Milton CAT Feller Bunchers User Manual

511/521/522/532

®

®

Track Feller Bunchers &

Track Harvesters - ZTS (Zero Tail Swing)

511/521/522/532 |

|

|

|

|

|

Engine Model |

Cat® C9 ACERT™ Tier II |

|

|

|

|

Gross Power @ 1800 rpm: |

|

|

Operating weights (w/o head): |

|

|

511 |

247 hp / 184.2 kW |

511 |

24362 kg/53710 lb* |

23790 kg/52440 lb** |

|

521/522 |

284 hp / 211.8 kW |

521 |

27084 kg/59710 lb* |

26050 kg/57440 lb** |

|

532 |

284 hp / 211.8 kW |

522 |

30410 kg/67040 lb* |

29806 kg/65710 lb** |

|

|

|

532 |

31620 kg/69710 lb* |

31450 kg/69340 lb** |

|

* Track Feller Bunchers |

** Track Harvesters |

Cat® 511/521/522/532 Track Feller

Buncher/Track Harvester

Power Train

The Cat® C9 ACERT™ Tier II high torque engine provides excellent power, fuel economy, serviceability and durability. With 5% greater fuel efficiency than its predecessor, and meeting the Tier II emission standards, the Cat C9 ACERT is a dependable performer.

Hydraulics

Closed Center hydraulic system with electronic programmable controls that produces excellent multi-function capability; dedicated pilot, travel, implement and saw pumps.

Operator Comfort

The Cat 500 Series has a purpose built forestry cab with heavy-duty guarding, meeting FOPS/ ROPS/OPS requirements. Designed with operator friendly controls and ergonomics,

the cab gives excellent front, side and rear visibility. Isolation mounted cab and engine reduce sound levels and vibration for quiet and comfortable operation.

Leveling System

The most reliable tilt mechanism in the industry provides stability and productivity even in the steepest applications for the 522 and 532 models.

Undercarriage

Cat track machines feature a rugged undercarriage custom designed for reliable operation in tough harvesting conditions, from wet bottomlands to steep rocky slopes.

