Milton CAT 773F User Manual

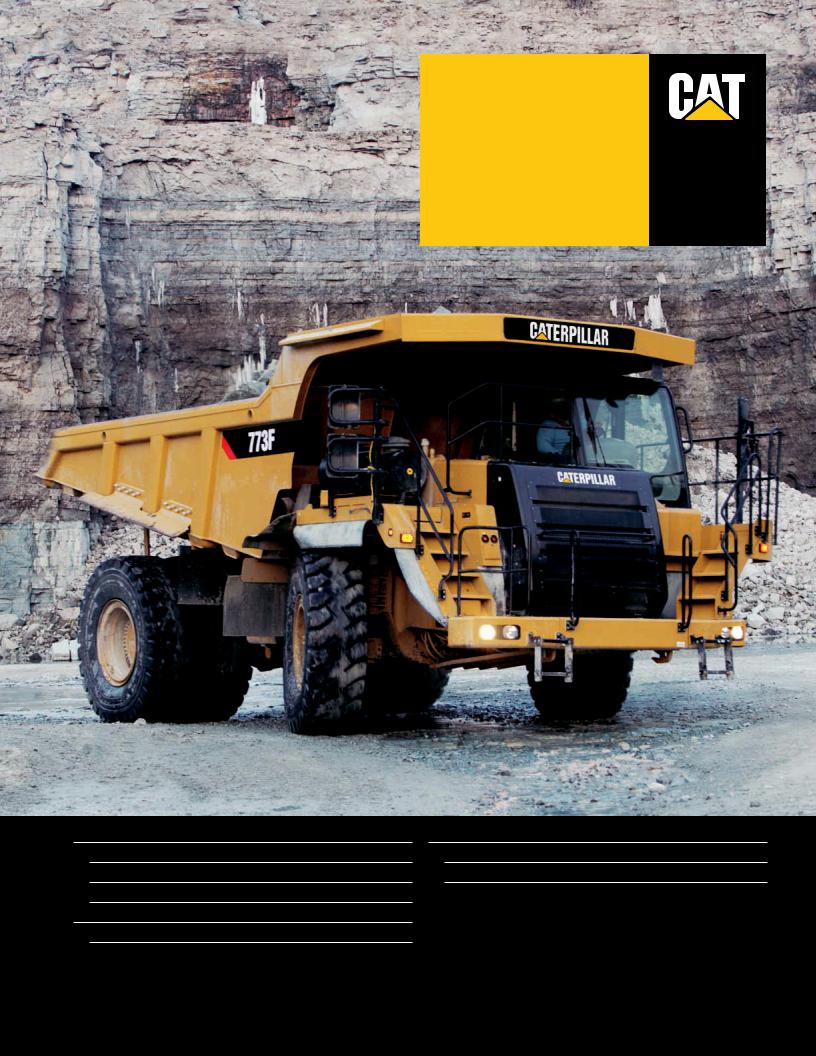

773F ®

Off-Highway Truck

Engine

Engine Model |

Cat® C27 ACERT® |

|

Gross Power – SAE J1995 |

552 kW |

740 hp |

Net Power – SAE J1349 |

524 kW |

703 hp |

Weights – Approximate |

|

|

Target Gross Machine |

100 698 kg |

222,000 lb |

Operating Weight |

|

|

Operating Specifications

Nominal Payload Class |

54.4 tonnes |

60 tons |

Body Capacity – SAE 2:1 |

35.6 m3 |

46.5 yd3 |

•Refer to the Caterpillar® 10/10/20 Payload Guidelines for maximum gross machine weight limitations.

•Capacity with dual slope body.

773F Off-Highway Truck

Engineered for performance, designed for comfort, built to last.

