Milton CAT 930H User Manual

930H

Wheel Loader

Cat® C6.6 Engine with ACERT™ Technology

Net power (SAE J1249) |

111 kW |

149 hp |

EPA Tier 3, EU Stage III Compliant |

|

|

Weight |

|

|

Operating weight |

13 029 kg |

28,725 lb |

Buckets |

|

|

Bucket capacity |

2.1-5.0 m3 |

2.6-6.5 yd3 |

930H Features

Loader Linkage

Cat exclusive VersaLink™ Loader Linkage delivers strength and versatility to help you do more tasks, faster. The high lift linkage option takes you places others can’t reach.

High Performance Power Train

Clean, quiet operation with superior power.

Powerful Hydraulic System

System senses work demand and adjusts flow and pressure to match for precise, efficient control.

Comfortable Cab

Large, spacious cab and low-effort, ergonomic joystick controls let you concentrate on

your work.

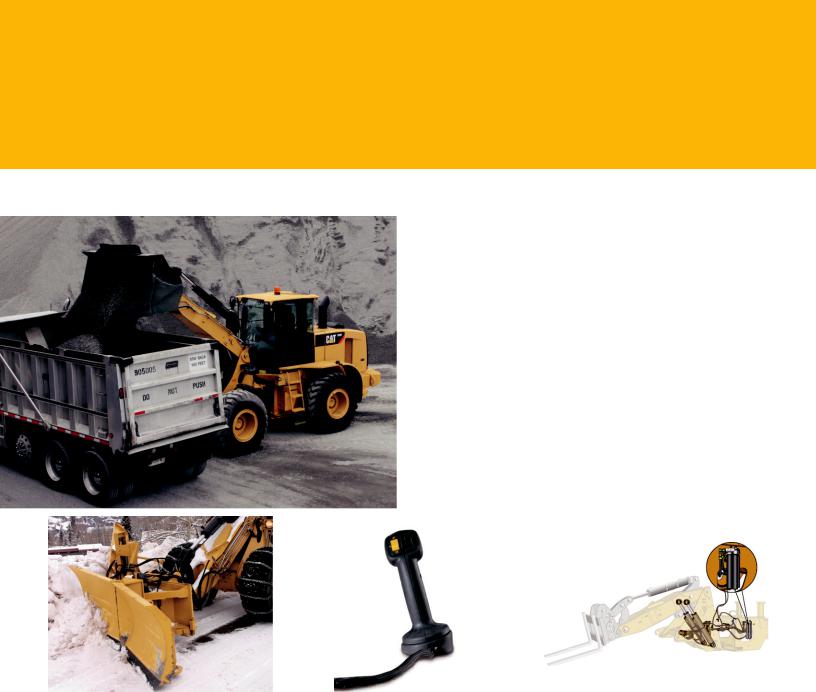

Work Tools

Make your 930H the most versatile machine on the jobsite with Caterpillar’s broad range of work tools.

Contents

VersaLink Loader Linkage . . . . . . . . . . . . .3

Power Train . . . . . . . . . . . . . . . . . . . . . . . . .4

Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . .5

Operator Station . . . . . . . . . . . . . . . . . . . . .6

Work Tools . . . . . . . . . . . . . . . . . . . . . . . . . .7

Serviceability . . . . . . . . . . . . . . . . . . . . . . . .8

Customer Support. . . . . . . . . . . . . . . . . . . .8

Specifications . . . . . . . . . . . . . . . . . . . . . . .9

Standard and Optional Equipment. . . . .17

The Cat® 930H Wheel Loader leads the industry in operator comfort, performance and versatility. Size, power, performance and work tool interchangeability make this machine ideal for a wide range of jobs. Fast cycle times help you move more material. Large spacious cab with joystick control keeps you comfortable throughout the work day, allowing you to get more done. Loader design delivers strength and durability with superior control and unmatched versatility. Discover how much more you can get done with the new 930H.

VersaLink™ Loader Linkage

Loader design delivers unmatched versatility.

Linkage Design

The Cat exclusive VersaLink™ design provides toolcarrier controllability, versatility and parallel lift with the strength, durability and speed of Z-Bar linkage. The 930H can be configured in several ways:

•Equipped with a Quick Coupler for quick and easy work tool changes for optimum utility and versatility.

•Equipped with pin-on work tools, such as a bucket, for a dedicated wheel loader application with exceptional breakout force, tipping load and dump height.

•Equipped with the High Lift VersaLink loader linkage option for special applications that require more reach and lift height.

Loader Performance

The VersaLink loader linkage is designed for exceptional loader performance in a wide range of applications, offering:

•Simultaneous tilt, lift and auxiliary hydraulics function for precise control of the work tool.

•Increased breakout force to shorten cycle times and increase bucket fill factors.

•Higher dump clearance for working in “high target” situations that ordinary loaders cannot.

