Milton CAT 140M User Manual

140M ®

Motor Grader

Cat® C7 ACERT™ VHP

Base Power (1st gear) – Net |

136 kW |

183 hp |

VHP Range – Net |

136-148 kW |

183-198 hp |

VHP Plus Range – Net |

136-163 kW |

183-218 hp |

AWD Range – Net |

144-174 kW |

193-233 hp |

Gross Vehicle Weight – Base

Total |

15 130 kg |

33,356 lb |

Front Axle |

4161 kg |

9,173 lb |

Rear Axle |

10 969 kg |

24,183 lb |

Moldboard |

|

|

Blade Width |

3.7 m |

12 ft |

140M Motor Grader

The 140M delivers multiple technological breakthroughs to give you the best return on your investment.

Operator Station

A technologically advanced cab, featuring joystick controls, provides unmatched comfort and visibility. pg. 4

Integrated Electronic Solutions

Full systems integration with advanced electronics including Cat® Messenger, AccuGrade™ blade control system and Cat ET, create a “Smart Machine” that optimizes performance and availability. pg. 14

Steering and Implement Controls

Two joysticks offer precise control and unparalleled ease of operation. This advanced technology makes the 140M the most operator-friendly motor grader in the world. pg. 6

All Wheel Drive, Work Tools

and Attachments

The Work Tools and optional attachments for the 140M, including the industry leading All Wheel Drive system, expand machine versatility, utilization and performance. pg. 16

Structures, Drawbar, Circle

and Moldboard

The 140M frame provides a solid working platform, and the DCM delivers service ease and precise blade control for maximum productivity. pg. 8

The 140M motor grader represents a revolution in operational efficiency, visibility, service ease and overall productivity, setting the new standard and building on the legacy

of high quality you can trust.

2

Power Train |

Engine |

Hydraulics |

An electronically controlled power shift transmission assures smooth shifting and maximum power to the ground.

A modular rear axle and hydraulic brakes simplify serviceability and reduce operating costs. pg. 10

