Page 1

be certain.

m

Site Preparation Guide

Landmark Testing Systems

100-209-144 C

Page 2

Copyright information © 2012 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation within the United

States. This trademark may be protected in other countries.

All other trademarks or service marks are property of their respective owners.

Publication information

Manual Part Number Publication Date

100-209-144 C March 2012

Page 3

Contents

Introduction 5

Facility Preparation 7

Preparing to Receive the System 7

Space Requirements 8

Foundation Requirements 8

Floor Loading Considerations 9

Mechanical Shock/Vibration 9

Electrical Power Distribution 9

Grounding Requirements 10

Console Control Power 10

Radiated Emissions 10

Fixture and Specimen Handling Considerations 10

Acoustics 11

Temperature 11

Heat Dissipation 11

Altitude 11

Relative Humidity 12

Leveling System Components 12

System Component Specifications 13

Load Unit Specifications 14

Environmental Requirements—Series 370 Load Frames 16

Electrical Requirements—Series 370 Load Frames 16

Hydraulic Power Unit Specifications 17

Model 505.07/.11 Specifications 18

Model 505.20/.30 Specifications 20

Controller Specifications 22

Environmental Requirements—Series 494 Hardware 22

Specifications–Model 494.04 Chassis 23

Specifications–Model 494.06 Chassis 24

Specifications–Model 494.10 Chassis 25

Specifications–Model 494.20 Chassis 26

Landmark Test System Site Prep Guide Contents

3

Page 4

Additional Considerations 27

HPU Considerations 28

HPU Cooling Water Requirements 28

HPU Electrical Requirements 28

Water Quality 28

Load Unit Considerations 30

Electronic Console Considerations 31

Console Handling Requirements 31

Computer Console Considerations 32

When You Get Your System 32

4

Contents

Landmark Test System Site Prep Guide

Page 5

Introduction

The MTS Landmark System is designed to operate in a laboratory or light

industry environment. To get the maximum intended use of the system, it is

recommended that careful consideration be given to planning its installation.

This includes:

• Considerations of the types of testing that will be performed

• The building facilities requirements for power, cooling water, air

conditioning, ceiling height, floor loading, and so on

• Contract services, such as riggers and moving equipment, to transport the

system components within the facility

• Support personnel that might be required during installation of the system

Each test application has its own requirements in addition to the test system

requirements. Therefore, it is recommended that overall planning be considered

as early as possible. Preparation for and setup of the major system components is

your responsibility. This guide will help answer most of your questions about the

physical characteristics and requirements of your system.

Landmark Test System Site Prep Guide Introduction

5

Page 6

6

Introduction

Landmark Test System Site Prep Guide

Page 7

Facility Preparation

This section describes the physical, electrical, and mechanical requirements that

must be considered before installing the Landmark System. Read the following

subsections thoroughly to identify installation considerations that apply to your

facility.

Preparing to Receive the System

Before you call MTS for installation, there are several customer responsibilities

before and after receiving your test system. If you have any questions or concerns

about any of the following, please contact MTS.

Before your system

arrives

Prior to receiving the system, ensure suitable rigging equipment is available for

lifting and transporting the system components. The major components of the

system consist of the hydraulic power unit (HPU), the load unit and the

electronics console. See System Component Specifications for more information.

Before your equipment arrives, ensure your facility is ready for installation.

Things that need to be in place include:

• Proper foundation where the load frame will be positioned.

• HPU cooling water available.

• Electrical power available for the HPU and test controller.

• Network set up and internet connections available.

• If you are supplying the computer workstation, make sure:

– it is set up with an appropriate Windows operating system,

– it has general business applications installed,

– it is connected to your network and has internet access.

After your system arrives After your system arrives, it is your responsibility to have the system uncrated

and moved to its final position before calling MTS for installation.

Be sure to have personnel available for training when the MTS Service Engineer

comes for installation. You should also have your network IT people available in

case there are internet or network issues that need to be resolved; for example IP

address assignments for the computer workstation.

