Mitsubishi TM-RG2M, TM-RU2M, Tm-rfm User Manual

General-Purpose AC Servo

MODEL

TM-RFM

TM-RG2M

TM-RU2M

DIRECT DRIVE MOTOR INSTRUCTION MANUAL

H

A - 1

Safety Instructions

Please read the instructions carefully before using the equipment.

To use the equipment correctly, do not attempt to install, operate, maintain or inspect the equipment until you

have read through this Instruction Manual and appended documents carefully. Do not use the equipment

until you have a full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

Note that the CAUTION level may lead to a serious consequence according to conditions.

Please follow the instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

Indicates what must not be done. For example, "No Fire" is indicated by

.

Indicates what must be done. For example, grounding is indicated by

.

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so

on are classified into "POINT".

After reading this Instruction Manual, keep it accessible to the operator.

A - 2

1. To prevent electric shock, note the following

WARNING

Before wiring and inspections, turn off the power and wait for 15 minutes or more until the charge lamp

turns off. Otherwise, an electric shock may occur. In addition, when confirming whether the charge lamp

is off or not, always confirm it from the front of the servo amplifier. Then, confirm that the voltage

between P+ and N- is safe with a voltage tester and others.

Ground the servo amplifier and direct drive motor securely.

Any person who is involved in wiring and inspection should be fully competent to do the work.

Do not attempt to wire the servo amplifier and direct drive motor until they have been installed.

Otherwise, it may cause an electric shock.

The cables should not be damaged, stressed, loaded, or pinched. Otherwise, it may cause an electric

shock.

To avoid an electric shock, insulate the connections of the power supply terminals.

2. To prevent fire, note the following

CAUTION

Install the servo amplifier, direct drive motor, and regenerative resistor on incombustible material.

Installing them directly or close to combustibles will lead to a fire or smoke generation.

Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the servo amplifier and direct drive motor.

3. To prevent injury, note the following

CAUTION

Only the power/signal specified in the Instruction Manual should be applied to each terminal. Otherwise,

it may cause an electric shock, fire, injury, etc.

Connect cables to the correct terminals. Otherwise, a burst, damage, etc. may occur.

Ensure that polarity (+/-) is correct. Otherwise, a burst, damage, etc. may occur.

The servo amplifier heat sink, regenerative resistor, direct drive motor, etc. may be hot while power is on

or for some time after power-off. Take safety measures, e.g. provide covers, to avoid accidentally

touching the parts (cables, etc.) by hand.

During operation, never touch the rotor of the direct drive motor. Otherwise, it may cause injury.

A - 3

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a malfunction, injury,

electric shock, fire, etc.

(1) Transportation and installation

CAUTION

Transport the products correctly according to their mass.

Stacking in excess of the specified number of product packages is not allowed.

Do not hold the cables, rotor, encoder, or connector when carrying the direct drive motor. Otherwise, it

may drop.

Install the servo amplifier and the direct drive motor in a load-bearing place in accordance with the

Instruction Manual.

Do not get on or put heavy load on the equipment. Otherwise, it may cause injury.

The equipment must be installed in the specified direction.

When you keep or use the equipment, please fulfill the following environment.

Item Environment

Ambient

temperature

Operation 0 °C to 40 °C (non-freezing)

Storage -15 °C to 70 °C (non-freezing)

Ambient

humidity

Operation 10 %RH to 80 %RH (non-condensing)

Storage 10 %RH to 90 %RH (non-condensing)

Ambience Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist, dust, and dirt

Altitude

TM-RFM_J10

TM-RFM_C20

TM-RFM_E20

TM-RFM_G20

TM-RG2M_C30

TM-RG2M_E30

TM-RG2M_G30

TM-RU2M_C30

TM-RU2M_E30

TM-RU2M_G30

Max. 2000 m above sea level (Note)

Vibration

resistance

TM-RFM_C20

TM-RFM_E20

TM-RFM_G20

TM-RG2M_C30

TM-RG2M_E30

TM-RG2M_G30

TM-RU2M_C30

TM-RU2M_E30

TM-RU2M_G30

X, Y: 49 m/s

2

TM-RFM_J10 X, Y: 24.5 m/s

2

Note. Contact your local sales office for the altitude for options.

Securely fix the direct drive motor to the machine. If being attached insecurely, the motor may come off

during operation.

Do not install or operate a servo amplifier or direct drive motor, which has been damaged or has any

parts missing.

Do not drop or strike the direct drive motor. Otherwise, it may cause injury, malfunction, etc.

Take safety measures, e.g. provide covers, to prevent accidental access to the rotor of the direct drive

motor during operation.

A - 4

CAUTION

Do not apply shocks, e.g. hit with a hammer, when coupling the rotor of the direct drive motor. Otherwise,

the encoder may malfunction.

Do not subject the rotor of the direct drive motor to more than the permissible load. Otherwise, the rotor

may break.

When the product has been stored for an extended period of time, contact your local sales office.

When handling the direct drive motor, be careful about the edged parts such as corners of the direct

drive motor.

Do not strike the connector. Otherwise, it may cause a connection failure, malfunction, etc.

Be sure to check the vibration level with the direct drive motor mounted on the machine. A great vibration

may cause the early damage of a bearing and encoder. The great vibration may also cause the poor

connector connection or bolt looseness.

For the gain adjustment at the equipment startup, check the torque waveform and the speed waveform

with a measurement device to check that no vibration occurs. If the vibration occurs due to high gain, the

vibration may cause the early damage of the direct drive motor.

To prevent a fire or injury in case of an earthquake or other natural disasters, securely install, mount, and

wire the servo motor in accordance with the Instruction Manual.

(2) Wiring

CAUTION

Wire the equipment correctly and securely. Otherwise, the direct drive motor may operate unexpectedly.

Make sure to connect the cables and connectors by using the fixing screws and the locking mechanism.

Otherwise, the cables and connectors may be disconnected during operation.

Do not install a power capacitor, surge killer, or radio noise filter (FR-BIF option) on the power wire of the

direct drive motor.

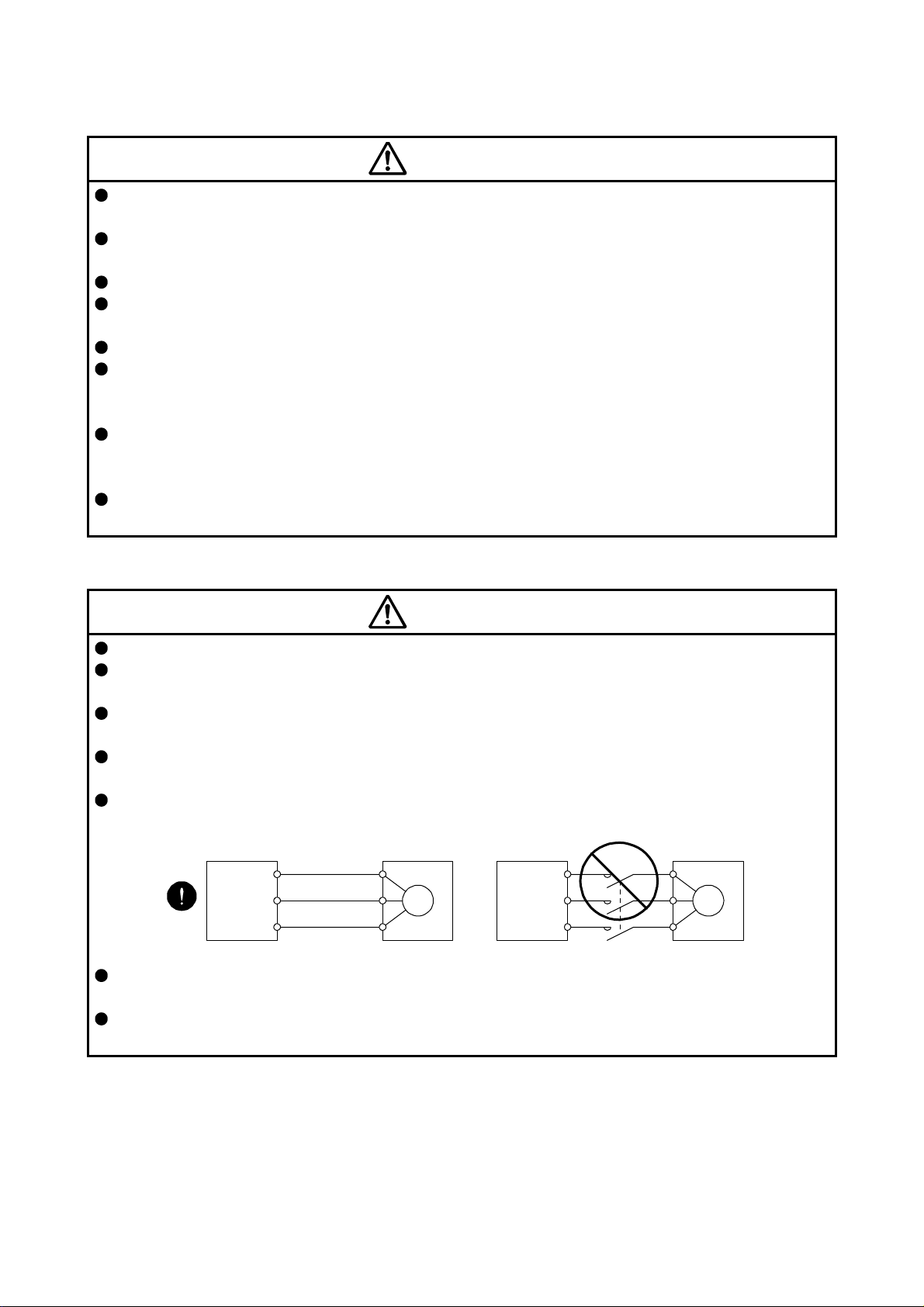

To avoid a malfunction, connect the power phases (U/V/W) of the servo amplifier and the direct drive

motor correctly.

