Page 1

BC-3000 Plus

Auto

Hematology

Analyzer

Service Manual

Page 2

Page 3

Copyright

®

SHENZHEN MINDRAY

Statement

SHENZHEN MINDRAY

Mindray) owns all rights to this unpublished work and intends to maintain this work as

confidential. Mindray may also seek to maintain this work as an unpublished copyright.

This publication is to be used solely for the purposes of reference, operation, maintenance,

or repair of Mindray equipment. No part of this can be disseminated for other purposes.

BIO-MEDICAL ELECTRONICS CO., LTD. 2003

®

BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called

In the event of inadvertent or deliberate publication, Mindray intends to enforce its rights to

this work under copyright laws as a published work. Those having access to this work may

not copy, use, or disclose the information in this work unless expressly authorized by

Mindray to do so.

All information contained in this publication is believed to be correct. Mindray shall not be

liable for errors contained herein nor for incidental or consequential damages in

connection with the furnishing, performance, or use of this material. This publication may

refer to information and protected by copyrights or patents and does not convey any

license under the patent rights of Mindray, nor the rights of others. Mindray does not

assume any liability arising out of any infringements of patents or other rights of third

parties.

Content of this manual is subject to changes without prior notice.

PROPERTY OF

®

SHENZHEN MINDRAY

BIO-MEDICAL ELECTRONICS CO., LTD.

ALL RIGHTS RESERVED

Responsibility on the manufacturer party

Mindray is responsible for safety, reliability and performance of this equipment only in the

condition that:

Auto Hematology Analyzer Service Manual (V1.1) i

Page 4

•

all installation, expansion, change, modification and repair of this equipment are

conducted by Mindray qualified personnel;

•

applied electrical appliance is in compliance with relevant National Standards;

•

the instrument is operated under strict observance of this manual.

Note

This equipment is not intended for family usage.

This equipment must be operated by skilled/trained clinical personnel.

Warning

It is important for the hospital or organization that employs this equipment to carry out a

reasonable maintenance schedule. Neglect of this may result in machine breakdown or

injury of human health.

Upon request, Mindray may provide, with compensation, necessary circuit diagrams,

calibration illustration list and other information to help qualified technician to maintain and

repair some parts, which Mindray may define as user serviceable.

ii Auto Hematology Analyzer Service Manual (V1.1)

Page 5

Warranty

Workmanship & Materials

Mindray guarantees new equipment other than accessories to be free from defects in

workmanship and materials for a period of one year from date of shipment under normal

use and service. Mindray's obligation under this warranty is limited to repairing, at

Mindray’s option, any part which upon Mindray's examination proves defective.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF MERCHANT ABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

Exemptions

Mindray's obligation or liability under this warranty does not include any transportation or

other charges or liability for direct, indirect or consequential damages or delay resulting

from the improper use or application of the product or the substitution upon it of parts or

accessories not approved by Mindray or repaired by anyone other than a Mindray

authorized representative.

This warranty shall not extend to any instrument which has been subjected to misuse,

negligence or accident; any instrument from which Mindray's original serial number tag or

product identification markings have been altered or removed, or any product of any other

manufacturer.

Safety, Reliability and Performance

Mindray is not responsible for the effects on safety, reliability and performance of the

BC-3000plus Hematology Analyzer if:

■ assembly operations, extensions, re-adjusts, modifications or repairs are carried out

by persons other than those authorized by Mindray.

■ Personnel unauthorized by Mindray repairs or modifies the instrument.

Auto Hematology Analyzer Service Manual (V1.1) iii

Page 6

Return Policy

Return Procedure

In the event that it becomes necessary to return a unit to Mindray, the following procedure

should be followed:

1. Obtain return authorization. Contact the Mindray Service Department and obtain a

Customer Service Authorization (Mindray) number . The Mindray number must appear

on the outside of the shipping container. Return shipments will not be accepted if the

Mindray number is not clearly visible. Please provide the model number, serial

number, and a brief description of the reason for return.

2. Freight policy. The customer is responsible for freight charges when equipment is

shipped to Mindray for service (this includes customs charges).

Company Contact

Address: Mindray Building, Keji 12th Road South, Hi-tech

Industrial Park, Nanshan, Shenzhen, P. R. China

Phone: +86 755 26582888

Fax: +86 755 26582680

Authorized Representative

Name: Shanghai International Holding Corp. GmbH (Europe)

Address: Eiffestrasse 80 D-20537 Hamburg Germany

Phone: +49 40 2513175

Fax: +49 40 255726

iv Auto Hematology Analyzer Service Manual (V1.1)

Page 7

Conventions Used in This Manual and Instrument

Warnings, Cautions and Notes

Warnings, cautions and notes are used in this manual to alert or signal the reader to

specific information.

WARNING

Warning alerts the user to the possible injury or death associated with the use or

misuse of the instrument.

CAUTION

Caution alerts the user to possible injury or problems with the instrument

associated with its use or problem such as instrument malfunction, instrument

failure, damage to the instrument.

NOTE

Note provides specific information, in the form of recommendations,

pre-requirements, alternative goods or supplemental information.

WARNING

Potential biohazard

Avoid contacting with the sample probe.

WARNING

Auto Hematology Analyzer Service Manual (V1.1) i

Page 8

Page 9

Content

Content

Chapter 1 General………………………………………………...……………………………1-1

1.1 Introduction ..............................................................................................................1-1

1.2 Service Policy...........................................................................................................1-2

1.3 Specification.............................................................................................................1-3

1.4 Panel Description.....................................................................................................1-7

1.4.1 Front Panel and Keys............................................................................................1-7

1.4.2 Rear Panel............................................................................................................1-9

1.4.3 Front review without front panel.......................................................................... 1-11

1.4.4 Right-side view without the door .........................................................................1-12

1.4.5 Left-side view without the door............................................................................ 1-13

1.5 Menu Structure Chart.............................................................................................1-14

Chapter 2 Troubleshooting…………………………………………………………………….2-1

2.1 Check Procedure .....................................................................................................2-1

2.2 Check Items before Instrument Check.....................................................................2-2

2.3 How to Check Sample Data.....................................................................................2-4

2.4 Troubleshooting Erroneous Data............................................................................2-16

2.5 Troubleshooting......................................................................................................2-21

2.6 Alarm......................................................................................................................2-27

Chapter 3 Hardware……………………………………………………………………………3-1

3.1 CPU Board...............................................................................................................3-2

3.2 Analog Signal Board.................................................................................................3-6

3.3 Power Drive Board.................................................................................................3-10

3.4 Keypad...................................................................................................................3-13

3.5 Recorder Board...................................................................................................... 3-14

3.6 Volumetric Metering Board.....................................................................................3-16

3.7 Power Supply Board ..............................................................................................3-18

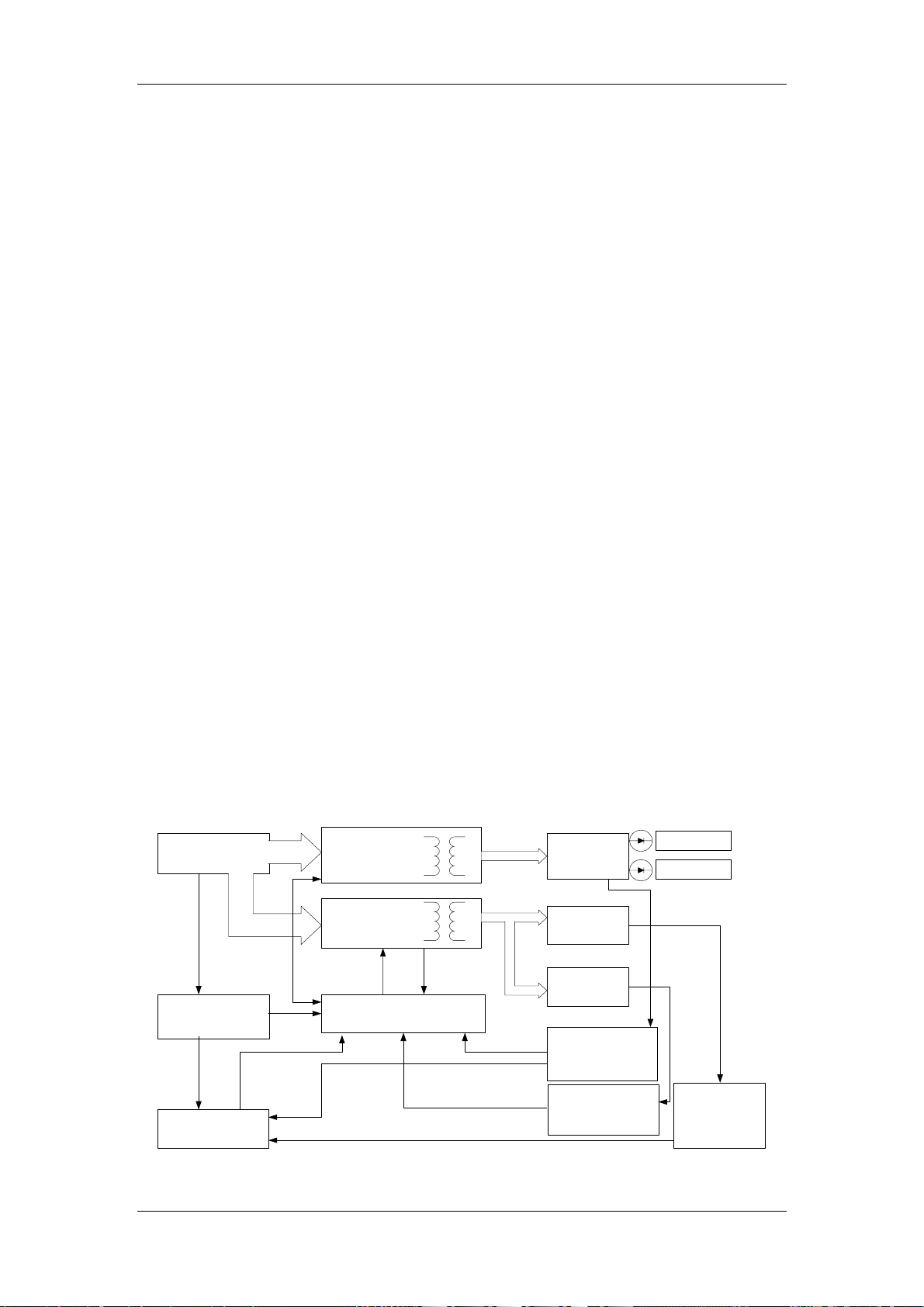

Chapter 4 Hydraulic System…………………………………………………………………..4-1

4.1 Hydraulic System Block Diagram.............................................................................4-1

4.2 Units of Hydraulic System........................................................................................4-2

4.3 Whole Blood Count Cycle........................................................................................ 4-3

4.4 Flow Charts of Main Procedures..............................................................................4-4

4.4.1 Power on...............................................................................................................4-4

4.4.2 Whole Blood Count ...............................................................................................4-5

4.4.3 Prediluted Count ................................................................................................... 4-6

4.4.4 Startup...................................................................................................................4-7

4.4.5 Flush Apertures.....................................................................................................4-8

4.4.6 Dispense Diluent...................................................................................................4-9

4.4.7 Shut Down ..........................................................................................................4-10

Auto Hematology Analyzer Service Manual (V1.1) 1

Page 10

Content

4.5 Hydraulic System Flow Diagram............................................................................ 4-11

4.5.1 Inspire Sample and Diluent (Whole Blood Mode)................................................ 4-11

4.5.2 Inspire Sample and Diluent (Prediluted Mode) .................................................... 4-12

4.5.3 WBC Injection & Lyse Preparation......................................................................4-13

4.5.4 RBC & Lyse Injection..........................................................................................4-14

4.5.5 Mixture ................................................................................................................4-15

4.5.6 Count Cycle.........................................................................................................4-16

4.5.7 Cleaning..............................................................................................................4-17

4.5.8 Flush...................................................................................................................4-18

4.5.9 Empty Tube.........................................................................................................4-19

Chapter 5 System Structure…………………………………………………………………..5-1

5.1 Disassemble/Replace Parts and Components.........................................................5-1

5.1.1 Disassemble Syringe and Replace Piston ............................................................5-1

5.1.2 Replace Sample Probe .........................................................................................5-7

5.1.3 Replace Sample Probe Wipe Block ....................................................................5-12

5.1.4 Replace Vacuum Chamber.................................................................................5-18

5.1.5 Replace Pump.....................................................................................................5-19

5.1.6 Replace Count Bath............................................................................................5-22

5.1.7 Clean or Replace V11 or V12 Valve....................................................................5-26

5.1.8 Replace V11 or V12 ............................................................................................5-27

5.1.9 Clean V11 or V12................................................................................................5-31

5.1.10 Replace TFT Screen.........................................................................................5-33

5.1.11 Replace Recorder Paper...................................................................................5-35

5.1.12 Replace Recorder Module ................................................................................ 5-37

5.2 Disassemble/assemble Circuit Boards...................................................................5-38

5.3 Connect Power Supply...........................................................................................5-39

5.4 Connect Circuit Boards..........................................................................................5-41

5.4.1 CPU board connectors defined...........................................................................5-43

5.4.2 Power Driver Board Connectors Defined ............................................................ 5-48

5.4.3 Analog Board’s connectors defined.....................................................................5-52

5.4.4 Keyboard Connectors defined.............................................................................5-54

5.4.5 Indicator Board Connector Defined.....................................................................5-55

5.4.6 MTB Connector Defined......................................................................................5-55

Chapter 6 Adjustment………………………………………………………………………….6-1

6.1 General....................................................................................................................6-1

6.2 Adjusted procedures ................................................................................................6-1

6.3 Gain of WBC (whole blood and prediluted) Channel................................................6-4

6.4 Gain of RBC Channel............................................................................................... 6-6

6.5 Gain of PLT Channel.............................................................................................. 6-10

6.6 Gain of HGB Channel ............................................................................................ 6-11

6.7 Adjust Display Brightness.......................................................................................6-12

6.8 Adjust Vacuum and Pressure.................................................................................6-13

2 Auto Hematology Analyzer Service Manual (V1.1)

Page 11

Content

6.9 Adjust Count time...................................................................................................6-14

6.10 Adjust Auto Clean Time........................................................................................6-16

6.1 1 Adjust Volumetric Metering Board ........................................................................6-17

6.12 Re-calibrating Instrument.....................................................................................6-19

Chapter 7 Maintenance………………………………………………………………………..7-1

7.1 Daily maintenance....................................................................................................7-1

7.2 Monthly maintenance...............................................................................................7-1

7.3Half-year maintenance..............................................................................................7-2

Chapter 8 Spare Part List…………..………………………………………………………….8-1

Chapter 9 Performance Test…………………………………………………………………..9-1

Chapter 10 Histograms and Pulse Graphs…………………………………………………10-1

10.1 Histograms...........................................................................................................10-1

10.2 Pulse Graphs .......................................................................................................10-4

10.2.1 Normal Pulse Graphs........................................................................................ 10-4

10.2.2 Abnormal Pulse Graphs .................................................................................... 10-6

Chapter 11 Password and Upgrade software………………………………………………11-1

11.1 Password.............................................................................................................. 11-1

11.2 Upgrade System Software.................................................................................... 11-2

Appendix………………………………………………………………………………………..A-1

Hardware Diagram of BC-3000PLUS.............................................................................A-1

Hydraulic Diagram of BC-3000PLUS .............................................................................A-2

Auto Hematology Analyzer Service Manual (V1.1) 3

Page 12

Page 13

General

Chapter 1 General

1.1 Introduction

CAUTION

To maintain the instrument in normal condition, the user must perform the periodic

maintenance. Refer to the user manual.

This service manual provides useful information to help service personnel to understand,

troubleshoot, service, maintain and repair the Hematology Analyzer.

All replaceable parts or units of this instrument and its optional units are clearly list with

exploded illustration to help you locate the parts quickly.

The maintenance must be periodically performed because the instrument has fluid paths

and precision parts. Accordingly, the user is responsible for performing the periodic

maintenance. The “maintenance” chapter in this service manual describes the

maintenance that should be performed by the qualified service personnel. The

“maintenance” chapter in the user manual describes the maintenance that can be

performed by the user.

NOTE

If the instrument has a problem and there has been no periodic maintenance, the

instrument will usually be normal again by cleaning the fluid paths or replacing a

consumable with a new one.

The information in the user manual is primarily for the user. However, it is important for

service personnel to thoroughly read the user manual and service manual before starting

to troubleshoot, service, maintain or repair this instrument. This is because service

personnel needs to understand the operation of the instrument in order to effectively use

the instrument in order to effectively use the information in the service manual.

Auto Hematology Analyzer Service Manual (V1.1) 1-1

Page 14

General

1.2 Service Policy

CAUTION

Be careful not to directly touch any place where blood is or may spread to.

Wear rubber gloves to protect yourself from infection before doing maintenance.

Our company’s basic policy for technical service is to replace faulty units, printed circuit

boards or parts. We do not support component-level repair of boards and units outside the

factory.

NOTE

When ordering parts or accessories from your nearest distributor, please quote the

part number and part name which is listed in the service manual, and the name or

model of the unit in which the required part is located. This will help us to promptly

attend to your needs.

Always use parts and accessories recommended or supplied by our company to

assure maximum performance from your instrument.

1-2 Auto Hematology Analyzer Service Manual (V1.1)

Page 15

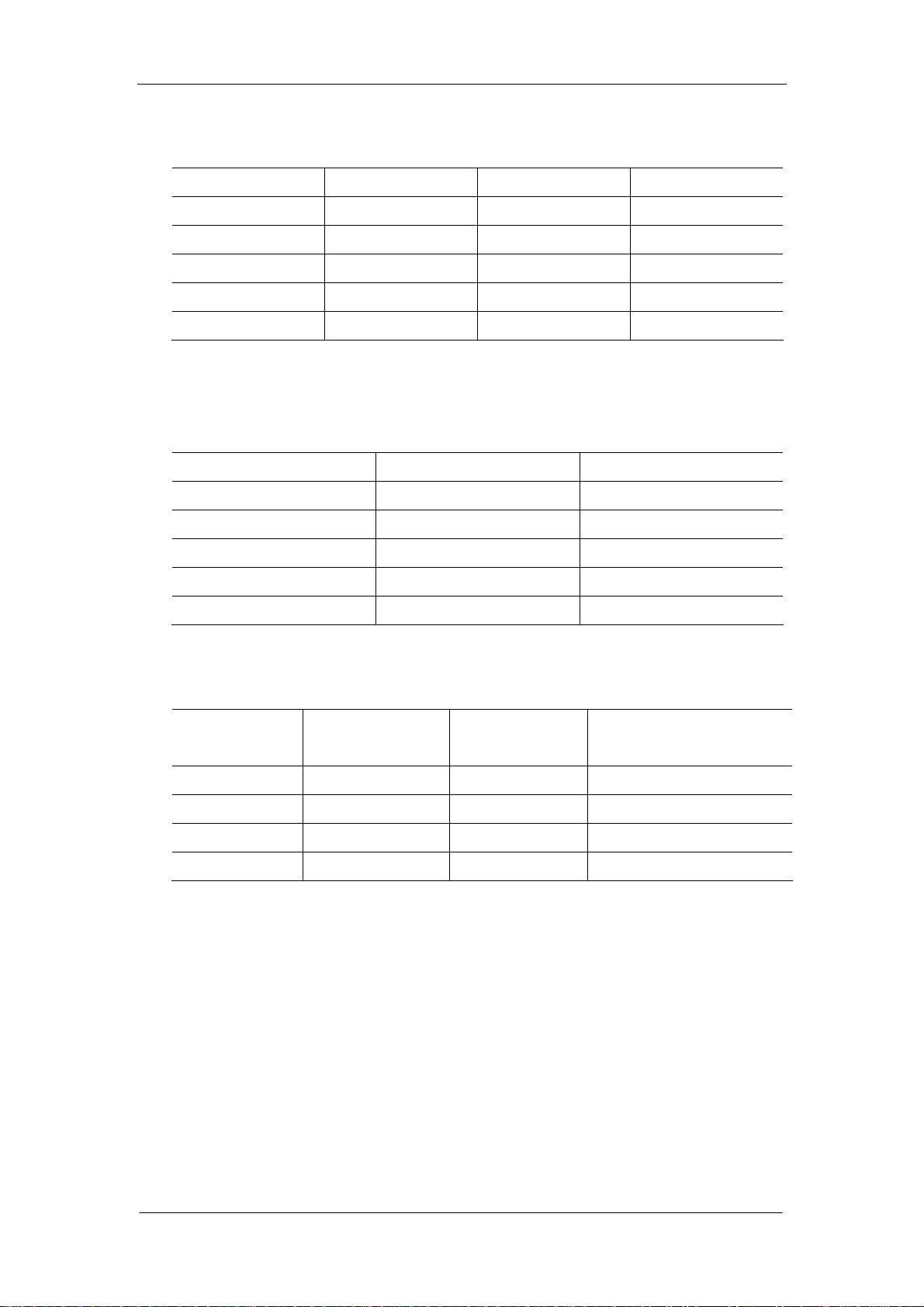

1.3 Specification

Hemoglobin Analysis

Wavelength 525nm

Sampling Features

Volumes Required for Each Analysis:

Whole Blood Mode (vein blood) 13uL

Prediluted Mode (capillary blood) 20uL

Aspirated volumes:

500uL of lyse first dilution per cycle for WBC measurement

300uL of second dilution per cycle for RBC and PLT measurement

Dilution Ratios Whole Blood Prediluted

General

WBC/HGB 1: 308 1:407

RBC/PLT 1:44833 1: 44274

Cell Counting Aperture Size:

WBC 100um

RBC 70um

Throughput more than 60 samples/hour

Check Diluent, Rinse and Lyse

The applied volume of each reagent is:

Diluent Rinse Lyse E-Z

Normal Startup 42ml 10ml

Prepare a sample

25.4ml 6ml 0.5ml

(whole blood)

Prepare a sample

25.1ml 6ml 0.26ml

(prediluted)

Normal Shutdown 32ml 10ml 1.6ml

Performance Specifications

Imprecision

Imprecision is based on replicate determinations of the same sample. The first

Auto Hematology Analyzer Service Manual (V1.1) 1-3

Page 16

General

result is not used in the calculation.

