Page 1

Silentwriter

SuperScript 610

User's Guide

Page 2

PROPRIETARY NOTICE AND LIABILITY DISCLAIMER

The information disclosed in this document, including all designs and related materials, is the valuable property of NEC Corporation (NEC) and/or its licensers. NEC and/

or its licensers, as appropriate, reserve all patent, copyright and other proprietary rights

to this document, including all design, manufacturing, reproduction, use, and sales

rights thereto, except to the extent said rights are expressly granted to others.

The NEC product(s) discussed in this document are warranted in accordance with the

terms of the applicable NEC product specification. However, actual performance of

each such product is dependent upon factors such as system configuration, customer

data, and operator control. Since implementation by customers of each product may

vary, the suitability of specific product configurations and applications must be

determined by the customer and is not warranted by NEC.

To allow for design and specification improvements, the information in this document

is subject to change at any time, without notice. Reproduction of this document or

portions thereof without prior written approval of NEC is prohibited.

Silentwriter is a U.S. registered trademark of NEC Corporation. All other product, brand, or trade

names used in this publication are the trademarks or registered trademarks of their respective owners.

© Copyright, WinRefs 1993, Destiny Technology Corp. Ver. 1.0

© Copyright, 1992, Microsoft Corporation

First Printing — Oct. 1993

Revised — April 1994

Copyright 1993

NEC Corporation

7-1 Shiba 5-Chome, Minato-ku

Tokyo 108-01, Japan

All Rights Reserved

Page 3

Contents iii

Contents

Using This Guide ............................................................... ix

