Milton CAT D6T User Manual

D6T ®

Track-Type Tractor

Engine – Standard

Engine Model |

Cat® C9 ACERT® |

|

Net Power – ISO 9249 |

138 kW |

185 hp |

Engine – XL / XW / LGP |

|

|

Net Power – Caterpillar |

149 kW |

200 hp |

D6T Track-Type Tractor

Operator Station

The comfortable operator’s station provides an excellent viewing area to the blade and rear of the machine for maximum operator productivity. Controls are low effort and easy to reach. pg. 4

Work Tools

Caterpillar® offers a variety of work tools to equip your D6T with the versatility needed to accomplish the job quickly and efficiently. pg. 14

Engine

ACERT® Technology works at the point of combustion to optimize engine performance and provide low exhaust emissions. Matched with the torque divider and power shift transmission, it provides years of dependable and efficient service. pg. 6

Integrated Electronic Solutions

Caterpillar offers technology options such as Product Link and AccuGrade™ Grade Control System that provide greater accuracy, higher productivity, lower operating costs and more profitability. pg. 16

Engineered for demanding work. The D6T is designed to be productive in a variety of applications. It keeps material moving with the reliability and low operating costs you expect from Cat machines.

Power Train

The electronically controlled power shift transmission and differential steering work together with the new C9 ACERT® engine for maximum efficiency. pg. 8

2

Structure |

Serviceability |

SystemOne™ Undercarriage |

A heavy, strong and durable mainframe, |

Major components have a modular |

With the elevated sprocket design, |

strong case steel castings and reinforced |

design for excellent serviceability and |

the final drives are located above the |

frame rails provide durable support to |

fast in-field component exchange. |

work area, isolating them from ground |

the undercarriage, elevated final drives |

pg. 11 |

induced impacts. The different |

and other integral frame components. |

|

undercarriage configurations allow |

pg. 10 |

|

the machine to be matched to the |

|

|

application needs. pg. 12 |

Total Customer Support

Your Cat® dealer offers a wide range of services that can be set up under a customer support agreement when you purchase your equipment. The dealer will help you choose a plan that can cover everything from machine and attachment selection to replacement – helping get the best return on investment. pg. 18

New Feature

3

Operator Station

The D6T operator’s station is designed for comfort and ease of operation.

4

Cab. An isolation-mounted, pressurized cab reduces noise and vibration for operator comfort. The cab is pre-wired for a 12-volt or 24-volt radio, equipped with two speakers, an antenna and a radio mount recessed in the headliner.

Clear Working View. The operator has an excellent view to the blade and rear of the machine for maximum productivity. The tapered hood, notched fuel tank and narrow single-shank ripper carriage give the operator a clear line of sight to the front and rear work areas. The large single-pane windows offer excellent viewing to the sides and blade. The low rear window lets the operator see the ripper tip.

Cat Comfort Series Seat. The Cat Comfort Series seat has a thick, contoured cushion, rolled down front edge and is adjustable eight-ways for optimal support and comfort. Seat side bolsters restrain side-to-side movement when working on steep grades or side slopes. The seat and suspension are designed for 10,000-hour life.

Adjustable Armrests. Standard, adjustable armrests provide additional comfort

for the operator. Adjustment can be performed without the use of any tools.