Imprecision Specifications

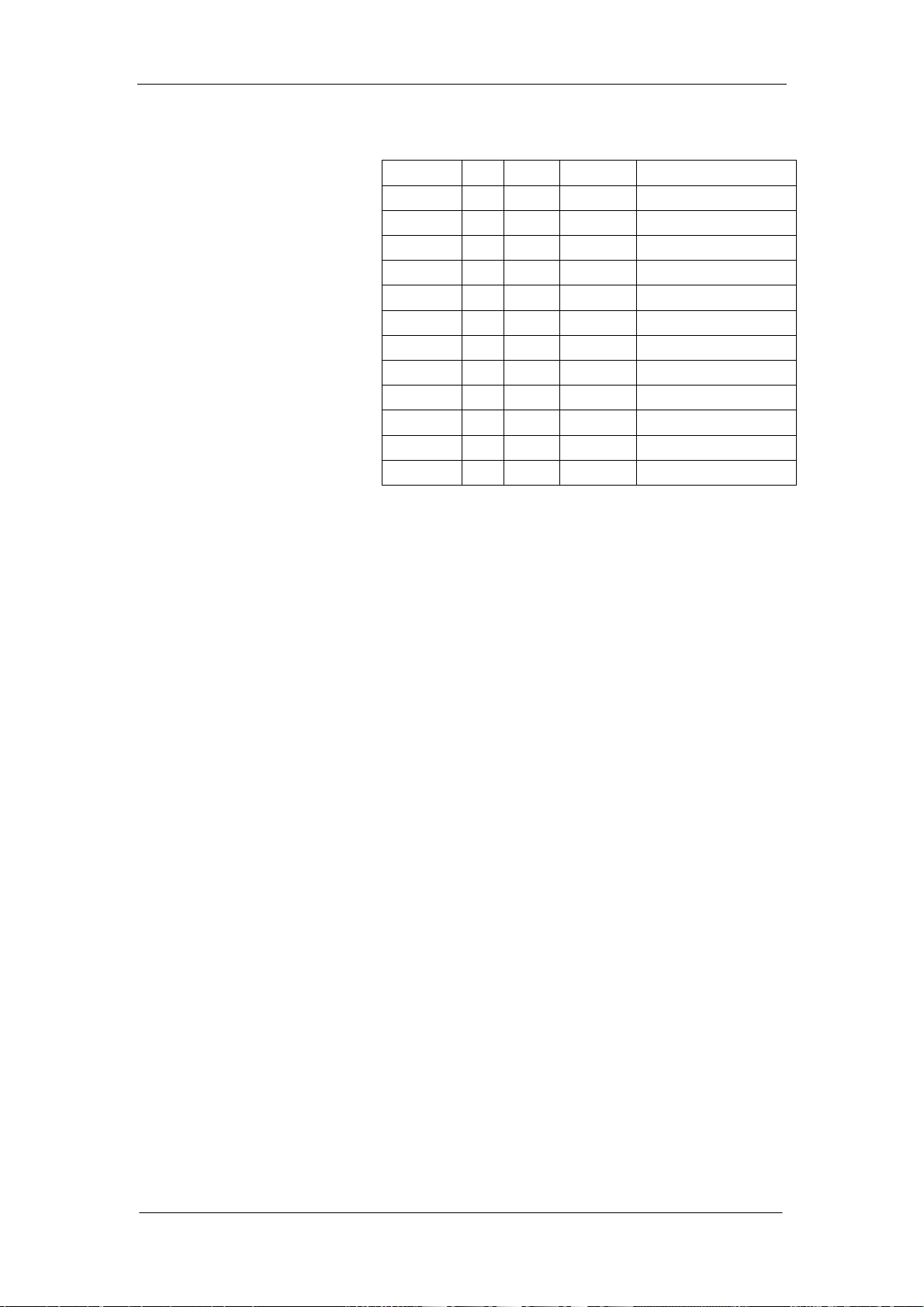

Parameter Level Units CV%

WBC 7.0-15.0 109/L

RBC 3.5-6.0 1012/L

HGB 110 – 180 g/L

MCV 80.0 – 110.0 fL

PLT 200 – 500 109/L

Operating Range

Parameter Range Units

WBC 0.0-999.9 109/L

RBC 0.00-9.99 1012/L

HGB 0-300 g/L

MCV 0-250 fL

PLT 0-3000 109/L

≤ 2.5

≤ 2

≤ 1.5

≤ 0.5

≤ 5

Linearity

Parameter Linearity Range Units

WBC 0.3-99.9 109/L ±0.3 or ±5%

RBC 0.20-9.99 1012/L ±0.05 or ±5%

HGB 0-300 g/L ±2 or ±3%

PLT 10-999 109/L ±10 or ±10%

Display

Liquid Crystal Display(LCD),resolution: 640×480

Input/Output

Two RS232/C serial ports

One printer port

One keyboard interface

Difference

(whichever is greater)

Built-in Thermal Recorder

1-4 Auto Hematology Analyzer Service Manual (V1.1)

Page 17

Printer (optional)

EPSON LX-300, EPSON LX-300+

Scanner(optional)

TYSSO CCD-82

Reagents Required

DILUENT M-30D DILUENT

RINSE M-30R RINSE

LYSE M-30L LYSE

E-Z CLEANSER(Enzyme cleanser) M-30E CLEANSER

PROBE CLEANSER M-30P CLEANSER

Power

Input: AC 220V±10% AC 110V±10%

General

50/60±1 Hz 50/60±1 Hz

Consumption: 180 VA 180 VA

Fuse: 2A 4A

Ambient Temperature and Humidity

Temperature:

15℃~35℃ (59℉~95℉)

Humidity:

10%~85% without condensation

Dimensions

Height Width Depth

46cm 39cm 40cm

Weight

25KG

Recommended Anticoagulant

A salt of K

EDTA with the proper proportion of blood to anticoagulant, as specified by

2

the tube manufacturer.

Sample Identification

An 8-digit identification number is mandatory sample identification.

Auto Hematology Analyzer Service Manual (V1.1) 1-5

Page 18

General

Results Output

The system can transmit sample and control data to an external computer.

Sample results screen shows sample identification number, sample mode, sample

results and any sample result flags.

The system provides a printout of all data.

1-6 Auto Hematology Analyzer Service Manual (V1.1)

Page 19

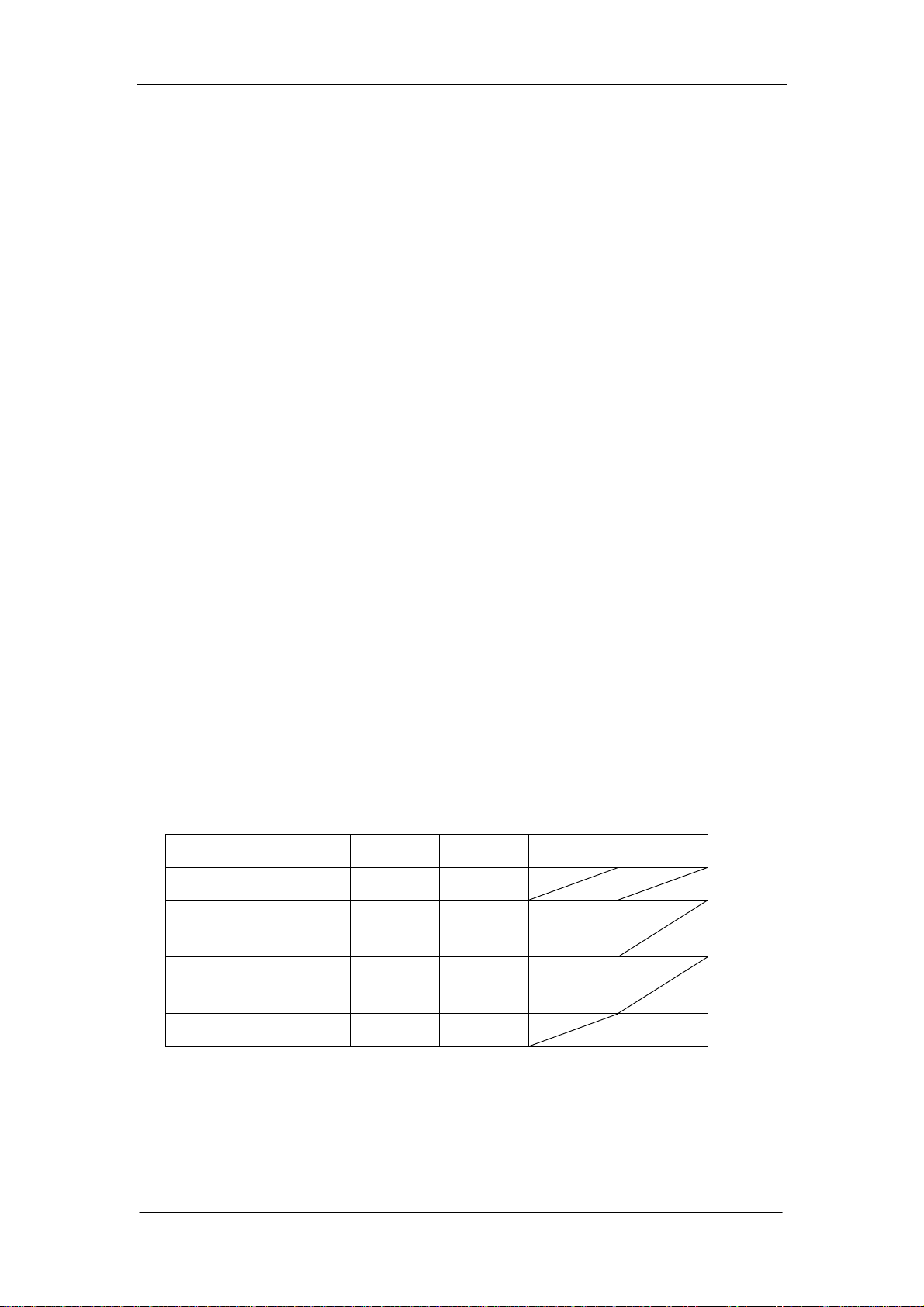

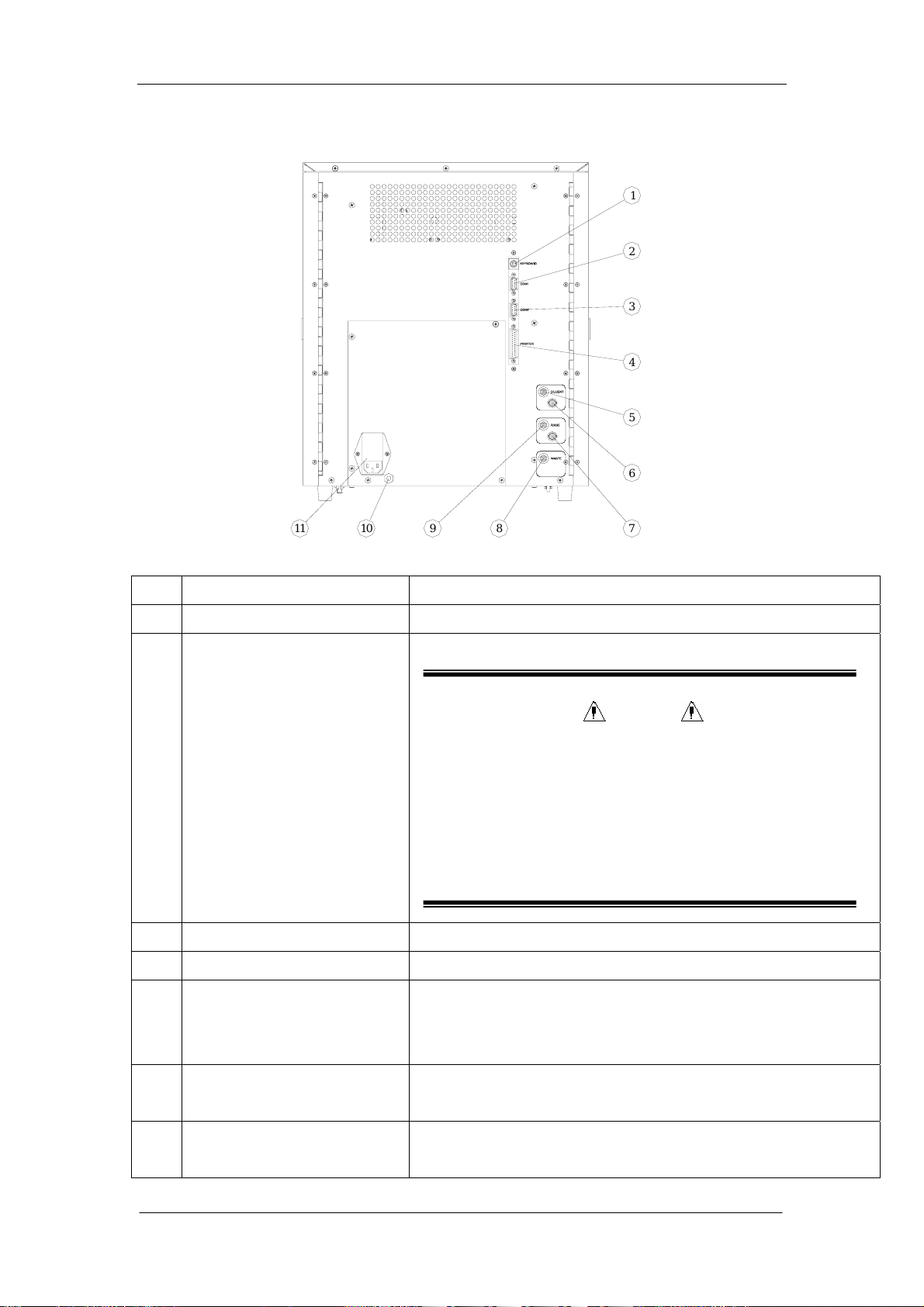

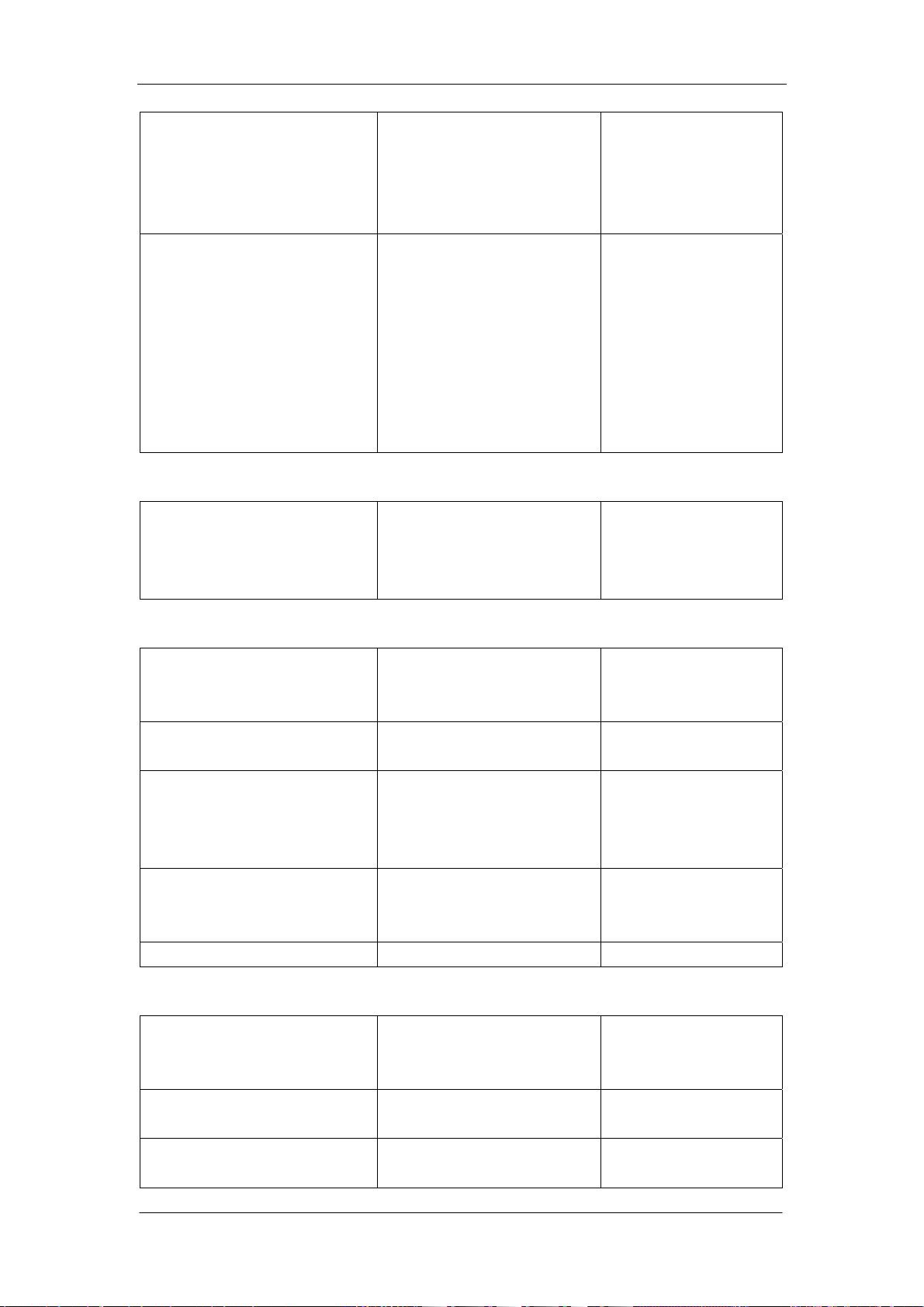

1.4 Panel Description

1.4.1 Front Panel and Keys

Figure 1-1

No. Name Description

General

1 Display Screen Display various messages, measured data and histograms

2 Keypad Touch key (all of the description refer to under lists), 23 buttons

3 Recorder Print out measured result

4 Power Light Show hematology analyzer work status

5 [Start] key Press to aspirate the sample and start counting

6 Sample Probe Aspirate the sample

Dispenses the diluent when in capillary blood mode.

