Milton CAT D9T User Manual

D9T

Track-Type Tractor

Engine Weights

Engine Model Cat

Gross Power 334 kW 448 hp Operating Weight 50 098 kg 110,447 lb

Flywheel Power 306 kW 410 hp

Net Power ISO 14396 329 kW 441 hp

®

C18 ACERT™ Shipping Weight 37 792 kg 83,317 lb

D9T Features

C18 with ACERT Technology

Optimizes engine performance and provides

lowexhaust emissions.

Drive Train

Electronically controlled powershift transmission,

differential steering, and durable nal drives

deliver outstanding power transfer and long life.

Operator Station

Designed for operator comfort, convenience, and

productivity. Machine controls and displays are all

at the operator’s ngertips to maximize operator

productivity.

Safety

Designed for safe operation by providing, among

other features, enhanced access/egress, and a

variety of technologies to help keep the operator

and others safe on the job.

Serviceability and Customer Support

Combine easy access, modular components with

the Caterpillar dealer repair and rebuild capability

ensures rapid machine repair and minimum

downtime.

Contents

C18 Engine with ACERT™ Technology............3

Cooling System....................................................4

Operator Station..................................................5

Implement and Steering Controls ....................6

Undercarriage .....................................................7

Drive Train ............................................................8

Structure...............................................................9

Work Tools..........................................................10

Sustainability .....................................................11

Safety..................................................................11

Serviceability and Customer Support............12

D9T Track-Type Tractor Specications.........13

D9T Standard Equipment.................................16

D9T Optional Equipment...................................17

The durable construction of the D9T is well suited for

tough working conditions. It has excellent productivity,

optimal operator comfort and robust reliability. Today’sD9T

will help you meet your businessobjectivesevery day.

