Page 1

909 UV Digester

Manual

8.909.8001EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

909 UV Digester

8.909.8001EN

Manual

01.2013 ebe

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://documents.metrohm.com.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.1.1 Supply voltage ......................................................................... 1

1.1.2 Intended use ........................................................................... 1

1.2 Function description ............................................................. 2

1.3 About the documentation ................................................... 3

1.3.1 Symbols and conventions ........................................................ 3

1.4 Safety instructions ................................................................ 4

1.4.1 General notes on safety ........................................................... 4

1.4.2 Electrical safety ........................................................................ 4

1.4.3 Personnel safety ...................................................................... 5

1.4.4 Flammable solvents and chemicals ........................................... 6

1.4.5 Recycling and disposal ............................................................. 6

Table of contents

2 Overview of the instrument 7

3 Installation 9

3.1 Setting up the instrument .................................................... 9

3.1.1 Packaging ................................................................................ 9

3.1.2 Checks .................................................................................... 9

3.1.3 Location .................................................................................. 9

3.2 Inserting the UV lamp .......................................................... 9

3.3 Mounting the UV protective shield ................................... 11

3.4 Preparing and connecting the temperature sensor ........ 14

3.5 Inserting the sample holder ............................................... 17

3.6 Connecting the power supply cable ................................. 18

4 Operation 20

4.1 Switching the instrument on and off ............................... 20

4.2 Dialog window overview ................................................... 20

4.2.1 Main dialog ........................................................................... 20

4.2.2 "Parameters" dialog ............................................................... 20

4.2.3 "Lamp info" dialog ................................................................ 21

4.2.4 "Lamp setup" dialog .............................................................. 21

909 UV Digester

4.3 The keypad .......................................................................... 23

4.3.1 The key functions .................................................................. 23

4.4 The display .......................................................................... 24

4.4.1 Display elements .................................................................... 24

4.4.2 Status display ........................................................................ 25

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

4.5 Changing numerical values ................................................ 25

5 Carrying out sample digestion 26

6 Application examples 31

7 Operation and maintenance 33

7.1 General ................................................................................ 33

7.2 Care ...................................................................................... 34

7.2.1 Maintaining and replacing the UV lamp ................................. 34

7.2.2 Clearing a jammed fan ........................................................... 35

7.2.3 Cleaning sample glasses ........................................................ 36

7.3 Quality Management and qualification with

Metrohm ............................................................................. 36

8 Troubleshooting 37

8.1 Error messages ................................................................... 37

8.2 Additional faults and their remedy ................................... 38

9 Technical specifications 39

9.1 Radiating ............................................................................. 39

9.2 Mercury vapor lamp ........................................................... 39

9.3 Temperature measuring input ........................................... 39

9.4 Power connection ............................................................... 40

9.4.1 220 - 240 V power connection .............................................. 40

9.4.2 100 - 127 V power connection with a transformer ................ 40

9.5 Safety specifications ........................................................... 40

9.6 Electromagnetic compatibility (EMC) ................................ 41

9.7 Ambient temperature ......................................................... 41

9.8 Reference conditions .......................................................... 42

9.9 Dimensions .......................................................................... 42

10 Warranty (guarantee) 43

11 Accessories 45

11.1 Scope of delivery ................................................................ 45

11.2 Optional accessories ........................................................... 49

■■■■■■■■

IV

Index 50

909 UV Digester

Page 7

■■■■■■■■■■■■■■■■■■■■■■

Table of figures

Figure 1 UV lamp spectrum ............................................................................. 2

Figure 2 Front 909 UV Digester ....................................................................... 7

Figure 3 Rear 909 UV Digester ........................................................................ 8

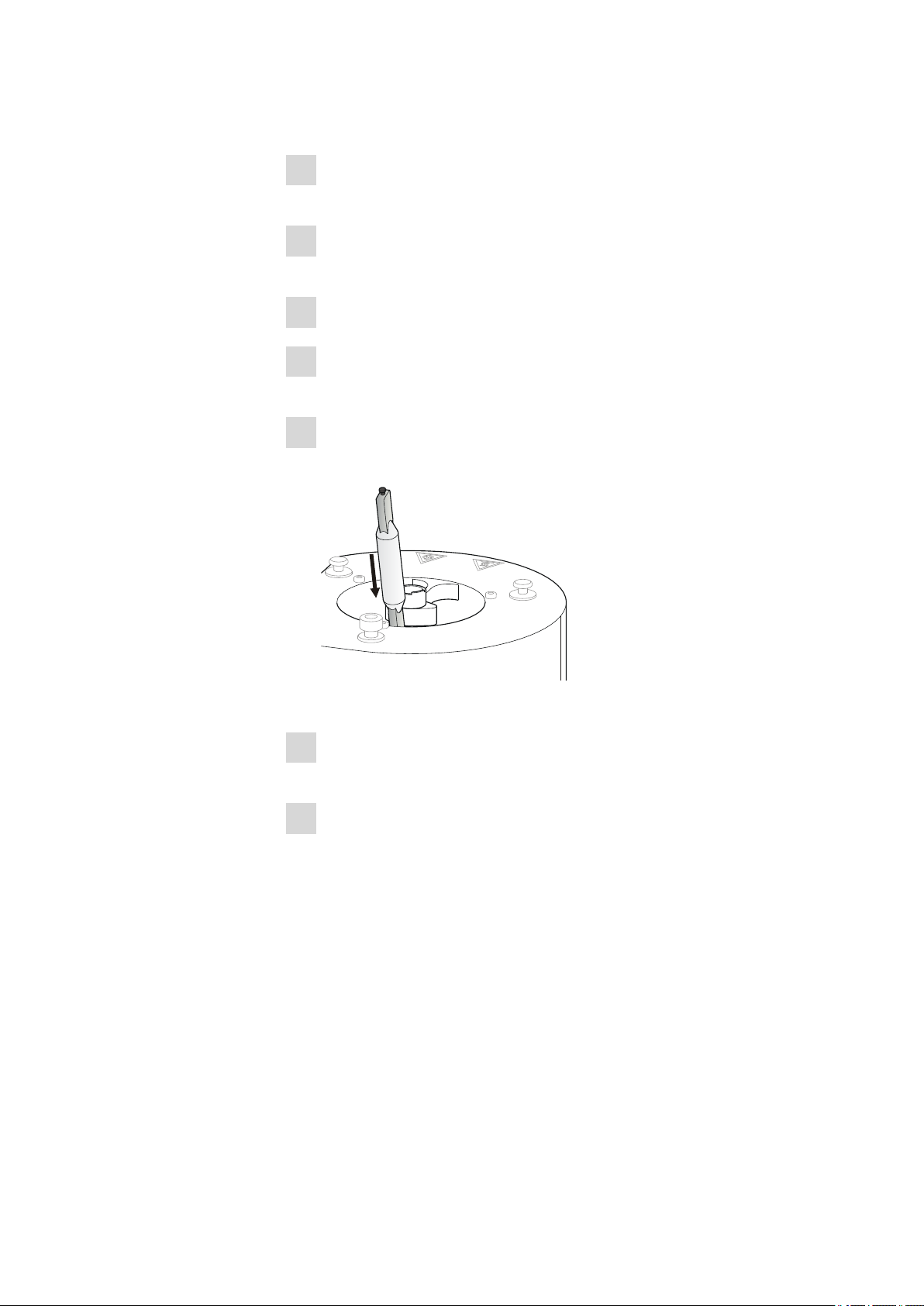

Figure 4 Guiding the UV lamp downward into the wet end ........................... 10

Figure 5 Installing the UV lamp in the wet end .............................................. 11

Figure 6 Removing the stop .......................................................................... 11

Figure 7 Positioning the UV protective shield over the wet end ..................... 12

Figure 8 Positioning the stop over the threaded hole ..................................... 13

Figure 9 Screwing the stop in place ............................................................... 13

Figure 10 Removing the temperature sensor from the storage vessel .............. 14

Figure 11 Removing the spacer from the temperature sensor .......................... 14

Figure 12 Removing the SGJ sleeve from the temperature sensor .................... 14

Figure 13 Attaching the thermometer plug on the temperature sensor ........... 15

Figure 14 Attaching the spacer to the temperature sensor .............................. 15

Figure 15 Inserting the storage vessel for the temperature sensor into the

holder ............................................................................................. 16

Figure 16 Connecting a temperature sensor .................................................... 16

Figure 17 Guiding the sample holder into the wet end .................................... 17

Figure 18 Positioning the cylindrical guide for the sample holder ..................... 18

Figure 19 Inserting the temperature sensor at sample position 6 ..................... 18

Figure 20 Keypad for the operating unit .......................................................... 23

Figure 21 Main dialog - Display elements ........................................................ 24

Table of figures

909 UV Digester

■■■■■■■■

V

Page 8

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The 909 UV Digester is used for the digestion of aqueous samples moderately loaded with organic material. Its primary use is sample preparation

for analyses in voltammetry, ion chromatography, AAS and ICP-AES. The

digestion of samples is based on the photolytic generation of hydroxyl

radicals, whose formation is initiated by a hydrogen peroxide radical initiator. The hydroxyl radicals immediately react with the organic compounds

and work to break them down. The temperature and time for digestion

can be entered conveniently using the operating unit. The temperature is

controlled automatically using air cooling and the UV lamp's emitter

power (medium pressure mercury lamp), which is regulated between

100% and 50% as needed.

