Page 1

772 Pump Unit

Manual

8.772.8001EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

772 Pump Unit

8.772.8001EN

Manual

07.2012 fpe

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://documents.metrohm.com.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.1.1 Model versions ........................................................................ 1

1.1.2 Connectors .............................................................................. 1

1.1.3 Intended use ........................................................................... 1

1.2 About the documentation ................................................... 2

1.2.1 Symbols and conventions ........................................................ 2

1.3 Safety instructions ................................................................ 3

1.3.1 General notes on safety ........................................................... 3

1.3.2 Electrical safety ........................................................................ 3

1.3.3 Tubing and capillary connections ............................................. 4

1.3.4 Flammable solvents and chemicals ........................................... 4

1.3.5 Recycling and disposal ............................................................. 4

2 Overview of the instrument 6

Table of contents

3 Installation 7

3.1 Setting up the instrument .................................................... 7

3.1.1 Packaging ................................................................................ 7

3.1.2 Checks .................................................................................... 7

3.1.3 Location .................................................................................. 7

3.2 Mounting the tubings .......................................................... 7

3.2.1 Mounting the pump tubing ..................................................... 7

3.2.2 Installing the inlet tubing and outlet tubing .............................. 9

3.3 Connecting the peristaltic pump ....................................... 10

3.3.1 Connection to a Sample Processor ......................................... 11

3.3.2 Connection to the 731 Relay Box .......................................... 11

4 Operation 14

5 Operation and maintenance 15

5.1 General notes ...................................................................... 15

5.1.1 Care ...................................................................................... 15

5.1.2 Maintenance by Metrohm Service .......................................... 15

5.2 Pump tubings ...................................................................... 16

5.2.1 Selecting the pump tubing ..................................................... 16

5.2.2 Suitability test for tubing materials ......................................... 17

5.2.3 Tubing dimensions ................................................................. 17

5.2.4 Tubing lifetime ...................................................................... 17

5.2.5 PharMed® pump tubing data sheet ....................................... 18

5.2.6 Viton® pump tubing data sheet ............................................ 19

772 Pump Unit

5.3 Tubings ................................................................................ 20

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

5.4 Quality Management and validation with Metrohm ....... 20

6 Troubleshooting 21

6.1 Problems ............................................................................. 21

7 Technical specifications 22

7.1 Peristaltic pump .................................................................. 22

7.2 Power supply ...................................................................... 22

7.3 Interfaces and connectors ................................................. 22

7.4 Safety specifications ........................................................... 22

7.5 Electromagnetic compatibility (EMC) ................................ 23

7.6 Ambient temperature ......................................................... 23

7.7 Reference conditions .......................................................... 23

7.8 Dimensions/material ........................................................... 24

8 Conformity and warranty 25

8.1 Quality Management Principles ........................................ 25

8.2 Warranty (Guarantee) ........................................................ 26

9 Accessories 28

9.1 Scope of delivery per model version ................................. 28

9.1.1 772 Pump Unit ...................................................................... 28

9.1.2 772 Pump Unit with aspiration equipment ............................. 29

9.1.3 772 Pump Unit with rinsing equipment .................................. 32

9.2 Optional accessories ........................................................... 35

9.2.1 772 Pump Unit ...................................................................... 35

9.2.2 772 Pump Unit with aspiration equipment ............................. 36

9.2.3 772 Pump Unit with rinsing equipment .................................. 36

Index 38

■■■■■■■■

IV

772 Pump Unit

Page 7

■■■■■■■■■■■■■■■■■■■■■■

Table of figures

Figure 1 Front 772 Pump Unit ......................................................................... 6

Figure 2 Inserting the tubing olives ................................................................. 7

Figure 3 Installing the pump tubing ................................................................ 8

Figure 4 Fastening the pressure clamp in place ................................................ 8

Figure 5 Connecting the tubings ..................................................................... 9

Figure 6 Screwing the union nuts tightly ....................................................... 10

Figure 7 772 Pump Unit directly on the Sample Processor ............................. 11

Figure 8 772 Pump Unit via the Remote Box and 731 Relay Box .................... 12

Figure 9 Direction of rotation ........................................................................ 13

Figure 10 Calculation formula for the permeability (C) ..................................... 19

Table of figures

772 Pump Unit

■■■■■■■■

V

Page 8

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The 772 Pump Unit is a versatile peristaltic pump for conveying or evacuating liquid media. It was designed specifically for the production operation and laboratory environment and enables a wide range of applications. Unlike membrane pumps, pumping organic solvents or liquids with

solids content is no problem for the 772 Pump Unit.

Therefore, the 772 Pump Unit is equally well suited for use in titration,

e.g. for evacuating titration samples with silver halide precipitation and as

a delivery pump in larger automation systems. By using the respective suitable tubing material, a wide variety of tasks can be managed.

The flow rate of up to 600 mL/min opens up a wide range of applications.

1.1.1 Model versions

The 772 Pump Unit is available in the following three versions:

1 Introduction

2.772.0110

2.772.0120 772 Pump Unit with aspiration equip-

2.772.0130 772 Pump Unit with rinsing equipment

Each version includes different accessories according to its use (see Chap-

ter 9, page 28).

1.1.2 Connectors

The 772 Pump Unit needs 16 - 24 V DC voltage.

Power is supplied to the pump via the direct connection to a Sample Processor (e.g. 814 or 815) or to the 731 Relay Box (connection via adapter

cable 6.2160.010).

1.1.3 Intended use

The 772 Pump Unit is designed for usage in automated systems in analytical laboratories.

