Page 1

BA-88A Semi-auto Chemistry Analyzer

Service Manual

Page 2

Page 3

i

© 2008-2009 Shenzhen Mindray Bio-medical Electronics Co., Ltd. All rights Reserved.

For this Operator’s Manual, the issued Date is 2009-03 (Version: 1.1).

Intellectual Property Statement

SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called

Mindray) owns the intellectual property rights to this Mindray product and this manual.

This manual may refer to information protected by copyrights or patents and does not

convey any license under the patent rights of Mindray, nor the rights of others. Mindray

does not assume any liability arising out of any infringements of patents or other rights of

third parties.

Mindray intends to maintain the contents of this manual as confidential information.

Disclosure of the information in this manual in any manner whatsoever without the written

permission of Mindray is strictly forbidden.

Release, amendment, reproduction, distribution, rental, adaption and translation of this

manual in any manner whatsoever without the written permission of Mindray is strictly

forbidden.

, , , , , BeneView, WATO,

BeneHeart, are the registered trademarks or trademarks owned by Mindray in China

and other countries. All other trademarks that appear in this manual are used only for

editorial purposes without the intention of improperly using them. They are the property of

their respective owners.

Responsibility on the Manufacturer Party

Contents of this manual are subject to changes without prior notice.

All information contained in this manual is believed to be correct. Mindray shall not be

liable for errors contained herein nor for incidental or consequential damages in

connection with the furnishing, performance, or use of this manual.

Mindray is responsible for the effects on safety, reliability and performance of this product,

only if:

all installation operations, expansions, changes, modifications and repairs of this

product are conducted by Mindray authorized personnel;

the electrical installation of the relevant room complies with the applicable national

and local requirements;

the product is used in accordance with the instructions for use.

Page 4

ii

NOTE:

This equipment must be operated by skilled/trained clinical

professionals.

WARNING:

It is important for the hospital or organization that employs this

equipment to carry out a reasonable service/maintenance plan.

Neglect of this may result in machine breakdown or personal injury.

Warranty

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

Exemptions

Mindray's obligation or liability under this warranty does not include any transportation or

other charges or liability for direct, indirect or consequential damages or delay resulting

from the improper use or application of the product or the use of parts or accessories not

approved by Mindray or repairs by people other than Mindray authorized personnel.

This warranty shall not extend to:

any Mindray product which has been subjected to misuse, negligence or accident;

any Mindray product from which Mindray's original serial number tag or product

identification markings have been altered or removed;

any product of any other manufacturer.

Return Policy

Return Procedure

In the event that it becomes necessary to return this product or part of this product to

Mindray, the following procedure should be followed:

1 Return authorization: Contact the Customer Service Department and obtain

a Customer Service Authorization number. This number must appear on the

outside of the shipping container. Returned shipments will not be accepted if

the number is not clearly visible. Please provide the model number, serial

number, and a brief description of the reason for return.

2 Freight policy: The customer is responsible for freight charges when this

product is shipped to Mindray for service (this includes customs charges).

3 Return address: Please send the part(s) or equipment to the address offered

by the Customer Service department

Page 5

iii

Company Contact

Manufacturer:

Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Address:

Mindray Building, Keji 12th Road South, Hi-tech Industrial Park,

Nanshan, ShenZhen518057, P.R. China

Tel:

+86 755 26582479 26582888

Fax:

+86 755 26582934 26582500

EC Representative

Name:

Shanghai International Holding Corp. GmbH

(Europe)

Address:

Eiffestraβe 80, 20537Hamburg, Germany

Phone:

0049-40-2513175

Fax:

0049-40-255726

Page 6

Page 7

Foreward 1

Foreword

Who Should Read This Manual

This manual is geared for service personnel authorized by Mindray.

What Can You Find in This Manual

This manual covers principles, installation procedures, theories, maintenance and

troubleshooting guidelines of the BA-88A. Please service the system strictly as instructed

by this manual.

Conventions Used in This Manual

This manual uses the following typographical conventions to clarify meanings in the text.

Bold and Italic font indicates text displayed on the screen, such as Sample Request.

Safety Symbols

This chart explains the symbols used in this manual.

When you see… Then…

WARNING

Read the statement following the symbol. The

statement is alerting you to an operating hazard

that can cause personal injury.

BIOHAZARD

Read the statement following the symbol. The

statement is alerting you to a potentially

biohazardous condition.

CAUTION

Read the statement following the symbol. The

statement is alerting you to a possibility of system

damage or unreliable results.

NOTE

Read the statement following the symbol. The

statement is alerting you to information that

requires your attention.

Labels Used On the System

The labels attached to the panels of the system use symbols to clarify the meaning of the

text. The chart below explains the symbols on the labels.

Serial Number

Page 8

Foreward 2

Date of Manufacture

Manufacturer

CE marking. The device is fully in conformity with the

Council Directive Concerning In Vitro Diagnostic

Medical Devices 98/79/EC.

Authorized Representative in the European

Community

The following definition of the WEEE label applies to

EU member states only: The use of this symbol

indicates that this product should not be treated as

household waste. By ensuring that this product is

disposed of correctly, you will help prevent bringing

potential negative consequences to the environment

and human health. For more detailed information with

regard to returning and recycling this product, please

consult the distributor from whom you purchased the

product.

In Vitro diagnostic equipment

Biohazard warning: risk of potentially biohazardous

infection

Warning: Risk of personal injury or equipment damage

Protective ground terminal

ON (Power)

Graphics

All graphics, including screens and printout, are for illustration purposes only and must

not be used for any other purpose.

EC Representative

Name: Shanghai International Holding Corp. GmbH (Europe)

Address: Eiffestraβe 80, 20537 Hamburg Germany

Phone: 0049-40-2513175

Fax: 0049-40-255726

Page 9

Foreward 3

Safety Precautions

Observe theses safety precautions when using the system. Ignoring any of the

precautions may lead to personal injury or equipment damage.

WARNING

If the instrument is used in a manner not specified by our company, the

protection provided by the system may be impaired.

Preventing Electric Shock

Please observe the following instructions to prevent electric shock.

WARNING

When the instrument is turned on, users must not open the cover.

Spillage of reagent or sample on the analyzer may cause equipment

failure and even electric shock. Do not place sample and reagent on

the analyzer. In case of spillage, switch off the power immediately,

remove the spillage and contact our company customer service

department or your local distributor.

This instrument is supplied with a slow-blow fuse (250V, 3.15A), which

must not be replaced by the user.

Power supply: 100-240V~, 50/60Hz.

The instrument is supplied with a three-wire power cord and should be

properly grounded during application.

Preventing Personal Injury Caused by Moving Parts

Please observe the following instructions to prevent personal injury caused by moving

parts.

WARNING

Do not put your finger or hand into any open part when the system is in

operation.

Page 10

Foreward 4

Preventing Personal Injury Caused by Photometer Lamp

Please observe the following instructions to prevent personal injury caused by

photometer lamp.

WARNING

Light sent by the photometer lamp may hurt your eyes. Do not stare into

the lamp when the system is in operation.

If you want to replace the photometer lamp, first switch off the Main

Power and then wait at least 15 minutes for the lamp to cool down

before touching it. Do not touch the lamp before it cools down, or you

may get burned.

Preventing Infection

Please observe the following instructions to protect against the biohazardous infection.

BIOHAZARD

Inappropriately handling samples may lead to biohazardous infection. Do

not touch the sample, mixture or waste with your hands. Wear gloves and

lab coat and, if necessary, goggles.

In case your skin contacts the sample, follow standard laboratory safety

procedures and consult a doctor.

Handling Reagents and Wash Solution

WARNING

Reagents and enhanced wash solution may hurt human skins. Exercise

caution when using the reagents and enhanced wash solution. In case

your skin or clothes contact them, wash them off with clean water. In

case the reagents or wash solution spill into your eyes, rinse them with

much water and consult an oculist.

Page 11

Foreward 5

Treating Waste Liquids

Please observe the following instructions to prevent environmental pollution and personal

injury caused by waste.

BIOHAZARD

Some substances in reagent, control, enhanced wash solution and

waste are subject to regulations of contamination and disposal. Dispose

of them in accordance with your local or national guidelines for

biohazard waste disposal and consult the manufacturer or distributor of

the reagents for details.

Wear gloves and lab coat and, if necessary, goggles.

