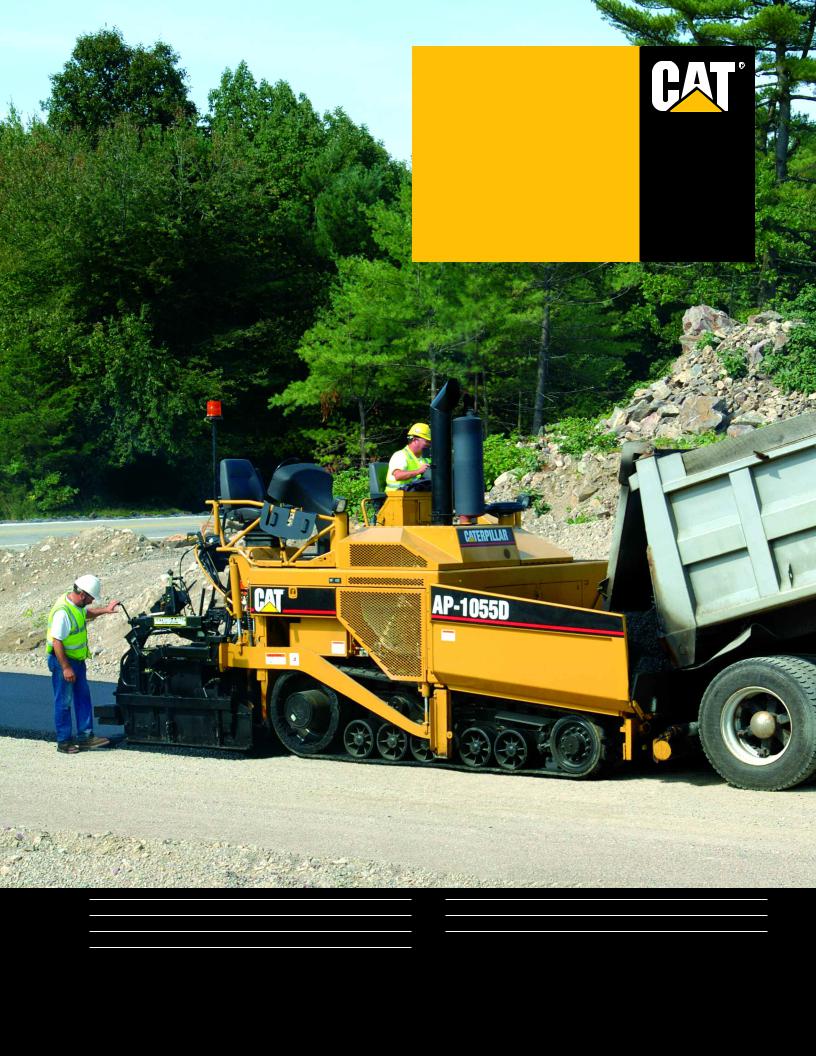

Milton CAT AP1055D User Manual

AP-1055D

Asphalt Paver

Cat® C7 Engine with ACERT® Technology

Gross Power (SAE J1995) |

167 kW (224 hp) |

Standard Paving Width |

3.05 m (10') |

Hopper Capacity |

6.1 m3 (13.2 tonne) |

|

215 ft3 (14.5 ton) |

Tractor Weight

AP-1055D with Mobil-trac™ |

17 601 kg (37,580 lb) |

AP-1055D with Steel Track |

16 601 kg (36,600 lb) |

Productivity and Reliability in a Durable Package

The AP-1055D Asphalt Paver with ACERT® Technology offers fuel efficiency, high performance, speed and job versatility to maximize productivity.

C7 Engine with ACERT®Technology

ACERT® Technology works at the point of combustion to optimize engine performance. ACERT® Technology incorporates an electronic controller to precisely deliver multiple injections of fuel. These multiple injections are combined with a refined air management system in order to generate fewer emissions and optimize fuel combustion while meeting U.S. EPA Tier 3 and E.U. Stage IIIa engine emission regulations. The C7 engine is a turbocharged, 6-cylinder diesel engine that provides 167 kW (224 hp) of gross power (SAE J1995) at

2200 rpm with a maximum torque of

872 N-m (643 ft/lb).

Page 4

High Capacity Cooling System

The high capacity cooling system performs efficiently in high ambient temperatures. The variable speed fan draws air across the engine compartment and exhausts it away from the operator and engine compartment in order to provide a cooler working environment for the tractor and screed operators.