The 909 UV Digester combines the wet end and control unit in one housing. The UV lamp is located in the center of the wet end. The sample vessels are inserted in the sample holder encircling the UV lamp. The fan for

air cooling is located in the lower portion of the wet end. The control unit

consists of the operating unit and all of the electronics including the electronic ballast for regulating the UV lamp. The 909 UV Digester is used as a

standalone instrument.

1 Introduction

1.1.1 Supply voltage

The 909 UV Digester can be operated only with a supply voltage of 220 to

240 V. Therefore, for a supply voltage of 100 to 120 V, a transformer has

to be connected between the power and the instrument. You can find

details on the transformer's specifications in Chapter Technical specifica-

tions, page 39.

1.1.2 Intended use

The 909 UV Digester is a sample preparation instrument that can be used

in analytical laboratories for preparing samples for the following analysis

processes:

■ Voltammetry

■ Ion chromatography

■ AAS

■ ICP-AES

Chemicals and flammable substances can be used as a sample additive or

auxiliary reagent in this instrument. Usage of the 909 UV Digester therefore requires the user to have basic knowledge and experience in handling

toxic and caustic substances. Knowledge with respect to the application

909 UV Digester

■■■■■■■■

1

Page 10

1.2 Function description

100

90

80

70

60

50

40

30

20

10

0

200 300 400 500

600

700

Intensity [%]

Wavelength [nm]

1 2

of the fire prevention measures prescribed for laboratories is also mandatory.

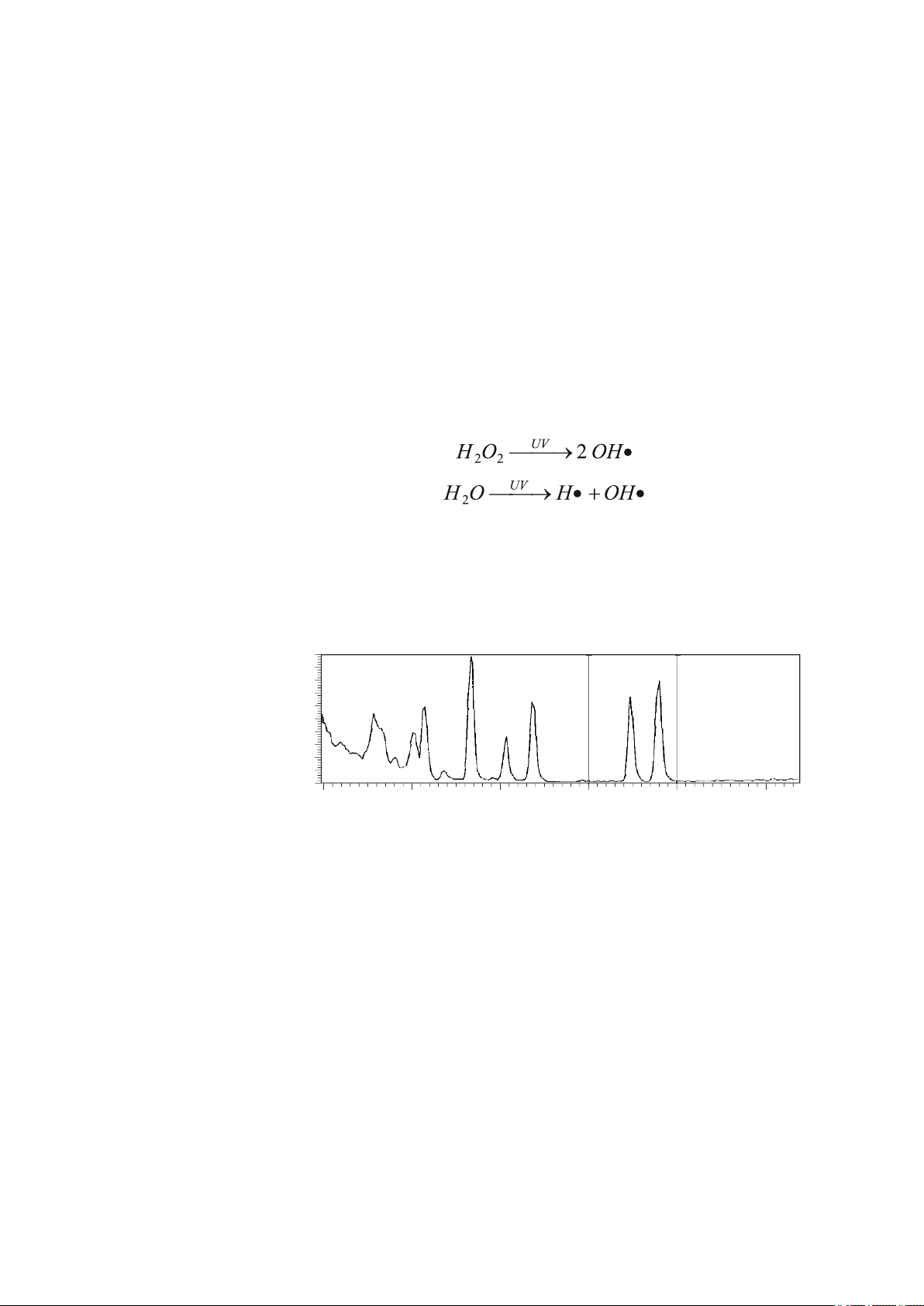

1.2 Function description

Through the effects of UV radiation, dissolved organic matter that disrupts

the trace analysis of heavy metals is decomposed. However, the UV radiation itself does not cause the digestion of the organic sample components; rather, hydroxyl radicals that form break down the organic matter.

Hydroxyl radicals are initially formed from the added hydrogen peroxide

that functions as the initiator for the radical chain reaction. Subsequently,

additional hydroxyl radicals are generated from the water if the temperature is high enough. Depending on the sample matrix, it may be necessary

to add more H2O2 during digestion.

■■■■■■■■■■■■■■■■■■■■■■

Spectrum of the UV lamp

The following figure shows a typical spectrum for the UV lamp. Certain

deviations from this spectrum are possible; this can be traced back to production-related factors.

Figure 1

UV lamp spectrum

■■■■■■■■

2

909 UV Digester

Page 11

■■■■■■■■■■■■■■■■■■■■■■

UV

1.3 About the documentation

Caution

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which the user must follow in order to ensure safe operation of the instrument.

1.3.1 Symbols and conventions

The following symbols and formatting may appear in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the second to the instrument part in the figure.

1 Introduction

Instruction step

Carry out these steps in the sequence shown.

Method Dialog text, parameter in the software

File ▶ New Menu or menu item

[Continue] Button or key

Warning

This symbol draws attention to a possible life-threatening hazard or risk of injury.

Warning

This symbol draws attention to a possible hazard due

to electrical current.

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

Warning

This symbol draws attention to hazardous UV radiation.

Warning

This symbol draws attention to a possible biological

hazard.

909 UV Digester

■■■■■■■■

3

Page 12

1.4 Safety instructions

1.4 Safety instructions

1.4.1 General notes on safety

Warning

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

■■■■■■■■■■■■■■■■■■■■■■

Caution

This symbol draws attention to possible damage to

instruments or instrument parts.

Note

This symbol marks additional information and tips.

1.4.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Warning

Warning

■■■■■■■■

4

909 UV Digester

Page 13

■■■■■■■■■■■■■■■■■■■■■■

UV

Warning

1 Introduction

Supply voltage

Warning

An incorrect supply voltage can damage the instrument.

Operate this instrument only with a supply voltage specified for it (refer

to the rear of the instrument). Use a transformer if necessary (for specifications for the transformer see Chapter 9.4.2, page 40).

Protection against electrostatic charges

Warning

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Do not fail to pull the mains cable out of the mains connection socket

before you set up or disconnect electrical plug connections at the rear

of the instrument.

1.4.3 Personnel safety

Hazardous chemical substances

Chemical substances can cause chemical burns and skin damage.

