Milton CAT D8T User Manual

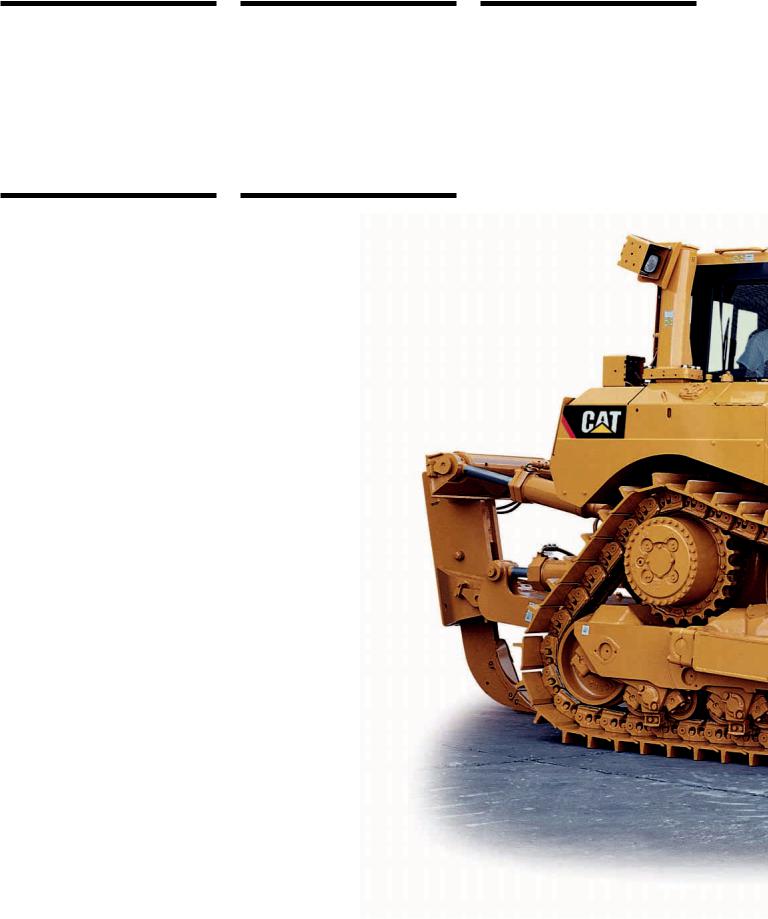

D8T ®

Track-Type Tractor

Engine

Engine Model |

Cat® C15 ACERT |

|

Gross Power |

259 kW |

347 hp |

Flywheel Power |

231 kW |

310 hp |

Weights |

|

|

Operating Weight |

38 488 kg |

84,850 lb |

Shipping Weight |

29 553 kg |

65,152 lb |

•Operating Weight: Includes hydraulic controls, blade tilt cylinder, coolant, lubricants, 100% fuel, ROPS, FOPS cab, SU-Blade, Single-Shank Ripper, 560 mm (22 in) MS shoes, and operator.

•Shipping Weight: Includes coolant, lubricants, 20% fuel, ROPS, FOPS cab, and 560 mm (22 in) MS shoes.

D8T Track-Type Tractor

Strength from the past. Power for the future.™ The D8T combines power and efficiency with advanced technology for outstanding production at a lower cost-per-yard.

C15 Engine with ACERT® Technology |

Operator Station |

Implement and Steering Controls |

ACERT Technology works at the point of combustion to optimize engine performance and provide low exhaust emissions. Matched with the torque divider and power shift transmission, it provides years of dependable and efficient service. pg. 4

Integrated Electronic Solutions

Caterpillar offers technology options such as Product Link and AccuGrade® Grade Control System that provide greater accuracy, higher productivity, lower operating costs and more profitability. pg. 12

Designed for operator comfort, convenience, and productivity. Machine control and vital information is provided at the operator’s fingertips. A full day of work is no problem in this efficient work place. pg. 6

Work Tools

Various bulldozer blades, rippers, winches, and other options allow you to adapt the D8T to match your specific application, making you more productive. pg. 14

Engineered for demanding work.