Landmark Test System Site Prep Guide Facility Preparation

7

Page 8

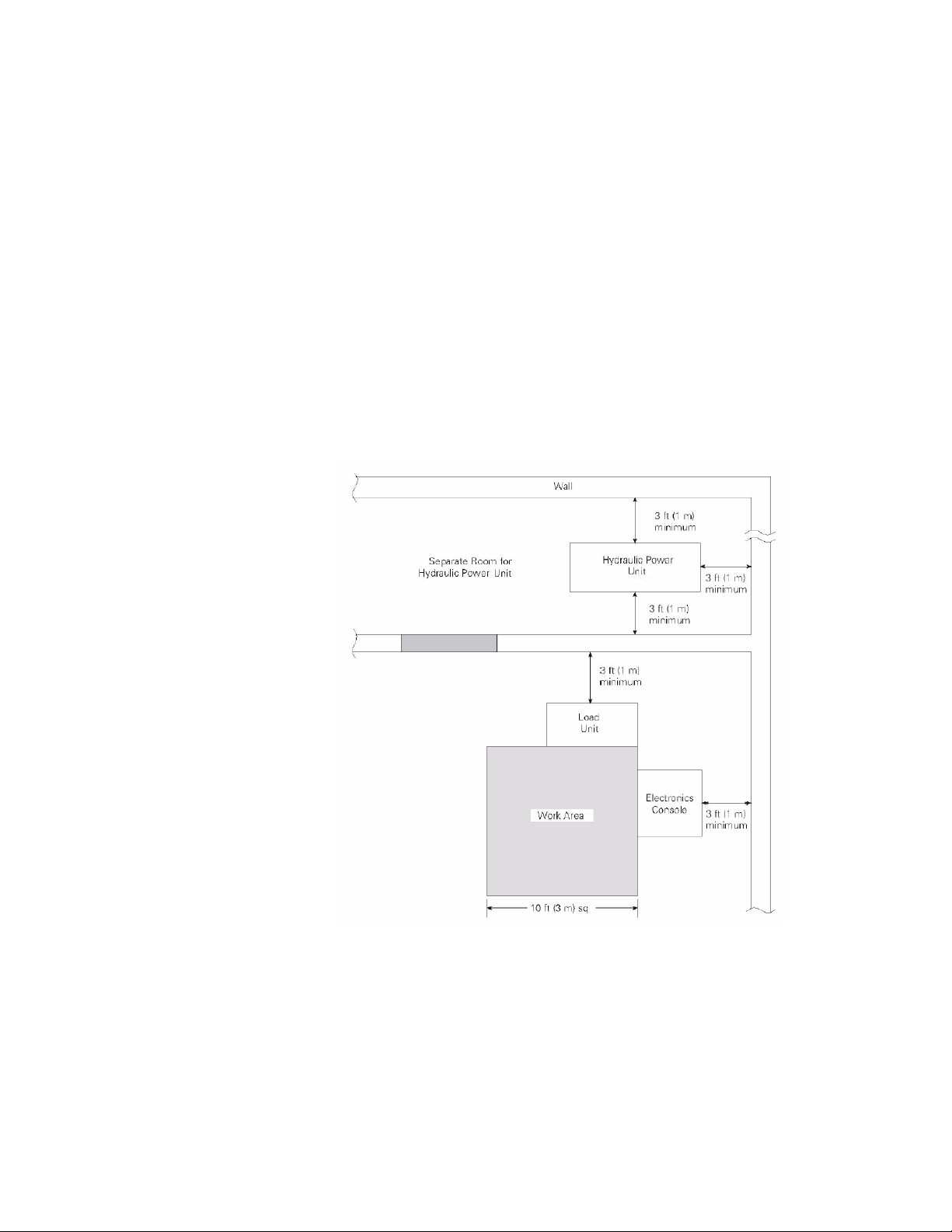

Space Requirements

Consideration must be given to planning the space requirements around the

equipment for loading specimens and for the proper maintenance of the

equipment. Also, during installation of the equipment, additional space (floor

space and ceiling height) might be required to facilitate moving the various

system components into place. Shown below, is a typical configuration for a

system laboratory plan allowing for relative placement of the test machine

controls and mechanical components for convenient use. This is only a

suggestion of how a Landmark System could be installed. Your requirements

should be considered and planned accordingly.

Consideration should also be given to handling specimens, test data, and storage

of fixturing and associated tools necessary for use and service of the system. If

hazardous test specimens (such as those pressurized internally with gas or

fragmentizing materials) are used in the test, protective enclosures and special

laboratory layouts are advised.

Foundation Requirements

Foundations for load frame systems will generally be reinforced concrete cast in

place in the ground. These are sometimes called fixed reaction masses, seismic

bases, etc. Still other methods of supporting a load frame can involve a strong

floor or other test floor already at the customer site.

