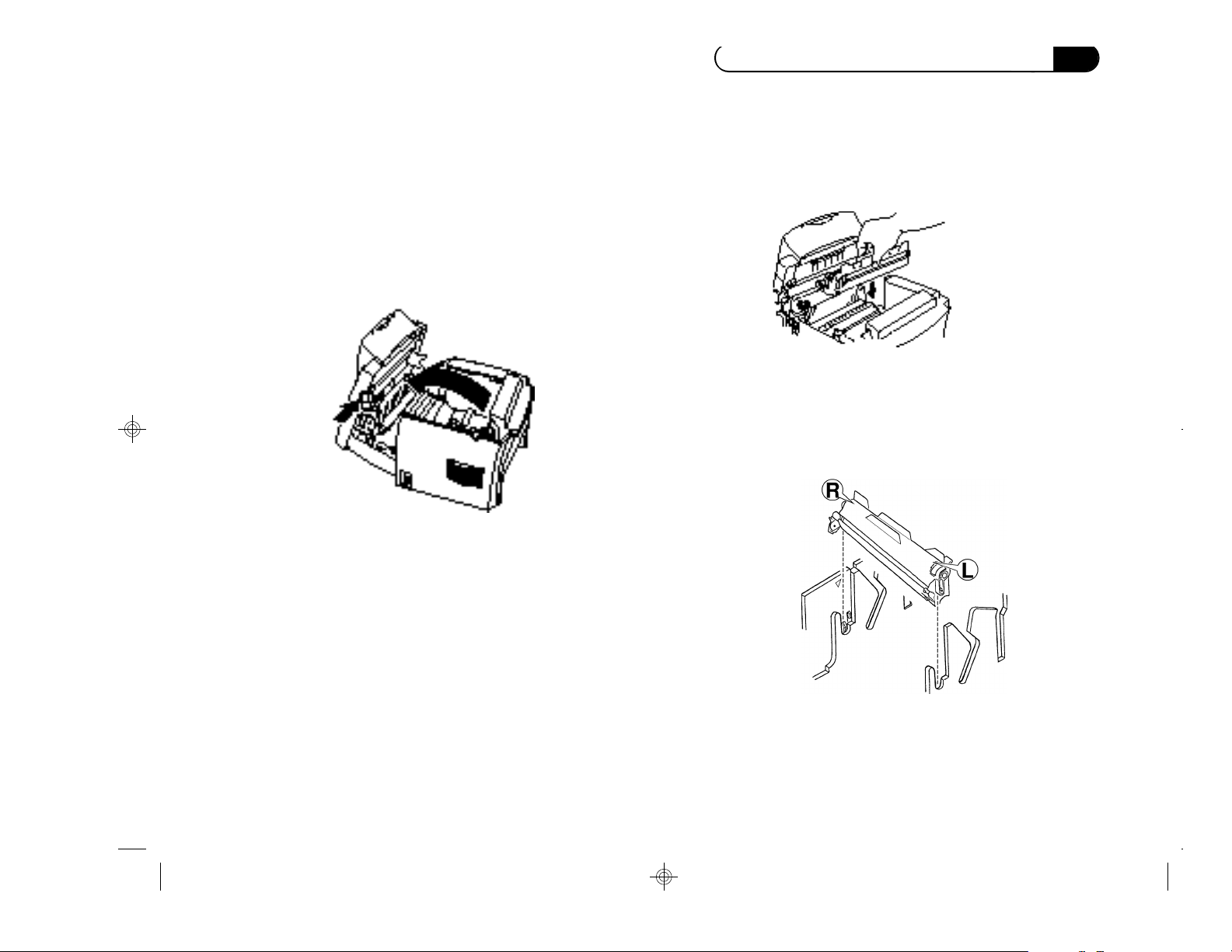

Installing the Photoconductor Module and

the Toner Module

Installing the photoconductor module and toner

module as follows:

1. Press the top cover release button, and swing the

top cover open completely.

2. Unpack the photoconductor module from its

carton.

Hold the photoconductor so that you see the L (left)

and R (right) markers on it, indicating how you hold it.

Caution! Whenever the photoconductor module is

removed from the printer be sure to cover it with a

cloth to prevent exposure to light.

03 Ch.2 Setting Up 96.9.24, 11:09 AM11

Right Left

2—11

Page 21

Chapter 2: Setting Up and Using the Printer

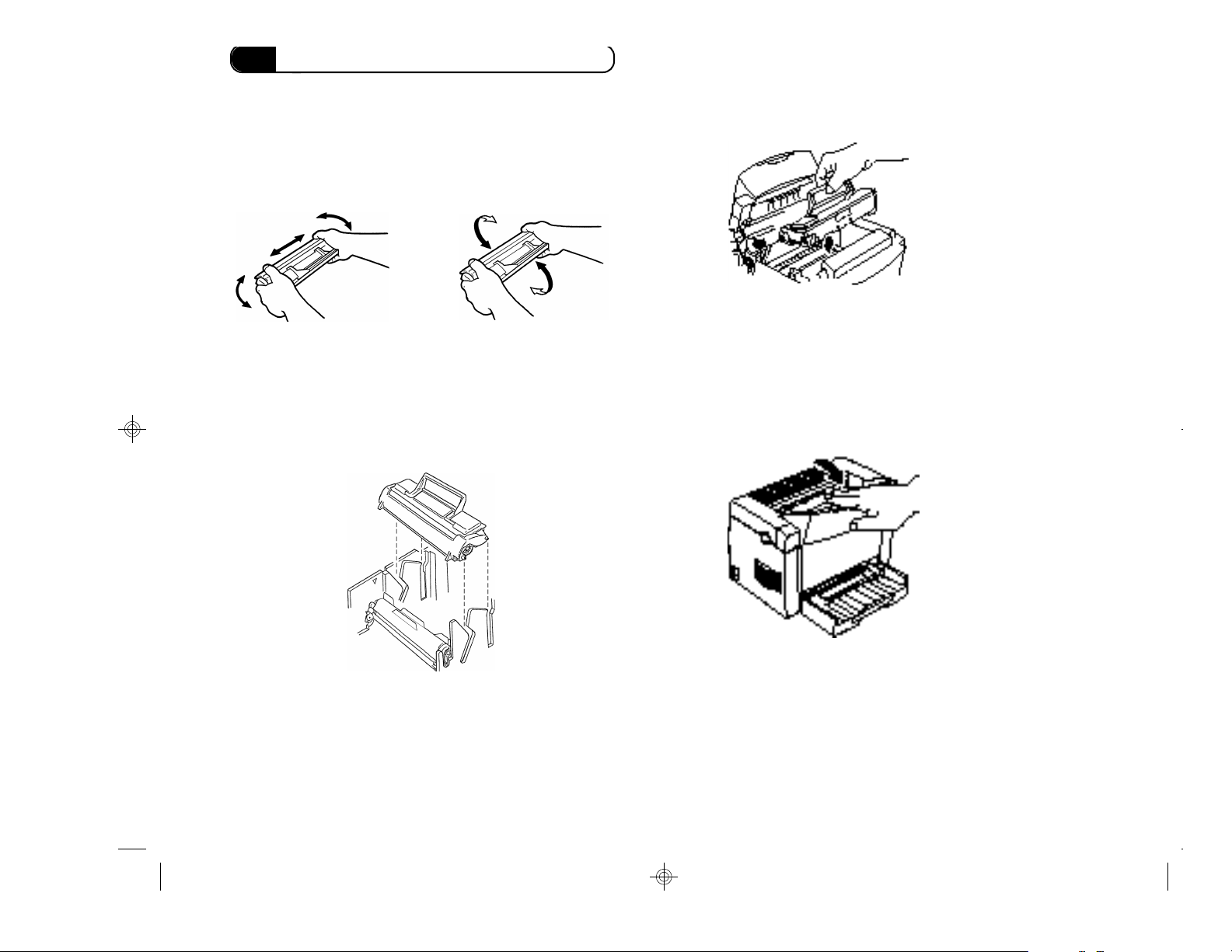

4. Unpack the toner module from its carton.

Holding the toner module with both hands, shake

it gently but firmly in the directions of the arrows.