Connect the servo amplifier power output (U/V/W) to the direct drive motor power input (U/V/W) directly.

Do not let a magnetic contactor, etc. intervene. Otherwise, it may cause a malfunction.

Servo amplifier

Direct drive motor

Servo amplifier

Direct drive motor

U

M

V

W

U

V

W

U

M

V

W

U

V

W

Do not connect AC power supply directly to the direct drive motor. Otherwise, it may cause a

malfunction.

When the cable is not tightened enough to the terminal block, the cable or terminal block may generate

heat because of the poor contact. Be sure to tighten the cable with specified torque.

A - 5

(3) Test run and adjustment

CAUTION

Before operation, check the parameter settings. Improper settings may cause some machines to operate

unexpectedly.

Never make a drastic change to the parameter values as doing so will make the operation unstable.

(4) Usage

CAUTION

Provide an external emergency stop circuit to ensure that operation can be stopped and power switched

off immediately.

For equipment in which the moving part of the machine may collide against the load side, install a limit

switch or stopper to the end of the moving part. The machine may be damaged due to a collision.

Do not disassemble, repair, or modify the product. Otherwise, it may cause an electric shock, fire, injury,

etc. Disassembled, repaired, and/or modified products are not covered under warranty.

Use the direct drive motor with the specified servo amplifier.

Wire options and peripheral equipment, etc. correctly in the specified combination. Otherwise, it may

cause an electric shock, fire, injury, etc.

If the dynamic brake is activated at power-off, alarm occurrence, etc., do not rotate the servo motor by an

external force. Otherwise, it may cause a fire.

(5) Corrective actions

CAUTION

When it is assumed that a hazardous condition may occur due to a stop or product malfunction, use a

motor with an external brake to prevent the condition.

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

Provide an adequate protection to prevent unexpected restart after an instantaneous power failure.

After an earthquake or other natural disasters, ensure safety by checking the conditions of the

installation, mounting, wiring, and equipment before switching the power on to prevent an electric shock,

injury, or fire.

A - 6

(6) Storage

CAUTION

Note the followings when storing the direct drive motor for an extended period of time (guideline: three

months or more).

Always store the direct drive motor indoors in a clean and dry place.

If it is stored in a dusty or damp place, make adequate provision, e.g. cover the whole product.

If the insulation resistance of the winding decreases, check how to store the equipment.

Though the motor is rust-proofed before shipment using paint or rust prevention oil, rust may be

produced depending on the storage conditions or storage period.

If the direct drive is to be stored for longer than six months, apply rust prevention oil again especially to

the machine processing surfaces of the rotor, etc.

Before using the product after storage for an extended period of time, hand-turn the direct drive motor

rotor (output shaft) to confirm that nothing is wrong with the direct drive motor.

When the product has been stored for an extended period of time, contact your local sales office.

(7) General instruction

To illustrate details, the equipment in the diagrams of this Instruction Manual may have been drawn

without covers and safety guards. When the equipment is operated, the covers and safety guards must

be installed as specified. Operation must be performed in accordance with this Specifications and

Instruction Manual.

DISPOSAL OF WASTE

Please dispose a direct drive motor and other options according to your local laws and regulations.

«About the manual»

This Instruction Manual is required if you use this direct drive motor for the first time. Ensure to keep this

manual accessible to use the direct drive motor safely.

«Cables used for wiring»

The wiring cables mentioned in this Instruction Manual are selected based on the ambient temperature of

40 °C.

«U.S. customary units»

U.S. customary units are not shown in this manual. Convert the values if necessary according to the

following table.

Quantity SI (metric) unit U.S. customary unit

Mass 1 [kg] 2.2046 [lb]

Length 1 [mm] 0.03937 [inch]

Torque 1 [N•m] 141.6 [oz•inch]

Moment of inertia 1 [(× 10

-4

kg•m

2

)] 5.4675 [oz•inch

2

]

Load (thrust load/axial load) 1 [N] 0.2248 [lbf]

Temperature N [°C] × 9/5 + 32 N [°F]

1

CONTENTS

1. INTRODUCTION 1 - 1 to 1 - 2

1.1 Rating plate ...................................................................................................................................... 1 - 1

1.2 Parts identification ............................................................................................................................ 1 - 1

2. INSTALLATION 2 - 1 to 2 - 8

2.1 Equipment configuration .................................................................................................................. 2 - 2

2.2 Mounting direction............................................................................................................................ 2 - 3

2.3 Load mounting/dismounting precautions ......................................................................................... 2 - 3

2.4 Permissible load for the rotor ........................................................................................................... 2 - 3

2.5 Protection from oil and water ........................................................................................................... 2 - 4

2.6 Inspection items ............................................................................................................................... 2 - 5

2.7 Parts having service life ................................................................................................................... 2 - 5

2.8 Machine accuracies ......................................................................................................................... 2 - 6

2.9 Flange size ....................................................................................................................................... 2 - 6

2.10 Restrictions when using this product at altitudes exceeding 1000 m and up to 2000 m

above sea level .............................................................................................................................. 2 - 7

2.11 Magnetic shielding ......................................................................................................................... 2 - 7

3. CONNECTORS USED FOR DIRECT DRIVE MOTOR WIRING 3 - 1 to 3 - 4

3.1 Selection of connectors ................................................................................................................... 3 - 1

3.2 Wiring connectors (connector configurations A/B/C/D/E/F) ............................................................ 3 - 2

4. CONNECTOR DIMENSIONS 4 - 1 to 4 - 4

5. CONNECTION OF SERVO AMPLIFIER AND DIRECT DRIVE MOTOR 5 - 1 to 5 - 8

5.1 Connection instructions ................................................................................................................... 5 - 2

5.2 Direct drive motor power cable wiring diagram ............................................................................... 5 - 2

5.3 Selection example of wires .............................................................................................................. 5 - 3

5.4 Servo amplifier terminal section ....................................................................................................... 5 - 4

6. WIRING OPTION 6 - 1 to 6 -10

6.1 Connector set ................................................................................................................................... 6 - 1

6.1.1 Combinations of connector set ................................................................................................. 6 - 2

6.1.2 Connector list ............................................................................................................................ 6 - 3

6.2 Encoder connector set ..................................................................................................................... 6 - 4

6.2.1 MR-J3DDCNS ........................................................................................................................... 6 - 4

6.2.2 MR-J3DDSPS ........................................................................................................................... 6 - 5

6.2.3 Combinations for the encoder cable ......................................................................................... 6 - 5

6.2.4 Fabrication of the encoder cable ............................................................................................... 6 - 6

6.3 Absolute position storage unit MR-BTAS01 .................................................................................... 6 - 9

2

7. TM-RFM SERIES 7 - 1 to 7 -12

7.1 Model code definition ....................................................................................................................... 7 - 1

7.2 Combinations of servo amplifier and direct drive motor .................................................................. 7 - 2

7.3 Specification list ............................................................................................................................... 7 - 3

7.4 Torque characteristics ..................................................................................................................... 7 - 6

7.5 Dimensions ...................................................................................................................................... 7 - 7

8. TM-RG2M SERIES/TM-RU2M SERIES 8 - 1 to 8 -10

8.1 Model designation ............................................................................................................................ 8 - 1

8.2 Combinations of servo amplifier and direct drive motor .................................................................. 8 - 2

8.3 Specification list ............................................................................................................................... 8 - 3

8.4 Torque characteristics ..................................................................................................................... 8 - 5

8.5 Mounting method ............................................................................................................................. 8 - 5

8.6 Dimensions ...................................................................................................................................... 8 - 6

APPENDIX App. - 1 to App. - 7

App. 1 Selection example of direct drive motor ............................................................................... App. - 1

App. 2 Manufacturer list ................................................................................................................... App. - 3

App. 3 Crimping connector for CNP3_ ............................................................................................ App. - 3

App. 4 Fabrication of the encoder cable .......................................................................................... App. - 4

App. 5 Compliance with the CE marking ......................................................................................... App. - 5

App. 6 Compliance with UL/CSA standard ...................................................................................... App. - 6

