Milton CAT D6K User Manual

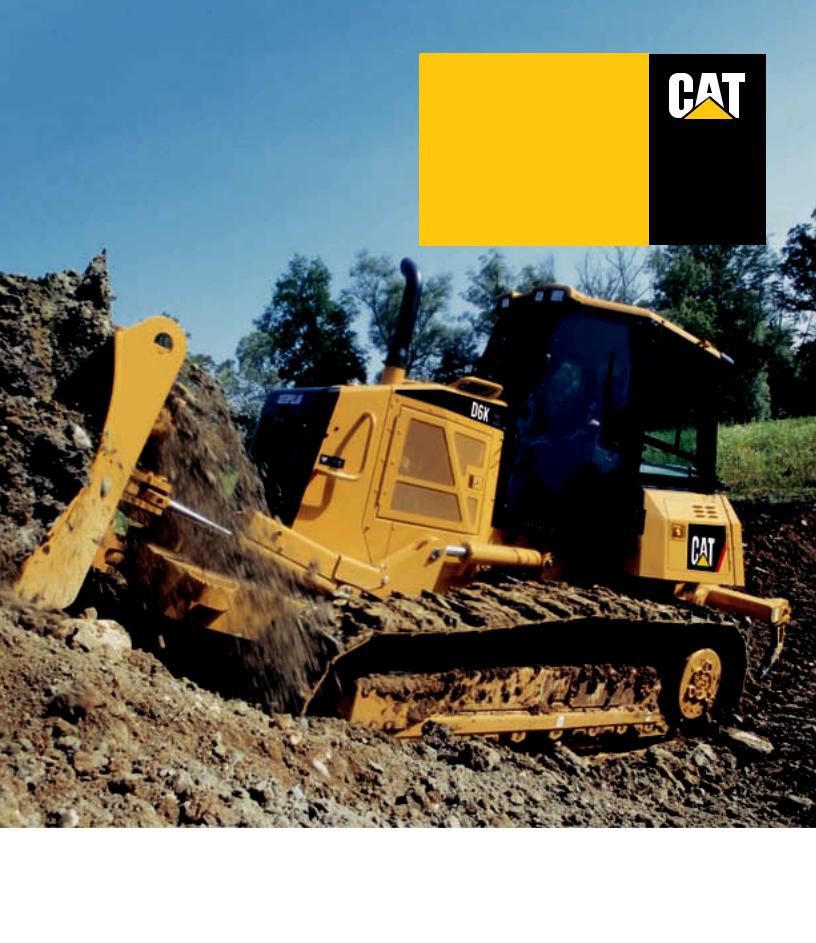

D6K ®

Track-Type Tractor

Engine |

|

|

Engine Model |

Cat® C6.6 ACERT™ |

|

Flywheel Power |

93.2 kW |

125 hp |

Weights |

|

|

Operating Weight – XL |

12 886 kg |

28,409 lb |

Operating Weight – LGP |

13 467 kg |

29,690 lb |

|

|

|

D6K Track-Type Tractor

Engine

The Cat® C6.6 engine meets stringent Tier 3/Stage IIIA emission standards while providing outstanding engine performance, fuel efficiency and long-term durability. pg. 4

Serviceability and Accessibility

Grouped service points allow for efficient checks and maintenance, from the ground level. The new design of the cooling package facilitates serviceability and cleaning of the radiator and cooling fan. pg. 12

Structure

Steel castings and heavy steel plates are welded to insure a rigid one-piece frame structure. Structures are designed to last throughout the extended service life of the D6K. pg. 5

Work Tools

Caterpillar offers a variety of work tools, designed with the strength and versatility needed to accomplish the job quickly and effectively. pg. 13

Drive Train

The hydrostatic drive with electronic control provides precise modulation for quick and smooth operation, superior maneuverability and comfortable operation, increasing productivity. pg. 6

2

Operator Station |

SystemOne™ Undercarriage |

A new operator station offers excellent visibility and superior comfort. Standard features include a fully adjustable air suspended seat, air conditioning, electro-hydraulic controls, advanced monitoring system and low sound levels for comfortable operation and maximum productivity. pg. 8

