Milton CAT CS-423E User Manual

CS-423E CS-433E CP-433E

Vibratory Soil Compactors

|

CS-423E |

CS-433E |

CP-433E |

|||

Gross Power |

62 kW |

83 hp |

75 kW |

100 hp |

75 kW |

100 hp |

Operating Weight (with ROPS/FOPS) |

6745 kg |

14,875 lb |

6745 kg |

14,875 lb |

7145 kg |

15,750 lb |

Compaction Width |

1676 mm |

66" |

1676 mm |

66" |

1676 mm |

66" |

Centrifugal Force |

|

|

|

|

|

|

High |

134 kN |

30,000 lb |

134 kN |

30,000 lb |

134 kN |

30,000 lb |

Low |

67 kN |

15,000 lb |

67 kN |

15,000 lb |

67 kN |

15,000 lb |

|

|

|

|

|

|

|

CS-423E Soil Compactor

The CS-423E Soil Compactor provides high compaction performance in the most cost-effective way. Designed for efficiency, while minimizing operating costs, the CS-423E features a Caterpillar® 3054C engine rated at 62 kW (83 hp). The CS-423E will meet your smooth drum compaction needs in the majority of applications.

Vibratory System

A pod-style weight housing ensures peak vibratory performance and minimal service. The pod is replaceable and features bearing lubrication change intervals of 3 years/3000 hours.

Page 4

Gradeability and Machine Control

The exclusive dual pump propel system provides a separate balanced hydraulic flow to both the rear drive axle and the front drum drive motor. This system enables the operator to achieve unmatched gradeability and maintain machine control while compacting on a grade or using the optional leveling blade. Dual pumps also minimize drum and wheel spin-out in low traction conditions.

Page 6

Productivity and reliability you can depend on.

Durable, field-proven powertrain and vibratory systems along with the world’s largest and most dedicated dealer support system ensure the 400E-Series Soil Compactors will provide maximum utilization. With exceptional productivity and reliability, the 400E-Series Soil

Compactors provide everything you expect from a

Caterpillar machine and more!

Operator’s Station

The 400E-Series Soil Compactors feature exceptional operator comfort and visibility. A propel lever wrist rest, grouped control gauges and conveniently located control switches enhance operator productivity and reduce operator fatigue. Four heavyduty isolation mounts provide a smooth ride. Standard rearview mirrors, two front-facing and two rear-facing working lights are provided. Machines with the open ROPS/FOPS platform are surrounded by handrails and features foot rests for sure footing when working on a grade.

Page 7

2

CS-433E and CP-433E Soil Compactors

The CS-433E and CP-433E Soil Compactors provide maximum productivity and versatility for both smooth and padfoot drum applications. Powered by the turbocharged, 75 kW

(100 hp) Caterpillar 3054C engine, these machines provide exceptional compaction performance in demanding applications.

Visibility

The one-piece sloped hood design provides exceptional operator visibility to the outside edge of the rear tires and to the rear of the machine.

Page 6

Cab

The cab on the 400E-Series Soil Compactors is engineered to provide the operator unparalleled viewing area and comfort. Integrated, factory installed air conditioning is optional. The cab may be an option in some areas and standard in others. Consult your dealer for specifics.

Page 8

Versatility

An optional two-piece padfoot conversion kit (for the CS models only) expands the application range to work in either cohesive or semi-cohesive materials. Simple changing procedure minimizes your conversion time.

Page 8

An optional foot-controlled leveling blade for the CS-433E and CP-433E increases machine utilization to tackle backfilling, material knockdown and light dozing applications.

Page 9

Serviceability

The one-piece fiberglass hood tilts forward to allow access to the engine and daily maintenance points. Daily check points are accessible from ground level. Sealed-for-life bearings in the articulation hitch never need to be greased. The operator’s station tilts forward to provide access to the hydraulic pumps. The engine lubrication change interval is 500 hours.

Page 10

Comfort and serviceability you deserve.

The operator’s station provides a spacious and comfortable work environment that allows simple and productive operation. Excellent service access and long service intervals minimize maintenance time and increase productive work time.