Treating Waste Analyzer

Please observe the following instructions to dispose of the waste analyzer.

WARNING

Materials of the analyzer are subject to contamination regulations. Dispose

of the waste analyzer in accordance with your local or national guidelines

for waste disposal.

Preventing Fire or Explosion

Please observe the following instructions to prevent fire and explosion.

WARNING

Ethanol is flammable substance. Please exercise caution while using the

ethanol.

Page 12

Foreward 6

Precautions on Use

To use the system safely and efficiently, please pay much attention to the following

operation notes.

Intended Use

WARNING

The system is an analyzer designed for in vitro quantitative

determination of clinical chemistries in serum, plasma, urine and CSF

samples. Please consult Mindray first if you want to use the system for

other purposes.

To draw a clinical conclusion, please also refer to the patient’s clinical

symptoms and other test results.

Operator

WARNING

The system is to be operated only by clinical professionals, doctors or

laboratory experimenters trained by our company or our authorized

distributors.

Environment

CAUTION

Please install and operate the system in an environment specified by this

manual. Installing and operating the system in other environment may lead

to unreliable results and even equipment damage.

To relocate the system, please contact our customer service department or

your local distributor.

Page 13

Foreward

7

Preventing Interference by Electromagnetic Noise

CAUTION

Electromagnetic noise may interfere with operations of the system. Do

not install devices generating excessive electromagnetic noise around

the system. The electromagnetic environment should be evaluated

prior to operation of the device. Do not use such devices as mobile

phones or radio transmitters in the room housing the system. Do not

use other CRT displays around the system. The electromagnetic noise

might lead to system failures.

Do not use other medical instruments around the system that may

generate electromagnetic noise to interfere with their operations.

NOTE

It is the manufacturer's responsibility to provide equipment

electromagnetic compatibility information to the customer or user.

NOTE

It is the user's responsibility to ensure that a compatible

electromagnetic environment for the equipment can be maintained in

order that the device will perform as intended.

Operating the System

CAUTION

Operate the system strictly as instructed by this manual. Inappropriate use

of the system may lead to unreliable test results or even equipment

damage or personal injury.

Before using the system for the first time, run the calibration program and

QC program to make sure the system is in normal status.

Be sure to run the QC program every time you use the system, otherwise

the result may be unreliable.

Do not touch the screen with wet hands or hands contaminated by

chemicals.

Do not place the Power to ON again within 10 seconds since placing it to

OFF;

Page 14

Foreward 8

Maintaining the System

CAUTION

Maintain the system strictly as instructed by this manual. Inappropriate

maintenance may lead to unreliable results, or even equipment damage

and personal injury.

To wipe off dust from the system surface, use a soft, clean and wet (not too

wet) cloth, soaked with mild soap solution if necessary, to clean the

surface. Do not use such organic solvents as ethanol for cleaning. After

cleaning, wipe the surface with dry cloth.

Switch off all the powers and unplug the power cord before cleaning. Take

necessary measures to prevent water ingression into the system,

otherwise it may lead to equipment damage or personal injury.

Replacement of such major parts as lamp assembly must be followed by a

calibration.

Check the pump tubing for leakage as needed and replace the tubing in

time. Otherwise, the normal aspiration of the system might be affected. It is

recommended that the inner system tubing should be replaced every 24

months to avoid possible blockage or invalidation brought about by aging.

Setting up the System

CAUTION

To define such parameters as calculation method and wavelength, follow

the instructions in this manual and the package insert of the reagents.

Page 15

Foreward 9

Samples

CAUTION

Use samples that are completely free of insoluble substances like fibrin, or

suspended matter; otherwise the probe may be blocked.

Medicines, anticoagulants or preservative in the samples may lead to

unreliable results.

Hemolysis, icterus or lipemia in the samples may lead to unreliable test

results, so a sample blank is recommended.

Store the samples properly. Improper storage may change the

compositions of the samples and lead to unreliable results.

Sample volatilization may lead to unreliable results. Do not leave the

sample open for a long period.

Some samples may not be analyzed on the system based on parameters

the reagents claim capable of testing. Consult the reagent manufacturer or

distributor for details.

Certain samples need to be processed before being analyzed by the

system. Consult the reagent manufacturer or distributor for details.

Reagents, Calibrators and Controls

CAUTION

Use appropriate reagents, calibrators and controls on the system.

Select appropriate reagents according to performance characteristic of the

system. Consult the reagent suppliers, our company or our authorized

distributor for details, if you are not sure about your reagent choice.

Store and use reagents, calibrators and controls strictly as instructed by

the suppliers. Otherwise, you may not obtain reliable results or best

performance of the system.

Improper storage of reagents, calibrators and controls may lead to

unreliable results and bad performance of the system even in validity

period.

Perform a calibration after changing reagents. Otherwise, you may not

obtain reliable results.

Contamination caused by carryover among reagents may lead to

unreliable test results. Consult the reagent manufacturer or distributor for

details.

Page 16

Foreward 10

External Equipment

WARNING

External equipment connected to the analogue and digital interfaces

must be complied with the relevant Safety and EMC standards (e.g., IEC

60950 Safety of Information Technology Equipment Standard and CISPR

22 EMC of Information Technology Equipment Standard (CLASS B)).

Any person, who connects additional equipment to the signal input or

output ports and configures an IVD system, is responsible for ensuring

that the system work normally and complies with the safety and EMC

requirements. If you have any problem, consult the technical services

department of your local representative.

Communication interface

CAUTION

The system is equipped with two USB ports which can be used in

connecting the keyboard, mouse, printer and other external

equipments or in system upgrading. RS232 is used in connecting the

PC with the analyzer to transfer data.

These three ports should not be used to operate the system for usage

other than those mentioned above. Otherwise, system might be

damaged.

Page 17

Contents

I

Contents

Contents.................................................................................................................. I

1

System Specifications .............................................................................. 1-1

1.1 System specifications............................................................................................. 1-1

1.2 Parameters ............................................................................................................ 1-1

1.3 Instrument Configuration ........................................................................................ 1-2

1.4 Overview................................................................................................................ 1-2

2

System Installation.................................................................................... 2-1

2.1 Basic...................................................................................................................... 2-1

2.2 Installation Procedures........................................................................................... 2-2

3

System Description................................................................................... 3-1

3.1 Operating Procedures ............................................................................................ 3-1

3.2 Component Structure and Functions....................................................................... 3-2

3.2.1 Photometer Assembly................................................................................ 3-2

3.2.2 Lamp assembly ......................................................................................... 3-3

3.2.3 Lamp Base Assembly ................................................................................ 3-5

3.2.4 Flow Cell Base Assembly........................................................................... 3-9

3.2.5 Base Plate Assembly............................................................................... 3-12

3.2.6 Enclosure Assembly ................................................................................ 3-13

4

Hardware....................................................................................................4-1

4.1 Overview................................................................................................................ 4-1

4.2 Safety Precautions................................................................................................. 4-1

4.3 Introduction of the Modules .................................................................................... 4-1

4.4 CPU Board............................................................................................................. 4-2

4.4.1 LED Indicator............................................................................................. 4-2

4.4.2 Memory Module......................................................................................... 4-2

4.4.3 Clock Module............................................................................................. 4-3

4.4.4 Interface Module........................................................................................ 4-3

4.5 CPU Extension Board ............................................................................................ 4-3

4.5.1 Overview ................................................................................................... 4-3

4.5.2 LED Indicator............................................................................................. 4-4

4.5.3 USB Functions........................................................................................... 4-4

4.5.4 LCD&Touchscreen Driver Control .............................................................. 4-5

4.5.5 Serial Port Communication ........................................................................ 4-5

4.5.6 Driver of the Step Motor............................................................................. 4-6

4.5.7 Driver of the Peristaltic Pump..................................................................... 4-6

4.5.8 Driver of the Refrigeration Plate ................................................................. 4-6

4.5.9 Detection of the Input Signal ...................................................................... 4-7

4.5.10 Analogue Board Control........................................................................... 4-7

Page 18

Contents II

4.6 Analogue Board ..................................................................................................... 4-7

4.7 LCD&Touchscreen Board....................................................................................... 4-8

4.8 Power board .......................................................................................................... 4-9