1. Introduction

How the Printing Process Works.............. 1-2

Standard Features ..................................... 1-3

Optional Features...................................... 1-6

Ordering Supplies and Accessories .......... 1-7

2. Setting Up

Unpacking................................................. 2-1

Unpacking ............................................. 2-1

Locating the Printer Items..................... 2-2

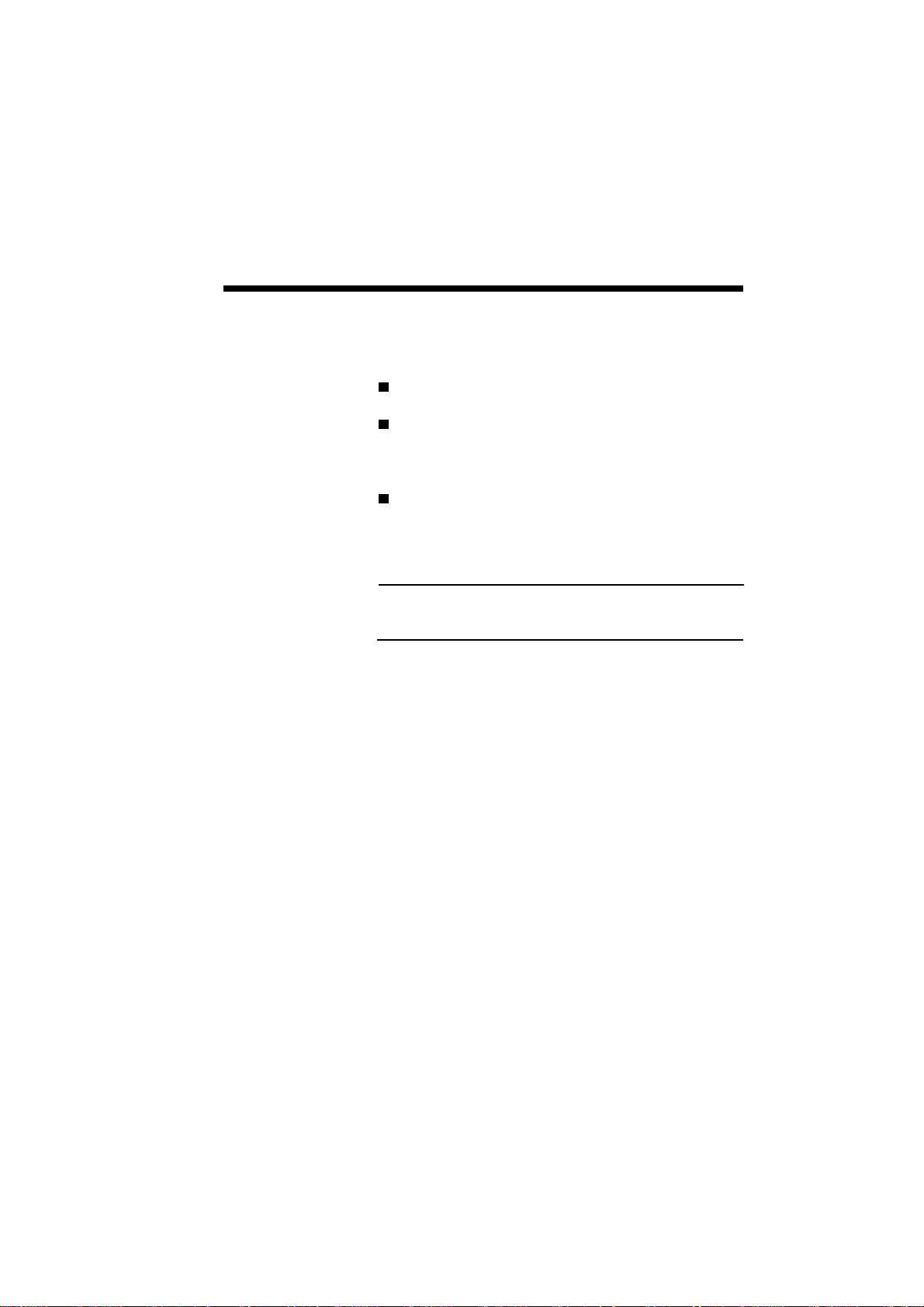

Operating Requirements........................... 2-3

Printer Dimensions................................ 2-5

Printer Dimensions

with 200-sheet Hopper........................ 2-6

System Requirements ............................... 2-7

External Printer Parts................................ 2-8

Internal Printer Parts............................... 2-11

Toner Cartridge ...................................... 2-13

Preparing the Toner Cartridge ............ 2-14

Installing the Toner Cartridge............. 2-17

Installing Paper....................................... 2-20

Interface Cable........................................ 2-23

Power Cord............................................. 2-25

Installing SuperScript Printing Software 2-27

3. Printing with Your Silentwriter SuperScript 610

Silentwriter SuperScript Print Modes....... 3-1

GDI Mode................................................. 3-2

GDI Setup Screen ................................. 3-2

GDI Option Screen ............................... 3-5

Printing Status Option........................... 3-6

Page 4

iv Contents

Manual Duplex Printing........................ 3-6

PCL Print Mode...................................... 3-11

Saving Downloaded Fonts and Macros3-12

Page Ejects - Form Feeds

(PCL Mode).................................... 3-13

Printing from a Windows Application ... 3-14

Printing from DOS Application.............. 3-14

Printing PCL Files from

DOS Command Line........................... 3-14

4. NEC SuperScript Print Manager

5. Print Status Window

6. Selecting Paper and Media

Paper Properties........................................ 6-2

Print Areas ............................................ 6-3

Paper and Media Use ............................ 6-4

Preprinted Forms................................... 6-5

Heavy Print Stock ................................. 6-6

Envelopes.............................................. 6-6

Adhesive Labels.................................... 6-8

Transparency Film ................................ 6-9

Media Purchasing Specifications ............. 6-9

Sheet Paper.......................................... 6-10

Envelopes............................................ 6-12

Adhesive Labels.................................. 6-13

Transparency Film .............................. 6-14

Storage Guidelines.................................. 6-14

7. Using Fonts

Fonts in GDI Mode................................... 7-1

Fonts in PCL Mode .................................. 7-3

8. Choosing Print Options

How to Print Using Various Media .......... 8-2

The Standard Hopper................................ 8-4

Page 5

Multi-sheet Feed and Single-sheet Feed8-4

Loading the Paper ................................. 8-4

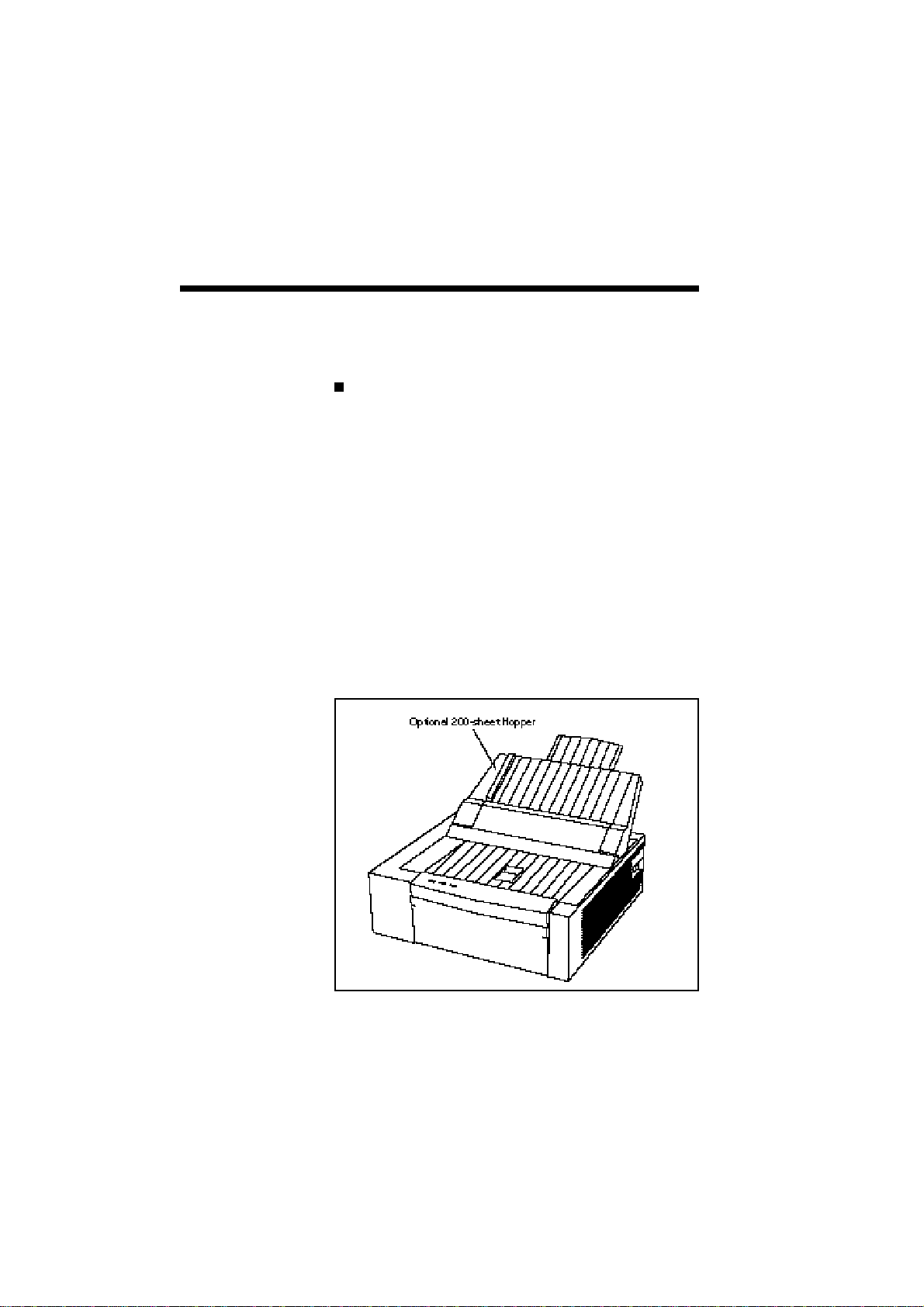

The 200-sheet Paper Hopper (Optional)... 8-7

Removing the Standard Hopper............ 8-8

Installing the 200-sheet Paper Hopper.. 8-9

Hopper Feed........................................ 8-10

Manual Feed........................................ 8-13

Removing the 200-sheet Hopper ........ 8-15

Output Paths ........................................... 8-16

Face-up Tray ....................................... 8-17

Face-down Door.................................. 8-17

9. Maintaining Your Printer

Redistributing the Toner........................... 9-2

Cleaning the Printer.................................. 9-7

Replacing the Toner Cartridge ................. 9-8

Cleaning the Printer Mechanism........... 9-8

Cleaning Conditions.......................... 9-9

Parts to Be Cleaned ......................... 9-10

Cleaning Procedure ......................... 9-12

Installing the Toner Cartridge............. 9-16

Transporting the Printer.......................... 9-22

Removing the Toner Cartridge ........... 9-22

Removing the 200-sheet Hopper ........ 9-24

Removing the Interface Cable ............ 9-24

Removing the Power Cord.................. 9-25

Check List Before

Transporting the Printer........................ 9-26

Contents v

10.Troubleshooting

Print Quality Maintenance...................... 10-2

Paper Jam................................................ 10-2

Locations of Potential Paper Jams ...... 10-3

Removing Jammed Paper ................... 10-3

Paper Jams in the Hopper................ 10-4

Paper Jams in the Fuser Unit........... 10-5

Points to Check to Avoid

Paper Jams ........................................ 10-7

Testing the Printer .................................. 10-8

Page 6

vi Contents

Status Messages.................................... 10-10

Installation Problems ........................ 10-10

Operating Problems .......................... 10-14

Output Quality ...................................... 10-26

Light Page ......................................... 10-26

Blank Page ........................................ 10-27

Black Page ........................................ 10-28

Streaked Page.................................... 10-29

Spots on Back of Paper..................... 10-30

Blank Spots ....................................... 10-31

Solid White Vertical Line ................. 10-32

Graphics Appear Coarse

in GDI Mode................................... 10-33

Text Appears Jagged or Low

Resolution in GDI Mode................. 10-33

Unexpected Font in Either GDI or

PCL Mode....................................... 10-34

Unexpected Font in PCL Mode ........ 10-35

Shifted or Broken Image................... 10-35

Allocating Virtual Memory .................. 10-36

Commonly Asked Questions................ 10-38

A Character Sets

B Optimizing Printer Performance

C Specifications

D Interface Cable Specifications

E Removing SuperScript Files from Your System

Glossary

Index

Page 7

List of Tables

Contents vii

1-1 Supplies and Accessories ............... 1-7

6-1 Paper Specifications ..................... 6-10

6-2 Envelope Specifications ............... 6-12

6-3 Label Specifications ..................... 6-13

6-4 Transparency Specifications ........ 6-14

8-1-a Recommended Printing Methods

[The Standard Hopper]................... 8-2

8-1-b Recommended Printing Methods

[Optional 200-sheet Hopper].......... 8-3

10-1 Simple Troubleshooting ............... 10-1

Page 8

viii Contents

Page 9

Using this Guide

This guide provides an introduction to the NEC

Silentwriter SuperScript 610 printer and includes

information about its setting up, features, operation,

and maintenance.

If you are just beginning to use it, you may want to

read this entire user’s guide to familiarize yourself

with the printer. If you have been using the printer

for some time, you can scan the Contents for specific information that you need.

Contents ix

Page 10

x Contents

Page 11

1

Introduction 1–1

Introduction

This guide provides complete instructions for operating your new NEC Silentwriter® SuperScript 610

printer. All printer features are explained and

illustrated in detail.

Silentwriter SuperScript 610 is a new laser printer

that has been developed specially for users of

WindowsTM version 3.1. This printer is provided

with the SuperScript software kit and requires no

special add-in cards, cartridges, or cables.

Silentwriter SuperScript 610 differs from other

printers in that it is directly driven by the CPU of

your computer; hence, it has faster response and

better status information. In addition, by expanding

the memory of your computer or upgrading to a

more powerful PC, the performance of your

SuperScript 610 can also be improved.

NEC SuperScript software supports two printing

modes, namely, GDI mode and PCL emulation

mode. GDI mode offers the full performance of the

total printing system while the PCL emulation mode

offers compatibility with existing PCL print files.

Your computer and Silentwriter SuperScript 610

communicate bi-directionally to exchange the

operating status information (i. e., warm-up, paper

out, paper jam, etc.) of SuperScript 610 to display

messages requiring your attention on your screen, if

necessary. Hence, you can focus on your work

without referring to the printer operator panel

periodically, a benefit brought by the SuperScript

software.

Page 12

1–2 Introduction

The SuperScript 610 is designed as a personal laser

printer to conserve desk space and it features low

power consumption .

HOW THE

PRINTING

PROCESS

WORKS

Whenever you send a job to the printer, an “image”

of the page to be printed is temporarily written to the

rotating surface of an electrophotographic (EP)

drum. This image acts like a magnet that attracts

toner to the drum. (The toner and the drum are

grouped in one self-contained cartridge.)

At the same time, paper (or transparency film or

envelope) passes through the printer and near the

drum. The paper is electrostatically charged as it

reaches the drum.

Toner, previously attracted to the drum as image

areas, is transferred to the charged paper. The paper

then passes between two rollers where a combination

of heat and pressure bonds the toner to the paper.

The paper is then moved to the output tray.

Page 13

Introduction 1–3

STANDARD

FEATURES

The following list highlights Silentwriter SuperScript

610 features.

Host-based Processing

As mentioned in the introduction section,

SuperScript uses your PC power to handle print

tasks.

Two Printing Modes

The Silentwriter SuperScript 610 software allows

you to select from two different modes of

printing:

• GDI mode provides fast, WYSIWYG (What

You See Is What You Get) output.

• PCL emulation mode provides compatibility

with the popular printer language used in the

LaserJet® IIP. Both Windows and DOS

applications running under Windows can use

PCL emulation mode for printing.

Print speed: up to 6 pages per minute.

Print resolution: 300 dots per inch.

Page 14

1–4 Introduction

Sharp Edge Technology

Silentwriter SuperScript 610 features the

patented Sharp Edge Technology (SET). This

feature detects and smoothes jagged edges of

raster images to be printed by dividing one full

dot into several subdots to be set in the appropriate position. The print quality of both text and

graphics will be improved.

Paper input: from a 50-sheet hopper supporting:

Paper:

1 Letter

2 A4

3 Executive

4 A5

Envelope:

1 Monarch

2 Commercial 10

3 DL

4 C5

Page 15

Introduction 1–5

Paper output: face-up tray with a maximum

capacity of 50 sheets (at 64 g/m2), or face-down

door.

Toner cartridge: clean, efficient printer

operation centered around one easily replaceable

cartridge. The Starter Toner Cartridge which is

shipped with your printer will print 2,000 pages

(at 5% coverage). Replacement toner cartridge

will print 4,000 pages (at 5% coverage).

Product quality and support: the design quality

and workmanship shared by all NEC printers,

backed by our total commitment to full product

support.

Power Saving Mode

This printer has the Power Saving Mode. In this

mode, if there is no print job within specified

time (default 15 minutes) while printer is idle,

the fuser unit pauses and power consumption

will be decreased. However the next printing

operation needs a certain warming up time.

The printer is in the Power Saving Mode when it

is turned on. You can also select either "Power

Saving Mode ON" or "Power Saving Mode

OFF" in NEC SuperScript Print Manager (See

Chapter 4, NEC SuperScript Print Manager).

Page 16

1–6 Introduction

OPTIONAL

FEATURES

The optional feature available for the Silentwriter

SuperScript 610 include the following.

Optional 200-sheet Paper Hopper supporting:

Paper:

1 Letter

2 A4

3 Executive

4 A5

Envelope:

1 Monarch

2 Commercial 10

3 DL

4 C5

Page 17

Introduction 1–7

ORDERING

SUPPLIES AND

ACCESSORIES

To order any of the following printer supplies or

accessories, contact your NEC printer dealer.

Table 1-1 Supplies and Accessories

PRODUCT

ORDER NUMBER

Toner Cartridge 135-037681-201-A

Optional 200-sheet Hopper 135-006432-201-A

For a detailed description of the PCL’s printer

language, the LaserJet IIP Printer Technical Refer-

ence Manual is available through the Hewlett

Packard Company.

Page 18

1–8 Introduction

Page 19

2

UNPACKING

Setting Up 2–1

Setting Up

Perform the following procedures to set up your

SuperScript 610.

Unpacking

1. Open the box.

2. Take out the documents (including software

diskettes) and the power cord from the box.

3. Take out the Starter Toner Cartridge.

4. Lift the printer together with the packing materi-

als.

Page 20

2–2 Setting Up

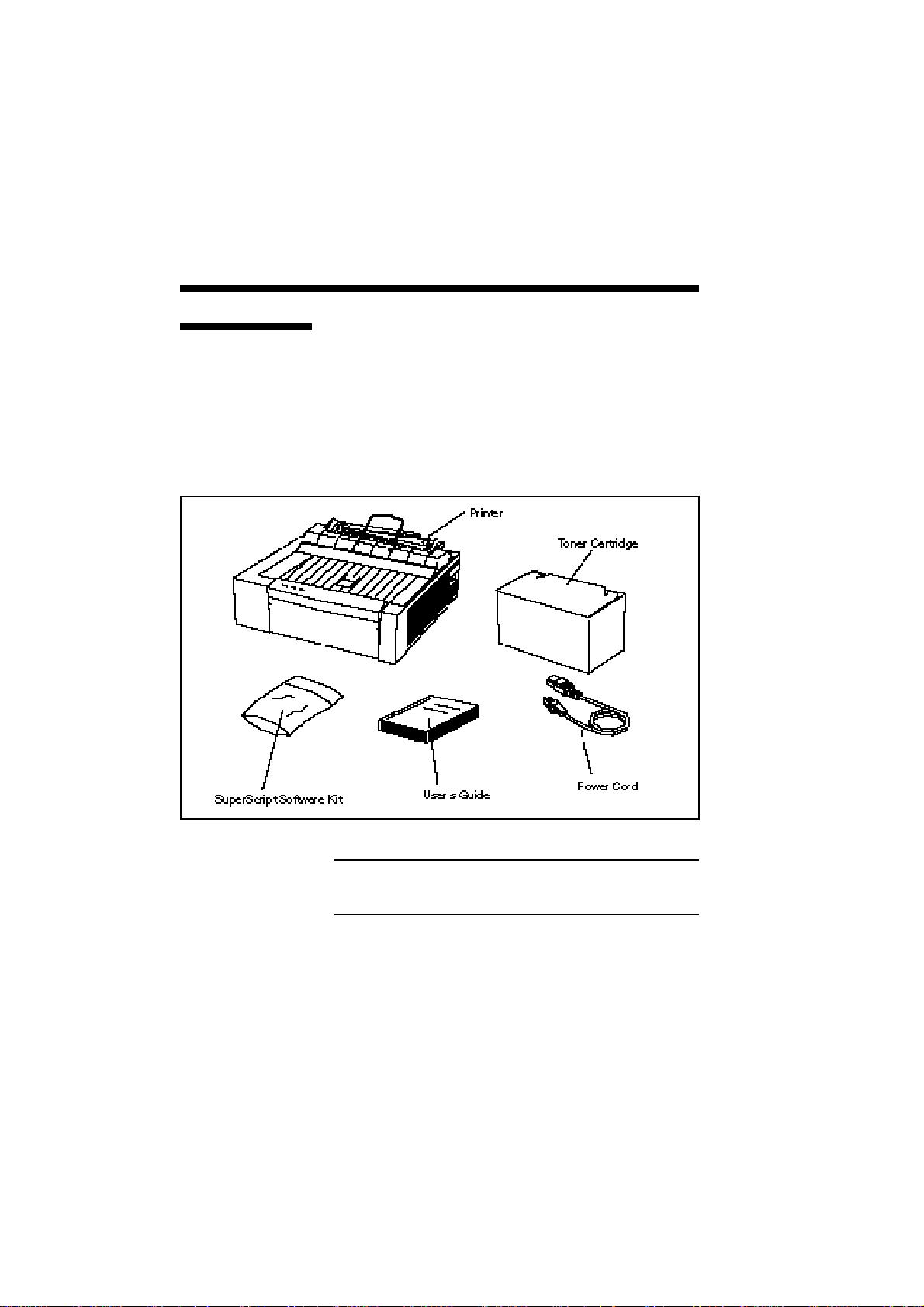

Locating the

Printer Items

Locate the following items:

• NEC Silentwriter SuperScript 610 Printer

• SuperScript software kit

• User’s guide

• Power cord

• Starter Toner Cartridge

• Packing material (not shown)

NOTE: Save this user’s guide and all packing

materials in case the printer needs to be repacked.

Page 21

Setting Up 2–3

OPERATING

REQUIREMENTS

The following operating requirements should be

satisfied:

Place the printer on a sturdy, flat surface.

Keep the room well ventilated with a relative

humidity between 20% and 80% and temperature

between 50˚F and 90.5˚F (10˚C to 32.5˚C)

Leave adequate space around the printer for easy

access (See the following figure.)

WARNING: Do not place objects near the printer

that may cover the ventilation holes on its sides.