Keypad

1

[START]

In Count screen, QC Count screen and Auto Calibration screen,

press it to count. In the status of Adding Diluent, press it to add

Diluent.

2

[MENU]

Press this key to switch between window operation and menu

operation

3

4

[PRINT]

[FEED]

Press this key to print using either recorder or printer

Press this key to feed paper of the recorder. Release it to stop the

operation.

5

6

[MUTE]

[DEL]

Mute the alarm and clear some of the error messages.

Delete the selected data in Review screen. Delete error message

in Error Message screen. Delete reference data and running

control data in QC Edit screen. Call default value in Normal

Range screen.

7

[0]...[9]

Auto Hematology Analyzer Service Manual (V1.1) 1-7

Enter numbers

Page 20

General

8

9

10

11

12

13

14

[↑][↓][←][→]

[ID]

[DILUENT]

[PgUp][PgDn]

[ENTER]

[STARTUP]

[FLUSH]

Move the cursor in the window area or menu area.

Enter the ID number of the sample

In the Count screen of Prediluted mode, press this key to enter

the Adding Diluent status.

Scroll the screen up or down page by page.

Confirm

Clean the tubing, baths and sample probe then check the

background.

Press the key to execute the Flush operation to remove the clogs

1-8 Auto Hematology Analyzer Service Manual (V1.1)

Page 21

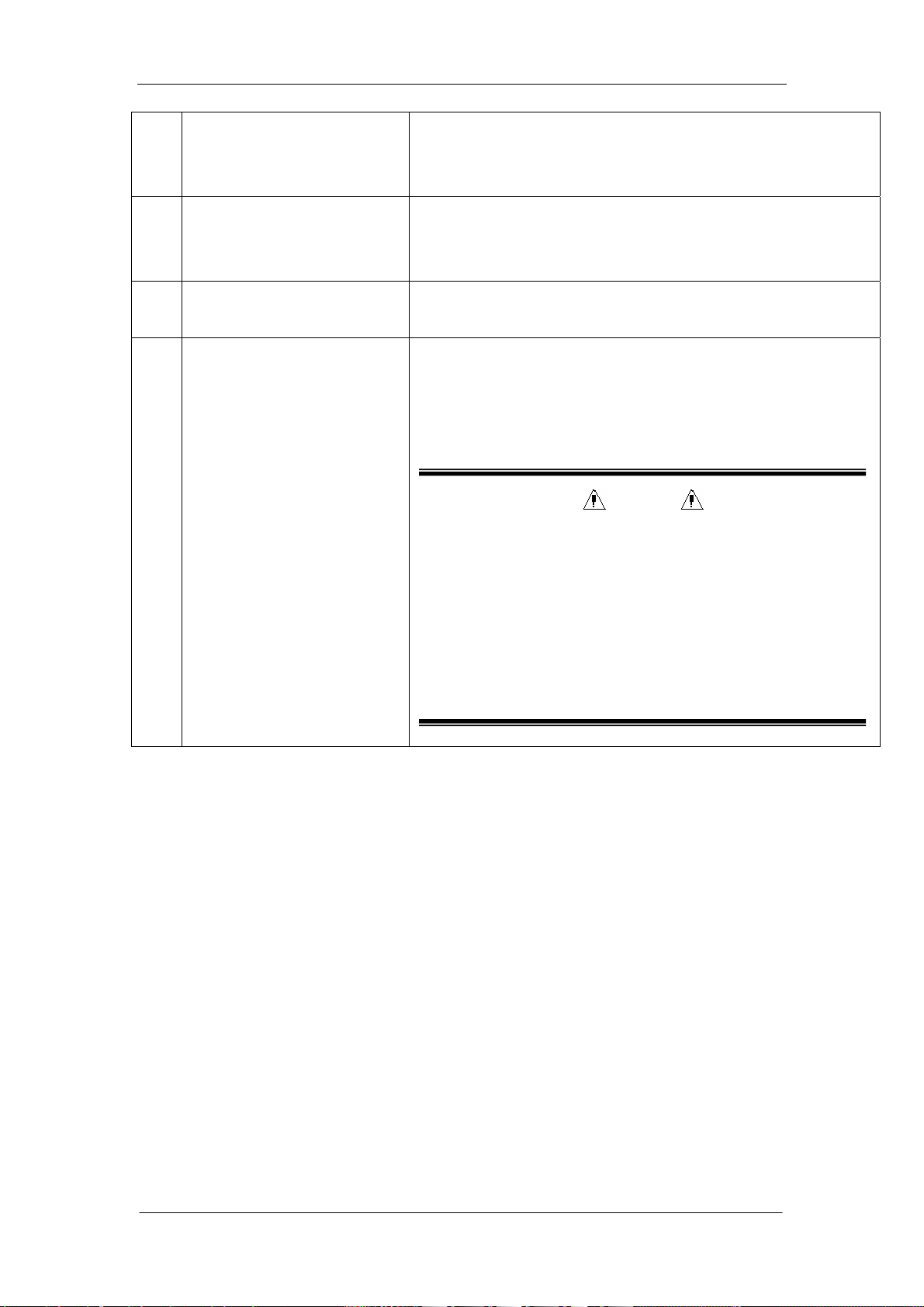

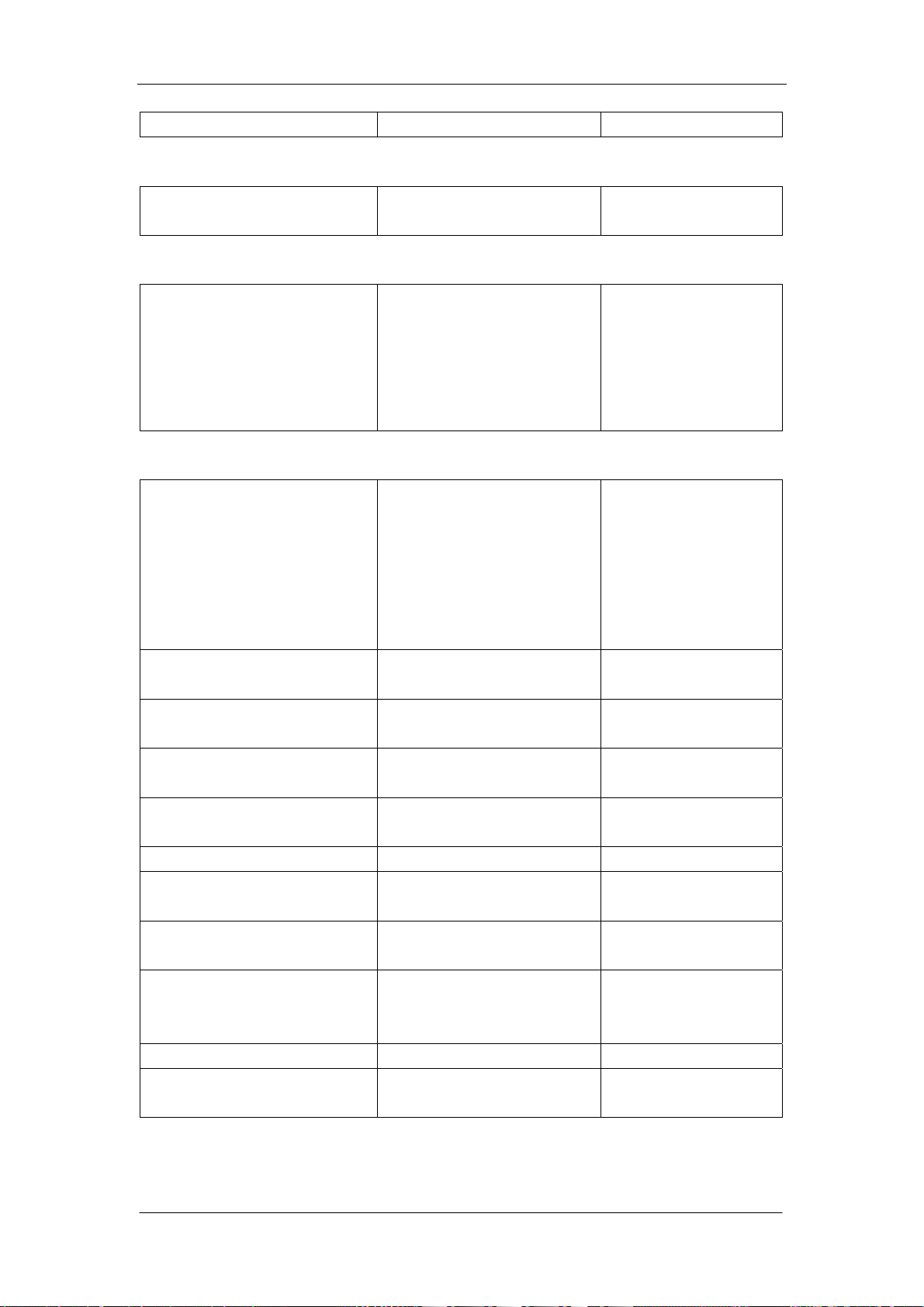

1.4.2 Rear Panel

General

1

2

3

4

5

6

1

1

1

0

9

8

7

Figure 1-2

No. Name Description

1 Keyboard Interface Connect the standard keyboard

2 RS-232C Serial Port 1 Connect computer and transfer data to computer

CAUTION

In order to avoid any safety hazard, only coonect personal

computer which are approved to IEC950

The instrument should only be connected to an external

instrument which complies with the CISPR 11 Second

Edition 1990-09, Group 1 and Class B standard

3 RS-232C Serial Port 2 Connect a bar code scanner

4 Printer Interface Connect the external print er LX-300+ (LX-300)

5 DILUENT Tubing Connector Inlet for diluent. Connect one end of the tube (standard

accessory) to the diluent inlet and attach the other end of the

tube to the diluent

6 BNC socket for DILUENT

sensor

7 BNC socket for RINSE

sensor

Auto Hematology Analyzer Service Manual (V1.1) 1-9

connector for diluent. Connect one end of the connector of the

cable.

connector for rinse. Connect one end of the connector of the

cable.

Page 22

General

8 WASTE Tubing Connector Inlet for waste. Connect one end of the tube (standard

accessory) to the waste inlet and attach the other end of the

tube to the waste

9 RINSE Tubing Connector Inlet for rinse. Connect one end of the tube (standard

accessory) to the rinse inlet and attach the other end of the

tube to the rinse

10 Equipotential ground

terminal

11 Power switch

AC source

Fuse holder

Connects the ground lead to the Equipotential ground terminal

on the wall for earth grounding

Turns power on or off

Connects the AC power cord to supply the AC power to the

instrument

Contains the time lag fuse (T 2A for 220V or T 4A for 110v)

Fuses cut the power off when an abnormality occurs in the

hematology analyzer. Remove the malfunction before

replacing the fuse.

Before replacing a fuse, turn the power off anf disconnect

the AC power cord from the instrument.

Fuse replacement should be done by a qualified person.

CAUTION

1-10 Auto Hematology Analyzer Service Manual (V1.1)