5. Install the toner module in the printer, making sure

that the four pins of the toner module (two at the

front and two at the rear) align with the slits inside

the printer frame, and slide it securely in position.

6. Swing the top cover down and press the front

down to lock it into position.

2—12

03 Ch.2 Setting Up 96.9.24, 11:09 AM12

Page 22

Chapter 2: Setting Up and Using the Printer

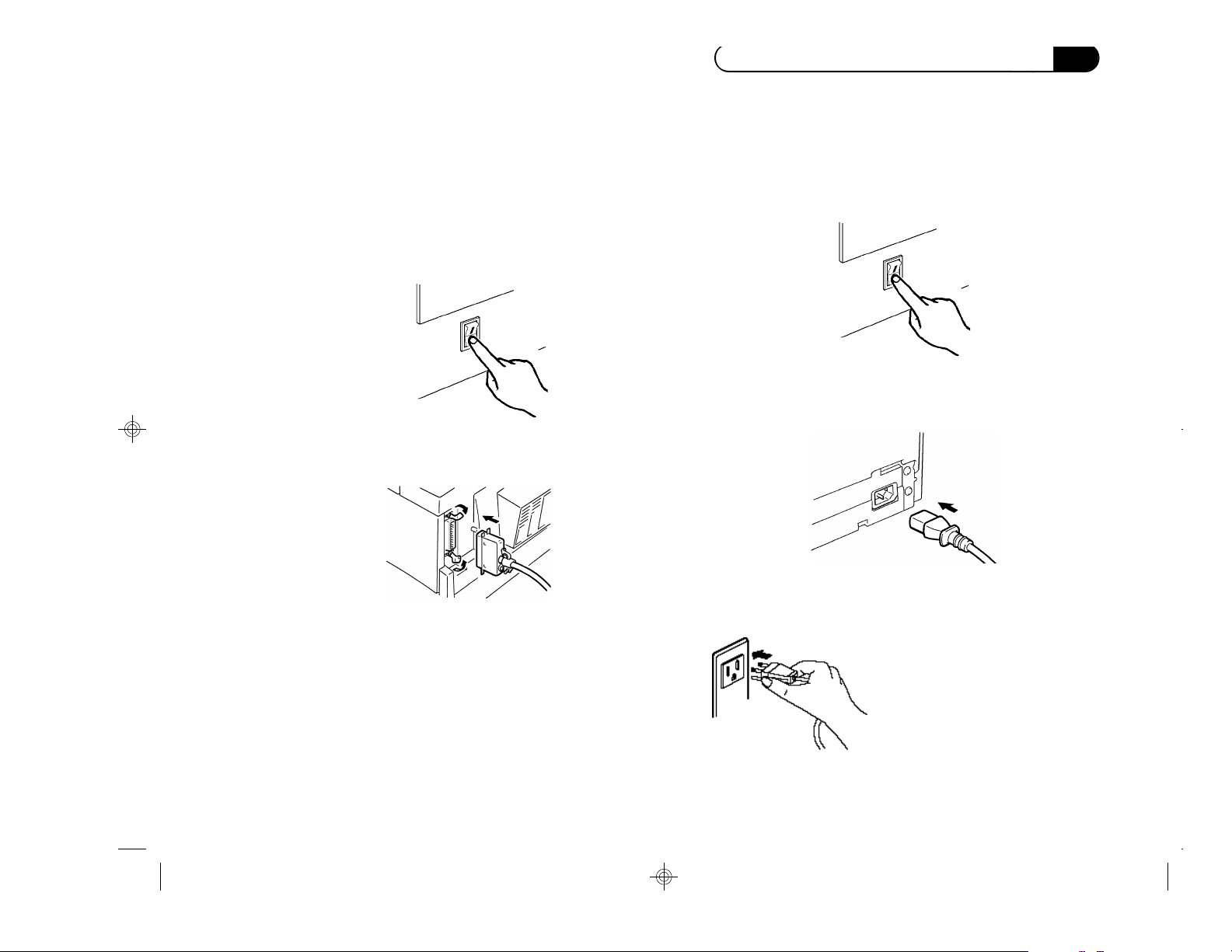

Power Cord

Connect the power cord as follows:

1. Switch OFF power to the printer.

Parallel Cable

Connect the parallel cable as follows:

1. Switch OFF power to the printer and to the

computer.

Caution! To protect your printer and computer from

possible damage, make sure the power switch is

OFF.

2. Plug the parallel cable into the printer, then secure

the lock springs.

2. Plug the power cord into the power plug on the

rear panel of the printer.

3. Connect the other end of the parallel cable to the

computer.

03 Ch.2 Setting Up 96.9.24, 11:10 AM13

3. Plug the other end of the power cord into a

properly grounded electric outlet.

Caution! Do not

connect the power cord

to the auxiliary outlet of

your computer.

2—13

Page 23

Chapter 2: Setting Up and Using the Printer

Some Dos and Donts for Using the Printer

To ensure the optimum performance of the printer,

follow these precautions and admonitions:

• NEVER open any door, or turn the printer OFF

while it is printing.

• NEVER bring any magnetized object, flammable

gas, or liquid near the printer.

• When unplugging the power cord, do not pull on

the cord; rather, hold the plug and pull it out. A

damaged cord could result in a fire or cause an

electrical shock.

• NEVER attempt to unplug the power cord with a

wet or damp hand, as it could cause an electrical

shock.

• ALWAYS unplug the power cord when attempting

to move the printer. Moving the printer with the

power cord plugged in can damage the cord, and

result in a fire, or cause an electrical shock.

• ALWAYS unplug the power cord when you will

not be using the printer for a long time.

• NEVER remove any panel or cover that is secured.

The printer contains a high-voltage component

inside, which can cause an electrical shock.

• NEVER place a heavy object on the power cord, or

pull or bend the cord, as a fire or electrical shock

could result.

• ALWAYS be sure that the printer does not ride on

the power cord or communications cable of any

other electrical equipment, and it does not get such

a cord or cable wedged into its own mechanism, as

a malfunction or fire could result.

• NEVER drop paper clips, staples, or other small

pieces of metal through the vents or other printer

openings, as a fire or electrical shock could result.

• NEVER place a vase or vessel containing water on

the printer. If fluid gets inside it can cause a fire or

electrical shock.

• In case a piece of metal or fluid gets inside the

printer, turn it OFF immediately, unplug the power

cord, and call your NEC Technical Support at:

1-800-632-4560

A fire or electrical shock could result if the printer is

run without taking the necessary action.

• NEVER leave the printer running when it becomes

very hot or emits smoke, an unusual smell, or

noise. If that happens, immediately turn the

printer OFF, unplug it, and call your NEC

Technical Support at 1-800-632-4650. A fire or

electrical shock could result if you run the printer

without taking the necessary action.

Note: Locate the printer in a well ventilated room. A

negligible amount of ozone is generated during

normal operation of this printer. An unpleasant odor

may be created in poorly ventilated rooms during

extensive printer operations. For a comfortable,

healthy, and safe operating environment, it is

recommended that the room be well ventilated.

03 Ch.2 Setting Up 96.9.24, 11:11 AM14

2—14

Page 24

Chapter 3: Installing the Software

Overview

This chapter gives you the information you need to

install the new SuperScript 660plus software, and to

remove any previous version you may have installed.

The chapter discusses

• The steps you take before you begin to install the

software

• Easy or Custom Installation

• The installation dialogs

• How to test that the installation is correct

• How to remove NEC SuperScript software

3

Installing the Software

04 Ch.3 Installing 96.9.24, 11:15 AM1

3—1

Page 25

Chapter 3: Installing the Software

SuperScript Software Installation

This section describes the steps to set up the

hardware and software necessary to configure your

printer. Installation includes the following steps:

• Pre-installation

• Installation of the SuperScript software

• Testing and verifying the installation

Some procedures described below, such as disk

defragmention, may not be necessary for your PC

configuration. The installation description provides a

general approach. Your configuration may provide an

alternate set of selections, such as an installation

folder.

To install both GDI and PCL you need 40 MB space

on your hard disk.