Facility Preparation

8

Landmark Test System Site Prep Guide

Page 9

The dynamic response characteristics of the foundation should be limited to low

levels so that the accuracy and performance of the MTS equipment mounted on

the foundation will not be affected. An improper foundation mass can affect

equipment performance. This is particularly true in strain-controlled, lowfrequency or strain-controlled monotonic testing.

If you have any questions or concerns about the suitably of your foundation,

contact MTS.

Floor Loading Considerations

Once the final layout for your system laboratory has been developed, the

dimensional and weight information for the various system components should

be supplied to the building facility personnel to ensure that proper building

loading and vibration considerations have been evaluated.

The load unit comes equipped with vibration isolators that are designed to

distribute the load into the floor and to provide isolation from excitation caused

by movement of the actuator rod. These vibration isolators will be found in a

carton which will accompany the load unit. This carton also contains other

accessories basic to load unit operation. If high cycle fatigue testing is to be

performed, place the load unit such that vibrations do not excite undesirable

resonances or cause excessive loads in the building structure.

Hydraulic power units rest on a special base flat on the floor. Resting flat on the

floor provides maximum loading distribution. See “Model 505.07/.11

Specifications” on page 18 and “Model 505.20/.30 Specifications” on page 20.

A review of the final installation plan by building personnel is recommended to

check static and dynamic floor loading.

Mechanical Shock/Vibration

Where impact testing is performed or in higher speed fatigue testing, cyclic loads

and simple shock pulses can be introduced into the laboratory floor. Adequate

isolation of the load unit is often possible with the supplied vibration isolators.

However, in some cases, an optional air bag isolation device might be required.

Contact your MTS representative for additional details.

Electrical Power Distribution

The input line voltage to the Landmark System must be adequately rated for the

loads under which the system operates. Size the power system with adequate

reserve for future equipment additions and installation expansion. Both the HPU

and the console controls must be considered in the distribution system, with

emphasis on providing “interference free” electrical power to the controls. Plan

routing of power cables away from instrumentation cables (for example,

transducer cables). Avoid long parallel runs of power cables in close proximity to

instrumentation cables. Power cables should be separated from instrumentation

cables by 1 to 3 ft (0.3 to 1 m).

Landmark Test System Site Prep Guide Facility Preparation

9

Page 10

Grounding Requirements

Each system has its own internal grounding system, which is common grounded

through the green or green/yellow wire in the power cable and must also return to

earth ground, through the conduit of the electrical distribution system. Note that

the green or green/yellow wire must not be a current-carrying conductor or a

neutral conductor. A ground strap is provided to tie the load unit assembly

directly to the console cabinet.

Where electrical power is of poor quality (noise spikes, poorly regulated, and so

forth) or the ground system in the facility contains electrical noise, attach a 4

AWG wire directly to a good earth ground point such as a 6 ft (2 m) copper

grounding rod driven at least 6 ft (2 m) into the ground. Grounding must conform

to local electrical codes.

Console Control Power

Electrical power to the system controls should be filtered from outside RF

interference and line regulated to provide 105-130 Vac or 200-240 Vac, 50-60

Hz. An isolated power source or uninterruptible power supply is recommended if

it is desirable to maintain control power for longer than the delay built into the

control electronics (approximately one second). Make sure that the service to the

Landmark System is not on a line that can be accidentally shut off. Power

supplied to the Landmark System should be on an isolated circuit, or on its own

transformer from the main power box.

Radiated Emissions

Operation of the Landmark System can be affected by sources of electromagnetic

interference (EMI) that are near the system controls, computer, instrumentation

cables, and related peripheral equipment. Common sources of EMI are electric

motors, broadcast systems, high-voltage power lines, power tools, mobile

communications, radar, vehicle ignition systems, static electricity, induction

heaters, fluorescent lights, and lightning. The effects of EMI are unpredictable,

additional grounding and shielding might be necessary. Techniques such as using

screen cages or other metal surfaces around the system, along with good

grounding practices and proper storage of magnetic memory medium, are

recommended.

Fixture and Specimen Handling Considerations

Movement of specimens in and out of the test system must be considered early in

the planning of the site layout. With smaller specimens, the use of a rolling work

cart with lift-off storage drawers is often recommended to facilitate the handling

of specimens and to minimize the chance of damage to the specimens prior to

and after the test. As specimen size and fixturing increase beyond the typical

lifting capacity of laboratory personnel, use of an overhead crane, lifting straps,

or a forklift might be necessary to handle specimens or fixtures.

If the load unit does not have hydraulic lifts and locks, an overhead crane or other

suitable lifting device can be used to change the crosshead position to

accommodate specimen or fixture length.