Contents |

|

Powertrain |

3 |

Hydraulic Packages |

4 |

Operator Comfort |

5 |

Leveling System |

6 |

Undercarriage |

7 |

Boom and Stick |

8 |

Owning and Operating Costs |

9 |

Serviceability |

10 |

Customer Focus |

11 |

Cat 511/521/522/532 Specifications |

12 |

Standard and Optional Equipment |

16 |

2 |

|

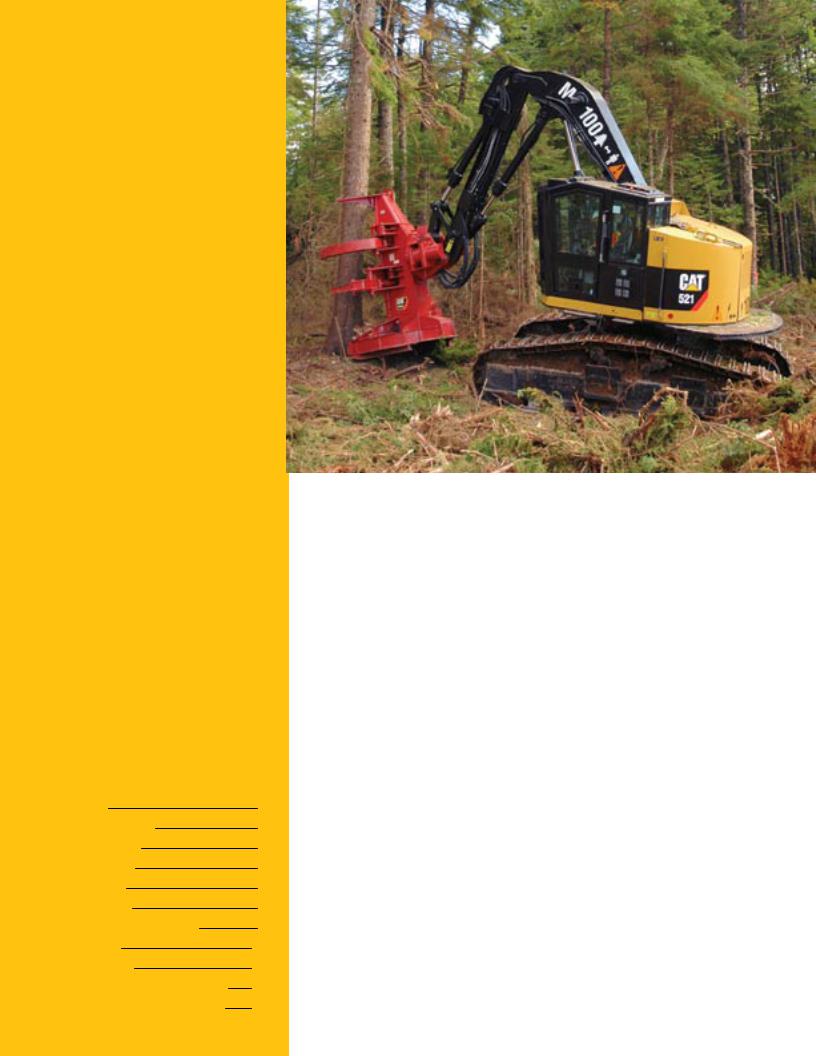

Versatility

Cat machines are available with factoryinstalled felling heads to meet your application needs. Cat 500 series machines utilize high pressure hydraulics and proven components. All models are available with hot saw intermittent or harvesting linkage fronts.

Serviceability

The hydraulically actuated clam-shell service door provides full service access to daily service points simplifying maintenance. Regularly scheduled maintenance extends machine service life and lowers overall operating costs.

ForestPro Consulting

Cat’s ForestPro Consulting Services provides application consulting, training, market development and leading forestry system solutions to meet dealer and customer needs.

Boom and Stick

Harvester and Feller Buncher Linkage Arrangements are available for all models. All boom and stick structures are stress relieved for extended service life.

Owning and Operating Costs

Proven fuel efficiency combined with easier access and extended service intervals maximize uptime, reduce operating costs and maximize productivity.

Customer Focus

Your Cat dealer offers a wide range of services that can be set up to meet your equipment needs. The dealer will help you choose a plan that can cover everything from machine and attachment selection, service and maintenance, to replacement.

A robust undercarriage utilizes proven components, customized for demanding forestry conditions. The unique boom design provides industry leading lift capacity throughout full reach range, a benefit in large timber.

Four models are available with just the right horsepower, track size and hydraulic configurations to fit your application needs.

Powertrain

Built for power, reliability, low maintenance, excellent fuel economy and low emissions.

Powerful Performance

The Cat® C9 electronically controlled ACERT delivers power while meeting all current Tier II emission standards. All models contain a fuel/water separator, engine air intake heater and a dual-stage combination air cleaner with pre-cleaner.

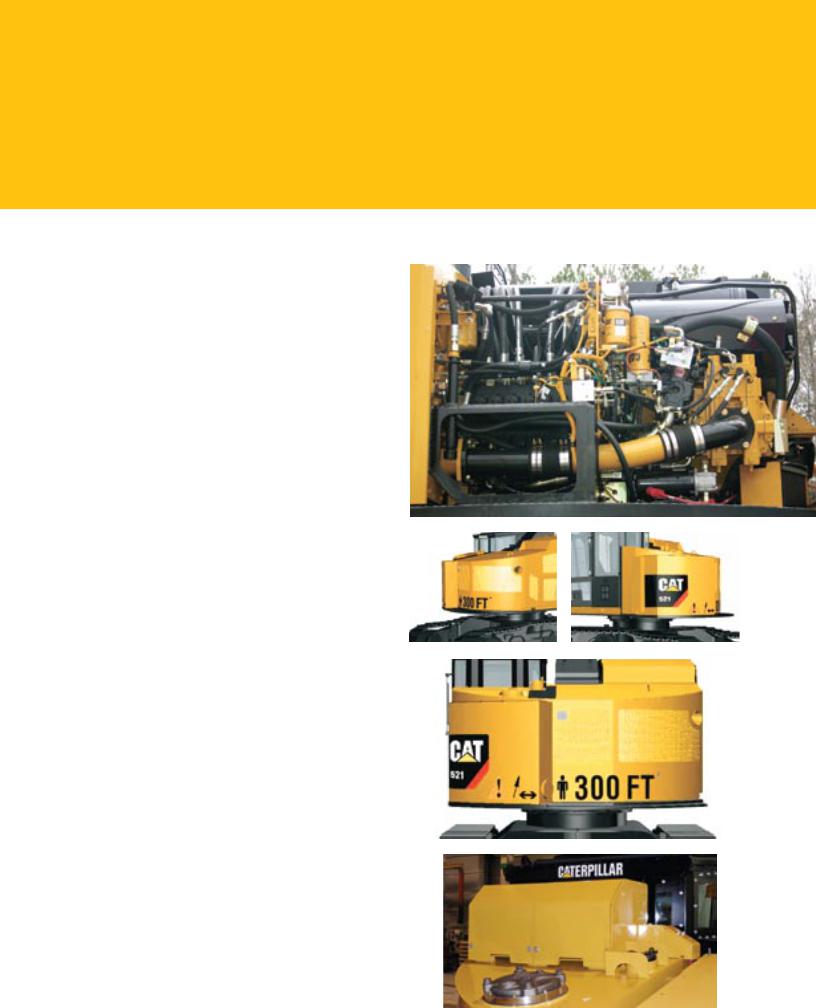

High Capacity Cooling System

The side-by-side radiator/oil cooler gives excellent cooling capacity for high production bunching and harvesting. The optional on-demand Flexxaire™ fan activates only when required and allows the cooling fan to purge debris from the radiator area, keeping a cleaner cooling system. The IQAN control system infinitely controls blade pitch angle to reduce horsepower demand from the cooling package, and lower operating costs..