Table 3-1 Pre-Installation Steps

1. Remove the current Click Start, then click Run.SuperScript software if it

installed in the PC. In Windows 95, type

C: \SSCRIPT\NECDELETE.EXE

in the command line box. Press Enter.

In Windows 3.1 and 3.11, if your current

SuperScript software is SuperScript

Network and PS option kit software, type

C: \NECSSFW\WSREMOVE.EXE in the

command line box. Press Enter.

2. Defragment the disk You can use Disk Defragmenter in Windows 95.

Refer to your Windows 95 documentation. This is

recommended, but not generally necessary.

Note: Be sure to remove the current SuperScript software

prior to installing the SuperScript 660plus in order to avoid

installation problems. Appendix A, Troubleshooting,

provides some instructions on what to do if you encounter

installation problems.

ACTION

COMMENT

04 Ch.3 Installing 96.9.24, 11:15 AM2

3—2

Page 26

Chapter 3: Installing the Software

Installing the SuperScript Software

The SuperScript software installation program

analyzes your system configuration, installs the

SuperScript software and fonts, and makes the

necessary changes to the Windows startup files. As

shown in the following tables, there are two ways to

install SuperScript software:

• Custom Installation, which you can do either from

the installation diskettes or from the CD.

• Easy Installation, which must be done from the

diskettes.

Note: If you need to make full featured SuperScript

software installation diskettes, you can do it from

the SuperScript for Windows 95 installation CD as

follows. (You need seven empty diskettes. The

following instruction assumes the CD drive is drive

d and the diskette drive is a.)

At the DOS prompt, type

1. d:

2. cd \software\win95\makedisk

3. makefd a:

Then follow the instructions on your screen to make

the installation diskettes.

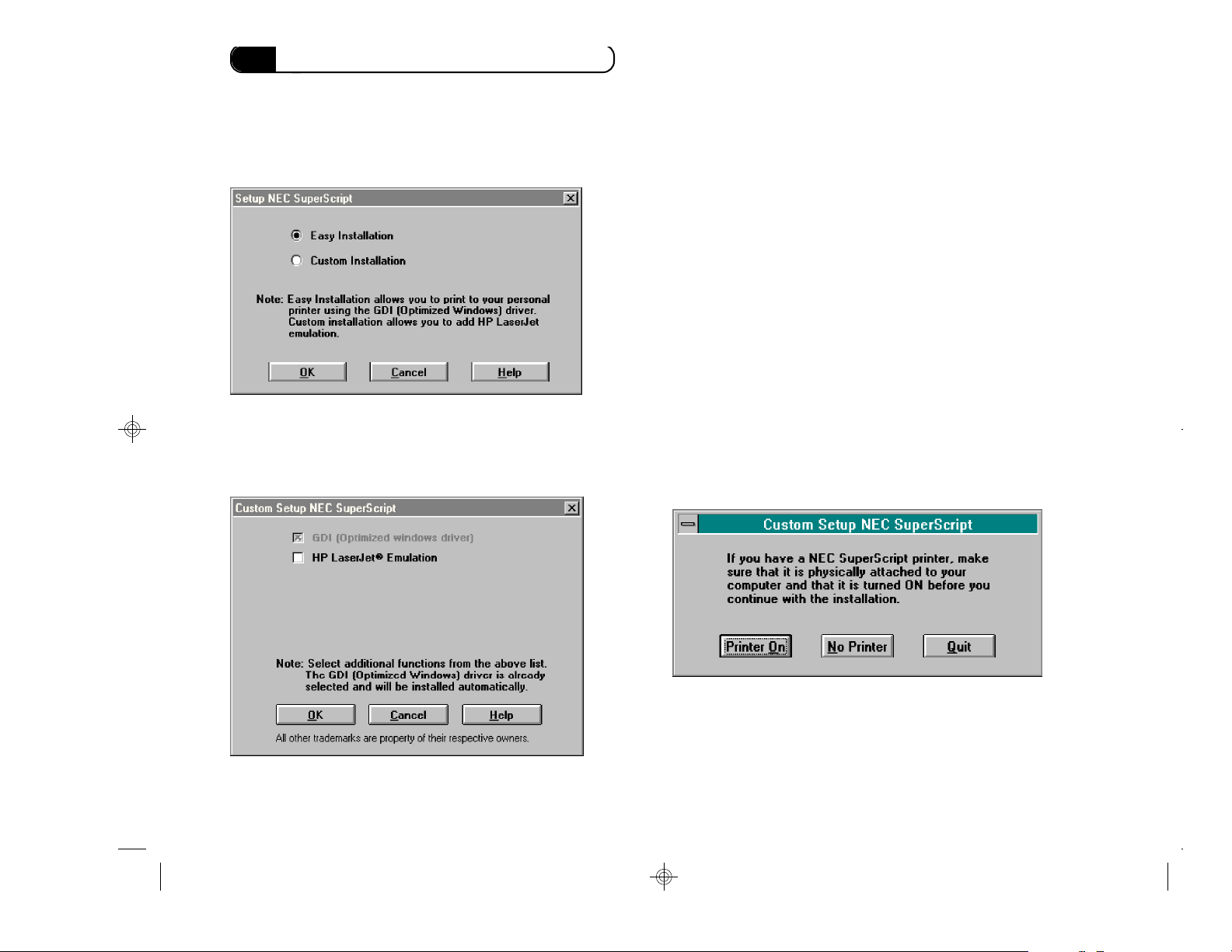

SuperScript Installation Dialogs

The installation dialogs presented during the setup

process are the same whether you install using

diskettes or the CD.

1. Once installation starts, the Welcome to

SuperScript setup screen appears, as shown in the

following figure. This screen is displayed for

approximately five seconds.

The first installation dialog box appears. You can

choose Easy Installation or Custom Installation.

04 Ch.3 Installing 96.9.24, 11:16 AM3

3—3

Page 27

Chapter 3: Installing the Software

If you choose Easy Installation, the default

configuration is used.

2. If you have a previously installed version of the

SuperScript Software on your system you will be

prompted to remove it before installing the new

software. Click OK to remove the older version of

the software and continue installing the new

software.

The installation program displays the following

dialog and asks you to turn on the printer. When the

printer is connected and you have turned it on, click

Printer On to continue. Select No Printer if no printer

is connected.

If you choose Custom Installation, you can install the

full featured software.

3—4

04 Ch.3 Installing 96.9.24, 11:17 AM4

You do not have to have a printer connected to

successfully install the program. You can connect a

printer later.