Facility Preparation

10

Landmark Test System Site Prep Guide

Page 11

Acoustics

Temperature

Heat Dissipation

Some types of fatigue testing can produce noise which is undesirable or

potentially damaging to hearing. Acoustical treatment of walls and ceiling might

be necessary to prevent harm to personnel. If disk drives are included in the

system, acoustical materials should not be of the type that generates or harbors

dust. The Series 505 SilentFlo™ Hydraulic Power Units are designed for

relatively quiet operation; no special acoustical considerations are necessary.

However, the use of hearing protection is recommended for personnel involved

in long-term testing in a noisy testing environment.

The operating temperature range of the electronics console is 64°F to 86°F (18°C

to 30°C). This includes most temperature sensitive equipment, such as disk

drives which are dependent on cooler air to maintain proper height of read/write

heads. Although the load cell or force transducer is temperature compensated, it

is recommended that room air heating and cooling outlets be directed so that they

uniformly distribute air throughout the room. This is primarily due to the

potential changes in specimen characteristics or test data associated with changes

in temperature.

Altitude

For comfortable working conditions and proper operation of the equipment, the

heat dissipation of the hydraulic power equipment, electronics console, and other

equipment must be considered in providing adequate heating or air conditioning

to the laboratory area.

The HPU is normally located in a room separate from the test system to reduce

heat loading and acoustical noise near operating personnel. For specific

requirements, see “Model 505.07/.11 Specifications” on page 18 and “Model

505.20/.30 Specifications” on page 20. A 40°C (104°F) maximum environment

is recommended for the HPU. Care must be taken to ensure that it is not placed in

a location subject to freezing when water cooling is used. Reservoir heaters and

oil-to-air coolers are available; consult your MTS representative.

Heat dissipation for the console and other electronic units can be estimated by

summing the losses going to heat in the room {approximately 6000 Btu/hr (1500

kcal/hr) for a single 15 amp power panel or 8000 Btu/hr (2000 kcal/hr) for a

single 20 amp power panel} and the gains from personnel and other heat inputs

such as furnaces. To this figure, you should add 20% additional heat gain for

future changes in test requirements.

Systems operated at high altitudes can have heat dissipation problems because of

the lower density of the air. This type of problem might require the use of an air

conditioned environment or cooling fans to reduce the heat load. The specified

equipment environment should be reduced by 0.55°F per 1000 feet (1.0°C per

1000 meters) above sea level. Most equipment can be operated at altitudes up to

8000 feet (2400 meters). Refer to equipment product specifications for any

altitude restrictions.

Landmark Test System Site Prep Guide Facility Preparation

11

Page 12

Relative Humidity

The recommended relative humidity for the test room is within the range of 40%

to 65% (non-condensing). The risk of static discharge, which easily damages

logic components and causes loss of data in memory devices, is increased by low

humidity. Excessive humidity can result in electrical leakage currents or

component failure.

Leveling System Components

Shims can be used under the load unit feet or isolation pads to level the load unit

on an uneven floor.

Console type cabinets have leveling feet that allow the cabinet to be leveled as

necessary. No particular level alignment of the console is necessary other than to

ensure the footing is solid and the console cannot be rocked. Disk storage drives

do, however, require proper leveling of the equipment to minimize wear on the

read/write heads and fan bearings.

Facility Preparation

12

Landmark Test System Site Prep Guide

Page 13

System Component Specifications

Contents Load Unit Specifications 14

Hydraulic Power Unit Specifications 17

Controller Specifications 22

Landmark Test System Site Prep Guide System Component Specifications

13

Page 14

Load Unit Specifications

Load Unit Specifications

System Component Specifications

14

Landmark Test System Site Prep Guide

Page 15

Load Unit Specifications

Landmark Test System Site Prep Guide System Component Specifications

15

Page 16

Load Unit Specifications

System Component Specifications

16

Landmark Test System Site Prep Guide

Page 17

Hydraulic Power Unit Specifications

The following tables provide the specifications for the following hydraulic power

units:

Model 505.07/.11 Specifications 18

Model 505.20/.30 Specifications 20

Hydraulic Power Unit Specifications

Landmark Test System Site Prep Guide System Component Specifications

17

Page 18

Hydraulic Power Unit Specifications

Model 505.07/.11 Specifications

General Specifications

Parameter Specification

Environmental

Operating temperature

Humidity

Heat load

Noise

Hydraulic fluid

Typical operating

temperature range

Filtration

Reservoir capacity

Heat exchanger

Flow requirements

Water pressure

Maximum pressure

Cooling

Water hose

*

rating at 1 m

For use in a controlled environment

5–40°C (41–104°F)