Engine Oil

Caterpillar® engine oil is formulated to optimize engine life and performance and is recommended for use in Cat diesel engines. The engine oil change interval has been increased to 500 hours.

Service

The clamshell engine compartment provides easy access to oil filters, oil dipstick, hydraulic fill pump and hoses reducing maintenance time.

Low Exhaust Emissions

The Cat C9 ACERT engine is a low emission engine designed to meet US EPA off-road Tier II emission regulations.

Pony Tank

An optional add on fuel tank is available for all 500 ZTS track feller buncher and track harvester models. The additional

90 gallon fuel capacity allows for increased work hours and productivity by reducing work stoppages needed for refueling machines.

Batteries

An optional starting aid for colder climates is available for all 500 ZTS track feller buncher and harvester models. This option provides two (2) additional batteries, a HD starter, and HD

battery cables.

3

Hydraulic Packages

Powerful hydraulic system combined with a powerful boom and stick maximize productivity in any felling or harvesting job.

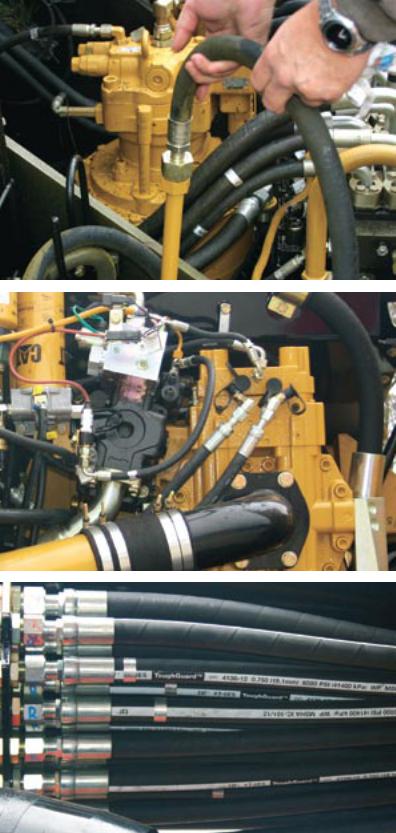

Electric Hydraulic Oil fill Pump

The hydraulic oil site gauge provides easy visibility to know when hydraulic oil needs to be added. An easy accessible service wand allows hydraulic oil to be pumped through the hydraulic filtering system and into the tank. This reduces maintenance time and helps to maintain oil cleanliness requirements.

Variable Displacement Pump

Cat® 511 ZTS Track Feller Bunchers and Harvesters contain a dedicated variable displacement pump for travel circuit and implement functions, and a dedicated variable displacement pump for felling attachments. Cat 521/522/532 ZTS Track Feller Bunchers and Harvesters contain a dedicated 200 cc

variable displacement pump for travel circuit, a 190 cc variable displacement pump for boom and implement functions, and

a dedicated 55 cc variable displacement pump for felling and processing attachments. Optional hydraulic configurations for dangle harvesting heads and intermittent saw heads are available for all ZTS models.

Caterpillar® Hydraulic Oil

Provides maximum protection against mechanical and corrosive wear in all hydraulic systems. It’s high zinc content reduces wear, and extends pump life. Provided certain requirements are met (e.g. S-O-SSM analysis every 500 hours), the hydraulic oil change interval is extended from 2,000 hours to 4,000 hours.

Biodegradable Hydraulic Oil

The optional biodegradable hydraulic oil (HEES) is formulated to provide excellent high-pressure and high-temperature characteristics and is fully compatible with the all hydraulic components. HEES is fully decomposed by soil or water microorganisms, providing a more environmentally-sound alternative to mineral-based oils.

ToughGuard Hoses™

Abrasion resistant hoses along the boom and stick provide strength and flexibility, increasing hydraulic hose service life. The ToughGuard cover consists of a thin layer of UHMW polyethylene bonded to the rubber cover, providing exceptional abrasion resistance. In many applications, it eliminates the need for external guarding.