Designed exclusively by Caterpillar for Cat Machines, SystemOne Undercarriage extends undercarriage system life, improves reliability and reduces Owning and Operating costs. pg. 10

AccuGrade® Laser and GPS Machine

Control and Guidance Systems

AccuGrade Laser and GPS systems can be easily installed on the AccuGrade ARO (Attachment Ready Option) equipped machine. pg. 11

Total Customer Support

Your Cat® Dealer offers a wide range of services that can be set up under a Customer Support Agreement when you purchase your equipment. The dealer will help you choose a plan that can cover everything from machine and attachment selection to replacementhelping get the best return on investment. pg. 14

New Feature

3

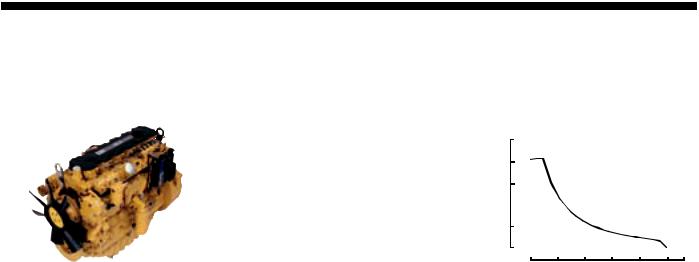

Engine

The new Caterpillar® C6.6 Diesel Engine with ACERT™ Technology meets worldwide emissions requirements for EPA Tier 3, EU Stage IIIA and Japan Moc Step 3 engine exhaust emission regulations, while providing excellent performance.

Cat® C6.6 Engine with ACERT™ Technology. The Cat® C6.6 is a 6.6 liters (403 in3) displacement,

six cylinder, inline configured engine equipped with a Caterpillar Common Rail fuel System. It uses ACERT Technology, a series of Caterpillar engineered innovations that provide advanced electronic control, precision fuel delivery and refined air management, resulting in outstanding performance and lower emissions. The Cat C6.6 with ACERT Technology meets the U.S. EPA Tier 3, European Union Stage IIIA and Japan MOC Step 3 emissions standards.

Design. The C6.6 features a compact design with heavy-duty engine features for outstanding durability, reliability and performance. The C6.6 incorporates a new cross flow cylinder head design, a 4 valve head and an ADEM A4 electronic controller.

Electronic Controls. The C6.6 engines use advanced electronic controllers, which have a proven track record for performance and reliability. ADEM A4 Electronic Control Module (ECM) receives data from engine-mounted sensors and adjusts critical parameters to maintain optimum performance. These adjustments also optimize fuel economy and emissions compliance. Electronics also make engines easier to troubleshoot and repair.

Fuel Delivery. Fuel is introduced in the combustion chamber in a number of precisely controlled microbursts. Injecting fuel in this way allows for precise shaping of the combustion process. The ADEM™ A4 module directs the injectors to deliver precise quantities of fuel at exactly the right times during combustion for optimum efficiency and performance.

Air Management. The C6.6 uses a turbocharger fitted with a smart waste gate to give precise control of the boost pressure. Over the entire engine operating ranges the result is improved: Throttle response, Lower fuel Consumption and optimized engine performance. A new cross-flow design in the cylinder head facilitates air movement, while tighter tolerances between the piston and cylinder liner are reducing blow by gases.

Turbocharged and Aftercooled. A wellmatched turbocharger and air-to-air aftercooler results in higher power while keeping rpm steady and exhaust temperatures low.