4.8.1 Overview ................................................................................................... 4-9

4.8.2 The Basic Feature of the Power Module..................................................... 4-9

4.9 LCD Background Adjustment ............................................................................... 4-10

4.10 Connection of the Hardware System..................................................................4-11

4.10.1 Definition of the CPU Board + CPU Extension Board Interface................4-11

4.10.2 Analogue Board Interface ...................................................................... 4-12

4.10.3 Power Board Interface ........................................................................... 4-12

4.10.4 LCD&Touchscreen Board Interface ........................................................ 4-13

5

Service and Maintenance..........................................................................5-1

5.1 Maintenance .......................................................................................................... 5-2

5.1.1 Daily Maintenance ..................................................................................... 5-2

5.1.2 Weekly Maintenance.................................................................................. 5-2

5.1.3 Irregular Maintenance................................................................................ 5-2

5.2 Software Upgrading................................................................................................ 5-3

5.2.1 Software Structure..................................................................................... 5-3

5.2.2 Software List.............................................................................................. 5-4

5.2.3 Upgrading Procedures for Software on CPU Board.................................... 5-5

5.2.4 Upgrading Procedures for Software on CPU Extension Board.................... 5-7

5.3 Maitenance .......................................................................................................... 5-12

5.3.1 Replacing the tubing................................................................................ 5-12

5.3.2 Replacing Aspiration Tubing..................................................................... 5-16

5.3.3 Replacing Lamp....................................................................................... 5-17

5.3.4 Replacing CPU Board.............................................................................. 5-19

6

Troubleshooting ........................................................................................6-1

6.1 Alarm Message Classification................................................................................. 6-1

6.2 Levels.................................................................................................................... 6-1

6.2.1 Errors to Warn User (0).............................................................................. 6-2

6.2.2 Errors to Invalidate Tests(1) ....................................................................... 6-2

6.2.3 Errors to Forbid Test(2).............................................................................. 6-2

6.3 Error Display.......................................................................................................... 6-2

6.3.1 Dialog Box................................................................................................. 6-2

6.3.2 Sound........................................................................................................ 6-2

6.4 Details.................................................................................................................... 6-3

Page 19

1 Systemystem Specifications 1-1

1 System Specifications

1.1 System specifications

Dimension: ≤420mm ×350mm ×158mm(L×W×H)

Weight: ≤7Kg

Power supply: 100-240V~, 50/60Hz;

Power consumption: maximum 140VA;

Operating methods: touchscreen, USB key board and mouse.

1.2 Parameters

Reaction type: Endpoint, Kinetics, Fixed-time, Absorbance;

Analyzing methods: single/double- wavelength;

Clinical chemistries, immunoassays, TDM (Therapeutic Drug Monitoring)

Aspiration volume: 200μl-9000μl ;

Temperature: room temperature, 25℃, 30℃, 37℃;

Capable of storing and outputting various data and tables/graphs, and

calculating among different tests

Storage capacity: capable of storing more than 3000 test results.

Page 20

1 Systemystem Specifications 1-2

1.3 Instrument Configuration

Wavelengths: 6 wavelengths (available): 340nm, 405nm, 510nm, 546nm,

578nm and 630nm.2 wavelengths (optional): 450nm and 670nm.

Reaction container: flow cell or cuvette.

Printing: thermal recorder.

1.4 Overview

Colorimetric system: The colorimetric analysis is realized through the

combination of optical collimating, mono-color filter, mechanical parts and

software, hardware module.

Aspiration system: it is used to aspirate the matter to be tested or to wash the

tubing system (only for flow cell system).

Software/hardware system: it is used to set tests, enter operating instructions,

control the data collection, calculate and save the results.

Page 21

2 System Installation 2-1

2 System Installation

2.1 Basic

Make sure the installation site of the hospital meet the system installation

requirements on space, power supply and environment. Please refer to the

operator’s manual for details.

If data management software or test and maintaenance software is used on PC,

please make sure the configuration of the PC meet the system requirement.

1 PC requirement for test and maintenance software:

CPU: Celeron 1.7 or above;

Memory: 256M or above;

Resolution of the screen: 1024*768;

Operating system: windows 2000(professional/server SP4), windows

xp(home/professional SP1 or above)

Communication interface: RS-232C

2 PC requirement for data management software:

CPU: Pentinum II or above;

Memory: at least 1G for Vista operating system; at least 512 M for other

operating system.

Resolution of the screen: 1024*768 or above;

Operating system: Windows XP/Vista/Windows 2000

Page 22

2 System Installation 2-2

Databse: SqlServer 2005 Express

Network communication: 10/100M 10/100M

Communication interface: RS-232C

Hard disk ( the disk on which the software is installed): 10G

Printer (connected with PC)

2.2 Installation Procedures

1 When you receive the system, carefully inspect the package. After opening

the package, check the delivered goods against the packing list.

2 Move the instrument to the installation site and remove all the package and

protective materials.

3 Connect the instrument to waste container.

4 Connect the power cable and power on the analyzer. After self-check and

tubing wash is completed, the main screen is displayed.

5 After the system is stable, request one or two routine tests and run. Assess

the test results. Please refer to the operator’s manual for details.

6 Follow the normal procedure to shutdown the analyzer.

7 Training:

Can the customer complete daily tests?

Yes □ No □

Is the customer familiar with the daily, weekly and monthly maintenance and

relevant maintenance methods? Yes □ No □

Is the customer familiar with cleaning and washing the system?

Yes □ No □

Is the customer familiar with troubleshooting the common failures?

Yes □ No □

Is the customer familiar with replacing the peristaltic pump tubing and

calibrating the flow volume? Yes □ No □

Is the customer familiar with replacing the aspiration tubing? Is the customer

familiar with replacing the lamp? Yes □ No □

Page 23

3 System Description 3-1

3

System Description

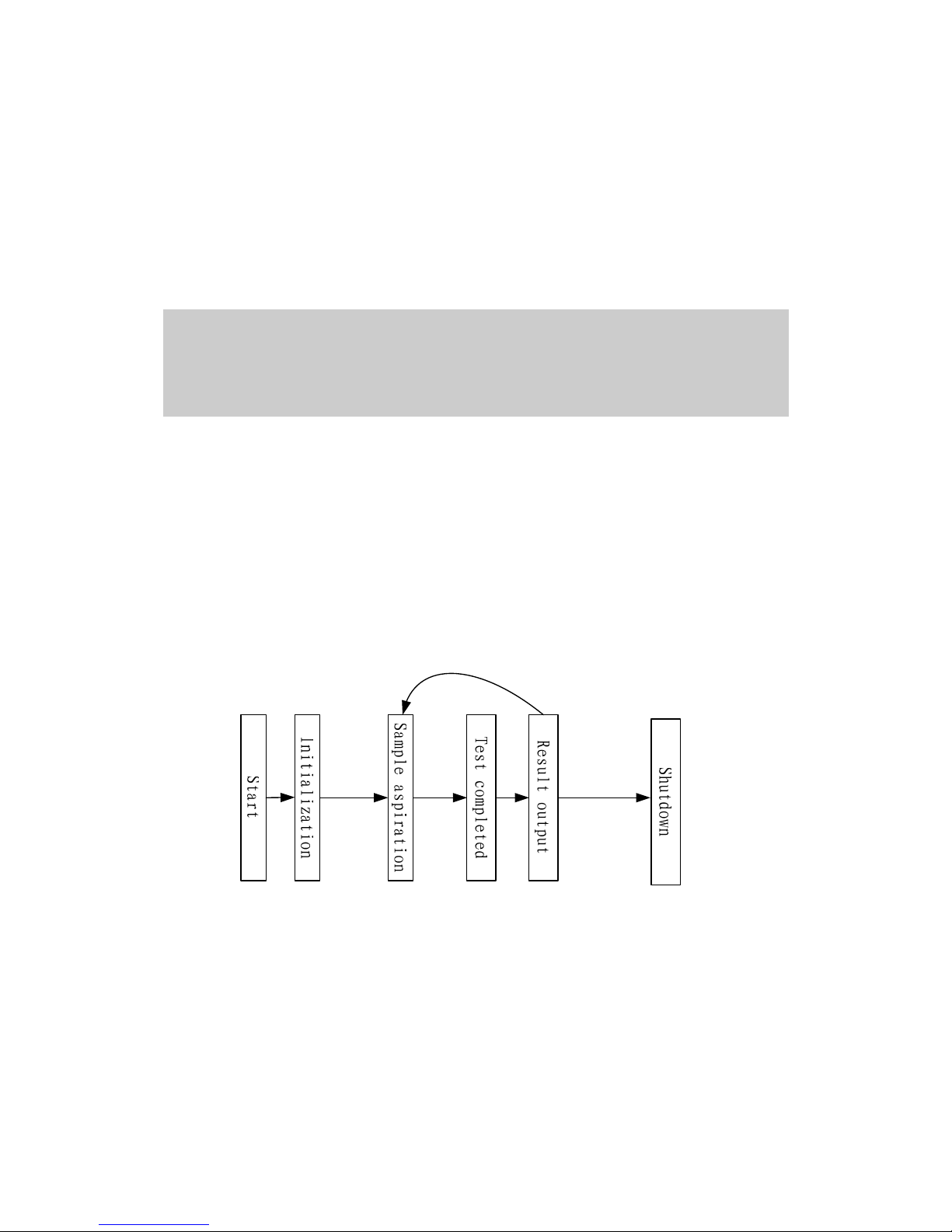

3.1 Operating Procedures

The typical operating procedure of BA-88A is shown as follows:

