Milton CAT 980H User Manual

980H ®

Wheel Loader

Engine |

|

|

Weights |

|

|

|

|

|

Engine Model |

Cat® C15 ACERT™ |

Operating Weight |

|

30 519 kg |

67,294 lb |

|||

Gross Power – SAE J1995 |

293 kW |

393 hp |

• For 5.7 m3 |

(7.5 yd3) general purpose bucket with BOCE |

||||

Net Power – ISO 9249 |

260 kW |

349 hp |

Operating Specifications |

|

|

|||

• Caterpillar® engine with ACERT Technology – EPA Tier 3, |

Static Tipping Load, Full Turn |

19 496 kg |

42,989 lb |

|||||

EU Stage III Compliant |

|

|

• For 5.7 m |

3 |

3 |

) general purpose bucket with BOCE |

||

Buckets |

|

|

|

(7.5 yd |

||||

|

|

|

|

|

|

|

|

|

Bucket Capacities |

3.8-6.1 m3 |

5.0-8.0 yd3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

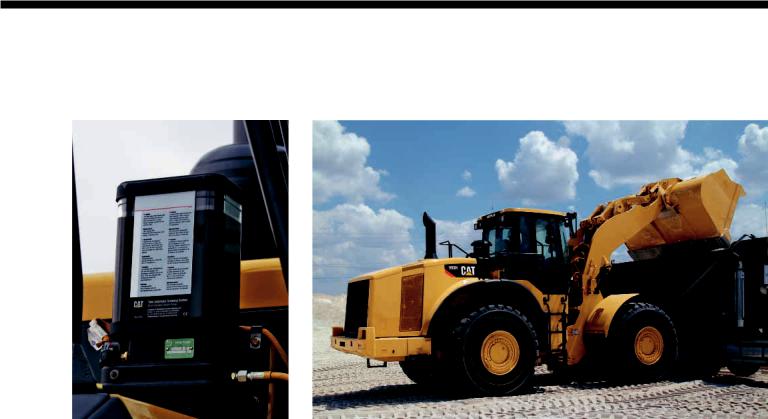

980H Wheel Loader

The new standard for midsize wheel loaders.

Reliability |

Durability |

Productivity |

• Proven Technologies |

• Structures Built To Last |

• Consistent Level Of Power |

• Dealer Support You Can Count On |

• Proven Planetary Transmission |

• Standard And Optional Features |

• Unmatched Parts Availability |

• C15 Engine With ACERT™ |

To Increase Productivity pg. 8 |

|

||

• Extensive Rebuild Program |

Technology |

|

|

|

|

• Exceptional Service Capabilities pg. 4 |

• Integrated Systems pg. 6 |

|

|

|

Serviceability

•Simple, Easy Daily Maintenance

•Minimal Downtime For Service

•Detect Problems Before They Happen

•Complete Customer Support pg. 16

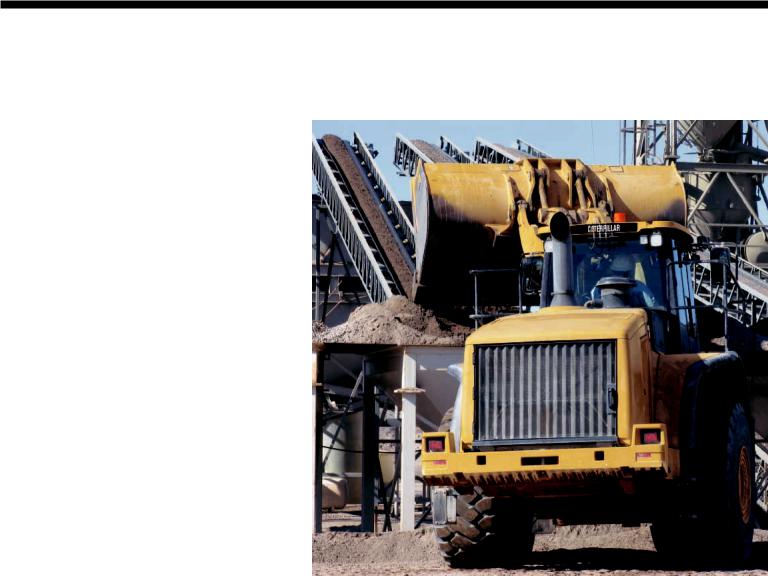

Performance you can feel with the capability to work in the most demanding applications. Unmatched operator comfort and efficiency in a world class cab. Revolutionary electronics and hydraulics for low-effort operation.