This instrument is suitable for pumping chemicals and flammable samples.

Use of the 772 Pump Unit therefore requires the user to have basic knowledge and experience in handling toxic and caustic substances. Knowledge

with respect to the application of the fire prevention measures prescribed

for laboratories is also mandatory.

772 Pump Unit

ment

772 Pump Unit

■■■■■■■■

1

Page 10

1.2 About the documentation

1.2 About the documentation

Caution

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which the user must follow in order to ensure safe operation of the instrument.

1.2.1 Symbols and conventions

The following symbols and formatting may appear in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the second to the instrument part in the figure.

■■■■■■■■■■■■■■■■■■■■■■

Instruction step

Carry out these steps in the sequence shown.

Method Dialog text, parameter in the software

File ▶ New Menu or menu item

[Next] Button or key

Warning

This symbol draws attention to a possible life hazard

or risk of injury.

Warning

This symbol draws attention to a possible hazard due

to electrical current.

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

Warning

This symbol draws attention to a possible biological

hazard.

■■■■■■■■

2

Caution

This symbol draws attention to a possible damage of

instruments or instrument parts.

772 Pump Unit

Page 11

■■■■■■■■■■■■■■■■■■■■■■

1.3 Safety instructions

1.3.1 General notes on safety

Warning

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

1.3.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

1 Introduction

Note

This symbol marks additional information and tips.

Warning

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

Warning

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Mains voltage

Warning

An incorrect mains voltage can damage the instrument.

772 Pump Unit

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

■■■■■■■■

3

Page 12

1.3 Safety instructions

Protection against electrostatic charges

Warning

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Do not fail to pull the mains cable out of the mains connection socket

before you set up or disconnect electrical plug connections at the rear

of the instrument.

1.3.3 Tubing and capillary connections

Caution

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

■■■■■■■■■■■■■■■■■■■■■■

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are mandatory.

1.3.4 Flammable solvents and chemicals

Warning

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location (e.g. fume cup-

board).

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

1.3.5 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

■■■■■■■■

4

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

772 Pump Unit

Page 13

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

772 Pump Unit

■■■■■■■■

5

Page 14

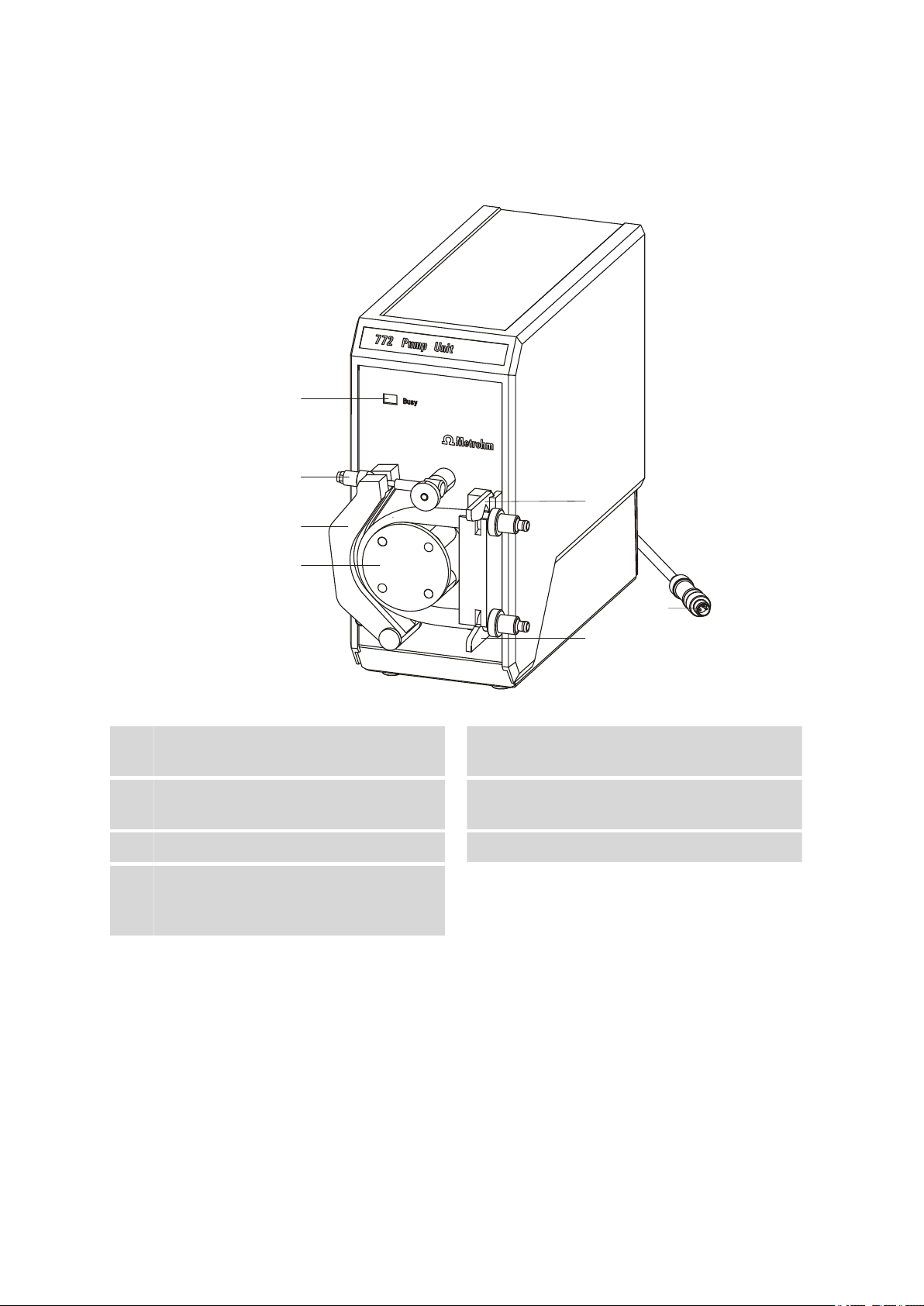

2 Overview of the instrument

1

2

3

4

5

6

7

■■■■■■■■■■■■■■■■■■■■■■

Figure 1 Front 772 Pump Unit

Status LED

1

For displaying the operating state.