Figure 3-1 Operating procedure

Lamp

stabilization

Reaction

All the

tests

finished

Temperature

stabilization

Other

tests

Procedures:

1 Empty the waste. Connect the waste tubing to the waste container. Prepare

the samples, reagents and distilled water;

2 Connect power cable correctly. Power on the analyzer. The instrument will

under go the initialization processes, including; system startup, hardware

self-check, parameters download, dark current testing. After initialization,

wait until the temperature and the light source are stable. The whole

process lasts for about 15 minutes;

3 After the system is stable, set the parameters of the tests, such as

wavelength, temperature, methods and etc. Start the test.

Page 24

3 System Description 3-2

4 After the test is completed, run other tests if necessary. Washing should be

inserted between two tests to minimize the carryover, when the

concentrations of the two tests are too different or the two tests are different.

5 After all the tests are completed, shutdown the analyzer. Cut off the

instrument power after washing is completed.

3.2 Component Structure and Functions

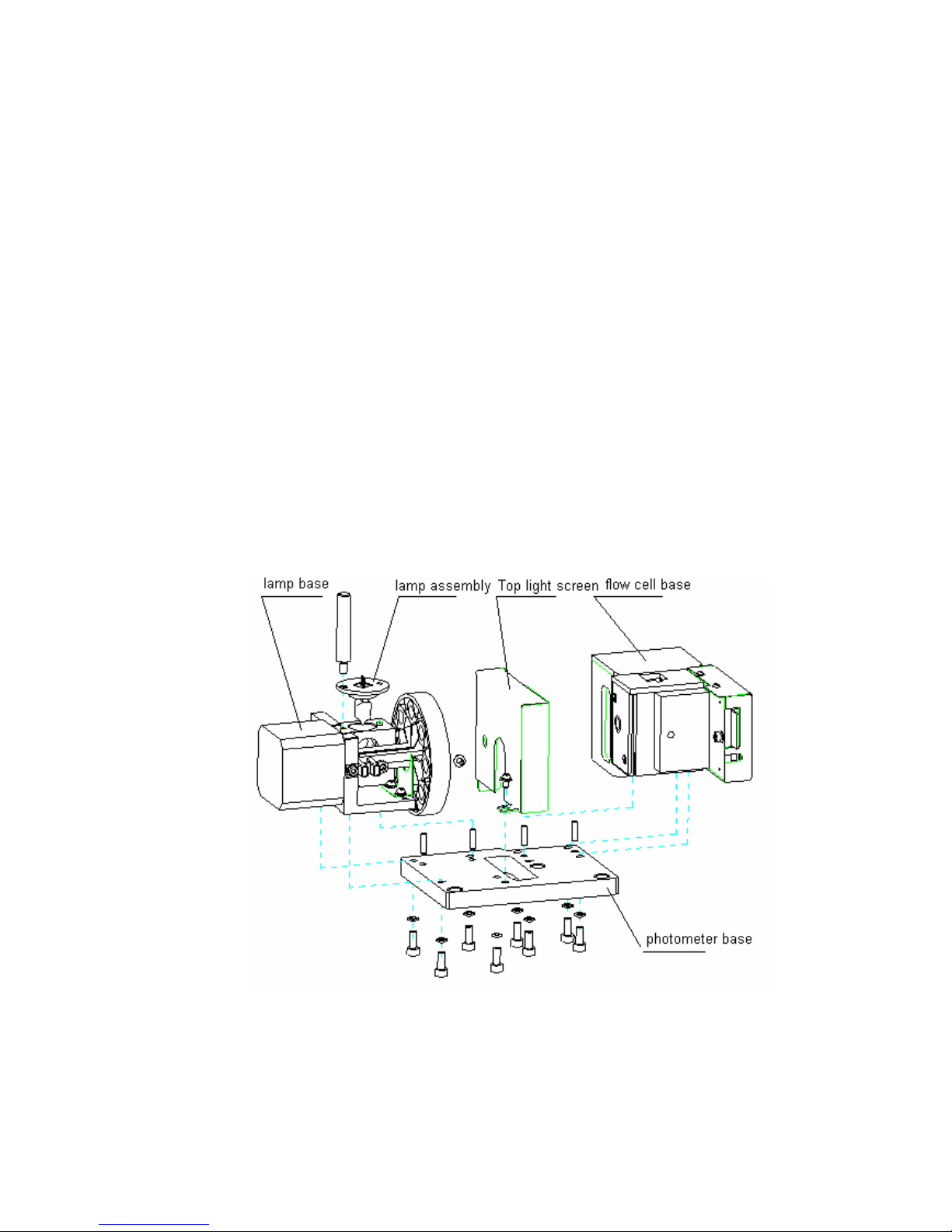

3.2.1 Photometer Assembly

3.2.1.1 Introduction

Photometer assembly is the core of BA-88A, integrating optical system, temperature

control system and photoelectrical collection system. The photometer assembly is the

key for reliability of the system. Photometer assembly includes lamp assembly, lamp

base assembly, flow cell assembly and other components, which are used to position

and install the optical components, thermal components and analogue board.

3.2.1.2 Components and Structure

The basic structure of the photometer assembly is shown as figure 3-2.

Figure 3-2 Photometer assembly structure

3.2.1.3 Assembly and Disassembly of the Photometer

Assembly

Photometer assembly is fixed on the instrument base by 3 M4 socket head screws.

Page 25

3 System Description 3-3

Maintenance of the system, except for replacing the assemblies or components other

than lamp assemblies will involve the assembly and disassembly of the photometer

assembly as a whole. Please pay attention to the following:

1 When disassembling the instrument, do not drag the cable with excessive force.

If necessary, you can disconnect the connection of some cables in advance. Do

not make any cable pressed, especially the cable under the photometer base.

2 When disassembling the instrument, do not press the air duct or conduct any

operation that might distort the air duct, otherwise the refrigeration plate might be

damaged.

3.2.2 Lamp assembly

3.2.2.1 Introduction

The lamp assembly is the light source of the instrument, providing energy source for

the detection system. Among the components of the lamp assembly, the lamp should

be replaced regularly, so when we design the system, we take the manual

replacement into consideration, taking the assembly as a whole connected with the

lamp base, fixing it with a long hand screw to facilitate manual disassembly.

3.2.2.2 Components and Structure

The basic structure of the lamp assembly is shown as figure 3-3.

Figure 3-3 Lamp assembly structure

3.2.2.3 Assembly and Disassembly of the Lamp Assembly

Lamp assembly is connected with lamp base assembly through lamp fixing screw

and aφ3 pin. (figure 3-2).

Page 26

3 System Description 3-4

The replacement of lamp assembly is shown in the following picture.

Figure 3-4 Procedure for lamp replacement

Components relevant to lamp replacement are shown in the following figure. For

more details please refer to 5.3.3.

Page 27

3 System Description 3-

5

Figure 3-5 Lamp assembly structure

WARNING

If you want to replace the lamp, first switch off the power and then wait at

least 15 minutes for the lamp to cool down before touching it. Do not touch

the lamp before it cools down, or you may get burned.