Page 5

New feature

Dual Operator Stations

The AP-1055D incorporates dual operator stations that can be rotated to four different positions. The stations have fully equipped consoles with meter per minute (feet per minute) gauges, adjustable suspension seats, armrests and retractable seat belts. The operator stations can be positioned beyond the machine frame. Extending beyond the frame provides the operator with good visibility when paving wider than 3.05 m (10 ft). This is important when matching a joint or when working along existing structures where precise paving control is required.

Page 5

Undercarriage Selection

The AP-1055D can be purchased with either the Mobil-trac™ undercarriage or the steel track undercarriage. The Mobil-trac™ system combines the traction and flotation benefits of a crawler undercarriage with the mobility, speed, and ride characteristics of a wheel paver. The steel track undercarriage incorporates track rollers and a rear bogey system in order to provide a smooth ride.

Page 6, 7

Performance and reliability you can depend on.

Based upon the industry-proven reputation

Caterpillar® AP-1050B and AP-1055B Asphalt Pavers, the

AP-1055D establishes new standards for productivity and reliability in the asphalt paver industry.

Durable, field proven powertrain, propel system and material handling system along with the world’s largest and most dedicated dealer support system ensure the AP-1055D will provide maximum return on investment.

2

Hydrostatic Drive System

The hydrostatic drive system eliminates chains and other mechanical linkages between the diesel engine and final drive components. A closed-loop hydrostatic propel system incorporates pave, travel and maneuver modes for maximum efficiency and versatility. The speed control system maintains preset paving speeds throughout the job. The machine controller provides accurate control of the steering and propulsion systems, and ensures straight-line tracking.

Page 7

Gateless Feeder System

The AP-1055D provides precise mix delivery through the most advanced material handling system. This exclusive feature reduces component wear and minimizes the potential for mix segregation.

Page 8, 9

Generator (Optional)

The generator is integrated within the machine frame and is located below the operator platform, between the dual operator stations. This integrated generator provides power to the electrically heated screed and the auxiliary power panel. A single control switch located on the tractor’s center control console activates the generator.

Page 10

Auxiliary Power Panel (Optional)

The optional auxiliary power panel is available for simultaneous use with the electric screed. The auxiliary power panel supplies power to four, 120-volt and two, 240-volt receptacles. The 120-volt receptacles are protected with ground fault circuit interruption (GFCI).

Page 10

Serviceability

Simplified service means more paving time and less maintenance time. Large swing-open doors and panels provide convenient access to service areas.

Transverse engine mounting provides ground-level access to hydraulic pumps and the engine cooling system. Color-coded and numbered wiring simplifies troubleshooting of the electrical systems. The standard 500-hour engine oil change interval increases machine

up-time.

Page 12

3

Cat® C7 Engine with ACERT® Technology

ACERT® Technology incorporates a series of innovations working at the point of combustion to optimize engine performance while meeting U. S. EPA Tier 3 and E. U. Stage IIIa engine emission regulations.

Cat® C7 Engine with ACERT® Technology

The C7 engine provides a full-rated gross power (SAE J1995) of 167 kW (224 hp) at 2200 rpm with a torque of 872 N-m (643 ft/lb). The combination of large displacement and high torque allow the AP-1055D to perform under the toughest conditions.

HEUI Fuel Injection

The HEUI™ fuel system is unique and combines the technical advancement of an electronic control system with the simplicity of HEUI fuel injection. The HEUI fuel system excels in its ability to control injection pressure over the entire engine operating speed range. These features allow the C7 engine to have complete control over injection timing, duration and pressure.

Multiple Injection Fuel Delivery

Multiple injection fuel delivery involves a high degree of precision. Precisely shaping the combustion cycle lowers combustion chamber temperatures, which generates fewer emissions, optimizes fuel combustion and translates into more work output for your fuel cost.

High Cylinder Pressures

High cylinder pressures combined with tightly controlled tolerances promote extremely efficient fuel burn, less blow-by and lower emissions.

C7 Cylinder Block

The C7 engine’s cylinder block offers increased tensile strength. It features improved sealing with gaskets to ensure fewer leaks. This new design supports the engine’s higher compression ratios and increases its power density. The incorporation of straight-thread “O” ring connection points reduce the loss of engine oil and fluids.