1. INTRODUCTION

1 - 1

1. INTRODUCTION

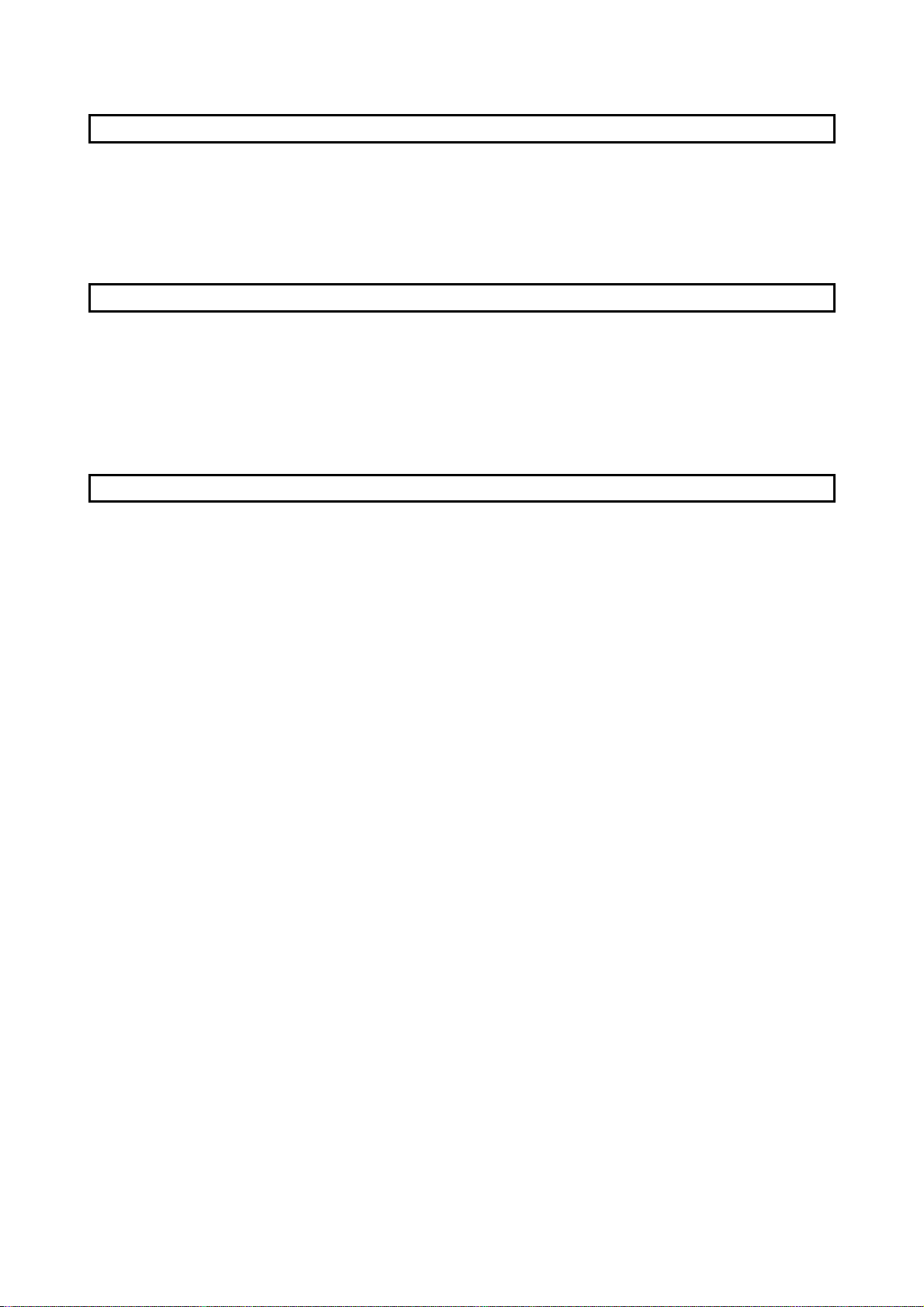

1.1 Rating plate

The following shows an example of rating plate for explanation of each item.

Model

Input power, rated torque, and mass

Insulation class, rated speed, and

maximum ambient temperature

Induced voltage constant, IP rating,

and serial number (Note 1)

(Note 2)

Manufacturer

Conforming standards,

and Country of origin

Note 1. Production year and month of the direct drive motor are indicated in a serial number on the rating plate.

The year and month are indicated by the last two digits of the year and one digit of the month [1 to 9, X (10), Y (11), and Z

(12)].

For January 2012, the Serial No. is like, "SER. _ _ _ _ _ _ _ _ _ 121".