Page 28

Chapter 3: Installing the Software

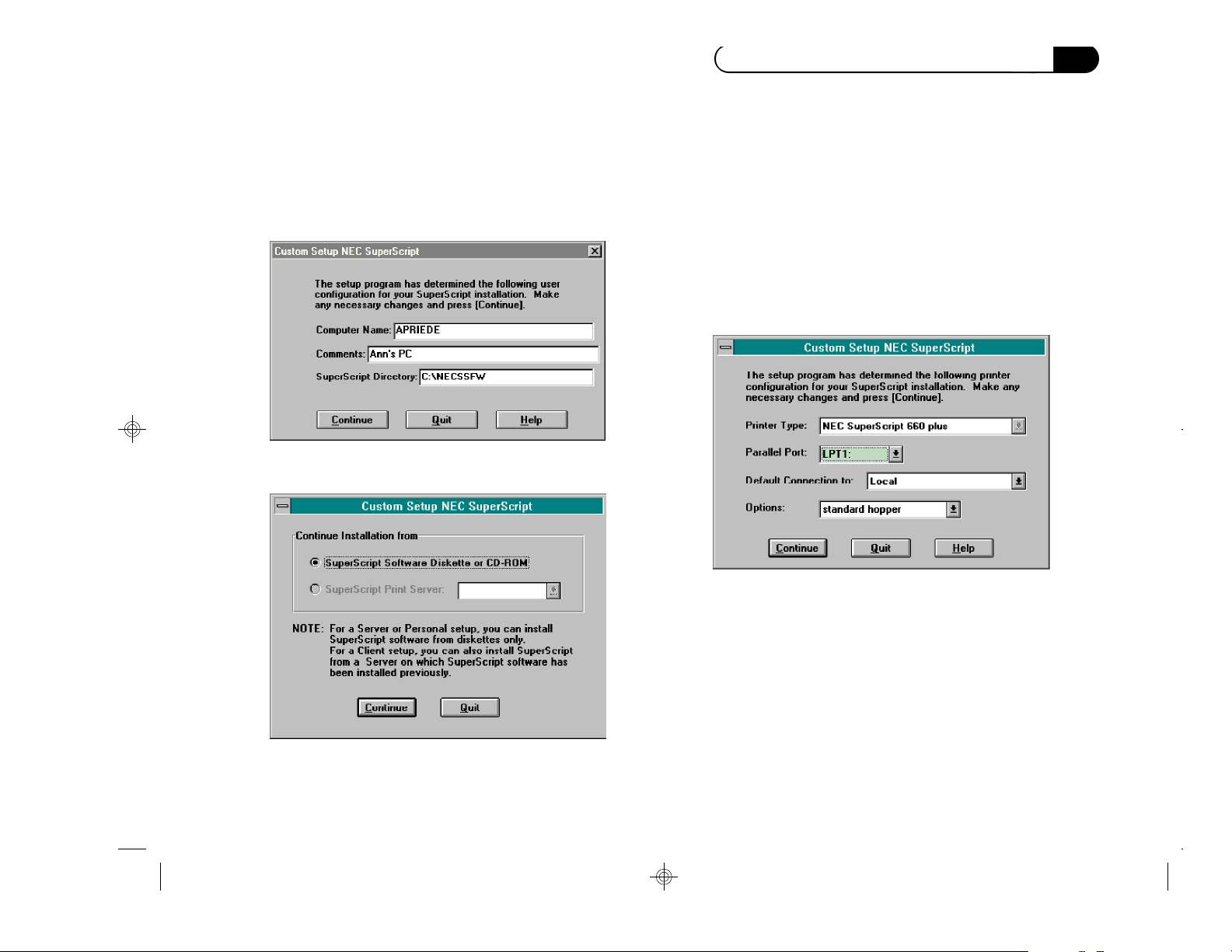

4. The SuperScript Setup Program presents the

configuration User type option, asks for a

computer name, provides a comments area, and

asks for the name of the folder in which you want

the files installed.

The SuperScript Setup Program examines your PC

hardware and system configuration to ensure that the

minimum configuration requirements have been met.

5. The Setup Program presents the default printer

configuration information. The parallel port field

shows the physical port to which the SuperScript

printer is attached.

04 Ch.3 Installing 96.9.24, 11:19 AM5

At this point the SuperScript Setup Program has all

the information necessary to install the SuperScript

software and configure the system.

3—5

Page 29

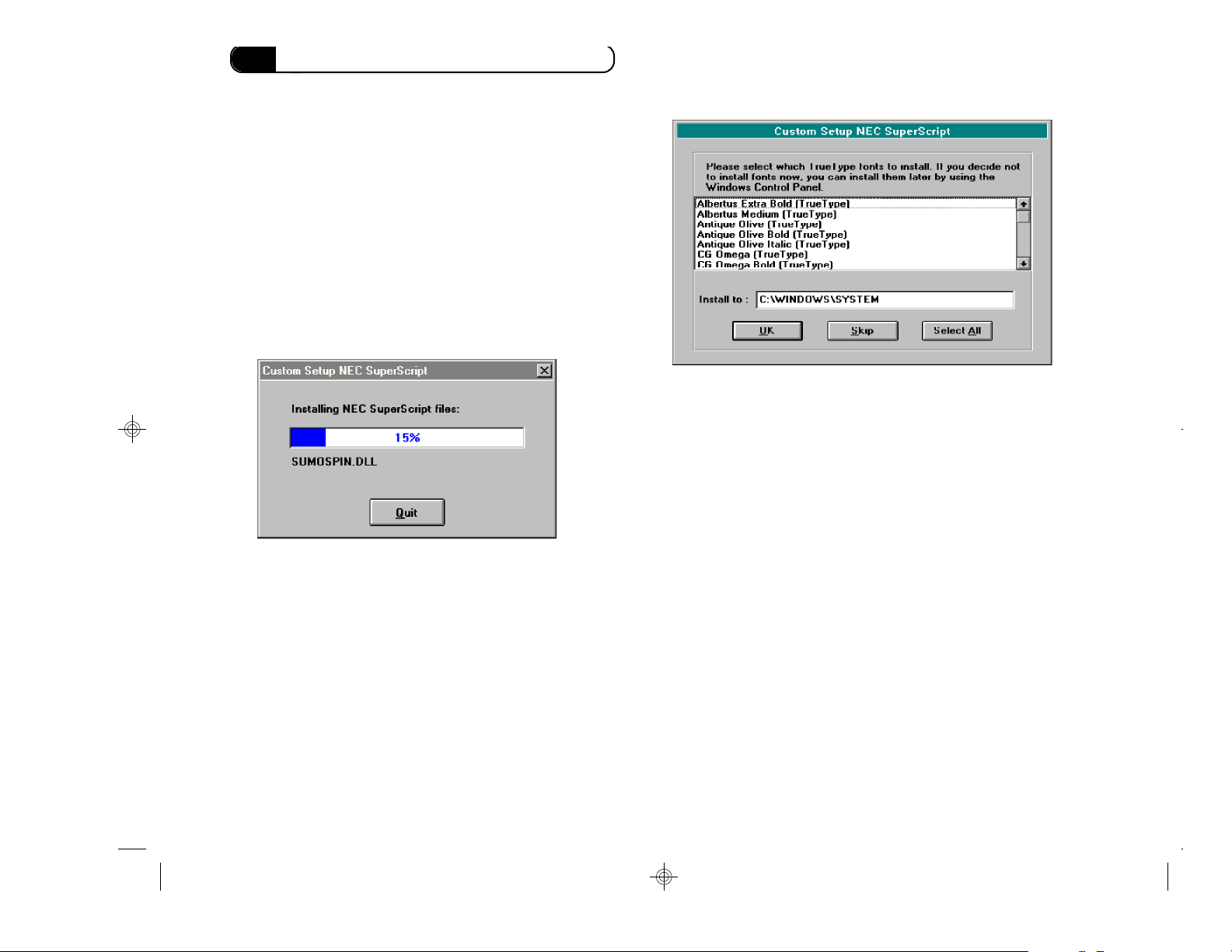

Chapter 3: Installing the Software

6. SuperScript Setup displays the installation

progress. If you choose to do so, you can click the

Quit button to abort the installation at any time.

Note: Quitting at any time means you will not be

able to print to the SuperScript printer. There is no

reason to quit the program. If you do quit you will

have to reinstall your old SuperScript software, or

the new SuperScript software later.

The default location for the fonts to be installed

is in the C:\WINDOWS\FONTS directory. You can

change the default directory by specifying a

different path. When you select OK after

choosing fonts, the installation program copies

the fonts to the folder and installs them in

Windows automatically. This requires

approximately 3.5 MB of hard disk space.

7. There are 53 TrueType fonts bundled with your

SuperScript software. You may choose to install

all, some, or none of the fonts. A custom

installation allows you to install only the fonts

you want.

3—6

04 Ch.3 Installing 96.9.24, 11:20 AM6

If you select Skip you will skip this step and

continue with the SuperScript installation. You

can install the fonts individually later.

Note: The fonts are not installed when you chose

Easy Installation.

Page 30

Chapter 3: Installing the Software

COMMENT

Table 3-2 SuperScript Installation-

Diskette or CD

ACTION

8. For the installation to take effect, you must restart

Windows. The final menu gives you the option of

restarting Windows or continuing without

restarting.

9. Once SuperScript software is installed, NEC

SuperScript device names appear in the Printers

window of My Computer (see the next figure for

Windows 95 systems).

At this point your installation is complete.

1. Connect your SuperScript printer to Your PC must be OFF before

your PC and turn the printer on. you turn the printer ON.