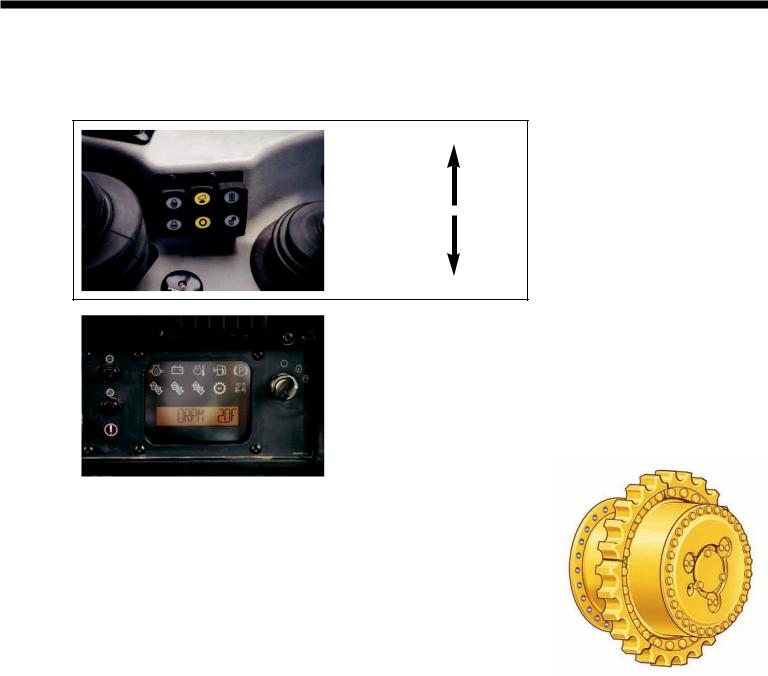

In-Dash Instrument Cluster.

The instrument panel, with easy-to-read gauges and warning lamps, keeps the operator aware of all system information. All gauges and readouts are easily visible in direct sunlight.

Cat Monitoring System Display.

The dash mounted instrument cluster provides on-the-go operating information and gives the operator

and service technician insight into the machine’s operation and maintenance needs. The Caterpillar Monitoring System includes:

•Fuel level gauge

•Hydraulic oil temperature gauge

•Engine coolant temperature gauge

•Power train oil temperature gauge

•Engine oil pressure indicator

•Digital readout

•Transmission gear indicator

Heating and Air Conditioning.

Conveniently located air circulation vents evenly distribute airflow within the cab. Controls are easily accessible from the operator seat.

Power Converter. The D6T features a 10-amp, 12-volt power converter for the convenient use of radios, wireless phones and laptop computers.

Work Tool Lock-Out Switch.

Redesigned from a mechanical rotary switch to an electronic rocker switch, the work tool lock-out valve prevents inadvertent operation of the hydraulic work tool attachments.

Throttle Rocker Switch. With the touch of a finger, the rocker switch activates high or low idle. A decelerator pedal gives the operator full control of engine speed when the rocker switch is in the high idle position. Engine speed can be set between high and low idle by simultaneously using the decelerator pedal and holding the Rabbit side of the throttle switch in for three seconds.

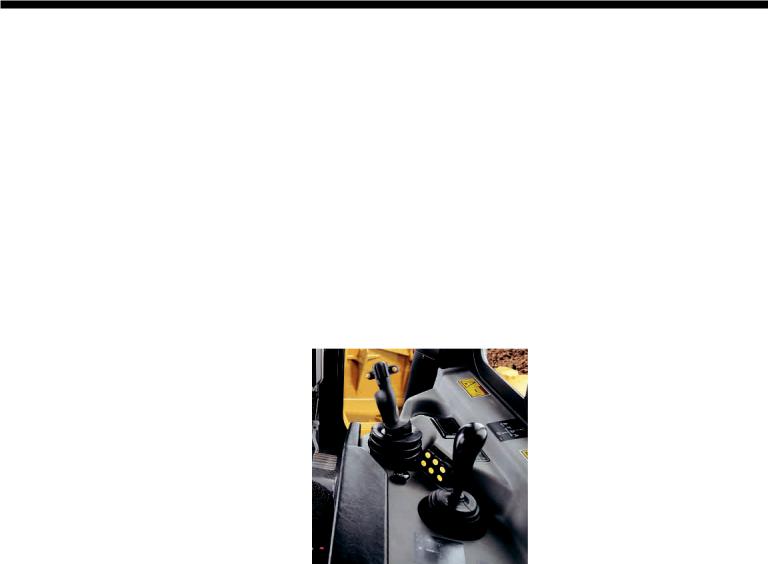

Steering and Transmission Control.

Differential steering controls the direction and degree of turns, forwardreverse shifting and gear selection in a single control handle which enhances operator comfort. Touch shift buttons on the steering control shifts the electronically controlled powershift transmission. The tiller allows the operator to work precisely in close areas around structures, grade stakes and other machines with the finest modulation in the industry.