Correctly install the UV protective shield and wear protective glasses,

protective gloves and work clothes appropriate for laboratory work

when operating the 909 UV Digester.

Harmful UV radiation

UV radiation damages the eyes.

Protect your eyes from UV light during operation. Correctly install the

UV protective shield and wear UV protective glasses.

The 909 UV Digester has to be operated in a closed fume cupboard or

in a closed laboratory and may be operated only by trained personnel.

Warning

909 UV Digester

Attach the supplied UV warning shield included in the accessories to

the fume cupboard.

■■■■■■■■

5

Page 14

1.4 Safety instructions

■■■■■■■■■■■■■■■■■■■■■■

Warning

Escaping ozone

Ozone can damage mucous membranes.

The 909 UV Digester has to be operated in a closed fume cupboard or

in a closed laboratory and may be operated only by trained personnel.

Warning

Hot surfaces

The UV lamp, sample vessels and sample holder become very hot during operation. The UV lamp can reach a temperature of 900 °C.

Skin contact during and immediately after a radiating procedure will

cause burns.

Avoid skin contact until the instrument is completely cool or wear heatinsulated gloves if necessary.

1.4.4 Flammable solvents and chemicals

Warning

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set the instrument up in a closed fume cupboard.

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

1.4.5 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

■■■■■■■■

6

909 UV Digester

Page 15

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

5

6

7

8

9

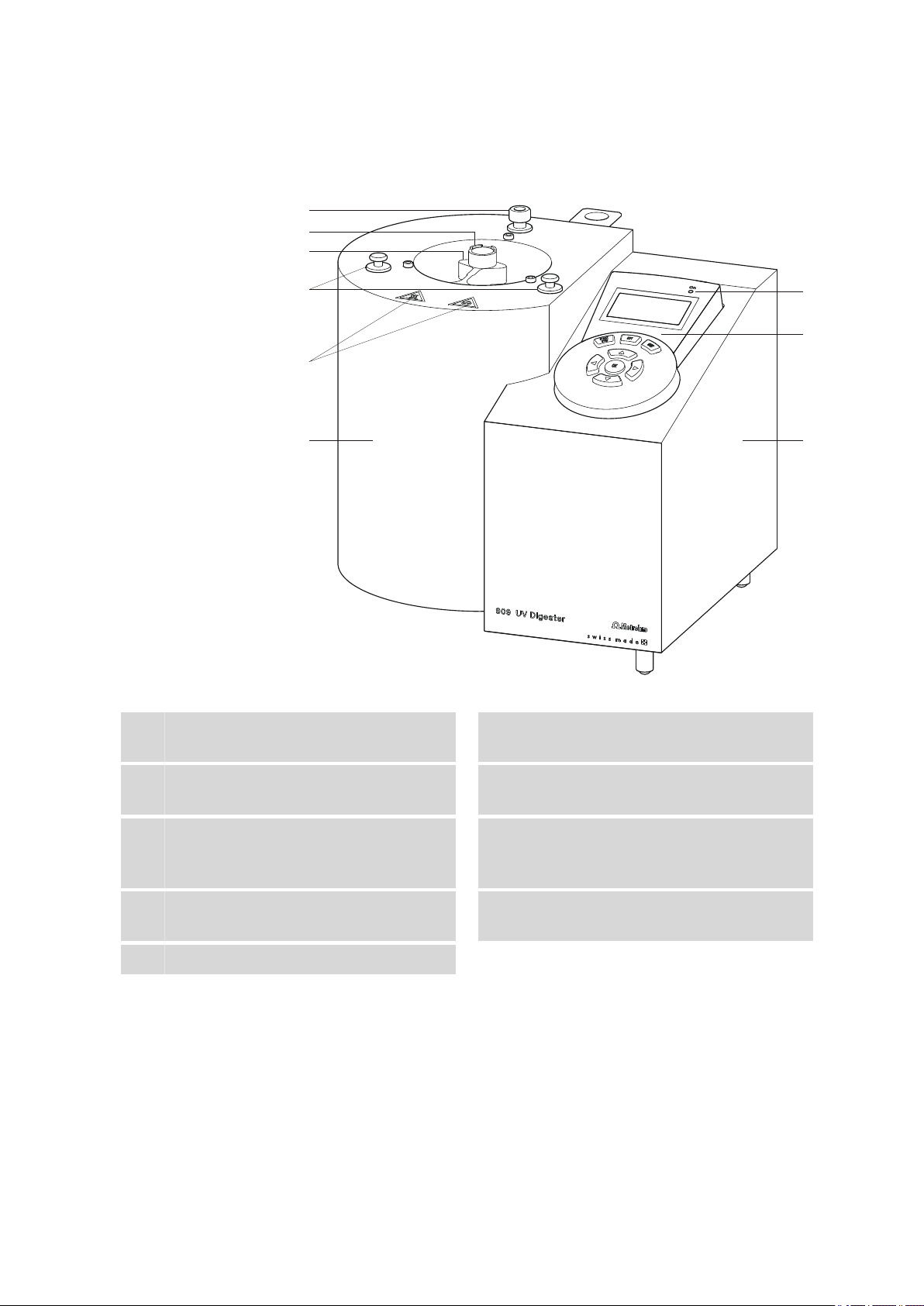

2 Overview of the instrument

2 Overview of the instrument

Figure 2 Front 909 UV Digester

Wet end

1

Stops

3

For positioning the UV protective shield.

Holder

5

For inserting the sample holder.

"On" LED

7

Lights up if the instrument is switched on.

Control unit

9

Warning symbols

2

"UV radiation" and "Hot surfaces".

Lamp holder

4

With upper lamp socket.

Stop

6

With hex socket head screw, for mounting

the UV protective shield.

Operating unit

8

With keyboard and display.

909 UV Digester

■■■■■■■■

7

Page 16

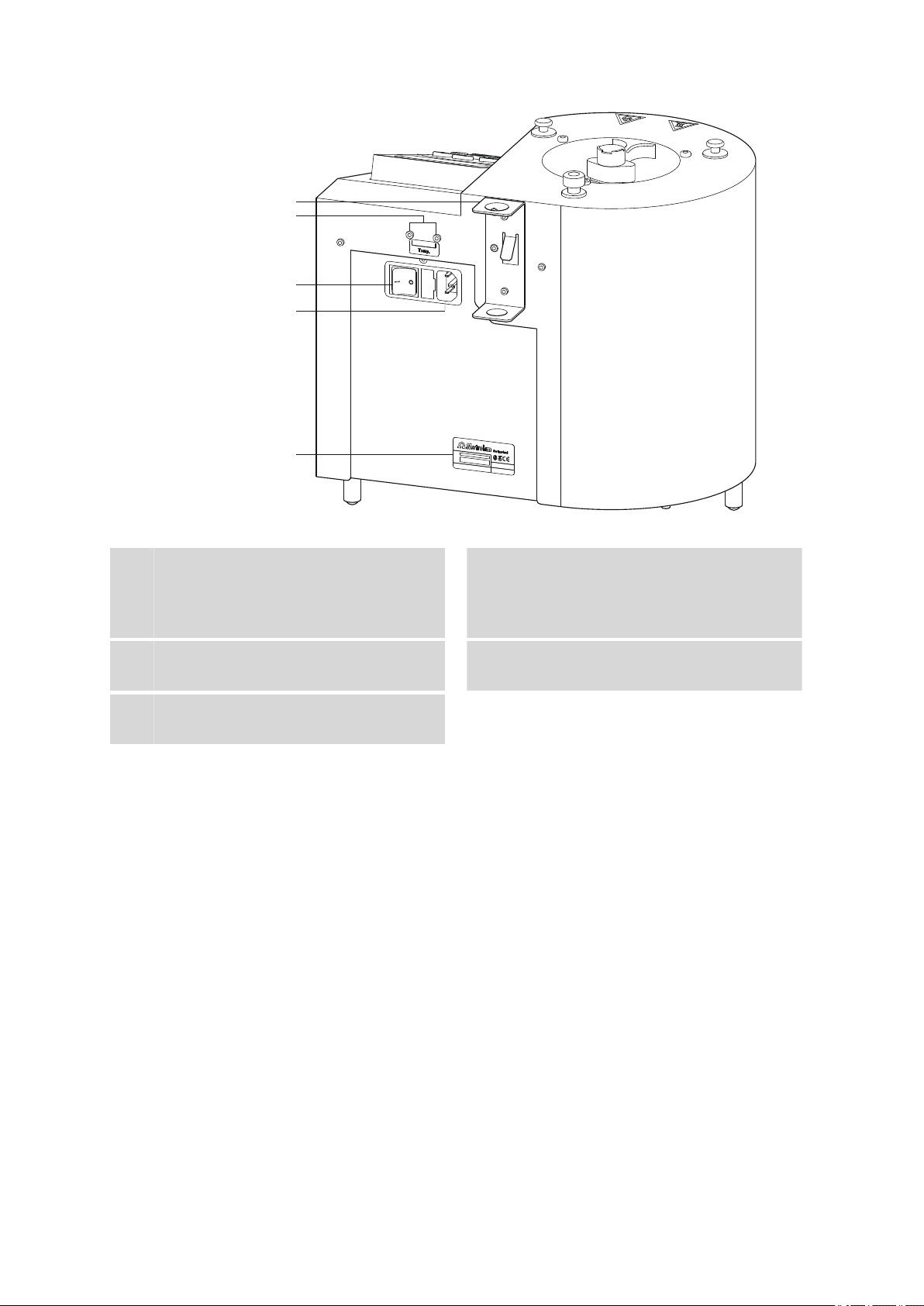

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

5

Figure 3 Rear 909 UV Digester

Holder

1

For storage vessel for temperature sensor.