0–85% noncondensing

<630 kcal/hr (2500 BTU/hr)

60 dB (A) fully compensated

Exxon Mobil DTE 25 or Shell Tellus

43–49°C (110–120°F)

3 microns nominal

174 L (46 gal) maximum

Water-cooled stainless steel plate

See “Water flow rating (input temperature)”

0.24–0.34 MPa (35–50 psi differential)

0.83 MPa (120 psi)

see the Model Specific Specifications table

19 mm (0.75 in)–inside diameter

46 AW

Hydraulic connections

Pressure

Return

Drain

Water Connections -12 (3/4 in NPT) for both In and Out

Electrical power

Line voltage

Control voltage

Dimensions

Height

Length

Width

* Sound pressure level [db (A)] is expressed as a free field value. Readings may vary with

the acoustic environment.

System Component Specifications

18

Each requires an O-ring face seal

-12

-12

-8 and -6 (two connections)

200–575 V AC, 3∅ at 50/60 Hz

24 V DC

1067 mm (42 in)

990 mm (39 in)

711 mm (28 in)

Landmark Test System Site Prep Guide

Page 19

Hydraulic Power Unit Specifications

Model Specific Specifications

Parameter 505.07 Specification 505.11 Specification

Pump/motor

Maximum Continuous

pressure

Maximum Flow

capacity

Motor rating

Water flow rating

(input temperature)

10.0°C (50°F)

15.5°C (60°F)

21.1°C (70°F)

26.7°C (80°F)

32.2°C (90°F)

Heat load (maximum)

Weight with maximum oil

174 L (46 gal))

Line voltage starter configuration

21 MPa (3000 psi)

22.7 L/m (6 gpm) at 50 Hz

26.5 L/m (7 gpm) at 60 Hz

11.2 Kw (15 hp) at 50/60 Hz

3.8 L/m (1.0 gpm)

4.9 L/m (1.3 gpm)

6.1 L/m (1.6 gpm)

8.3 L/m (2.2 gpm)

15.9 L/m (4.2 gpm)

12.3 kW (42,000 Btu/hr)

450 kg (992 lb) 473 kg (1042 lb)

Wye-Delta starter configuration

21 MPa (3000 psi)

41.6 L/m (11 gpm) at 50/60 Hz

18.6 Kw (25 hp) at 50/60 Hz

7.2 L/m (1.9 gpm)

9.1 L/m (2.4 gpm)

12.1 L/m (3.2 gpm)

18.9 L/m (5.0 gpm)

49.2 L/m (13.0 gpm)

20.5 kW (70,000 Btu/hr)

Landmark Test System Site Prep Guide System Component Specifications

19

Page 20

Hydraulic Power Unit Specifications

Model 505.20/.30 Specifications

General Specifications

Parameter Specification

Environmental

Operating temperature

Humidity

Heat load

Noise

Hydraulic fluid

Typical operating

temperature range

Filtration (microns)

Reservoir capacity

Heat exchanger

Flow requirements, cooling

Water pressure

Maximum pressure

Water hose

*

rating at 1 m

For use in a controlled environment.

5–40°C (41–104°F)

0–85% noncondensing

< 630 kcal/hr (2500 Btu/hr)

63 dB (A) fully compensated

Exxon Mobil DTE 25 or Shell Tellus 46 AW

43–49°C (110–120°F)

3 microns nominal

341 L (90 gal) maximum

208 L (55 gal) minimum

Water-cooled

See Water flow rating (input temperature)

0.24–0.31 MPa (35–45 psi differential)

0.83 MPa (120 psi)

25 mm (1 in)—inside diameter

Hydraulic connections

Pressure

Return

Drain

Water connections -16 (1 in NPT) for both In and Out

Electrical power

Line voltage

Control Voltage

Dimensions

Height

Length

Width

* Sound pressure level [db (A)] is expressed as a free field value. Readings may vary with the

acoustic environment.