2. Turn the PC on. Windows starts.

3. Windows 95 may display the New If this dialog box does not appear,

Hardware Found dialog box. or if you are using Windows 3.1

Select Driver from disk provided by or 3.11, go to step 4.

hardware manufacturer and click OK.

When the Install From Disk dialog box

appears, insert software diskette #1,

or the CD, in the drive. Click OK and

follow the displayed directions.

4. Insert software diskette #1, or the CD, These items are located in the

in the drive. SuperScript 660plus software kit.

5. Windows 95 users click Start, then The Run Program dialog

click Run. box appears.

Windows 3.1 or 3.11 users select Run The Run Program dialog

from the File menu. box appears.

6. a: \necsetup.exe or d: \necsetup.exe Type the command and press

Enter.

04 Ch.3 Installing 96.9.24, 11:21 AM7

Note: Once you start the installation, you can cancel at

any time by clicking Quit.

3—7

Page 31

Chapter 3: Installing the Software

Testing the Installation

When you restart Windows, you can use the

SuperScript printer test function to make sure the

installation was successful. The printer test utility is

available through the Print Test Page button on the

Control Panel tab of the SuperScript Console. The test

utility prints several pages during the test. To begin a

test print, do the following:

1. Confirm that the printer is connected to the parallel

printer port you selected in the installation.

2. Confirm that the printer is turned on.

3. In Windows 95, click Start, point to Programs, NEC

SuperScript Tools, and then click NEC SuperScript

Console.

In Windows 3.1 and 3.11, double click NEC

SuperScript Tools Program Group, then double

click NEC SuperScript Console.

4. Click the Control Panel tab of the SuperScript

Console.

5. Click the Print Test Page button.

6. Choose the print mode, and click OK.

Print Test Page Button

Removing SuperScript Software

You can easily remove any installed SuperScript

software.

1. In Windows 95, click Start, then click Run. The

Run program dialog box appears. In Windows

3.1 or 3.11, click Run on the File menu.

2. In all of these cases, type

c:\necssfw\wsremove.exe. This is the

path to the folder containing wsremove.exe.

Press Enter.

By default, the de-install program is loaded in

c:\necssfw. If you have set up the SuperScript

files in a different folder, specify the location of

your setup folder.

3—8

04 Ch.3 Installing 96.9.24, 11:22 AM8

Page 32

Chapter 4: SuperScript Console

Overview

This chapter explains the four windows in the

SuperScript Console program that you use to

configure and control your print jobs. You are given

information about

• Selecting your printer

• The Control Panel, where there are buttons you

can select to control a variety of printer functions.

• The Local Queue, where you control the jobs you

have sent to the printer. You can add a job to the

queue, delete a job, or rearrange the order in which

they print.

• The Job Log, which maintains a historical log with

useful information about your last ten jobs

4

SuperScript Console

05 Ch.4 Console 96.9.24, 11:54 AM1

4—1

Page 33

Chapter 4: SuperScript Console

The SuperScript Console program provides a single

access point to the four major SuperScript program

windows. The purpose of the SuperScript Console

program is to provide an easy way to configure the

SuperScript printer and to monitor and control print

jobs.

To activate the SuperScript Console in Windows 95,

click the Start button, point to Programs, NEC

SuperScript Tools, and then click NEC SuperScript

Console.

In Windows 3.1 or 3.11 select NEC SuperScript Tools

Program group, then double click NEC SuperScript

Console.

Printer Selection 14 buttons

Printer Information

Each of the four major program features can be

accessed by clicking the folder tab under the menu

bar. The four tabs are:

• Local Queue

• Remote Queue

• Job Log

• Control Panel

Note: The Remote Queue is specific to NEC peer to

peer sharing and may not be functional. NEC

developed a proprietary sharing system for

environments with multiple NEC SuperScript

printers. For most environments, standard Windows

sharing is more suitable and the NEC SuperScript

660plus is fully compatible.

4—2

Control Panel

The Control Panel, the rightmost folder tab in the

window, provides a mechanism to configure and

control the SuperScript printer. The Control Panel

has 14 buttons that you use to control the printer, a

printer selection section to the left just below the

buttons, and the printer information section at the

bottom of the window.

The Printer selection list bar displays your currently

selected printer and provides a list of additional

printer selections. The printer selections applicable

to SuperScript software are:

• NEC SuperScript GDI (standard)

• NEC SuperScript PCL (custom installed)

Table 4.1 lists the Control Panel icons with a brief

description of what they do.

05 Ch.4 Console 96.9.24, 11:55 AM2

Page 34

Chapter 4: SuperScript Console

ICON DESCRIPTION

Connect Port: Identifies the port to which your

printer is connected, such as LPT1.

PCL Control Panel: Displays the PCL Control

Panel menu that is used to set up PCL mode

when printing from a DOS file.

DOS Printing Option: Allows you to select a

printing mode for printing from DOS within

Windows. Refer to the section on DOS printing

in this chapter.

Status Report Options: Provides status report

options. You can select from the following

options: Minimize Printer Status Display

Beep When a Job is Complete

Beep on Printer Error

Note: This item is specific to NEC peer to peer

sharing and may not be functional. NEC developed a

proprietary sharing system for environments with

multiple NEC SuperScript printers. For most

environments, standard Windows sharing is more

suitable and the NEC SuperScript 660plus is fully

compatible.

Print Test Page: Outputs the printer test page.

You can test the connection between your PC

and the SuperScript printer by this function.

ICON DESCRIPTION

Toner Saving Mode: Allows you to save toner

by controlling print density. You can select on or

off. Default is off. Not available when SET

is on.

.

Sharp Edge Technology: SuperScript features

the patented Sharp Edge SET Technology .

This feature detects and smooths the jagged

edges of vectors by dividing one full dot into

several subdots set in the same area. The print

quality of both text and line graphics is thus

improved. Default is on. Not available when

Toner Saving is on.

Print Darkness/Line Width: Allows you to

control the line width darkness (not images).

You can set this mode to light, medium, or dark.

Default is medium.

Page Save Mode: When enabled, the current

page is saved in memory until printing is

complete. Enable for sensitive documents where

loss of data cannot be tolerated. Disable this

feature to increase throughput. Default is off.

Power Saving Mode: This printer has Power

Saving Mode. In this mode, if the printer is idle

for a specified time, the fuser unit pauses and

power consumption is decreased. Default is off.

Printer Setup: Allows you to set up the printer.

Clicking this icon displays a setup screen for the

printing mode currently selected. (Refer to the

next section on the GDI Setup Window.)

Table 4.1 SuperScript Control Panel Buttons

4—3

05 Ch.4 Console 96.9.24, 11:56 AM3

Page 35

Chapter 4: SuperScript Console

Use the list bar to highlight the print mode you want to

use. To use the selected printer as a default, click on Set

As Default. You can also request current printer status

information by clicking on Local Printer Status..

At the bottom of the Control Panel window the printer

information section shows the picture and information

of the currently selected printer in each mode (GDI,

PCL). You can also select a printer by clicking one of

the two parts.

If you did not install PCL, the PCL Printer selection

will be grayed out and cannot be selected. If you want

to install PCL, you must do a Custom Installation

using the CD.

GDI Setup Window

With the printer selected in GDI mode, when you click

the printer setup button (the sixth button in the row) in

the Control Panel, the GDI setup window appears.

Paper

When you select Paper from the top of the GDI Setup

screen you can select the following:

• Paper Source: Hopper

Manual Feed

Second Hopper

• Orientation: Portrait

Landscape

• Paper Size: Letter 8-1⁄2 x 11 in.

Legal 8-1⁄2 x 14 in.

A4 210 x 297 mm

B5 182 x 257 mm

Executive 7-1⁄4 x 10-1⁄2 in.

Envelope Monarch 3-7⁄8 x 7-1⁄2 in.

Envelope #10 4-1⁄8 x 9-1⁄2 in.

Envelope DL 110 x 220 mm

Envelope C5 162 x 229 mm

• Number of copies: 1 up to 99

4—4

05 Ch.4 Console 96.9.24, 11:57 AM4

• Scaling: 10% to 200%

Page 36

Chapter 4: SuperScript Console

Advanced Options

When you select Advanced Options from the top of

the GDI Setup screen you can select the following:

• Use NEC SuperScript Print Manager

You must select Use NEC SuperScript Print Manager

to use the Print Order and Duplex features.