2. Products approved by Certification Bodies are marked. The marks depends on the Certification Bodies.

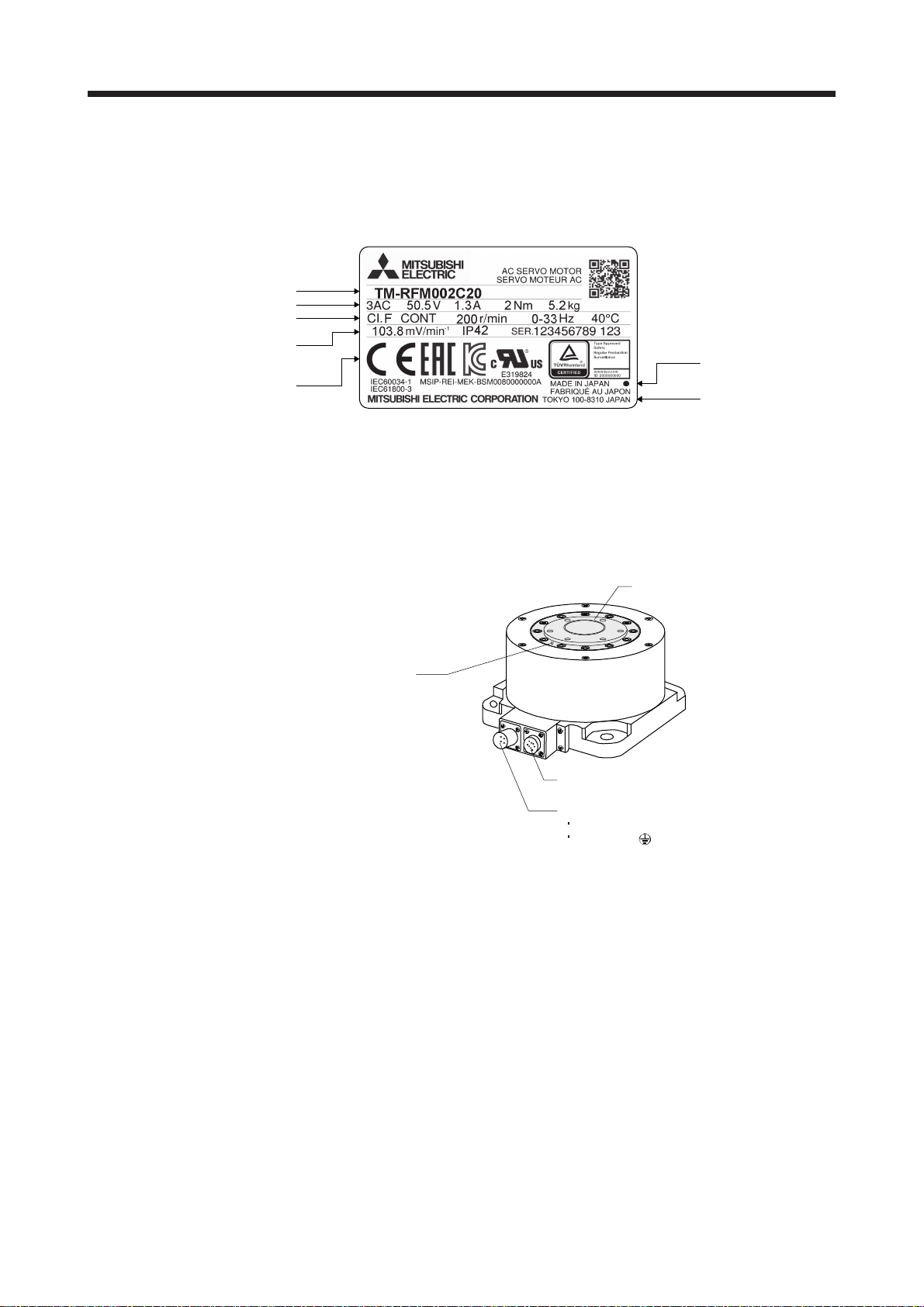

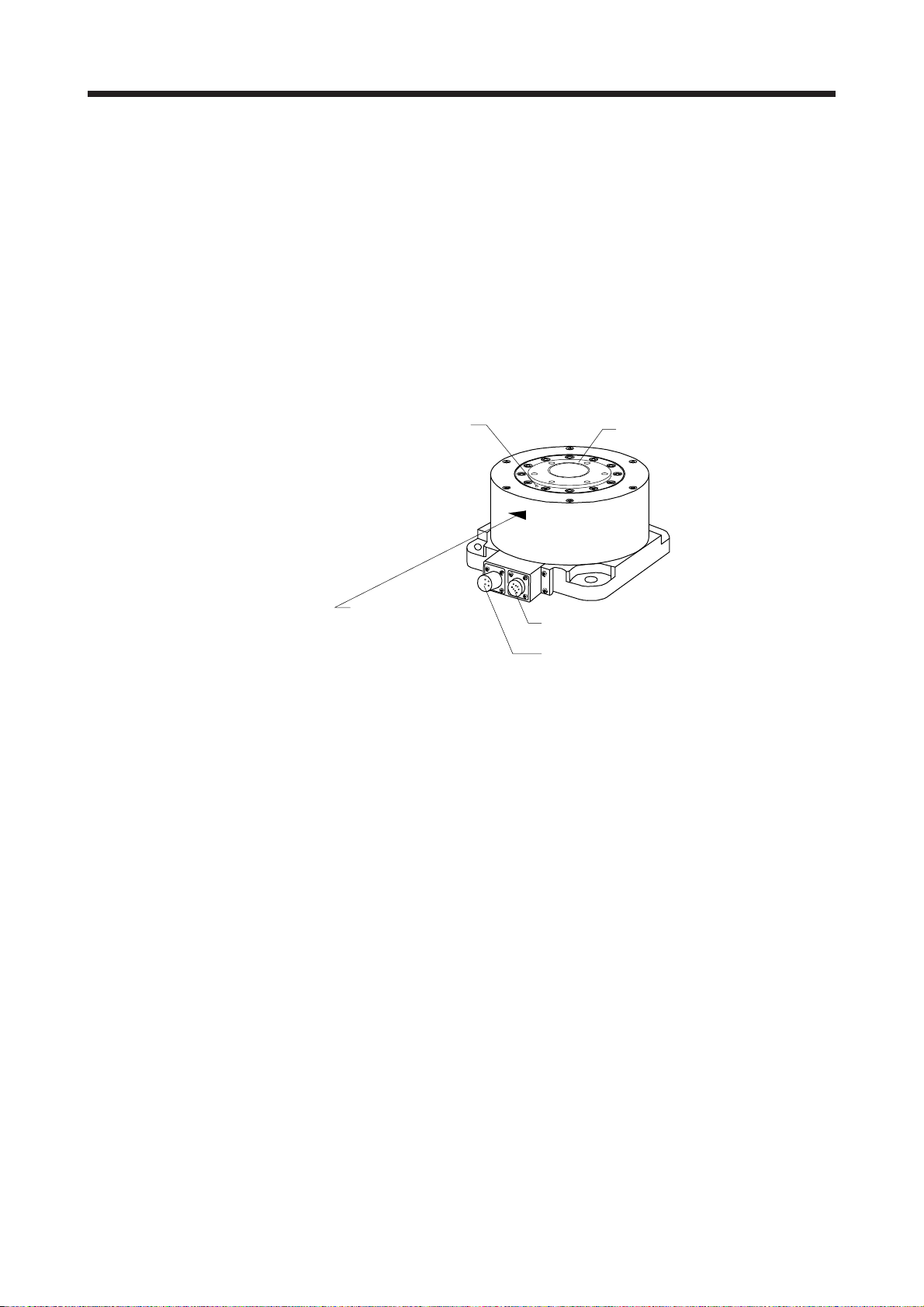

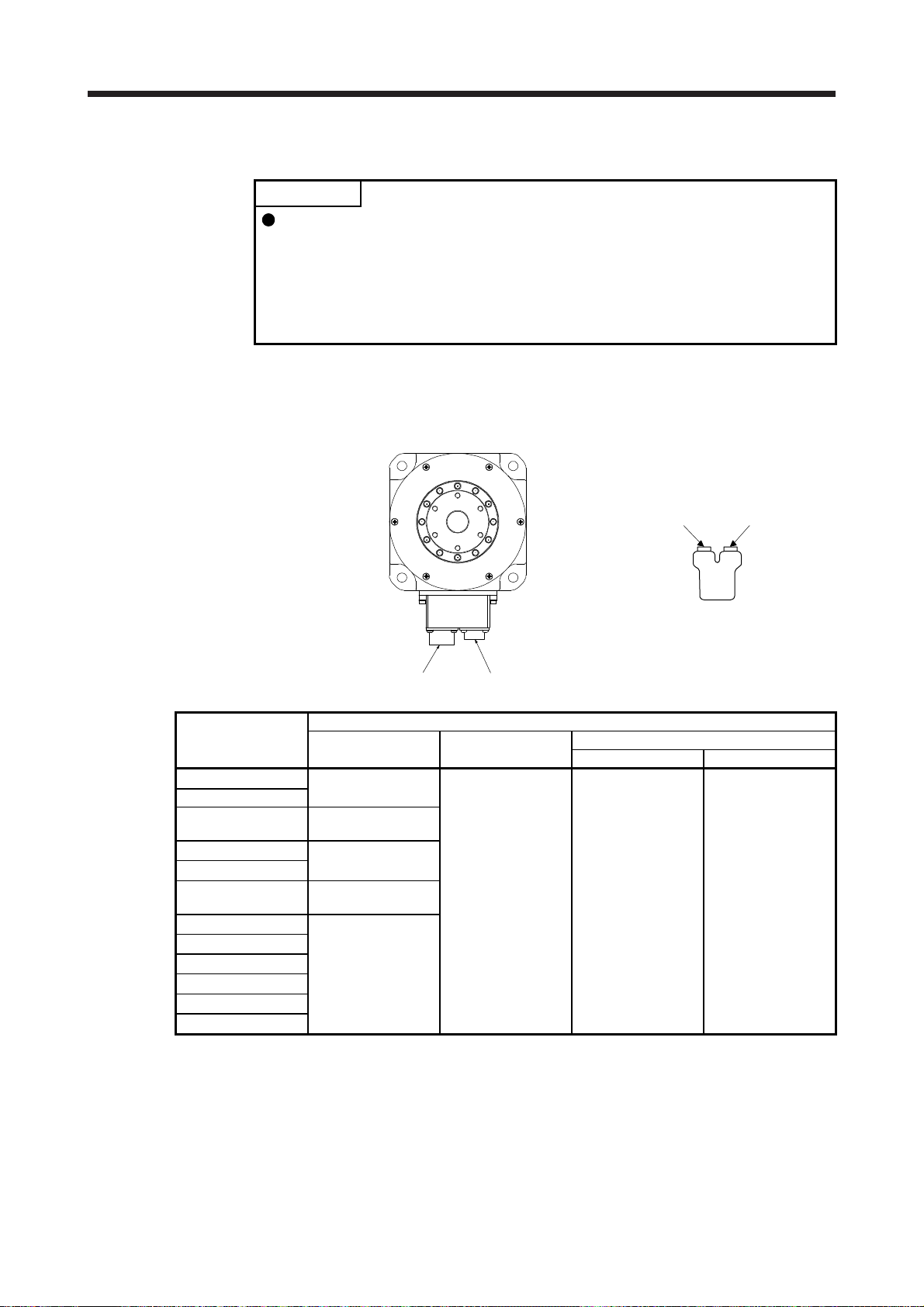

1.2 Parts identification

Rotor (output shaft)

Encoder connector

Power supply connector

Power supply (U/V/W)

Grounding ( )

Z-phase mark

1. INTRODUCTION

1 - 2

MEMO

2. INSTALLATION

2 - 1

2. INSTALLATION

WARNING

To prevent electric shock, ground each equipment securely.

CAUTION

Stacking in excess of the specified number of product packages is not allowed.

Install the direct drive motor on incombustible material. Installing them directly or

close to combustibles will lead to smoke or a fire.

Install the servo amplifier and the direct drive motor in a load-bearing place in

accordance with the Instruction Manual.

Do not get on or put heavy load on the equipment. Otherwise, it may cause injury.

Use the equipment within the specified environment. For the environment, refer to

section 7.3.

Do not drop or strike the direct drive motor as it is precision equipment.

Do not install or operate a direct drive motor, which has been damaged or has

any parts missing.

Do not hold the cables, rotor, encoder, or connector when carrying the direct drive

motor. Otherwise, it may drop.

Securely fix the direct drive motor to the machine. If being attached insecurely,

the motor may come off during operation, leading to injury.

Do not apply shocks, e.g. hit with a hammer, when coupling the rotor of the direct

drive motor. Otherwise, the encoder may malfunction.

When coupling a load to the direct drive motor, make sure to align and center the

load on the motor flange rabbet. Particularly, when a rigid coupling is used, even

a slight center deviation may reduce position accuracy or damage the rotor.

Balance the load to the extent possible. Not doing so can cause vibration during

direct drive motor operation or damage the bearings and encoder.

Take safety measures, e.g. provide covers, to prevent accidental access to the

rotor of the direct drive motor during operation.

Do not subject the rotor of the direct drive motor to more than the permissible

load. Otherwise, the rotor may break, leading to injury.

When the product has been stored for an extended period of time, contact your

local sales office.

Be sure to check the vibration level with the direct drive motor mounted on the

machine. A great vibration may cause the early damage of a bearing and

encoder. The great vibration may also cause the poor connector connection or

bolt looseness.

For the gain adjustment at the equipment startup, check the torque waveform and

the speed waveform with a measurement device to check that no vibration

occurs. If the vibration occurs due to high gain, the vibration may cause the early

damage of the direct drive motor.

Do not use the direct drive motor where the shaft-through portion may be subject

to pressure (e.g. compressed air). Applying air pressure to the inside of the direct

drive motor may cause a malfunction.

2. INSTALLATION

2 - 2

2.1 Equipment configuration

The following shows the configuration of a direct drive motor. When using the direct drive motor, note the

following.

(1) Minimum oscillation angle

If the direct drive motor rotates repeatedly by a small angle (by 70

or less), make the direct drive motor

rotate by 90

or more at least once a day in order to keep the bearing lubricated.

(2) Z-phase position

A Z-phase pulse turns on (Z-phase mark passing) when the Z-phase mark on the rotor end of the direct

drive motor passes over the connector area. Keep the Z-phase position visible even after the direct drive

motor is installed to a machine.

Rotor (output shaft)

Encoder connector

Power supply connector

A Z-phase pulse turns

on when the Z-phase

mark passes over

the connector area.

Z-phase mark

(3) Precautions for Z-phase mark passing

After power on, the Z-phase mark of the direct drive motor must pass the connector area once. In a

system which prevents the direct drive motor from making a full rotation, install the direct drive motor in a

position where the Z-phase mark can pass over the connector area.

(4) Vertical axis (lift)

For the system where the unbalanced torque occurs, such as a vertical axis system (lift), use the direct

drive motor in the absolute position detection system. In the absolute position detection system, the

absolute position is established when the Z-phase mark passes the connector area once. Therefore, at

system startup, make the Z-phase mark pass over the connector area, and switch the servo amplifier's

power supply from off to on.

If the direct drive motor can be rotated manually, make the Z-phase mark pass over the connector area

while only the servo amplifier's control circuit power supply is on. After that, switch the servo amplifier's

power supply from off to on.

If the direct drive motor cannot be rotated manually, detect the magnetic poles while the torque is

balanced, then run the direct drive motor in the test mode to make its Z-phase mark pass over the

connector area. After that, switch the servo amplifier's power supply from off to on. After the Z-phase

mark passes over the connector area once, magnetic pole detection is not required.

2. INSTALLATION

2 - 3

2.2 Mounting direction

The following table indicates the mounting direction of the direct drive motor.

Direct drive motor series Mounting direction

TM-RFM

TM-RG2M

TM-RU2M

All directions

2.3 Load mounting/dismounting precautions

POINT

During assembling, the rotor must not be hammered. Otherwise, the encoder

may malfunction.

(1) The direction of the encoder on the direct drive motor cannot be changed.

(2) When mounting the direct drive motor, use spring washers, etc. and fully tighten the bolts so that they do

not become loose due to vibration.

2.4 Permissible load for the rotor

CAUTION

Because the rigid coupling may damage the rotor, make sure to align and center

the load on the rotor.