The durable construction of the D8T is well suited for tough working conditions. Combined with the C15 engine for superior performance, fuel economy and meeting emission targets with the help of ACERT Technology, it keeps material moving with the reliability and low operating costs you expect from Cat tractors.

Electro-hydraulic implement controls allow low operator effort for dozing and ripping. Steering and gear selection in a one-hand control system enhances operator comfort. pg. 8

2

Drive Train

The electronically controlled power shift transmission, efficient differential steering and durable planetary final drives deliver outstanding power transfer and long life to ensure maximum productivity. pg. 9

Undercarriage |

Structure |

The proven elevated sprocket undercarriage isolates the drive train components from ground-induced impacts. The suspended undercarriage puts more track on the ground for higher traction and less track slip.

It absorbs shocks for a smoother ride and longer machine life. pg. 10

Mainframe is heavy, strong and durable. Full box sections, steel castings and continuous rolled rails provide durable support to the suspended undercarriage, elevated final drives and other integral frame components. pg. 11

Serviceability and Customer Support

Combining easy to access, modular components with your Caterpillar® Dealer’s advanced rebuild and repair capabilities ensures rapid component replacement and minimum downtime. pg. 15

New Feature

3

C15 Engine with ACERT® Technology

A combination of innovations working at the point of combustion, ACERT Technology optimizes engine performance while meeting EPA Tier 3 and EU Stage IIIa engine exhaust emission regulations for off-road applications.

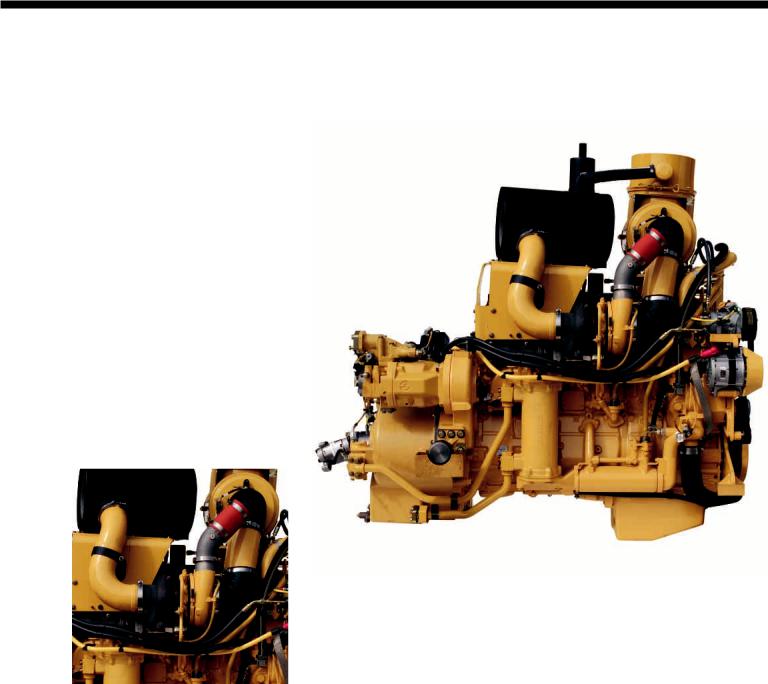

C15. Performing at full-rated net power of 231 kW (310 hp) at 1,850 rpm, the large displacement and high torque rise allow the D8T to doze through tough material. Matched to the high-efficiency torque divider and electronically controlled power shift transmission,

it will provide years of dependable service.

Constant Net Horsepower. Constant net horsepower allows the operator to maintain high standards of performance and response, even when parasitic loads, such as the on-demand cooling fan,

are applied. The engine automatically adjusts to maintain power output and conversely lowers output when demands are low. This converts to a fuel savings in cooler climates.

C15 Block. The one-piece, grey iron block features generous ribbing for stiffness and heavy bearing bulkheads for rigidity and strength. Incorporation of straight o-ring connection points reduces the loss of engine oil and fluids.

ADEM™ A4 Engine Controller.

The ADEM A4 electronic control module manages fuel delivery to get the best performance per gallon (liter) of fuel used. It provides flexible fuel mapping, allowing the engine to respond quickly to varying application needs.