Increased productivity with lower owning and operating costs.

2

Versatility |

Operator Comfort |

Owning and Operating Costs |

|

• Customize The 980H For Your |

• Quiet, Comfortable Cab |

• Proven Fuel Efficiency |

|

Operation |

• Easy Entry And Exit |

• Simple, Convenient Maintenance |

|

|

|||

• Large Variety Of Cat® Work Tools |

• Excellent Visibility |

• Unsurpassed Parts Availability |

|

|

|||

• Machine Arrangements For |

• Reduced Operator Effort |

• Excellent Resale Value |

|

Specialized Applications pg. 10 |

|||

• Comfortable Seating pg. 12 |

|

||

|

• Financing Tailored To Your Operation |

||

|

|

pg. 14 |

3

Reliability

The Cat® 980H midsize loader – ready to work any time, any season.

•Proven technology that provides reliability from day one

•Cat design and manufacture of systems that work together as a unit

•Excellent uptime provided by the best dealer support network in the industry

•Unmatched genuine Cat parts availability

•Outstanding Cat dealer service capabilities on your job site or in the dealer shop

Proven Technology. The Cat 980H is built on the legendary 980 platform. Many of the systems designed for and proven on the 980G Series II and previous models are still in use today for the 980H. Planetary powershift transmission, cab, separated cooling system, integrated braking system, free wheel stator torque converter, frames – all contribute to the proven reliability of the 980H.

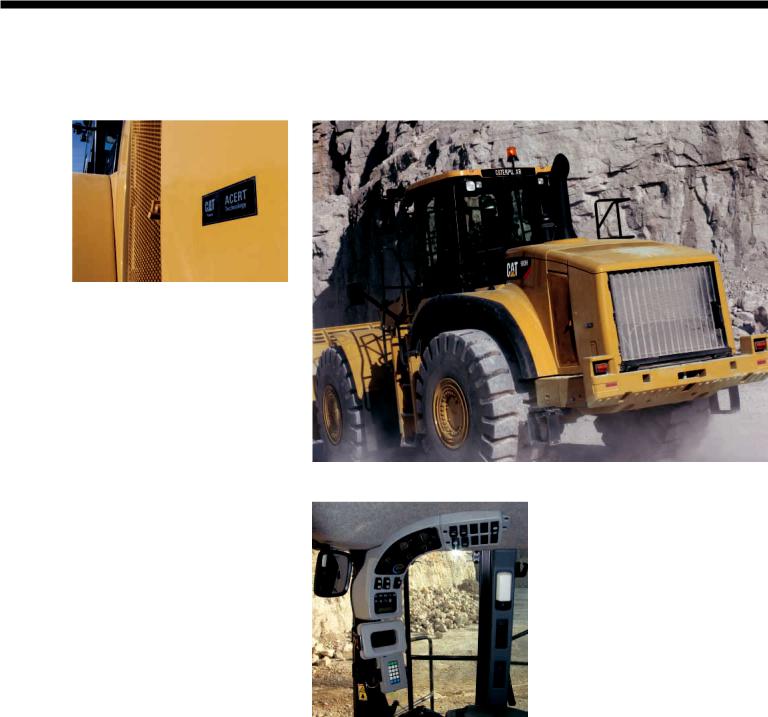

ACERT™ Technology. ACERT Technology has been proving itself in on-highway trucks since March 2003, and more recently in field tests of off-highway equipment. This technology allows Cat engines to meet durability and reliability expectations without sacrificing fuel economy or performance.

Dealer Support. The first priority of the Caterpillar® dealer is to keep your loader up and running when you need it. The entire global network of 206 independently-owned Cat dealers is the best in the world at distributing parts and equipment. They are there when and where you need them.

Parts Availability. Caterpillar provides an unsurpassed level of personalized service for your wheel loader.

With 23 parts distribution centers in 11 countries, most parts can be delivered in 24 hours.

All parts supplied by Caterpillar are manufactured to original equipment specifications. Retrofit kits are available to update machines to current technology. Cat Classic™ Parts for older machines are specially made to Cat specifications at a lower cost.

All parts to repair your machine – batteries, seals, filters, fluids, hydraulics, engine parts – are designed and manufactured to work together efficiently and effectively as a system.