For the permissible rotor load specific to the direct drive motor, refer to section 7.3.

(1) When coupling a load to the direct drive motor, the load applied to the rotor must be within the

permissible load.

(2) The load, which exceeds the permissible load, can cause the bearing life to reduce and the rotor to

break.

(3) The load indicated in this section is static load in a single direction and does not include eccentric load.

Make eccentric load as small as possible. Not doing so can cause the direct drive motor to be damaged.

2. INSTALLATION

2 - 4

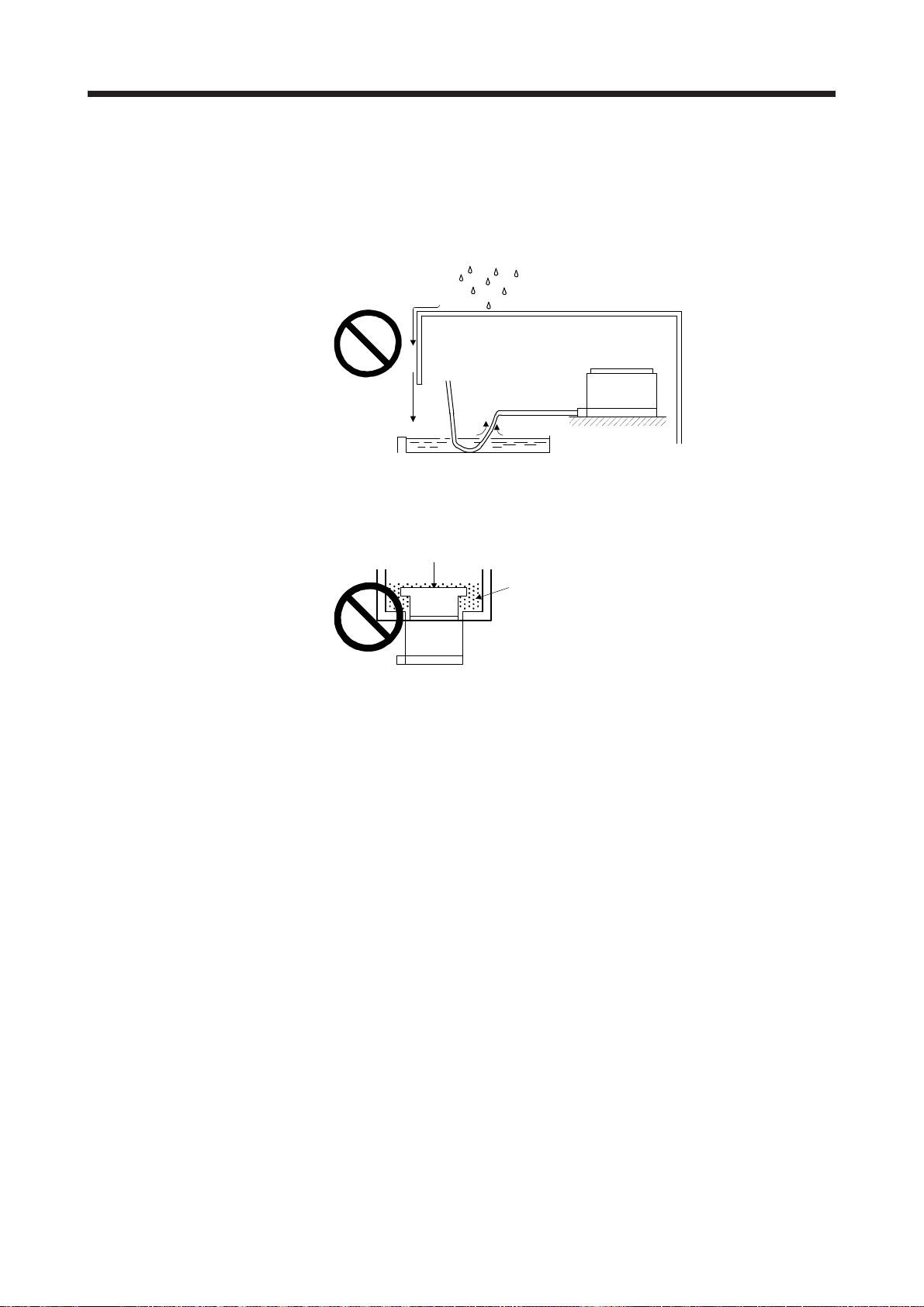

2.5 Protection from oil and water

Provide adequate protection to prevent foreign matter, such as oil and water, from entering the rotor of the

direct drive motor. When mounting the direct drive motor, consider the items in this section.

(1) Do not use the direct drive motor with its cable soaked in oil or water.

Cover

Oil/water pool

Capillary action

Direct drive motor

Provide measures so that the direct drive motor is not exposed to oil and water entering from the

machine side, rotating table, etc.

Lubricating oil

Rotary table, etc.

Direct drive motor

(3) If liquid such as coolant drops on the direct drive motor, the sealant, packing, cable and others may be

affected depending on the liquid type.

(4) In the environment where the direct drive motor is exposed to oil mist, steam, oil, water, grease, and/or

the like, a standard specification direct drive motor cannot be used. Provide measures to prevent dust

and/or water on the machine side.

2. INSTALLATION

2 - 5

2.6 Inspection items

WARNING

Before starting maintenance and/or inspection, turn off the power and wait for 15

minutes or more until the charge lamp turns off. Then, confirm that the voltage

between P+ and N- is safe with a voltage tester and others. Otherwise, an electric

shock may occur. In addition, when confirming whether the charge lamp is off or

not, always confirm it from the front of the servo amplifier.

To avoid an electric shock, only qualified personnel should attempt inspections.

For repair, contact your local sales office.

CAUTION

Do not perform insulation resistance test on the direct drive motor. Otherwise, it

may cause a malfunction.

Do not disassemble and/or repair the equipment on customer side.

It is recommended that the following points to be periodically checked.

(1) Check the bearings, etc. for unusual noise.

(2) Check the cables and the like for scratches or cracks. Especially when the junction cable is movable,

perform periodic inspection according to operating conditions.

(3) Check the power connector and encoder connector connections for looseness.

2.7 Parts having service life

Service life of the following parts is listed below. However, the service life varies depending on operation and

environment. If any fault is found in the parts, they must be replaced immediately regardless of their service

life. For parts replacement, contact your local sales office.

Part name Life guideline Remark

Bearings

20,000 hours to

30,000 hours

The Guideline of Life field gives the reference

time.

If any fault is found before this time is

reached, the part must be changed.

Encoder

20,000 hours to

30,000 hours

Absolute position

storage unit

(option)

20,000 hours to

30,000 hours

When the motor is run at rated speed under rated load, bearings should be exchanged in 20,000 to

30,000 hours as a guideline. This differs on the operating conditions. The bearings must also be changed if

unusual noise or vibration is found during inspection.

2. INSTALLATION

2 - 6

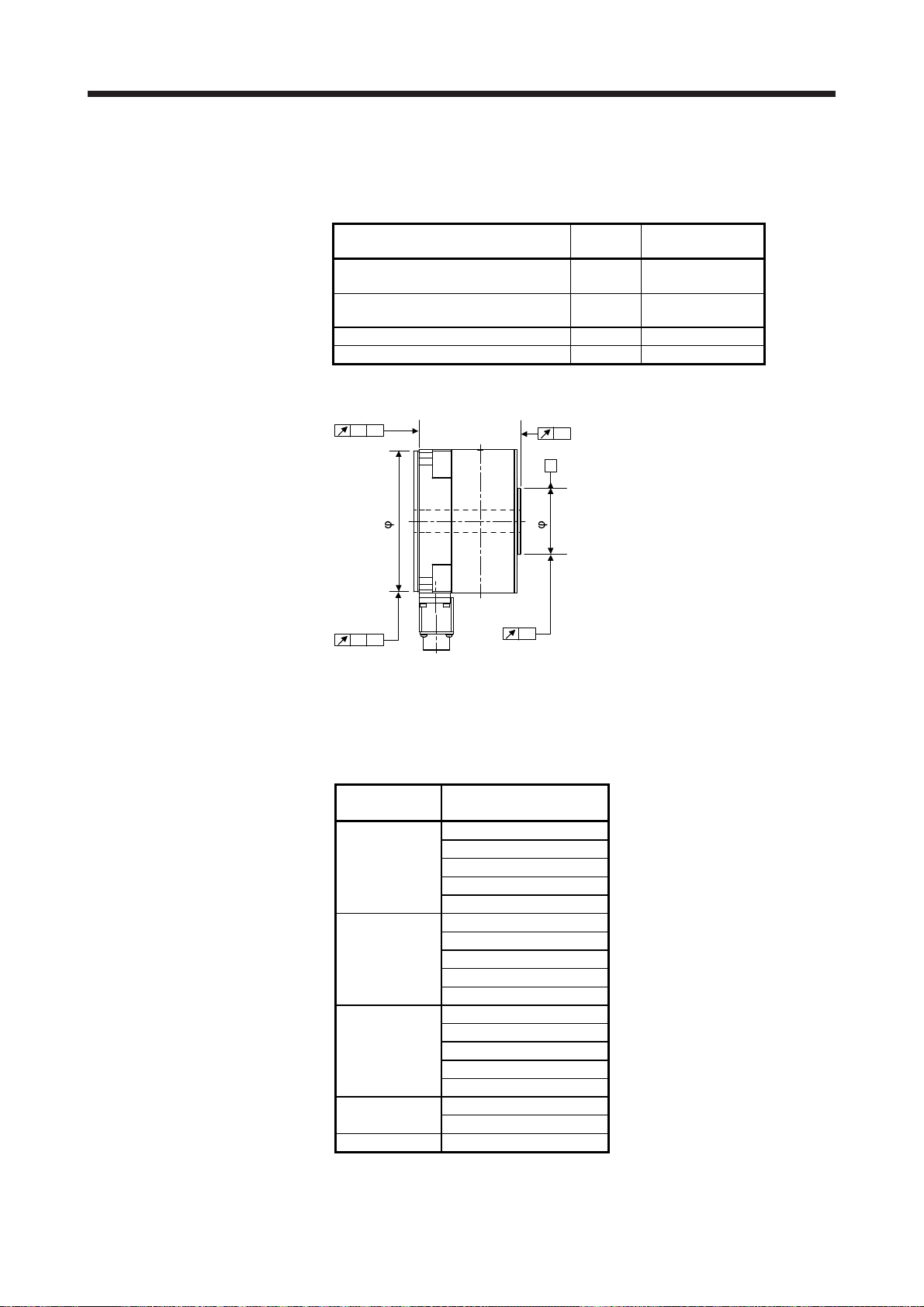

2.8 Machine accuracies

The following table indicates the machine accuracies of the rotor (output shaft) and the mounting area of the

direct drive motor (except special products).