NOTE

When replacing the lamp assembly, do not touch the surface of the bulb to

avoid contamination.

icult to

3.2.3 Lamp Base Assembly

3.2.3.1 Introduction

The lamp base assembly supports the installation and positioning of the lamp

assembly and in the meantime supports the installation and positioning for filter wheel

and driver motor.Integration structure design will increase the positioning accuracy of

the optical elements.

Page 28

3 System Description 3-6

3.2.3.2 Components and Structure

The assembly is composed of lamp base, filter wheel, step motor and etc. The

structure is shown as the following figure.

Figure 3-6 Lamp base assembly structure

3.2.3.3 Assembly and Disassembly of the Lamp Base Assembly

Lamp base assembly is fixed on the instrument base by 4 M4 socket head screws

and positioned by 2φ3 pins. When the assembly is dismounted as a whole, you can

disassemble the components, but you have to pay attention to the following

problems:

1 If fixture is not used when you assemble or disassemble the filter, extra care

should be taken lest the filter is scratched by the screw driver. Please follow the

correct order to install the filter. The order is shown in the following table.

No. 1 2 3 4 5 6 7 8

Wavelength

nm

340 405 546 670 450 510 578 630

450 nm and 670 nm are optional wavelengths. When these two wavelengths are

not configured, relevant position is shielded by stop plate; when relevant filters are

installed, the arrow on the circle should point outward of the hole.

2 When assembling or disassembling the home position sensor, place the surface

with text onward (refer to the base plate).

3 When assembling or disassembling the lens, make sure the spherical surface

face the outside. Press it until secure with clamping ring. Make sure that the

outer surface of the clamping ring is at the same level with or higher than the

Page 29

3 System Description 3-

7

surface of the lamp base. If obvious blow-up is found, skewed installation of the

lens might be the cause and the readjustment might be needed.

4 When disassembling, if it is not necessary to replace the motor, filter wheel or

sensor stop plate, we recommend you to keep the connection between the motor

and the filter wheel, thus the installing procedure would be simplified; otherwise,

the relative position between the filter wheel and the motor positioning surface

might change. Fixture BA89-J01 should be used to position. If there is no fixture

on the spot, ensure distance between the position surface of the control motor

and the filter wheel end face is 59.6±0.5mm. Please refer to the following figure.

Figure 3-7 Filter wheel positioning

5 During assembly and disassembly, ensure that optical elements like filter, lens

and bulb are properly protected. When installation is completed, use balloon to

blow away the dust or other impurities from the surface of the optical elements.

3.2.3.4 Adjust the Filter Wheel Home Position

If any of the following components: filter wheel, home position sensor, motor is

dismounted or conduct any operation that might lead to the dismounting of these

components, the home position of the filter wheel might be modified, so the test result

might be inaccurate. Thus, dismounting of these elements should be followed with

the adjustment of home position of the filter wheel. During adjustment, PC, serial

cable and test&maintenance software are used. The procedure for adjusting is shown

as follows:

1 After the instrument is reassembled, power on the analyzer.

2 Click Maintenance on the main screen of the instrument. Select Maintenance

tab. Click Advanced and enter the password “analyzer” to enter the advanced

adjustment interface.

3 Click H pos..

4 When the system is in Standby (if Lamp stabilizing is displayed, tests can only

be started when lamp is stabilized), Put the aspiration tubing into a tube filled

with about 2 ml of distilled water. Click Asp.. When the aspiration is completed,

click Start to calculate the deviation.

Page 30

3 System Description 3-8

5 After completing the serial port setting, click Enable Para. Modification on the

screen. Select the tab Photoele. And Fluid and then select Filter wheel home

position to enter the following screen.

Figure 3-8 Adjusting home position of the filter wheel

6 It will take 3 minutes to complete the test. When the test is completed, the

deviation of the filter wheel will be displayed in Deviation. The deviated steps

should be within 0-63, otherwise, the position of the home position sensor should

be adjusted before testing.

Tips: when the value of the deviated steps is higher than 63, move the sensor

downward; when the value is lower than 0, move it upward. When the above

requirements are met, click Save.

Figure 3-9 View parameters

7 When operations above are completed, click Return to go back to the main

screen. The analyzer will restart automatically. When analyzer is stable (after

about 15-20 minutes), click Maintenance-Maintenance on the analyzer to enter

the maintenance screen. Select Gain adjust on the screen to adjust the

photoelectric gain of the system. When adjustment is completed, wait at least 15

minute to start testing. Please refer to the operator’s manual for details on

photoelectric adjustment.

Page 31

3 System Description 3-9

NOTE

Wear clean cotton gloves, when replacing the filter or lens. If contaminant is

found on the surface of the filter or lens, clean it with ethanol.

NOTE

The assembly or disassembly of the filter wheel, motor or home position

sensor should be followed with home position deviation adjustment.

Otherwise, the test result might not be reliable.

The home position deviation adjustment of the filter wheel should be followed

with the adjustment of photoelectric gain. Otherwise, the test result might not

be reliable.

3.2.4 Flow Cell Base Assembly

3.2.4.1 Introduction

The flow cell, temperature control elements, analogue board and etc are installed and

positioned by the flow cell base assembly. Two modes—flow cell and cuvette are

available on the system. Manual replacement is supported. The temperature control

system is composed of semi-conductor refrigeration plate, air duct, temperature

sensor and insulation material, providing 37℃, 30℃ and 25℃ which are needed on

the system. Analogue board collects the data of absorbance and temperature.

3.2.4.2 Components and Structure

The structure of the flow cell assembly is shown in the following figure.

Page 32

3 System Description 3-10

Figure 3-10 Flow cell assembly structure

3.2.4.3 Assembly and Disassembly of the Flow Cell Base Assembly

Flow cell assembly is fixed on the instrument base by 4 M4 socket head screws and

positioned by 2φ3 pins. When maintaining the components on the side of analogue

board and air duct, it is not necessary to dismount the flow cell base assembly and

maintenance can be done on the dismounted photometer assembly. When

dismounting the components other than the position mentioned above, dismounting

of the whole assembly is needed. When dismounting the assembly and relevant

components, please pay attention to the following:

1

When replacing the refrigeration plate, we recommend you to replace it after

dismounting the photometer assembly. The order is: 1. dismount the photometer

assembly as a whole; 2. dismount the flow cell air duct; 3. dismount the

refrigeration plate; 4. replace the refrigeration plate. Reverse the above

procedures to install.

2

When installing the refrigeration plate, please pay attention to the installing

direction. The cable should project at the side of the analogue board and the red

cable should be lower;

3

The semi-conduct refrigeration plate should be installed between the air duct

and the flow cell base. Before installing, apply heat conducting gel to both sides

of the refrigeration plate (the thickness is about 0.05-0.1mm, the gel should be

evenly applied and no granule or nodular matter is allowed; the gel should not be

too watery). Correctly stick the plate inside the groove of the flow cell assembly

(follow step 2).Stick the air duct to the other side of the plate and tighten it with

spring and spring lightener. The two longer spring lightener should be inside the

hole on the upper side of the air duct and insulation is needed. Use straight slot

head screw driver to tighten the screws.

Page 33

3 System Description 3-11

4

When replacing the optical components, take care to protect the components.

Do not touch the surface of the optical elements with bare hand.

5

Wear antistatic gloves to dismount and mount the analogue board;

6

Do not drag the cable with excessive force. If necessary, you can disconnect the

connection of some cables in advance.

7

When replacing the temperature sensor, please take care to dismount the

insulation cotton, otherwise damage might occur; when reinstalling, use double

glue to stick the insulation back.

3.2.4.4 Replacement of the Temperature Measurement Assembly

The analogue board and the temperature sensor are components for measuring the

temperature on flow cell base assembly, so they should be replaced together.

Replacement of the two should be followed with parameter configuration. The

method is indicated as follows:

1 When the instrument is reinstalled, power on the system.

2 Click Maintenance on the main screen of the instrument. Select Maintenance

tab. Click Advanced and enter the password “analyzer” to enter the advanced

adjustment interface.

3 Select Temp. to enter the following screen. Select Cell. Enter the A, B, C

parameters on the flow cell accessory into their respective positions, making sure

that they are in accordance with those on the accessory. Click Save.

Figure 3-11 Parameter configuration

4 Select Cuvette. Repeat the operation in step 3 to configure the A, B and C

parameters.

5 After above operations are completed, click Return. Click View para. and make

sure the inquired A, B and C parameters are in accordance with those on the

accessory. Click Return.