Pressure clamp

3

For the counterpressure to the pump tubing.

Tubing clamp (outlet)

5

Connection cable

7

With M8 plug for connection to a Sample

Processor.

Locking lever with clamping screw

2

Rotor

4

Tubing clamp (inlet)

6

■■■■■■■■

6

772 Pump Unit

Page 15

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

3.1 Setting up the instrument

3.1.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

3.1.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

3.1.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

3 Installation

Place the instrument in a location of the laboratory which is suitable for

operation, free of vibrations, protected from corrosive atmosphere, and

contamination by chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

3.2 Mounting the tubings

3.2.1 Mounting the pump tubing

Note

Selecting the correct pump tubing is very important for its function and

lifetime (see Chapter 5, page 15).

Cut the pump tubing to a length of approx. 17 cm.

1

Insert the tubing olives (6.1820.050) into the two tubing ends.

2

772 Pump Unit

Figure 2 Inserting the tubing olives

■■■■■■■■

7

Page 16

3.2 Mounting the tubings

1

2

3

4

5

■■■■■■■■■■■■■■■■■■■■■■

Clamp the pump tubing 1 into the pump head according to the

3

drawing below such that the tubing and the tubing olives are fastened by the tubing clips 2 and 3. The tubing must be as centered

on the roller as possible.

Figure 3 Installing the pump tubing

Press on the pressure clamp 5 and fasten it in place using the locking

4

lever 4.

Figure 4 Fastening the pressure clamp in place

Tighten the clamping screw 4 so that the pump tubing cannot slip.

5

With the pump running, gently tighten the clamping screw until the

■■■■■■■■

8

772 Pump Unit

Page 17

■■■■■■■■■■■■■■■■■■■■■■

liquid flows evenly. After a run-in period, correct the setting again if

necessary.

Note

Do not clamp the pump tubing too tightly or apply too much pressure, as this causes greater wear to the pump tubing and the

pump will generate excessive pump pressure.

3.2.2 Installing the inlet tubing and outlet tubing

As the inlet tubing and outlet tubing, two different tubing types are available. Both tubings are included in the scope of delivery .

■ PVC tubing (6.1801.120), 2 x 2 m

■ PTFE tubing (6.1812.000), 1 x 4 m

Note

3 Installation

Which of the two tubings to use depends largely on the solvent used.

PVC tubing is more flexible and has the advantage of making less noise

during the pumping operation. It must be noted that the PVC tubing is

not resistant to solvents.

Install the inlet tubing and outlet tubing as follows:

Cut the inlet tubing and outlet tubing to the suitable length.

1

Connect the tubings to the tubing olives of the pump tubing using

2

union nuts.

772 Pump Unit

Figure 5 Connecting the tubings

■■■■■■■■

9

Page 18

3.3 Connecting the peristaltic pump

■■■■■■■■■■■■■■■■■■■■■■

Note

To fasten PTFE tubings in place, you have to widen their openings

(e.g. using a Phillips screwdriver). You can use a piece of sandpaper to make the PTFE tubing easier to handle.

Do not heat the tubing ends to widen them, as otherwise the connecting nipples can be damaged.

Screw the union nuts tightly to ensure a secure tubing connection.

3

Figure 6 Screwing the union nuts tightly

3.3 Connecting the peristaltic pump

Warning

Follow the instructions listed below for connecting to a control device.

The instrument can be damaged if operated with the wrong supply

voltage.

Voltage

The 772 Pump Unit needs 16 - 24 V DC voltage. It can be connected

directly to Sample Processor models 814, 815, 855 or 864.

When using the 772 Pump Unit in an automation system with remote

control, we recommend using a 731 Relay Box for the power supply.

■■■■■■■■

10

772 Pump Unit

Page 19

■■■■■■■■■■■■■■■■■■■■■■

1 2

3.3.1 Connection to a Sample Processor

■ Plug the M8 plug into the socket on the Sample Processor provided for

this purpose.

3 Installation

Figure 7 772 Pump Unit directly on the Sample Processor

Sample Processor 814, 815, 855, 864

1

Instruments with Pump Connector.

2

Note

The Sample Processor 824 Easy Sample Changer does not have an M8

socket. However, the adapter cable 6.2160.010 can be used for the

connection. For details about connecting the 772 Pump Unit to the

adapter cable, refer to the manual for the 824 Easy Sample Changer.

3.3.2 Connection to the 731 Relay Box

Connect the 772 Pump Unit with connection via the Remote Box

(6.2148.010) and the 731 Relay Box to a remote interface.

■ Connect the M8 plug (1-7) of the 772 Pump Unit to the corresponding

socket on the adapter cable.

■ Plug the adapter cable into low-voltage DC current output DC1 or DC2

of the 731 Relay Box.