Auto-Shift/Auto-Kickdown. Auto-shift allows the operator to pre-select a forward and reverse gear for easy, efficient directional changes. Auto-shift settings include first forward to second reverse, second forward to second reverse, and second forward to first reverse. Auto-kickdown allows the transmission to automatically downshift when significant load increases are detected.

Dozer Control Lever. The D6T features ergonomically designed dozer controls with low-effort, pilot-operated hydraulics for added operator comfort, easy operation and precise work tool control. When equipped with a VPAT blade, the blade control allows simultaneous six-way control of the blade with a thumb rocker control to adjust blade angle. The dozer control is changed to an electro-hydraulic control when the AccuGrade Ready Option is installed.

Ripper Control Lever. The ripper control with low-effort pilot-operated hydraulics contributes to operator comfort, easy operation and precise work tool control.

5

Engine

A combination of innovations working at the point of combustion, ACERT ® Technology optimizes engine performance while meeting emission regulations for off-road applications.

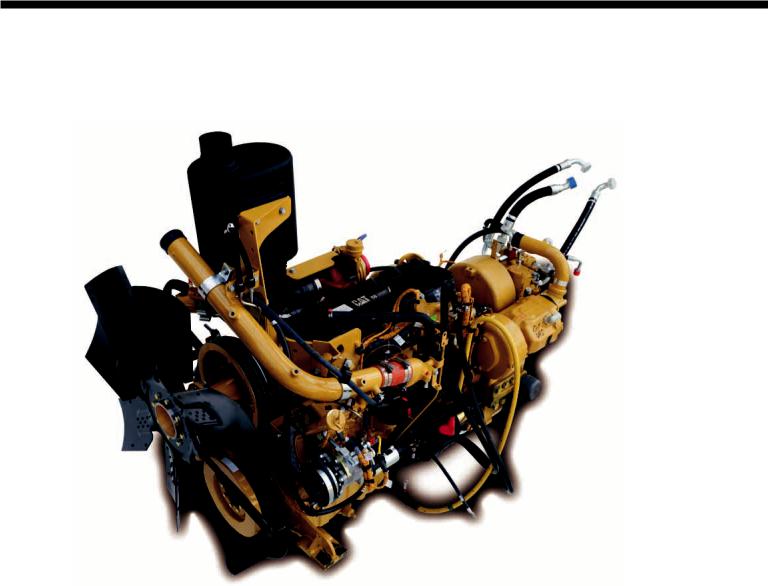

Cat C9 with ACERT Technology.

The Cat C9 is an 8.8 L (537 in3) displacement, six cylinder, in-line configured engine with hydraulically actuated electronic fuel injection or HEUI™. It uses ACERT Technology, a series of Caterpillar engineered innovations that provide advanced electronic control, precision fuel delivery and refined air management, resulting in outstanding performance and lower emissions. The C9 with ACERT Technology meets U.S. EPA Tier 3 and European Union Stage IIIa emissions standards.

Cylinder Block. Increased block and head material strength minimizes the effect of high cylinder pressure.

A strengthened flywheel housing joint reduces leaks. The sculpted heavy-duty design reduces sound and vibration levels. The mid-supported liner has fewer sealing joints for a reduced risk of leaks. The integral oil cooler reduces engine width, weight and potential leaks while improving coolant and oil flow.

Cylinder Head. A new cross-flow air design with four valves per cylinder and updated port geometry dramatically improve airflow and engine breathability. The cylinder head block features a robust six-bolt design for an improved seal between the head and block at the fire ring which prevents combustion gas leaks. It also minimizes bore/liner distortion. The improved intake port geometry provides a smoother transition and less flow restrictions.

Fractured-Split Connecting Rods.

The new fractured-split connecting rods are designed to create near-perfect joint alignment, maximizing rod bearing life. This, in combination with a high efficiency oil filter, ensures long engine life.