Item

Measuring

position

Accuracy [mm]

Runout of mounting surface to rotor

(output shaft)

a 0.05

Runout of fitting outer diameter of

mounting surface

b 0.07

Runout of rotor (output shaft) c 0.04

Runout of rotor (output shaft) end d 0.02

Reference diagram

a

A

A

A

d

b

c

_

_

2.9 Flange size

The rated torque of the direct drive motor indicates the continuous permissible torque value that can be

generated when the motor is mounted on the aluminum flange specified in this table and used in the

environment of 0 °C to 40 °C ambient temperature.

Flange size

[mm]

Direct drive motor

TM-RG2M002C30

TM-RU2M002C30

400 × 400 × 20 TM-RFM002C20

TM-RFM004C20

TM-RFM006C20

TM-RG2M004E30

TM-RU2M004E30

550 × 550 × 35 TM-RFM006E20

TM-RFM012E20

TM-RFM018E20

TM-RG2M009G30

TM-RU2M009G30

650 × 650 × 35 TM-RFM012G20

TM-RFM048G20

TM-RFM072G20

750 × 750 × 45

TM-RFM040J10

TM-RFM120J10

950 × 950 × 50 TM-RFM240J10

2. INSTALLATION

2 - 7

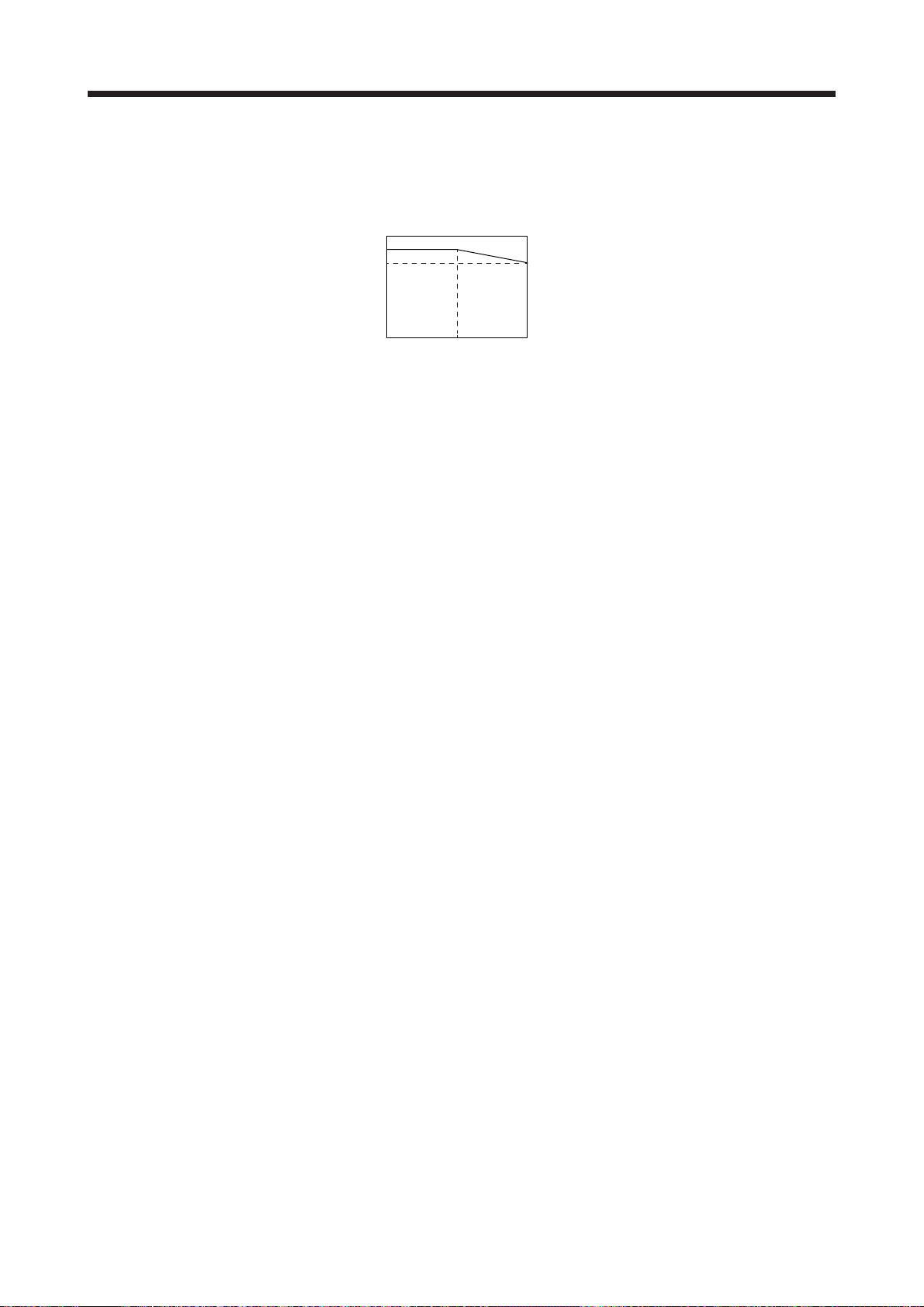

2.10 Restrictions when using this product at altitudes exceeding 1000 m and up to 2000 m above sea level

As heat dissipation effects decrease in proportion to the decrease in air density, use the product within the

effective load ratio and regenerative load ratio shown in the following figure.

0

20001000

Altitude

95

100

0

Regenerative load ratio

Effective load ratio

[%]

[m]

2.11 Magnetic shielding

Do not place the direct drive motor near magnetic sources, such as a magnet. If it is unavoidable, block the

magnetic force by installing a shielding plate, etc.

2. INSTALLATION

2 - 8

MEMO

3. CONNECTORS USED FOR DIRECT DRIVE MOTOR WIRING

3 - 1

3. CONNECTORS USED FOR DIRECT DRIVE MOTOR WIRING

POINT

The IP rating indicated is the connector's protection against ingress of dust and

water when the connector is connected to a servo amplifier, direct drive motor,

or absolute position storage unit.

If the IP rating of the connector, servo amplifier, direct drive motor and absolute

position storage unit vary, the overall IP rating depends on the lowest IP rating of

all components.

3.1 Selection of connectors

Use the connector configuration products given in the table as the connectors for connection with the direct

drive motor. Refer to section 3.2 for the compatible connector configuration products.

Power supply connector Encoder connector

Absolute position

storage unit

MR-BTAS01

Servo amplifier

side connector

Encoder side

connector

Direct drive motor

Wiring connector

For power supply For encoder

Absolute position storage unit (option) (Note)