772 Pump Unit

Peristaltic pump with M8 connector.

772 Pump Unit

■■■■■■■■

11

Page 20

3.3 Connecting the peristaltic pump

1 2

3

4 5

6

■■■■■■■■■■■■■■■■■■■■■■

Figure 8 772 Pump Unit via the Remote Box and 731 Relay Box

Sample Processor 814, 815, 855, 864

1

Connection via remote interface.

Remote cable (6.2125.100)

3

Adapter cable (6.2160.010)

5

Ensure the correct polarity of the banana plugs.

The red plug (positive pole) belongs in the red socket, the black plug

(negative pole) belongs in the black socket. Reversing the polarity of the

connecting plugs also reverses the direction of pumping.

Note

Remote Box (6.2148.010)

2

731 Relay Box (2.731.0010)

4

772 Pump Unit

6

■■■■■■■■

12

772 Pump Unit

Page 21

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

3 Installation

Figure 9 Direction of rotation

Direction of rotation

1

Correct direction of rotor rotation with correct polarity (clockwise).

Inlet

3

For information on controlling the 772 Pump Unit using the 731 Relay

Box and a suitable control device, refer to the manual of the 731 Relay

Box.

Note

Outlet

2

772 Pump Unit

■■■■■■■■

13

Page 22

4 Operation

■■■■■■■■■■■■■■■■■■■■■■

The 772 Pump Unit does not have its own operating units. It is operated

and controlled via the main instrument in the linked system.

■■■■■■■■

14

772 Pump Unit

Page 23

■■■■■■■■■■■■■■■■■■■■■■

5 Operation and maintenance

5.1 General notes

5.1.1 Care

The 772 Pump Unit requires appropriate care. Excess contamination of the

instrument may result in functional disruptions and a reduction in the lifetime of the sturdy mechanics and electronics.

Spilled chemicals and solvents should be removed immediately. Above all,

the plug connections on the rear of the instrument (in particular the mains

connection socket) should be protected from contamination.

Caution

Although this is extensively prevented by design measures, the mains

plug should be unplugged immediately if aggressive media have penetrated the inside of the instrument, so as to avoid serious damage to

the instrument electronics. In such cases, Metrohm Service must be

informed.

5 Operation and maintenance

5.1.2 Maintenance by Metrohm Service

Maintenance of the 772 Pump Unit is best carried out as part of an annual

service, which is performed by specialist personnel of the Metrohm company. If working frequently with caustic and corrosive chemicals, a shorter

maintenance interval could be necessary.

Metrohm Service offers every form of technical advice for maintenance

and service of all Metrohm instruments.

772 Pump Unit

■■■■■■■■

15

Page 24

5.2 Pump tubings

5.2 Pump tubings

Aggressive liquids

Leaking liquids can pose a risk of injury and damage instruments.

■ Use suitable tubing only.

■ Regularly check tubing for proper fastening and for damage and

wear.

In every case, the user has sole responsibility with regard to suitability

and safety of pump tubing. Therefore, it is extremely important that

before each use, the safety and effectiveness of tubing is tested based

on application-specific laboratory, field or clinical tests.

■■■■■■■■■■■■■■■■■■■■■■

Warning

Note

5.2.1 Selecting the pump tubing

The most important decision when using peristaltic pumps is the selection

of suitable tubing material. Always use tubings particularly intended for

peristaltic pumps.

The 772 Pump Unit is shipped with PharMed® pump tubing (6.1826.100,

ø 6.4/9.6 mm, see Chapter 5.2.5) made of thermoplastic polypropylene,

which is highly suitable for aqueous media.

If you need other tubings for your application, take care to ensure the following points when evaluating the pump tubings:

■ Chemical resistance

■ Pressure build-up in the pump tubing

■ Sterilizability

■ Temperature of the pump medium and the environment

■ Viscosity of the liquid

■ Permeability of the pump tubing

■ Demanded flow rate

■ Tubing dimensions

We recommend using PVC, silicone, Viton® and PharMed® as the tubing

materials. Contact your laboratory dealer for information on suitable products and their data sheets.

■■■■■■■■

16

772 Pump Unit

Page 25

■■■■■■■■■■■■■■■■■■■■■■

5.2.2 Suitability test for tubing materials

Place a piece of the tubing in question for 48 hours in a closed container

filled with the liquid in question. Then examine the piece of tubing for

signs of swelling, embrittlement or other damage.

5.2.3 Tubing dimensions

Note

Use tubing with a wall thickness of 1.6 mm only.

The largest usable inner diameter is 6.4 mm.

5.2.4 Tubing lifetime

The pump tubing has a limited lifetime and therefore has to be replaced

regularly. The following are examples of factors that can influence the lifetime of tubing in peristaltic pumps:

5 Operation and maintenance

■ Chemical resistance of the pump tubing

■ Pump rate (rotational speed)

■ Properties of the pumped liquid

■ Outlet pressure

■ Ambient temperature

■ Shearing force of the rollers

■ Twisted or kinked tubing

■ Tubing too long

■ Wall thickness of 1.6 mm not complied with

772 Pump Unit

■■■■■■■■

17

Page 26

5.2 Pump tubings

■■■■■■■■■■■■■■■■■■■■■■

Note

■ If the tubing is not tightened sufficiently around the rotor, this has a

negative impact on the lifetime of the tubing, as in this case the tubing tends to fold up. If the tubing is tightened too much, the flow is

restricted.

■ The tubing will last longer if the pressure clamp is detached when

the pump is not in use.