6 Exit the Maitenance screen and the system will restart. Follow the instruction to

complete the configuration of the temperature.

Page 34

3 System Description 3-12

NOTE

If either of the temperature sensor or analogue board is damaged, both

of the two should be replaced by one assembly at the same time. And

the replacement should be followed with temperature paremter

configuration.

During configuration, modifying parameters other than temperature

parameters should not be allowed. Otherwise, the test result might be

affected.

3.2.5 Base Plate Assembly

3.2.5.1 Introduction

The base plate assembly supports the system, providing fixing and support for

photometer assembly, hardware board, interface and other components.

3.2.5.2 Components and Structure

The basic structure of the base plate assembly is shown as figure 3-12.

Figure 3-12 Base plate assembly structure

3.2.5.3 Assembly and Disassembly of the Base Plate Assembly

The base plate assembly is a strutting piece of sheet metal, providing fixing and

support for photometer assembly, hardware board, interface and other components.

Pay attention to the following while assembling and disassembling it.

1 When assembling and disassembling the photometer assembly, do not drag the

cable with excessive force, especially the cable of the semiconductor

Page 35

3 System Description 3-13

refrigeration plate, lamp cable and the connection cable of analogue board. If

necessary, you can disconnect the connection of some cables in advance.

2 Replacement of the peristaltic pump should be followed with flow volume

calibration (this is not for system configured with cuvette). Please refer to the

operator’s manual for details.

3 Wear antistatic gloves to replace the hardware board.

WARNING

When the enclosure is opened, do not touch the boards, sockets, switch

and etc, when the system is powered on, otherwise, electric shock might

occur.

3.2.6 Enclosure Assembly

3.2.6.1 Introduction

The enclosure assembly supports and fixes the touchscreen, recorder, aspirate

button, other input and output components and etc. Optical window cover and lamp

replacement window cover are designed to facilitate the replacement of flow cell,

cuvette and lamp.

3.2.6.2 Components and Structure

The basic structure of the enclosure assembly is shown as figure 3-13.

Figure 3-13 Enclosure assembly structure

Page 36

3 System Description 3-14

3.2.6.3 Assembly and Disassembly of the Enclosure Assembly

The enclosure assembly is fixed by 11 screws which are connected to the base plate.

Of the 11 screws, 3 are located at the back of the system and the remaining which

can be dismounted directly are located under the enclosure. When assembling and

disassembling the enclosure, please pay attention to the following:

1 If the system is configured with flow cell, before opening the enclosure, move the

flow cell out of the installing location and place it in the hole for holding flow cell

temporarily. Otherwise, the tubing connection will be dragged off.

2 When opening the enclosure, do not drag the cable with excessive force.

3 Place the enclosure in a stable location to make it stand vertically. If the

enclosure falls down, some cables, especially the touchscreen board cable,

aspirate button cable, might be dragged.

When installing the LCD/touchscreen module, pay attention to the following as shown

in figure 3-14.

1 When installing LCD cable, the blue face (untouchable face) of the FPC should

face outward;

2 When installing the LCD data cable of LCD&touchscreen board, the metal face

of the FPC cable (touchable face) should face outward;

3 When installing the touchscreen data cable of LCD&touchscreen board, the

metal face of the FPC cable (touchable face) should face outward;

4 When installing the supporting plate of the touchscreen, tighten the four screws

gradually one by one to avoid uneven force on the screen and excessive

tightening force on the screw which will result in false reaction of the

touchscreen.

Enclosure Touchscreen

Aspirate button

Recorder

Touch screen

supporting board

Aspirate button movement

switch

Cover of

lamp

replacement

window

Enclosure

fixing screw

hole

Hole for holding

flow cell t

temporarily

Page 37

3 System Description 3-15

Figure 3-14 LCD/touchscreen cable

The blue face

should face

outward

The metal face

should face

outward

The metal face

should face

outward

Touchscreen

FPC cable

Page 38

Page 39

4 Hardware 4-1

4

Hardware

4.1 Overview

This chapter describes the function of circuit boards in the BA-88A.

4.2 Safety Precautions

WARNING

Don’t touch the circuit boards by hand or others, when the analyzer is

working.

If you are about to detach the circuit boards, you should cut off the

power of the analyzer.

Please wear the glove to protect the circuit boards from ESD or release

the charge first when you detach the circuit boards.

4.3 Introduction of the Modules

The hardware system of the BA-88A is divided into the following modules or boards:

1 Main unit: CPU board, CPU extension board;

2 Data collection board: analogue board;

3 Human-machine communication module: LCD&touchscreen board;

4 The power module: Power board

Page 40

4 Hardware 4-2

Figure 4-1 The structure of hardware system

4.4 CPU Board

CPU board which is the minimum structure system of CPU system uses 32 digit chip

microcomputer as its core. CPU board and CPU extension board make up of the

main module.

The CPU communicates with the CPU extension board via CPU external interface in

multiple-buses communication mode.

Figure 4-2 Structure of the CPU board

4.4.1 LED Indicator

D3: +3.3V power indicator

4.4.2 Memory Module

Flash which communicates with CPU via local bus, is used to store the CPU program,

system parameters and test results.

SDRAM which is configured on CPU board, is used to run the software.

Page 41

4 Hardware 4-3

4.4.3 Clock Module

The real time clock circuit which is composed of real time clock and battery, is to

realize the function of real time clock on CPU board.

4.4.4 Interface Module

CPU communicates with the CPU extension board via various bus interfaces on CPU

board. The sockets on CPU board are, J2, J3 and J10; the sockets on CPU extension

board are J5, J6 and J4.

4.5 CPU Extension Board

4.5.1 Overview

The CPU extension board realizes some functions of the CPU external interfaces.

Such as:

USB functions;

LCD driver control;

Touchscreen control;

Recorder serial port communication;

Hummer control;

PC serial port communication.

In the meantime, the CPU extension board receives the command and completes the

following tasks:

Control and driving of the moving parts;

Checking of the input signal;

Data collection;

Data transfer of the CPU board.

The function graph is shown in the following figure:

Page 42

4 Hardware 4-4

Figure 4-2 Structure of the CPU extension board

4.5.2 LED Indicator

D3: ++12V power indicator

D6: ++24V power indicator

D7: ++5.0V power indicator

D17: +3.3V power indicator

4.5.3 USB Functions

USB controller is configured on the CPU extension board which communicates with

the CPU via bus and realizes the USB communication function via USB interface.

USB power control and ESD protector is added between the USB controller and the

USB interface.

Page 43

4 Hardware 4-

5

Figure 4-4 Structure of USB functions

4.5.4 LCD&Touchscreen Driver Control

CPU realizes the functions of LCD drive control, reading touch screen data,

transforming data transfer protocol.

Figure 4-5 Graph of LCD/touchscreen drive control

4.5.5 Serial Port Communication

The COM0 of CPU board uses RS232 level translator to translate the level, realizing

the serial port communication with PC. The communication between COM3 and

recorder is realized through the level translation between LVTTL and TTL.

Figure 4-6 Graph of serial port communication

Page 44

4 Hardware 4-

6

4.5.6 Driver of the Step Motor

Figure 4-7 Graph of the step motor driver

The control module of the CPU extension board (including: MCU and FPGA) outputs

motor control signal, which can control the step motor of the filter wheel via step

motor driver circuit.

4.5.7 Driver of the Peristaltic Pump

Figure 4-8 Graph of the peristaltic pump driver

The control module of the CPU extension board (including: MCU and FPGA) outputs

peristaltic pump control signal, which can control the motor of peristaltic pump via

power driver circuit.

4.5.8 Driver of the Refrigeration Plate

Figure 4-9 Graph of the refrigeration plate driver

The control module of the CPU extension board (including: MCU and FPGA) outputs

motor control signal, which can control the refrigeration plate via power driver circuit.

Page 45

4 Hardware 4-

7

4.5.9 Detection of the Input Signal

Figure 4-10 Graph of input signal detection

The system should detect the signal from filter position sensor, aspirate button,

cuvette temp. controlling fan blocking. Before detected by control module, all input

signals should go through the level translation circuit.

4.5.10 Analogue Board Control

Figure 4-11 Graph of analogue board controlling

Three signals are controlled by analogue board: digital potentiometer control signal

(DCPx), channel selection signal (CH), AD collection and control signal (AD_Ox and

AD_lx). All control signals are generated by control module. The signals between the

control module end and analogue board should go through level translation (TTL to

LVTTL).