Servo amplifier side Encoder side

TM-RFM_C20

Connector

configuration B

Connector

configuration A

Connector

configuration A

Connector

configuration F

TM-RFM_E20

TM-RFM_G20

Connector

configuration C

TM-RFM040J10

Connector

configuration D

TM-RFM120J10

TM-RFM240J10

Connector

configuration E

TM-RG2M002C30

Connector

configuration B

TM-RU2M002C30

TM-RG2M004E30

TM-RU2M004E30

TM-RG2M009G30

TM-RU2M009G30

Note. Used in the absolute position detection system

3. CONNECTORS USED FOR DIRECT DRIVE MOTOR WIRING

3 - 2

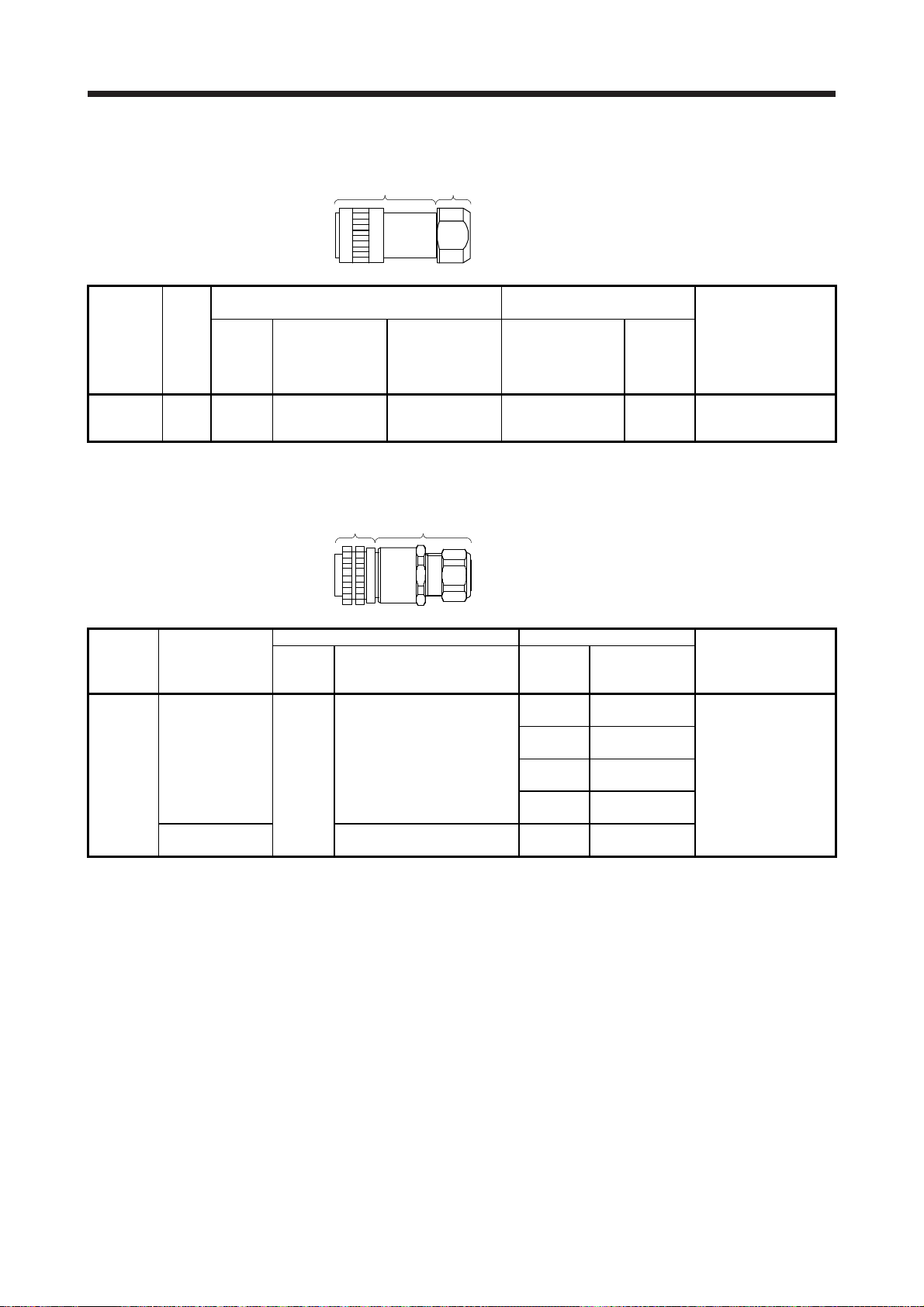

3.2 Wiring connectors (connector configurations A/B/C/D/E/F)

Cord

clamp

Plug

Connector

configuration

Feature

Plug (Hirose Electric)

Recommended cable

(Bando Densen)

Direct drive motor encoder

connector

or

Absolute position storage

unit connector

(servo amplifier side)

(Note 1)

Type Plug Cord clamp Model

Cable OD

[mm]

(reference)

A IP67 Straight RM15WTPZK-12S JR13WCCA-8(72)

20276

VSVPAWG#23×6P

KB-0492 (Note 2)

8.2 RM15WTRZB-12P(72)

Note 1. The connector to be mated.

2. Purchase from Toa Electric Industrial Co. Ltd., Nagoya Branch

Plug

Cable

clamp

Connector

configuration

Feature

Plug (DDK) Cable clamp

Direct drive motor power

connector (Note 2)

Type Model

Cable OD

[mm]

(reference)

Model

B

Straight

4 to 8

ACS-08RL-MS14F

(Nippon Flex)

CE05-2A14S-2PD-D

IP67

EN compliant

CE05-6A14S-2SD-D

Applicable wire size: AWG 22 to 16

8 to 12

ACS-12RL-MS14F

(Nippon Flex)

5 to 8.3

YSO14-5 to 8

(Daiwa Dengyo)

8.3 to 11.3

YSO14-9 to 11

(Daiwa Dengyo)

General environment

(Note 1)

D/MS3106B14S-2S

Applicable wire size: AWG 22 to 16

7.9 or less

(bushing ID)

D/MS3057-6A

Note 1. Not comply with EN.

2. The connector to be mated.

3. CONNECTORS USED FOR DIRECT DRIVE MOTOR WIRING

3 - 3

Cable clamp

Plug

Connector

configuration

Feature

Plug (DDK) Cable clamp (DDK)

Direct drive motor power

connector (Note 2)

Type Model

Cable OD

[mm]

(reference)

Model

C

IP67

EN compliant

Straight

CE05-6A18-10SD-D-BSS

Applicable wire size: AWG 14 to 12

8.5 to 11 CE3057-10A-2-D

CE05-2A18-10PD-D

10.5 to 14.1 CE3057-10A-1-D

General environment

(Note 1)

D/MS3106B18-10S

Applicable wire size: AWG 14 to 12

14.3 or less

(bushing ID)

D/MS3057-10A

Note 1. Not comply with EN.

2. The connector to be mated.

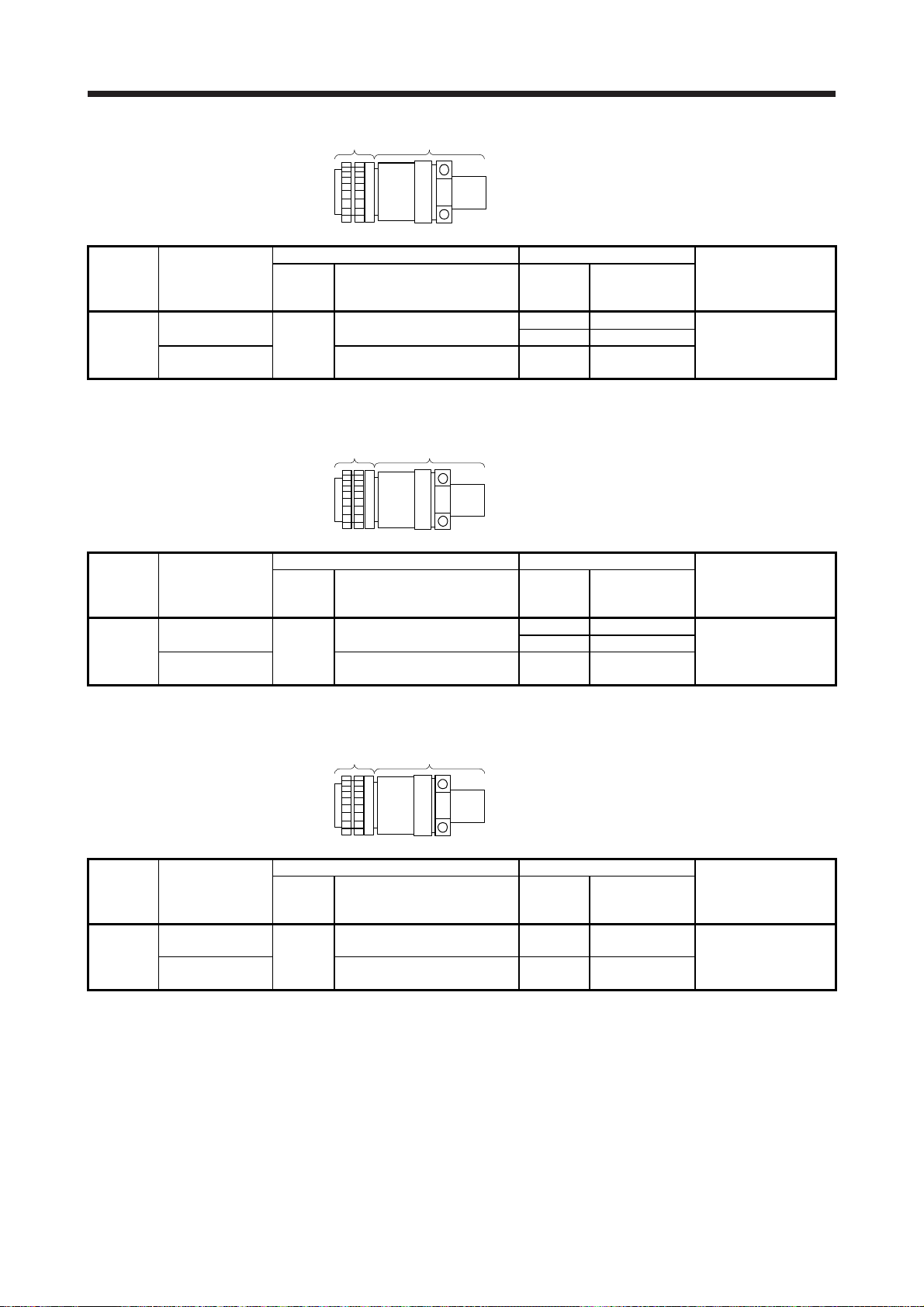

Cable clampPlug

Connector

configuration

Feature

Plug (DDK) Cable clamp (DDK)

Direct drive motor power

connector (Note 2)

Type Model

Cable OD

[mm]

(reference)

Model

D

IP67

EN compliant

Straight

CE05-6A22-22SD-D-BSS

Applicable wire size: AWG 10 to 8

9.5 to 13 CE3057-12A-2-D

CE05-2A22-22PD-D

12.5 to 16 CE3057-12A-1-D

General environment

(Note 1)

D/MS3106B22-22S

Applicable wire size: AWG 10 to 8

15.9 or less

(bushing ID)

D/MS3057-12A

Note 1. Not comply with EN.

2. The connector to be mated.

Cable clampPlug

Connector

configuration

Feature

Plug (DDK) Cable clamp (DDK)

Direct drive motor power

connector (Note 2)

Type Model

Cable OD

[mm]

(reference)

Model

E

IP67

EN compliant

Straight

CE05-6A32-17SD-D-BSS

Applicable wire size: AWG 6 to 4

22 to 23.8 CE3057-20A-1-D

CE05-2A32-17PD-D

General environment

(Note 1)

D/MS3106B32-17S

Applicable wire size: AWG 6 to 4

23.8 or less

(bushing ID)

D/MS3057-20A

Note 1. Not comply with EN.