It tracks engine and machine conditions while keeping the engine operating at peak efficiency.

Fuel Delivery. Multiple injection fuel delivery involves a high degree of precision. Precisely shaping the combustion cycle lowers combustion chamber temperatures generating fewer emissions and optimizing fuel

combustion; translating into more work output for your fuel cost.

4

MEUI Fuel System. A highly evolved fuel system with a proven record of reliability in the field. MEUI combines the technical advancement of an electronic control system with the simplicity of direct mechanically controlled unit fuel injection. The MEUI system excels in its ability to control injection pressure over the entire engine operating speed range. These features allow the C15 to have complete control over injection timing, duration, and pressure.

ATAAC and Airflow. Air-to-air aftercooling keeps air intake temperatures down and, in concert with the tight tolerance combustion chamber components, maximizes fuel efficiency and minimizes emissions. Significant improvements in air flow are generated by a water-cooled turbocharger, unique cross-flow head and single overhead cam.

Turbocharging and Air-to-Air Aftercooling. Provides high horsepower with faster response time while keeping intake temperatures low for long hours of continuous operation.

Service. Easier maintenance and repair through monitoring key functions and logging critical indicators. Electronic diagnostic access is possible with a single tool, the Cat Electronic Technician.

5

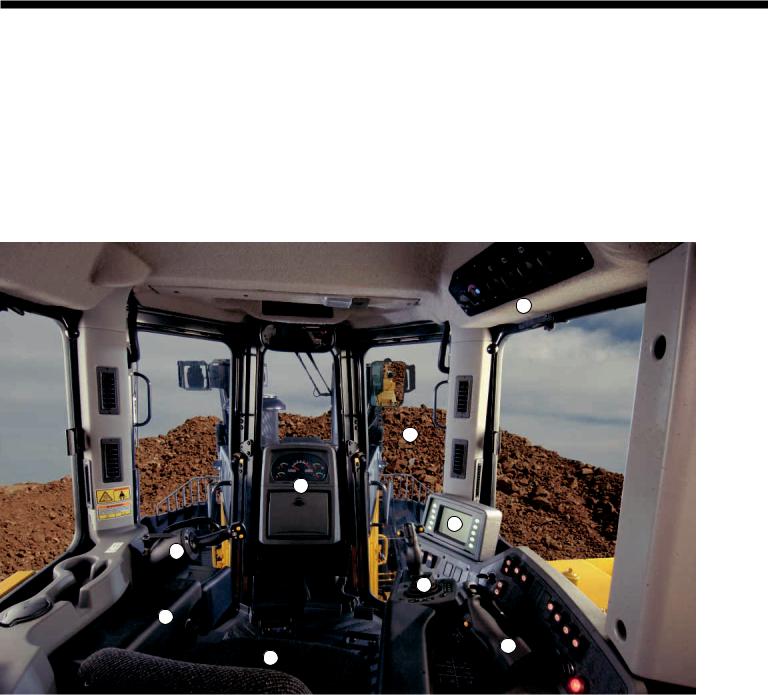

Operator Station

Designed for operator comfort, convenience, and productivity, the state-of-the-art cab sets a new standard.

8

7

6

6

1

5

3

4

2

6

1)Steering Control. Dual-twist tiller control with standard differential steering controls direction and degree of turns, forward-reverse shifting, and gear selection in a single control handle— enhancing operator comfort.

2)Cat Comfort Series Seat.

Fully adjustable and designed for comfort and support. Thick seat and back cushions provide support for the lower back and thighs, while allowing unrestricted arm and leg movement. Wide retractable seat belt provides positive and comfortable restraint.

3) Adjustable Armrests. Standard adjustable armrests provide additional comfort for the operator.

4) Electronic Ripper Control. A rigidly mounted handgrip, with low effort thumb and finger controls, provides firm support and positive control of the ripper when operating in tough conditions. Programmable features, such as Auto Lift, Shank-Out and Auto Stow, increase efficiency for the operator.