4.6 Analogue Board

The analogue board realizes the functions of photoelectric signal, temperature

sensor signal modulation and amplification, AD collection.

The photodiode transforms the light signal which has passed through the flow

cell (or cuvette) into voltage signal. The voltage signal will be filtered,

amplified inversely, and finally output at the outputting end of the AD

converter through selectable switch.

Page 46

4 Hardware 4-

8

The temperature sensor outputs the voltage signal to the analogue board,

where it will go through amplification and modulation. Finally, it will be output

at the inputting end of the AD converter through selectable switch.

The AD converter receives control signal from the CPU extension board and

samples the processed photoelectric/temperature signal and sends the AD

value to CPU extension board for processing.

The power of the analogue board is provided by power board.

Figure 4-12 Structure of the analogue board

D12: +12V power indicator

D13: -12V power indicator

D14: +5.0V power indicator

4.7 LCD&Touchscreen Board

LCD&touchscreen board realizes the functions of LCD and touchscreen driver and

signal transmission.

LCD&touchscreen board receives the LCD display control/data signal which

is exported from CPU extension board and outputs the LCD display

control/data to LCD screen.

LCD&touchscreen board realizes the function of four-wire resistance

touchscreen AD collection. It receives the touchscreen control signal from the

CPU extension board and output the touchscreen data to CPU extension

board.

Figure 4-13 LCD&touchscreen structure

D6: +3.3V power indicator

Page 47

4 Hardware 4-9

D5: touchscreen valid-clicking indicator

4.8 Power board

4.8.1 Overview

The power board provides stable and reliable DC power to the modules and devices

of the system. The circuit is of Flyback converter structure, providing +24V, ±12V

and +5V voltage to the system and the functions of over-current protection,

over-power protection and over-voltage protection are available on the system.

4.8.2 The Basic Feature of the Power Module

4.8.2.1 Alternating Voltage Input

Input power: 140VA

Input AC voltage: 100-240V~

AC2 frequency: 50/60±3Hz

4.8.2.2 Output

A5V output – for circuit board

A12V output – for circuit board (analogue)

-12V output – for circuit board (analogue)

24V output- board motor/power driver

B12V output-recorder/fan/peristaltic pump motor/semi-conductor heater

and power driver

9.9V output-LCD background light power

B5V output-lamp power supply

4.8.2.3 Output Protection

Over-current and over-power protection

Over-voltage protection

Short circuit protection

Over-heating protection

Page 48

4 Hardware 4-10

4.9 LCD Background Adjustment

If the power board or CPU extension board is serviced or replaced, the LCD

background voltage might change. To ensure the voltage meet the requirement, it is

necessary to adjust it. The procedure for adjusting is shown as follows:

1 Install all the boards back and ensure all the connections are well connected;

2 Set the digital universal meter to volt measurement. Connect the connectors of

the universal meter to LCD background cable connectors. (“+” is connected to

red cable; “-“ is connected to white cable). Turn on the power of the analyzer.

3 Observe the voltage result measured by digital universal meter, if the voltage is

within the range of 9.80V≤V≤10.10V, it meets the requirement; Otherwise, the

voltage should be adjusted by operating software. The procedure for adjusting is

shown as follows:

4 Click Maintenance on the main screen of the instrument. Select Maintenance

tab. Click Advanced and enter the password “analyzer” to enter the advanced

adjustment interface as shown in figure 4-14.

5 Click Optional to enter the advanced setting interface. Use “+” or “-“in Screen

brightness area to adjust the background voltage. Click “+” to increase the LCD

background voltage (LCD background is brightening); click “-“to decrease the

LCD background voltage (LCD background is darkening). The adjustment range

is: 9.80V≤V≤10.10V;

6 Return to the main screen when adjustment is completed.

Figure 4-14 LCD background adjustment

Page 49

4 Hardware 4-11

4.10 Connection of the Hardware System

Figure 4-15 System connection

4.10.1 Definition of the CPU Board + CPU Extension Board

Interface

Figure 4-16 CPU board + CPU extension board interface

Page 50

4 Hardware 4-12

4.10.2 Analogue Board Interface

Figure 4-17 Analogue board interface

4.10.3 Power Board Interface

Figure 4-18 Power board interface

Page 51

4 Hardware 4-13

4.10.4 LCD&Touchscreen Board Interface

Figure 4-19 LCD& touchscreen board interface

Page 52

Page 53

5 Service and Maintenance

5-1

5

Service and Maintenance

To ensure reliability, good performance and service life of the system, regular

maintenance is required. Be sure to follow the instructions given below to maintain

the system. Even you’re only an operator, it’s very important for you to learn this

chapter. Your thorough understanding will help you obtaining the best performance of

the system.

WARNING

Do not perform any maintenance procedures that are not described

in this chapter.

Do not touch the components other than the ones specified in this

chapter.

Performing unauthorized maintenance procedures may damage

your system, void any applicable warranty or service contract and

even cause personal injury.

After performing any maintenance actions or procedures, ensure that

the system runs normally.

Do not spill water or reagent on mechanical or electrical components

of the system.

BIOHAZARD

Wear gloves and lab coat and, if necessary, goggles during

maintaining process.

Page 54

5 Service and Maintenance

5-2

5.1 Maintenance

5.1.1 Daily Maintenance

1 Use neutral wash solution and wet cloth to clean the spillage on the instrument.

2 Wash the tubing with distilled water or DI water before shutting down the

analyzer (for instrument installed with flow cell).

3 When the system is not in use, make sure that the tubing and the flow cell is

filled with clean distilled water (or DI water).

5.1.2 Weekly Maintenance

1、 Wash the waste bottle interior with clean water. Soak the bottle with disinfector if

necessary.

2、 If the instrument will not be in use for a long time. Detach the pump head from

the pump to elongate the service life of the pump tubing. Refer to the step 2 in

5.3.1 for details about detaching pump head. Do not disconnect the connection

of the tubing.

5.1.3 Irregular Maintenance

5.1.3.1 Cleaning Flow Cell

1 Low Background

Contamination of the flow cell or bubble in the flow cell might cause low

background. You can use the absolute alcohol to clean the flow cell ( also

applies for bubble in the flow cell). The procedure is as follows:

A) Click Wash on the software to wash the tubing. After 10 seconds, click

Stop.

B) Prepare about 5 ml absolute alcohol in the tube. Put the aspiration tubing

into the tube and click Wash. After 5 seconds, click Stop. Wait for 10

seconds.

C) Wash with absolute alcohol for 5 seconds again, and then wait for 10

seconds. Wash the tubing with DI water for 10-20 seconds. The cleaning is

completed.

D) Other recommended wash solutions include: 0.1N NaOH (KOH) solution

(with some surfactant); or, enzyme solution capable of decomposing the

protein; or, reagent used in chemistry analysis, capable of removing the

protein, total protein reagent (biuret) and etc.

2 Before switching to other tests

Before switching to other tests, it is recommended the flow cell be washed with

distilled water (or DI water). This is very necessary for tests which carryover

might take place, or samples whose concentration differs a lot. The cleaning

should last for no less than 5 seconds. The amount of distilled water (or DI water)

should be around 1.5 ml. You can also use the wash solution specifically for

chemistry analyzer to wash first, then with the distilled water (or DI water).

3 Cleaning Exterior of the Flow Cell

Page 55

5 Service and Maintenance

5-3

If the optical surface of the flow cell is contaminated, use cloth soaked with

certain amount of absolute alcohol to clean it.

5.1.3.2 Adjust the photoelectric gain

Photoelectric gain should be adjusted, if it is low. After entering the Maintenance

screen, click Gain adjust to pop up the Gain adjust page. Click Start and do as the

system prompts. The system will complete the photoelectric adjustment and

parameter configuration automatically. If the adjustment failed, possible reasons are:

bubble in the flow cell or dirty optical elements or low intensity of the lamp, or

damaged boards. After photoelectric gain is completed, wait for 10 min before testing.

Otherwise, test result might be affected because of unstable light source.

5.1.3.3 Calibrate the Peristaltic Pump

The flow volume of the peristaltic pump might change after being used for a certain

period, so it is necessary to calibrate the flow volume of the pump. If obviously

incorrect aspiration volume of the pump is observed. Please refer the operator’s

manual for details on adjustment.