•More dig depth for better excavation performance, even when equipped with larger tires.

•Greater rackback angle for improved material retention, resulting in higher productivity.

•Greater dozing angle for improved control of material when fine grading.

Parallel Lift

Parallel lift simplifies working with palletized or stacked material. Operators can concentrate on material placement while the load automatically remains parallel throughout the lift range. And, like a toolcarrier, the 930H can easily manipulate loads at all heights.

High Lift Version

Special applications call for special equipment. The optional High Lift VersaLink loader linkage provides an additional clearance of 483 mm (19 in) and is ideal for jobs that require higher lift of lighter materials. The high lift VersaLink is available in both pin-on and quick coupler versions.

3

Power Train

Delivers maximum rimpull to the ground and full power to loader hydraulics.

Cat Engine

The Cat C6.6 engine provides cleaner, quieter operation while delivering superior performance and durability. The 111 kW (149 hp) rated net power engine meets all worldwide emissions standards and features:

flatter power curve for outstanding response in the working RPM range (1,900 to 2,300), noise reduction technologies for up to 5 dB reduction, and patented ACERT™ Technology combined with common rail fuel system, smart waste gate turbocharger and crossflow head design for reduced emissions.

Cat Axles

Heavy-duty axles feature hardened gears and bearings for durable performance. Rear axle oscillates up to 12 degrees to help assure four-wheel ground contact for optimum traction and stability. Optional front and rear Limited Slip Differentials enable outstanding traction in poor underfoot conditions.

Cat Transmission

Rugged Cat transmission uses heavy-duty components for durable and reliable operation. The operator can choose between manual shift and two autoshift modes, Performance or Economy. Performance mode provides maximum acceleration while the economy mode increases fuel economy and improves operator comfort.

4

Hydraulics

Modular system provides high efficiency with low effort, precise control.

Load-Sensing Hydraulics

Modular hydraulic system delivers precise control with

low effort operation. This load-sensing, variable flow system senses work demand and adjusts flow and pressure to match. This allows full hydraulic forces at any engine speed for delicate jobs in tight areas. Combined with the VersaLink linkage, the hydraulic system allows simultaneous lift, tilt and auxiliary hydraulic function.

Auxiliary Hydraulics

Auxiliary hydraulics provide unparalleled versatility allowing you to select the configuration that best suits your application. Third function only or packaged with fourth enables the use of almost all work tools. Fifth and sixth function hydraulics are also available for responsive independent positioning of work tools with multiple hydraulic cylinders such as snow plows with hydraulically movable snow wings.

Optional Joystick with Integrated

Third Function Controls

An optional joystick combines lift and tilt functions with transmission controls and third function auxiliary hydraulic controls in one ergonomic joystick. This allows the operator to maintain control of the load linkage

while operating hydromechanical tools. The system can operate in two modes: the Work Tool and Continuous Flow mode, which allows bi-directional flow to be controlled with a thumbwheel, and the Continuous Flow mode, which provides infinitely variable flow to tools with hydraulic motors.

Ride Control System

The optional Ride Control System provides a comfortable ride and excellent material retention.

Four nitrogen charged accumulators set to different pressures enable optimum cushioning over uneven terrain for all loads and speeds.

The system operates in Automatic; as the loader ground speed exceeds

5 km/h (3 mph) the system will activate, below 5 km/h (3 mph) the system is off, providing maximum lift power.

5

Operator Station

Superior comfort keeps you productive, all day long.

Experience comfort and convenience in the H-Series cab. The spacious interior and ergonomic controls keep you comfortable throughout the work day. Choose the seat that meets your needs – the standard, fully adjustable seat or the optional Cat Contour seat for added adjustment and air suspension. The two-door

design lets you enter and exit from either side of the machine and wide, serrated steps provide stable footing. Both doors lock open 180 degrees and feature sliding glass windows for better communication with workers on the ground. Large flat glass windows provide excellent visibility all around the machine. The rear window features a standard electric defroster.

Controls

Low effort, ergonomic joystick controls provide easy operation of lift and tilt functions. The standard joystick features an integrated directional control switch for added convenience. The operator programmable transmission neutralizer can be set in seconds optimizing brake effort for all applications.

Instrument Panel

The sealed instrument panel with easy to read white faced gauges and indicators keeps the operator informed of system conditions. The large LED readout provides ground speed and other critical information.

Optional Rear View Camera

This work area visual enhancement system uses a closed circuit video monitoring system. Up to three cameras can be mounted on the machine frame. Objects can be viewed on a color LCD monitor in the cab.

Optional Dual Mode Steering

The operator can select traditional steering or QuickSteer mode for faster, low effort truck loading. QuickSteer requires only 50 degrees steering wheel deflection for full articulation drastically reducing operator effort.

6

Loading...

Loading...