Milton CAT 287C User Manual

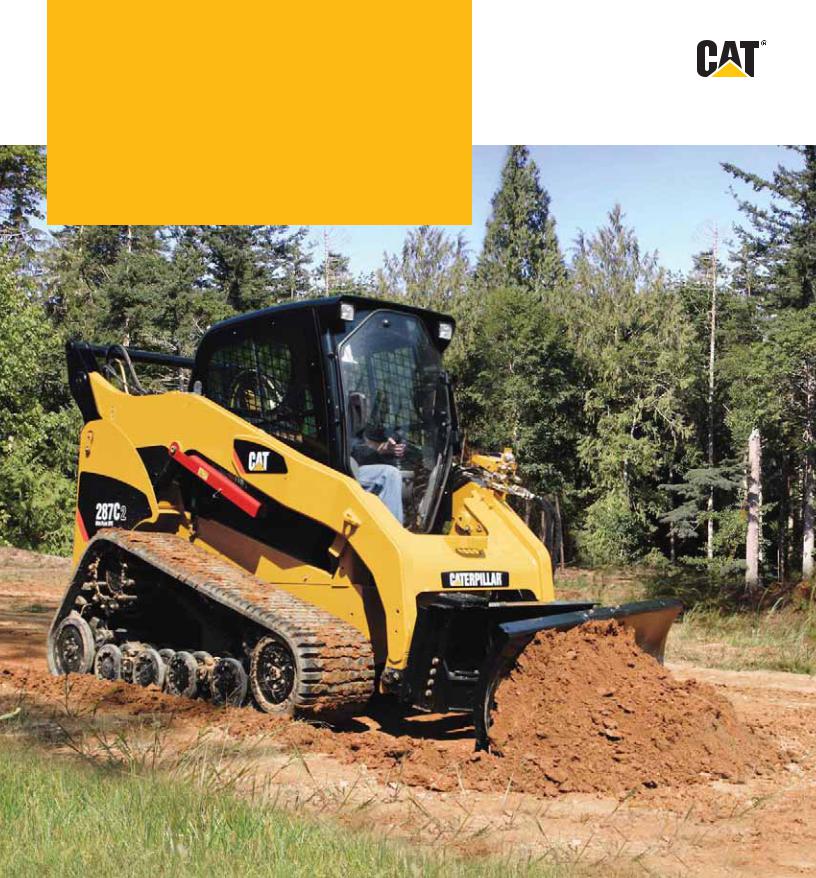

277C Series 2

287C Series 2

Multi Terrain Loaders

|

277C Series 2 |

287C Series 2 |

Cat® C3.4 DIT Diesel Engine |

|

|

Net Power (SAE J1349) |

54 kW (73 hp) |

54 kW (73 hp) |

Weights |

|

|

|

|

|

Operating Weight |

4307 kg (9,495 lb) |

4517 kg (9,958 lb) |

Operating Specifications |

|

|

|

|

|

Rated Operating Capacity at 50% Tipping Load |

1451 kg (3,200 lb) |

1724 kg (3,800 lb) |

Features

Sealed and Pressurized Cab

Sealed and pressurized cab option provides a cleaner and quieter operating environment.

Seat Mounted Adjustable Controls

Ergonomic seat mounted adjustable controls and available air ride seat can be adjusted to meet your personal preference.

Suspended Undercarriage

Suspended undercarriage features low ground pressure so you can work on sensitive surfaces and in soft underfoot conditions.

High Performance Power Train

Increased horsepower and higher torque deliver outstanding performance.

High Flow XPS Hydraulic System

High flow XPS hydraulic system available on all models for applications demanding maximum hydraulic work tool performance.