2. The connector to be mated.

3. CONNECTORS USED FOR DIRECT DRIVE MOTOR WIRING

3 - 4

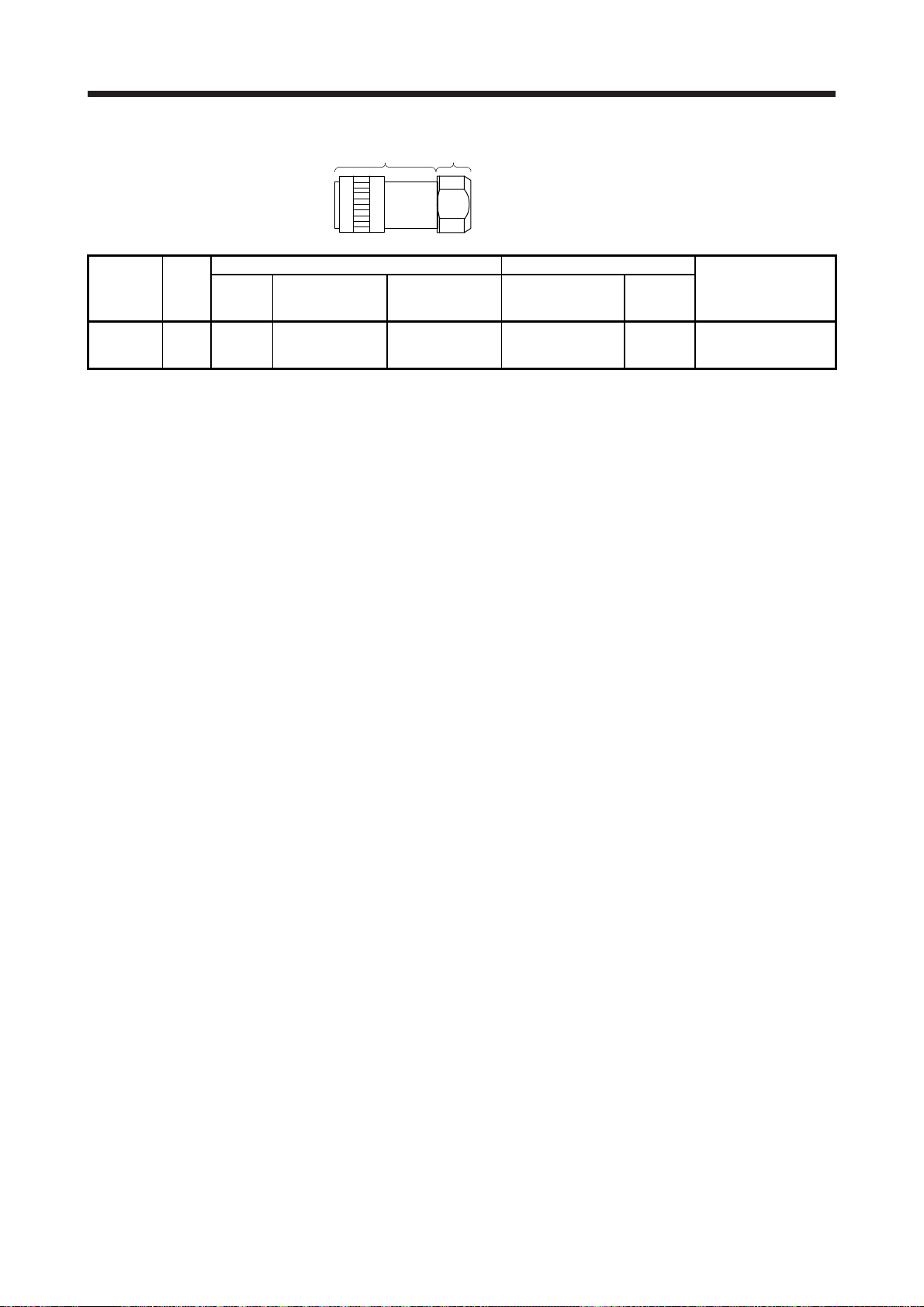

Cord

clamp

Plug

Connector

configuration

Feature

Plug (Hirose Electric) Recommended cable (Bando Densen)

Absolute position storage

unit connector

(encoder side) (Note 1)

Type Plug Cord clamp Model

Cable OD

[mm]

(reference)

F IP67 Straight RM15WTPZ-12P(72) JR13WCCA-8(72)

20276

VSVPAWG#23×6P

KB-0492 (Note 2)

8.2 RM15WTRZB-12S(72)

Note 1. The connector to be mated.

2. Purchase from Toa Electric Industrial Co. Ltd., Nagoya Branch

4. CONNECTOR DIMENSIONS

4 - 1

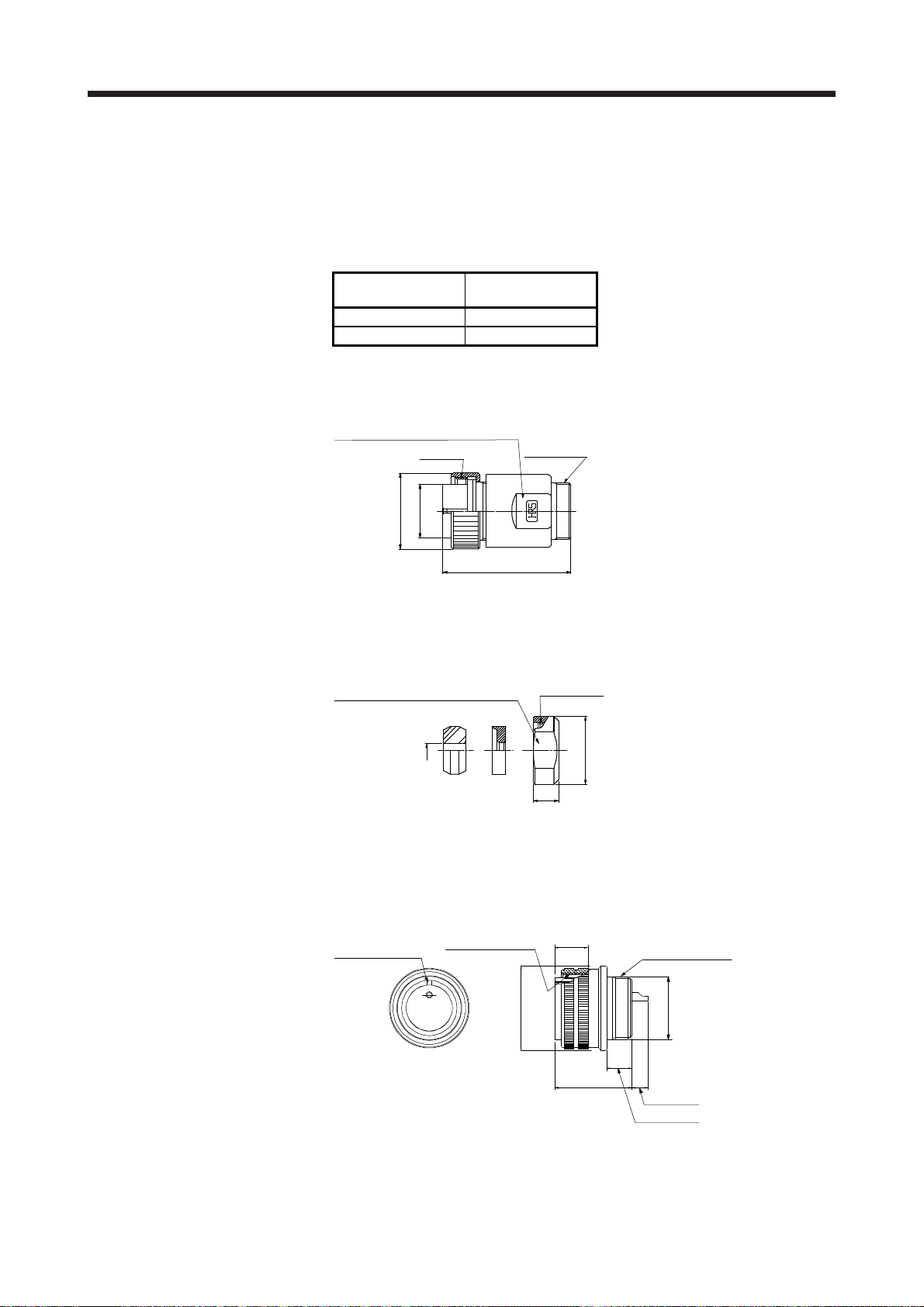

4. CONNECTOR DIMENSIONS

The following shows the dimensions of the connectors used for wiring the direct drive motor.

(1) Hirose Electric

(a) RM15WTPZK-12S/RM15WTPZ-12P(72)

Model

Connector

configuration (Note)

RM15WTPZK-12S A

RM15WTPZ-12P(72) F

Note. Refer to section 3.2 for the connector configuration.

[Unit: mm]

Spanner hook gap dimension: 18

M16 × 0.75

36.3

M19 × 1

φ21.5

φ15.2

(b) JR13WCCA-8(72)

Refer to the connector configurations A and F of section 3.2 for the connector configuration.

[Unit: mm]

8

φ20

7.5

M16 × 0.75

Spanner hook gap dimension: 17

(2) DDK

(a) CE05-6A14S-2SD-D

Refer to the connector configuration B of section 3.2 for the connector configuration.

[Unit: mm]

7/8-20UNEF-2B

(13.2)

24.0 ± 1

Positioning key

8.46 ± 0.5

5.6 ± 0.1

φ17.0 ± 0.25

φ28.57

3/4-20UNEF-2A

+ 0

- 0.38

Loading...

Loading...