Page 22

2–4 Setting Up

Page 23

Setting Up 2–5

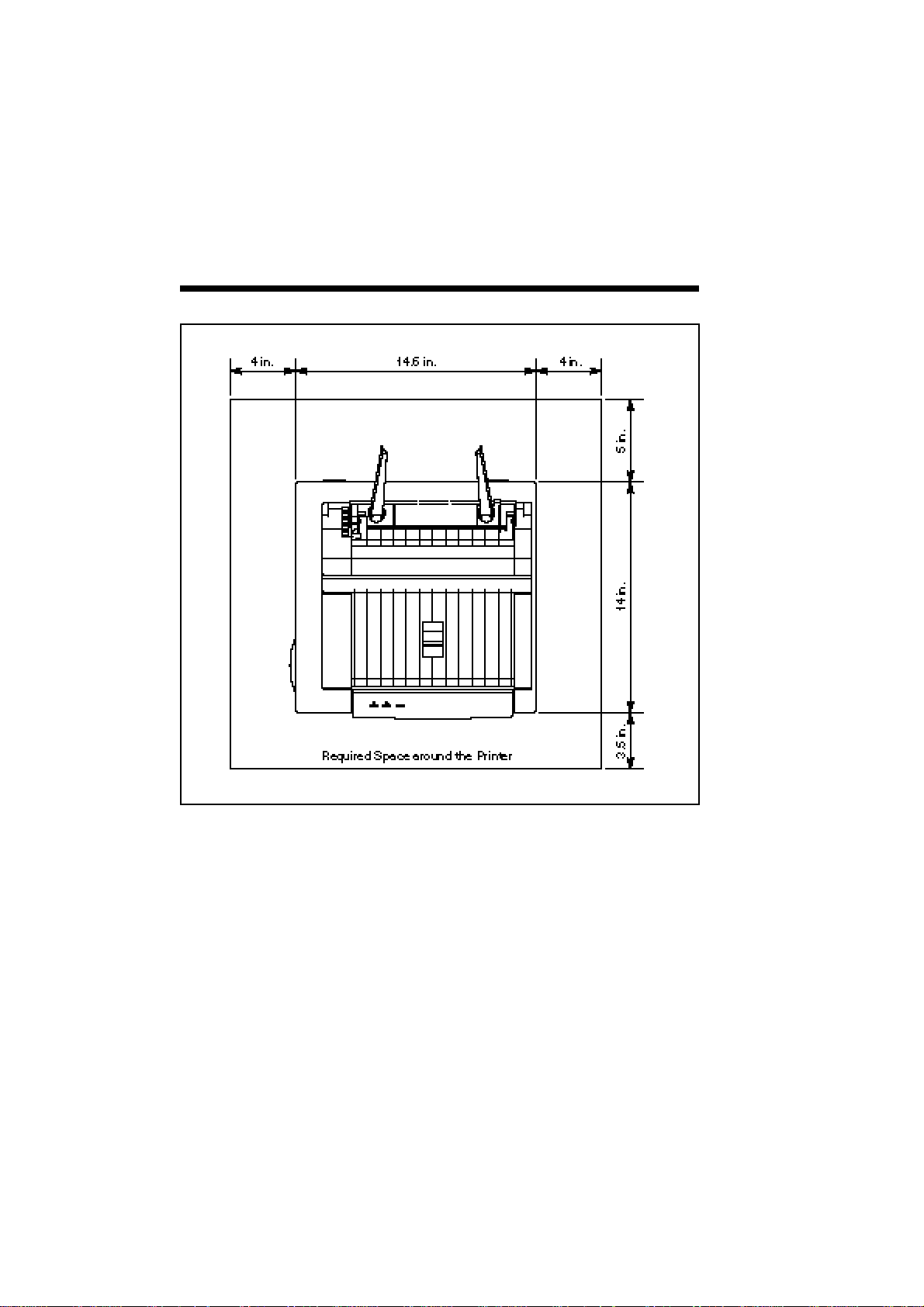

Printer

Dimensions

The following illustration shows the standard dimensions of a Silentwriter SuperScript 610 printer.

Page 24

2–6 Setting Up

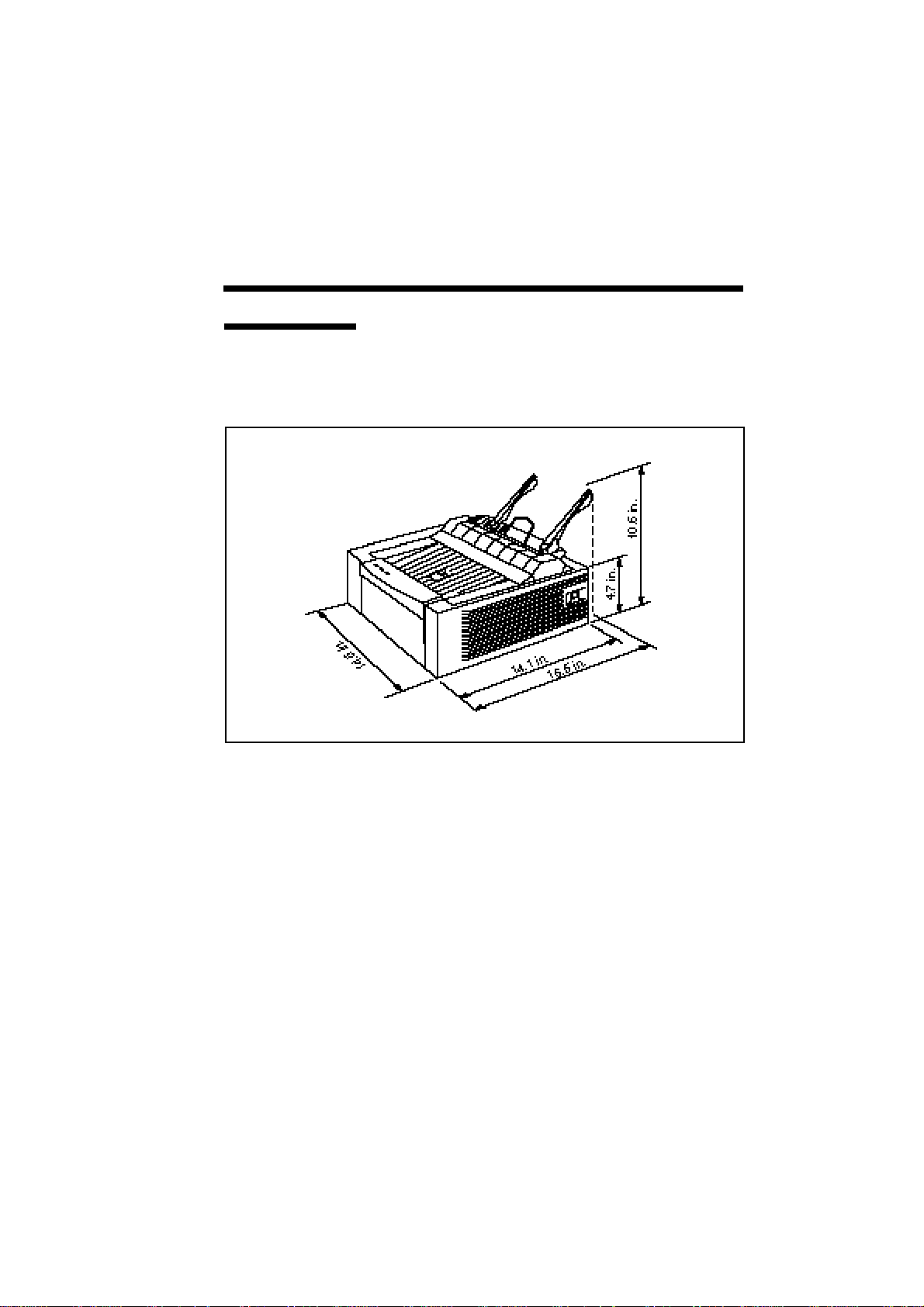

Printer Dimensions with 200sheet Hopper

The following illustration shows the dimensions of a

Silentwriter SuperScript 610 printer when the 50sheet hopper is replaced by the optional 200-sheet

hopper.

Page 25

Setting Up 2–7

SYSTEM REQUIREMENTS

Silentwriter SuperScript 610 works with Windows

3.1, in Enhanced Mode, and requires MS-DOS 3.3 or

later.

To run SuperScript, you will need an IBMcompatible PC with at least a 386SX 16-MHz CPU.

This includes all 486-based and most 386-based PCs.

Some older 386s cannot run in Windows Enhanced

Mode, which means that SuperScript will not work

properly on those systems. SuperScript will not run

on 286-based PCs and other earlier systems. If you

have Windows installed on your PC, you can verify

whether it runs in Enhanced Mode by typing WIN/3

at the MS-DOS prompt. If your PC cannot run

Windows in Enhanced Mode, the system will tell

you.

SuperScript requires at least 4 megabytes PC

memory (RAM), which is the amount of memory

recommended by Microsoft for use with Windows

3.1. Adding more memory to your PC will increase

the overall system and printer performance.

The SuperScript software requires approximately 1.4

megabytes disk space on your system’s hard disk

drive. About 2 megabytes more disk space is needed

to install the SuperScript TrueTypeTM Fonts. In

addition, up to approximately 8.5 megabytes disk

space is required for virtual memory under Windows. (If you have more than 4 megabytes RAM,

you won’t need the entire 8.5 megabytes virtual

memory. The total memory – PC RAM plus virtual

memory – should add up to at least 12.5 megabytes.

See Allocating Virtual Memory, in Chapter 10,

Troubleshooting)

A standard PC parallel printer port is required to

connect with the SuperScript 610 printer through a

standard parallel cable.

Page 26

2–8 Setting Up

NOTE: Because of Silentwriter SuperScript 610’s

high speed interface, it is important to use a properly

manufactured parallel cable. Use of a poor quality

parallel cable may affect your output. See Interface

Cable specification, Appendix D.

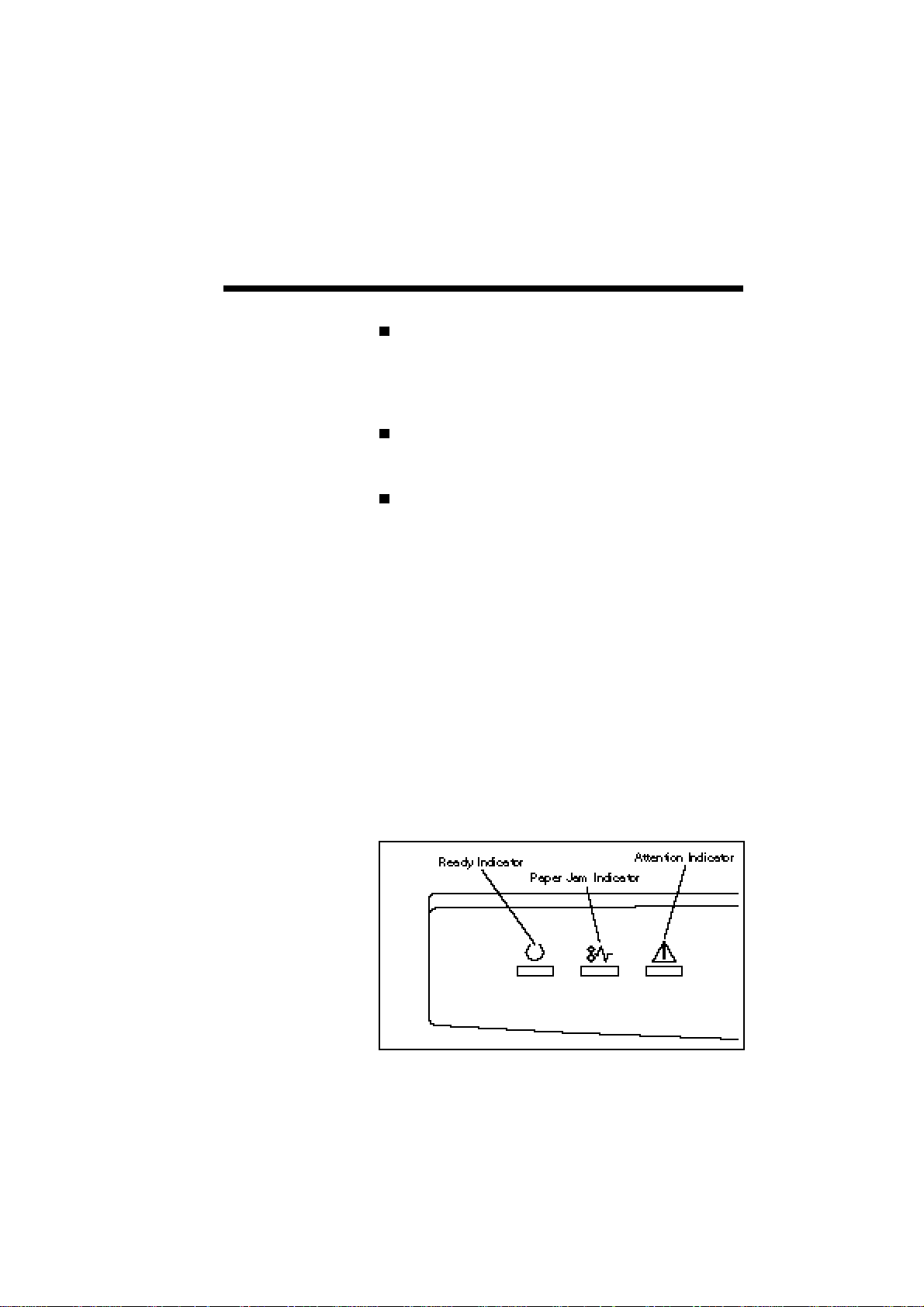

EXTERNAL

PRINTER

PARTS

The following two illustrations show external printer

parts.