Power switch

3

For switching the instrument on and off.

Type plate

5

Contains the serial number.

Temperature sensor connection

2

(Temp.)

For connecting the Pt1000 temperature sensor. Two B sockets, 2 mm.

Power socket

4

■■■■■■■■

8

909 UV Digester

Page 17

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

3.1 Setting up the instrument

3.1.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

3.1.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

3.1.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

3 Installation

In the wet end of the 909 UV Digester, ozone from the air is released due

to the UV radiation. Set up the instrument in a fume cupboard or closed

laboratory at a location in the laboratory that is suitable for operation and

free of vibrations. The location should be protected from corrosive atmospheres and contamination from chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

3.2 Inserting the UV lamp

The UV lamp (6.2804.090) is included in the scope of delivery for the 909

UV Digester.

Caution

Spots on the quartz tube

Spots will be burned into the quartz glass if you touch the UV lamp's

quartz tube with bare hands and put it into operation without cleaning

it first. This lowers the power of the UV lamp.

909 UV Digester

Always use the cotton glove included with the UV lamp to install the

lamp and only touch the UV lamp at the two flattened ends. Remove

any grease spots or dust particles stuck to the quartz tube before starting the UV lamp.

■■■■■■■■

9

Page 18

3.2 Inserting the UV lamp

■■■■■■■■■■■■■■■■■■■■■■

Proceed as follows to insert the UV lamp:

Ensure that the power for the 909 UV Digester has been disconnec-

1

ted.

Remove the sample holder from the wet end if it has already been

2

inserted.

Put on the cotton glove included with the UV lamp.

3

Wipe off any spots on the quartz tube using a clean towel wetted

4

with pure alcohol.

Hold the UV lamp by one of the two flattened ends and guide it

5

downward into the wet end.

Figure 4 Guiding the UV lamp downward into the wet end

Insert the metal contact projecting on the lower end of the UV lamp

6

into the lower lamp socket and press it down gently.

While holding the UV lamp down, click the metal contact projecting

7

upwards into the upper lamp socket.

■■■■■■■■

10

909 UV Digester

Page 19

■■■■■■■■■■■■■■■■■■■■■■

1

2

3 Installation

Figure 5 Installing the UV lamp in the wet end

3.3 Mounting the UV protective shield

A UV protective shield (6.2745.100) pre-installed on a metal ring is included in the scope of delivery for the 909 UV Digester.

Proceed as follows:

Using the hex key (6.2621.100), unscrew the stop's hex socket head

1

screw (2-6) on the back of the housing and remove the stop.

Keep the stop with the hex socket head screw in reach. It will have

to be screwed back in place on the housing afterwards.

Figure 6 Removing the stop

Place the UV protective shield over the wet end's opening so that the

2

metal ring rests on the two front stops (2-3).

909 UV Digester

■■■■■■■■

11

Page 20

3.3 Mounting the UV protective shield

■■■■■■■■■■■■■■■■■■■■■■

Ensure that the UV protective shield is positioned towards the front.

Figure 7 Positioning the UV protective shield over the wet end

Place the stop removed earlier over the threaded hole in the back on

3

the housing.

Ensure that the metal ring for the UV protective shield is located in

the slot between the lower and upper part of the stop.

■■■■■■■■

12

909 UV Digester

Page 21

■■■■■■■■■■■■■■■■■■■■■■

Figure 8 Positioning the stop over the threaded hole

Screw the stop back in place on the housing with the hex socket

4

head screw.

3 Installation

909 UV Digester

Figure 9 Screwing the stop in place

Check whether the UV protective shield can be turned back all the

way to the stop (2-6) on both sides.

■■■■■■■■

13

Page 22

3.4 Preparing and connecting the temperature sensor

■■■■■■■■■■■■■■■■■■■■■■

3.4 Preparing and connecting the temperature sensor

The temperature sensor (6.1110.010) is included in the scope of delivery

for the 909 UV Digester.

Preparing

Proceed as follows:

Remove the temperature sensor from the storage vessel.

1

Figure 10 Removing the temperature sensor from the storage ves-

sel

Remove the spacer in the lower part of the glass tube.

2

Figure 11 Removing the spacer from the temperature sensor

Keep the spacer in reach. It will have to be attached back on the

glass tube afterwards.

Remove the SGJ sleeve.

3

Figure 12 Removing the SGJ sleeve from the temperature sensor

Guide the thermometer plug (6.1446.190) over the temperature sen-

4

sor from the bottom until it is flush with the head of the temperature

sensor.

■■■■■■■■

14

909 UV Digester

Page 23

■■■■■■■■■■■■■■■■■■■■■■

Figure 13 Attaching the thermometer plug on the temperature

sensor

Insert the spacer back into the notch in the glass tube.

5

Figure 14 Attaching the spacer to the temperature sensor

The spacer ensures that the temperature sensor is positioned in the

middle of the sample, thereby ensuring optimal temperature measurement.

3 Installation

Inserting the storage vessel for the temperature sensor

Insert the storage vessel (6.2008.040) included in the scope of deliv-

1

ery in the holder (3-1) on the rear of the instrument.

909 UV Digester

■■■■■■■■

15

Page 24

3.4 Preparing and connecting the temperature sensor

■■■■■■■■■■■■■■■■■■■■■■

Figure 15 Inserting the storage vessel for the temperature sensor

into the holder

For storing the temperature sensor between digestion processes.

Insert the temperature sensor equipped with the temperature plug

2

and spacer into the storage vessel.

Connecting

Proceed as follows:

Insert the plugs for the temperature sensor into the Temp. sockets.

1

■■■■■■■■

16

Figure 16 Connecting a temperature sensor

909 UV Digester

Page 25

■■■■■■■■■■■■■■■■■■■■■■

12

1

Note

Always insert the red plug into the red socket. This is the only way

that shielding against electrical interference can be ensured.

3.5 Inserting the sample holder

The sample holder has to be fully filled to ensure uniform temperature distribution in the samples (see "Preparing samples", page 26).

Proceed as follows:

Guide the sample holder on the mounting bracket into the wet end

1

so that the slot between sample positions 1 and 12 ends up located

at the front at the lamp holder (2-4).

3 Installation

909 UV Digester

Figure 17 Guiding the sample holder into the wet end

Ensure that the cylindrical guide on the bottom of the sample holder's mounting bracket clicks in place in the holder (2-5).

■■■■■■■■

17

Page 26

3.6 Connecting the power supply cable

12

1

6

2

■■■■■■■■■■■■■■■■■■■■■■

Figure 18 Positioning the cylindrical guide for the sample holder

Always insert the temperature sensor into the sample vessel filled

with sample at Position 6 of the sample holder.

Figure 19 Inserting the temperature sensor at sample position 6

3.6 Connecting the power supply cable

Warning

An incorrect supply voltage can damage the instrument.

The 909 UV Digester is designed for 220 to 240 V. You need to use a

transformer if your power supply provides 100 to 120 V. You can find

the specification for the transformer in Chapter 9.4.2, page 40.

Proceed as follows to connect the instrument to the power supply.

■■■■■■■■

18

909 UV Digester

Page 27

■■■■■■■■■■■■■■■■■■■■■■

Without a transformer

Connect the UV Digester to the power supply using the power sup-

1

ply cable included in the scope of delivery.

With a transformer

Connect the transformer to the power supply.

1

Connect the UV Digester to the transformer using the power supply

2

cable included in the scope of delivery.

3 Installation

909 UV Digester

■■■■■■■■

19

Page 28

4.1 Switching the instrument on and off

4 Operation

4.1 Switching the instrument on and off

The toggle switch for switching on and off is located on the rear of the

instrument (3-3).