Power Train – Engine |

Power Train – Transmission |

Structures |

The Cat® C27 engine with ACERT® Technology uses advanced engine technology to reduce emissions without after-treatment. The turbocharged, aftercooled 12-cylinder engine has higher horsepower and faster response for superior performance in demanding applications. pg. 4

Serviceability

The 773F offers 500-hour engine service intervals – 250 hours more than the 773E. Simplified service and maintenance features combined with improved service access are designed to reduce downtime. pg. 12

The Cat® seven-speed power shift transmission matched with the Cat C27 engine with ACERT Technology provides constant power and efficiency over a wide operating speed range for optimal power train performance. pg. 5

Information & Monitoring Systems

Standard on the 773F, the Cat Messenger system provides real-time engine performance and operating data. The 773F also offers the optional VIMS Advisor monitoring system, providing data for more than

250 machine functions. pg. 13

Top Performance.

Developed specifically for mining, quarry and construction applications, the 773F keeps material moving at high volume

to lower cost-per ton.

Reliable, Durable, Dependable. Rugged construction and easy maintenance procedures ensure long life with low operating costs.

The 773F features a mild-steel, boxsection type frame, proven on the 773E to deliver durability and long life with low operating costs. Castings and forgings are strategically placed in highstress areas to evenly distribute stresses and provide long fatigue life. pg. 6

2

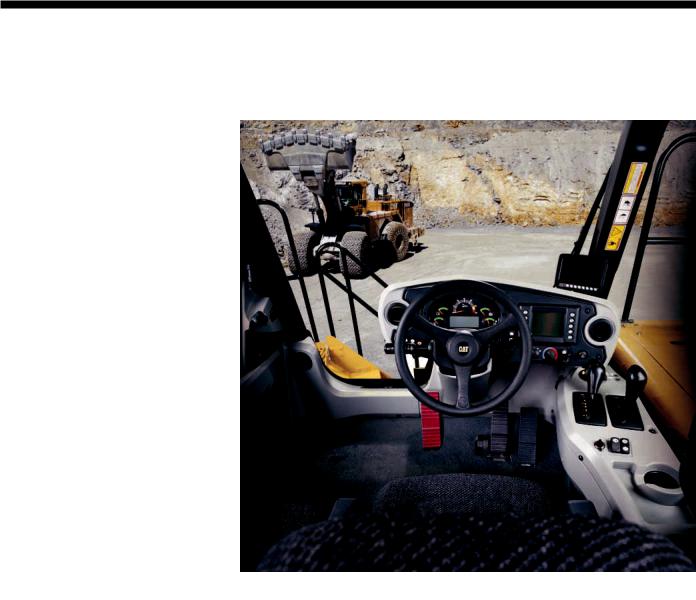

Operator’s Station |

Engine – Power Train Integration |

Brake System |

The 773F features an all new operator station with enhanced visibility, increased operator space and ergonomically designed controls that set new industry standards for operator comfort. All controls and gauges are positioned for optimum efficiency and total machine control. pg. 7

The Cat Data Link electronically combines engine, transmission, brake and operational information to optimize overall truck performance. Stored diagnostic data can be accessed via the Cat Electronic Technician (Cat ET) service tool to improve troubleshooting and reduce downtime. pg. 8

Truck Body Systems

The 773F offers five different Body System selections to accommodate almost any type of application.

These systems are designed to maximize strength and durability through rigorous testing in harsh environments to ensure the lowest cost per ton. pg. 14

Front dry disc and rear oil-cooled, multiple disc brakes are now hydraulically controlled, reducing maintenance costs and improving operator control and modulation. They provide exceptional, fade-resistant braking and retarding for maximum performance and productivity in all haul-road conditions. pg. 10

Customer Support

Caterpillar® dealers provide unmatched product support, anywhere in the world. With industry-best parts availability and a wide range of maintenance and service options, Cat dealers have what it takes to keep your hauling machines productive. pg. 16

Safety

Caterpillar sets the standard when it comes to safety in the design and manufacturing of heavy equipment. Safety is not an afterthought at

Caterpillar, but an integral part of all machine and systems designs. pg. 17

New Feature

3

Power Train – Engine

The Cat® C27 engine with ACERT® Technology is built for power, reliability and efficiency for superior performance in the toughest applications.