Page 27

Setting Up 2–9

Upper Cover (also functions as a face-up tray)

Provides access to the inside of the printer and

stacks printed sheets with printed side facing up.

Maximum capacity: 50 sheets.

Lock Release Lever

Unlocks and opens the upper cover.

Status Panel

There are three indicator lights to show the

operating status of the printer.

- Ready indicator: the left panel light is used to

show that the printer is ready (steady green),

warming up (rapid blinking), or in power

saving mode (slow blinking).

- Paper Jam indicator: the middle panel light

appears in red when the printer detects a paper

jam.

- Attention indicator: the right panel light appears

in red in error conditions other than the paper

jams. For example, paper out, cover open,

toner cartridge missing, or engine malfunction.

Page 28

2–10 Setting Up

Standard Hopper

Holds up to 50 sheets of paper (at 17 lbs).

Face-down Door

Ejects the printed sheets with printed side facing

down.

Power Switch

Turns the printer off or on.

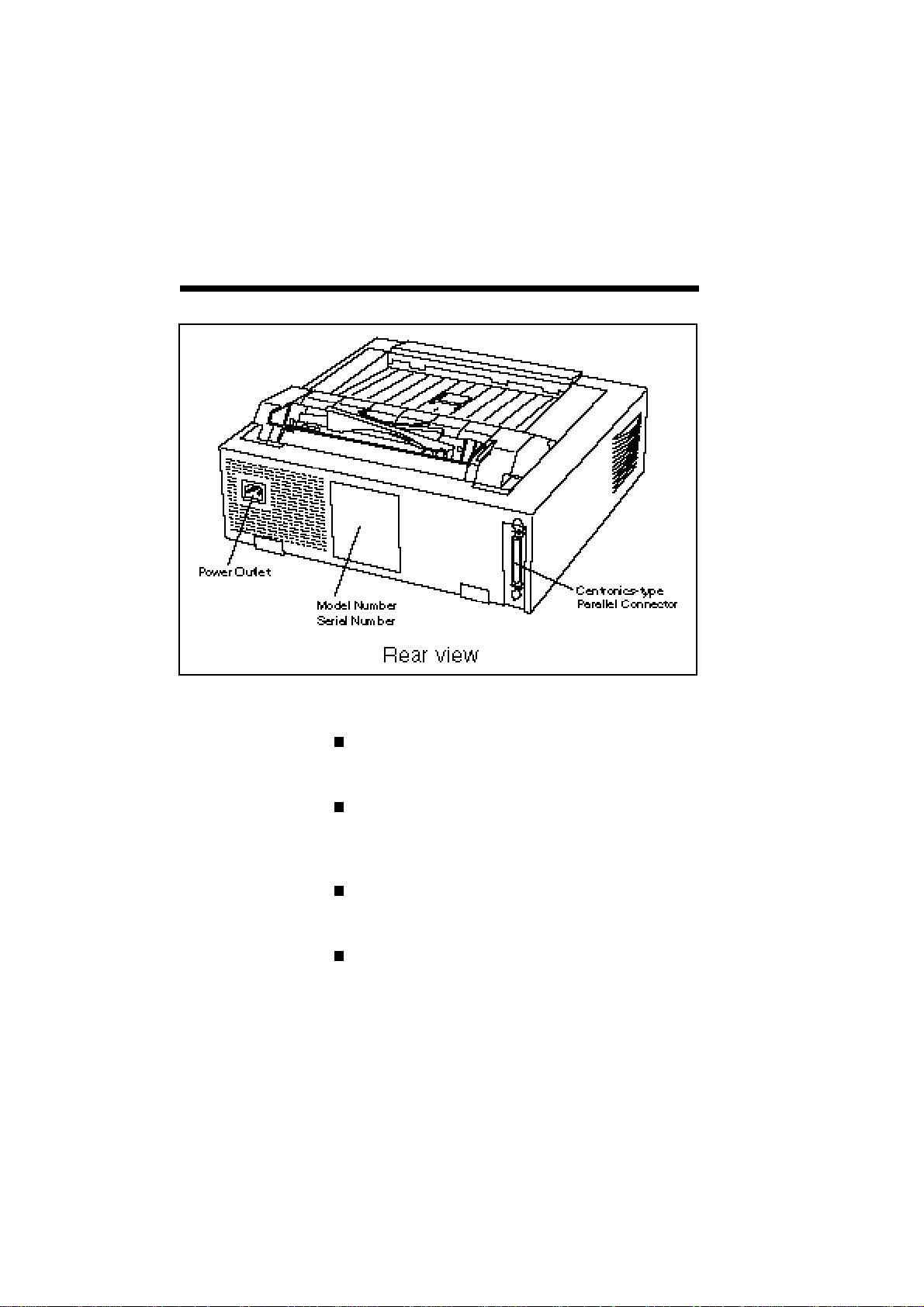

Model Number

Indicates the model number of your printer.

Page 29

Setting Up 2–11

Serial Number

Indicates the serial number of your printer

(You need to enter this number on the warranty

registration)

Parallel Interface

Provides connection to the Centronics-type

parallel interface connector of your computer.

Power Outlet

Connects the power cord to a power outlet.

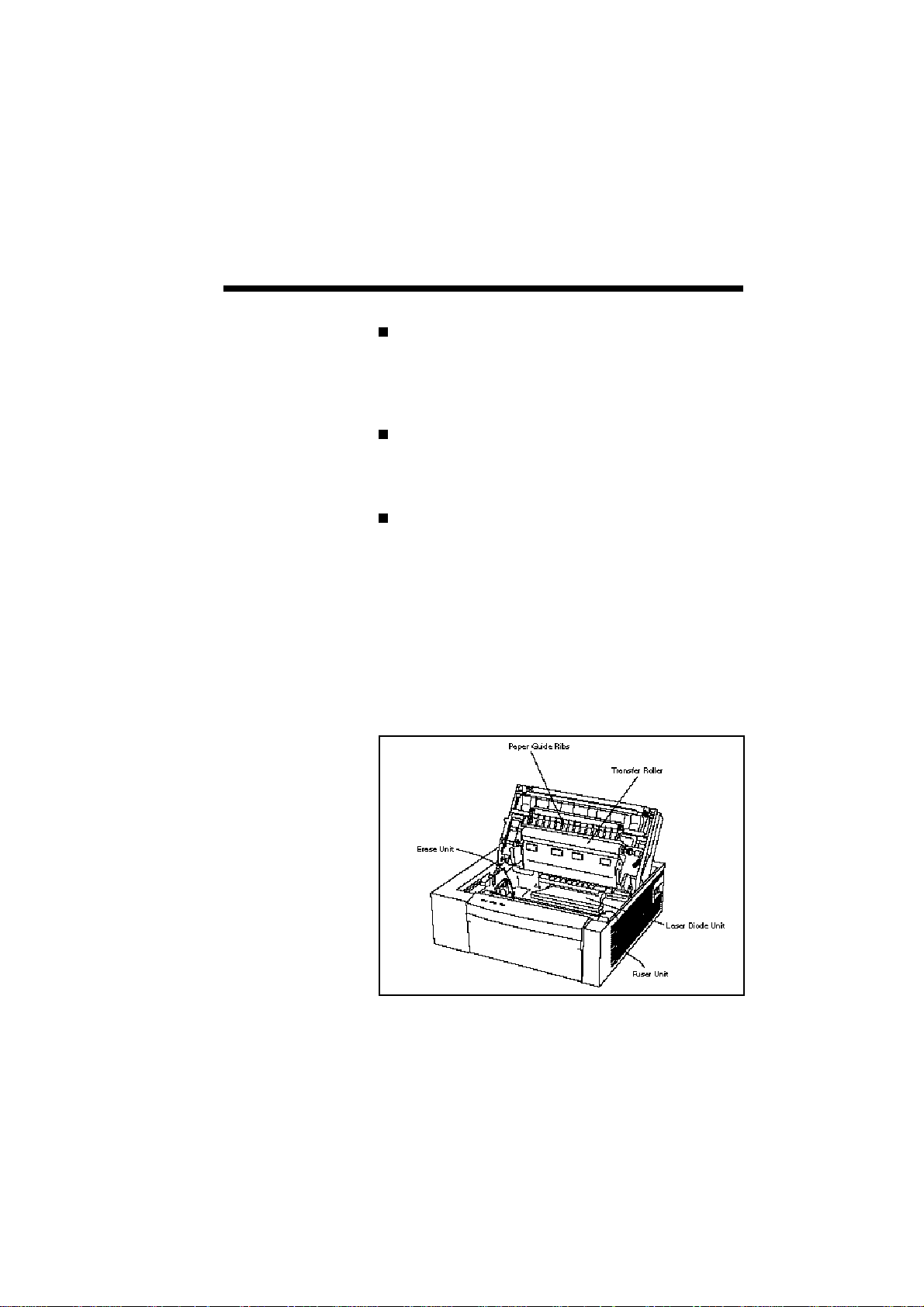

INTERNAL

PRINTER

PARTS

Page 30

2–12 Setting Up

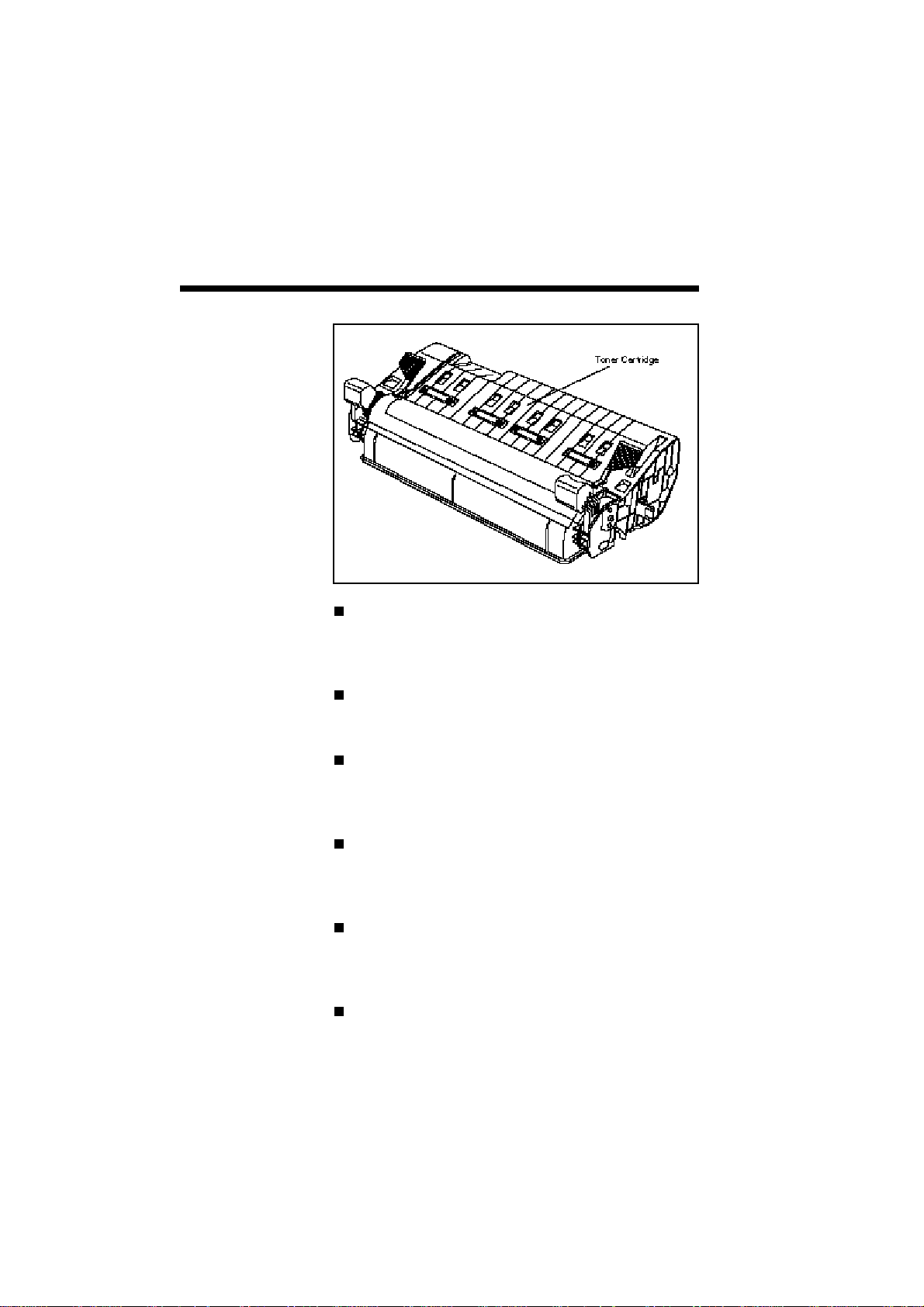

Toner Cartridge

Contains the toner powder used in the printing

process and the EP drum.

Paper Guide Ribs

Guides the sheets to the fuser unit.

Transfer Roller

A high voltage roller that attracts the toner on the

EP drum.