Page 23

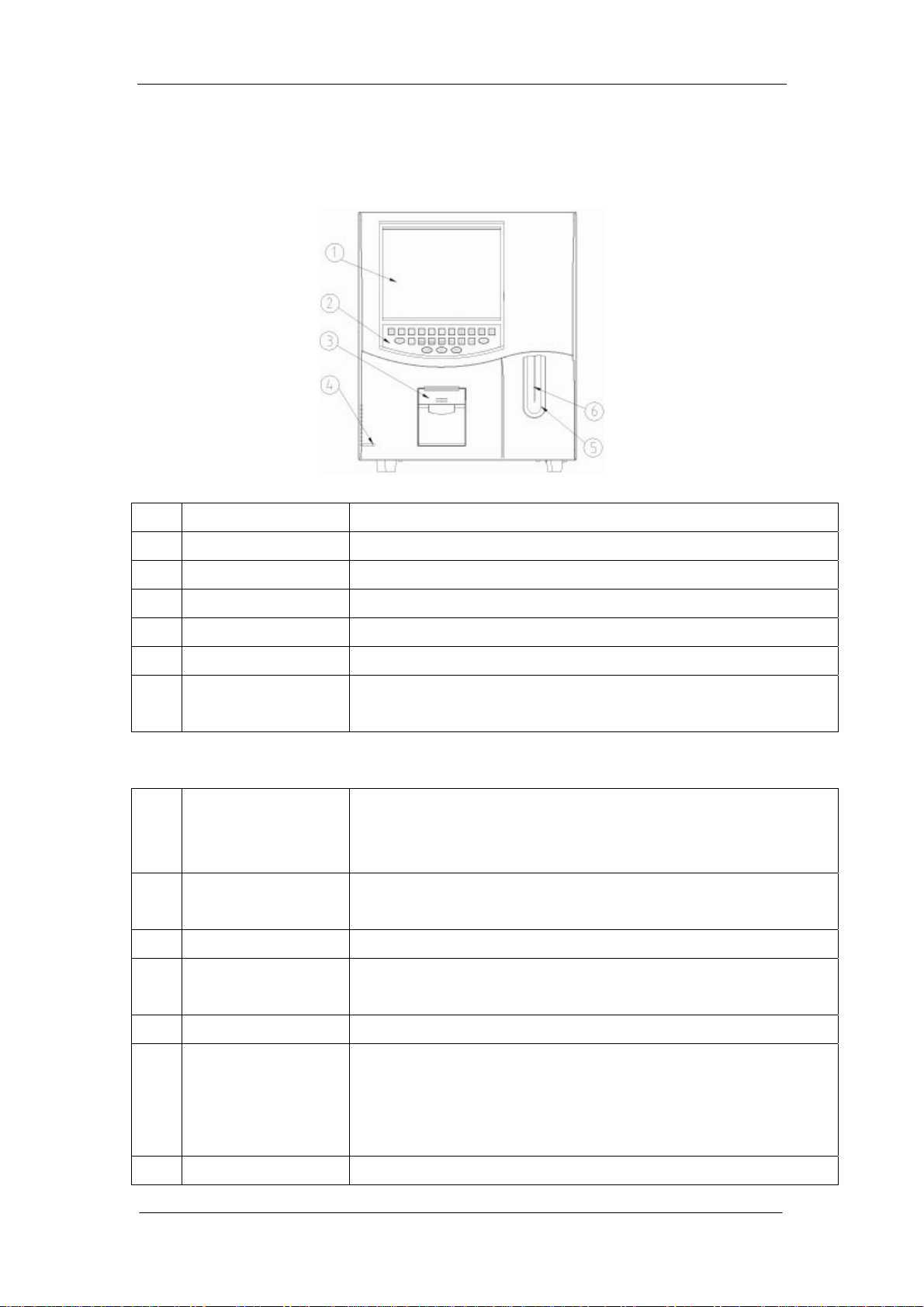

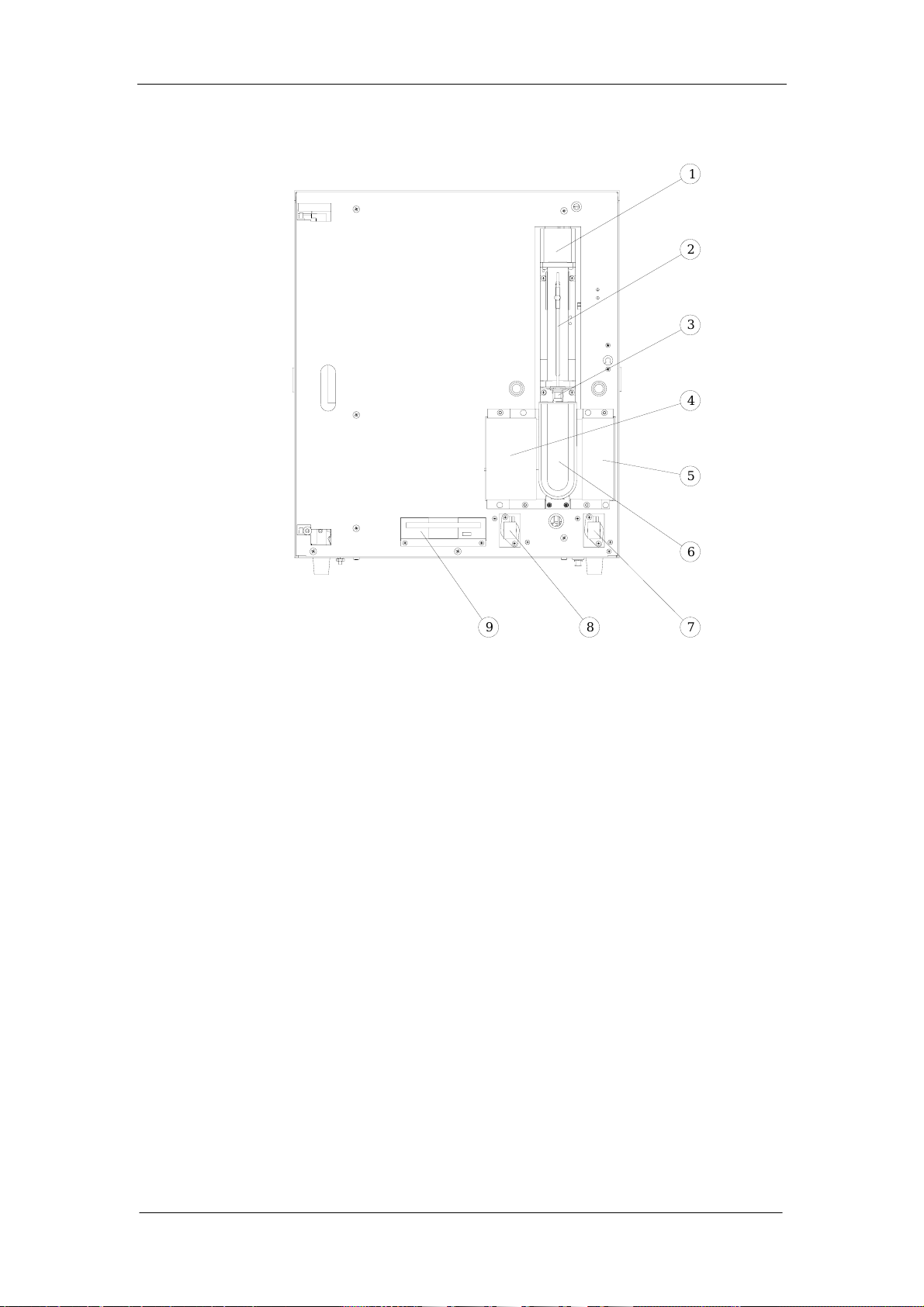

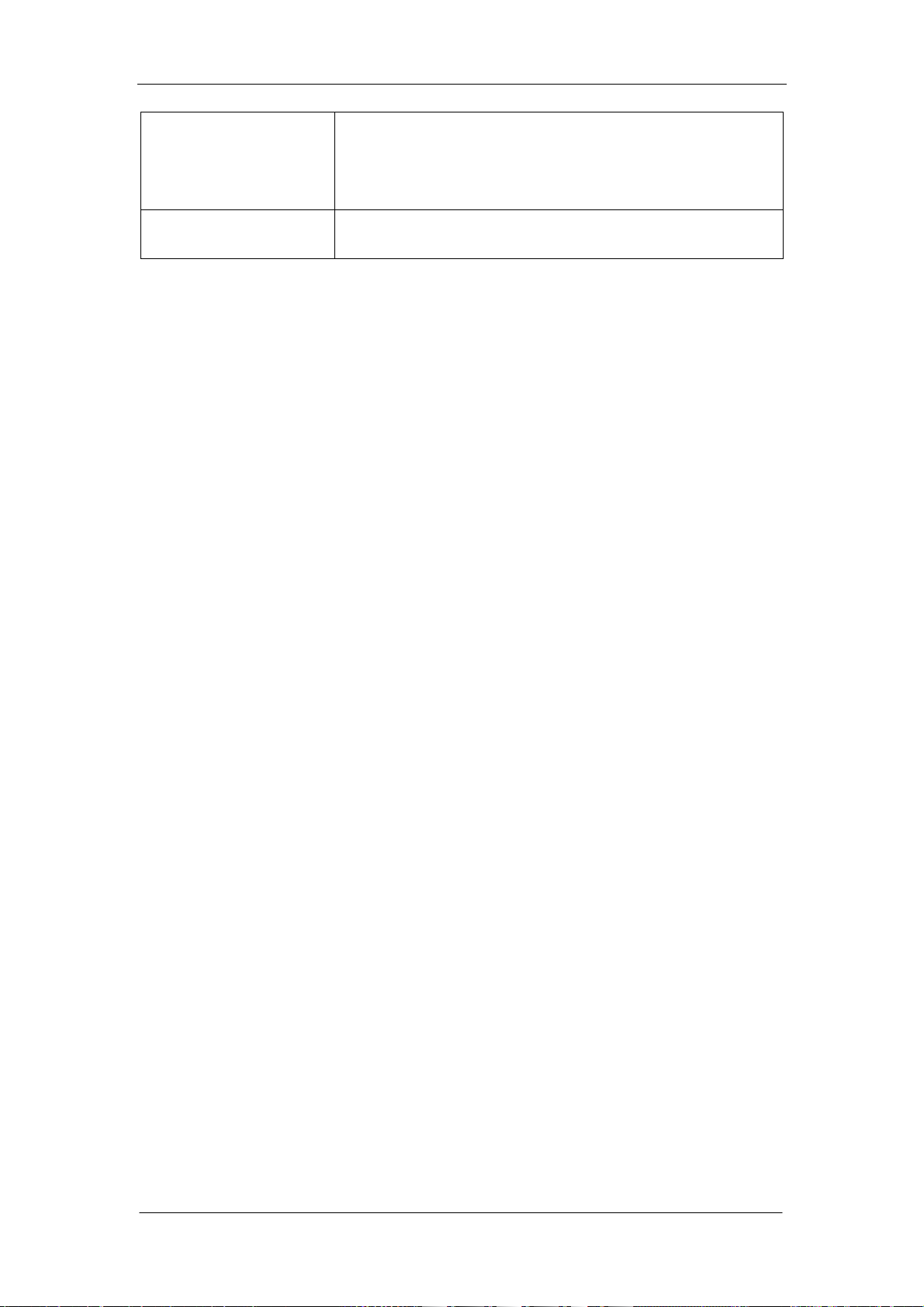

1.4.3 Front review without front panel

General

1

2

3

4

5

9

Figure 1-3

1--- Fluctuating Motor

2--- Sample Probe

3--- Sample Probe Wipe Block

4--- WBC unit shield

5--- RBC/PLT unit shield

6--- [Start] key

7---Valve 11

8--- Valve 12

9---Floppy Disk Driver

6

8

7

Auto Hematology Analyzer Service Manual (V1.1) 1-11

Page 24

General

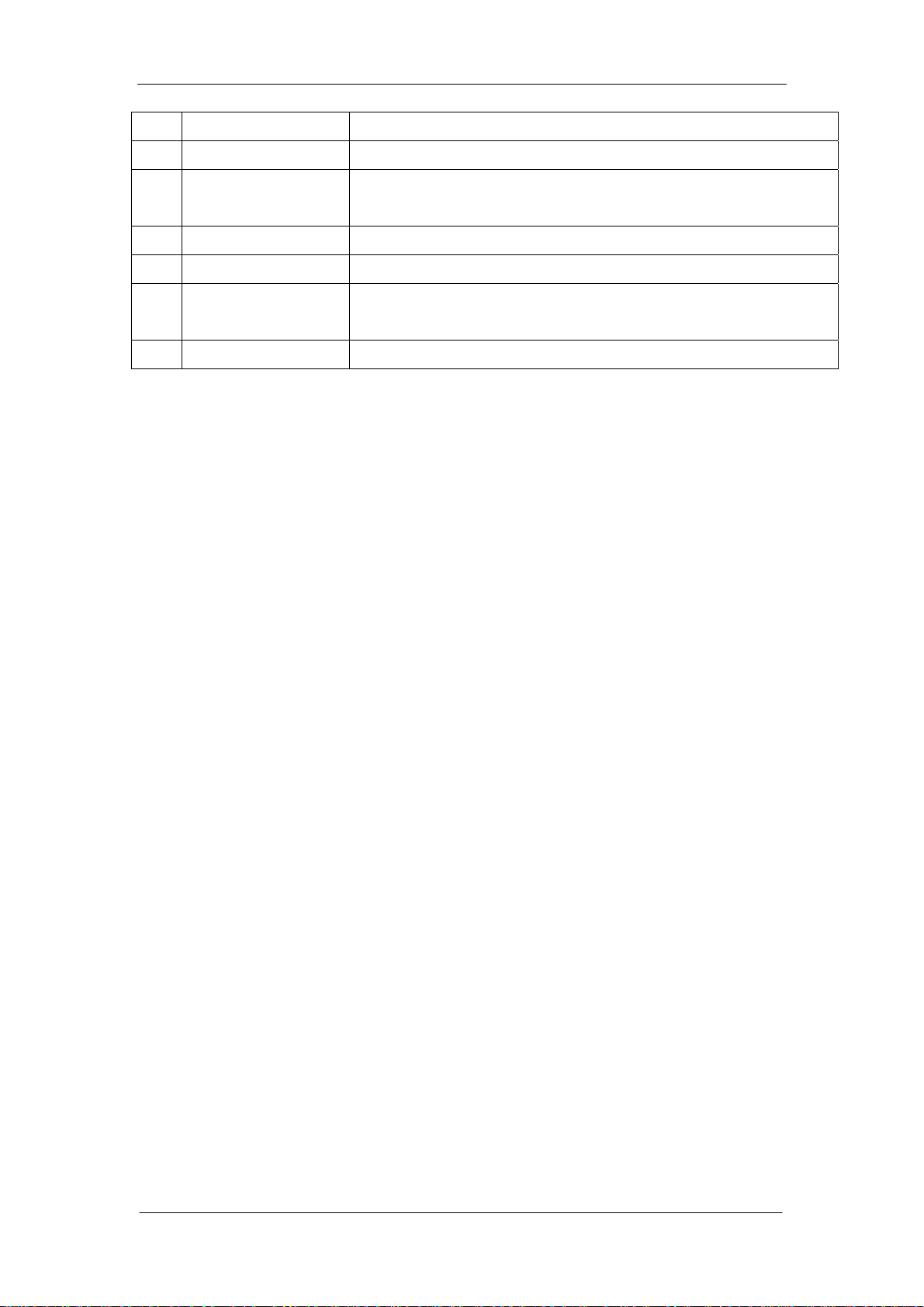

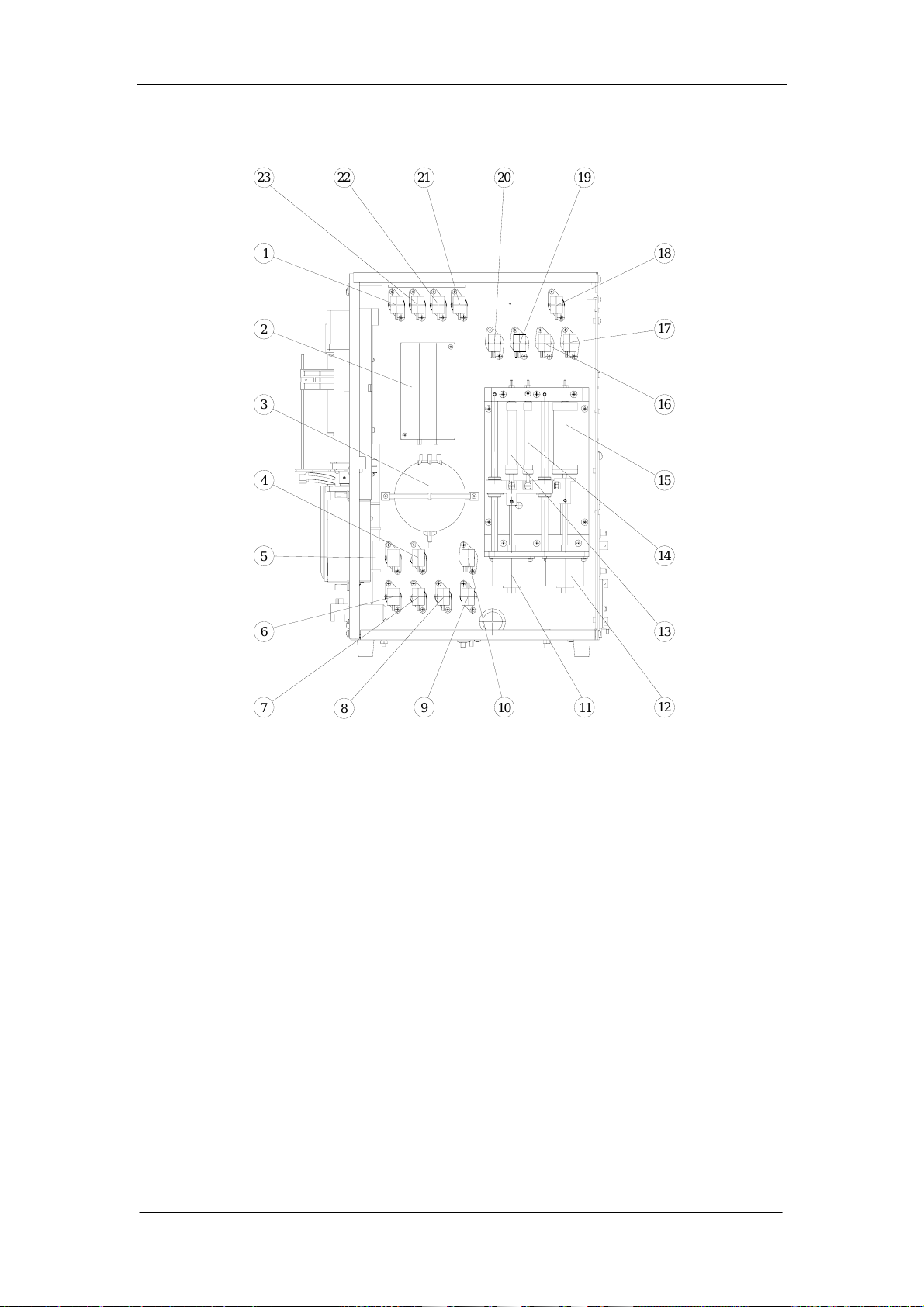

1.4.4 Right-side view without the door

2

2

3

1

2

3

4

2

2

1

2

1

0

9

1

8

1

7

1

6

1

5

1

5

6

7

8

9

1

0

1

1

4

1

3

1

2

Figure 1-4

1--- valve 8 2---volumetric unit

3---vacuum chamber 4---valve 15

5---valve 16 6---valve 14

7---valve 13 8---valve 10

9---valve 2 10--- valve 9

11---2.5ml and 50ul motor 12---10ml motor

13---2.5ml syringe 14---50ul syringe

15---10ml syringe 16---valve 4

17---valve 3 18---valve 1

19---valve 6 20---valve 5

21---valve 17 22---valve 7

23---valve 18

1-12 Auto Hematology Analyzer Service Manual (V1.1)

Page 25

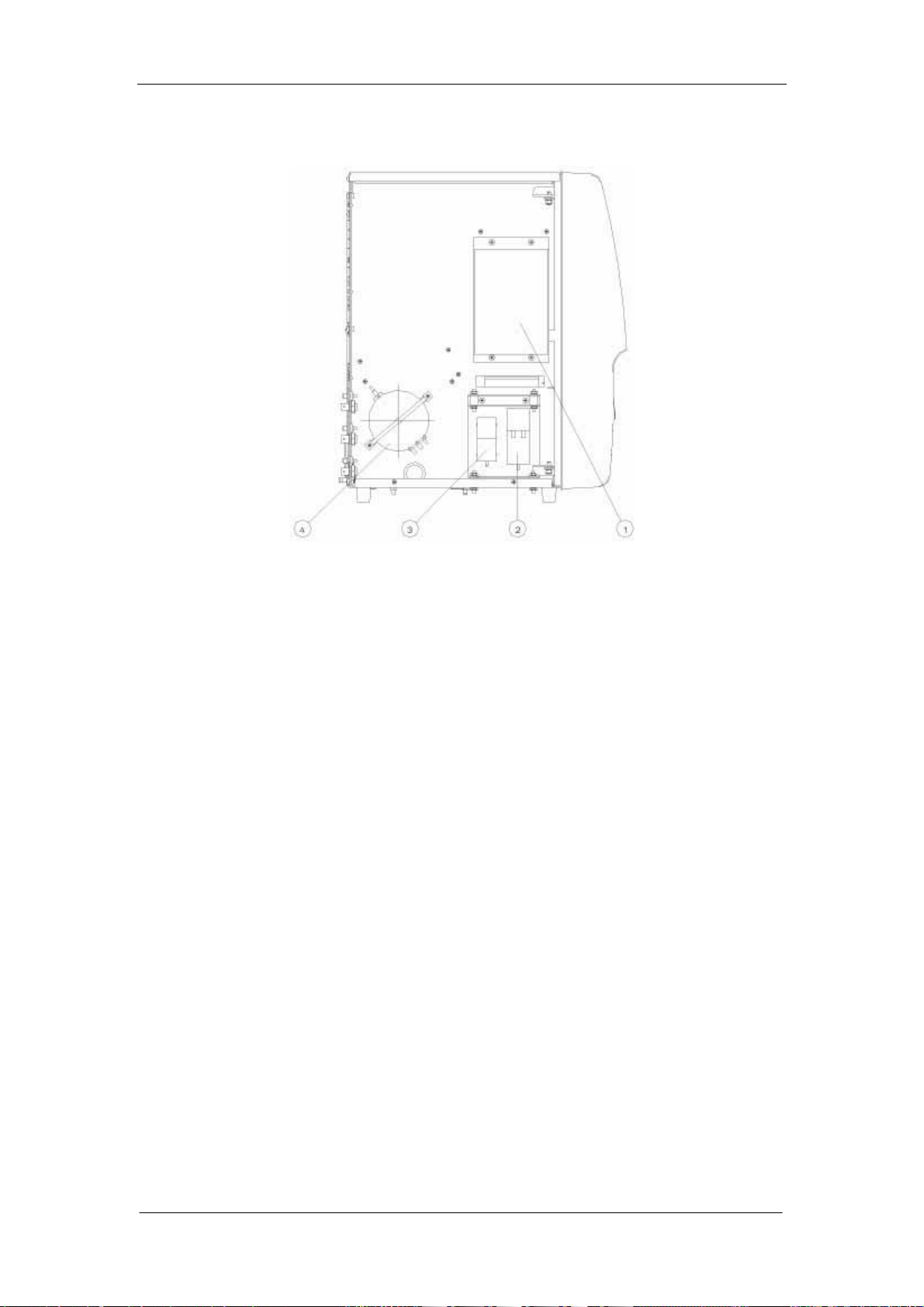

1.4.5 Left-side view without the door

General

Figure 1-5

1---hard disk (Module on disk)