Sound Reduction Features

The C7 engine sound reduction features include composite valve covers with a fully isolated base, a steel oil pan and a cast iron front cover. The HEUI™ fuel systems rate-shaping technology also provides control of sound and vibration levels.

Service, Maintenance and Repair

Easier service, maintenance and repair is accomplished by monitoring key functions and logging critical indicators. Advanced electronic diagnostic capabilities are possible using CAT® Electronic Technician.

Turbocharged and Air-To-Air Aftercooling (ATAAC)

The turbocharged air-to-air aftercooling system provides high horsepower with increased response time while keeping exhaust temperatures low for long hours of continuous operation. Air-to-air aftercooling keeps air intake temperatures down, maximizing fuel efficiency and minimizing emissions.

ADEM™ A4 Electronic Control Module

The ADEM A4 electronic control module manages fuel delivery, valve timing and airflow to get the most performance per liter (gallon) of fuel used. The control module provides flexible fuel mapping, allowing the engine to respond quickly to varying application needs. The control module also monitors engine and machine conditions while keeping the engine at peak efficiency.

4

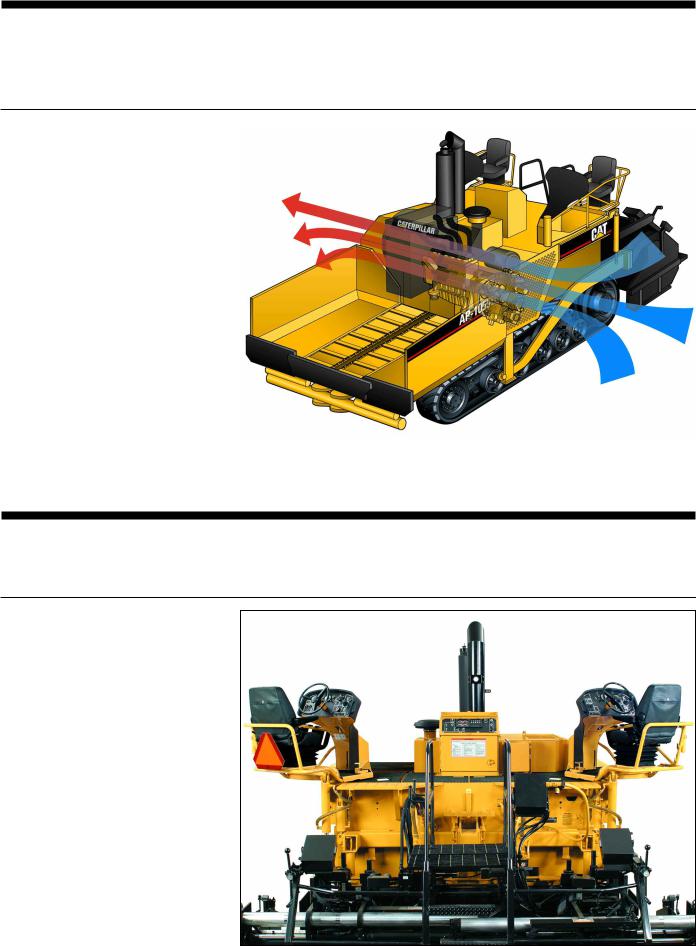

High Ambient Temperature Cooling System

The standard, high-capacity cooling system provides efficient operation in high ambient temperatures. The new system design also provides quiet operation that benefits the operator and the surrounding environment.

Airflow

The airflow design draws ambient air across the engine compartment and through the radiator. This new design allows the exhaust air to exit the right side of the machine in order to provide a cooler engine compartment and operator platform.

High Capacity Cooling Package

The high capacity cooling system allows the fan to run slower, reducing power demand while extending component life.

Variable Speed Fan

The variable speed fan is electronically controlled and hydraulically driven to provide on-demand cooling. This on-demand operation reduces engine power demand and provides quiet operation.

Dual Operator Stations

The dual operator stations provide complete control and good visibility from either side of the operating platform.

Dual Operator Stations

The dual operator stations incorporate fully equipped consoles with meter per minute (feet per minute) gauges, adjustable suspension seats, armrests and retractable seat belts.

Operator Visibility

The dual operator stations can be positioned in one of four different locations to provide optimum visibility. The stations can extend beyond the machine frame for good visibility when joint matching or while paving other applications where precise control is required.

Center Control Console

The center control console includes analog gauges, switches and a digital display for machine functions. The center console also houses a majority of the electrical components for fast, easy service.

5

Loading...

Loading...