Cat® C27 engine with ACERT® Technology. With the C27 engine, Caterpillar optimizes engine performance while meeting U.S. EPA Tier 3 and European Union Stage IIIa regulations. ACERT® Technology reduces emissions during the combustion process by using advanced technology in the air and fuel systems, in conjunction with integrated electronics. Caterpillar meets emission regulations at the combustion source, rather than recycling exhaust.

Engine Design. The Cat C27 engine uses ACERT Technology and iron-specific features to deliver strong performance and long-term durability.

EPA Compliant. The C27 engine is compliant with U.S. EPA Tier 3 and European Union Stage IIIa emissions regulations, reducing NOx 27.5 percent from 4.8 g/bhp-hr to 3.0 g/bhp-hr over the 3412E.

Altitude Compensation. Electronic engine control automatically compensates for load demand, high-altitude conditions and cold starting.

Single-Piece Piston Design.

New single-piece forged steel pistons with integrated forged steel skirt are more robust to withstand high engine heat and pressure, and enable enhanced combustion efficiency, improved

fuel efficiency and lower emissions. Corrosion-resistant, stainless steel top ring reduces ring, groove and liner wear for greater reliability and longer life.

MEUI Fuel System. Fuel delivery, provided by the MEUI mechanically actuated electronic unit injection system, involves a high degree of precision. Precisely shaping the combustion cycle lowers combustion chamber temperatures, generating fewer emissions and optimizing fuel combustion. The system senses operating conditions and regulates fuel delivery for optimum fuel efficiency, improved response times, lower emissions and less smoke.

Electronic Control Module (ECM).

ECM uses advanced engine management software to monitor, control and protect the engine using self-diagnosing electronic sensors. The computerized system senses operating conditions and power requirements and adjusts the engine for peak performance and the most efficient operation at all times.

Advanced Diesel Engine Management A4 Engine Controller. The ADEM™ A4 electronic control module delivers optimum fuel performance. The engine management system provides flexible fuel mapping, allowing the engine to respond quickly to varying application needs. It tracks engine and machine conditions while keeping the engine operating at peak efficiency.

4

Power Train – Transmission

Cat power train delivers more power to the ground for greater productivity and lower operating costs.

Mechanical Power Train. The Cat mechanical drive power train and power shift transmission provides unmatched operating efficiency and control

on steep grades, in poor underfoot conditions, and on haul roads with high rolling resistance.

Transmission. Pairing the Caterpillar seven-speed planetary power shift transmission with the C27 diesel engine with ACERT Technology delivers constant power over a wide range

of operating speeds.

• Transmission Chassis Control (TCC).

TCC uses electronically transferred engine rpm data to execute shifts at preset points for optimum performance, efficiency and clutch life.

Lock-Up Torque Converter. Combines maximum rimpull and cushioned shifting of torque converter drive with the efficiency and performance of direct drive. The lock-up torque converter engages at approximately 8 km/h (5 mph), delivering more power to the wheels.

•Lock-Up Clutch. Quickly releases and re-engages to reduce power train torque loads for smoother shifting, long life and a more comfortable ride.

•ECPC (Electronic Clutch Pressure Control) System. ECPC modulates clutch engagement individually, allowing for smoother speed and directional shifts. ECPC provides controls for both the torque converter lock-up clutch and the transmission clutches that are tailored to each particular upshift or downshift. This provides the operator a superior ride and reduced fatigue.

Final Drives. Cat final drives work as a system with the planetary power shift transmission to deliver maximum power to the ground. Built to withstand the forces of high torque and impact loads, double reduction final drives provide high torque multiplication to further reduce drive train stress.

• Steering System. Hydraulic steering control system is designed for exceptional smoothness and precise control.

A separate circuit prevents cross contamination for long life.

•Battery Powered Supplemental Steering. A battery powered supplemental steering system uses pressure accumulators and allows up to three

90 degree turns in case of engine failure.

•Wheels and Rims. Cast rear wheels and Cat center-mount rims are mounted using studs and nuts to minimize maintenance and maximize durability.

5

Structures

Rugged Cat structures are the backbone of the 773F off-highway truck’s durability.