3

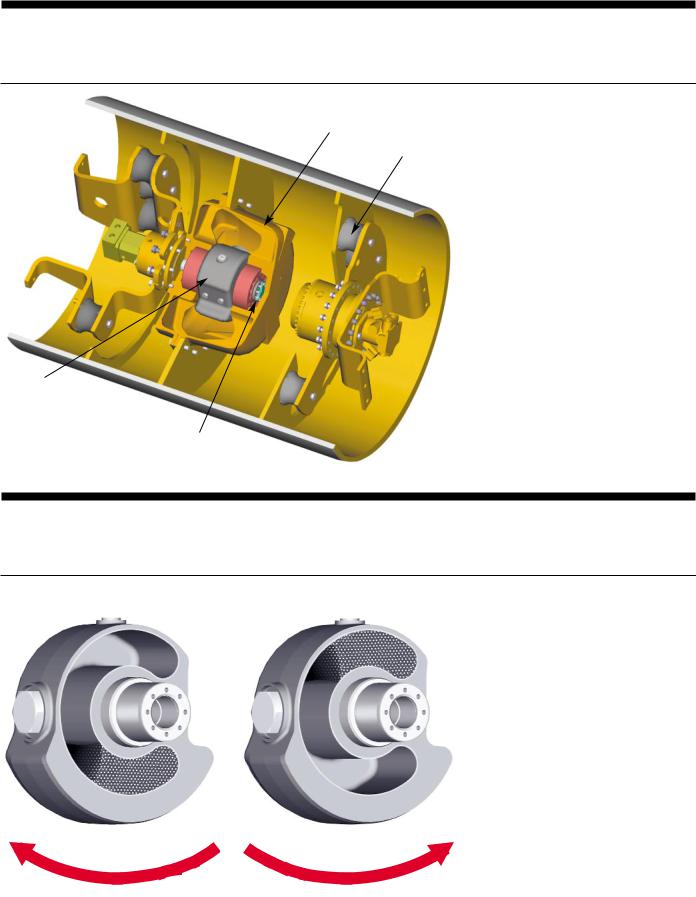

Vibratory System

The pod-style vibratory system delivers superior compactive force while offering serviceability advantages.

b

e

|

c |

|

|

1 |

Pod-style Weight Housing |

|

|

2 |

Proprietary Eccentric Weight |

d |

|

3 |

Heavy-duty Bearings |

||

|

|||

4 |

Isolation Mounts |

|

Pod-style weight housing is assembled and sealed at the factory to ensure cleanliness, longer bearing life and easier field exchange or service.

Dual amplitude works efficiently in a wider range of applications. Selection is controlled from the operator’s station.

Vibratory frequency of 31.9 Hz (1914 vpm) for maximum compaction results. Optional variable frequency control allows frequency to be better matched to varying job conditions.

Large heavy-duty bearings for the eccentric weight shaft designed for high compactive forces.

3 year/3000 hour vibratory bearing lube service interval reduces maintenance.

Heavy-duty isolation mounts allow more force to be transmitted to the ground and less vibration to the drum yoke.

Proprietary Eccentric Weights

Reliable dual amplitude selection and innovative design ensure precise performance.

High Amplitude |

Low Amplitude |

Positive amplitude selection is |

|

|

accomplished when the steel shot is |

|

|

repositioned inside the hollow eccentric |

|

|

weight. Direction of weight shaft |

|

|

rotation determines amplitude level. |

|

|

Simplified control from the operator’s |

|

|

station with a selection switch on the |

|

|

operator’s console. |

|

|

High reliability since there is no chance |

|

|

of the high-strength spherical steel shot |

|

|

wedging together. System reliability is |

|

|

superior to swinging mechanical |

|

|

weights and is also quieter during starts |

|

|

and stops. |

|

|

Long service life. No heavy weights to |

|

|

slam together, no metal fragments to |

|

|

contaminate the bearing lubrication |

|

|

system. |

4

Caterpillar 3054C Series Diesel Engine

High-tech four cylinder engine provides outstanding durability, performance, reliability and operating economy.

The CS-433E and CP-433E are turbocharged for top performance and efficiency even at high altitudes with no derating required up to 3000 m (9840 ft).

The CS-423E is naturally aspirated.

Adjustment-free direct injection fuel system provides individually metered high-pressure, direct injection of fuel for maximum efficiency.

Large engine oil cooler reduces oil deterioration and varnishing of internal components. Allows for 500 hour engine oil change intervals.

Low-mounted oil pump for quicker start-up lubrication.

Combination fuel filter and water separator offers superior protection for the fuel injection system.

Engine meets U.S. EPA Tier 2 and European EU Stage II emissions control standards worldwide.

Dual Pump Propel System

High tractive effort and gradeability for outstanding productivity and machine control in demanding environments.

b |

c

e

d |

1 Dual Propel Pumps

2 Caterpillar 3054C Engine

f 3 Limited Slip Differential

4 Rear Wheel Drive Motor

5 Drum Drive Motor

Dual propel pumps provide separate, balanced hydraulic flow to the rear wheel axle and the drum drive motors. Provides high gradeability and increases tractive effort in loose or poor underfoot conditions.

Limited slip differential provides balanced tractive effort and smooth torque transfer to both rear wheels.

Two speed ranges for versatile operation. Low speed range for vibratory operation and maximum torque when climbing grades. High speed range moves machine quickly over longer distances.

Flushing valves in each propel circuit help keep hydraulic oil cool and clean for maximum system efficiency.

5

Loading...

Loading...