• Print Order: Page 1 on top

Prints in reverse order

• Duplex printing:

Manual Duplexing Book Style (side binding)

Report Style (top binding)

Print Instruction Page Printed with your

duplex job to explain

how to re-feed pages

to print the second side

Settings for GDI printing can be made in this window.

Note: If you want print jobs in GDI to be listed in the

Local Queue or Job Log, you must activate

SuperScript Print Manager by selecting Use NEC

SuperScript Print Manager on the GDI Setup window.

The GDI Setup Window has the following five tabs:

Paper, Advanced Options, Print

Quality, 2Up/4Up, and Form Settings.

Print Quality

When you select Print Quality from the top of the Setup

window, you can select:

• Print Resolution: 600 x 600

300 x 300

• Brightness To lighten or darken an

image.

• Contrast To adjust the difference in

the light and dark areas of

an image, to improve a flat

image.

• Image Box An image that demonstrates

how the brightness

and contrast settings affect

the printed output.

05 Ch.4 Console 96.9.24, 11:58 AM5

4—5

Page 37

Chapter 4: SuperScript Console

2Up/4Up

When you select 2Up/4 Up from the top of the GDI

Setup window you can select the following:

• Draw Frame Border

Allows you to draw a frame or border around

multiple images on the same page.

Form Settings

Form Settings allows you to set up a Cover/Trailer

Page or Print Overlay. You must select Use the NEC

SuperScript Print Manager to use these features.

• Use NEC SuperScript Print Manager

• Print Cover Page

When selected, a cover page is printed at the

beginning of each print job. The File Name

designates the GDI file to be used as the cover

page.

• Print Trailer Page

When selected, a trailer page is printed after each

print job. The File Name designates the GDI file to

be used as the trailer page.

• Print Overlay

When selected, this feature will overlay a GDI file

on the print job. The File Name designates the GDI

file to be used as the overlay.

The following instructions are for NEC SuperScript

under Windows 95.

Create a Cover/Trailer Page or Overlay file

You can create a Cover/Trailer Page or an Overlay File

using any Windows application. The following instructions are for Microsoft WordPad as an example.

1. Using your application, create or open the

document to use as the Cover/Trailer.

2. Select Print from the File menu.

3. In the Print Setup window check to be sure the

printer selected is NEC SuperScript GDI.

Click on Print to File on the Setup window, and

click OK.

4. In the Print to File window, type the filename.

Check Save in the list box to see where the file is

saved. Click Save.

You are now ready to print using your Cover/Trailer

Page or Overlay.

05 Ch.4 Console 96.9.24, 11:59 AM6

4—6

Page 38

Chapter 4: SuperScript Console

Local Queue

The Local Queue is used to review the status of your

queued print jobs.

The local queue shows

• the print job name

• the format of the print job (GDI, PCL)

• the size in bytes of the print job

• the time the job was sent to the queue

• the owner of the print job

Note: If the print job is in GDI without the NEC

SuperScript Print Manager active, the job is not listed

in the Local Queue. (Refer to the section on the GDI

Setup Window in this chapter.) The job will be listed

in the standard Windows printer queue.

If you double-click an entry in the job queue, a Print

Job Information dialog pops up to show you more

information about the job.

You can use drag-and-drop for jobs that have not yet

started printing. This allows you to rearrange the order

of your print jobs.To drag-and-drop, follow these steps:

1. Move the cursor to the entry you want to move.

2. Press the left mouse button. Do not lift your finger.

The entry will turn blue indicating that it has been

selected.

05 Ch.4 Console 96.9.24, 0:00 PM7

4—7

Page 39

Chapter 4: SuperScript Console

Table 4.2 Local Queue Buttons

ICON DESCRIPTION

Pause: Pauses the printer

Resume: Resumes printing

Add: Adds a print job to the print queue

Delete: Deletes the highlighted print job fro the print queue

Job Log

The Job Log provides a historical log of the last 10 jobs

originated by your PC.

The Job Log includes

• the time the job was printed

• the server name of the print job

• the job name

• the format of the print job (GDI, PLC)

• the print result

3. Holding the button down, drag the print job to the

desired location in the queue.

4. Release the mouse button. The print job will now

show up in its new location, and the other print

jobs will move up or down in the queue.

The following table shows the Local Queue icons with

brief descriptions of what they do:

Note: If the print job is in GDI without the NEC

SuperScript print manager active, the job is not listed

in the Job Log. (Refer to the GDI Setup Window

section in this chapter.) The job is listed in the

standard Windows printer queue.

4—8

05 Ch.4 Console 96.9.24, 0:01 PM8

Page 40

Chapter 4: SuperScript Console

• Toner saving

• Sharp edge technology

• Print darkness

• Page save

• Power saving

• Printer setup

• Connect port

• PCL control panel

• DOS printing option

• Print priority

• Local printer change

“Print Priority” and “Local Printer Change” can be

accessed only through this pull-down menu.

Priority

Windows lets you run several applications at the same

time. This helps productivity, but means you are

sharing your PC resources among several activities.

SuperScript software priority settings let you control

the priority of printing relative to other applications

running at the same time.

The menu lets you select high, medium, or low priority processing when you print. High priority produces

output faster, but it may slow down your system as

well. On the other hand, printing at a lower priority

lets other applications run faster, but your document

will take longer to print.

SuperScript Console Menu

Superscript software provides the standard Windows

menu items available in most Windows applications as

well as application-specific menu items. Some of the

menu items match buttons in the tabbed dialog. Some

SuperScript software functions can only be accessed

through the pull-down menus, such as the print

priority setting.

File

The File pull-down menu provides the application exit

item, as well as items to pause and resume printing,

and adding or deleting a document from the queue.

View

The View pull-down menu allows you to display the

print servers.

Note: This item is specific to NEC peer to peer

sharing and may not be functional. NEC developed a

proprietary sharing system for environments with

multiple NEC SuperScript printers. For most

environments, standard Windows sharing is more

suitable and the NEC SuperScript 660plus is fully

compatible.

Settings

The Settings pull-down menu lets you to make

changes to the following printer settings:

05 Ch.4 Console 96.9.24, 0:06 PM9

4—9

Page 41

Chapter 4: SuperScript Console

Local Printer Change

If you have another NEC SuperScript printer and

want to replace the currently connected SuperScript

printer with it, you have to reinstall the SuperScript

software or use this function.

After the new SuperScript printer is connected to your

PC and turned on, select Local Printer Change and

then click Printer On.

Network

The Network pull-down menu allows you to share

and connect to a network printer, Monitor Clients if

configured as a Server, select Status Report Options,

and Change Name. Change Name can be accessed

only through the pull-down menu.

Change Name

This selection is available to all users and allows the

user to change the computer name. You must exit and

restart Windows before this change takes effect.

Note: This item is specific to NEC peer to peer

sharing and may not be functional. NEC developed a

proprietary sharing system for environments with

multiple NEC SuperScript printers. For most

environments, standard Windows sharing is more

suitable and the NEC SuperScript 660plus is fully

compatible.

Run

The Run pull-down menu allows you to view local

printer status, and print a test page.

Help

The Help menu links you to the SuperScript Help

system. You can select the Index to see a list of topics

related to SuperScript Software. Clicking About shows

version and copyright information for SuperScript.

Exiting before printing has completed

If you try to close the SuperScript console, or exit

Windows while there are print jobs queued and

waiting to be printed, the SuperScript program displays a message asking if you want to save the remaining print jobs.

If you select Yes the print jobs are saved as you exit.

When the SuperScript Console next starts up, it

resumes processing and printing the documents.

Selecting No deletes all pending print jobs on exit. The

original applications files, from which the print jobs

were created, are not affected. Selecting Cancel cancels

the exit selection and you return to the previous

window.

4—10

05 Ch.4 Console 96.9.24, 0:07 PM10

Page 42

Chapter 4: SuperScript Console

Printing from a DOS Application

SuperScript is a Windows printer, designed for use

with Windows.