Laser Diode Unit

Exposes and generates the print image on the EP

drum surface.

Erase Unit

Equalizes the distribution of electric potential on

the EP drum.

Fuser Unit

Fixes the toner to the paper.

Page 31

Setting Up 2–13

TONER

CARTRIDGE

The toner cartridge contains toner (a dry ink substance) and an EP drum that transfers the toner to

paper. Unpack the toner cartridge from its box and

install it in the printer as follows:

Unpack the cartridge box.

The cartridge box consists of a carton box, inserts,

and a toner cartridge.

Unpacking illustration

Page 32

2–14 Setting Up

Preparing

the Toner

Cartridge

1. Remove the new toner cartridge from its bag.

2. Hold the cartridge horizontally and gently shake

it five to six times to distribute the toner evenly.

NOTE: Shake the cartridge in the direction indicated

in the illustration. While shaking, take care not to

touch the drum protection shutter (red transparent

plastic) of the toner cartridge.

Page 33

Setting Up 2–15

3. Grasp the yellow toner sealing tape tab and pull

the tape out. The toner sealing tape is

approximately 20 inches long when completely

removed.

NOTE: Be sure to pull the tape straight and slowly

out of the cartridge to prevent it from being broken

in the middle. Be careful not to get toner from the

tape on your hands. If you get toner on your hands,

wash with cold water.

Page 34

2–16 Setting Up

4. Carefully remove the yellow shutter lock pins of

the toner cartridge (2 pieces).

NOTE: Do not touch the drum protection shutter.

Page 35

Setting Up 2–17

Installing

the Toner

Cartridge

1. Check that the power switch is off.

2. Pull the lock release lever of the upper cover and

carefully open it.

Page 36

2–18 Setting Up

3. Hold the toner cartridge by its two green handles

and gently release it bottom first into the printer.

NOTE: Check that the toner cartridge is securely

seated inside the printer.

Page 37

Setting Up 2–19

4. Carefully push down the upper cover to close it.

NOTE: Check that the lock release lever has securely returned to its locked position.

Page 38

2–20 Setting Up

INSTALLING

PAPER

1. Unfold and lock the paper guides of the hopper

starting with 1 and then 2. Then hold the right

paper holder by its foot and position it to the right

edge 3.

2. Pull the paper setting lever in the direction

indicated by the arrow.

Page 39

Setting Up 2–21

3. Insert paper as far as it will go with its edges

evenly touching the left paper guide.

The hopper can accommodate up to approximately 50 sheets. However, load one sheet at a

time in single-sheet feed mode if you are using

legal size paper, heavier paper, envelopes, labels

and transparencies (refer to Chapter 8). To

protect unused sheets from getting excessively

damp or dry, replace them in their protective

cover.

Page 40

2–22 Setting Up

4. Move the right paper guide until it gently touches

the edge of paper.

5. Return the paper setting lever down to its original

position.

NOTE: Check that edges of paper are even.

Otherwise, sheets may not be fed properly, which

may cause print errors.

Page 41

Setting Up 2–23

INTERFACE

CABLE

Use a parallel cable to connect this printer to a

computer.

Connect the interface cable as described below.

1. Switch off power to the printer and the computer.

NOTE: To protect your printer and computer from

possible damage, make sure they are powered down

prior to connection.

Page 42

2–24 Setting Up

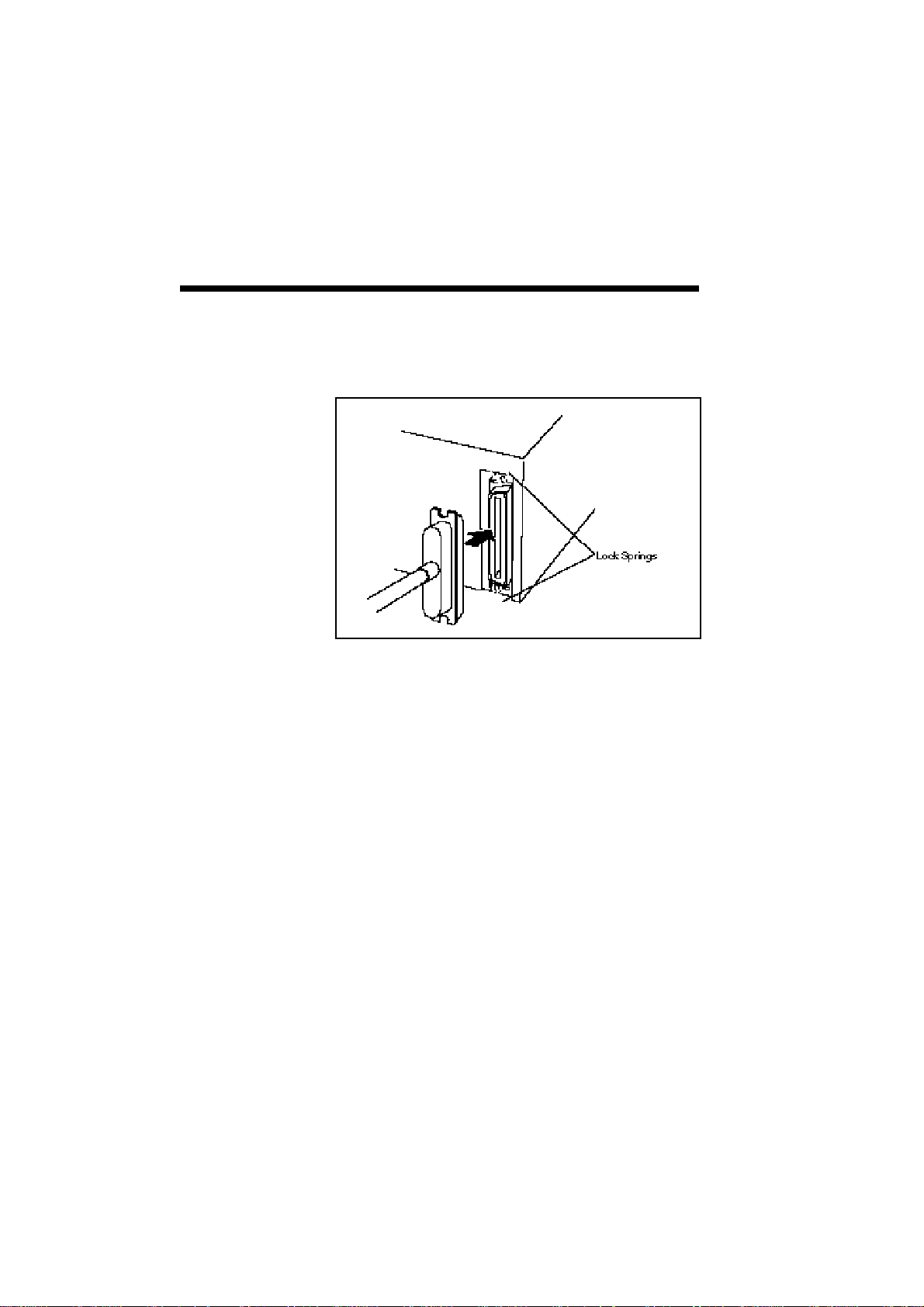

2. Plug the connector of the interface cable into the

printer and then secure the lock springs.

3. Connect the other end of the cable to the compu-

ter. Refer to the computer manual for details

about selection of a proper connector to interface

your printer to.

Page 43

Setting Up 2–25

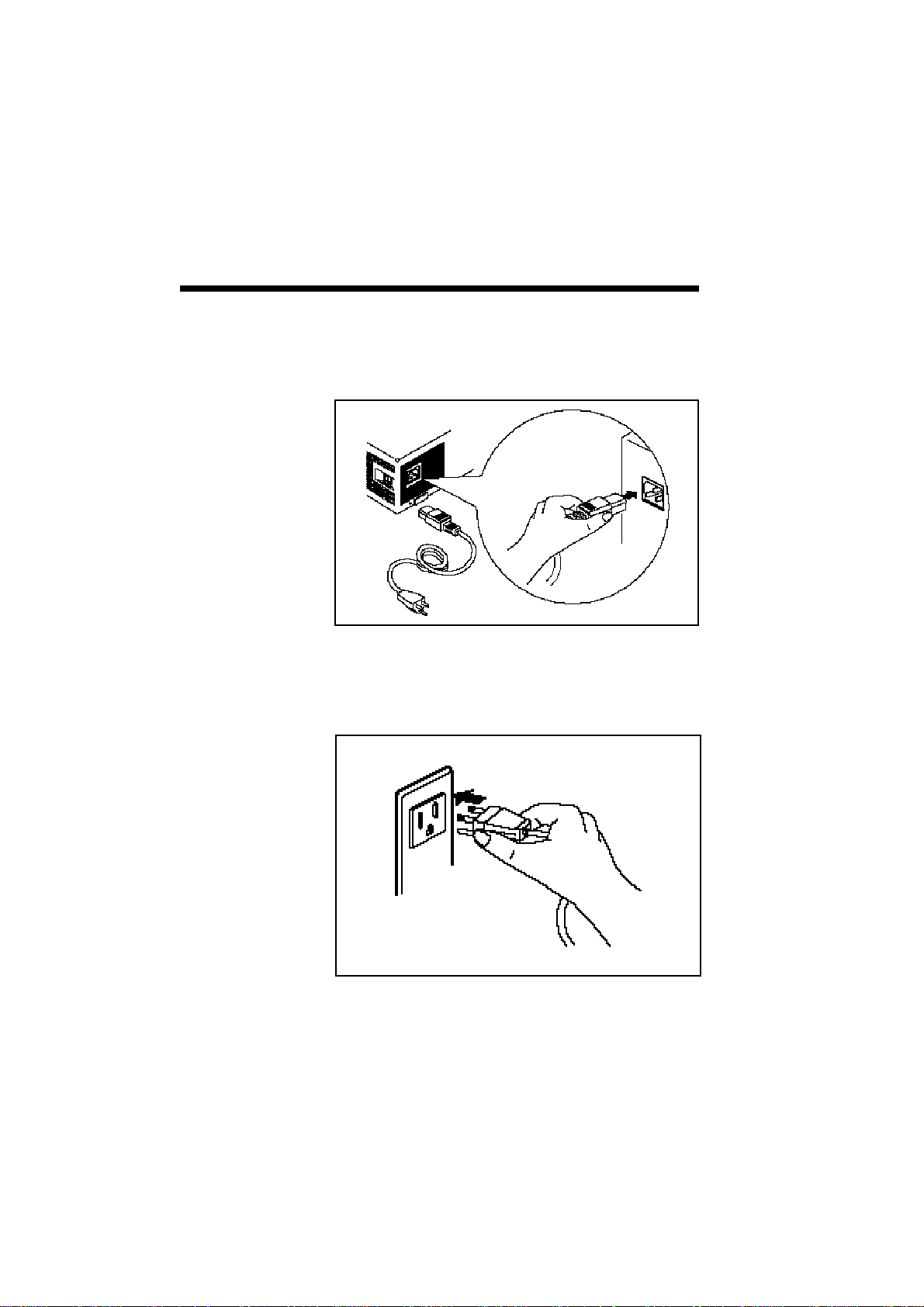

POWER CORD

Use the power cord provided and connect it to an

outlet.

NOTE: Do not connect the power cord to the

auxiliary outlet of your computer.

Connect the power cord as described below.

1. Switch off power to the printer.

NOTE: Check that the power switch is off.

Page 44

2–26 Setting Up

2. Plug the power cord into the power connector on

the rear panel of the printer.

3. Plug the other end of the power cord into an

outlet.

Page 45

Setting Up 2–27

INSTALLING

SUPERSCRIPT

PRINTING

SOFTWARE

Silentwriter SuperScript 610 includes a software

installation program to make the setup easier. The

installation program analyzes your system configuration, installs the SuperScript software and fonts, and

makes any necessary changes to Windows startup

files.

Once you have started the NEC SuperScript setup

program, you can cancel the installation at any time.

Just click on the Cancel button that appears in the

setup program window.

NOTE: You must have a minimum of 4 megabytes

of RAM and 8.5 megabytes hard disk space. The

following information shows how to identify the

available space on your hard disk. You may skip

this page if you are sure that your system meets both.

To verify your available disk space,you can try the

following:

1. From the C:\ prompt (or whichever drive you

intend to install the SuperScript software), type

DIR.

2. Examine the disk space information given near

the end of the screen.

.

.

.

DOS <DIR> 06-15-93 9:00a

CONFIG SYS 30 06-15-93 9:15a

50 file(s) 12345678 bytes

113483442 bytes free

.

.

.

3. The number appearing in bold here is the relevant

information you need to look for on your screen.

Make sure your number is greater than 8,910,000.

Page 46

2–28 Setting Up

To install the SuperScript software:

1. Place the NEC SuperScript software diskette #1

into the appropriate disk drive of your computer,

say A:. Close the drive door or lever if the drive

has one.