■ In order to achieve good repeatability of flow rate following a

change in tubing, it is imperative that you always select the same

tubing length.

Before changing tubing:

■ Pump all of the liquid out of the tubing so that none remains.

■ Pull out the connection cable of the peristaltic pump to prevent acci-

dental starting of the pump.

■ Detach the pressure clamp, open the tubing clamps and remove the

tubing.

5.2.5 PharMed® pump tubing data sheet

Physical properties Polypropylene-based thermoplastic elastomer, contains

plasticizer

Dimensions Inner diameter = 6.4 mm

Wall thickness 1.6 mm

Advantages Ideal for aqueous media

Impermeable to normal light and UV radiation

Tubing can be welded, glued and thermoformed.

Very long lifetime

Restrictions Additives can be dissolved out by the pumped medium.

Applications: Acids

Bases

Solvents

Pressure

Vacuum

Viscous media

Sterile media

Good resistance

Good resistance

Not suitable

Well suited

Very well suited

Well suited

Very well suited

■■■■■■■■

18

Temperature range –60 - +130 °C

772 Pump Unit

Page 27

■■■■■■■■■■■■■■■■■■■■■■

5 Operation and maintenance

Permeability (C) for:

(see Figure 10, page 19)

CO

O

N

Corresponds to the following standards:

USP Class VI

FDA 21CFR177.2600

NSF (Standard 51)

Cleaning/sterilization The tubing can be sterilized in the autoclave without

being damaged.

Figure 10 Calculation formula for the permeability (C)

5.2.6 Viton® pump tubing data sheet

Physical properties Viton®; rigid, impermeable, black

Dimensions Inner diameter = 6.4 mm

Wall thickness 1.6 mm

2

2

2

1,200

200

80

Advantages High chemical resistance

Low gas permeability

Wide temperature range

Restrictions Limited lifetime

Applications: Acids

Bases

Solvents

Pressure

Vacuum

Viscous media

Sterile media

Temperature range –31 °C - +204 °C

Permeability (C) for: CO

Corresponds to the fol-

O

2

N

2

None

2

lowing standards:

Outstanding

Outstanding

Limited

Not recommended

Good

Good

Satisfactory

38

14

5

772 Pump Unit

Cleaning/sterilization Not recommended

■■■■■■■■

19

Page 28

5.3 Tubings

■■■■■■■■■■■■■■■■■■■■■■

5.3 Tubings

The tubing requires regular inspection in order to work properly:

■ Do not kink PTFE tubing.

■ Ensure resistance to solvents.

■ Check the tubing regularly for any damage.

5.4 Quality Management and validation with Metrohm

Quality Management

Metrohm offers you comprehensive support in implementing quality management measures for instruments and software. Further information on

this can be found in the brochure «Quality Management with

Metrohm» available from your local Metrohm agent.

Validation

Please contact your local Metrohm agent for support in validating instruments and software. Here you can also obtain validation documentation

to provide help for carrying out the Installation Qualification (IQ) and

the Operational Qualification (OQ). IQ and OQ are also offered as a

service by the Metrohm agents. In addition, various application bulletins

are also available on the subject, which also contain Standard Operat-

ing Procedures (SOP) for testing analytical measuring instruments for

reproducibility and correctness.

Maintenance

Electronic and mechanical functional groups in Metrohm instruments can

and should be checked as part of regular maintenance by specialist personnel from Metrohm. Please ask your local Metrohm agent regarding the

precise terms and conditions involved in concluding a corresponding

maintenance agreement.

Note

You can find information on the subjects of quality management, validation and maintenance as well as an overview of the documents currently available at www.metrohm.com/com/ under Support.

■■■■■■■■

20

772 Pump Unit

Page 29

■■■■■■■■■■■■■■■■■■■■■■

6 Troubleshooting

6.1 Problems

Problem Cause Remedy

6 Troubleshooting

The flow is not set

correctly.

The liquid is not

aspirated, but just

"bubbles" instead.

The peristaltic pump

is not running.

The peristaltic pump

is pumping too little

or not at all.

The tubing connection of the inlet tubing and/or outlet

tubing is dripping.

The flow is too strong or

too weak.

The inlet tubing and the

outlet tubing have been

switched.

The connecting cable is not

connected.

The pressure clamp is set

insufficiently or not at all.

The tubing clamp is pinching off the tubing.

The tubings are not

screwed on correctly.

Loosen or tighten the locking lever with the

clamping screw.

Switch the tubings so that the inlet tubing

goes into the solution and the outlet tubing

goes into the waste canister.

Connect the connecting cable.

Set the correct pressure using the locking lever

and clamping screw.

Fasten the tubing end piece and the tubing

olive in the tubing clip correctly. The tubing

clamp must clamp the tubing in the area of

the tubing olive.

Check the screw connectors.

The tubing connection of the pump

tubing is dripping or

spraying.

772 Pump Unit

The pressure is too high. Loosen the locking lever of the pressure clamp

slightly.

If necessary, also use a cable tie to tie down

the cable ends at the tubing olives.

■■■■■■■■

21

Page 30

7.1 Peristaltic pump

7 Technical specifications

7.1 Peristaltic pump

■■■■■■■■■■■■■■■■■■■■■■

Direction of rota-

Clockwise

tion

Rotational speed 160 - 250 rpm, at 20 V / 200 mA

Flow rate 400 - 600 mL/min

(depending on the supply voltage and the selection of pump tubing)

Pump tubings

Wall thickness 1.6 mm

Inner diameter 0.8 - 6.4 mm

Material Depending on the medium.