5)Electronic, Programmable Dozer Control. Features such as blade response, blade float, auto blade pitch, and spread rate can be set and adjusted using the Advisor panel. Auto Blade Assist and AutoCarry options make the tractor even more efficient in specific applications.

6)Cat Monitoring Display System.

The combination dash mounted instrument cluster and the Advisor Monitoring System provide key machine operating information and give the operator and service technician insight into the machine’s operation and maintenance needs.

In-Dash Instrument Cluster.

The instrument panel, with easy to read gauges and warning lamps, keeps the operator aware of any potential problems. All gauges and readouts are easily visible in direct sunlight.

Advisor Monitoring System (AMS).

On-board diagnostic abilities minimize downtime and maximize machine performance.

7) Wide Panoramic View. The operator station offers an exceptional viewing area. A large view hole in the singleshank ripper frame provides a view of the ripper tip. The tapered hood, notched fuel tank and narrow single-shank ripper carriage give the operator a clear line of sight to the front and rear work areas. The large single-pane door windows provide an excellent view to the sides and blade.

8) Heating and Air Conditioning.

Conveniently located air circulation vents evenly distribute airflow within the cab. Controls are easily accessible from the operator seat.

Fuse Panel and Diagnostic Access.

The new compartment features a single location fuse panel that includes a diagnostic port for the Cat ET to connect for rapid machine diagnostics.

Comfortable Operation. Standard isolation-mounted cab reduces noise and vibration. The cab is pre-wired for a 12-volt or 24-volt radio, equipped with two speakers, an antenna and a radio mount recessed in the headliner.

7

Implement and Steering Controls

Low effort control functions significantly reduce operator fatigue for increased performance.

Dozer Control Lever. A low-effort, electronic dozer control handle gives the operator control of all dozer functions with one hand. Fore/aft movement of the lever lowers and raises the blade. Left/right movement directionally tilts the blade. When equipped with the optional Dual Tilt feature, the thumb lever at the top of the handle controls blade pitch fore and aft. The trigger switch toggles between single and

dual tilt.

The left and right side thumb buttons provide control over the semi-automated blade pitch functions, that the Dual Tilt attachment provides. Blade pitch for load, carry and spread segments can

be preset on Advisor and controlled by the buttons. The left side button cycles between the pitch settings for each segment of the push cycle. The right side button cancels out of the pitch functions without loosing the preset pitch angles. This Auto Blade Assist (ABA) feature is turned on and off using a switch on the right side console.

The two buttons also provide control over the AccuGrade™ blade control attachment when the machine is

so equipped. The buttons turn on AccuGrade, provide manual increment and decrement control, and turn off AccuGrade.

Auto Pitch. Presetting blade pitch angles for optimal performance during the dozing cycle: one setting each for load, carry, spread and return. Auto Pitch is activated on the Advisor keypad; the operator can select the dozing segment by pushing the yellow button on the left side of the dozer handle.

AccuGrade® Ready Option (ARO).

The AccuGrade Ready Option (ARO) provides a factory installed on-board platform for the AccuGrade GPS installation. All of the changes required to the electrical system, hydraulic system, blade, and cab are incorporated into the ARO. Mounting brackets added on the blade allow easy installation of the masts. Console mounting in the cab secure the in-cab display. Plug-in points inside the cab and on the front of the machine make it easy to install electronic components.

Computer Aided Earthmoving System (CAES) (optional). This on-board electronic site plan directs machine operators, in real-time, where to cut and fill. A graphical map of the design plan and a view of the machine’s horizontal and vertical position simplify operation and enhance production. This advanced information tool combines GPS technology (centimeter-level) and in-cab computing capabilities for precise grade and slope control. It has proven to provide measurable impact on work quality and overall productivity.

Ripper Control Lever. A rigidly mounted handgrip provides firm support for

the operator even when ripping in the roughest terrain. The low effort thumb lever controls raising and lowering.

The finger lever controls shank-in and shank-out positioning. The thumb button automatically raises the ripper.

Tiller Control System. A single lever, dual-control tiller controls machine speed, direction, and steering. The tiller allows the operator to work precisely in close areas, around structures, grade stakes, other machines and during fine grading work.

8

Loading...

Loading...