2---vacuum pump

3---pressure pump

4---pressure chamber

Auto Hematology Analyzer Service Manual (V1.1) 1-13

Page 26

General

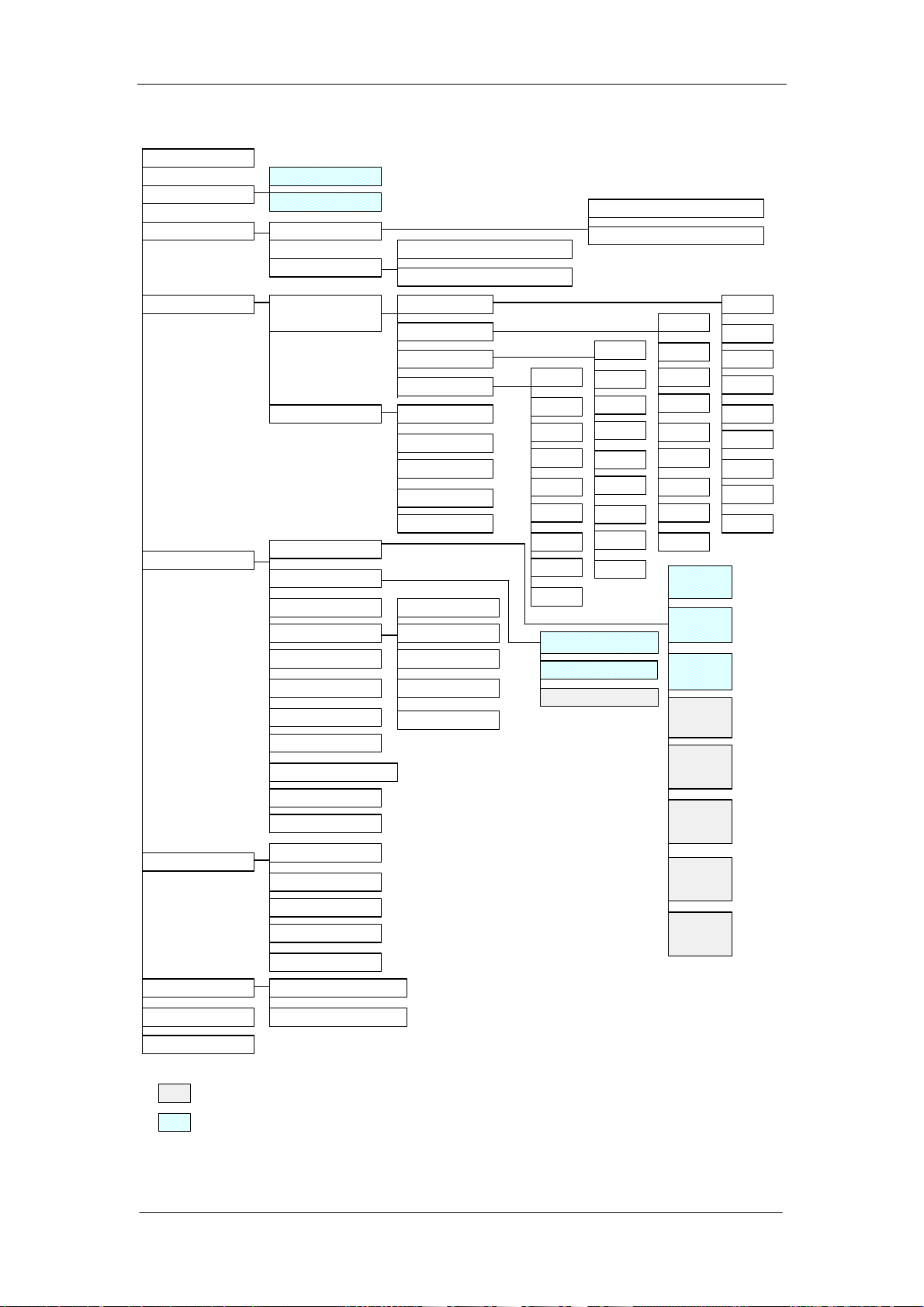

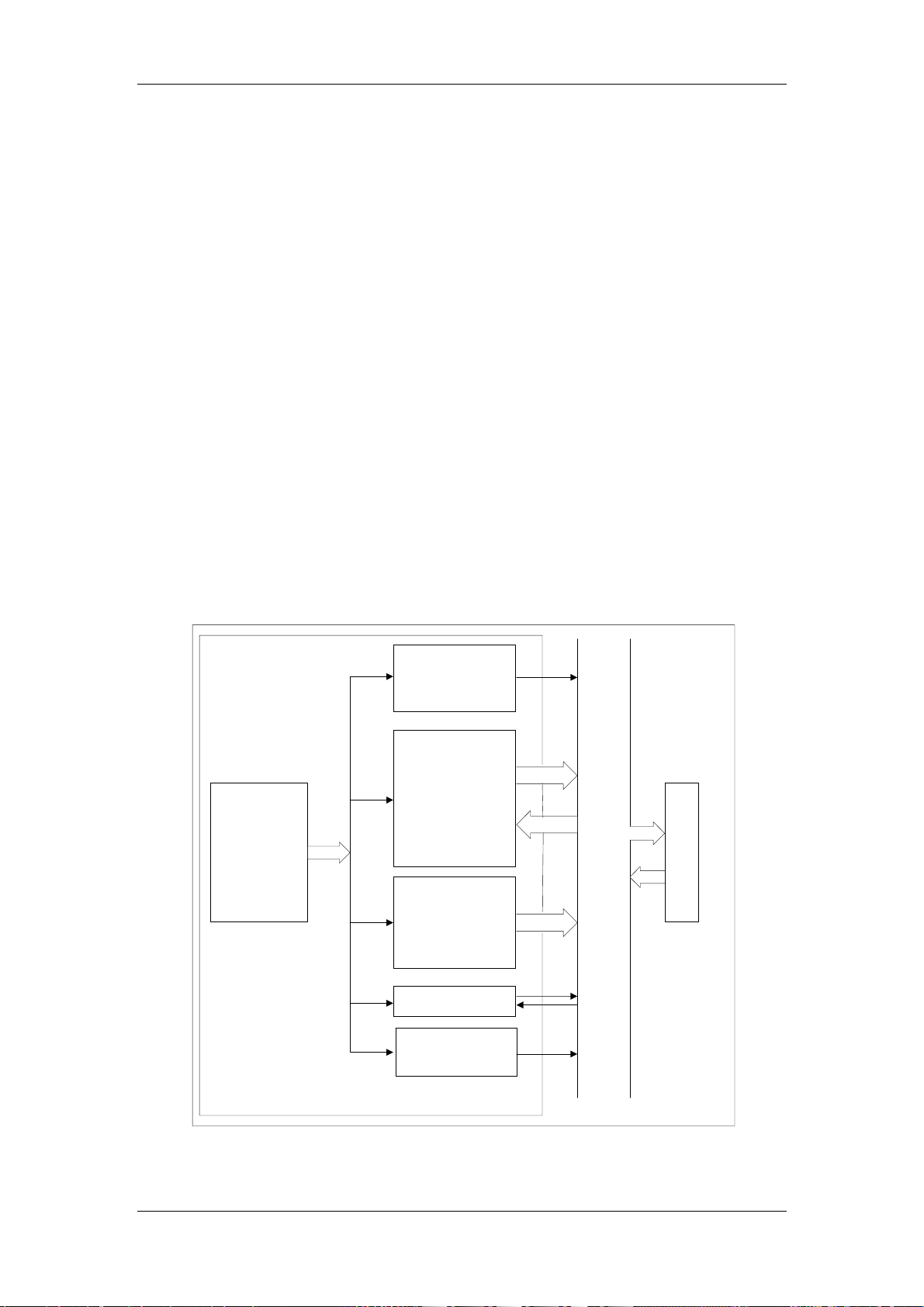

1.5 Menu Structure Chart

Count

Whole Blood

Sample Mode

Review

Prediluted

Sample Review

Search Review

Sample Table R eview

Sample Histogram Review

Search Table Review

Search Histogram Review

Qu a lity Control

Setup

Com merical

Control

X-B Analysis

Print

Count Time

Password

Patie n t L imits

Transm ission

Date & Time

Gain

Auto Clean Time

Re ag e n t E x p. Date

Prin t C a ptio n

Parameter U n its

QC Edit

QC Count

QC Graph

QC Table

Limit

Sample /B atc h

Start/Stop

X-B Graph

X-B Table

General

Man

Woman

Ch ild

Neonate

File 1

File 1

File 2

File 3

File 4

File 5

File 6

File 7

File 8

File 2

File 3

File 4

File 5

File 6

File 7

File 8

File 9

File 9

WBC Count Time

RBC Count Time

Mid Max Width

File 1

File 2

File 3

File 4

File 5

File 6

File 7

File 8

File 9

Prin t

Select

Prin t

Format

Auto

Print

Version

Language

Type

File 1

File 2

File 3

File 4

File 5

File 6

File 7

File 8

File 9

Service

M ain te na n ce

System Status

Valve Test

Prepare to Ship

Error Messa ge

Ca libr atio n

Help

M an u a l C a lib ra ton

Au to C a lib rat ion

Shutdown

:item s ca n be v ie w e d O n ly af ter in pu t th e co rr es po n d in g pa s sword

:included items, not sub-menu

1-14 Auto Hematology Analyzer Service Manual (V1.1)

Pale tte

Recorder

Type

Page 27

Chapter 2 Troubleshooting

r

A

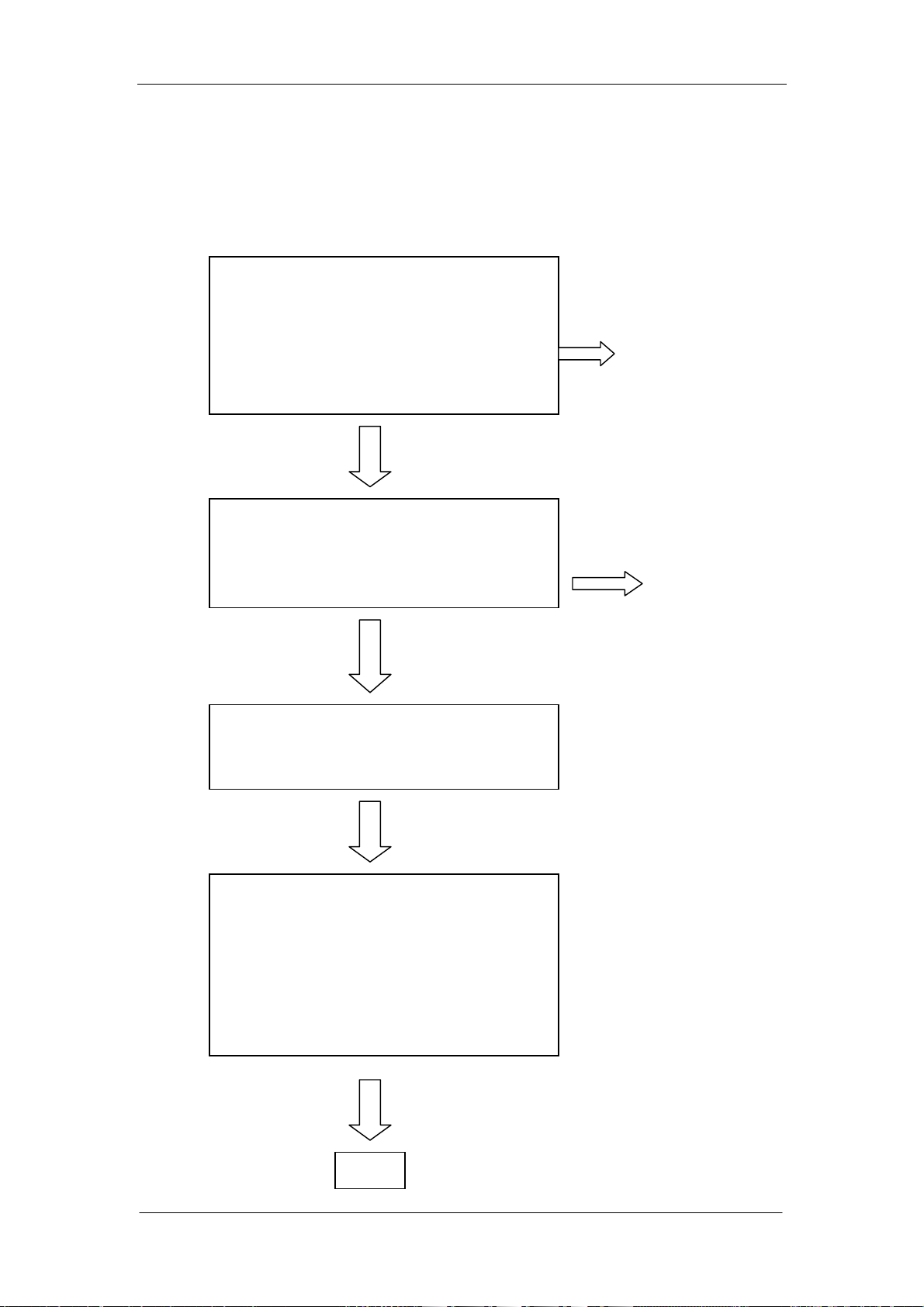

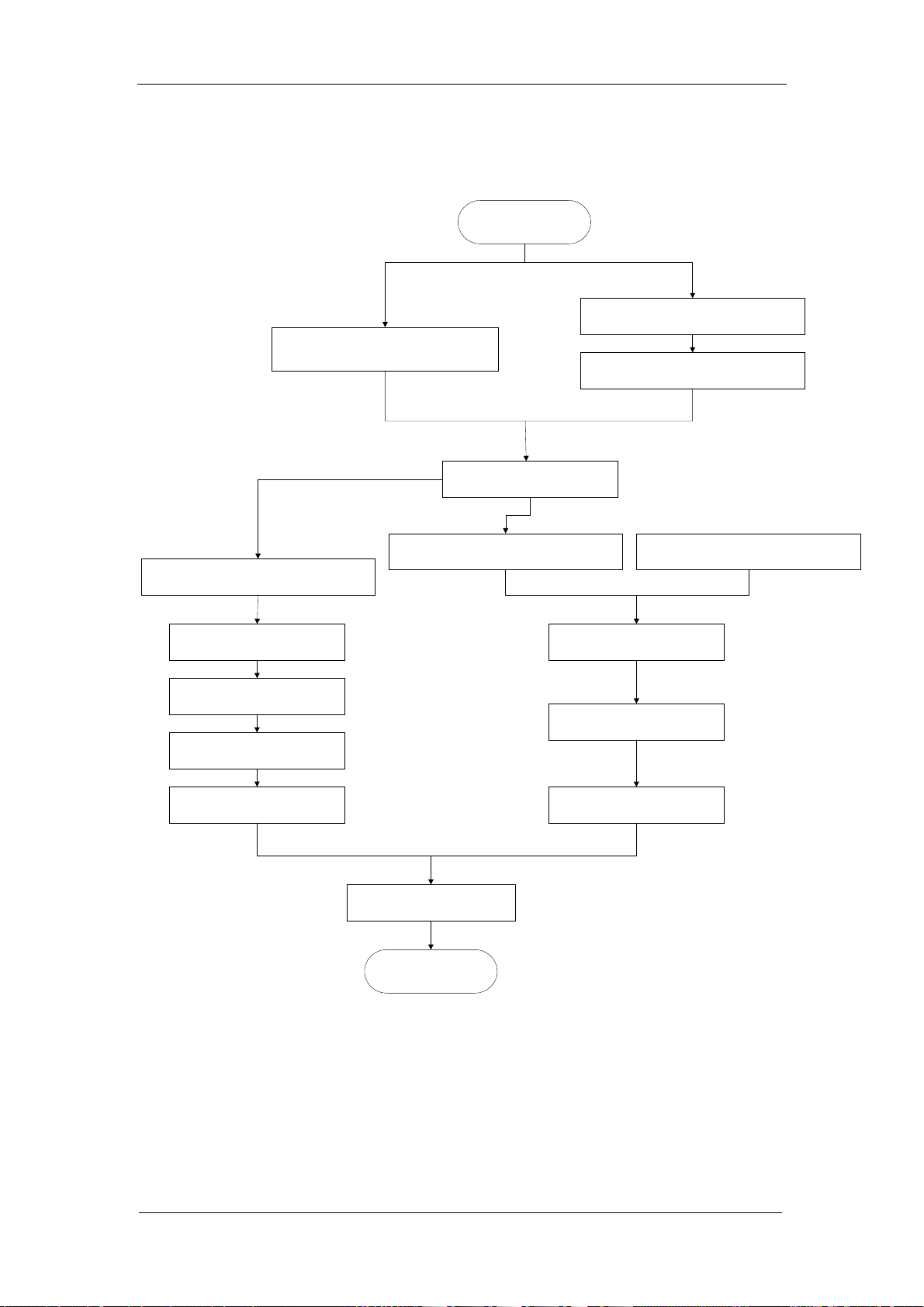

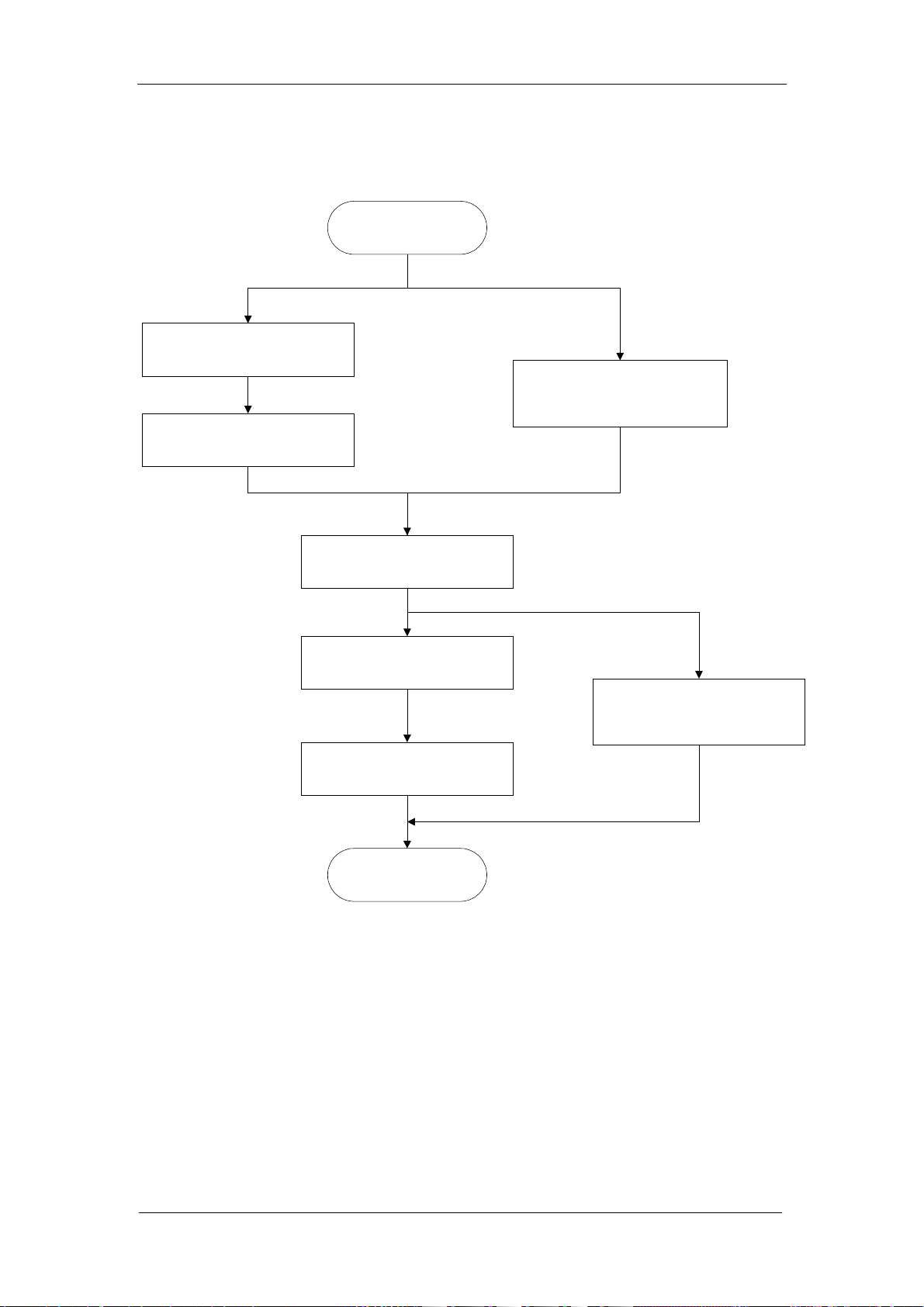

2.1 Check Procedure

Check the instrument according to the check procedure below.

Measurement operation check

Was the quantity of each reagent sufficient fo

measurement?

Were the correct or recommended reagents used?

Was the operating temperature proper?

Was the supplied main power voltage correct?

fter turning on the instrument.

Did the instrument fail to generate an alarm?

NO DILUENT

HARDWARE FAIL

Background noise measurement.

Did the instrument fail to generate an alarm?

Was the result within the specification?

Control measurement

Did the instrument fail to generate an alarm?

Was the result reproducibility good for:

HGB? RBC?

WBC? PLT?

HCT?

(Was the obtained data within the range?)

END

before Instrument Check”

Troubleshooting

Refer to “Check Items

Refer to

“Troubleshooting

and Alarm”

Auto Hematology Analyzer Service Manual (V1.1) 2-1

Page 28

Troubleshooting

2.2 Check Items before Instrument Check

Use the instrument and diluent under the following

Check items before

Instrument check

operating conditions:

Around instrument Diluent

- temperature: 15 to 35℃ temperature: 15 to 30℃

- humidity: 10 to 85%

- atmospheric pressure: 860 to 1060hPa (Working)

If the temperature is less than 15℃, it slows the

reaction rate from hemoglobin to cyanmethemoglobin.

This may result in increase of the hemoglobin data. It

may also result in increase of the WBC count because

the RBCs are not sufficiently hemolysed due to the

lower temperature. Insufficiently hemolyzed RBCs will

be included in the WBC count as RBC ghosts.

Sampled Whole Blood

Handling Check

Storage for Blood Sample

Measure all required parameters soon after sampling

the whole blood from a patient. As time elapses after

blood sampling, the blood cells’ volume and density

change. The ratios of the volume and density

variations depend on the environmental conditions and

patient. If the blood sample isleft in an air conditioned

room for a long time, the volume of the red blood cell

increases and the MCV, RDW and MPV will be

affected, and moreover, the PLT will be easily

aggregated.

WBC part differential

To get high reliability on the acquired data, measure

the blood samples within 6 hours after sampling the

whole blood. If the blood sample is left in an air

conditioned room for a long time, geerally, the WBC

membrane’s resistance against hemolysing reagent is

decreased. Therefore the WBC histogram of the

correct shape cannot be obtained.

Blood Sample from a Patient with Specified Conditions

To measure a blood from a patient who has

hepatopathy, certain special treatments, or is a

neonate, it may be necessary to use a method other

than the hematology. Analyzer. This is because the

RBC membrane’s resistance against hemolysing

2-2 Auto Hematology Analyzer Service Manual (V1.1)

Page 29

Capillary Blood Handing

Check

Troubleshooting

reagent is increased (insufficient hemolysing) and it

will cause an increase of the WBC count when the

blood is measured with the hematology analyzer.

Furthermore, the bilirubin and WBC in the blood may

affect the hemoglobin concentration in the

measurement.

CAUTION

In the capillary blood mode, the instrument

aspirates the diluted sample of 20uL. In this mode,

if the venous blood is incorrectly aspirated instead

of capillary blood, there is a high possibility that

the fluid path is clogged or the background noise

is not easily decreased.

Most causes of data error using capillary blood are due

to incorrect technique for the capillary blood sampling

and diluting. Therefore, take care the following notes

and make a capillary blood sample.

NOTE

Dilute the sampled capillary blood correctly the

first time, because it is difficult to sample the

blood twice from the capillary.

Auto Hematology Analyzer Service Manual (V1.1) 2-3

Page 30

Troubleshooting

2.3 How to Check Sample Data

Background Noise Check

This check is used to make sure that the counted and

calculated data of a diluent sample is not affected by

background noise. If the background checking value

exceeds the tolerable dilute data shown in the table

below, the diluent data counted and calculated before

background noise is reduced erroneous. In the table

below, each diluent data is defined as follows:

Recommended diluent data

This data is best for acquiring accurate data of the

sample.