7.2 Power supply

Voltage

Power consumption

16 - 24 V DC

≤ 550 mA

7.3 Interfaces and connectors

The 772 Pump Unit does not have any control interfaces. It is operated

and controlled via the power supply.

7.4 Safety specifications

This instrument fulfills the following electrical safety requirements:

CE designation in accordance with the EU directives:

■ 2006/95/EC (Low Voltage Directive, LVD)

■ 2004/108/EC (EMC Directive, EMC)

Design and testing ■ EN/IEC/UL 61010-1

■ CSA-C22.2 No. 61010-1

■ Protection class III

■ EN/IEC 60529

■ Degree of protection IP20

Safety instructions This document contains safety instructions which have to be followed

by the user in order to ensure safe operation of the instrument.

■■■■■■■■

22

772 Pump Unit

Page 31

■■■■■■■■■■■■■■■■■■■■■■

7.5 Electromagnetic compatibility (EMC)

Emission

Standards fulfilled

Immunity

Standards fulfilled

■ EN/IEC 61326-1

■ EN/IEC 61000-6-3

■ EN 55011 / CISPR 11

■ EN/IEC 61326-1

■ EN/IEC 61000-6-2

■ EN/IEC 61000-4-2

■ EN/IEC 61000-4-3

■ EN/IEC 61000-4-4

■ EN/IEC 61000-4-5

■ EN/IEC 61000-4-6

■ EN/IEC 61000-4-11

■ EN/IEC 61000-4-14

■ EN/IEC 61000-4-28

7 Technical specifications

7.6 Ambient temperature

Nominal function

range

Transport and

storage

+5 - +45 °C

–40 - +70 °C

7.7 Reference conditions

Ambient temperature

Relative humidity ≤ 60%

+25 °C (±3 °C)

772 Pump Unit

■■■■■■■■

23

Page 32

7.8 Dimensions/material

7.8 Dimensions/material

Width 100 mm

Height 210 mm

Depth 260 mm

Weight 3.20 kg (without accessories)

Material

Housing, upper

part

Bottom part of

housing

Polyurethane, coated

Steel sheet, stove-enameled

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

24

772 Pump Unit

Page 33

■■■■■■■■■■■■■■■■■■■■■■

8 Conformity and warranty

8.1 Quality Management Principles

Metrohm Ltd. holds the ISO 9001:2000 Certificate, registration number

10872-02, issued by SQS (Swiss Association for Quality and Management

Systems). Internal and external audits are carried out periodically to assure

that the standards defined by Metrohm’s QM Manual are maintained.

The steps involved in the design, manufacture and servicing of instruments

are fully documented and the resulting reports are archived for ten years.

The development of software for PCs and instruments is also duly documented and the documents and source codes are archived. Both remain

the possession of Metrohm. A non-disclosure agreement may be asked to

be provided by those requiring access to them.

The implementation of the ISO 9001:2000 quality management system is

described in Metrohm’s QM Manual, which comprises detailed instructions on the following fields of activity:

8 Conformity and warranty

Instrument development

The organization of the instrument design, its planning and the intermediate controls are fully documented and traceable. Laboratory testing

accompanies all phases of instrument development.

Software development

Software development occurs in terms of the software life cycle. Tests are

performed to detect programming errors and to assess the program’s

functionality in a laboratory environment.

Components

All components used in the Metrohm instruments have to satisfy the quality standards that are defined and implemented for our products. Suppliers of components are audited by Metrohm as the need arises.

Manufacture

The measures put into practice in the production of our instruments guarantee a constant quality standard. Production planning and manufacturing

procedures, maintenance of production means and testing of components, intermediate and finished products are prescribed.

Customer support and service

Customer support involves all phases of instrument acquisition and use by

the customer, i.e. consulting to define the adequate equipment for the

analytical problem at hand, delivery of the equipment, user manuals, train-

772 Pump Unit

■■■■■■■■

25

Page 34

8.2 Warranty (Guarantee)

ing, after-sales service and processing of customer complaints. The

Metrohm service organization is equipped to support customers in implementing standards such as GLP, GMP, ISO 900X, in performing Operational Qualification and Performance Verification of the system components or in carrying out the System Validation for the quantitative determination of a substance in a given matrix.

8.2 Warranty (Guarantee)

Metrohm guarantees that the deliveries and services it provides are free of

errors in materials, design or manufacturing.

The general warranty period is 36 months (exclusions below) from the

date of delivery or 18 months in the event of continuous operation. The

warranty remains valid on the condition that the servicing is provided by a

Service Organization authorized by Metrohm at defined intervals and with

a defined scope.

The warranty period for anion suppressors is 120 months from the date of

delivery or 60 months in the event of continuous operation.

■■■■■■■■■■■■■■■■■■■■■■

The warranty period for IC separation columns is 90 days after start-up.

For third-party components that are recognizable as such, the manufacturer's warranty regulations apply.

Consumables and materials with limited storage life and glass breakage in

the case of electrodes or other glass parts are excluded from the warranty.

Warranty claims cannot be asserted if the customer has failed to meet his

payment obligations according to schedule.

During the warranty period, Metrohm undertakes either to replace free of

charge or to credit the purchaser for any assemblies or components that

can be shown to be faulty. Any transport or customs fees that may apply

are the ordering party’s responsibility.