After switching on the instrument, the main dialog is displayed with the

most recently configured parameters.

When starting for the first time, the standard parameters Sample Temp.

= 90 °C and Rad. Time = 90 min appear.

4.2 Dialog window overview

The following four dialogs are available for operating the 909 UV Digester:

■■■■■■■■■■■■■■■■■■■■■■

4.2.1 Main dialog

The main dialog is displayed after switching on the 909 UV Digester.

The following information is displayed:

■ The temperature currently being measured in the sample (Curr.

Temp.).

■ The sample setpoint temperature configured in the Parameters dialog

(Set Temp.).

4.2.2 "Parameters" dialog

■■■■■■■■

20

You can open the Parameters dialog from the main dialog by pressing

the [SET] key.

You must configure the following parameters in this dialog:

909 UV Digester

Page 29

■■■■■■■■■■■■■■■■■■■■■■

Sample Temp.

Rad. Time

4 Operation

■ The sample setpoint temperature (Sample Temp.).

■ The radiating time (Rad. Time).

Setpoint temperature for the samples.

Input range 80 - 100 °C (Increment: 1)

Default value 90 °C

Radiating time for the samples.

Input range 1 - 999 min (Increment: 1)

Default value 90 min

Note

■ The configured parameters can be modified during digestion.

■ The configured parameters remain stored in the instrument after it is

switched off.

4.2.3 "Lamp info" dialog

You can open the Lamp info dialog from the main dialog by pressing the

[OK] key twice.

The following information is displayed:

■ The cumulative number of operating hours for the current UV lamp in

use since the last replacement (Hours).

■ The number of times the current UV lamp in use has been switched on

since the last replacement (Ignitions).

4.2.4 "Lamp setup" dialog

909 UV Digester

■■■■■■■■

21

Page 30

4.2 Dialog window overview

Replace after

Reset counters

■■■■■■■■■■■■■■■■■■■■■■

You can open the Lamp setup dialog by pressing and holding the [SET]

key while switching on the 909 UV Digester.

You have to edit the following parameters if you have inserted a new UV

lamp:

■ Reset the counters back to zero for the cumulative operating hours and

number of times the lamp has been switched on (Reset Counters).

■ Configure the number of operating hours for the new UV lamp until

the next replacement (Replace after).

Maximum number of operating hours for the UV lamp until the next

replacement.

Input range 0 - 1000 h (Increment: 1)

Default value 750 h

We recommend replacing the UV lamp after 750 h

of operating time.

For resetting both counters for cumulative operating hours and the number of times the UV lamp has been switched on (ignitions) to 0.

Confirming with [OK] triggers the following confirmation prompt:

Selection [OK] | [QUIT]

[OK]

Both counters are reset to 0.

[QUIT]

Both counters remain at their current values.

Caution

The counters cannot be reset during the ongoing service life of a UV

lamp currently in use.

■■■■■■■■

22

909 UV Digester

Page 31

■■■■■■■■■■■■■■■■■■■■■■

4.3 The keypad

Below you will find an overview of the operating unit's keypad and the

functions of the keys in the various dialog windows.

4 Operation

Figure 20 Keypad for the operating unit

4.3.1 The key functions

Key Main dialog Parameters Lamp info Lamp setup

[START

STOP]

[SET] Open the Parameters

[QUIT] Acknowledge an error

[OK] Open the Lamp info

■ Start lamp radiat-

ing.

■ Stop lamp radiat-

ing.

dialog.

message.

dialog.

– – –

– – –

Depending on the cur-

Leave the dialog. Depending on the cur-

sor position:

■ Discard a change.

■ Leave the dialog.

Depending on the cursor position:

■ Save a change and

switch to the next

parameter.

■ Save a change and

Display the number of

cumulative operating

hours and times the

lamp has been

switched on (ignitions).

leave the dialog.

sor position:

■ Discard a change.

■ Leave the dialog.

Depending on the cursor position:

■ Save a change.

■ Trigger the confir-

mation prompt for

resetting the counters.

■ Reset the counters

to zero.

909 UV Digester

■■■■■■■■

23

Page 32

4.4 The display

T

1

2

3

4

Key Main dialog Parameters Lamp info Lamp setup

■■■■■■■■■■■■■■■■■■■■■■

[▲] Increase the display's

contrast.

[▼] Decrease the display's

contrast.

[▶] – Depending on the cur-

[◀] – Depending on the cur-

Depending on the cursor position:

■ Go up one line.

■ Page up by one

value list.

Depending on the cursor position:

■ Go down one line.

■ Page down by one

value list.

sor position:

■ Move the cursor to

the value range.

■ Move the cursor

one position to the

right.

sor position:

■ Move the cursor to

the value range.

■ Move the cursor

one position to the

left.

Go up one line. Depending on the cur-

sor position:

■ Go up one line.

■ Page up by one

value list.

Go down one line. Depending on the cur-

sor position:

■ Go down one line.

■ Page down by one

value list.

– Depending on the cur-

sor position:

■ Move the cursor to

the value range.

■ Move the cursor

one position to the

right.

– Depending on the cur-

sor position:

■ Move the cursor to

the value range.

■ Move the cursor

one position to the

left.

4.4 The display

4.4.1 Display elements

Figure 21

Radiating time

1

Shows the remaining radiating time since

the UV lamp was started.

Temperature display

3

Shows the configured sample setpoint temperature.

Main dialog - Display elements

Temperature display

2

Shows the current temperature measured in

the sample.

Status line

4

Contains the current status or an error message along with the respective symbol.

■■■■■■■■

24

909 UV Digester

Page 33

■■■■■■■■■■■■■■■■■■■■■■

4.4.2 Status display

The following symbols and the respective text can be displayed in the status line:

Symbol Text Meaning

4 Operation

Heating The samples are being heated.

Temp. reached The configured sample setpoint

temperature has been reached.

Lamp cooling The samples are being cooled.

Various error messages

4.5 Changing numerical values

The various parameters can be selected using the arrow keys [▼] and [▲].

The colors on the current line are reversed.

Change parameters as follows:

Use the arrow keys [▶] or [◀] to select a numerical value.

1

The selected digit is displayed in black on white. The colors for the

rest of the line remain reversed.

Change the digit using the arrow keys [▲] or [▼].

2

Select the next digit and change it, etc.

3

Apply the modified value with the [OK] key.

4

see Chapter 8.1, page 37.

909 UV Digester

Press [QUIT] if the previous value is to be restored.

■■■■■■■■

25

Page 34

5 Carrying out sample digestion

The following steps can be used as a model describing the steps for sample digestion using the 909 UV Digester. You can find additional useful

tips on analysis methods in the Application Bulletins and Application Notes

listed in Chapter 6, page 31.

Preparing the 909 UV Digester

Installing the 909 UV Digester (see Chapter 3, page 9).

1

Set the sample setpoint temperature to the desired value (see "Sam-

2

ple Temp.", page 21).

Set the radiating time to the desired period (see "Rad. Time", page

3

21).

■■■■■■■■■■■■■■■■■■■■■■

Preparing samples

Warning

Samples with increased organic load

Overflowing chemical substances can cause chemical burns and skin

damage. They can also damage the instrument.

Ensure that the sample vessel with the temperature sensor has the

same sample as the rest of the sample vessels. Otherwise the PTFE stoppers can be pushed out during heating and the sample can overflow.

Wear protective glasses, protective gloves and work clothes suitable for

laboratory work.

Add, at most, 12 mL of sample to be broken down per sample ves-

1

sel.

■■■■■■■■

26

909 UV Digester

Page 35

■■■■■■■■■■■■■■■■■■■■■■

5 Carrying out sample digestion

Note

Use the provided sample vessels

Only use the sample vessels made of quartz glass (6.2414.000)

that have been provided. Normal reagent glasses do not let UV

radiation through and do not ensure complete digestion. Clean

the sample glasses before use as described in Chapter 7.2.3, page

36.

Add nitric acid (w(HNO3) = 65%, for trace analysis) and hydrogen

2

peroxide (w(H2O2) = 30%, for trace analysis).

Samples with a low organic load are offset with the following

reagent concentrations:

■ 0.01 mL HNO

■ 0.05 mL H

(w(HNO3) = 65%, for trace analysis)

3

(w(H2O2) = 30%, for trace analysis)

2O2

The sample volume, the volume of the reagents and the digestion

parameters must be adjusted accordingly for samples with increased

organic load.

Place the PTFE stopper (6.1446.100) on the sample vessels. Leave the

3

sample vessel at Position 6 free for measuring the temperature.

Insert the sample holder into the wet end (see Chapter 3.5, page

4

17).

Note

Fully filled sample holder

Only a fully filled sample holder enables even temperature distribution to the samples. If you use fewer than twelve samples, fill the

remaining sample vessels with distilled water.