Acceptable dilunt data

This data is the minimum value for acquiring accurate

data of the sample.

Recommended diluent Data Acceptable diluent Data

WBC 0.0 WBC

RBC 0.00 RBC

HGB 0 HGB 1g/L or 0.1g/dL

HCT 0.0 HCT 0.5%

PLT 3 PLT

Refer to “Troubleshooting Erroneous Data” of this

chapter for the possible causes of background noise

and how to reduce it.

Check Procedure

1. Press the start key to count and calculate the

2. Make sure the counted and calculated data is less

Parameter Data Check with Diluent

Check that the background values are less than or

equal to the data in the previous table. Discard the

other parameter values because they are not affected

by noise.

Especially check the data for the PLT parameters.

When the diluent includes the particles of dust smaller

9/L

10

0.3x

12/L

10

0.03x

9/L

10

10x

diluent. There is no need to aspirate the diluent

from the sampling probe.

than or equal to the acceptable diluent data as

shown upper. If they are out of range, decrease the

background noise.

2-4 Auto Hematology Analyzer Service Manual (V1.1)

Page 31

Troubleshooting

than WBC and RBC parameters, the data of them is

not affected by the dust but the data for the PLT

parameter increases because the volume for the PLT

parameter is smaller than the WBC and RBC

parameters. I f the data for the PLT parameter exceeds

10X10

9

/L, do the action described below to reduce the

background noise.

Reducing Background Noise

To reduce the background noise when the background

check value exceeds the acceptable diluent data

shown in the previous table, perform the following.

1. Make sure connecting grounding well.

2. Execute the “clean Bath” program which in the

service menu. If this does not reduce the

background noise, perform the following steps.

3. Execute the “E-Z cleanser cleaning” and “Diuent

Prime” program.

4. Perform the background check to make sure that

the background noise is reduced.

If the data of the background check is still outside the

acceptable diluent data values shown in the previous

table, replace the diluent with diluent from a new,

sealed container.

NOTE

When the instrument is used every day and the

background noise rarely exceeds the lower limit

for the diluent data, the instrument is not severely

contaminated. However, this contamination builds

up in the instrument and cannot be easily removed

if the instrument is not cleaned periodically.

Auto Hematology Analyzer Service Manual (V1.1) 2-5

Page 32

Troubleshooting

Reproducibility Check This check is used to check reproducibility of the

instrument, using pintout data value of a diluted

sample from the same hematology control. When the

values are out the specification range, the

reproducibility of the instrument is poor. If the

reproducibility is found to be poor, this printed result is

used to troubleshoot the instrument as described in

“Troubleshooting Erroneous Data” of this chapter.

Check Procedure

1. Reduce the background noise. Refer to

“Background Noise Check” of this chapter.

2. Access “Quality Control” → normal level

Controls→ QC Edit→ File “X” to set a new control

file and input each parameter’s specification.

3. Access “Quality Control” → Commercial

Controls→ QC Count→ Count a diluted sample

from the same sufficiently mixed hematology

control 10 times.

4. Access “Quality Control” → Commercial

Controls→ QC Graph→ File “X” to review the

result and CV value.

5. If you want to print out the displayed values with an

built-in thermo-printer unit, press the print key

which on the keypad directly in the graph screen or

table screen.

Data Check with Hematology Control

The CV (Coefficient of Variation) indicates the data

reproducibility on each parameter. A lower CV value

for a parameter indicates better reproducibility for the

parameter (i.e. each sample data for the parameter

deviates less).

Check the CV value for each parameter by comparing

it with the CV specifications (as shown in the next page)

described in the brochure. You get the CV value by

counting a normal concentration hematology control

10 times consecutively.

If the acquired CV values are out of the CV

specifications, the reproducibility of the instrument is

poor. To troubleshoot the instrument, refer to

“Troubleshooting Erroneous Data” of this chapter.

2-6 Auto Hematology Analyzer Service Manual (V1.1)

Page 33

Troubleshooting

<Data example and CV specifications>

N X CV% CV Specification

WBC 10 10.0 1.05 2.5% or less

RBC 10 4.23 1.22 2% or less

HGB 10 130 0.77 1.5% or less

PLT 10 201 3.25 5% or less

Lymph# 10 4.0 1.47

Lymph% 10 41.0 1.28

Gran# 10 4.9 1.77

Gran% 10 48.2 1.15

HCT 10 36.1 1.28

MCV 10 86.9 0.24 0.5% or less

MCH 10 31.6 1.02

MCHC 10 353 1.08

N: Number of samples for each parameter

X: Mean of sample data for each parameter

CV: Standard deviation divided by mean X

Note

Normally, the hematology analyzer counts approx

4.0X10

4

blood cells for 16 seconds per one RBC

counting. The reproducibility for the hematology

analyzer is statistically determined by the number of

blood cells aspirated through the aperture. The

reproducibility is better as the number of counted blood

cells increases; the reproducibility is worse as the

number of counted blood cells decreases. That is, the

acquired data has more deviation when a blood

sample of lower concentration is counted.

The following explanation and diagram show what the

CV values mean for data of each parameter.

For example, when noting the RBC data on the

printout (see the previous table), the mean of the RBC

data is 4.43 and CV is 0.8%. 0.8% of 4.43 is 0.035.

Therefore the range is 4.395 to 4.465 (4.43±0.035).

This means that six of the ten acquired RBC data are

within the range.

Auto Hematology Analyzer Service Manual (V1.1) 2-7

Page 34

Troubleshooting

Accuracy Check

4.37 4.39 4.40 4.43 4.44 4.45 4.45 4.45 4.46 4.47 4.48

(2 data) (6 data) (2 data)

4.395 4.465

This check is used to check the accuracy of the

measurement by comparing the actually measured

data of the hematology control with expected value on

the assay sheet of the hematology control. If there is a

large difference between them, calibrate the

instrument by resetting the calibration coefficient for

each parameter.

Check Procedure

1. Gently take the hematology control out of the

refrigerator and place it in a normal temperature

environment for a while to raise it to room

temperature. The hematology control must be

within the expiration data.

2. Confirm that the hematology control is not

hemolysed. Normally the hematology control is

separated into blood plasma and blood serum of

the hematology control may be mixed. Also, if the

hematology control is frozen, it is hemolysed.

3. Measure each parameter with the hematology

control.

4. Check that the obtained sample data for each

parameter is within the range between the lower

and upper expected values on the assay sheet.

Run the control again, replace a new control to try

again if the results are out of range. After that, if

the result are still unacceptable, recalibrate the

instrument with the following procedures.

5.

When the condition temperaare range is out of (20

to 26℃), control results maybe out of limits.

2-8 Auto Hematology Analyzer Service Manual (V1.1)

Page 35

Troubleshooting

×

Parameter Data Check with Hematology Control

Check that the obtained sample data for each

parameter is within the range of the assay values on

the assay sheet.

NOTES

If the data for any parameter is out of range,

calibrate the instrument according to “Calibration”

of the operator’s manual.

To calibrate the instrument for more accuracy,

refer to the following “Procedure for Instrument

Fine Calibration” of this chapter.

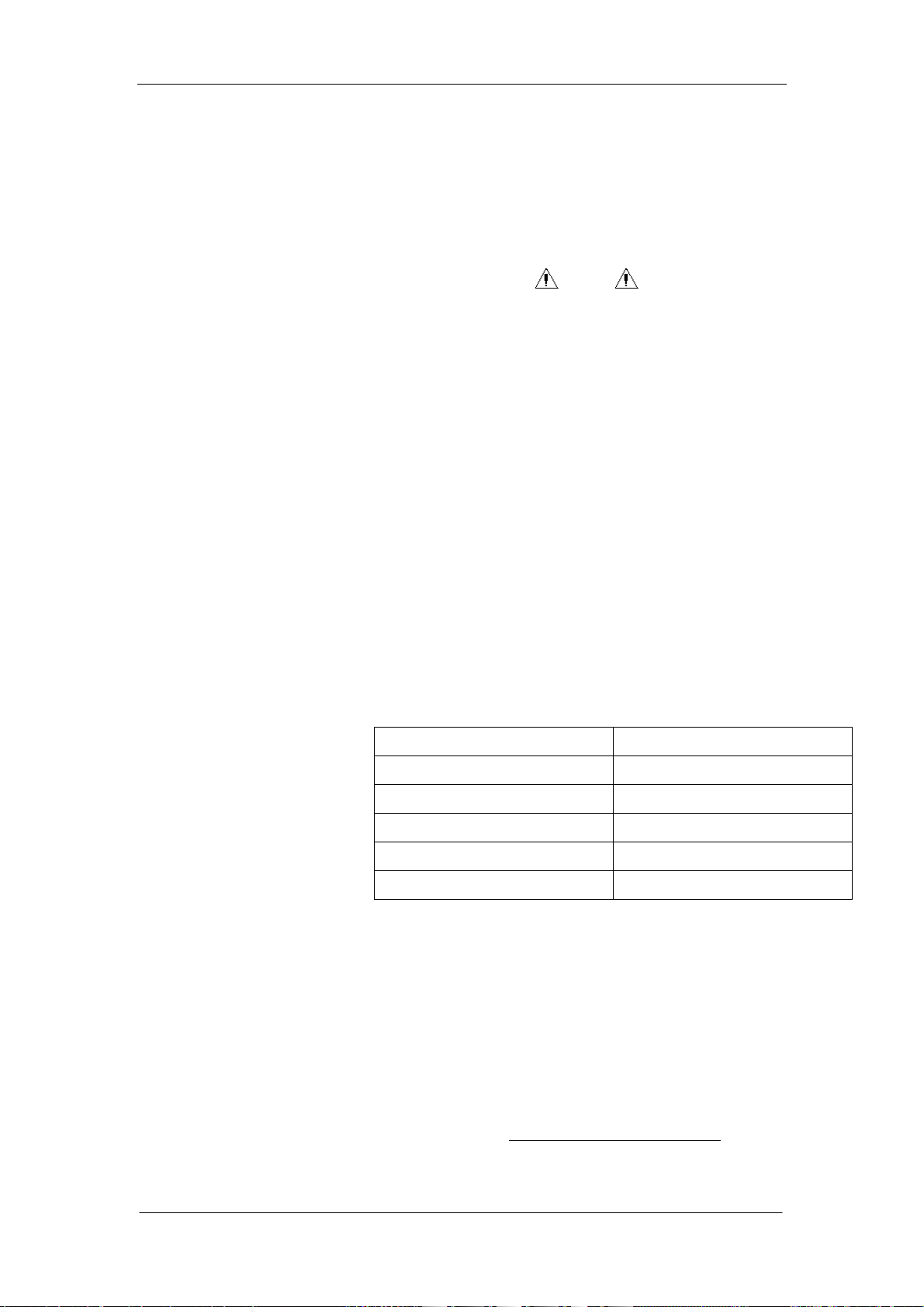

Procedure for Instrument Fine Calibration

The instrument allows the user to input the factors

manually with the range between 75% and 125%.

The procedures of manual are:

1 . Confirm the sample mode.

2 . Run the calibrator in Count screen for at least five

times. The reproducibility of WBC, RBC, HGB, MCV

and PLT must satisfy following limits.

Parameter CV

WBC

RBC

HGB

MCV

PLT

≤2.5

≤2.0

≤1.5

≤0.5

≤5

3. Calculate the new calibration factors.

4. Enter the new calibration factors.

Calculate the New Calibration Factors

Use the below formula to calculate the new calibration

factors

factornew

=

valuereferencefactorold

valuetestofaverage

Auto Hematology Analyzer Service Manual (V1.1) 2-9

Page 36

Troubleshooting

×

Example:

Reference value of WBC = 8.4

In whole blood mode, three running values of WBC are

8.1, 8.0, 8.1, 8.1 and 8.3. The mean value of WBC is

8.12. Old calibration factor in the whole blood mode is

98.9%.

n

x

∑

i

i

1

Mean

=

12.8

==

n

CV < 2%

4.8%9.98

=

factornew

valuereferencefactorold

valuetestofaverage

=

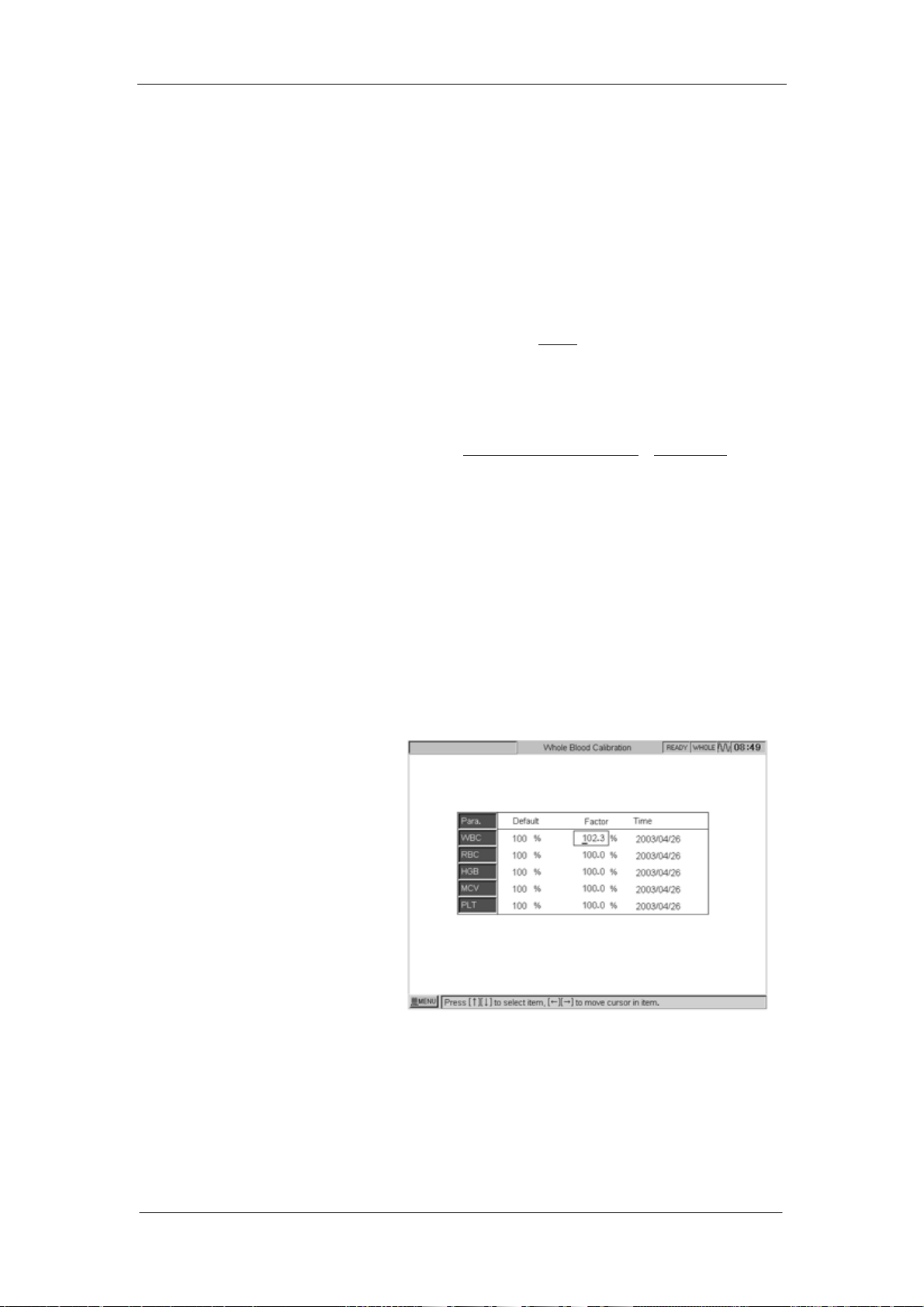

Enter the Calibration Factors

In the menu operation, move the cursor to the

“Calibration/Manual Calibration” and press [ENTER] to

access the manual calibration screen as shown in

below figure.

Press [ENTER] to access the Edit Parameter state.

×

12.8

%3.102

=

Figure 2-1

Press [↑][↓] to select the item and [←][→] to move

the cursor within the item.

Press [0] – [9] to enter numbers.

The “fixed decimal” format is adopted so that the user

need not enter the decimal point.

2-10 Auto Hematology Analyzer Service Manual (V1.1)

Page 37

Troubleshooting

The factor should be within the range of 75% -- 125%.

Confirm the New Calibration Factors

After entering the new factors, press [MENU] key to

return to menu operation, then the dialog box pops up

as shown in below figure.

Figure 2-2

Select “Yes”, store the new factors.

Select “Cancel”, reserve the old factors.

Verification

After entering the new factors, run the calibrator in

Count screen. Verify that the results are within the

specified range.

•The Automatic Calibration procedures are:

1. Set up the sample mode to Whole Blood or

Prediluted.

2. Enter the reference value of the calibrator.

3. Run the calibrator.

4. Confirm the calibration factors.

Auto Hematology Analyzer Service Manual (V1.1) 2-11

Page 38

Troubleshooting

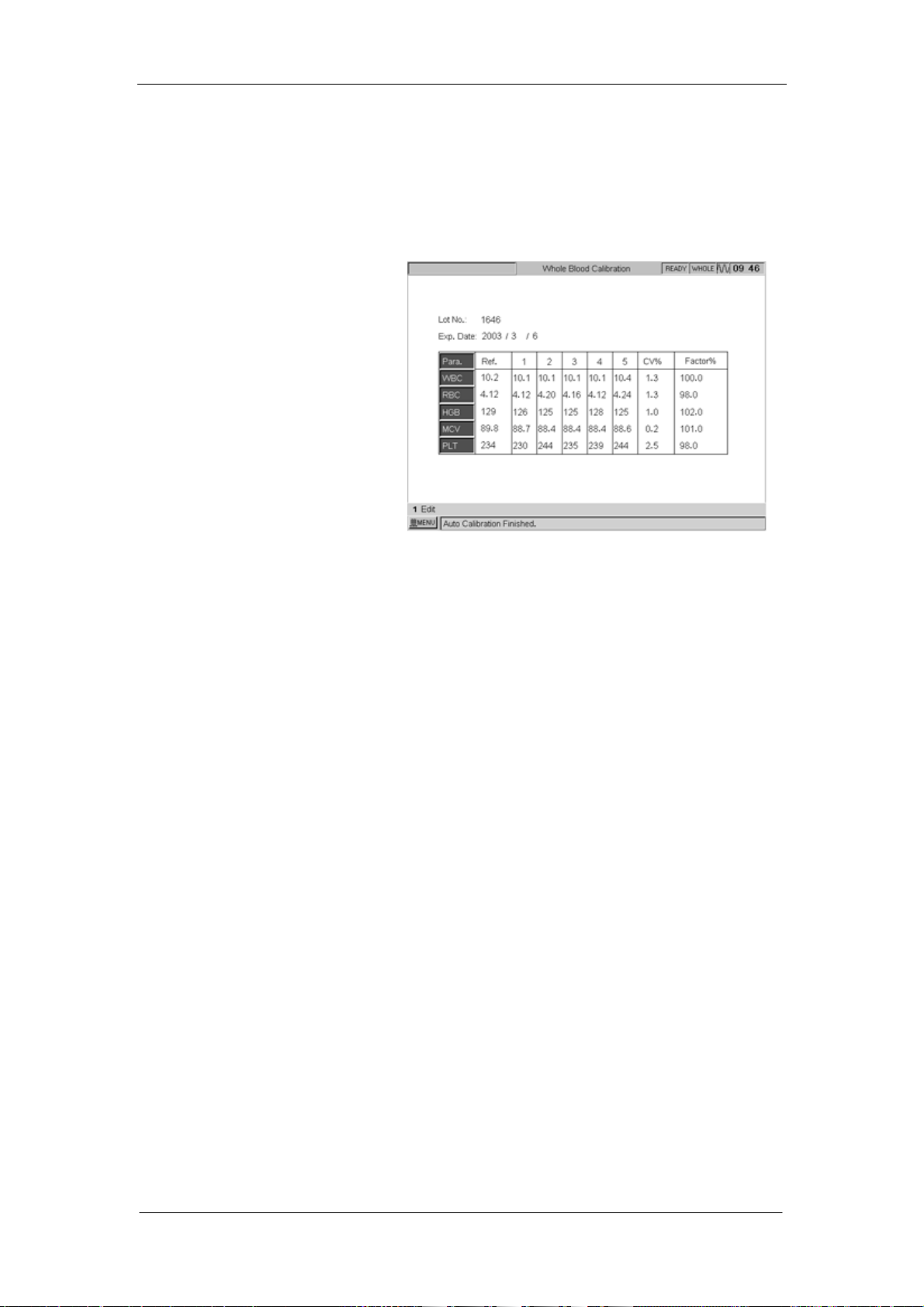

Figure 2-3

In menu operation, move the cursor to

“Calibration/Auto Calibration”, press [ENTER] key to

access Auto Calibration screen.