The Cat® C7 engine combines power |

The electro-hydraulic load-sensing system |

management with ACERT™ Technology |

provides the foundation for advanced |

to deliver maximum power and efficiency |

machine controls, enabling superior |

in every gear while reducing the |

controllability and precise and predictable |

environmental impact. pg. 12 |

hydraulic movements, with the reliability |

|

you expect from Caterpillar. pg. 13 |

Safety |

Serviceability and Customer Support |

Caterpillar has been and continues to be |

Fast component replacement and |

proactive in developing machines that |

minimum downtime are possible with |

meet or exceed safety standards. pg. 18 |

Caterpillar’s exceptional parts availability |

|

and dealers’ advanced rebuild and repair |

|

capabilities. pg. 20 |

New Feature

3

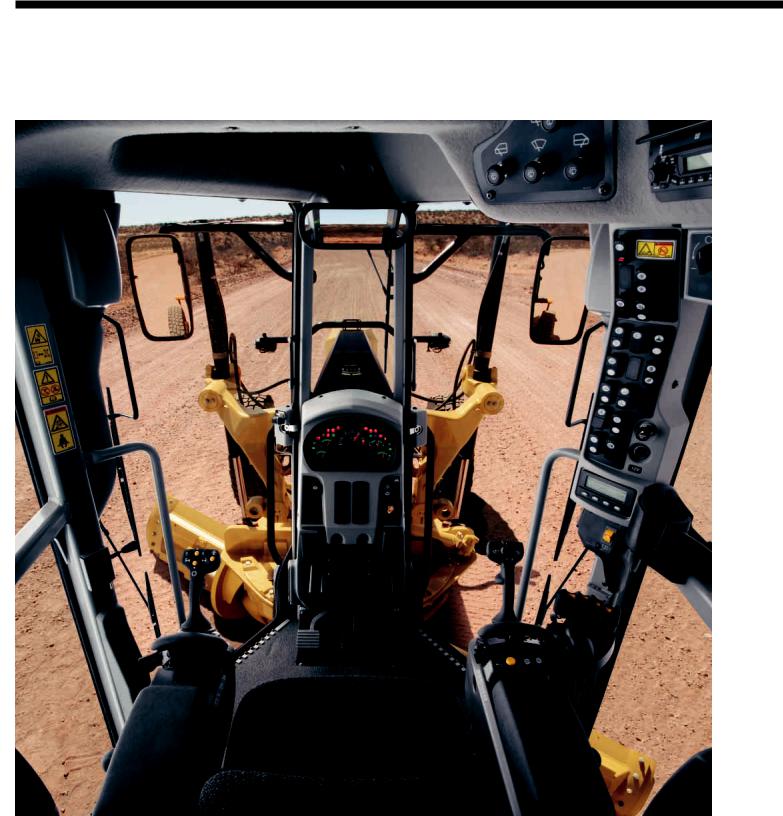

Operator Station

The 140M features a revolutionary cab design that provides unmatched comfort, visibility and ease of use, making the operator more confident and productive.

4

Advanced Joystick Controls. Two electrohydraulic joysticks reduce hand and wrist movement as much as 78% compared to conventional lever controls for greatly enhanced operator efficiency. The intuitive pattern is easy to learn and provides the precise implement control you expect from Caterpillar.

Auxiliary Pod and Ripper Control.

The optional ripper control and auxiliary control pod are ergonomically positioned to allow simple, comfortable operation for the multiple hydraulic options.

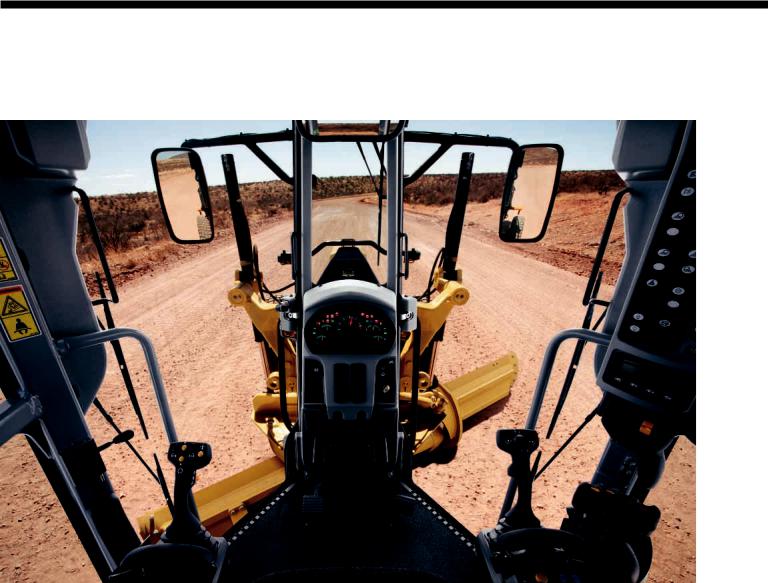

Visibility. The 140M boasts excellent visibility to the work area, made possible with angled cab doors, a tapered engine enclosure and a patented sloped rear window.