909 UV Digester

Insert the temperature sensor (6.1110.010) with attached thermom-

5

eter plug (6.1446.190) and spacer into the sample vessel at Position

6 and press it down.

■■■■■■■■

27

Page 36

■■■■■■■■■■■■■■■■■■■■■■

UV

Warning

Starting sample digestion

1

Hazardous UV radiation

UV radiation damages the eyes.

Protect your eyes from UV light during operation. Position the UV

protective shield on the front of the instrument and wear UV protective glasses.

The 909 UV Digester has to be operated in a closed fume cupboard or in a closed laboratory and may be operated only by

trained personnel.

Press the [START / STOP] key.

The UV lamp is switched on. You can track the current temperature

and time until the end of radiating on the display.

You can top off the hydrogen peroxide (w(H2O2) = 30%, for trace

analysis) as needed during radiating. This may be necessary for samples with a larger organic load.

Note

The digestion temperature and radiating time can be modified during the digestion process. Proceed as described in Chapter 4.2.2,

page 20 as needed.

Procedure after sample digestion

Sample digestion ends and the UV lamp is switched off automatically once

the configured radiating time elapses. The fan cools the samples for 10

min.

Proceed as follows after sample digestion:

Wait for the samples to cool (the fan switches off after 10 min).

1

Remove the sample holder with the samples from the wet end.

2

■■■■■■■■

28

909 UV Digester

Page 37

■■■■■■■■■■■■■■■■■■■■■■

5 Carrying out sample digestion

Note

Leave the PTFE stoppers on the sample vessels until you are ready

to continue using the samples.

Switch off the 909 UV Digester or carry out additional sample diges-

3

tion processes.

Canceling sample digestion

Proceed as follows if you would like to stop a sample digestion process

before the radiating time has elapsed:

Press the [START / STOP] key.

1

The UV lamp is switched off.

Wait for the samples to cool (the fan switches off after 10 min).

2

Remove the sample holder with the samples from the wet end.

3

Switch off the 909 UV Digester or carry out additional sample diges-

4

tion processes.

Note

Opened samples smell like ammonia or fish (amine)

If an open sample smells like ammonia or fish, you need to increase the

amount of acid and/or H2O2 being added.

909 UV Digester

■■■■■■■■

29

Page 38

■■■■■■■■■■■■■■■■■■■■■■

Note

Nitrite interference

Nitrite forms from the effects of UV radiation on nitrate. It is voltammetrically active and shows a wide peak at –1.2 V. This peak can overlap with signals from metals such as zinc, thereby causing interference.

You can prevent this reaction in two ways:

■ Add acid to the sample solutions using HCl instead of HNO

■ Reduce the nitrite using sulfamic acid: add 0.025 mL (β(sulfamic

.

3

acid) = 40 g/L) to 10 mL of open, hot sample solution.

■■■■■■■■

30

909 UV Digester

Page 39

■■■■■■■■■■■■■■■■■■■■■■

6 Application examples

You can find useful examples of analysis methods in the Application Bulletins and Application Notes below.

Table 1 Application Bulletins

6 Application examples

Application

Bulletin No.

74 Tl, Sb, Bi, Fe, Cu, V

96 Hg

116 Cr

117 Se

123 Fe, Mn

131 Al

146 Mo

176 Sn, Pb

186 Al

207 Ag

220 Pt, Rh

226 As

231 Zn, Cd, Pb, Cu, Tl, Ni, Co

Analytes

909 UV Digester

242 W

243 Cr

266 Ti, U

Table 2 Application Notes

Application

Note No.

V-83 Zinc, cadmium, lead and copper in waste water after

V-84 Total chromium in waste water after UV digestion

V-89 Mercury in waste water

V-92 Nickel in white wine

Title

UV digestion

■■■■■■■■

31

Page 40

■■■■■■■■■■■■■■■■■■■■■■

Application

Title

Note No.

V-93 Zinc, cadmium, lead and copper in red wine

V-94 Rhodium and platinum in red wine

V-96 Platinum in urine

V-106 Nickel and cobalt in waste water

V-107 Tin in waste water

V-108 Thallium in waste water

V-109 Selenium in waste water

V-110 Chromium in waste water

V-120 Nickel in glycol after UV digestion

V-121 Determination of total iron in waste water of UV

digestion

V-176 Total selenium in tap water after reduction of sele-

nium(VI) to selenium(IV) by means of UV Digester

V-201 Nickel and cobalt in red wine

■■■■■■■■

32

909 UV Digester

Page 41

■■■■■■■■■■■■■■■■■■■■■■

7 Operation and maintenance

Warning

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

7.1 General

The 909 UV Digester requires appropriate care. Excess contamination of

the instrument may result in functional disruptions and a reduction in the

lifetime of the sturdy mechanics and electronics of the instrument.

7 Operation and maintenance

Severe contamination can also have an influence on sample digestion.

Regular cleaning of exposed parts can prevent this to a large extent.

Spilled chemicals and solvents must be removed immediately. In particular,

the power plug should be protected from contamination.

Warning

Hot surfaces

The UV lamp, sample vessels and sample holder become very hot during operation. The UV lamp can reach a temperature of 900 °C.

Skin contact during and immediately after sample digestion will cause

burns.

Only clean the wet end once it has cooled completely.

909 UV Digester

■■■■■■■■

33

Page 42

7.2 Care

7.2 Care

7.2.1 Maintaining and replacing the UV lamp

Keep the following information in mind so that the lifetime of the UV

lamp is not shortened unnecessarily:

■ Clean the UV lamp as needed using a clean towel wetted with pure

alcohol. This lets you remove particles from the quartz glass that have

not yet been burned in.

Do not touch any part of the UV lamp other than the two flattened

ends during cleaning and wear the provided cotton glove when removing or installing the lamp.

■ Avoid switching the UV lamp on and off unnecessarily. Each time the

lamp is switched on shortens its lifetime.

Removing the old UV lamp

Warning

■■■■■■■■■■■■■■■■■■■■■■

Risk of electric shock due to defective electronic components

Coming into contact with potentially defective electronic components

in the instrument could result in an electric shock.

Ensure that the instrument is unplugged before replacing the UV lamp.

Proceed as follows:

Ensure that the wet end has cooled completely.

1

Remove the sample holder from the wet end if it has been inserted.

2

Put on the glove included with the UV lamp.

3

Hold the UV lamp by the upper flattened end and gently press it

4

down.

While holding the UV lamp down, release the upper end from the

5

lamp socket.

Take the UV lamp out of the lower lamp socket and remove it from

6

the wet end.

■■■■■■■■

34

909 UV Digester

Page 43

■■■■■■■■■■■■■■■■■■■■■■

Inserting the new UV lamp

Insert the new UV lamp in accordance with Chapter 3.2, page 9.

1

Configuring parameters for the new UV lamp

Reset the counters to zero for the number of operating hours and

1

the number of times the lamp has been switched on under Lamp

setup ▶ Reset Counters (see "Reset counters", page 22).

Set the number of operating hours for the new UV lamp under

2

Lamp setup ▶ Replace after (see "Replace after", page 22).

We recommend 750 h of operating time.

7.2.2 Clearing a jammed fan

The wet end with inserted sample holder is designed so that no parts such

as PTFE stoppers can fall down. If the fan happens to get jammed anyway,

keep the following safety instruction in mind:

7 Operation and maintenance

Warning

Jammed fan

Improper work on the fan may result in injuries.

Ensure that the instrument is unplugged before clearing the jammed

fan.

Proceed as follows to remove PTFE stoppers that have fallen into the wet

end of the 909 UV Digester:

Remove the sample holder.

1

Turn the instrument upside down.

2

Gently shake the overturned instrument until the PTFE stoppers come

3

out.

909 UV Digester

■■■■■■■■

35

Page 44

7.3 Quality Management and qualification with Metrohm

■■■■■■■■■■■■■■■■■■■■■■

7.2.3 Cleaning sample glasses

Clean the sample glasses after each sample digestion process:

Proceed as follows:

Thoroughly rinse the sample glasses with double-distilled water.

1

Place the sample glasses in dilute nitric acid overnight or until their

2

next use.

Rinse the sample glasses again using double-distilled water.

3

7.3 Quality Management and qualification with

Metrohm

Quality management

Metrohm offers you comprehensive support in implementing quality management measures for instruments and software. Further information on

this can be found in the brochure "Metrohm Quality Management"

available from your local Metrohm representative.