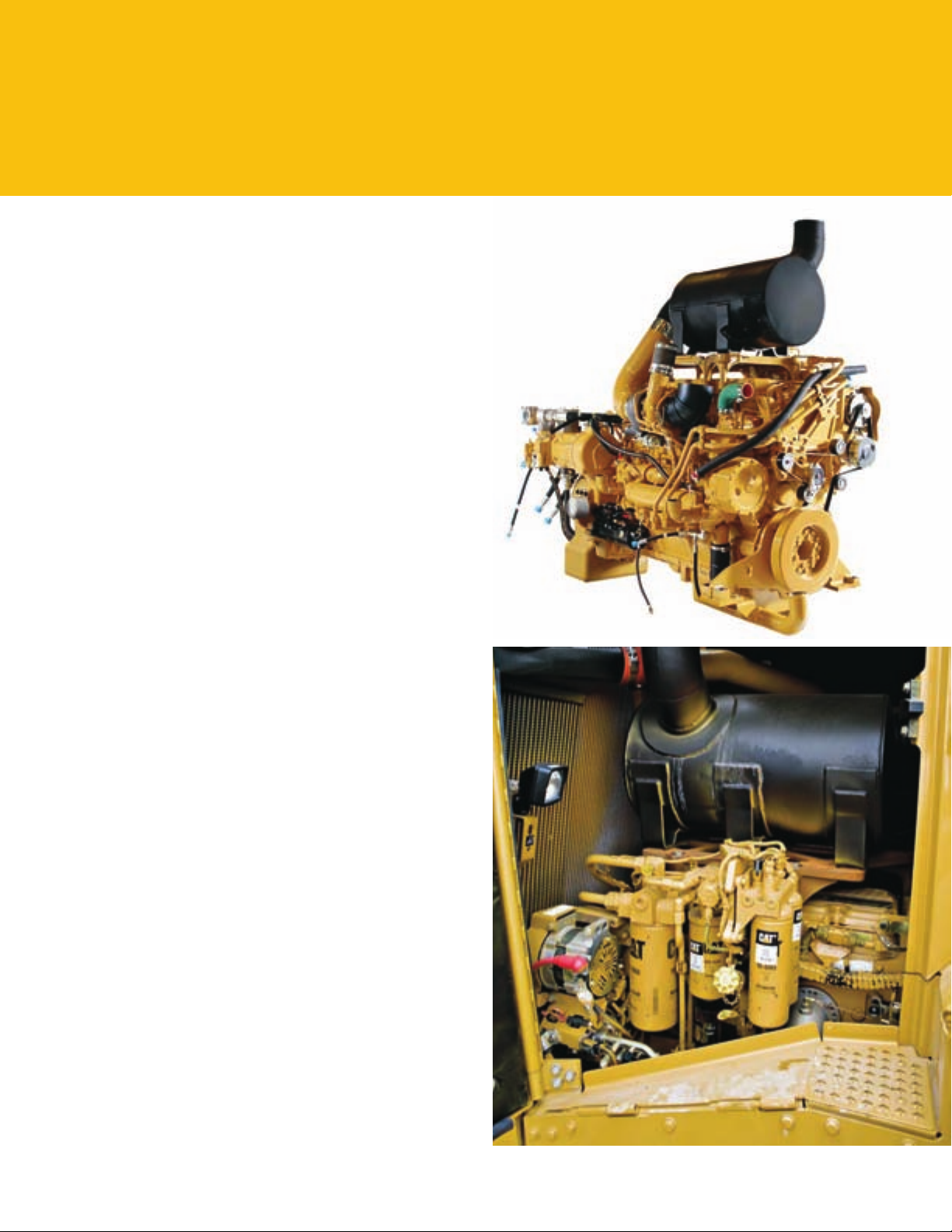

C18 Engine with ACERT™ Technology

Power and reliability

C18

Performing at full-rated net power of 306 kW (410 hp),

thelarge displacement and high torque rise allow the D9T

toripthrough tough material. Matched to the high-efciency

torque converter and electronically controlled power shift

transmission, it will provide years of reliable service.

ADEM™ A4 Engine Controller

Manages fuel delivery for optimal performance per liter

(gallon) of fuel used. Provides exible fuel mapping,

allowing the engine to respond quickly to application

needs.Tracksconditions and keeps engine operating

at peak efciency.

ATAAC and Airow

Air-to-air aftercooling keeps air intake temperatures down

and, in concert with the tight tolerance combustion chamber

components, maximizes fuel efciency and minimizes emissions.

Signicant improvements in air ow are generated by a

water-cooled turbocharger, unique cross-ow head and

singleoverhead cam.

Turbocharging and Air-to-Air Aftercooling

Provides high horsepower with faster response time while

keeping intake temperatures low for long hours of

continuous operation.

Fuel Heater (optional)

Uses the temperature of the engine coolant to warm the cold

fuel coming directly from the tank. The fuel heater allows an

easier transition to winter blended fuels during season changes.

High Altitude Arrangement (optional)

New with the D9T is an optional high altitude arrangement.

The attachment provides an updated turbo and control

software that allows full tractor performance up to 4420 m

(14,500 ft) altitude.

3

Cooling System

Durable and efcient

Aluminum Bar Plate Radiator

Cooling system uses a radiator built with rugged, highly efcient aluminum bar plate cores.

Thealuminum bar plate construction aids durability and allows for higher heat transfer and superior

corrosion resistance.

Hydraulic Air to Oil Cooler

The new air to hydraulic oil cooler reduces hydraulic oil temperatures improving component life.

Thecore is built using the same rugged aluminum bar plate design as the jacket water cooler. It is

designed in-line with the water cores to minimize debris plugging in allapplications.

Hydraulically Variable, Demand Fan

Provides engine cooling capability that is matched to theambient conditions. In cooler conditions,

thefan turnsat a slower speed, reducing power demands. Thisreduces fuel consumption in lower load

factor operations. Lowspeed fan operation also reduces both operator andspectator sound levels.