Remanufactured Parts. Cat engines and major components are designed to be remanufactured and provide multiple life cycles. The Cat Reman program

is more extensive than most rebuild programs. Components are actually remanufactured in the factory to original specifications with necessary product updates.

Strict reuse guidelines and unparalleled quality control ensure that reman products provide the reliability and durability that you expect from Caterpillar. Reman products are stocked in distribution centers around the world and are ready to install to minimize downtime, maintain productivity and profitability.

Service Capabilities. Need routine maintenance or unplanned repair? Cat field service technicians have the

experience and tools necessary to service your loader on site. Field service trucks are fully loaded with state-of-the-art tools and diagnostic equipment as well as specifications and schematics for every Cat machine. Technical experts at the dealer shop and at Caterpillar provide assistance to every field service technician.

When on-site repair isn’t enough, Cat dealer shops are fully-equipped to service your loader quickly.

4

Dealer Support Programs. Caterpillar dealers support you with a variety of programs from financing a purchase to complete after-sale support.

•Purchase/Lease/Rent

•Caterpillar Insurance

•Investment Options

•Cat Equipment Training

•Customer Support Agreements

•S•O•SSM Services

Purchase, Lease or Rent? Your Cat dealer can help you decide the best acquisition options for your operation. They can help you calculate owning and operating costs and how the available financing options can contribute to your bottom line.

5

Durability

Durability built in, not added on.

•Strong, solid structures built to last

•Major components designed and manufactured to provide long hours of use and to be rebuilt for additional life

•Cat C15 engine with ACERT Technology maintains engine performance, efficiency and durability while reducing emissions

•Improved hood strength and faster lift and lower times

•Main ladder integrated into side of machine to protect steps from debris build-up

Structures. The 980H retains the same basic structures as the 980G Series II. Full box section engine end frame absorbs shock loads and twisting forces while supporting the drive line for rigid component alignment. The frame is over 90 percent robotically welded providing deep weld penetration for maximum durability and fatigue strength.

The non-engine end frame provides a solid base for the front axle, lift arms and tilt cylinders. The fabricated four-plate loader tower resists shock loads and loading stresses.

Lift arms are solid steel, providing superior strength, excellent dump clearance and reach while maintaining visibility to the bucket. The cast steel cross tube is heat treated for maximum resistance to torsion and impact loads. Z-bar linkage generates exceptional breakout forces and good rack back angle for better bucket loading and material retention.

The spread hitch design of the 980H articulation joint reduces stress loads on the hitch pin and roller bearings for long service life.

New Hood. A new hood has been designed for the 980H. Two layers thick, the new hood provides improved durability while maintaining visibility to the ground. The reinforced hood is more resistant to wind and mud build-up. The actuation system has also been improved. Electrohydraulically activated twin lift cylinders significantly reduce lift and lower time.

New Ladder. The ladder on the 980H is integrated into the side of the machine. The self-cleaning steps are protected from debris build-up. A five-degree incline allows easy entry and exit to the cab.

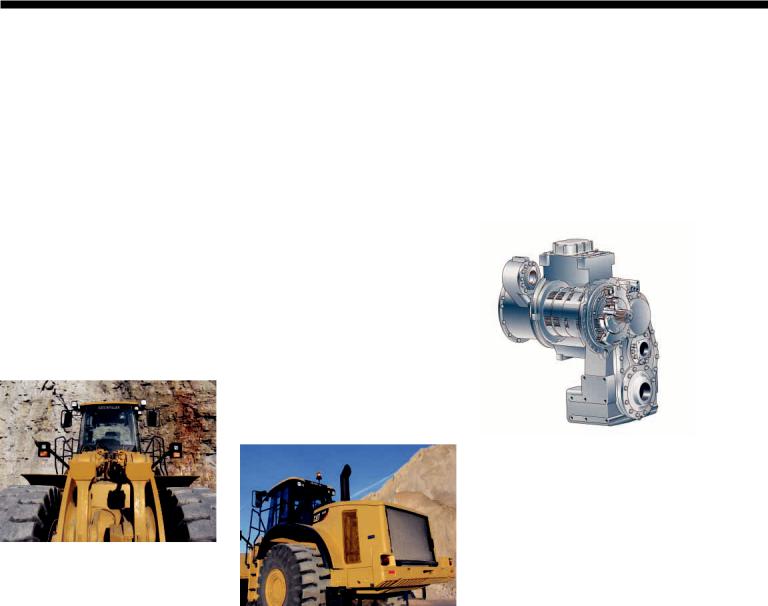

Powershift Transmission. The 980H is equipped with a transmission that has proven itself for over 40 years. And the addition of the Electronic Clutch Pressure Control (ECPC) system adds a new level of durability to the transmission.