You can print from a DOS application, but you must

enter DOS from Windows 3.1 or 95. Click on the MSDOS icon in the main window, from the Program

Manager screen.

When you are ready to print, start your DOS application and print as you normally would.

To specify the printer port and printing mode, do the

following:

1. Double-click the SuperScript Console icon in the

SuperScript group window in the Program Manager.

2. Select DOS Printing from the Setting menu.

3. Select the Printer Port you want to use (usually

LPT1) and Printing mode for the file. Click OK.

Be sure the NEC SuperScript 660plus driver is the

default driver in Windows, and that the DOS application is set to an HP IIP driver.

05 Ch.4 Console 96.9.24, 0:07 PM11

4—11

Page 43

Chapter 5: Monitoring the Printer Status

Overview

You can monitor the current status of the printer on

your screen. In this chapter you will find information

about

• The Printer Status window and what it does

• Controls you can exercise over the printer from

this window

• Problems that may arise when you print, and how

you can resolve them from this window

5

Monitoring the Printer Status

06 Ch.5 Monitoring* 96.9.24, 0:53 PM1

5—1

Page 44

Chapter 5: Monitoring the Printer Status

Monitoring the Printer Status

The SuperScript 660plus printer allows you to monitor

the current status of the printer on your computer

using the SuperScript Status program. The program

has two primary functions:

• To let you monitor the status of the printer.

• To alert you when there is a problem, such as

paper running out.

There are two ways to run the Printer Status software.

In Windows 95, click the Start button, point to Programs, NEC SuperScript Tools, and then click Local

Printer Status Display.

In Windows 3.1 or 3.11, double click the NEC

SuperScript Tools program group, then double click

Local Printer Status Display.

Another way to access Printer Status is to click the

Local Printer Status button on the Control Panel tab of

the SuperScript Console.

The Printer Status window also appears automatically

when the software detects a printer error.

Note: On some PCs, when the Printer Status display

appears, shortcut keys are not available but you can

continue to use the mouse.

The SuperScript Printer Status display has three status

indicators, two boxes with information for you, and

various printer control buttons. The status indicators

mimic what you would see on the status panel of your

printer, and provide a quick view of the printer’s

status.

The information box at the top of the Printer Status

window shows the current printer status and displays

an icon if there is an error condition. The information

box at the bottom has specific job information when a

print job is printing or paused.

5—2

06 Ch.5 Monitoring* 96.9.24, 0:54 PM2

Page 45

Chapter 5: Monitoring the Printer Status

The SuperScript Printer Status icons with brief descriptions of what they do are as follows:

Table 5-1 Printer Status

ICON DESCRIPTION

Expand: Expands the Printer Status

display. You use this when an error

occurs and you want more detailed

information about the recommended

solution.

Reduce: Reduces the Printer Status

display.

Pause: Pauses the printer.

Resume: Resumes the print job if it has

been paused. There are some error

conditions where fixing the problem

causes the printer to resume automatically. However, some error conditions

require that you resume printing after

the problem is fixed.

Expanded SuperScript Printer

Status Display

The Expanded Printer Status display has several

features that monitor, control, and resolve printer

errors. To expand the information you can get on the

Printer Status display, click the Expand button.

Printer Error Status Messages and Recovery

Part of the display shows a printer animation that

highlights the problem area on the printer and provides instructions on how to resolve it. To access the

printer animation, click the button in the upper left

corner of the dialog box with the picture of the printer.

This window provides animated help and walks you

through the steps required to get your printer running

again. In most cases, printing will resume automatically once the problem has been resolved. In some

06 Ch.5 Monitoring* 96.9.24, 0:55 PM3

Delete: Deletes the job that is currently

printing.

5—3

Page 46

Chapter 5: Monitoring the Printer Status

cases you must click Resume.

Paper Out

The printer has run out of paper. Add more paper to

the paper tray.

Paper Jam

Paper has jammed inside the printer, making it impossible to continue printing. Open the printer cover,

remove all paper, and close the cover.

The printer starts up again automatically once the jam

has been cleared. The printer reprints the page that

jammed before continuing with the rest of your document.

Cover Open or Toner Cartridge Missing

Either your printer cover is open, or there is no toner

cartridge in the printer. Insert a toner cartridge if

necessary, then firmly close the printer cover.

Duplex Printing

Duplex (double-sided) mode is enabled, and the

printer has finished printing one side of your document. Turn the sheets over and reinsert them in the

paper feeder to print the other side. Click on Resume

to continue printing.

Power Off or Cable Problem

The NEC SuperScript software cannot find your

printer, either because the power is off, the cable is not

installed properly, or there is a problem with the

connection. Make sure the power switch is turned on,

the cable fits snugly, and nothing else is wrong with

the connection.

Engine is Warming Up

Wait until the printer’s engine has finished warming

up. The NEC SuperScript will be ready to start printing

as soon as it is warmed up.

Engine Error

If there is a problem with the printer engine, call NEC

Technical Support at 1-800-632-4650. See the Appendix

on Technical Support for more information about

obtaining technical support.

06 Ch.5 Monitoring* 96.9.24, 0:56 PM4

5—4

Page 47

Chapter 6: Maintaining the Printer

Overview

This chapter provides the information you use when

you need to

• Replace the Toner Module

• Replace the Photoconductor Module

• Clean the printer

6

Maintaining the Printer

07 Ch.6 Maintaining* 96.9.24, 0:57 PM1

6—1

Page 48

Chapter 6: Maintaining the Printer

Maintaining the Printer

Replacing the Toner Module

Each toner module contains toner that can print up to

3,000 letter size prints. (The number of prints is

calculated based on an average image density

equivalent to a black-to-white ratio of 5% or lower.)

More or fewer will print depending on the image

density.

As the amount of toner still available for use in the

toner module is reduced, the print image gradually

becomes lighter. When that happens, remove the toner

module from the printer, shake it two to three times,

and reinstall it. If this still does not make the image

darker, replace the toner module with a new one,

following the procedure in the Setting Up the

Photoconductor Module and Toner Module section in

Chapter 2.

Replacing the Photoconductor Module

Each photoconductor module can print up to about

20,000 prints under the following conditions: NEC

recommended paper, continuous printing, and a black

to white ratio of 5%. The number of prints may be

fewer depending on print conditions, such as number

of prints you make at a time, the kind of paper, or the

print density.

After the photoconductor module has turned out more

than 20,000 prints, the print image may become faint

and blurred. If this happens, replace the

photoconductor module with a new one, following the

procedure in the Setting Up the Photoconductor

Module and Toner Module section in Chapter 2.

Cleaning the Printer

Dust, dirt, and paper dust inside and outside the

printer aggravate printer performance and affect print

quality, making it necessary to clean the printer at

regular intervals.

Caution! Before starting the cleaning procedure,

be sure to turn the Power Switch OFF, and unplug

the power cord from the outlet.

Caution! The fuser unit inside the printer can

become very hot. Wait at least 10 minutes after the

printer has been shut down, and make sure that the

fuser unit has cooled down before touching the

interior.

07 Ch.6 Maintaining* 96.9.24, 0:58 PM2

6—2

Page 49

Chapter 6: Maintaining the Printer

Cleaning the Outside

• Using a soft cloth dampened with mild detergent,

wipe the outside of the printer. Do not use abrasives

or corrosive detergents.

Cleaning the Transport Roller and Transfer Unit

1. Press the top cover release button, and swing open

the cover completely.

2. Remove the toner module, and then the

photoconductor module.

Caution! Whenever you remove the

photoconductor module, wrap it in a cloth

immediately to prevent light from striking it.

3. Turning the transport roller drive gear, wipe the

transport roller clean with a soft cloth.

07 Ch.6 Maintaining* 96.9.24, 0:59 PM3

4. Unsnap the transfer unit cleaner from the printer

cover.

6—3

Page 50

Chapter 6: Maintaining the Printer

6. Press the cleaner slightly, then gently slide it

over the transfer unit, from right end to left end.

Then gently slide the cleaner on the transfer unit

from left end to right end. Repeat this motion three

times.