Attachments

• Ultra low speed option for cold weather applications

• Reversing cooling fan forheavy debris applications

4

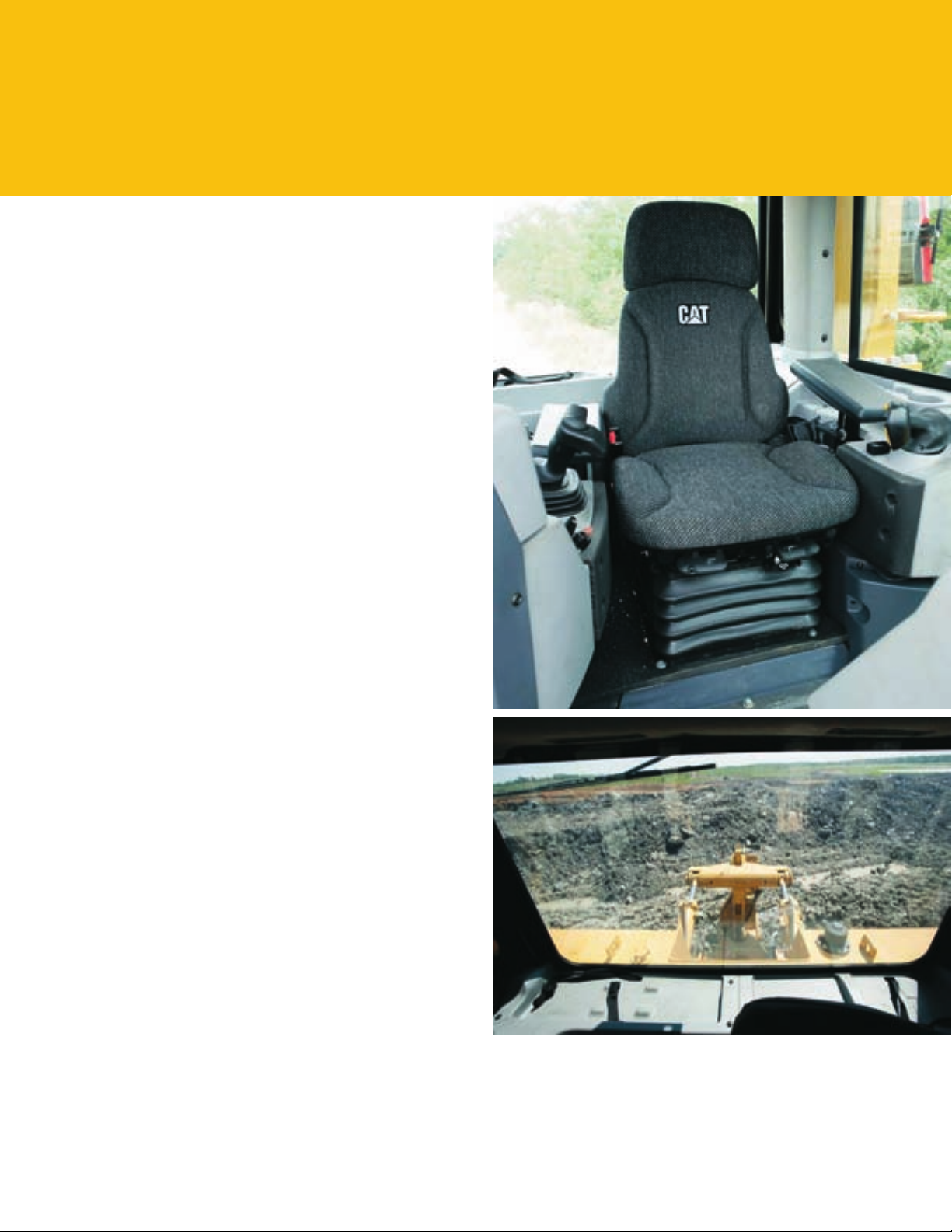

Operator Station

Comfort and convenience

The D9T cab is designed and equipped for operator productivity,

safety andcomfort. The standard isolation-mounted cab

reduces noise and vibration. Overall operator sound levels

have been reduced by 2 dB(A). Largewindows, tapered hood,

and notched fuel tank provide excellent visibility to all sides

of the machine and around the job site.

The D9T comes with an updated in-dash display with new

features. An improved Advisor Monitoring System tracks

machine operating conditions in real time. Dimmable lights

allow the operator to choose between night and day backlight

settings, through Advisor, to adjust the brightness of all

switches and thekeypad in the cab.

Operators will enjoy comfort features like standard

CatComfort Series Seat, adjustable arm rests and automatic

climate control. The climate control system automatically

adjusts heater and air conditioning controls to maintain a

consistent cab temperature throughout the day. Both heater

and air conditioner deliver ltered, pressurized, temperature

controlled air to the operator and/or windows. Thesystem

performs 5 functions: heating, cooling, defrosting,

pressurizing and defogging.

Additional cab features include:

• Entertainment radio ready and IPOD/MP3 player ready

• Communications radio mounting

• Finishes that make the cab easy to clean

• Heated and ventilated seat option

• Deep storage space

• Two cup holders

• Window wipers (intermittent, low and high speeds)

5

Implement and Steering Controls

Ergonomically designed for ease of operation

Dozer Control Lever

A low-effort electronic dozer control handle gives the

operator control of all dozer functions with one hand.

Fore/aft movement of the control handle lowers and raises

the blade. Left/right movement directionally tilts the blade.

Blade response and blade oat can be set/adjusted using the

Advisor System.

The thumb lever at the top of the handle and trigger switch

controls blade pitch fore and aft when equipped with dual tilt.

Dual tilt also provides automated blade assist control capability.

Electronic Ripper Control

A rigidly mounted handgrip provides rm support for

the operator even when ripping in the roughest terrain.

The low effort thumb lever controls raising and lowering.

The nger lever controls shank-in and shank-out positioning.

Performance Monitor

The monitoring system collects machine data and provides

real-time feedback on machine productivity to optimize

performance. Data summaries can be sent to off-board tools

for site managers to review.

Terrain for Grading (optional)

Provides high precision management of dozing and grading

applications for enhanced safety, productivity and efciency.

The system enables an electronic site plan to be sent to the

machine from the ofce in real-time, directing the operator

where to cut and ll.

Automatic Ripper Control (optional)

A new feature that reduces operator fatigue and decreases

wear and tear on the machine. This is done by monitoring

thetractor ground speed with the new cab mounted Global

Navigation Satellite System (GNSS) to automatically adjust

engine speed and ripper depth to minimize track slip.

Autocarry (optional)

Enhances operators productivity by coninuously monitoring

ground speed and automatically adjusts blade load.

Cat Grade Control (optional)

Integrates traditional machine control and guidance with

machine hardware and software to help improve productivity,

usability, reliability and value.

Cat Grade Control software is enhanced to not only

automatically guide the blade to the desired design contours,

but also integrated with Autocarry to sense and automatically

control the load of the blade for improved performance and

efcient blade loading in high production dozing applications.

Loading...

Loading...