|

N x |

lb x |

|

|

D6K Drawbar Pull |

|

|

|

|

|

||

|

1000 |

1000 |

|

|

|

|

|

|

|

|

||

|

250 |

55 |

|

|

|

|

|

|

|

|

|

|

|

|

50 |

|

|

|

|

|

|

|

|

|

|

|

200 |

45 |

|

|

|

|

Drawbar Pull |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Pull |

150 |

40 |

|

|

|

|

vs. |

|

|

|

|

|

35 |

|

|

|

|

Ground Speed |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Drawbar |

|

30 |

|

|

|

|

|

|

|

|

|

|

|

100 |

25 |

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

|

|

|

|

50 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

mph |

|||

|

|

0 |

||||||||||

|

|

0 |

2 |

|

4 |

6 |

8 |

10 |

|

|

km/h |

|

Speed

Torque Rise. The direct injection electronic fuel system provides a controlled fuel delivery increase as the engine lugs back from rated speed. This results in increased horsepower below rated power. A combination

of increased torque rise and maximum horsepower improves response, provides greater drawbar pull and faster dozing cycles.

Cooling System. The cooling system is a single coolant unit including hydraulic oil cooler, radiator, ATAAC and fan installation. Aluminum cores and hydraulically driven demand fan provide optimum cooling and fuel efficiency.

Electric Fuel Priming Pump. A standard electric fuel priming pump is located in the primary fuel filter base above the combined water separator/primary fuel filter. A switch enables to easily prime the fuel system after a fuel filter service.

4

Structure

The frame is engineered to handle the most demanding applications, and is built to last throughout the extended service life of the D6K.

Main Frame. The D6K one-piece main frame is designed to absorb high impact shock loads and twisting forces. Robotic welding provides deep penetration and consistency, ensuring high quality, durability and reliability throughout the structure.

Track Roller Frame. Track roller frames feature an engineered box-section design, which provides superior strength and resistance to bending.

Equalizer bars are pinned in their center to the machine main frame and at the ends to each track roller frame. This allows the forward ends of the track roller frames to oscillate to keep more track on the ground in uneven underfoot conditions while providing maximum traction and operator comfort.

Heavy Duty Components. Heavy duty radiator grill, bottom guards and fuel tank guard are available, for additional protection in severe applications.

5

Drive Train

The D6K features an electronically controlled hydrostatic drive system with independent power and control of each track for fast acceleration, variable speed control, and on-the-go direction changes.

Hydrostatic Drive. The electronically controlled hydrostatic drive system automatically maintains engine speed to match the power requirements of the application for peak performance. The hydrostatic drive train also offers independent power and control of each track, for fast acceleration, infinitely variable speed control and on-the-go, direction changes. The operator can command smooth “power turns” or even counter-rotation of the tracks for precise steering control in tight areas.

The Caterpillar hydrostatic drive system manages itself, freeing the operator to concentrate on using the Caterpillar track-type tractor’s superb agility, speed, and maneuverability to do more productive work.

Infinitely Variable Speed Control.

Hydrostatic drive provides infinite speed selection from 0 to 10 km/h

(0 to 6.2 mph) in forward and reverse. This lets the operator select the optimum speed for ground and job conditions.

It also eliminates power interruption during shifting.

Ground Speed Balancing. Hydrostatic drive provides a completely “step-less” transmission of power and automatically matches travel speed and implement loads for increased efficiency and easier operation.

High Power Utilization. The hydrostatic drive system on the D6K is designed to use full available engine power throughout the machine working cycle.

If the implement hydraulic system is not in use, this engine power can be delivered to the drive train, providing high drawbar pull and fast travel speeds. If the implement hydraulics are being worked hard, the machine control ECM will automatically slow the tracks as necessary to use the full remaining engine power, without overloading

and stalling the engine. As soon as the implement hydraulic load is decreased, the machine control ECM will automatically speed up the tracks until the machine is traveling at the speed the operator has commanded with the Hystat Control (left).

Unsurpassed Maneuverability.

Power turn and counter-rotation capability improve machine maneuverability and productivity. On the D6K, power turns are accomplished by slowing the speed of one track versus the other, while maintaining power to both tracks.

The Cat Hystat power turn feature also enables the D6K to handle large loads around corners or through hard spots encountered when dozing. Power turn capability improves machine mobility in soft underfoot conditions and is very effective for controlling machine

operation on side slopes. Counter-rotation also provides easy, quick maneuvering in tight areas or congested job sites.

6

Loading...

Loading...