2. Start Microsoft Windows. At the DOS prompt,

type:

WIN/3

Windows will start up as usual, after which the

Program Manager group window should be

displayed on your screen. If the Program Manager group appears as an icon, restore it by

double-clicking on the icon.

3. From the Program Manger menu, click on File.

Then click on the Run... option. The Run Program dialog box appears.

4. At the prompt, type:

[A:] NECSETUP

where [A:] is the letter of the drive containing the

SuperScript software diskette. The first setup

screen appears as shown in the following figure.

Page 47

Setting Up 2–29

Click the mouse or press any key to continue.

Page 48

2–30 Setting Up

5. You will be prompted to choose 50-sheet hopper

or 200-sheet hopper. Unless you have purchased

the optional 200-sheet hopper, select the standard

50-sheet hopper.

6. Tell the setup program which parallel port you

wish to use: LPT1, LPT2, or LPT3. The setup

program only shows you the port names available

on your system. The default is LPT1.

Later, after the installation, you can select a

different port by using the NEC SuperScript

Print Manager (see Chapter 4).

Page 49

Setting Up 2–31

7

. Tell the setup program which drive and directory

you want to install the NEC SuperScript

software on. You can accept the default

supplied by the setup program, or give it the

name of another drive on your PC on which to

install the software. You should select a drive

with at least the amount of free disk space (1.4

megabytes) required for the NEC SuperScript

installation.

As shown in the next figure, “Setup Directory

Selection”, the setup program will create and set

up the directory “C:\SSCRIPT” as the default

installation directory. You can change the

default directory at this time by specifying a

different directory.

Click on the OK button.

The installation program then copies the NEC

SuperScript software to the specified directory.

Page 50

2–32 Setting Up

8. During the installation, NEC SuperScript shows

you progress and status messages, as shown in

the next figure.

Page 51

Setting Up 2–33

9. There are 20 TrueType fonts bundled with your

SuperScript 610 printer. You may choose to

install the fonts now or later. If you select OK

the installation program will copy the fonts to the

Windows System directory and install all 20

fonts automatically. This requires approximately

2 MB of hard disk space. If you select Cancel

you will skip this step and continue with the

SuperScript installation. You can install the

fonts individually later from the standard Windows Control Panel Font Utility. See chapter 7

Installing SuperScript TrueType Fonts

(page 7-4) or your Windows documentation for

more information.

Click on OK to proceed with the font installation.

Page 52

2–34 Setting Up

The installation program modifies the Windows

initialization files so that NEC SuperScript runs

properly when you start Windows.

The setup program also creates the NEC

SuperScript Tools group. This group contains

icons for NEC SuperScript programs, including

the NEC SuperScript Print Manager and the NEC

SuperScript Test Program. Once NEC

SuperScript is active, you will be able to run

these programs by double-clicking on their icons.

Page 53

Setting Up 2–35

10

. The installation program now displays a message

telling you that setup is complete. Choose

Restart Windows to start Windows over again,

or Exit to quit the setup program.

NOTE: You will have to restart Windows before

SuperScript can start running.

11.

When Windows is restarted, NEC SuperScript

Test Program will check to make sure all the

print modes work correctly. The Test program

will print several pages during the test, including

a configuration page containing information

about your system and printer.

NOTE: It is a good idea to save a copy of the most

recent configuration page with your manual. It may

be useful if you ever need to call Customer Support.

Page 54

2–36 Setting Up

12. The following notice will appear:

NOTE: This program performs some timeconsuming test operations. Before continuing, make

sure the printer is ready. The power switch should

be turned on, and the hopper should have paper in it.

Press OK to continue with the print tests, Cancel to

exit to the program's main menu.

13. Before printing starts, you will see the following

message as SuperScript sets up the tests.

Page 55

Setting Up 2–37

14. The Test Program prints a configuration page that

shows information about your PC and printer.

Save a copy of the most recent configuration page

with this manual. You may find it useful if you

ever need to call Customer Support.

Page 56

2–38 Setting Up

15. SuperScript will now ask to print one test page in

each print mode. Click on Yes to continue, No

to bypass the current test.

Page 57

Setting Up 2–39

16. After printing all test pages, the Test Program

will ask if you want to exit. Click OK to quit the

program.

Clicking Cancel instead of OK will return you to the

Test Program's main screen. The File pull-down

menu gives you the choice of repeating the test

sequence or exiting the program.

Page 58

2–40 Setting Up

Once SuperScript software is installed, NEC

SuperScript 610 device names appear in the Printers

window of your Control Panel (see the next figure).

Page 59

Printing with Your SuperScript 610 3–1

Printing with Your

3

SILENTWRITER

SUPERSCRIPT

610 PRINT

MODES

Silentwriter

SuperScript 610

Silentwriter SuperScript 610 lets you choose

between two print modes, GDI and PCL emulation.

GDI mode, which prints what you see on your

screen, is very fast and works well for most users.

However, some applications can create output that is

too complex for Windows to display accurately on

the screen—a file with a sophisticated embedded

graphic image might be an example. Windows may

not always display graphics intensive files

accurately. Therefore, as an alternative, try printing

the file using the SuperScript PCL mode. Printing

with the SuperScript PCL mode will be slower than

the GDI mode because GDI is the language of

Windows with direct access to Windows resources.

PCL emulation also gives you the ability to print

from a DOS application running within Windows,

and from the MS-DOS command line within Windows.

You can select the print mode from many Windows

applications, or through the Windows Control

Panel’s Printers window. To print in GDI mode,

select “NEC SuperScript 610 GDI on NEC.GDI” as

the current printer. To print in PCL emulation mode,

select “NEC SuperScript 610 PCL on NEC.PCL”. If

you have the optional 200-sheet hopper, you should

see “NEC SuperScript 610 GDI 200 on NEC.GDI”

and “NEC SuperScript 610 PCL 200 on NEC.PCL”

instead.

Page 60

3–2 Printing with Your SuperScript 610

GDI MODE

GDI Setup

Screen

GDI mode takes advantage of Windows’ own

internal design to produce documents faster than

most conventional printers can. Other printers

require Windows to translate a document into a

printer language, such as PCL on LaserJet printers.

GDI mode reduces overhead by eliminating this

translation step before starting to print. This results

in faster printing—as much as four times faster for

some files. SuperScript GDI mode includes some

additional features such as manual duplex printing.

You can set options for GDI mode by using the

Control Panel in Windows:

1. Switch to the Program Manager. You should see

a window titled Main. If this window has been

minimized, restore it.

2. Double-click on the Control Panel icon in the

Main window.

3. Double-click on the Printers icon in the Control

Panel window.

4. Select NEC SuperScript 610 GDI on

NEC.GDI

5. Click on the Setup button. You should see a

screen that looks like this:

Page 61

Printing with Your SuperScript 610 3–3

NOTE: Most of the popular Windows applications

also have shortcuts to the setup screen so you don’t

have to go through the Control Panel. For example,

Microsoft Write includes a command called Print

Setup, under the File menu, which allows you to set

up the printer directly, without going through the

Control Panel.

Page 62

3–4 Printing with Your SuperScript 610

The setup screen lets you select

Paper Source: Hopper Feed

Paper Size: Letter 8-1/2 × 11 in

Number of copies: 1 up to 99

Orientation: Portrait

Manual Feed

(Optional 200-sheet Hopper

only)

A4 210 × 297 mm

Executive 7-1/4 × 10-1/2 in

A5 148 × 210 mm

Envelope Monarch

3-7/8 × 7-1/2 in

Envelope #10 4-1/8 × 9-1/2 in

Envelope DL 110 × 220 mm

Envelope C5 162 × 229 mm

Landscape

The OPTIONS button takes you to the Advanced

Options screen, described below.

Press the OK button if you are satisfied with the

selections shown in each box in the Options dialog

window. The changes you have made will take

effect, and you will leave this window. If you press

the CANCEL button, you will leave the window, but

any changes you made will not take effect.

Page 63

GDI Option

Screen

Printing with Your SuperScript 610 3–5

Putting an X in the box marked Use NEC

SuperScript Print Manager turns the NEC

SuperScript Print Manager on when you use GDI

mode. (The NEC SuperScript Print Manager is

always on for PCL compatible mode.) The NEC

SuperScript Print Manager lets you use some additional features in GDI mode, including manual

duplexing and the use of the NEC SuperScript Print

Manager control screen (see Chapter 4).

NOTE: Turn off the NEC SuperScript Print

Manager to get the fastest printing (but not necessarily the fastest return to application).

Page 64

3–6 Printing with Your SuperScript 610

Printing Status Option lets you decide how you want

Printing Status

Option

feedback from the printer when you print.

If you put an X in the box marked Display Status

While Printing, the printer will pop up a Print Status

Window whenever you print to the SuperScript 610

printer. If you leave this box blank, you will only

see this window when the printer needs to inform

you of an error or warning condition, for example, to

let you know that it has run out of paper. (Chapter 5

gives more information on the Printer Status

Window.)

If you put an X in the box marked Beep When

Print Job is Complete, the printer will “beep” to let

you know that it has finished printing. Likewise, if

you put an X in the box marked Beep On Printer

Error, the printer will always beep as a result of an

error condition, such as paper out or paper jam.

Manual Duplex

Printing

If you put an X in the box marked Manual

Duplexing, NEC SuperScript , with a little help

from you, will print your file on both sides of the

paper. You can also choose one of two formatting

options:

• Book Style prints out so that if you opened the

document in the manner of a book, pages 2 and

3 would face each other.

• Report Style prints the even-numbered pages

upside down, so that if you opened the document in the manner of a report bound at the

top, pages 2 and 3 would face the same way.

Here’s how double-sided printing works.

[Using the Standard Hopper] (refer to page 8-4)

1. SuperScript prints every odd-numbered page of

your document, starting with the last oddnumbered page.

Page 65

Printing with Your SuperScript 610 3–7

2. Pick up the printed sheets of paper, straighten*

them, then reinsert them one by one into the

Silentwriter SuperScript 610 printer, starting with

the sheet having the smallest page number.

The reinserting directions are as follows.

3. Set the printed sheets into the hopper as described

on pages 8-4 to 8-6. Click the RESUME button.

Even-numbered pages can then be printed on the

back sides of the previously printed odd pages.

After printing, the printer detects a Paper Out

condition and then pauses. Set the sheet with the

next odd page number into the hopper and click

the RESUME button. The next even-numbered

page will be printed on the back of the sheet.

Page 66

3–8 Printing with Your SuperScript 610

* : Some printed sheets may be curled. Curled

sheets may cause jamming. Straighten the

sheets before reinserting them into the hopper.

Page 67

Printing with Your SuperScript 610 3–9

[Using the Optional 200-sheet Hopper] (refer to page

8-13)

1. Specify "Manual Feed."

2. Open the manual feed cover and insert print

sheets into the printer one by one (refer to

Chapter 8 "Manual Feed"). **

SuperScript prints every odd-numbered page of

your document, starting with the last odd-numbered page.

3. Pick up the printed sheets of paper, straighten*

them, then reinsert them one by one into the

Silentwriter SuperScript 610 printer, starting with

the sheet having the smallest page number. **

The reinserting direction is the same as in [Using

the Standard Hopper].

4. SuperScript prints every even-numbered page on

the backs of the pages already printed.

* : Curled printed sheets may cause jamming.

Straighten the sheets before reinserting them

into the hopper.

** : To feed sheets continuously, you must insert

sheets following the printer’s timing. The next

sheet should be inserted within 5 seconds after

the current sheet has completely entered into

the printer.

If the timing is not satisfied, SuperScript

detects a Paper Out condition and then

pauses. In this case, click the RESUME

button to restart.

Page 68

3–10 Printing with Your SuperScript 610

When finished, you should have a complete,

double-sided document.

You can also put an X in the box marked Print

Instructions. If you do this, then the Silentwriter

SuperScript 610 printer will print out a sheet of

paper giving you detailed instructions every time

you print in manual duplex mode.

NOTE: If an error occurs during duplex printing,

please recover as follows:

• If an error (e.g. paper jam) occurs while printing

the front side of the page (i.e. odd numbered pages),

clear the error as instructed in Print Status Window

and click the Resume button to continue the current

duplex print job as usual.

• If an error occurs while printing the back side of

the page (i.e. even numbered pages), clear the error

as instructed in Print Status Window . If the page

being printed when the error occurs is damaged

insert a new piece of paper in the printer. Click the

Resume button to continue the print job. After all

pages are finished printing, if a new page was

inserted in the printer, re-print the corresponding

odd numbered page on the opposite side to complete

the duplex print job.

Page 69

Printing with Your SuperScript 610 3–11

PCL PRINT

MODE

PCL mode printing is provided to meet specific

printing needs which can not be fully satisfied by the

GDI mode:

1. Compatibility with non-Windows applications.

2. Compatibility with previously saved PCL-format

files.

3. Ability to print text or ASCII formatted files (i.e.

DOS print screen) directly.

4. Ability to print complex graphic files which

Windows may not display well for some applications.