System Component Specifications

20

Each requires an O-ring face seal

-16

-16

-6 and -8 (two connections)

200-575 V AC, 3Φ

24 V DC

1423 mm (56 in)

1575 mm (62 in)

864 mm (34 in)

at 50/60 Hz

Landmark Test System Site Prep Guide

Page 21

Hydraulic Power Unit Specifications

Model Specific Specifications

Parameter 505.20 Specification 505.30 Specification

Pump/Motor

Maximum continuous

pressure

Maximum flow

capacity

Motor rating

Current draw

Operating voltages

Control voltage

Water flow rating

(input temperature)

15.5°C (60°F)

21.1°C (70°F)

26.7°C (80°F)

32.2°C (90°F)

Heat load (maximum)

Type NEMA compliant

21 MPa (3000 psi)

75 L/m (20 gpm) at 60 Hz

62 L/m (16.5 gpm) at 50 Hz

30 kW (40 hp) at 50/60 Hz

52 A continuous at 460 V AC 3Ø

66 A continuous at 380 V AC 3Ø

200–575 V AC

24 V DC

23.4 L/m (6.26 gpm)

30.2 L/m (8.06 gpm)

42.7 L/m (11.3 gpm)

60.4 L/m (16 gpm)

31.65 kW (108,000 Btu/hr)

Type NEMA compliant

21 MPa (3000 psi)

113 L/m (30 gpm) at 60 Hz

101 L/m (26.6 gpm) at 50 Hz

45 kW (60 hp) at 50/60 Hz

77 A continuous at 460 V AC 3Ø

97 A continuous at 380 V AC 3Ø

200–575 V AC

24 V DC

35.2 L/m (9.3 gpm)

45.4 L/m (12 gpm)

64.7 L/m (17.1 gpm)

91.2 L/m (24 gpm)

49.2 kW (168,000 Btu/hr)

Weight

Empty

With 227 L (60 gal) oil

542 kg (1195 lb)

733 kg (1615 lb)

588 kg (1295 lb)

778 kg (1715 lb)

Landmark Test System Site Prep Guide System Component Specifications

21

Page 22

Controller Specifications

Controller Specifications

Environmental Requirements—Series 494 Hardware

All Series 494 hardware components are intended for indoor use only. This

indoor environment must conform to the following environmental specifications.

Note All Series 494 Controller must only be operated under the installation

and ambient conditions (such as, temperature, moisture, and EMC)

specified.

Parameter Specification

Temperature 5ºC–40ºC (41ºF–104ºF)

Humidity 5–85%, non-condensing

Altitude 3048 m (10,000 ft) maximum

Space

Requirements

Note To maintain EMC compliance, the controller must be installed in a

location that does not exceed the EN 61000-6-4 emission standard for

industrial environments.

For proper ventilation, allow 51 mm (2 in) clearance

on all sides of the chassis.

The rear of the chassis requires a minimum

clearance of 15.24 cm (6 in) for cable connections.

System Component Specifications

22

Landmark Test System Site Prep Guide

Page 23

Specifications–Model 494.04 Chassis

All equipment related to the controller should be connected to the same fused

power circuit.

Note Electrical connections must be made by qualified personnel and conform

to local codes and regulations. Local electrical codes supersede any

information found here.

Model 494.04 Chassis Specifications

Parameter Specification

Input Voltage 100–240 V AC (single phase)

Input Frequency 50–60 Hz

Input Current 5 A at 100 V AC

Facility Power Requirements Provide a dedicated circuit for the

Controller Specifications

power factor corrected universal input

3 A at 240 V AC

chassis, computer, and monitor.

Input Surge <40 A

Insulation Over Voltage Category I

Pollution Degree 2

Weight Approximately 8.6 kg (19 lb)

Dimensions Width: 43 cm (17 in)

Height: 14 cm (5.5 in)

Depth: 44.5 cm (17.5 in)

Landmark Test System Site Prep Guide System Component Specifications

23

Page 24

Controller Specifications

Specifications–Model 494.06 Chassis

All equipment related to the controller should be connected to the same fused

power circuit.

Note Electrical connections must be made by qualified personnel and conform

to local codes and regulations. Local electrical codes supersede any

information found here.

Model 494.06 Chassis Specifications

Parameter Specification

Input Voltage 100–240 V AC (single phase)

Input Frequency 50–60 Hz

Input Current 10 A at 100 V AC

Facility Power Requirements Provide a dedicated circuit for the

power factor corrected universal input

5 A at 240 V AC

chassis, computer, and monitor.

Input Surge <40 A

Insulation Over Voltage Category I

Pollution Degree 2

Weight Approximately 14 kg (31 lb)

Dimensions Width: 21.6 cm (8.5 in)

Height: 44.2 cm (17.4 in)

Depth: 64.8 cm (25.5 in)

System Component Specifications

24

Landmark Test System Site Prep Guide

Page 25

Specifications–Model 494.10 Chassis

All equipment related to the controller should be connected to the same fused

power circuit.