ECPC modulates clutch engagement individually to allow smoother speed and directional shifts and provide longer component life than the transmission in the 980G Series II.

6

Engine. ACERT Technology combines proven systems with innovative new technologies to precisely deliver fuel

to the combustion chamber. It maintains engine performance, efficiency and durability while dramatically reducing emissions.

The C15 engine used in the 980H has a strong track record of reliability, durability and power density in both

off-highway equipment and on-highway trucks. In fact, millions of reliable road miles have garnered it the J.D. Power & Associates award for customer reliability. The robust design of the C15 required very few modifications to accommodate the higher cylinder pressures associated with ACERT Technology.

Although ACERT Technology itself is new, much of the componentry is the same as used in previous engines. Electronic controllers are the brains of ACERT Technology. The advanced

electronic controllers used in Cat engines were first introduced in the early 1990s and have a proven track record of performance and reliability.

The C15 engine features the Cat Mechanically Actuated Electronic Unit Injection (MEUI) fuel system. The MEUI fuel system is a highly evolved system with proven reliability and durability in the field.

Integrated Systems. The Caterpillar Monitoring System (CMS) tracks critical machine systems to alert the operator to potential need for service. Three levels of warning allow the operator to assess the situation more accurately. CMS is tied to the engine, transmission, hydraulics and brakes – connecting all major systems allows the loader to work as

a fully integrated system – from the linkage to the engine.

7

Productivity

Move more material.

•Transmission features that optimize machine performance

•Engine maintains a consistent level of productivity

•Standard and optional features that increase productivity

Autoshift. Choose between manual or automatic shift modes in the cab.

This flexible feature increases operator efficiency and optimizes machine performance.

Variable Shift Control (VSC). Match transmission shifting patterns to machine applications requirements. Variable Shift Control improves shift quality and fuel efficiency in certain applications by allowing the transmission to upshift at lower engine RPMs.

Engine Idle Management System (EIMS).

Four idle control settings help maximize fuel efficiency and provide flexibility in managing idle speeds based on application requirements.

Hibernate Mode allows idle speed to drop after a preset time to provide lower fuel consumption, reduced sound and emissions.

Work Mode provides flexibility in working engine idle speeds.

Warm Up Mode is designed to keep the machine consistently warm in cold conditions.

Low Voltage Mode prevents battery drain due to high electrical loads from attachments.

980H with On-Demand Fan and Electronic Engine

GROSS

NET

Horsepower

Min fan |

Max fan |

Min fan |

speed |

speed |

speed |

|

Fan Speed |

|

Constant Net Horsepower. The engine automatically compensates for parasitic loads, like the fan and air conditioner, to maintain a consistent level of productivity.

Command Control Steering. Reduce steering movements by a factor of 14 with Command Control Steering as compared to conventional steering.

A conventional steering wheel requires two to three 360° turns to complete one turn of the loader – the Command Control wheel moves ±70° with only 26 N (6 lb) steering pressure to complete a turn – reducing operator fatigue.

Ride Control. The optional Ride Control System improves ride, performance and load retention when traveling over rough terrain. Operators gain confidence moving at higher speeds in load and carry operations decreasing cycle time

and increasing productivity.

Payload Control System. Scales, designed specifically for Cat machines, are built into the lift arms to allow on-the-go weighing of material in the bucket. Operators load trucks more accurately and efficiently. Loading trucks right the first time equates to quicker cycles for the operator, increased efficiency at the scale house and more productivity for your operation.

Payload Control is available as a factory-installed option. A printer is also available for printing driver tickets and a variety of reports.

8

Autolube. The optional Caterpillar Autolube System provides precise, automatic lubrication of pins and bushings – during loader operation. Automatic lubrication reduces time spent on daily maintenance and downtime for unplanned repairs due to inadequate greasing – improving productivity.

Aggregate Autodig. Well-received by both experienced and novice operators, the optional Aggregate Autodig is available to automate the loading process. Operators get consistently full payloads without touching the controls.

9

Loading...

Loading...