Figure 2-4

Edit the reference:

Press [1] to access “Edit Reference” status. Enter

the reference values of the calibrator.

Press [↑][↓] to select the item and [←][→] to

move the cursor within the item.

Press [0] – [9] to enter numbers.

The “fixed decimal format” is adopted so that the user

need not enter the decimal point.

Press [ENTER] to exit edit status and access the

Count status.

2-12 Auto Hematology Analyzer Service Manual (V1.1)

Page 39

Troubleshooting

A

Figure 2-5

Run Calibrator Procedure

WARNING

WARNING

void contacting with the sample probe.

1. Place the well-mixed calibrator to the probe so that

the tip is well into the tube, and press the [START] to

run. The process of run is the same as that of count.

After running, the screen displays as shown in below

figure.

Figure 2-6

Select “Yes” to validate the results.

Auto Hematology Analyzer Service Manual (V1.1) 2-13

Page 40

Troubleshooting

Select “Cancel” to invalidate the results.

The below figure shows an example of the results after

five times of running.

Figure 2-7

The average value of calibration and the new

calibration factors automatically calculated by the

system are displayed in the right side of the screen.

“***” refers to invalid results, which means that the

average value of the parameter and the calibration

factor are invalid.

Maximum 5 samples can be counted for auto

calibration. The auto calibration result will be displayed

only after 3 samples are counted. If the calibration

factor of a parameter is out the range of 75% ~ 125%,

it will not be displayed, find the reason. If necessary,

contact the Mindray Customer Service Department or

the distributor.

Confirm the New Calibration Factors

Press [MENU] to return to the menu operation. The

dialog box pops up as shown in below figure.

2-14 Auto Hematology Analyzer Service Manual (V1.1)

Page 41

Troubleshooting

Figure 2-8

Select “Yes”, save the new calibration factors.

Select “Cancel”, keep the original calibration factors.

Verification

When the new calibration factors are adopted, count

the calibrator in the Count screen and verify that the

result is within the specified range.

Auto Hematology Analyzer Service Manual (V1.1) 2-15

Page 42

Troubleshooting

2.4 Troubleshooting Erroneous Data

Background Noise

When the count data of a container filled with diluent

just exceeds the tolerable value of the parameter

shown in the table in ”Background Noise Check” of this

chapter, the seven possible causes of error are:

(1) Dirty diluent

(2) Dirty diluent container

(3) Dirty baths

(4) Dirty valves

NOTE

Before storing the instrument for a long time, clean

and empty all fluid tubings in the instrument with

distilled water. Otherwise, the diluent salt adheres

to the baths and cannot be removed easily.

(5) Electronic noise affecting the counting/calculation

circuit:

AC line, backlight converter, peripheral equipment

such as microwave treatment machine, motors in

the instrument

(6) Mechanical noise affecting the counting/calculation

circuit:

Vibration from motor in or around the instrument,

such as a centrifuge

(7) Tubing noise affecting the counting/calculation

circuit:

Liquid flow with some remained electric charges

As a countermeasure to the above 7 causes, take the

following actions.

Cause (1) or (2)

− Replace the diluent with diluent from a sealed

container.

Cause (3) or (4)

− Clean the baths with E-Z cleanser

− Clean the baths with probe cleanser

2-16 Auto Hematology Analyzer Service Manual (V1.1)

Page 43

Troubleshooting

− Clean valves with distilled water

− Exchange the other same model valves to try

Cause (5)

−Securely ground the instrument, including any

optional units such as external printer.

Cause (6)

− Keep the instrument away from the vibration source.

Cause (7)

− Securely ground the tubing.

Auto Hematology Analyzer Service Manual (V1.1) 2-17

Page 44

Troubleshooting

For Reproducibility

This subsection describes the cases when the

reproducibility for the following measuring parameter

or calculated parameter is poor.

− PLT

− HGB

− WBC

− RBC

− Data other than red cell indexes (MCV, MCH and

MCHC)

− RBC and PLT coefficient related parameters

− HCT and MCV

2-18 Auto Hematology Analyzer Service Manual (V1.1)

Page 45

Troubleshooting

Poor Reproducibility for PLT

Possible Cause Countermeasure

The background data on PLT is

Refer to “Background Noise Check“ of this chapter

high

Dirty RBC aperture Clean the aperture.

Dirty RBC bath Clean the bath. Refer to the “Maintenance” of the

operator’s manual.

Dirty measuring tube Clean the tube below the RBC bath

Dirty wipe block Clean the wipe block

Replace a new wipe block

The sample probe position is not

Adjust the probe position using localizer

correct

The 3-way valve (SV11) is dirty Clean the valves

Replace this valve

The 3-way valve (SV11) cannot

Replace the 3-way valve (SV11).

drain liquid empty.

The diuent syringe exists

Remove the bubbles from the syringe

bubbles

Faulty circuit Replace the ANALOG board

Poor Reproducibility for HGB

Possible Cause Countermeasure

Dirty WBC measurement bath Clean the WBC bath with E-Z cleanser or probe

cleanser

The voltage output from the HGB

sensor is not optimal

Adjust the HGB voltage. Refer to “Adjust Gain” of

this manual.

Adjust the adjustable resistance VR3 & VR4 to

adjust the output voltage of HGB to 4.4v-4.6v

The 3-way valve (SV12) cannot

Replace the 3-way valve (SV12).

drain liquid empty.

The 3-way valve (SV12) is dirty Clean or replace the valves

The specified diluent and

Use the correct reagent

hemolysing reagent were not

used

Cyanide in the hemolysing

reagent has been dissolved by

Replace the hemolysing reagent with a new

reagent and tighten the cap of the reagent bottle.

sunlight or heat

The HGB 2.5 mL syringe exists

Remove the bubbles from the syringe

bubbles

The light axis of the HGB LED is

deviated

Adjust the light position

Replace the light

Auto Hematology Analyzer Service Manual (V1.1) 2-19

Page 46

Troubleshooting

The light of HGB is aging Replace the HGB unit

The diuent syringe exists

Remove the bubbles from the syringe

bubbles

Faulty the Analog board Replace the analog board

Poor Reproducibility for WBC

Possible Cause Countermeasure

The background data on WBC is

Refer to “Background Noise Check“ of this chapter

high

Dirty WBC measurement bath Clean the WBC bath with E-Z cleanser or probe

cleanser

Dirty measuring tube Clean the tube below the WBC bath

Dirty wipe block Clean the wipe block

Replace a new wipe block

The sample probe position is not

Adjust the probe position using localizer

correct

The 3-way valve (SV12) cannot

Replace the 3-way valve (SV12).

drain liquid empty.

The 3-way valve (SV12) is dirty Clean the valves

Replace this valve

The lyse reagent has been

dissolved by sunlight or heat

The constant current is not

Replace the lyse reagent with a new reagent and

tighten the cap of the reagent bottle.

Change the transformer or analog board

stable

The diuent syringe exists

Remove the bubbles from the syringe

bubbles

Faulty the Analog board Replace the analog board

Poor Reproducibility for RBC

Possible Cause Countermeasure

The background data on RBC is

Refer to “Background Noise Check“ of this chapter

high

Dirty RBC measurement bath Clean the RBC bath with E-Z cleanser or probe

cleanser

Dirty measuring tube Clean the tube below the RBC bath

Dirty wipe block Clean the wipe block

Replace a new wipe block

The sample probe position is not

Adjust the probe position using localizer

correct

The 3-way valve (SV11) cannot

Replace the 3-way valve (SV11).

drain liquid empty.

2-20 Auto Hematology Analyzer Service Manual (V1.1)

Page 47

The 3-way valve (SV11) is dirty Clean the valves

Replace this valve

The constant current is not

Change the transformer or analog board

stable

The diuent syringe exists

Remove the bubbles from the syringe

bubbles

Faulty the Analog board Replace the analog board

Troubleshooting

Auto Hematology Analyzer Service Manual (V1.1) 2-21

Page 48

Troubleshooting

2.5 Troubleshooting

B

Burn fuse when power on unit AC input power is not stable

Power supply board is short

circuit

Bubbles Bubbles in the sample

Regents are not enough

Setting count time is long

The aperture is broken

Counting channel is leakage

Background testing is

abnormal

C

Counting time is sometimes

too short and sometimes

normal

Clog Big cells or debris in the

D

Diluent injection time becomes

longer, and make WBC bath

full

Display is not clear Backlight is too bright or too

F

Fluctuating and rotatory motor

error

Regents are dirty

Electronic noise

Dirty bath

Dirty valves

The CPU board has some

problem

sample

Setting count time is short

The aperture is blocked

Diluent is not enough

Volumetric board is broken

SV3 valve doesn’t close

properly

dark

LCD screen is old

The environment

temperature is low

Tubing which on the sample

Using a manostat

(voltage regulator)

Replace the power

supply board

Remove the bubbles

Re-prime the regents

Re-set the count time

Change a new aperture

Replace the leakage

parts

Change new regents

Connect ground well

Clean the bath

Clean the valves

Replace the CPU

board

Remove the debris

from the sample

Re-set the count time

Clean the aperture

Check the diluent

syringe and diluent

Replace the

volumetric board

Replace the SV3 valve

Adjust the unique

resistor on the CPU

board

Replace the LCD

screen

Increase environment

TEMP and add UPS

Loose the tubing

2-22 Auto Hematology Analyzer Service Manual (V1.1)

Page 49

Troubleshooting

probe assembly is too tight

The detectors are broken

Replace the two

detectors

H

Hang during initiation

(Initiation stop)

Software has some problem

Power supply board is

broken

Re-install the software

or replace a new

Moduleondisk

Replace power supply

board

HGB always alarm WBC bath is dirty Clean WBC bath

HGB error and WBC clog The 10ml syringe’s piston

Re-fix the piston

falls off

Hematology analyzer leakage

and vacuum is abnormal

HGB background voltage is

abnormal, no chance to make

The tubing of waste

assembly is kink

WBC bath is dirty or HBG

gain is not correct

Release the tubing

and empty the liquid

Dip in the WBC bath

and adjust HGB gain

it down

HGB error HGB background voltage is

abnormal (0-3.2v or

4.9-5.0v), it’s out of

acceptable range

Adjust the HGB gain

or the resistor (VR3

&VR4 which on the

analog board) to

4.2V-4.6V

HGB adjust error HGB background voltage is

abnormal (3.2-3.4v or

4.8-4.9v), it’s out of

acceptable range

Adjust the HGB gain

or the resistor (VR3

&VR4 which on the

analog board) to

4.2V-4.6V

I

Initiation time is too long disk on module is broken Replace hard disk

(disk on module)

K

Keyboard, some buttons no

response

CPU board or keyboard is

broken

Replace the CPU

board or keyboard

L

LCD screen, there is a line on

the screen

CPU board is broken if the

line is a dot line and the

position is fixed

LCD screen is faulty if the

line is a continuous black or

light line

Replace the CPU

board

Replace the LCD

screen

Auto Hematology Analyzer Service Manual (V1.1) 2-23

Page 50

Troubleshooting

LCD screen is dark The color palette setting is

not correct

The backlight is too dark

Re-set the color

palette to 8-color

Adjust the unique

resistor on the CPU

board

Leakage Vacuum chamber is broken,

waste liquid tubing is kink,

tubing leakage

Analog board is broken

The air filters are dirty

Change the vacuum

chamber

Loose the waste liquid

tubing

Check the default

point

Replace a new analog

board

Replace this two fiters

M

mid-size cell’s percent is

sometime too high and

sometime normal

Put the sample to long time

Add too much anti-coagulant

Count the sample in

30mins

Reduce the value of

anti-coagulant

N

No diluent injected Diluent is empty

The piston falls off

No sample inspired and no

SV4 valve doesn’t work Replace the SV4 valve

Change a new bottle

of diluent

Re-fix the piston

diluent injected

No initialization, but exist

backlight and a moment it

The CPU board is broken Replace the CPU

board

becomes black, the indicators

flash like saver

No rinse (diluent, lyse) alarm The rinse (diluent, lyse)

sensor is broken or plastic

washer falls off

Replace the rinse

(diluent, lyse) sensor

or re-fix the washer

No backlight The inverter is broken Replace the inverter

P

PLT/RBC’s result shows “**.*” Test the RBC aperture

Replace the RBC bath

voltage is not stability, the

range is 4.5-11.0V

PLT result is always over 1000 The RBC bath is dirty Clean or replace the

RBC bath

Power-on is normal, but the

screen is black suddenly after

Power supply board and

CPU board are broken

Replace the power

supply board and CPU

2-24 Auto Hematology Analyzer Service Manual (V1.1)

Page 51

Troubleshooting

initiation board

Power-on is normal, but no

display, no initiation, no

The CPU board is broken Replace the CPU

board

response

PLT background is abnormal Connecting ground is not

proper, or with high voltage

Pressure error Pressure pump leakage or

tubing broken

Pressure filters are blocked

Reconnect ground

wire

Replace pump or

tubing

Replace new filters

R

Rotatory motor error The tubing connecting

sample probe is loose, and

Replace the proble

mosule

liquid enters the motor to

make the resistance higher

RBC bath full and liquid

overflows

RBC/PLT’s result shows “**.*” Test the RBC aperture

The V11 valve doesn’t work

or dirty or doesn’t work well

Clean or replace the

V11 valve

Replace the RBC bath

voltage is not stability, the

range is 4.5-11.0V

RBC always clog 1. RBC bath is dirty

2. The count time is a little

longer than the setting

time

3. One of the sensor which

on the MTB board is broken

1. Clean the bath

using E-Z

cleanser or probe

cleanser

2. Re-set the count

time

3. Replace the MTB

board

RBC bath is leakage RBC bath is broken with

Replace the RBC bath

cranny

RBC background and value is

too high

RBC bath is broken with

cranny

Replace the RBC bath

RBC no result Analog board is broken Replace the analog

board

S

Stability is bad, and PLT over

1000 sometime

There are some bubbles in

Diluent syringe and make

Replace the SV3 valve

the injected diluent not

enough

Sample probe leakage SV4 valve is leakage Replace the SV4 valve

Show “8002 error code” The disk on module is

broken

Replace the disk on

module

Show ”48V is low” The transformer or analog Replace transformer

Auto Hematology Analyzer Service Manual (V1.1) 2-25

Page 52

Troubleshooting

board is broken or analog board

T

TEMP is low The environment

temperature is low

Increase the

environment TEMP

V

Vacuum is low Air filters are so dirty

Waste liquid tube is kink

Tube is leakage

Vacuum pump is leakage

Vacuum chamber is leakage

Replace the filters

Loose the tube

Replace one new tube

Replace a new pump

Replace a new

chamber

W

WBC always clog 1. WBC bath is dirty

2. The count time is a little

longer than the setting

time

3. One of the sensor which

on the MTB board is broken

1. Clean the bath

using E-Z cleanser

or probe cleanser

2. Re-set the count

time

3. Replace the MTB

board

WBC bath leakage WBC bath is broken with

Replace the WBC bath

cranny

WBC background and value is

too high

WBC bath full and liquid

overflows

WBC result is not stable WBC bath is broken with

WBC bath is broken with

cranny

The V12 valve doesn’t work

or dirty or doesn’t work well

Replace the WBC bath

Clean or replace the

V12 valve

Replace the WBC bath

cranny

Wipe-block is leakage Wipe-block is old Replace wipe-block

WBC value is too high and

RBC is zero or “***”

Mis-use the Rinse and

diluent

Exchange the two

reagents

WBC clog, no count time WBC aperture clog Clean the aperture

using probe cleanser

WBC differential part is

abnormal, and it’s end point at

WBC channel gain is not

correct

Adjust WBC channel

gain

200fl

WBC bubbles during counting SV8 valve is leakage Replace the SV8 valve

WBC no result Analog board is broken Replace the analog

board

2-26 Auto Hematology Analyzer Service Manual (V1.1)

Page 53

2.6 Alarm

Error Message Possible Cause

Com Error

2.5ml & 50ul Motor Error

10ml Motor Error

Rotatory Motor Error

Fluctuating Motor Error

DC/DC Error

12V Power Error

48V Power Error

WBC A/D Error 1. The CPU board is abnormal.

RBC A/D Error 1. The CPU board is abnormal.

PL T A/D Error 1. The CPU board is abnormal.

WBC Interrupt Error 1. The CPU board is abnormal.

1. The transmission settings between BC-3000PLUS and

the external computer are different.

1. The position optical coupler is abnormal.

2. The driving motor is abnormal.

3. The communication wire of the motor is bad connected.

4. The 2.5ml syringe or/and 50ul syringe is damaged or

the resistance of it has increased.

5. The 2.5ml syringe or/and 50ul syringe is not mounted to

the right position.

1. The position optical coupler is abnormal.

2. The driving motor is abnormal.

3. The communication wire of the motor is bad connected.

4. The 10ml syringe is damaged or the resistance of it has

increased.

5. The 10ml syringe is not mounted to the right position.

1. The position optical coupler is abnormal.

2. The driving motor is abnormal.

3. The communication wire of the motor is bad connected.

4. The motor compone nts loosen or mounted to the wrong

position.

5. The pin clip loosens, if the tubing connecting the sample

probe moves randomly or touches the wall when the

motor operates.

6. The tubing connecting the wipe block is over tightly

fastened.

1. The position of the optical coupler is abnormal.

2. The driving motor is abnormal.

3. The communication wire of the motor is bad connected.

4. The motor compone nts loosen or mounted to the wrong

position.

5. The screw lever is not enough smooth.

1. The DC/DC component is abnormal.

2. The analog signal board is abnormal.

1. The power supply board is abnormal.

2. The analog signal board is abnormal.

1. The power supply part is abnormal.

2. The analog signal board is abnormal.

Troubleshooting

Auto Hematology Analyzer Service Manual (V1.1) 2-27

Page 54

Troubleshooting

RBC Interrupt Error 1. The CPU board is abnormal.

PLT Interrupt Error 1. The CPU board is abnormal.

1. The HGB LED loosens.

2. The HGB unit is bedabbled.

HGB Error

3. The HGB LED is damaged.

4. WBC bath is dirty.

5. Diluent is polluted or exceeds its Exp. date.

1. The HGB LED loosens.

2. The HGB unit is bedabbled.

HGB Adjust

3. Light intensity of the HGB LED is set incorrectly.

4. WBC bath is dirty.

5. Diluent is polluted or exceeds its Exp. date.

Vacuum Filter Error 1. The filter is clogged by dirt.

1. Vacuum pump is damaged.

2. Tubing or vacuum chamber has leaks.

3. Tubing connecting vacuum chamber to sensor loosens

Vacuum Low

or falls off.

4. The valve connecting the vacuum chamber is damaged.

5. The waste container is placed over normal position, or

the waste tubing is too thin or too long, or the waste

tubing cannot drain the liquid smoothly.

1. The environment temperature is over the range

Envir. Temp. Abnormal

15℃~35℃

2. The temperature sensor is abnormal.

1. The count baths or apertures are dirty.

2. There are bubbles in the tubing system.

Background Abnormal

3. The reagents are polluted or exceed their Exp. date.

4. There is clog or bubbles error when test the

background.