Note Electrical connections must be made by qualified personnel and conform

to local codes and regulations. Local electrical codes supersede any

information found here.

Model 494.10 Chassis Specifications

Parameter Specification

Input Voltage 100–240 V AC (single phase)

Input Frequency 50–60 Hz

Input Current 12 A at 100 V AC

Facility Power Requirements Provide a dedicated circuit for the

Controller Specifications

power factor corrected universal input

6 A at 240 V AC

chassis, computer, and monitor.

Input Surge <80 A

Insulation Over Voltage Category I

Pollution Degree 2

Weight Approximately 45.4 kg (100 lb)

Dimensions Width: 37 cm (14.5 in)

Height: 56 cm (22 in)

Depth: 66 cm (26 in)

Landmark Test System Site Prep Guide System Component Specifications

25

Page 26

Controller Specifications

Specifications–Model 494.20 Chassis

All equipment related to the controller should be connected to the same fused

power circuit.

Note Electrical connections must be made by qualified personnel and conform

to local codes and regulations. Local electrical codes supersede any

information found here.

Model 494.20 Chassis Specifications

Parameter Specification

Input Voltage 100–240 V AC (single phase)

Input Frequency 50–60 Hz

Input Current 16 A at 100 V AC

Facility Power Requirements Provide a dedicated circuit for the

power factor corrected universal input

8 A at 240 V AC

chassis, computer, and monitor.

Input Surge <100 A

Insulation Over Voltage Category I

Pollution Degree 2

Weight Approximately 60 kg (132 lb)

Dimensions Width: 60 cm (24 in)

Height: 98 cm (38 in)

Depth: 90 cm (35 in)

System Component Specifications

26

Landmark Test System Site Prep Guide

Page 27

Additional Considerations

Contents HPU Considerations 28

Load Unit Considerations 30

Electronic Console Considerations 31

Computer Console Considerations 32

When You Get Your System 32

Landmark Test System Site Prep Guide Additional Considerations

27

Page 28

HPU Considerations

HPU Considerations

HPU Cooling Water Requirements

The hydraulic power units (HPUs) water connections are supplied with hose

nipples for the recommended type of hoses. The common type of recommended

hose is Uniroyal P-340 or equivalent hose rated for 150 psi (1.03 MPa) operation.

Shutoff valves should be included in the facility supply and drain lines should be

included to allow for unit maintenance. If the cooling water contains

contaminants (such as sediment) water filtration might be necessary to prevent

clogging of the heat exchanger tubes. See “Hydraulic Power Unit Specifications”

on page 17 to find water pressure, hose size requirements, and water cooling

requirements for the HPU.

HPU Electrical Requirements

The electrical interface to the HPU occurs at the HPU starter box located on the

unit. Power cable access is provided into the box with cables coming from a

customer-supplied, fused electrical service disconnect. This disconnect must be

provided to safely remove all power to the HPU for maintenance work. Hookup

must conform to local electrical codes and regulations, see “Model 505.07/.11

Specifications” on page 18 and “Model 505.20/.30 Specifications” on page 20.

Water Quality

HPUs are equipped with water-to-oil heat exchangers that are designed to

remove 100% of the HPUs heat load. Water-to-oil heat exchangers, also referred

to as oil coolers, use heat transfer to cool the hot oil in the HPU by passing it over

tubes filled with cooling water.

Water chemistry is critical for a successful heat exchange system. Generally

speaking, municipal drinking water that is available in developed countries is

perfectly acceptable for copper tube heat exchangers. This water is non-polluted,

bacteriologically safe and has a neutral pH.

Cooling towers and natural water sources such as wells, rivers or ponds must be

free of pollutants and treated to limit contaminants to the same levels as

municipal drinking water.

Additional Considerations

28

Landmark Test System Site Prep Guide

Page 29

HPU Considerations

Softened or distilled water might not be good to use as a cooling liquid because

although most of the minerals have been removed there is a higher than desirable

level of carbon dioxide and oxygen present in the water. High levels of carbon

dioxide and oxygen will act to decrease the protective layer of minerals that form

on the surface of the tube, and increase the formation of copper oxide.