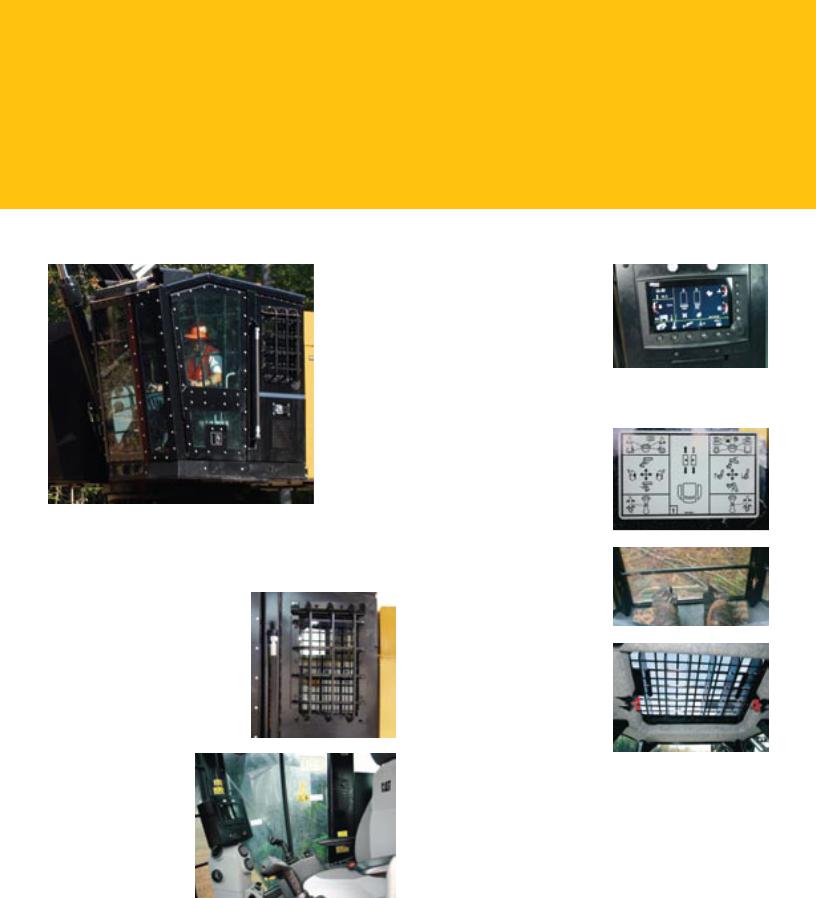

Operator Comfort

The interior layout maximizes operator space, provides exceptional comfort and reduces operator fatigue.

Viewing

Cab design optimizes post structures and window placement to provide excellent operator visibility to front, sides and rear. Standard 1.25" thick “Margard” front window maximizes operator protection. All purpose

built forestry cabs are designed with heavy-duty guarding, meeting FOPS/ROPS/OPS requirements.

Fresh Air

Large sliding side window with screen to allow fresh air into cab.

Interior Operator Station

The operator station is quiet with conveniently placed controls, joysticks and an ergonomically designed seat reducing operator fatigue.

Quiet Operation

Isolation mounted cab and engine reduces sound levels and vibration for quiet and comfortable operation.

Large Storage Compartment

A large storage space behind the seat, provides

sufficient room for a lunch box, hard hats and work tools.

IQAN

IQAN display allows the operator to continuously monitor the operating systems of the machine. This provides early warning for potential problems, and allows the

operator to adjust control parameters maximizing performance and productivity.

Control Convenience

Each control is placed within easy reach of the operator. Joysticks control the implement and attachment functions, providing easy operation.

Foot Pedals

Ergonomically located pedals with side-by-side foot rests provide for maximum operator comfort while operating machine travel.

Skylight

A unique large polycarbonate skylight provides excellent upward visibility, and acts as an alternate escape hatch.

Electrical System

24-volt electrical system with in-cab 24-12 volt converter,

dual in-cab 12 volt power points and one 24 volt power point. Power is provided by two 12 volt maintenance free batteries and 95 amp alternator. An optional cold weather starting attachment may be selected to provide two additional batteries, a HD starter, and HD cables.

5

Leveling System

Tilting mechanism provides stability and comfort in steep slope conditions.

Tilt Mechanism

With the most robust tilt mechanism in the industry, the ZTS tilting models (522 and 532) have a patented 3-cylinder tilt mechanism with simultaneous tilting forward and side-to-side. Trunion cylinders are mounted on 2” (51 mm) steel plates and transfer vertical loads down to the interface of the track frames and carbody, putting the load into the track and ground.

Cylinders

Three-cylinder tilt mechanism with simultaneously 20 degree forward tilt and 11 degree side-to-side tilt.

Ground Clearance

ZTS machines have excellent ground clearance and open carbody design. This provides increased mobility by eliminating debris interference and other obstacles encountered in rugged working conditions.

6

Loading...

Loading...