The precondition for this is that the ordering party must use the Return

Material Authorization (RMA) to report the faulty part, along with specification of the article number, the article designation, an adequate error

description, the delivery date and (if applicable) the serial number or the

chip data, respectively. In addition, the ordering party undertakes to store

the faulty part for at least 24 months in accordance with current storage

directives (in compliance with ESD guidelines) and to hold it in readiness

for onsite inspection or for return shipment to Metrohm. Metrohm

reserves the right to invoice the ordering party for these articles, including

retroactively, in the event of noncompliance with these pre-conditions.

■■■■■■■■

26

The original warranty periods for the original part apply to parts that are

replaced or repaired under the above-referenced warranties (no extension

of the warranty period).

772 Pump Unit

Page 35

■■■■■■■■■■■■■■■■■■■■■■

8 Conformity and warranty

Deficiencies arising from circumstances that are not the responsibility of

Metrohm, such as improper storage or improper use, etc., are expressly

excluded from the warranty.

Metrohm also offers a 120-month spare parts availability guarantee and a

60-month PC software support warranty, calculated from the date on

which the product is withdrawn from the market. The content of this warranty is the ability of the customer to obtain functioning spare parts or

appropriate software support at market prices during the time of the warranty period.

If Metrohm AG is unable to meet this obligation due to circumstances

beyond the control of Metrohm AG, then the ordering party shall be

offered alternative solutions at preferential conditions.

772 Pump Unit

■■■■■■■■

27

Page 36

9.1 Scope of delivery per model version

9 Accessories

Note

Subject to change without notice.

9.1 Scope of delivery per model version

Note

After receiving the instrument, check the shipment to ensure that it is

complete. In doing so, check the version (order number) of your 772

Pump Unit.

■■■■■■■■■■■■■■■■■■■■■■

772 Pump Unit

2.772.0110

Qty.

Order no. Description

1 1.772.0110 Pump Unit

Peristaltic pump for direct connection to Sample Processors.

2 6.1801.120 PVC tubing 4 mm / 6 mm / 2 m

Material: PVC (transparent)

Outer diameter (mm): 6

Inner diameter (mm): 4

Length (m): +2

1 6.1812.000 PTFE tubing 4 mm / 6 mm / 4 m

Material: PTFE

Outer diameter (mm): 6

Inner diameter (mm): 4

■■■■■■■■

28

772 Pump Unit

Page 37

■■■■■■■■■■■■■■■■■■■■■■

Qty. Order no. Description

2 6.1820.050 Screw connector

For 6.1826.010 pump tubing, to peristaltic pumps.

1 6.1826.100 PP pump tubing 6.4 mm / 1 m

Replaces the pump tubing used with the 772 Pump Unit.

Material: PP

Outer diameter (mm): 9.6

Inner diameter (mm): 6.4

Length (m): 1

9 Accessories

1 6.1828.000 PVDF connection nipple

For canister 6.1621.000.

Material: PVDF

1 8.772.8001EN Manual for 772 Pump Unit

9.1.2 772 Pump Unit with aspiration equipment

2.772.0120

Qty.

Order no. Description

1 1.772.0110 Pump Unit

Peristaltic pump for direct connection to Sample Processors.

772 Pump Unit

■■■■■■■■

29

Page 38

9.1 Scope of delivery per model version

Qty. Order no. Description

1 6.1446.160 Thermometer plug / B-14/15 / oblique insert

For oblique position of inserts in the titration head 6.1458.010.

Material: PTFE

Height (mm): 21

Outer diameter (mm): 13

Ground-joint size: B-14/15

1 6.1543.170 Aspiration tip / M8 thread

Aspiration tip for the Sample Processors.

Material: PTFE

Length (mm): 198

■■■■■■■■■■■■■■■■■■■■■■

1 6.1621.000 Canister / 10 L

As rinsing or waste canister in automated systems.

Material: PE

Width (mm): 265

Height (mm): 400

Volume (mL): 10,000

2 6.1801.120 PVC tubing / 4 mm / 6 mm / 2 m

Material: PVC (transparent)

Outer diameter (mm): 6

Inner diameter (mm): 4

Length (m): 2

■■■■■■■■

30

772 Pump Unit

Page 39

■■■■■■■■■■■■■■■■■■■■■■

Qty. Order no. Description

1 6.1805.510 PTFE tubing / M8 / 60 cm

With kink protection.

Material: PTFE

Inner diameter (mm): 3

Length (mm): 600

1 6.1812.000 PTFE tubing 4 mm / 6 mm / 4 m

Material: PTFE

Outer diameter (mm): 6

Inner diameter (mm): 4

9 Accessories

2 6.1820.050 Screw connector

For 6.1826.010 pump tubing, to peristaltic pumps.

772 Pump Unit

■■■■■■■■

31

Page 40

9.1 Scope of delivery per model version

Qty. Order no. Description

1 6.1820.070 Coupling 4 mm / 6 mm / M8 inner

For extending aspiration tubing in automated systems. Connects the

M8 aspiration tubing directly to the PTFE tubing 6.1812.000.

Material: PTFE

1 6.1826.100 PP pump tubing 6.4 mm / 1 m

Replaces the pump tubing used with the 772 Pump Unit.

Material: PP

Outer diameter (mm): 9.6

Inner diameter (mm): 6.4

Length (m): 1

■■■■■■■■■■■■■■■■■■■■■■

1 6.1828.000 PVDF connection nipple

For canister 6.1621.000.

Material: PVDF

1 8.772.8001EN Manual for 772 Pump Unit

9.1.3 772 Pump Unit with rinsing equipment

2.772.0130

Qty.