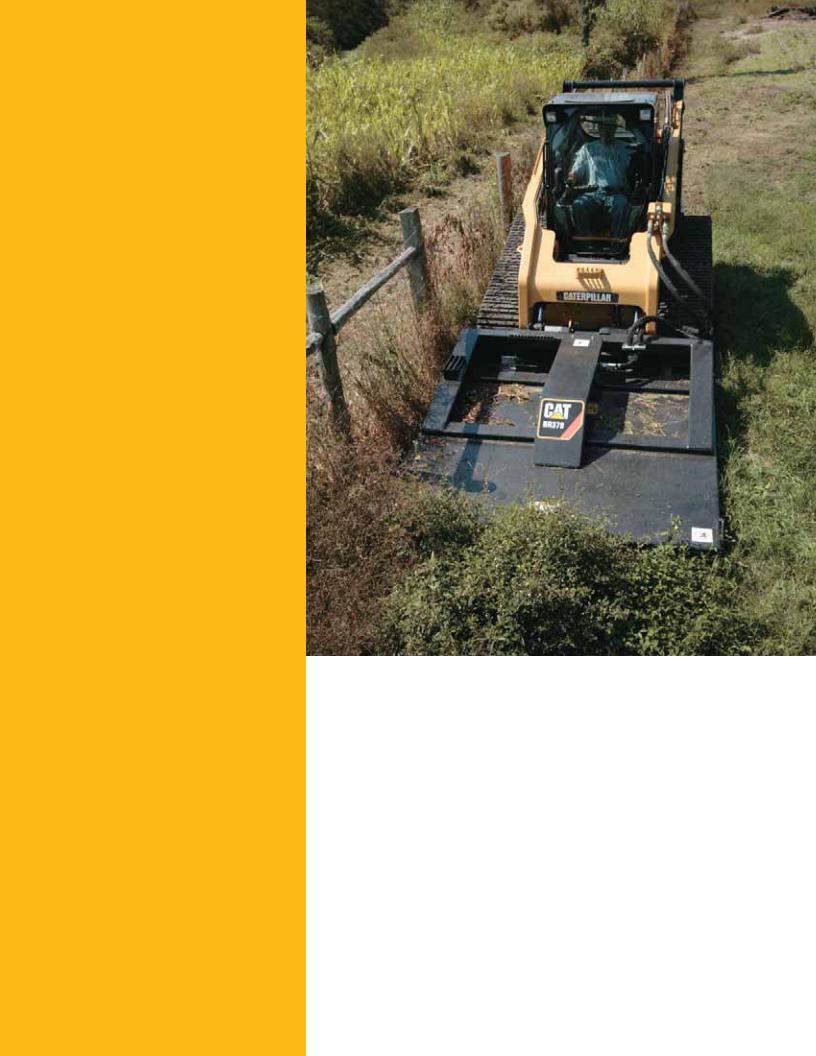

More Work Tools

The broad range of performance matched Cat Work Tools make the Cat Multi Terrain Loader the most versatile machine on

the job site.

Contents

Operator Station . . . . . . . . . . . . . . . . . . . . .3

Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . .4

Rubber Track Undercarriage . . . . . . . . . .4

Power Train . . . . . . . . . . . . . . . . . . . . . . . . .5

Lift Linkages . . . . . . . . . . . . . . . . . . . . . . . . .5

Work Tools . . . . . . . . . . . . . . . . . . . . . . . . . .6

Serviceability . . . . . . . . . . . . . . . . . . . . . . . .7

Customer Support . . . . . . . . . . . . . . . . . . . .7

Specifications . . . . . . . . . . . . . . . . . . . . . . .8

Standard Equipment . . . . . . . . . . . . . . . . .11

Optional Equipment . . . . . . . . . . . . . . . . .11

Cat® Multi Terrain Loaders lead the industry in operator comfort, performance and versatility. Inside the spacious operator station, feel the superior comfort of a sealed and pressurized cab. Adjustable seat mounted controls and an available air ride seat keep you comfortable throughout the work day. Low ground pressures, increased rated operating capacities, higher horsepower and improved drawbar performance help you get more

done and increase your bottom line.