NOTE: If you can not determine which print mode is

best suited for your printing applications under

Windows, we recommend you to always use GDI

mode first. For DOS applications running under the

Windows DOS shell, the PCL mode is automactically

enabled. The next two pages discuss PCL-specific

features. You may skip the pages for now if you

only use Windows applications.

Page 70

3–12 Printing with Your SuperScript 610

Saving Downloaded Fonts

and Macros

( PCL Mode)

By default, when your application prints using

SuperScript's PCL mode, the PCL interpreter will

start up, print the document, and then shut itself off

automatically. This means the PCL interpreter does

not take up memory on your PC except when

needed.

However, when the PCL interpreter turns itself off,

any downloaded fonts or macros will be lost, just as

if you had turned off a regular PCL printer (e.g.

LaserJet IIP).

You can preserve this information by using the NEC

SuperScript Print Manager to keep the PCL interpreter active.

1. From the Windows Program Manager, doubleclick on the NEC SuperScript Printer Manager

icon in the NEC SuperScript Tools group.

2. Minimize the NEC SuperScript Print Manager to

an icon, if desired.

3. Download macros or soft fonts in advance, using

the downloading utility provided by your fonts.

4. Start or return to your application and print your

document.

This will preserve your downloaded fonts and

macros. Also, if your next print job also uses PCL, it

will take less time to print because the SuperScript

PCL interpreter has already been loaded. However,

if you switch from PCL to GDI mode, this information will be lost, just as if you were changing printer

languages in a conventional printer.

Page 71

Printing with Your SuperScript 610 3–13

Page Ejects Form Feeds

( PCL Mode)

Some PCL files do not include a form feed (a command to eject a page) at the end of the file, so if you

are printing to a conventional PCL printer, you have

to press a form feed key to see your output. For

example, if you use the DIR>LPT1: command in the

MS-DOS prompt in Windows, the job sent to the

PCL interpreter will not have a form feed at the end,

so that the last page (or a single page) won't print.

If you turn the conventional printer off, the last page

is lost. Unlike a conventional PCL printer, if the

SuperScript PCL interpreter shuts itself off, as

described above, it will print the last page automatically.

However, if you launch the NEC SuperScirpt Print

Manager, as described above, before printing, then

you will have control over whether the unprinted

page will be saved. The PCL interpreter provides a

form feed function in its program menu, which can

be displayed by clicking once on the PCL icon.

Clicking Form Feed on the program menu will eject

the retained page (just like the form feed key on a

conventional PCL printer).

Besides form feed, a reset feature is also provided for

the user to return the printer to its reset state (just

like the reset key on a conventional PCL printer).

Page 72

3–14 Printing with Your SuperScript 610

PRINTING

FROM A

WINDOWS

APPLICATION

PRINTING

FROM DOS

APPLICATION

Once you have selected your printer mode (GDI or

PCL emulation), just print from your Windows

application as you would to any other printer.

Note: Silentwriter SuperScript 610 is a Windows

printer, designed for use with Windows. In particular, SuperScript’s GDI mode is based on Windows

and does not work with MS-DOS. However,

SuperScript will work in PCL mode if you create an

MS-DOS session from within Windows.

SuperScript will not run if you exit Windows completely.

Enter MS-DOS prompt from Windows by clicking

on the MS-DOS icon in the Main window from the

Program Manager screen.

When ready to print, start your DOS application and

print as you normally would. Set up your application

to print to the parallel port LPT1 (or LPT2 or LPT3

if you have SuperScript set to print to one of these

ports instead). Be sure to select the NEC

SuperScript PCL driver or an HP LaserJet IIP driver.

PRINTING PCL

FILES FROM

DOS COMMAND LINE

If you have a file in PCL or ASCII (text) format, you

can print it from the MS-DOS command line within

Windows. At the command line prompt, type

COPY/B <filename.ext> LPT1

where <filename.ext> is the name of your PCL- or

ASCII-formatted file. (If you have configured

SuperScript to print to a different parallel port, give

its name instead of LPT1.)

Page 73

NEC SuperScript Print Manager 4–1

NEC SuperScript

4

Print Manager

When you use the NEC SuperScript Print Manager,

the program helps you manage the output flow and

operation of your SuperScript 610 printer. You can

see all files waiting to be printed, and change their

order. You also can see how much of the current

print job has been processed. You can control the

priority setting for printing relative to other

applications running at the same time. Furthermore,

when the NEC SuperScript Print Manager is in use,

you can print double-sided pages in GDI mode.

When minimized, the NEC SuperScript Print Manager appears as an icon at the bottom of your screen.

Page 74

4–2 NEC SuperScript Print Manager

Options

1. Priority

Windows lets you run several applications at

the same time. This helps productivity, but it

also means that you are sharing your PC’s

resources among several activities.

SuperScript’s priority settings let you control

the priority of the printing activity relative to

other applications running at the same time.

Page 75

NEC SuperScript Print Manager 4–3

The Options menu lets you select high,

medium, or low priority processing for when

you print. Printing at a high priority produces

output faster, but it may slow down your

system as well. On the other hand, printing at

a lower priority lets your other applications

run faster, but also means your document will

take longer to print. (For more information,

see Appendix B Optimizing Printing

Performance.)

2. Beeps

If Beep on Printer Error is checked, your

system will beep after encountering an error

condition with the printer.

If Beep When Print Job is Complete is

checked, your system will beep when printing

has completed.

3. Display Print Status

If you check this item, the Print Status

Window will pop up on your screen during

printing. If this item is not checked, the Print

Status Window only pops up when an error

occurs. (See Chapter 5 for more information

on the Print Status Window.)

4. Time Format

This option allows you to change the display

format: 12 hour or 24 hour. (01:30 PM is an

example of 12 hour format. The same time

appears as 13:30 in 24 hour format.) The

time stamp is provided by your system clock.

Page 76

4–4 NEC SuperScript Print Manager

5. Sharp Edge Technology (SET)

This option allows you to turn on or off the

Sharp Edge Technology, a resolution

enhancement feature.

6. Connect Port

The Port option lets you select a different

parallel port for your SuperScript 610 printer.

Depending on the ports available on your PC,

you can choose LPT1, LPT2, or LPT3.

7. Power Saving Mode On or Power Saving

Mode Off

Silentwriter SuperScript 610 has a power

saving mode built-in. After idling for 15

minutes (as default), the printer will reduce its

power consumption by shifting into a power

saving mode. This option allow you to select

either “Power Saving Mode On” or “Power

Saving Mode Off”. If you choose the Power

Saving Mode Off option, your printer will

remain active and consume more power.

When you select the Power Saving Mode

On option, you can enter a time interval from

1 to 30 minutes. After the specified time

interval of idling,the printer will shift into the

power saving mode and the left panel light

will blink slowly.

As soon as you send a print job to the printer,

it will shift back into the active mode.

Size

The Size menu lets you change the size of the

display window for the NEC SuperScript Print

Manager. “Normal” shows the full display.

“Minimum” takes up less space on your screen.

Page 77

NEC SuperScript Print Manager 4–5

Help

1. Contents

It gives you a list of subjects available in the

help menu.

2. Search for Help On...

This option opens up a window allowing you

to get information on SuperScript features.

3. How to Use Help

This is the standard Windows Help guide to

show users how to access the help menu.

4. About

The About option provides you with the

information about the version of the NEC

SuperScript software currently running.

Page 78

4–6 NEC SuperScript Print Manager

Queue Information

This part of the NEC SuperScript Print Manager

screen shows jobs in queue waiting to be printed.

JOB NAME The software application and file

that created the print job

FORMAT Either GDI or PCL format

SIZE How large the print job is, in

bytes

TIME Time of day the print job was

created

Page 79

NEC SuperScript Print Manager 4–7

On a color monitor, the job currently printing

will be highlighted in dark blue. A job that you

have selected with the mouse will appear against

a light blue background. On a monochrome

monitor, the current print job will be highlighted.

A paused or selected job will also appear highlighted, but somewhat darker gray than the

current job.

The NEC SuperScript Print Manager will take

the first print job in the queue and send it to be

processed and printed. However, if you have a

mouse, you can change the order of print jobs

that remain in the queue by following a “dragand-drop” procedure:

1. Move the mouse to the entry you want to re-

order.

2. Press down on the left button of your mouse.

Do not lift your finger. The entry will turn

blue to indicate that it has been selected.

3. Without lifting your finger, drag the print job

(in other words, move the mouse) to the

desired new location in the queue.

4. Release your finger from the mouse button.

The print job will now show up in its new

location, and the other print jobs will

subsequently move up or down in the queue.

Page 80

4–8 NEC SuperScript Print Manager

Status Bar

The status bar shows whether SuperScript is

printing, paused, or ready to print. During

printing, the status bar shows the page number

currently being processed.

Progress Bar

The progress bar shows the percentage of the

current print job processed by the SuperScript

software on the PC. Once this processing is

completed, the actual printing starts.

PAUSE

The PAUSE button lets you pause the current

print job. Once the job is paused, you can use

the RESUME button to continue printing, or

cancel the print job by clicking the DELETE

button.

RESUME

RESUME lets you resume printing a job that has

been paused.

ADD

The ADD button lets you select a GDI or PCL

print job file previously stored on your hard disk

and add it to the end of the print queue.

DELETE

DELETE lets you cancel a current print job that

has been paused. You can also select any

pending print job, then click on DELETE to

remove it.

Page 81

NEC SuperScript Print Manager 4–9

Exiting the NEC SuperScript Print Manager

To exit the NEC SuperScript Print Manager,

click on the System menu (the horizontal bar at

the upper left-hand corner of the window), and

select Close. Another way to do this is to press

Alt-F4.

Exiting Windows will also close the NEC

SuperScript Print Manager.

Exiting Before Printing Has Completed

If you try to close the NEC SuperScript Print

Manager, or exit Windows, while there are still

documents waiting to be printed, SuperScript

will display a message asking if you want to save

the remaining print jobs.

If you select “Yes”, the print jobs will be saved

as you exit. When you start up the NEC

SuperScript Print Manager next time, you can

resume printing of the unfinished documents.

If you select “No”, the print jobs will be lost, and

you will exit. (The original application files,

from which the print jobs were created, will not

be affected.)

If you select “Cancel”, you will not exit Windows or the NEC SuperScript Print Manager.

Page 82

4–10 NEC SuperScript Print Manager

Page 83

5

Print Status Window 5–1

Print Status Window

The Print Status Window has two functions. The

first is let you know when something is printing.

For both PCL and GDI modes, you can use the NEC

SuperScript Print Manager to choose whether or not

you want the Print Status Window to display during

printing. (See page 3-5 and Chapter 4.)

The Print Status Window will also alert you in case

of a problem. It displays a warning or error message.

In addition, it points to the problem area on the

printer, and gives instructions for what to do next.

Page 84

5–2 Print Status Window

Please refer to the Print Status Window chart above.

Options

Animate Icon: Lets you decide whether or not

to animate the printer icon that appears in the

Print Status Window or when this window is

minimized to an icon. If Animate Icon is

checked, then the printer will show paper

printing and panel lights blinking.

Help

1. Contents

It gives you a list of subjects available in the

help menu.

2. Search for Help On...

This option opens up a window allowing you

to get information on SuperScript features.

Page 85

Print Status Window 5–3

3. How to Use Help

This is the standard Windows Help guide to

show users how to access the help menu.

4. About

The About option provides you with the

information about the version of the NEC

SuperScript software currently running.

JOB NAME & PAGE NO.

This box shows the name of the application, file,

and page number for the job currently being

printed.

Picture of your printer

This box shows a picture of your SuperScript

610 printer. If a problem has occurred, an arrow

points to where the printer is affected.

STATUS MESSAGE

This box shows an error or status message and

corresponding icon. The display also tells you

what to do for each error or warning message.

The possible messages include:

Cover Open or Toner Cartridge Missing

Either your printer's cover is open, or

there is no toner cartridge in the printer.

Insert a toner cartridge, if necessary, and

then firmly close the printer's cover.

Page 86

5–4 Print Status Window

Duplex Printing

Duplex (double-sided) mode is enabled,

and SuperScript has finished printing on

one side of your document. Turn sheets

over and reinsert them into the paper

hopper to print on the other side. (For

paper insertion details, see page 3-6)

Engine Error

There is a problem with your printer’s

engine. Follow the instructions on the

screen to correct the problem. If the

problem persists, call Customer Support.

Manual Cover Closed

Manual Feed has been selected for the

current print job; however, the Manual

Feed Cover is closed. Open the Manual

Feed Cover to the manual feed position

and insert a sheet of paper. Click the

RESUME button to start again.

Manual Cover Open

Hopper Feed has been selected for the

current print job; however, the Manual

Feed Cover is open. Close the Manual

Feed Cover. Click the RESUME button

to start again.

Manual Feed

Manual Feed has been selected for the

current print job; however, the printer has

run out of paper. Insert one sheet of

paper alongside the edge of the manual

feed guide of the manual feed cover.

Click the RESUME button to start again.