1. The WBC aperture is clog or dirty.

2. Foreign object has clogged the WBC bath.

3. WBC reference count time is set up improperly.

4. Optical couplers on the volumetric metering board are

damaged or the values of potentiometers are set

improperly.

5. The liquid cannot flow in the tubing smoothly (pressed,

WBC Clog

bends or clogged by foreign object).

6. Inadequate reagent.

7. Can not form stable surface in WBC metering glass

tube.

8. The tubing has leaks or the vacuum system has

problem.

9. The sample has problem, such as the type and

proportion of anticoagulant is selected improperly or

2-28 Auto Hematology Analyzer Service Manual (V1.1)

Page 55

WBC Bubbles

RBC Clog

RBC Bubbles

Diluent Empty

Rinse Empty

Lyse Empty

Pressure1 Low

Troubleshooting

there is blood clots.

1. WBC reference count time is set up improperly.

2. Optical couplers on the volumetric metering board are

damaged or the values of potentiometers are set

improperly.

3. Inadequate reagent.

4. not form stable surface in WBC metering glass tube.

5. tubing has leaks or the vacuum system has problem.

1. The RBC aperture is clog or dirty.

2. Foreign object has clogged the RBC bath.

3. RBC reference count time is set up improperly.

4. Optical couplers on the volumetric metering boa rd are

damaged or the values of potentiometers are

improperly set.

5. The liquid cannot flow in the tubing smoothly (pressed,

bends or clogged by foreign object).

6. Inadequate reagent.

7. Can not form stable surface in RBC metering glass

tube.

8. The tubing has leaks or the vacuum system has

problem.

9. The sample has problem, such as the type and

proportion of anticoagulant is selected improperly or

there is blood clots.

1. RBC reference count time is set up improperly.

2. Optical couplers on the volumetric metering board are

damaged or the values of potentiometers are

improperly set.

3. Inadequate reagent.

4. Can not form stable surface in RBC metering glass

tube.

5. The tubing has leaks or the vacuum system has

problem.

1. There are no diluent in the diluent container.

2. The liquid sensor is not connected correctly.

3. The liquid sensor is damaged.

1. There is no rinse in the rinse container.

2. The liquid sensor is not connected correctly.

3. The liquid sensor is damaged.

6. There are no lyse in the lyse container.

7. The liquid sensor is not connected correctly.

8. The liquid sensor is damaged.

9. Pressure pump has fault.

10. Tubing, vacuum chamber has leaks.

Auto Hematology Analyzer Service Manual (V1.1) 2-29

Page 56

Troubleshooting

Pressure2 Low

Recorder Out of Paper

Recorder Too Hot

File Error

Bar Code Invalid

Bar Code Com Error

Printer Error

Diluent Expiry

Rinse Expiry

Lyse Expiry

11. Tubing connecting vacuum chamber to sensor loosens

or falls off.

12. The valve connecting the vacuum chamber is damaged.

13. Pressure pump has fault.

14. Tubing, pressure chamber has leaks.

15. Tubing connecting pressure chamber to sensor loosens

or falls off.

16. The valve connecting the pressure chamber is

damaged.

1. There are no papers in the recorder box.

2. The sensor is abnormal.

1. The thermal head is too hot.

2. The sensor is abnormal.

1. The system software is destroyed.

2. The DiskOnModule disk has bad pars.

1. The format of bar code inputted is invalid for

BC-3000PLUS.

1. There are some errors when the bar code scanner

communicates with BC-3000PLUS host.

1. The printer is not connected correctly.

2. There are no papers in the printer.

3. Wrong type printer which BC-3000PLUS does not

support.

1. Diluent exceeds its Exp. date.

2. The diluent Exp.data inputted is incorrect.

1. Rinse exceeds its Exp. date.

2. The rinse Exp.data inputted is incorrect.

1. Lyse exceeds its Exp. date.

2. The Lyse Exp.data inputted is incorrect.

Trouble Possible Cause

1. Operation is not normalized, sample is not completely

mixed up.

2. Sample is heavily polluted.

Poor repeatability

3. Sample is improperly selected (such as the sample has

blood clots).

4. Wipe block is inaccurately positioned.

5. Instrument has interference.

6. Reagents are polluted or exceed their Exp. date.

1. Shielding box of sample bath is not well mounted.

Severe interference

2. Shielding wire of analog signal board is not connected

correctly.

2-30 Auto Hematology Analyzer Service Manual (V1.1)

Page 57

Troubleshooting

3. Valve V11 or V12 connecting count bath is not well

closed or has dirt.

4. The gain is set incorrectly.

5. The input power is unstable.

Power-off during running 1. Unstable input power, it exceeds the protective range.

Auto Hematology Analyzer Service Manual (V1.1) 2-31

Page 58

Page 59

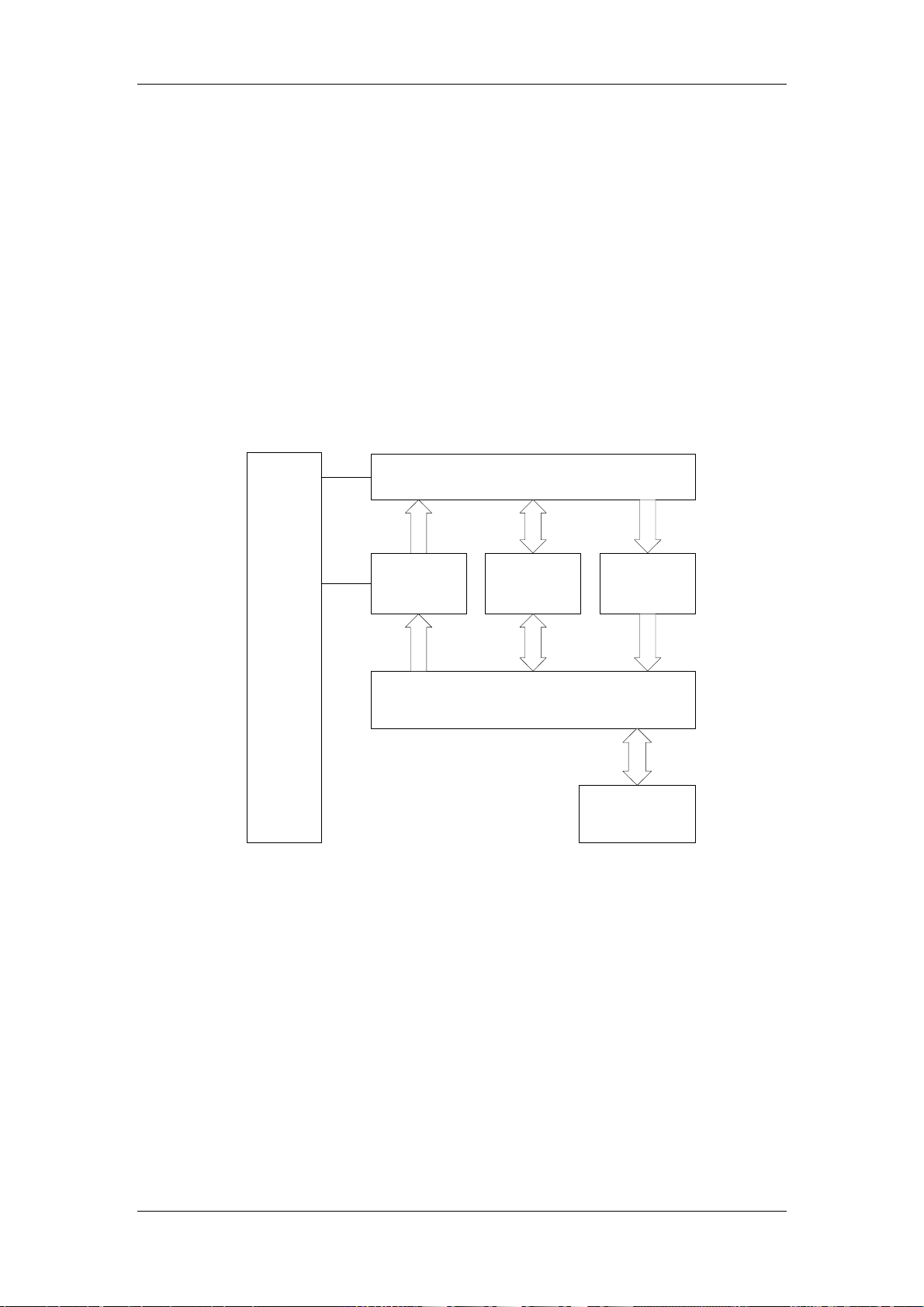

Chapter 3 Hardware

The instrument has the following hardware:

CPU Board

Power Drive Board

Analog Signal Board

Keypad

Recorder Board

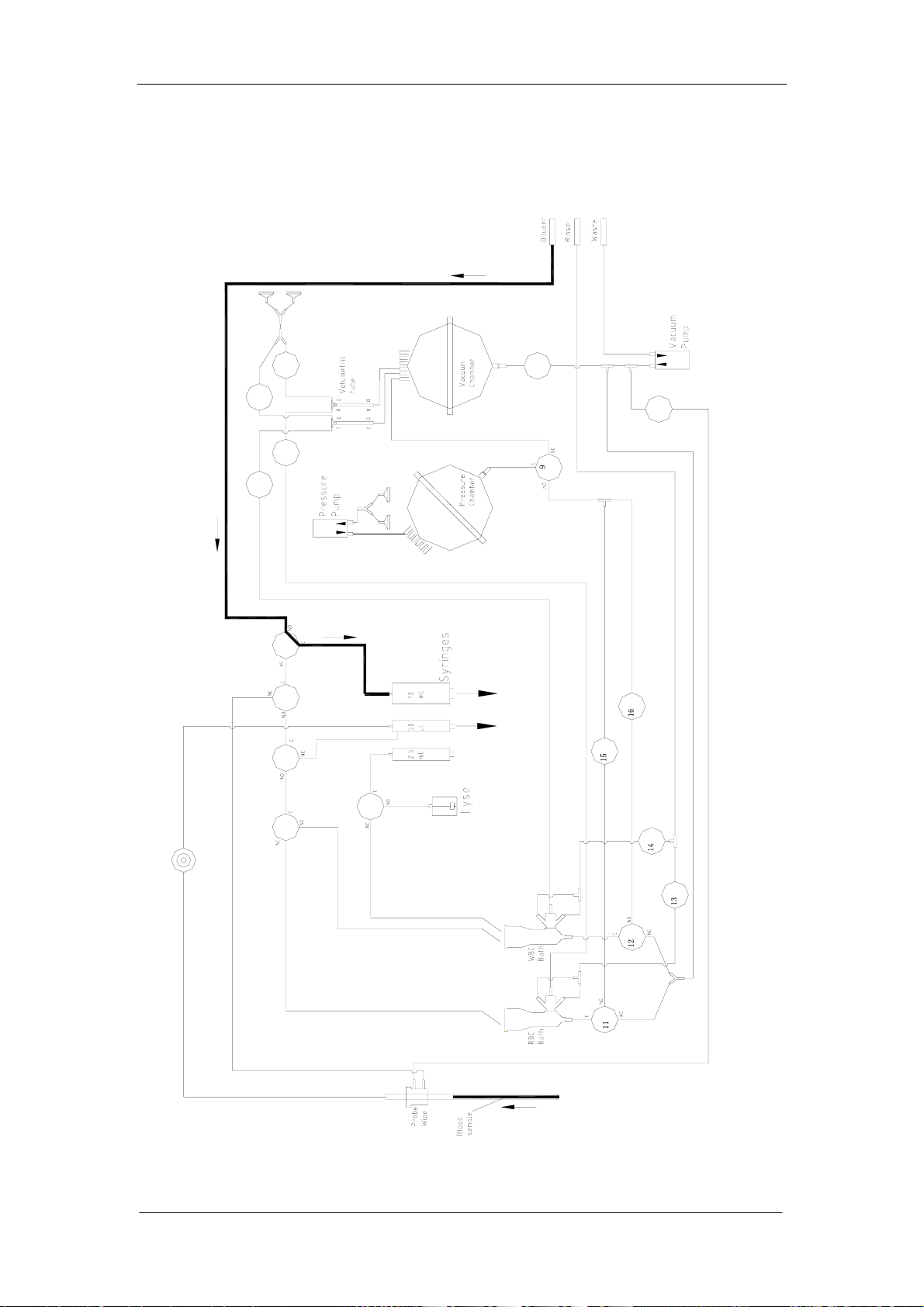

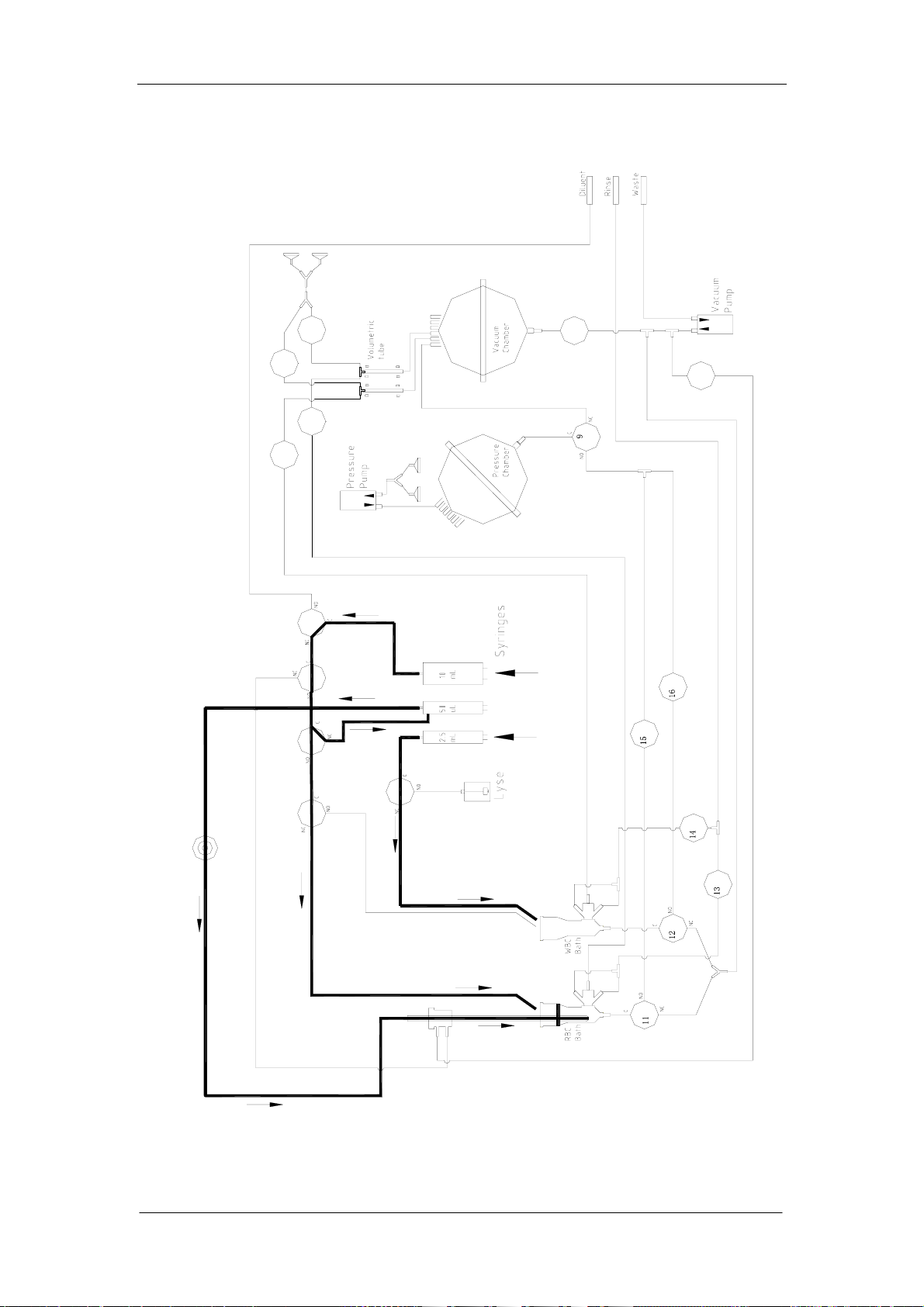

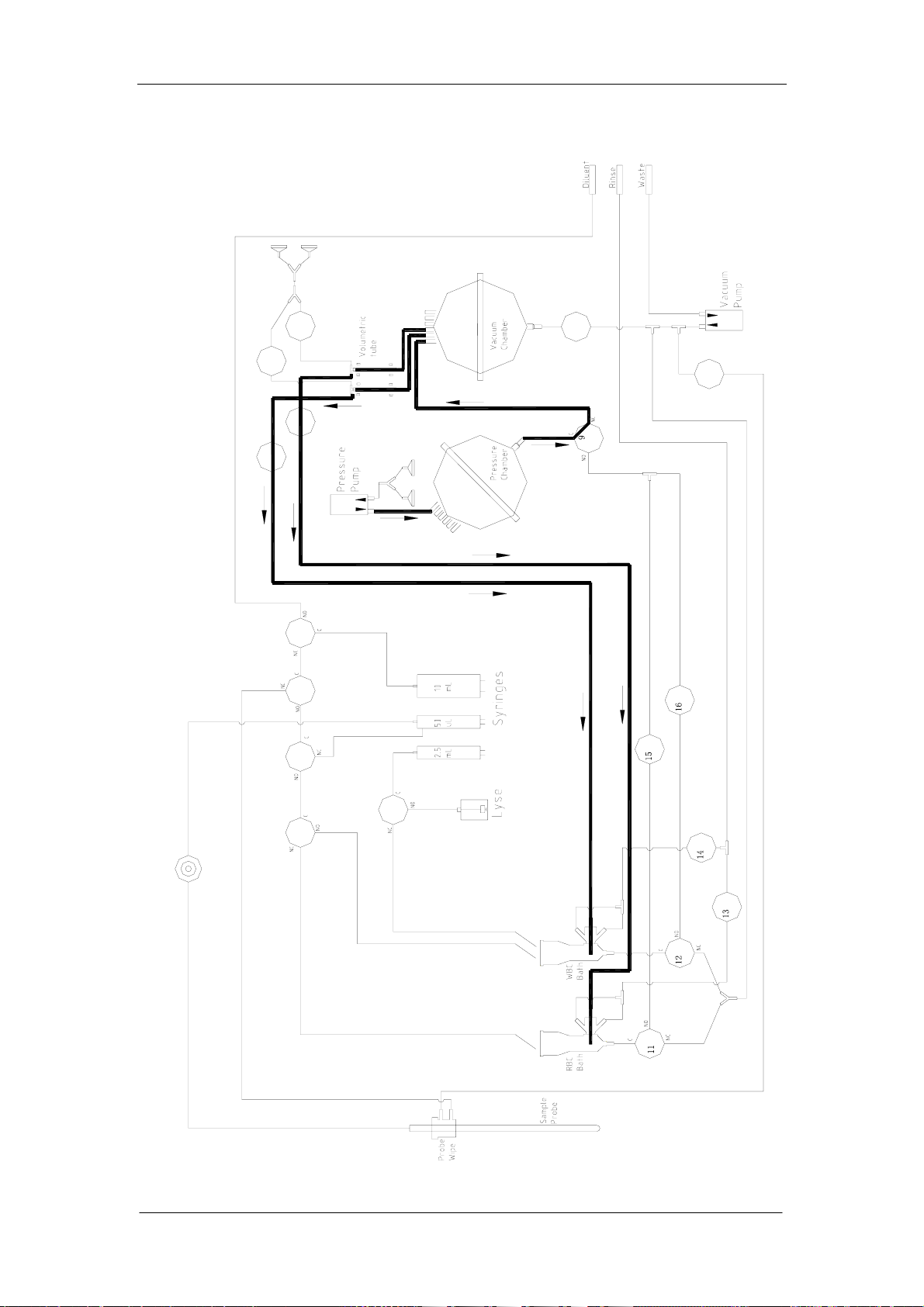

Volumetric Metering Board