Qualification

Please contact your local Metrohm representative for support in qualification of instruments and software. The Installation Qualification (IQ)

and Operational Qualification (OQ) are offered by Metrohm representatives as a service. They are carried out by trained employees using standardized qualification documents and in accordance with the currently

applicable requirements of the regulated industry. Further information on

this can be found in the brochure "Analytical Instrument Qualifica-

tion – Confidence in quality with IQ/OQ".

Maintenance

The electronic and mechanical functional groups of Metrohm instruments

can and should be checked by specialist personnel from Metrohm as part

of a regular preventive maintenance schedule. Please ask your local

Metrohm representative regarding the precise terms and conditions

involved in concluding a corresponding maintenance agreement. Further

information on this can be found in the brochure "Metrohm Care Con-

tracts – Protect your investment the smart way" available from your

local Metrohm representative.

■■■■■■■■

36

909 UV Digester

Page 45

■■■■■■■■■■■■■■■■■■■■■■

8 Troubleshooting

8.1 Error messages

The following error messages can occur when operating the 909 UV

Digester. Follow the instructions in the "Remedy" column and acknowledge each of the error messages by pressing the [QUIT] button.

Error message Cause Remedy

8 Troubleshooting

Max. temp. reached The temperature in the wet

end is above 105 °C. The UV

lamp is switched off automatically.

Adj. data missing

The instrument is not ready

for operation since the checksum for the calibration data

was incorrect when the

instrument was switched on.

Lamp exhausted The maximum lifetime config-

ured for the UV lamp in the

Lamp setup dialog has been

reached.

■ Check the sample matrix

and adjust it if necessary.

■ Check whether sample fluid

may have evaporated and

refill the sample if necessary.

■ Check the fan and clear it if

jammed (see Chapter 7.2.2,

page 35).

■ Contact your local Metrohm

Service department.

■ Switch the instrument off

and back on.

■ Contact your local Metrohm

Service department.

Replace the UV lamp (see

Chapter 7.2.1, page 34).

No sensor connectd The temperature sensor is

either not connected or incorrectly connected.

909 UV Digester

■ Check the temperature sen-

sor's connection.

■ Connect the temperature

sensor.

■■■■■■■■

37

Page 46

8.2 Additional faults and their remedy

Error message Cause Remedy

■■■■■■■■■■■■■■■■■■■■■■

Check Sensor/Lamp No increase in temperature is

being recorded. Possible causes:

■ The temperature sensor

has not been inserted in

the sample.

■ The sample holder includ-

ing the temperature sensor

has not been inserted into

the wet end.

■ The UV lamp is defective.

■ The electronics are defec-

tive.

Dev. busy cooling The UV lamp is too hot to be

switched on again.

Thermo switch open The instrument is defective.

Overtemperature protection is

switching off the electronic

ballast.

■ Insert the temperature sen-

sor into the sample.

■ Insert the sample holder

including the temperature

sensor into the instrument.

■ Replace the UV lamp (see

Chapter 7.2.1, page 34).

■ Contact your local Metrohm

Service department.

Wait for the end of the cooling

process (Lamp cooling status

message disappears).

Contact your local Metrohm

Service department.

8.2 Additional faults and their remedy

Problem

The configured

digestion temperature cannot be

saved.

Cause Remedy

The entered temperature is

outside the input range of

80 - 100 °C.

Set a temperature within the input range.

■■■■■■■■

38

909 UV Digester

Page 47

■■■■■■■■■■■■■■■■■■■■■■

9 Technical specifications

9.1 Radiating

9 Technical specifications

Digestion temperature

Ambient temperature

Duration 1 - 999 min

Power 600 - 300 W

Control accuracy ±3 °C

+80 - +100 °C

+5 - +35 °C

9.2 Mercury vapor lamp

UV-A radiation

UV-B radiation 280 - 315 nm

UV-C radiation 200 - 280 nm

Dimensions

Length 137 - 139 mm

Outer diameter approx. 16 mm

315 - 400 nm

35 W

40 W

70 W

9.3 Temperature measuring input

A measuring input for the Pt1000 type temperature sensor.

Accuracy

Measuring range –20.0 - +150.0 °C

909 UV Digester

±0.2 °C

(under reference conditions)

■■■■■■■■

39

Page 48

9.4 Power connection

9.4 Power connection

9.4.1 220 - 240 V power connection

Supply voltage 220 - 240 V (± 10%)

Frequency 50 - 60 Hz (± 3%)

■■■■■■■■■■■■■■■■■■■■■■

Power consump-

630 W

tion

Fuse 6.3 ATH

9.4.2 100 - 127 V power connection with a transformer

Specification for

the transformer

Input voltage 110 V typical

Output voltage 230 V typical

Frequency 50 - 60 Hz

Power > 700 VA

9.5 Safety specifications

This instrument fulfills the following electrical safety requirements:

CE marking in accordance with the EU directives:

■ 2006/95/EC (Low Voltage Directive, LVD)

■ 2004/108/EC (EMC Directive, EMC)

Federal Inspectorate for Heavy Current Installations ESTI (Accreditation

Number SCESp 033)

■ Safety mark for certification type 2 in accordance with NEV (type

testing with market monitoring, EMC conformity)

Design and testing According to EN/IEC/UL 61010-1, CSA-C22.2 No. 61010-1, protection

class I, EN/IEC 61010-2-010, EN/IEC 60529.

Safety instructions This document contains safety instructions which have to be followed

by the user in order to ensure safe operation of the instrument.

■■■■■■■■

40

909 UV Digester

Page 49

■■■■■■■■■■■■■■■■■■■■■■

9.6 Electromagnetic compatibility (EMC)

Emission

Standards fulfilled

Immunity

Standards fulfilled

■ EN/IEC 61326-1

■ EN/IEC 61000-6-3

■ EN 55011 / CISPR 11

■ EN/IEC 61000-3-2

■ EN/IEC 61000-3-3

■ EN/IEC 61326-1

■ EN/IEC 61000-6-2

■ EN/IEC 61000-4-2

■ EN/IEC 61000-4-3

■ EN/IEC 61000-4-4

■ EN/IEC 61000-4-5

■ EN/IEC 61000-4-6

■ EN/IEC 61000-4-11

■ EN/IEC 61000-4-14

■ EN/IEC 61000-4-28

9 Technical specifications

9.7 Ambient temperature

Nominal function

range

Storage –20 - +70 °C

Transport –40 - +70 °C

+10 - +35 °C

(Humidity < 80%)

(Humidity < 95%)

(Humidity < 95%)

909 UV Digester

■■■■■■■■

41

Page 50

9.8 Reference conditions

9.8 Reference conditions

■■■■■■■■■■■■■■■■■■■■■■

Ambient temperature

Supply voltage 230 V

Relative humidity ≤ 60%

Operating temperature status

Validity After adjustment

+25 °C (± 3 °C)

Instrument in operation at least 30 min

9.9 Dimensions

Width

Height 290 mm

With UV protective shield

Depth 310 mm

Weight (without

accessories)

330 mm

500 mm

10.90 kg

Material of housing

Metal, surface-treated

■■■■■■■■

42

909 UV Digester

Page 51

■■■■■■■■■■■■■■■■■■■■■■

10 Warranty (guarantee)

Metrohm guarantees that the deliveries and services it provides are free of

defects in materials, design or manufacturing.

The general warranty period is 36 months (exclusions below) from the

date of delivery or 18 months in the event of continuous operation. The

warranty remains valid on the condition that the servicing is provided by a

service organization authorized by Metrohm at defined intervals and with

a defined scope.

The warranty period for anion suppressors of the type "MSM" is 120

months from the date of delivery or 60 months in the case of continuous

operation.

The warranty period for IC separation columns is 90 days after start-up.

For third-party components that are recognizable as such, the manufacturer's warranty regulations apply.

10 Warranty (guarantee)

Consumables and materials with limited storage life and glass breakage in

the case of electrodes or other glass parts are excluded from the warranty.

Warranty claims cannot be asserted if the ordering party has failed to

meet its payment obligations according to schedule.

During the warranty period, Metrohm undertakes either to replace free of

charge or to credit the purchaser for any modules or components that can

be shown to be faulty. Any transport or customs fees that may apply are

the ordering party’s responsibility.

The precondition for this is that the ordering party has to specify the article number, the article designation, an adequate error description, the

delivery date and (if applicable) the serial number or chip data in the Support Tracker. Metrohm then decides whether a replacement or a credit

note is to be issued or whether the faulty part has to be returned using

the Return Material Authorization (RMA). If a replacement or credit note is

issued, the ordering party undertakes to store the faulty part for at least

24 months in accordance with the current storage directives (in compliance with ESD guidelines) and to hold it in readiness for onsite inspection

or for return shipment to Metrohm. Metrohm reserves the right to invoice

the ordering party for these articles, including retroactively, in the event of

noncompliance with these preconditions.