5. Insert the cleaner into the transfer unit as

shown in the illustration below.

Rear side

Front side

1.

2.

.

6—4

07 Ch.6 Maintaining* 96.9.24, 0:59 PM4

Page 51

Chapter 6: Maintaining the Printer

7. Take the cleaner out of the transfer unit, then

re-attach the cleaner back on to the printer cover.

8. Reinstall the photoconductor module and the toner

module according to the directions in Chapter 2.

9. Press the top cover down gently, and close it securely.

07 Ch.6 Maintaining* 96.9.24, 0:59 PM5

6—5

Page 52

Appendix A: Troubleshooting

Troubleshooting

Overview

This Appendix contains information about common

problems that arise using a printer, and it suggests

solutions for them. It has information about

• The meaning of the indicator lights on the printer

• Suggestions for maintaining high-quality output

• How to deal with pages that print badly

• How to deal with paper jams

• What to do about installation problems, hardware

problems, a shortage of disk space, or a problem

with the printer port

• How to remove previously installed SuperScript

software

A

08 App.A Trouble 96.9.24, 1:01 PM1

A—1

Page 53

Appendix A: Troubleshooting

Maintaining Print Quality

Following are some suggestions for maintaining the

highest print quality from your printer.

• When the print output becomes light, redistribute

the toner. If light print persists, replace the toner

module or the photoconductor module. Refer to

Chapter 2 for information about replacing these

modules.

• Use high-quality paper or transparencies to obtain

sharp, crisp characters and maximum contrast.

Refer to Appendix D, Selecting Print Media, for

detailed specifications.

• Clean the appropriate parts of the printer. Refer to

Chapter 6, Maintaining the Printer, for instructions.

This section has information about resolving paper

jams and other printer output quality problems. Table

A-1 lists some solutions for occasional printer problems.

Table A-1 Simple Problems and Solutions

CONDITION SOLUTION

Check that the power cord is plugged

into a live outlet and the printer

power switch is turned on.

Check that upper cover is closed by

opening and closing it.

Check that the toner module and/or

the photoconductor module are

installed.

Try powering the printer off and on.

Check that all interface cable

connections are tightly secured.

Check for a paper jam or misfeed.

Check that the toner module and/or

the photoconductor module are

installed.

Check that the hopper has paper

loaded.

Check for a paper jam or misfeed.

Check that the paper is between 16

and 22 pounds base weight.

Power light is off

Red Attention light is steady and

printer does not print

Amber paper light is on and

printer does not print

Paper does not output to tray

Paper does not stack correctly

Red Attention light is blinking

and printer does not print

08 App.A Trouble 96.9.24, 1:02 PM2

A—2

Page 54

Appendix A: Troubleshooting

Output Quality

This section has information to help you resolve print

output quality problems.

Light Page

• Clean the transfer unit with the Transfer Unit

Cleaner.

(Refer to Chapter 6, Maintaining the Printer.)

• Check to see if the toner is running low.

• Redistribute the toner. (Shake the toner module.

Reinsert the module and print several pages.)

• Replace the toner module.

• Replace the photoconductor module.

• If the problem persists, the transfer unit may need

to be replaced. Contact NEC Customer Service .

Light Page

Blank Page

• Clean the transfer unit with the Transfer Unit

Cleaner. (Refer to Chapter 6, Maintaining the

Printer.)

• Make sure the toner module and the

photoconductor module are installed correctly

• Make sure you are using a standard Centronics

parallel cable, and that your PC has a standard

parallel port.

• If necessary, replace the toner module or

photoconductor module.

• If the problem persists, the transfer unit may need

to be replaced. Contact NEC Customer Service.

Blank Page

08 App.A Trouble 96.9.24, 1:03 PM3

A—3

Page 55

Appendix A: Troubleshooting

Blank Spots

• Use a fresh ream of paper. Paper should be stored

in its original package to keep it from absorbing

moisture.

• Check paper specifications (See Appendix D).

• Clean the transfer unit with the Transfer Unit

Cleaner.

• Shake the toner module. Reinsert the module and

print several pages.

• Reinsert the photoconductor module correctly and

print several pages.

• Install a new toner module.

• Install a new photoconductor module.

• If the problem persists, the transfer unit may need

to be replaced. Contact NEC Customer Service.

Black Page

• Reinstall the toner module and the

photoconductor module.

• If necessary, replace the photoconductor module.

Black Page

Streaked Page

• Check for any torn pieces of paper in the paper

path from a previous paper jam.

• Clean the transfer unit with the Transfer Unit

Cleaner (Refer to chapter 6, Maintaining the

Printer.)

• Shake the toner module. Reinsert the module and

print several pages.

• Install a new toner module or photoconductor

module, or both.

• If the problem persists, the Transfer Unit or Eject

Roller may need to be replaced. Contact NEC

Customer Service.

Streaked Page

A—4

08 App.A Trouble 96.9.24, 1:04 PM4

Page 56

Appendix A: Troubleshooting

Solid White Vertical Lines

• Check for any torn pieces of paper remaining in

the paper path from a previous paper jam.

• Clean the transfer unit with the transfer unit

cleaner.

• Rock the toner module, reinsert it, and print

several pages. If necessary, install a new toner

module.

• If the problem persists, the transfer unit may need

to be replaced. Contact NEC Customer Service.

Solid White Vertical Lines

Incomplete Page

• An incomplete page may be printed when you are

printing a complex image. Add an optional

memory expansion module to the printer. Refer to

Appendix C, Printer Options.

Correcting Paper Jams

When the paper path is blocked, the printer stops

printing, and “Paper Jam” is displayed on your screen.

Do not pull the paper out forcefully because it may

tear, leaving pieces of paper in the printer that may

prevent the printer from feeding sheets normally.

Remove the jam with care according to the following

procedures.

Caution! Do not touch the fuser unit, it is extremely

hot.

1. Press the top cover release button, then swing the

cover open completely.

08 App.A Trouble 96.9.24, 1:04 PM5

A—5

Page 57

Appendix A: Troubleshooting

2. Take the toner module and the photoconductor

module out of the printer.

Caution! Whenever the photoconductor module is

removed from the printer, be sure to cover it with a

cloth to prevent light from striking it.

3. Pull the misfed sheet out from inside the printer.

• The leading edge of the paper is visible after

the paper take-up section.

front of the fusing unit.

4. Pull the misfed sheet at the exit toward the print

tray.

• The trailing edge of the paper is visible in

A—6

08 App.A Trouble 96.9.24, 1:05 PM6

5. Remove the stack of paper from the paper tray

Page 58

Appendix A: Troubleshooting

and pull out the misfed sheet from inside

the printer.

6. If you used the manual feeding slot, pull out the

paper that was inserted into it.

main feeder.

• Press the paper lifting plate of the 250-sheet

hopper, together with the paper stack on the

tray, down into locked position.

• Remove the paper stack from the tray and pull

out the misfed sheet.

7. If you used the optional 250-sheet hopper, remove

08 App.A Trouble 96.9.24, 1:05 PM7

A—7

Page 59

Appendix A: Troubleshooting

8. Reinstall the photoconductor module and then the

toner module. Refer to Chapter 2 for details on

how to install these modules.

Installation Problems

If you have any problems installing the printer, review

the following information to help you resolve any

difficulty.

Wrong System or Hardware Configuration

If the installation program detects that your PC is not

powerful enough, it quits without installing

SuperScript. Refer to Chapter 2 for information about

detailed system requirements.

9. Press down gently on the printer cover to close it

securely.

Note: If the paper jams frequently, the fuser unit

may need to be replaced. Contact NEC Customer

Service.

A—8

Insufficient Memory

SuperScript requires at least 8 megabytes of memory

(8MB RAM) to install. If the installation program

detects that your PC does not have sufficient memory, it

will quit without installing SuperScript.

No Printer Port

To connect to a SuperScript printer, a parallel port is

required. If the installation program does not detect a

parallel port it will notify you, but it will allow you to

continue installation.

Insufficient Disk Space

SuperScript software requires at least 40 megabytes of

free disk space. Clear enough disk space on your hard