5.2 Software Upgrading

In order to facilitate operation, U disk is used at the customer end to upgrade the

software. All softwares that might be upgraded at the customer end are located in 2

boards: CPU board and CPU extension board.

CPU extension board: lower computer software and FPGA software

CPU board: operating software, operating software resource package,

device driver, printing software, printing software resource package, printer

driver, printing template.

5.2.1 Software Structure

Page 56

5 Service and Maintenance

5-4

Figure 5-1 System structure of the software

5.2.2 Software List

The software on CPU board that should be upgraded:

Name Code Example of

Version

File or file folder

BA89 operating

software

G87048 G87048-xxxxxx analyzer

BA89 operating

software resource

package

G87057 G87057-xxxxxx

mdres(file folder)

BA89 printing template G87054 G87054-xxxxxx

templates(file folder)

BA89 printing software

GS

G87052 G87052-xxxxxx

Gs

BA89 printing software

GS resource package

G87053 G87053-xxxxxx

share(file folder)

BA89 printing driver

Hpijs

G87055 G87055-xxxxxx

hpijs

BA89 device driver G87051 G87051-xxxxxx gpio_drv.o

Page 57

5 Service and Maintenance

5-

5

The software on CPU extension board that should be upgraded:

Name Code Example of

Version

File or file folder

BA89 control software

( lower computer )

_ijsresource

packagepgraded: ce

driver, printing

software, printing

software resource

package, pringer dir

G87049 G87049-xx semiauto_mcu.hex

CPU extension board

EPCS1SI8N write

software (FPGA

software)

G87045 G87045-xx ba89cpuextendboard.pof

5.2.3 Upgrading Procedures for Software on CPU Board

1 Connect the U disk to the computer. Clear the U disk to ensure it is not infected

by virus.

2 Set up a file directory in U disk: \hd\soft\ and copy the software to be upgraded as

shown in the figure.

NOTE

Only the copy the software that needs to be upgraded to the

relevant directory. The upgrading time is in direct proportion to

the size of the file.

3 Remove the U disk from the PC.

4 Connect the U disk which contains the upgrading program to the analyzer, and

power on the analyzer.

Page 58

5 Service and Maintenance

5-6

5 It will take about 15 minutes for the system to initialize, then the interface to

detect the upgrading program on the U disk will be displayed.

6 Click Yes to pop up the interface for upgrading.

7 The upgrading time is in direct proportion to the size of the file. It will take 10

minutes to upgrade the operating software. After upgrading is completed, the

following interface is displayed, click OK. And the system will be restarted.

Remove the U disk.

Page 59

5 Service and Maintenance

5-

7

5.2.4 Upgrading Procedures for Software on CPU Extension

Board

1 Please make sure the FPGA software or lower computer software has been copied to

relevant directories on U disk.

If not, execute the CPU board software upgrading again. But only FPGA software or

lower computer software is needed to be copied the U disk.

Page 60

5 Service and Maintenance

5-

8

2 After confirming that the FPGA software or the lower computer software has been copied

to the instrument memory, enter the Maintenance interface.

Click Advanced to pop up the dialog box shown in the following figure. Enter the

password—analyzer and click OK.

And the following screen will be displayed:

Page 61

5 Service and Maintenance

5-9

Click Lower upgr and the Lower computer upgrading dialog box will be displayed.

Click start and a dialog box notifying the user to shut down lower computer

communication will be displayed.

Page 62

5 Service and Maintenance

5-10

After upgrading is completed, a dialog box will pop up to notify the user to restart.

Restart the system.

3 Click Advanced to enter the following screen;

Page 63

5 Service and Maintenance

5-11

Click FPGA upgr and the FPGA upgrading dialog box will be displayed.

Click Start and a dialog box notifying the user to shut down lower computer

communication will be displayed.

After upgrading is completed, a dialog box will pop up to notify the user to restart.

Page 64

5 Service and Maintenance

5-12

Restart the system.

4 When the software upgrading is completed, enter Setup-Basic to check whether the

software is of the latest version.

5.3 Maintenance

5.3.1 Replacing the tubing

The tubing is a component that should be replaced regularly. When the instrument is

in use, if you notice that the instrument can not aspirate or aspiration volume

decreases obviously, check for leakage in the peristaltic pump. If yes, the pump

tubing might be broken and it should be replaced. A pump tubing is in the accessory

package (outer diameter 3.2mm, length 150-160mm, yellow).The procedure for

replacing is shown as follows:

1 Shutdown the instrument and disconnect the power cable between the

instrument and the power supply.

Page 65

5 Service and Maintenance

5-13

2 Locate the position where the peristaltic pump is installed. Pull out the

tubing that goes through the backboard of the analyzer for 40-50mm until

the adapter is exposed. Pinch the two buckles on the left and right side of

the pump shell and detach the pump head carefully.

3 After detaching the pump head, unplug the tubing (yellow) whose adapters

are closer to the pump head.

Unplug the

tubing

(yellow)

whose

adapters

are closer

to the pump

head.

Pinch the

buckles to

detach the

pump head

Pull the

tubing out

slightly

Page 66

5 Service and Maintenance

5-14

4 After unplugging the adapters, pinch the buckles on the pump head and

detach the pump shell.

5 After detaching the pump shell, press the roller inside the pump to take the

used pump tubing out. Remove the red ring on the used tubing and install

them on the new tubing. Install the new pump tubing on the pump and

carefully pull it to make the tubing fit well with the inside of the pump without

any twisting. Make sure the lengths exposed at both ends are roughly the

same. If necessary, pull both ends of the tubing slightly.

Pinch the

buckles on

the pump

head and

detach the

pump shell.

Page 67

5 Service and Maintenance

5-15

6 After mounting the pump shell, install the pump head on the pump.

7 After installing the pump head, connect the tubing with the tubing that goes

through the backboard and the waste tubing. The pump tubing on the left

should be connected to the tubing that goes through the backboard, the

pump tubing on the right to the waste tubing.

8 After connecting the tubing, slip the tubing that goes through the backboard

into the analyzer until the adapters does not expose to the outside.

9 Check the installation for any errors. Connect the analyzer to the power

supply and calibrate the pump. Please refer to the relevant part of the

operator’s manual for calibration method.

Pinch the

buckles to lock

the pump head

the pump tubing on

the right to the waste

tubing.

Install the pump

head on the pump,

with the motor

shaft into the

installation hole

The pump tubing on

the left should be

connected to the

tubing that goes

through the

backboard.

Page 68

5 Service and Maintenance

5-16

BIOHARZARD

When replacing the pump tubing, wear gloves and lab

coat and, if necessary, goggles. In case your skin

contacts the waste, follow standard laboratory safety

procedure and consult a doctor.

NOTE

The service life of the pump tubing is 18 month. Tubing

should be checked irregularly and replaced in time.

Do not use excessive force while pulling, slipping the

tubing or doing any operation that might pulling the

tubing. Otherwise, the tubing might be damaged or the

inner connection might be cut off.

While connecting the tubing, insert the tubing into the

adapter until the tubing reaches the bottom of the adapter

so as to ensure the reliability of the connection.

While installing the pump tubing into the pump, avoid

twisting. If necessary, pull the tubing back and forth

slightly.

Calibrate the pump after replacing the pump tubing.

Otherwise, the aspiration volume might not be correct

and the test may be affected.

5.3.2 Replacing Aspiration Tubing

During operation, if the aspiration tubing is blocked and can not be unblocked,

replace it with the tubing (OD: 1.6mm; length: 200-220mm, transparent material),

with one end connected with silicone tube-OD: 4mm; length: about 30mm) in the

accessory. The replacement procedure is as follows:

1 Open the optical window cover and press the bottom of the flow cell ( if flow

cell fastening screw is installed, you do not have to press), then carefully pull

the metal inlet tubing which is connected with the flow cell ( the slimmer one

which is closer to the front of the instrument)

Pull the

tubing

out

Page 69

5 Service and Maintenance

5-

17

2 Connect the thicker end of the new tube to the inlet metal tube and then guide

the tube through the deflection tube.

BIOHAZARD

When replacing the pump tubing, wear gloves and lab coat and, if

necessary, goggles. In case your skin contacts the waste, follow

standard laboratory safety procedure and consult a doctor.

NOTE