909 UV Digester

The same warranty periods that are specified for a corresponding new

part apply to parts that are replaced or repaired within the above-mentioned warranty periods. However, replacement or repair of a part does

not extend the warranty period of the entire system.

■■■■■■■■

43

Page 52

■■■■■■■■■■■■■■■■■■■■■■

Deficiencies arising from circumstances that are not the responsibility of

Metrohm, such as improper storage or improper use, etc., are expressly

excluded from the warranty.

Metrohm also offers a 120 month spare parts availability guarantee and a

60 month PC software support warranty, calculated from the date on

which the product is withdrawn from the market. The content of this warranty is the ability of the customer to obtain functioning spare parts or

appropriate software support at market prices during the time of the warranty period.

If Metrohm AG is unable to meet this obligation due to circumstances

beyond the control of Metrohm AG, then the ordering party shall be

offered alternative solutions at preferential conditions.

■■■■■■■■

44

909 UV Digester

Page 53

■■■■■■■■■■■■■■■■■■■■■■

11 Accessories

Note

Subject to change without notice.

11.1 Scope of delivery

2.909.0014 909 UV Digester

11 Accessories

Qty.

Order no. Description

1 1.909.0014 909 UV Digester 220-240 V/50-60 Hz

Digestion instrument for UV photolysis of water samples with low to

medium organic load. For sample preparation in trace element determination by means of voltammetry, ion chromatography and spectroscopy (AAS, ICP). Integrated instrument with operating unit and

wet end. With air cooling and automatic control of digestion temperature and time. For 12 samples with a maximum of 12 mL sample

volume each. Instrument for 220 - 240 V and 50 - 60 Hz.

1 6.1110.010 Pt1000 temperature sensor

Pt1000 temperature sensor (Class B), 1 mm plug for 909 UV Digester

Shaft material: Glass

Measuring range: -50 ... 180

Measuring unit: °C

Max. installation length (mm): 120

SGJ sleeve: Flexible SGJ sleeve

Shaft diameter top (mm): 12

Shaft diameter bottom (mm): 5

Min. immersion depth (mm): 20

Electrode plug-in head: Fixed cable (l = 0.5 m) with plug 2

x 1 mm

909 UV Digester

■■■■■■■■

45

Page 54

11.1 Scope of delivery

Qty. Order no. Description

12 6.1446.100 PTFE stopper for UV quartz sample vessel

12 mL

For quartz sample vessel 6.2414.000

Material: PTFE black

Height (mm): 35

Outer diameter (mm): 19

1 6.1446.190 Thermometer stopper for Pt1000 tempera-

ture sensor

For 6.1110.010 Pt1000 temperature sensor and 6.2414.000 12 mL

quartz sample vessel.

Material: PP

Material remark: Stopper

Material 2: Nitrile rubber

Material remark 2: O-ring

Height (mm): 22

Outer diameter (mm): 18

Inner diameter (mm): 12.2

■■■■■■■■■■■■■■■■■■■■■■

1 6.2008.040 Storage vessel

Together with 6.2008.050 storage vessel holder provides a support

for the electrode on 6.3032.XXX dosing units.

■■■■■■■■

46

909 UV Digester

Page 55

■■■■■■■■■■■■■■■■■■■■■■

Qty. Order no. Description

1 6.2041.240 Sample holder for 12 quartz sample vessels

12 mL

For 909 UV Digester.

Material: Stainless steel (AISI 304)

Height (mm): 185

Outer diameter (mm): 100

12 6.2414.000 Quartz sample vessel 12 mL

For UV Digester

Material: Quartz

Outer diameter (mm): 15.6

Length (mm): 125

Volume (mL): 12

11 Accessories

1 6.2621.100 Hexagon key 3 mm

Hexagon key 3 mm for IC Sample Processors

Length (mm): 73

909 UV Digester

■■■■■■■■

47

Page 56

11.1 Scope of delivery

Qty. Order no. Description

1 6.2745.100 UV protective shield

For 909 UV Digester.

Material: Plexiglas (PMMA)

Material remark: Protective shield

Material 2: Aluminum

Material remark 2: Mounting ring

Height (mm): 212

Outer diameter (mm): 160

Inner diameter (mm): 140

1 6.2804.090 UV mercury vapor lamp

Medium pressure mercury vapor lamp for 909 UV Digester

Material: Quartz

Outer diameter (mm): 16 ... 18

Length (mm): 137 ... 139

■■■■■■■■■■■■■■■■■■■■■■

1 6.2225.000 UV warning plate

For 909 UV Digester

Material: PVC

Width (mm): 100

Height (mm): 92

1 6.2122.0x0 Power supply cable with IEC 60320 line

socket, type C13

Cable plug according to customer requirements.

Switzerland: SEV 1011, Type 12

6.2122.020

Germany, …: CEE 7, Type VII

6.2122.040

USA, …: NEMA 5-15, Type 498

6.2122.070

Length: 1.5 m

1 8.909.8001EN 909 UV Digester Manual

■■■■■■■■

48

909 UV Digester

Page 57

■■■■■■■■■■■■■■■■■■■■■■

11.2 Optional accessories

2.909.0014 909 UV Digester

Qty. Order no. Description

1 6.2042.050 Spacer for Pt1000 temperature sensor

Material: PTFE

Height (mm): 1.5

Outer diameter (mm): 11.5

Inner diameter (mm): 4.8

11 Accessories

909 UV Digester

■■■■■■■■

49

Page 58

Index

Index

■■■■■■■■■■■■■■■■■■■■■■

A

Accessories

Optional ............................. 49

Application

Examples ............................ 31

C

Control end ................................ 1

Control unit ................................ 7

D

Dialog window

"Lamp info" ........................ 21

"Lamp setup" ..................... 21

"Parameters" ...................... 20

Display elements ................. 24

Main dialog ........................ 20

Symbols .............................. 25

Digestion

Cancel ................................ 29

End .................................... 28

Interference ........................ 30

Start ................................... 28

Digestion temperature

Cannot be saved ................ 38

E

Electrostatic charge .................... 5

Error message .......................... 37

F

Fan

Jammed ............................. 35

Front of the instrument .............. 7

Function description ................... 2

G

GLP .......................................... 36

Guarantee ................................ 43

I

Installation

Storage vessel ..................... 15

UV lamp ............................... 9

UV protective shield ............ 11

K

Keypad

Operating unit .................... 23

Keys

Function ............................. 23

L

Lamp ignitions

Reset .................................. 22

Lamp use

Number .............................. 21

Literature

Application Bulletins ........... 31

Application Notes ............... 31

M

Maintenance Agreement .......... 36

Mercury vapor lamp

Radiation data .................... 39

O

Operating hours

UV lamp ....................... 21, 22

Operating hours counter

Reset .................................. 22

Operation ................................... 2

Keypad ............................... 23

Organic load

High ................................... 26

Ozone emission

Protective measures .............. 6

P

Parameter

Change .............................. 25

Configure ........................... 20

Power connection

100 to 120 volts ................. 19

220 to 240 volts ................. 19

Transformer .................... 1, 19

Q

Quality Management ................ 36

R

Radiating time

Configure ........................... 21

Reaction equation ...................... 2

Reagents

Add .................................... 27

Rear of the instrument ................ 8

Reset

Lamp ignitions .................... 22

Operating hours counter

S

Safety instructions ...................... 4

Personnel safety ................... 5

Sample digestion

Procedure ........................... 26

Sample glasses

Clean .................................. 36

Sample holder

Insert .................................. 17

Sample temperature

Configure ........................... 21

Samples

Prepare ............................... 26

Scope of delivery ...................... 45

Service ....................................... 4

Setup location ............................ 9

Supply voltage ...................... 5, 18

Symbols

Meaning ............................. 25

T

Temperature

Configure ........................... 21

Temperature sensor

Insert .................................. 27

Temperature sensor

Connect ............................. 16

Prepare ............................... 14

Storage .............................. 15

Transformer

Power connection ................ 1

U

UV digester

Prepare ............................... 26

UV lamp

Clean .................................. 34

Handling .............................. 9

Ignitions ............................. 21

Install ................................... 9

New ................................... 22

Operating hours ........... 21, 22

Radiation data .................... 39

Replace .............................. 34

Spectrum .............................. 2

UV protective shield

Mount ................................ 11

.... 22

■■■■■■■■

50

909 UV Digester

Page 59

■■■■■■■■■■■■■■■■■■■■■■

Index

UV radiation

Protective measures ............ 28

Protective measures .............. 5

V

Validation ................................. 36

W

Warranty .................................. 43

Wet end ................................. 1, 7

909 UV Digester

■■■■■■■■

51

Loading...

Loading...