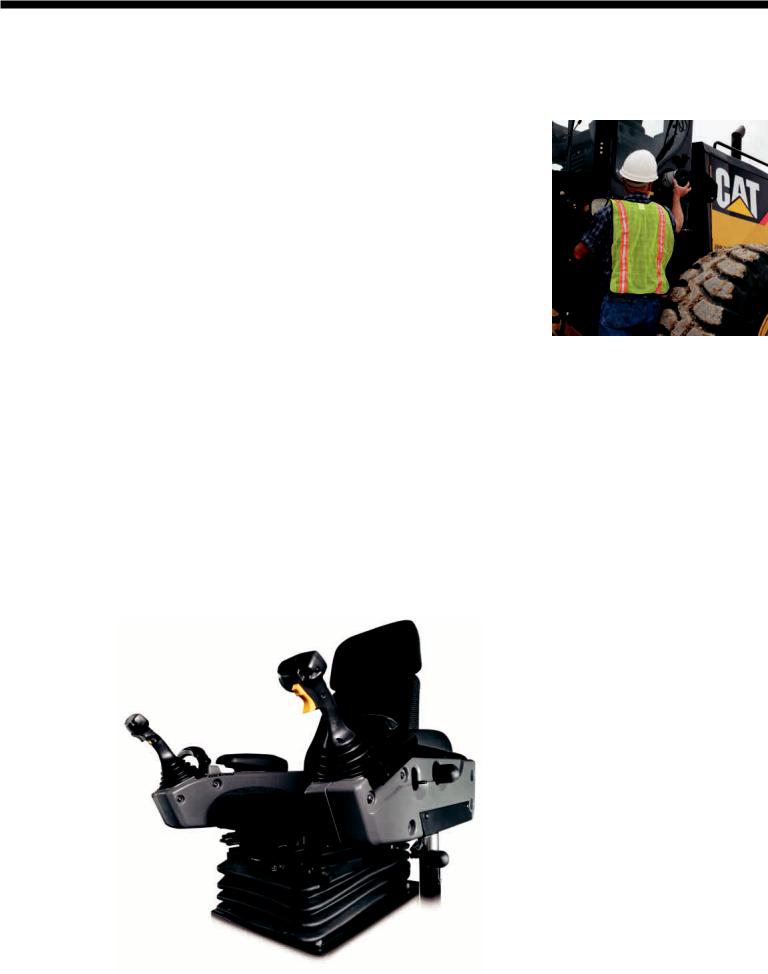

Cat Comfort Series Seat. The Cat® Comfort Series suspension seat has an ergonomic high-back design, with extra thick contoured cushions and infinitely adjustable lumbar support that evenly distributes the operator’s weight. Multiple seat controls and armrests

are easy to adjust for optimal support and comfort all day. The optional air suspension seat enhances ride quality for additional comfort.

In-Dash Instrument Cluster.

The instrument panel, with easy-to-read, high-visibility gauges and warning lamps, keeps the operator aware

of critical system information.

Cat Messenger. Cat Messenger provides real-time machine performance and diagnostic data. You can quickly view critical performance and operating information, in multiple languages, helping to maximize the life and productivity of the machine.

Controls and Switches. Reliable, longlife rocker switches are located on the right side cab post and front instrument cluster, within easy reach for the operator.

Comfort and Convenience. Caterpillar has built the most comfortable cab in the industry by replacing the control levers and steering wheel with two joystick controls, and lengthening the cab to give more leg room.

Multiple adjustment capabilities for the arm rest, wrist rests and joystick pods help keep the operator comfortable throughout a long shift.

Optional HVAC. The optional heating, ventilation and air conditioning system uses intelligent vent placement for consistent climate control and clear windows for every condition. The highcapacity system dehumidifies air and pressurizes the cab, circulating fresh air and sealing out dust. An easily accessible fresh air filter is located outside the cab at ground level for quick replacement or cleaning.

Low Interior Sound and Vibration Levels.

Isolation mounts for the cab, engine and transmission, in addition to the relocation of the hydraulic pump and valves, provide significant sound and vibration reductions. The low vibration levels and quiet interior provide a comfortable work environment.

Additional Cab Features. Additional cab features include cup holder, lighter and ashtray, coat hook, storage area, night time light, power port and heater. Optional rearview camera, 25 amp power converter and satellite radio

are also available.

5

Steering and Implement Controls

The 140M sets the new standard for motor grader operational efficiency.

Ease of Operation. The revolutionary joystick controls and exceptional visibility make the 140M easier to operate without sacrificing control.