Order no. Description

1 1.772.0110 Pump Unit

Peristaltic pump for direct connection to Sample Processors.

■■■■■■■■

32

772 Pump Unit

Page 41

■■■■■■■■■■■■■■■■■■■■■■

Qty. Order no. Description

1 6.1621.000 Canister / 10 L

As rinsing or waste canister in automated systems.

Material: PE

Width (mm): 265

Height (mm): 400

Volume (mL): 10,000

2 6.1801.120 PVC tubing / 4 mm / 6 mm / 2 m

Material: PVC (transparent)

Outer diameter (mm): 6

Inner diameter (mm): 4

Length (m): 2

9 Accessories

3 6.1805.060 FEP tubing / M6 / 60 cm

Kink-proof and protected against light.

Material: FEP

Inner diameter (mm): 2

Length (mm): 600

1 6.1808.170 Distributor piece for rinsing and aspirating

for Sample Processors

Distributor piece for installation on Sample Processors for rinsing and

aspirating when using externally connected pumps.

772 Pump Unit

■■■■■■■■

33

Page 42

9.1 Scope of delivery per model version

Qty. Order no. Description

1 6.1812.000 PTFE tubing 4 mm / 6 mm / 4 m

Material: PTFE

Outer diameter (mm): 6

Inner diameter (mm): 4

2 6.1820.050 Screw connector

For 6.1826.010 pump tubing, to peristaltic pumps.

■■■■■■■■■■■■■■■■■■■■■■

1 6.1826.100 PP pump tubing 6.4 mm / 1 m

Replaces the pump tubing used with the 772 Pump Unit.

Material: PP

Outer diameter (mm): 9.6

Inner diameter (mm): 6.4

Length (m): 1

1 6.1828.000 PVDF connection nipple

For canister 6.1621.000.

Material: PVDF

■■■■■■■■

34

772 Pump Unit

Page 43

■■■■■■■■■■■■■■■■■■■■■■

Qty. Order no. Description

3 6.2740.020 Spray nozzle

For the fine-spraying of the rinsing solution.

Material: ETFE

Outer diameter (mm): 10

Length (mm): 47

1 8.772.8001EN Manual for 772 Pump Unit

9.2 Optional accessories

9 Accessories

772 Pump Unit

2.772.0110

Order no.

6.1826.160 Viton® pump tubing

For peristaltic pumps.

Notes on material: Viton®

Outer diameter (mm): 6.4

Length (m): 1

6.5323.010 VA rinsing equipment for pump units

VA rinsing equipment for automatic rinsing of the measuring container in the

VA stand for use with pump units.

6.2160.010 Adapter cable / 2 m / M8 socket / 2 x plug B

Adapter cable / 2 m / M8 socket / 2 x plug B for 772 Pump Unit.

Description

8.772.3001EN Declaration of Conformity for 772 Pump Unit

772 Pump Unit

■■■■■■■■

35

Page 44

9.2 Optional accessories

Order no. Description

9.2.2 772 Pump Unit with aspiration equipment

2.772.0120

Order no. Description

6.1826.160 Viton® pump tubing

For peristaltic pumps.

Notes on material: Viton®

Outer diameter (mm): 6.4

Length (m): 1

6.2160.010 Adapter cable / 2 m / M8 socket / 2 x plug B

■■■■■■■■■■■■■■■■■■■■■■

Adapter cable / 2 m / M8 socket / 2 x plug B for 772 Pump Unit.

8.772.3001EN Declaration of Conformity for 772 Pump Unit

9.2.3 772 Pump Unit with rinsing equipment

2.772.0130

Order no.

6.1826.160 Viton® pump tubing

For peristaltic pumps.

Notes on material: Viton®

Outer diameter (mm): 6.4

Length (m): 1

Description

■■■■■■■■

36

772 Pump Unit

Page 45

■■■■■■■■■■■■■■■■■■■■■■

Order no. Description

6.2160.010 Adapter cable / 2 m / M8 socket / 2 x plug B

Adapter cable / 2 m / M8 socket / 2 x plug B for 772 Pump Unit.

8.772.3001EN Declaration of Conformity for 772 Pump Unit

9 Accessories

772 Pump Unit

■■■■■■■■

37

Page 46

Index

Index

■■■■■■■■■■■■■■■■■■■■■■

C

Connect

731 Relay Box .................... 11

Peristaltic pump .................. 10

Sample Processor ............... 11

D

Dimensions .............................. 24

E

Electrostatic charge .................... 4

F

Front of the instrument .............. 6

G

GLP .......................................... 20

Guarantee ................................ 26

I

Instrument description ................ 1

M

Mains voltage ............................. 3

Material .................................... 24

Model versions ........................... 1

O

Operation ................................. 14

Optional accessories ................. 35

P

Peristaltic pump

Direction of rotation ........... 22

Flow rate ............................ 22

Power supply

Power consumption ........... 22

Voltage .............................. 22

Problems .................................. 21

Pump tubing ............................ 16

Dimensions ......................... 17

Lifetime .............................. 17

Mount .................................. 7

Select ................................. 16

Suitability test ..................... 17

Q

Quality Management ................ 20

S

Safety instructions ...................... 3

Scope of delivery ...................... 28

Service ....................................... 3

Service Agreement ................... 20

Standards ........................... 22, 23

T

Tubing

Maintenance ...................... 20

V

Validation ................................. 20

W

Warranty .................................. 26

■■■■■■■■

38

772 Pump Unit

Loading...

Loading...