6

ADEM™ A4 Engine Controller. The aircooled ADEM A4 controller is the brain of the engine and contains the engine’s control software. It regulates fuel delivery, airflow and other engine functions. In addition, it directs the HEUI injectors to deliver multiple injections of fuel during the engine’s compression stroke.

Fuel Delivery. Multiple injection fuel delivery involves a high degree of precision. Precisely controlling the combustion cycle lowers combustion chamber temperatures, which lowers emissions and optimizes fuel economy. This translates into more work output per unit of fuel.

HEUI™ Fuel System. The HEUI fuel system is highly evolved, with a proven record of reliability. HEUI uses the technical advancement of an electronic control system with the flexibility of hydraulically controlled unit fuel injection. The system excels in its ability to control injection pressure over the entire engine operating speed range. These features allow the C9 to have complete control over injection timing, duration, and pressure.

Air-to-Air Aftercooler. The air-to-air aftercooler (ATAAC) brings cool air to the engine which increases life and lowers emissions. In addition, the

ATAAC, together with the tight tolerance combustion chamber components, maximizes fuel efficiency.

Wastegate Turbocharger. The wastegate allows high-volume exhaust to be routed around the turbocharger to the exhaust piping to prevent wheel spin overspeed at high rpm but low load conditions.

Service. The new C9 engine offers easier maintenance and repair through monitoring key functions and logging critical indicators. Electronic diagnostic access is possible with a single tool, the Cat Electronic Technician.

Next Generation Modular Radiator (NGMR). Improves cooling capabilities by using a parallel flow system with six cores. Serviceability is improved with NGMR since there is no top tank to remove.

Serviceability. This modular core design permits removal of a single core without removing the entire radiator so repair costs and downtime are reduced. The top tank, side channels and one sealing surface makes AMOCS more reliable and easier to service. A site gauge allows for quick service checks.

Leak Protection. To reduce the potential for coolant leaks, brass tubes are welded to a large, thick header to improve the strength of the tube-to-header joint.

In conditions where abrasive materials can be airborne, the attachment sand blast grid should be used to prevent core damage.

Sand Blast Grid. In an application where airborne debris is prevalent, radiator core protection is a concern. To extend radiator life in harsh applications, a sand blast grid is available as an option to deflect the damaging debris the engine fan propels at the radiator.

Demand Fan Option. Based primarily on ambient air temperature, the optional demand fan can improve productivity up to three percent and reduce fuel consumption up to four percent since the demand fan will only run at a speed needed to meet the cooling requirements of the machine. As cooling requirements increase above 24° C (75° F), the demand fan performance converges towards that of the standard fan so lesser benefit is achieved.

7

Power Train

The power shift transmission and differential steering work in tandem with the new C9 engine to deliver the outstanding power and reliability expected from Caterpillar.