The intuitive joystick control pattern allows both new and experienced operators to become productive quickly.

Logical grouping of hydraulic functions in the joysticks allow any operator to easily control several functions at the same time. This allows the operator

to be more productive and remain comfortable throughout the work shift.

Intuitive Steering Control. The 140M introduces a breakthrough in joystick steering control. This technology creates a direct relationship between the lean angle of the joystick and the turning angle of the steer tires.

A brake tensioning system holds the joystick in position until the operator moves it. In addition, the steering control automatically reduces steering sensitivity at higher ground speeds for comfortable and predictable control.

Electronic Throttle Control. Electronic Throttle Control (ETC) provides the operator with easy, precise, and consistent throttle operation. An automatic and manual mode on a single switch offers flexibility for different applications and operator preferences.

6

7

1 |

|

1 |

7

4 6 4

3

6

5

2

Left Joystick Functions. The left joystick primarily controls the machine direction and speed.

1 – Steering: Lean joystick left and right

2 – Articulation: Twist joystick left and right

3 – Articulation Return to Center: Yellow thumb button

4 – Wheel Lean: Two black thumb buttons

5 – Direction: Index trigger shifts transmission to forward, neutral or reverse

6 – Gear Selection: Two yellow thumb buttons upshift and downshift

7 – Left moldboard lift cylinder: Push joystick to lower, pull joystick to raise

–Left moldboard lift cylinder float: Pushing joystick through detent engages float

Articulation Return-to-Center.

This exclusive feature automatically returns the machine to a straight frame position from any articulation angle with the touch of a single button. Return-to-Center helps improve productivity and safety by allowing the operator to focus on controlling the moldboard.

Right Joystick Functions. The right joystick primarily controls the Drawbar, Circle and Moldboard functions.

1 – Right moldboard lift cylinder: Push joystick to lower, pull joystick to raise

–Right moldboard lift cylinder float: Pushing joystick through detent engages float

2 – Moldboard slide: Lean joystick left and right

3 – Circle turn: Twist joystick left and right

4 – Moldboard tip: Thumb switch fore and aft

5 – Drawbar center shift: Thumb switch left and right

6 – Electronic Throttle Control: Trigger switch is resume and decrement

7 – Differential Lock/Unlock:

Yellow button

1

2

1 – Ripper Control Pod. Infinitely variable roller switches control the rear ripper and/or front lift group (when equipped), for easy and comfortable control.

2 – Programmable Auxiliary Hydraulic Pod. Four fingertip controls and a mini joystick maximize hydraulic control flexibility, accommodating up to six hydraulic circuits. Individual functions are easily programmable through Cat ET to meet the configuration you need.

The optional auxiliary hydraulic pod is provided when the machine is configured with three or more auxiliary functions.

7

Structures, Drawbar, Circle and Moldboard

Durable structures with fast and simple DCM adjustments deliver precise material control while lowering operating costs.

Front Frame Structure. The 140M front frame is a formed structural carbon steel tube. Advanced fabrication technology significantly reduces the number of weld joints, which more evenly distributes stress loads. The result is a robust machine that delivers the durability

you expect from Caterpillar.

Rear Frame Structure. The box-sectioned hitch design helps resist torsion loads and ensure structural durability. The integrated bumper ties the rear frame together as

a single, solid unit, so the frame can withstand heavy-duty applications such as ripping and winging snow.