Box-Section Design. The 773F frame uses a box-section design, incorporating two forgings and 19 castings in highstress areas with deep penetrating and continuous wrap-around welds to resist damage from twisting loads without adding extra weight.

•Steel Structures. Mild steel used throughout the frame provides flexibility, durability and resistance to impact loads, even in cold climates, and allows for easy field repairs.

•Castings. Castings have large radii with internal reinforcing ribs to dissipate stress in areas of high stress concentration. Castings move welds to lower stress areas for greater frame life.

Integral Four-Post ROPS Cab.

Resiliently mounted to the main frame with all-new cab mounts that reduce vibration and sound, the integral ROPS is designed as an extension of the truck frame. The ROPS/FOPS structure provides “five-sided protection” for the operator.

Suspension System. Designed to dissipate haul-road and loading impacts for longer frame life and a more comfortable ride.

•Cylinders. Four independent selfcontained, oil pneumatic, variablerebound suspension cylinders are designed to absorb shocks in the most severe applications.

•Durable Design. Rugged cylinders use a large diameter bore and low pressure nitrogen/oil design for long life with minimal maintenance.

–Front. Front cylinders with preset caster and camber are mounted to the frame and serve as steering kingpins for a tight turning radius with excellent maneuverability and low maintenance.

–Rear. Rear cylinders allow axle oscillation and absorb bending and twisting stresses caused by uneven and rough haul roads rather than transmitting them to the frame.

Technology Enhanced. Caterpillar structures are tested using System Structural Analysis (SSA) to dynamically simulate operations in field environments and identify potential structural improvements in high stress areas. With analysis of machine structures and variables, such as haul road and payload, structural improvements were made to the frame to accommodate the new cab, platform, engine and radiator.

Quality Control. A Coordinate Measuring Machine (CMM) is used to inspect truck frames for consistency in the manufacturing process. Easy rebuild ability is thereby achieved by ensuring the frames are within tolerance, removing the need to alter down-stream parts.

6

Operator’s Station

Ergonomically designed for operator comfort, superior control and high productivity.

Ergonomic Layout. The 773F operator station is ergonomically designed for total machine control in a comfortable, productive and safe environment.

All controls, levers, switches and gauges are positioned to maximize productivity and minimize operator fatigue.

New ISO Designed Cab Mounts.

Integral, sound-suppressed cab is resiliently mounted to the frame to isolate the operator from sound and vibration for a quiet, secure and comfortable ride.

Viewing Area. Designed for excellent all-around visibility and clear sight lines to the haul road. The large viewing area, with 100 percent more glass, enables the operator to maneuver with confidence for greater productivity.

Air Suspension Seat w/Three-Point Operator Restraint. Ergonomically designed, fully adjustable air suspension seat with adjustable armrests provides optimal driving comfort. A wide, retractable 3-point seat/shoulder belt provides a secure, comfortable restraint.

Hoist Lever. Four-position, low effort electronic hoist control system is positioned next to the gear selector in the right-hand console.

Secondary Brake Pedal. Conveniently located on the floor for easy operator control.

Steering Column. Comfortable steering wheel with tilt and telescoping function provides a comfortable driving position for all operators.

Transmission Console. Ergonomic gear shift lever with backlit gear indicators provides easy operation. The parking brake function is integrated into the gear selector.

Trainer Seat. The trainer seat is relocated to the left of the operator, which allows trainer to use same stairway.

When not in use, the fold-down trainer seat creates a working surface with cup holder. The seat also folds up, providing more room for the operator. Under seat storage is convenient for stowing a lunch box.

Operator Controls. Easy to reach turn signal, high beam, intermittent windshield wiper and windshield washer controls are located on the left side of the steering column, and are designed for optimum efficiency and comfort.

Heating/Air Conditioning. Electronically controlled, four-speed fan and 13 vents deliver temperature-controlled air circulation for a comfortable working environment in any climate. Electronic controls reduce maintenance. More robust air compressor offers a 25 percent increase in BTU’s, greater durability and longer life.

Radio Ready. Cab is prewired with power converter, speakers, wiring harness, antenna and necessities for add-on communication systems.