Paper Out

The printer has run out of paper. Add

more paper to the hopper. Click the

RESUME button to start again.

Page 87

Print Status Window 5–5

Paper Jam

Paper has jammed inside the printer,

making it impossible to continue printing. Open the printer’s cover. Remove

all paper. Close the cover.

Silentwriter SuperScript 610 will start up

again automatically once the jam has

been cleared. In most cases, the printer

will reprint the page jammed before

continuing with the rest of your document.

Paper Size Error

The printer is loaded with sheets of a

different paper size than what the

software has been setup to handle. You

need to load a different size paper, or

change paper size selection in your

printer setup screen.

Power Off or Cable Problem

NEC SuperScript software can’t find

your printer. This error may be caused

by:

1. the printer is off.

2. the printer's parallel cable is not

installed properly.

3. a problem exists within the

connection or the parallel cable is

not good.

Verify the printer is powered on and the

left printer status light (LED) is lit or

blinking. Check the parallel cable is

correctly connected to the printer and the

PC.

Warming Up

Wait until the engine has finished warming up.

Page 88

5–6 Print Status Window

Pause

The PAUSE button lets you pause printing while

you do something else. For example, you can

pause in order to delete the print job from the

SuperScript Print Manager.

Resume

The RESUME button lets you continue printing

after you have paused printing, or after the

printer recovers from an error situation.

Delete

The DELETE button lets you delete the current

print job. You must pause the job before you can

delete it. Additionally, you may delete a print

job halted due to an error situation like paper out.

Page 89

Selecting Paper and Media 6–1

Selecting Paper and

6

Media

Your NEC Silentwriter SuperScript 610 printer

supports a wide variety of print media.

Choosing quality paper is your best bet for avoiding

many of the output problems common to heatintensive printing. It is the most wide-ranging

preventative measure you can take to achieve consistently good results from your printer.

Though we do not endorse particular manufacturers,

this chapter notes products that have consistently

demonstrated high quality. This chapter shows you

how to recognize quality media products and gives

detailed specifications for print materials. Recommended handling and storage guidelines are also

given.

You must judge the quality and performance of any

paper. We strongly recommend that you test several

reams of selected paper for Silentwriter SuperScript

610 compatibility before you make a large purchase.

Because we cannot control the quality or manufacturing of your selected media, we cannot warrant the

use or results of any specific media with the NEC

Silentwriter SuperScript 610 printer.

Page 90

6–2 Selecting Paper and Media

Note the following media guidelines.

Check that the media meets all specifications

noted in this chapter.

Order a small quantity to test with your printer

and your work environment. Some paper vendors offer print quality guarantees to insure that

the output meets a predetermined standard when

used with laser printers. If you don’t like the

paper, you may be able to return it for another

type — but test that one, too.

Tell both the supplies buyer and the prospective

seller that you are using this media in a laser

printer.

PAPER

PROPERTIES

Paper manufactured from 100% chemical wood pulp

containing no more than 25% cotton fiber is recommended. Paper should be dust-free and have cleanly

cut edges. Do not use wrinkled, curled, or damp

paper; it often causes misfeeds, paper jams, and

illegible output.

Most writing paper has two sides: top, often called

the “felt” side, and bottom, or “wire” side. The

package label generally has an indicator arrow

showing you how to load paper so that output goes to

the wire side.

NEC tested Xerox® 4024™ (20 lb.) paper and

obtained satisfactory results. Generally, paper

manufactured for photocopying has good print

quality and paper handling characteristics.

Page 91

Selecting Paper and Media 6–3

NOTE: Paper properties can be changed by the

manufacturers. NEC has no control over such

changes. Thus NEC neither warrants nor recommends the use of any particular paper and the user

assumes all responsibility as to the quality and

performance of paper selected.

No matter which manufacturer you select, note the

following considerations.

Smoother surface paper generates sharper output

resolution and detail.

Coated paper can melt, discolor, or release

hazardous emissions at temperatures greater than

200˚C (392˚F).

The acceptable range of media weight for use is

60 to 105 g/m2 (16 to 28 pounds).

Print Areas

Acceptable media sizes and their corresponding print

areas are as follows.

Letter 8.5 in. × 11 in. (216 mm × 279 mm): print

area of 8.1 in. x 10.6 in. (206 mm ×

269 mm)

Envelope

Monarch 3.875 in. × 7.5 in. (98.4 mm ×

190.5 mm): print area of 3.2 in. × 6.9 in.

(82.4 mm × 174.5 mm)

Page 92

6–4 Selecting Paper and Media

Commercial 10 4.125 in. × 9.5 in. (105 mm ×

241 mm): print area of 3.5 in. × 8.9 in.

(89 mm × 225 mm)

Internationl DL 110 mm × 220 mm (4.33 in. ×

8.66 in.): print area of 94 mm × 204 mm

(3.70 in. x 8.03 in.)

Internationl C5 162 mm × 229 mm (6.38 in. ×

9.02 in.): print area of 146 mm × 213 mm

(5.75 in. × 8.39 in.)

NOTE: You should load envelopes in landscape

orientation, with the flap edge to the left.

Paper and

Media Use

Observe the following guidelines for media selection. Do not attempt to print on any of the following

types of paper.

recycled paper

extremely smooth or shiny coated paper

very rough, textured, or embossed paper

multipart forms or carbonless papers

paper coating, dyes, or inks not compatible with

the fusing temperature of 200˚C (392˚F)

paper that produces hazardous emissions when

exposed to 200˚C (392˚F) temperatures for 0.1

seconds

paper that offsets or discolors

damaged, wrinkled, or irregularly shaped paper

paper containing large amounts of clay or talc

paper that does not lie flat

Page 93

Selecting Paper and Media 6–5

preprinted forms with inks containing metallic

substances

perforated feed paper and cutout paper

Preprinted

Forms

During the print operation, heat applied to preprinted

forms can remove ink from the form and leave

residue (called offset) inside the printer.

In addition to offset residue problems, ink residues

may generate harmful gases and emissions. Note the

following considerations.

Forms should be printed with heat-resistant inks

that do not vaporize or generate harmful emissions at temperatures greater than 200˚C (392˚F)

for 0.1 seconds.

Don’t use paper printed with low-temperature

inks.

Inks must not be flammable.

Inks must not be affected by the resin compo-

nents found in toner.

Care must be taken to avoid changing the mois-

ture content of paper being preprinted or using

materials that change the electrical or handling

properties of the paper. Forms should be sealed

in moisture-proof wrapping after preprinting to

prevent moisture changes during storage.

Page 94

6–6 Selecting Paper and Media

Heavy Print

Stock

Envelopes

Heavy (thick) printed stock can generate misfeeds

and paper jams, in addition to causing excessive

wear to the print mechanism.

Bond paper exceeding 82 g/m2 (22 lbs.) must be

placed in and fed from the hopper one sheet at a

time (do not place several sheets in the hopper).

In order to minimize curling, heavy bond paper

must be ejected from the face-down door.

Don’t use paper heavier than 105 g/m2. The

acceptable range of media weight for use is 60 to

105 g/m2 (16 to 28 pounds).

Envelopes must be ejected from the face-down door

in order to minimize curling and wrinkling.

The printer accepts one of four standard envelope

sizes:

Monarch 3.375 in. × 7.5 in. (98.4 mm ×

190.5 mm)

Commercial 10 4.125 in. × 9.5 in. (105 mm ×

241 mm)

DL 110 mm × 220 mm (4.33 in. × 8.66 in.)

C5 162 mm × 229 mm (6.38 in. × 9.02 in.)

NEC tested Eaton 25% Cotton (75 g/m2, diagonal

seamed) and obtained satisfactory results.

NOTE: NEC neither warrants nor recommends the

use of any particular envelope and the user assumes

all responsibility as to the quality and performance of

the envelopes selected.

Page 95

Selecting Paper and Media 6–7

The leading edge of an envelope that feeds into the

printer must be straight. The fold must be firmly

creased and be no thicker than two paper thicknesses. As a rule, the larger the envelope is, the

more difficult it is to feed properly.

The base weight of envelope paper must be 75 g/m

(20 pounds). Commercial envelopes, called regular

or business envelopes, are the most widely used and

are probably the most reliable for your printing

needs.

Neither envelopes with peel-off adhesive strips nor

envelopes that are heavily embossed feed well.

Avoid heavily textured or coated envelopes. In

addition, avoid

envelopes with snaps, clasps, tie strings, cellophane windows, or curved or thick leading paper

edges. (They don’t feed consistently.)

envelopes composed with glues, inks, and

adhesives that could discolor, scorch, or melt

when heat is applied

2

adhesives that generate harmful emissions at

temperatures greater than 200˚C (392˚F) for 0.1

seconds

envelopes made with recycled paper

envelopes that use an adhesive that relies on

pressure for sealing

envelopes that have already been through the

printer once. (Don’t feed envelopes into the

printer a second time.)

envelope seams that do not have a continuous

and even glue line (excluding the envelope flap).

Page 96

6–8 Selecting Paper and Media

Adhesive

Labels

Adhesive labels consist of a top (print surface) sheet,

an adhesive layer, and a liner (peel-away backing).

The top sheet is usually xerographic paper and must

meet the general specifications for that kind of paper.

The liner must be coated for easy release of the top

sheet and adhesive layer sheets, particularly after

being subjected to print head heat.

NEC tested Avery® 5162 labels and obtained

satisfactory results.

NOTE: Label properties can be changed by the

manufacturers. NEC has no control over such

changes. Thus NEC neither warrants nor recommends the use of any particular label and the user

assumes all responsibility as to the quality and

performance of labels selected.

Note the following considerations regarding the

adhesive layer.

Labels must be set on and fed from the paper

hopper one piece at a time (do not place more

than one in the hopper). In order to minimize

curling, labels must be ejected from the facedown door.

The adhesive cannot melt or generate harmful

emissions at temperatures greater than 200˚C

(392˚F) for 0.1 seconds.

Labels should cover the entire surface of the liner

sheet. Labels placed on a liner sheet with interrupting spaces make it difficult for consistent

feeding because one sheet contains multiple

“double-thickness” areas.

Page 97

Selecting Paper and Media 6–9

Adhesive must not “spill over” its paper edge or

any die cuts. Excess adhesive can bond to the

print mechanism to cause poor quality output or

mechanical problems.

To test for excessive adhesive, put a piece of

paper on top of the adhesive-based paper and

press down. The two pieces should not stick

together.

Transparency

Film

MEDIA

PURCHASING

SPECIFICATIONS

When you are printing on transparency film, always

remove the first printed transparency from the output

door before feeding a second one through. This

prevents scratching the film surface of the first

transparency. The transparency must be able to

withstand temperatures of 200˚C (392˚F) for 0.1

seconds.

Transparencies must be tested for satisfactory performance prior to purchase.

Transparent film must be placed in and fed from

the paper hopper one sheet at a time (do not

place several sheets in the paper hopper). In

order to minimize curling, transparent film must

be ejected from the face-down door.

The following purchase specifications are intended

for the person who orders your print media. It is

possible that even when these specifications are met,

operating environment inconsistencies may keep the

paper from measuring up to its optimum capabilities.

Once again, always test a representative sample

before making a large purchase of any print media.

Because we cannot control the quality or manufacturing of your selected media, we cannot warrant the

use or results of any specific media with the NEC

Silentwriter SuperScript 610 printer.

Page 98

6–10 Selecting Paper and Media

Sheet Paper

specifications listed in Table 6-1.

Table 6-1 Paper Specifications

ITEM

Acid content

Ash content

Single-sheet feed*1

Multi-sheet feed*2

Brightness

Caliper

Furnish

Curl

Cut edge condition

Electrical surface resistivity

All sheet paper properties must match the paper

SPECIFICATION

5.5 pH to 8.0 pH.

Cannot exceed 10% or contain large amounts of

clay or talc.

60 to 105 g/m2 (16 to 28 pounds)

60 to 82 g/m2 (16 to 22 pounds)

83% minimum.

0.094 to 0.19 mm (3.7 to 7.5 mils.)

100% chemical wood pulp with up to 25% cotton

fiber recommended.

Zero curl toward image side, minimum 15-inch

radius curl toward opposite side.

Sharp edges, no visible fray.

2.0 to 15 × 1010 ohms/square (conditioned at 22˚C

(71.6˚F ) plus 50% relative humidity).

Electrical volume resistivity

Finishing

Fusing capability

*1 “Single-sheet Feed” refers to the method of placing print media in the hopper

one sheet at a time.

*2 “Multi-sheet Feed” refers to the method of placing print media in the hopper

several sheets at a time for continuous feeding.

1.2 to 15 × 1011 ohm × centimeter (conditioned at

22˚C (71.6˚F ) plus 50% relative humidity).

Cut sheets must be within ±0.8 mm of nominal,

corners at 90˚ ±0.2˚.

Cannot scorch, melt, offset, or release emissions

when heated to 200˚C (392˚F) for 0.1 seconds.

Page 99