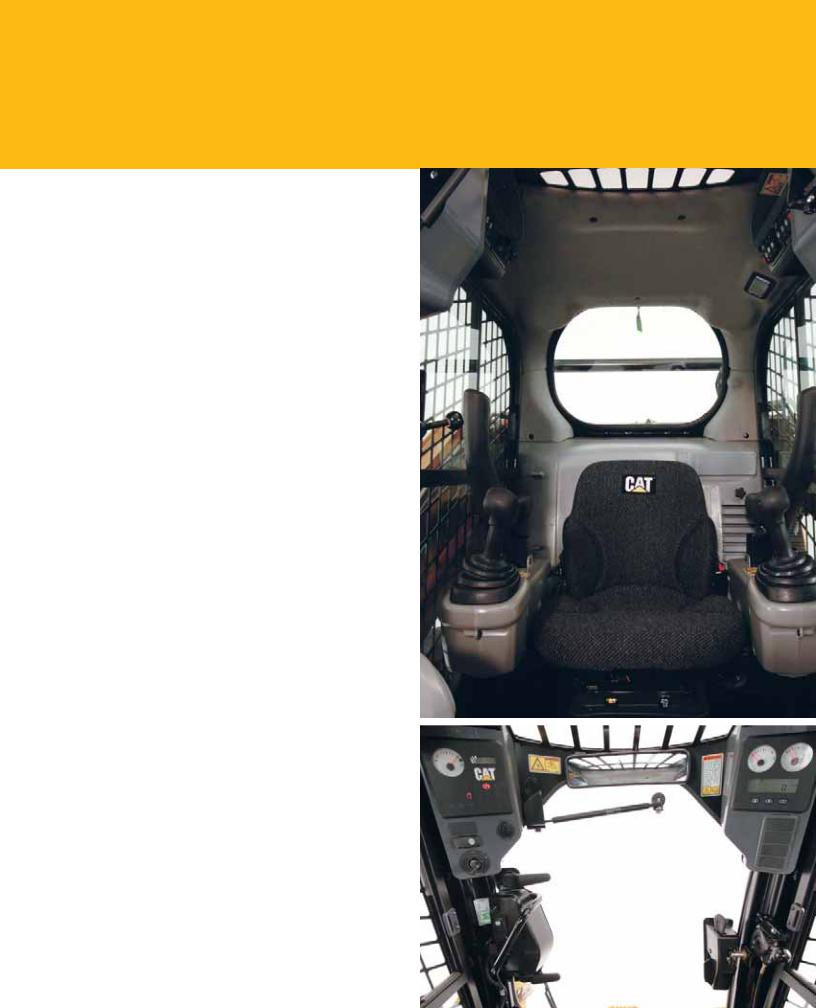

Operator Station

Superior comfort to keep you productive throughout the work day.

Superior Comfort

Comfort and ease of operation have been designed into every aspect of the operator station. The wide, spacious interior and uncluttered floor provide a comfortable work environment with excellent head, shoulder and leg room to keep productivity high and help reduce fatigue.

Sealed and Pressurized Cab

Operators spend long hours in the machine. The optional sealed and pressurized cab keeps dust out and clean air in for greater operator comfort. Reduced sound levels within the cab also help reduce fatigue.

Seat Mounted Joystick Controls

Ergonomic, seat mounted joystick controls enable a wide range of comfortable operating positions for operators of any size. The seat and controls are independently adjustable to meet the specific needs of the operator.

Advanced Machine Information and Control System

The optional Advanced Machine Information and Control System (AMICS) provides easy to read analog gauges for hydraulic oil and engine coolant temperature. The electronic display provides additional operating information such as engine speed, job clock and diagnostic service codes. This display also provides the user interface for the optional AccuGrade™ Grade Control System. The Selectable Work Speed Control, Selectable Implement Control and Selectable Hystat Response Control modes allow the operator to “dial in” his machine to maximize production.

Additional Features for Maximum Comfort

•Air ride seat available for an unparalleled level of comfort in a multi terrain loader.

•Easy to read instrument panels.

•Optional air conditioner and heater for greater comfort in extreme conditions.

•Optional Selectable Pattern Control which allows the operator to select the control pattern they are most familiar with for greater productivity.

3

Hydraulics

Exceptional lift, breakout and power to meet your needs.

High Performance Hydraulic System

Maximum power and reliability are built into the Cat Multi Terrain Loader hydraulic system. In addition to providing power to the tracks, this system also powers the loader lift and tilt functions, powers the auxiliary circuit to drive work tools and drives the engine cooling fan. The hydraulic system features increased lift and tilt breakout forces allowing you to move more material and get more done. The continuous demand fan provides improved fuel efficiency, increased horsepower, reduced sound levels and improved cold weather performance. Cat ToughGuard™ hoses increase reliability and durability. High capacity hydraulic tank and side-by- side cooling package keep components cool for maximum durability.

High Flow XPS

High flow XPS hydraulic system is available on all models for greater machine versatility. Maximum performance can be maintained regardless of the work tool speed or conditions with this load sensing, pressure compensating system. Cat cooling systems are sized to allow the operator to continuously power high flow work tools in conditions that cause competitive machines to overheat.

Selectable Implement Control

The Selectable Implement Control option with three levels of control gives the operator the ability to adjust the responsiveness and speed of the lift and tilt functions for more precise implement control.

Two Speed Option

Two speed option increases top speed up to 14.9 km/h (9.3 mph) allowing you to finish jobs faster.

Rubber Track Undercarriage

Unique undercarriage delivers low ground pressure, superior suspension.

Cat Multi Terrain Loaders feature a rugged, durable rubber track that is lightweight and pliable, yet reinforced with high tensile strength cords. The undercarriage provides low ground pressure, allowing the machine to operate over sensitive surfaces and in soft underfoot conditions. Elevated, internal positive track drive keep drive components away from ground debris. Heavy duty torsion axles suspend each side of the machine frame independently for a smoother ride over rough terrain. Components are replaceable as individual wear items, reducing owning and operating costs.

Dual Level Suspension Undercarriage

The standard dual level suspension undercarriage provides oscillating roller wheel assemblies that independently pivot to provide maximum track on the ground, better load retention, improved operator comfort and one of the smoothest rides in the industry.

4

Loading...

Loading...