Multiple Power Ports. Power ports are conveniently located in three locations in the cab: one in the right-hand console, two behind the trainer seat, and one in the dash.

Truck Production Management System (TPMS) (optional). TPMS provides valuable payload and cycle time data, which is viewed through Messenger or VIMS™ Advisor to improve productivity.

7

Engine – Power Train Integration

This system electronically combines critical power train components to work together more intelligently to optimize overall truck performance.

1 |

Engine Control Module (ECM) |

|

|

|

2 |

Sensors |

|

|

|

3 |

Electronic Unit Injector (EUI) |

|

|

|

4 |

Automatic Retarder Control (ARC) |

|

ET |

|

|

and Traction Control System (TCS) |

10 |

||

|

|

|||

5 |

Transmission/Chassis Control (TCC) |

|

|

|

6 |

Transmission |

|

|

|

7 |

Wheel Sensor |

|

|

|

8 |

Brakes |

4 |

|

|

9 |

CAT Data Link |

|

|

|

|

|

3 |

||

10 |

Cat Messenger |

|

|

|

|

7 |

|

5 |

|

|

|

|

|

|

|

8 |

6 |

9 |

2 |

|

|

|||

|

|

|

|

1 |

Cat Data Link. Electronically integrates machine computer systems to optimize overall power train performance, increase reliability and component life, and reduce operating costs. All control modules communicate via the Cat Data Link and work together as an integrated system to maximize production efficiency and extend component life.

Transmission Chassis Control (TCC).

TCC uses electronically transferred engine rpm data to execute shifts at preset points for optimum performance, efficiency and clutch life.

Electronic Technician (Cat ET). Cat ET service tool provides service technicians with easy access to stored diagnostic data through the Cat Data Link to simplify problem diagnosis and increase machine availability.

Controlled Throttle Shifting. Regulates engine rpm during shifting to reduce power train stress and clutch wear

by controlling engine speed, torque converter lock-up, and transmission clutch engagement for smoother shifts and longer component life.

Directional Shift Management.

Regulates engine speed during directional shifts to prevent damage caused by high-speed directional changes.

Neutral Coast Inhibitor. Prevents the transmission from shifting to neutral at speeds above 6.5 km/h (4 mph), protecting the transmission from operating with insufficient lubrication.

Body-up Shift Limiter. Prevents the transmission from shifting above a pre-programmed gear without the body being fully lowered. This function is programmable via Cat Electronic Technician (Cat ET) and Messenger or Advisor.

Body-up Reverse Neutralizer.

Automatically shifts the transmission to neutral if the hoist lever is activated while the transmission is shifted

in reverse.

Overspeed Protection. The transmission control electronically senses engine conditions and automatically up-shifts one gear to prevent overspeeding.

If overspeeding occurs in the top gear, the lock-up clutch is disengaged, and the brakes are applied.

8

Programmable Top Gear. Transmission top gear maximum can be set using Cat Messenger, VIMS Advisor or the Cat ET service tool to help the operator maintain speed limits.

Anti-Hunt Function. This function minimizes shifting by not allowing the transmission to up or down shift immediately after a shift has occurred. This prevents gear hunting when operating near a shift point and minimizes transmission shifting

for increased component life.

Downshift Inhibitor. Prevents engine overspeeding by keeping the transmission from downshifting until engine speed reaches the downshift point.

ECPC Control. Both the torque converter lock-up clutch and the transmission clutches now have software-control for clutch fill and slip characteristics to provide superior smooth shifting.

Economy Shift Mode. Modifies engine maps for greater fuel economy.

Reverse Shift Inhibitor. Protects the engine from abrupt directional changes by slowing down the engine before shifting the transmission into reverse.

Cat Messenger. Critical data from the engine and transmission, including transmission shifting, engine speed and fuel consumption, provides service technicians with enhanced diagnostic capability, through Cat Messenger, to reduce downtime and operating costs.

Traction Control System (TCS) (optional). TCS electronically monitors and controls rear wheel slippage for greater traction and enhanced truck performance in poor underfoot conditions.

9

Loading...

Loading...