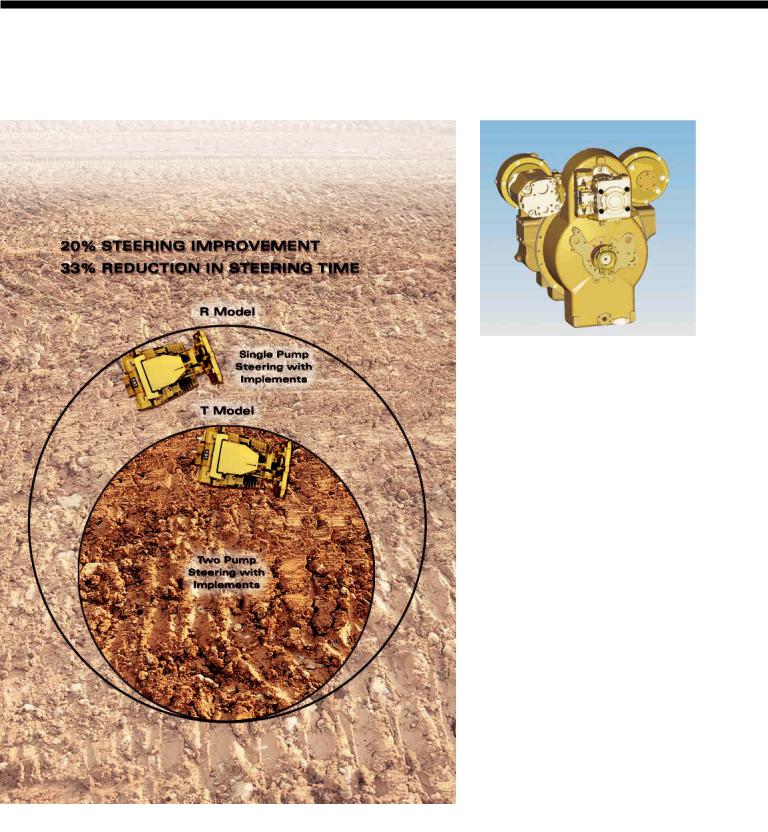

Two Pump Hydraulic System.

• Split pump design for dedicated hydraulic power to steering and implements, improving blade and ripper response and overall power in steering-intensive applications

• Improved steering performance independent of implement operation

• Constant flow in steering circuit improves hydraulic cooling, increasing cooling capacity of the machine

• Improved response in simultaneous steering/implement applications, making the machine more maneuverable overall

• Enhanced blade response when using AccuGrade

Torque Divider. A single-stage torque divider sends 70 percent of engine torque through a converter and

30 percent through a direct drive shaft for greater drive line efficiency and higher torque multiplication.

The D6T torque divider provides:

• High reliability

• Low dynamic torque

• Optimum combination of operator efficiency and drive line reliability

• Components designed to absorb full engine power

8

5 Speed

3 Speed

|

|

|

|

|

|

|

DISPLAY |

|

|

|

5 Speed |

|

3 Speed |

|

|

1.5 |

|

1 |

|

|

2.0 |

|

|

|

|

2.5 |

|

2 |

|

|

3.0 |

|

|

|

|

3.5 |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Differential Steering System.

Differential steering maintains power to both tracks while turning. The tractor turns when one track speeds up and the other slows down an equal amount. The operator can steer and control the transmission simultaneously, which can reduce cycle times in some applications. The differential steering tiller bar has touch shift buttons for upshifts and downshifts. Low tiller bar efforts assure operator comfort during long shifts. Large blade loads can be maneuvered around buildings, bridge abutments, trees or other obstacles. Steering modulation is also optimized for precise control in these applications. Greater load capacity, power and speed control are possible

in soft underfoot conditions on steep slopes because both tracks are powered during turns.

Multi Velocity Program (MVP).

The Multi Velocity Program (MVP) is an innovative machine control system that allows the operator to choose from five different speed ranges in Forward and Reverse, providing the operator with the flexibility to match machine speed to a variety of applications and ground conditions. This exclusive solution allows the operator to maximize production, minimize fuel consumption,and lower overall machine operating costs.

MVP provides the operator with

five speed ranges in both Forward and Reverse. The engine speed in each speed range has been optimized to provide the best performance, fuel economy, and drawbar pull. The operator retains the ability to operate the machine in either the 3 speed or 5 speed mode.

Operating Efficiency and Drive Line Reliability. The D6T torque divider attains the best combination of operating efficiency and drive line reliability.

It acts as a hydrodynamic component between the engine and transmission to reduce dozing shock loads to the transmission and final drives.

Planetary Power Shift Transmission.

The D6T planetary power shift transmission utilizes large diameter, high capacity, oil-cooled clutches. These clutches provide higher torque capacity and increased service life. The planetary power shift transmission offers several key features and benefits, including:

•Electronically controlled modulation system that allows fast, smooth speed and direction changes

•Modular transmission and differential slide into rear case for servicing ease, even when a ripper is installed

Elevated Final Drive. Elevated final drives are isolated from ground and work tool-induced impact loads for extended power train life. The modular design ensures quick and easy service when required.

Load Compensating Shifting. With load compensating shifting, clutch engagement timing automatically adjusts according to the load factor. This allows improved tractor performance and operator comfort during speed changes and reduces the amount of energy dissipated through the clutches to help extend transmission component life.

9

Loading...

Loading...