Water Chemistry

Compounds found in Water Allowable Quantity (parts per million)

Ammonia none

Bacteria must be bacteriologically safe

Calcium <800 ppm

Chlorides <5 ppm

Dissolved solids >50 but <500 ppm; limit to 150 ppm if abrasive

solids present

Iron 3 ppm

Nitrates <10 ppm

Nitrogen compounds none

Oxidizing salts or none

pH level 6–8.5 recommended

Silica as SiO

Sulfides <1 ppm

Sulfur dioxide <50 ppm

2

<150 ppm to limit silica scale

Some contaminants in the cooling water supply can operate together to create

corrosion rates a hundred times higher than would be seen by either contaminant

acting alone. Cooling towers, unless regularly treated and controlled, are the

systems that have had the most problems with corroded heat exchangers.

Local industrial water treatment specialists can provide information on your

water conditions and solutions to contaminant problems.

Landmark Test System Site Prep Guide Additional Considerations

29

Page 30

Load Unit Considerations

Load Unit Considerations

The load unit is typically shipped in a horizontal position on a pallet or in a crate.

Lifting and moving instructions that describe proper handling methods are placed

in a protective envelope and shipped with the load unit. These instructions

include recommended methods to remove the unit from the pallet, raise the unit

erect, and move it into position. Read all provided instructions carefully to

understand how to handle the weight of the components. It is recommended that

personnel experienced in the practice of rigging for construction and industrial

operations be employed. The proper use of lifting slings where the center of

gravity is elevated above the floor is essential to the safety of personnel and

equipment.

After the load unit is moved into position, install the vibration isolation pads to

ensure proper vibration isolation between the load unit and floor.

The routing path of the hydraulic hoses and electrical cables should be noted with

respect to any obstructions that could cause the hose or cable to be abraded by

rubbing during machine operation. It is recommended that electrical cabling be

routed in overhead wire trays or, as a minimum, be protected on the floor with

adequate covering to prevent damage caused during fixturing, by dropping

specimens and tools, or by walking on them. Sufficient space should also be left

around the load unit for maintenance and final hook-ups.

Additional Considerations

30

Landmark Test System Site Prep Guide

Page 31

Electronic Console Considerations

Console Handling Requirements

The electronic console is shipped with a protective covering to prevent damage to

the controls and cable connectors and to prevent dust infiltration. It is

recommended that the covering not be removed until the unit has been placed in

its final position for expected use.

Large stand-up consoles have lifting eyes as well as casters for easy movement.

When moving the console using the lifting eyes, lift it only as high as necessary.

When moving the unit using the casters, be sure the surface is smooth and level

and the leveling pads are fully screwed up into the base of the cabinet. Due to the

high center of gravity of the console, two people are required to roll the console if

the floor has obstructions or is uneven or bumpy; use one person on each side of

the console to watch for obstructions. Move the unit with the front controls away

from the direction of travel, thereby minimizing the damage that could occur if

the console tipped over. Cable exit from the console is at the rear, through a slot

below the rear door; therefore, location of the cable trays and routing should be

considered from this point. Use the same methods for protecting the electronic

cables as those used for the hydraulic hoses. Adequate clearance must be

provided for rear console access to permit cable attachment, fuse replacement, air

filter replacement, and component maintenance.

Electronic Console Considerations

Landmark Test System Site Prep Guide Additional Considerations

31

Page 32

Computer Console Considerations

Computer Console Considerations

Packaging and movement of the computer console is similar to the electronic

console. Other peripheral components (such as disk drives) that are susceptible to

dust contamination should be placed away from obvious sources of

contamination, and the room should be slightly positively pressurized to prevent

migration of dust and dirt into the room.

When You Get Your System

Operation of your system can involve exposure to hazardous situations: high

voltages are present at the hydraulic power unit and the control consoles. The

control consoles control the movement of the actuator which uses high pressure

hydraulic fluid. Because of these potential hazards, your system is provided with

documentation that includes information on safety practices. Read this

information before attempting to operate your system.

If the source of cooling water is a cooling tower, the presence of contaminants

that are corrosive to metals will vary over time. Contaminants must be controlled

to the quantities listed in the following table. Ideally, the pH should be

maintained in the 6.5-8.0 range for most applications, and chlorine should be

used to limit the growth of microbiologic organisms that are generated by protein

decay. You must be careful not to use excessive amounts of chlorine: the chloride

concentration in the cooling water must be kept to less than 5 ppm.

Additional Considerations

32

Landmark Test System Site Prep Guide

Page 33

Page 34

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

Internet: www.mts.com

ISO 9001 Certified QMS

Loading...

Loading...