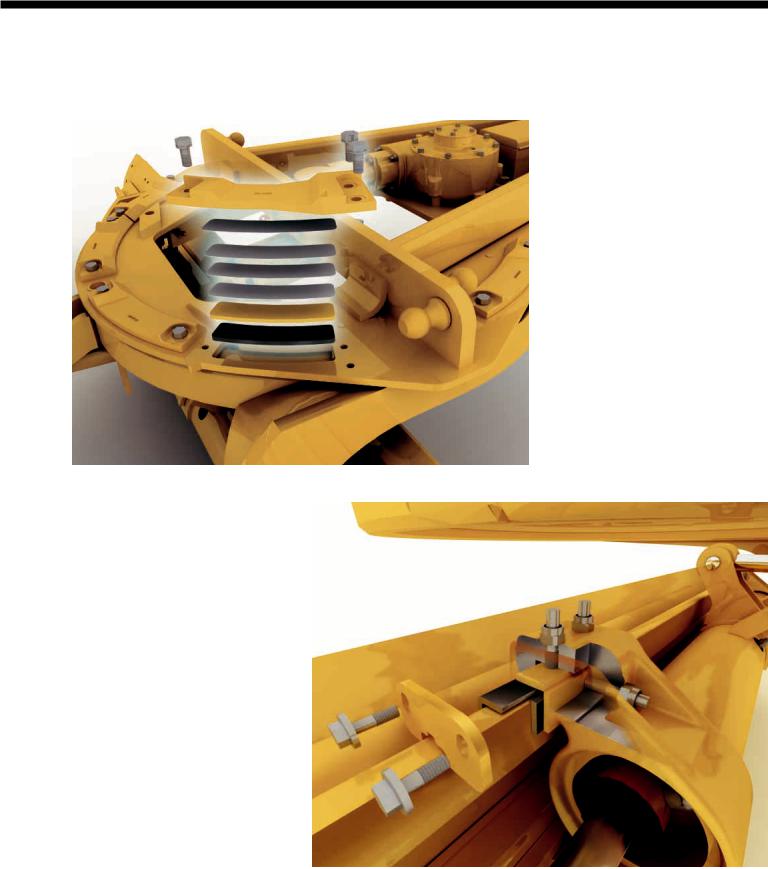

Articulation Hitch. A large tapered roller bearing at the lower pivot carries loads evenly and smoothly. This joint is sealed to prevent contamination

in this critical area.

A mechanical locking pin prevents frame articulation to help ensure safety when servicing or transporting the machine.

Circle Construction. Our one-piece forged steel circle is built to stand up to high stress loads and provide structural durability. The front 240° of circle teeth are hardened to reduce wear and ensure component reliability.

Drawbar Construction. The A-frame drawbar features a tubular design for high strength and optimum durability.

Aggressive Blade Angle. With a long wheelbase the operator can obtain aggressive moldboard angles, so material rolls more freely along the length of the blade. This is particularly helpful when handling very dry materials or cohesive soils. Better material control gets the job done faster, requires less power and saves fuel.

8

Top-adjust drawbar wear strips

Top-Adjust Drawbar Wear Strips.

The patented top-adjust wear strips dramatically reduce drawbar/circle adjustment time. By removing the access plates on top of the drawbar, shims and wear strips can easily be added or replaced. This feature reduces service downtime and lowers overall machine operating costs.

Replaceable Wear Inserts.

Tough, durable nylon composite wear inserts reduce rotational friction for maximum circle torque and longer component life. They are located between the drawbar and circle, and between the support shoes and circle. High loadresistant brass wearstrips are placed between the blade mounting group and moldboard. This sacrificial wear system can be replaced easily and helps keep components tight for fine grading.

Moldboard. The optimal curvature and large throat clearance help move material quickly and efficiently. Heat-treated moldboard rails, hardened cutting edges and end bits, and large diameter bolts assure reliability and longer service life. The moldboard side shift cylinder is positioned on the left side to eliminate snow wing interference.

Moldboard Positioning. The blade link bar design extends the possibilities for moldboard positioning, most beneficial in mid-range bank sloping and in ditch cutting and cleaning.

Shimless Moldboard Retention System.

The unique shimless moldboard retention system reduces the potential for blade chatter. Vertical and horizontal adjusting screws keep the moldboard’s wear strips aligned for precise blade control and dramatic reductions in service time.

Shimless moldboard retention system with adjusting screws

9

Loading...

Loading...