Maytag MEDB800YW, WED8800YW, WED8800YC, WED8600YW, WED8600YC Installation Instructions

...

Electric Dryer Installation Instructions

Table of Contents |

|

DRYER SAFETY.......................................................................... |

2 |

INSTALLATION REQUIREMENTS............................................. |

3 |

Tools and Parts....................................................................... |

3 |

LOCATION REQUIREMENTS.................................................... |

4 |

ELECTRICAL REQUIREMENTS................................................ |

5 |

INSTALL LEVELING LEGS......................................................... |

6 |

ELECTRICAL CONNECTION..................................................... |

7 |

VENTING................................................................................... |

12 |

Venting Requirements.......................................................... |

12 |

Plan Vent System.................................................................. |

13 |

Install Vent System............................................................... |

15 |

CONNECT INLET HOSES........................................................ |

15 |

CONNECT VENT....................................................................... |

17 |

LEVEL DRYER.......................................................................... |

17 |

COMPLETE INSTALLATION CHECKLIST............................... |

18 |

REVERSE DOOR SWING......................................................... |

18 |

TROUBLESHOOTING............................................................... |

19 |

Para obtener acceso al manual de uso y cuidado en español, o para obtener información adicional acerca de su producto, visite: www.whirlpool.com

Tenga listo su número de modelo completo. Puede encontrar el número de modelo y de serie dentro de la cavidad superior de la puerta.

INSTALLATION NOTES

Date of purchase:_________________________________

Date of installation:_ _______________________________

Installer:_________________________________________

Model number:____________________________________

Serial number:____________________________________

W10392124B

W10392125B-SP

1

DRYER SAFETY

2

INSTALLATION REQUIREMENTS

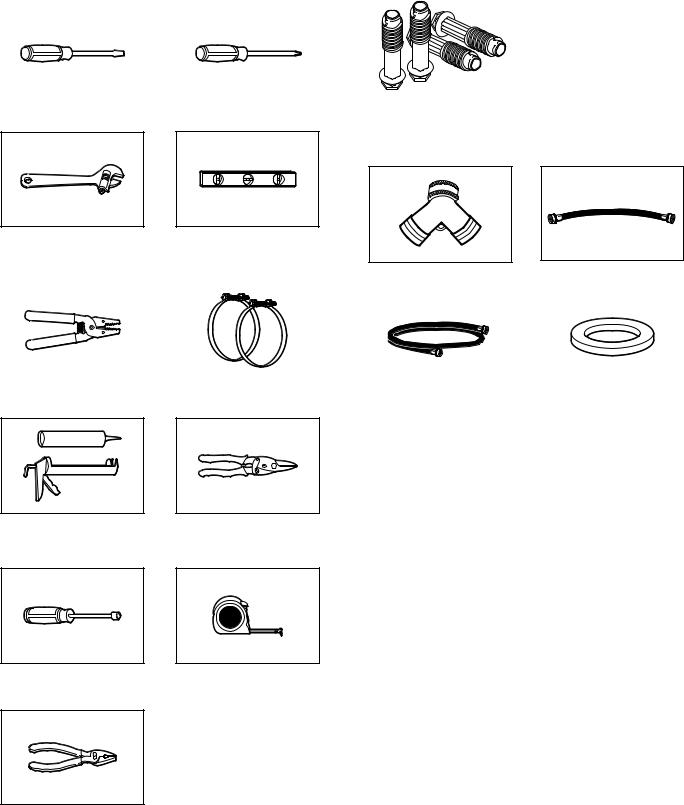

TOOLS AND PARTS

Gather the required tools and parts before starting installation. Read and follow the instructions provided with any tools listed here.

Tools needed: Parts supplied (all models):

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Leveling legs (4) |

||||||||

Flat-blade screwdriver |

|

#2 Phillips screwdriver |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

||

Parts supplied (steam models):

Adjustable wrench that |

Level |

|

opens to 1" (25 mm) or |

|

|

hex-head socket wrench |

“Y” connector |

Short inlet hose |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wire stripper (direct wire |

|

Vent clamps |

|

|

|

|

|

|

5' (1.52 m) inlet hose |

|

Rubber washer |

||

installations) |

|

|

|

|

||

|

|

|

|

|

|

Caulking gun and compound (for installing new exhaust vent)

1/4" nut driver (recommended)

Pliers

Tin snips (new vent installations)

Tape measure

Parts package is located in dryer drum. Check that all parts are included.

Parts needed: (Not supplied with dryer)

Check local codes. Check existing electrical supply and venting. See “Electrical Requirements” and “Venting Requirements” before purchasing parts.

Mobile home installations require metal exhuast system hardware available for purchase from the dealer from whom you purchased your dryer. For further information, please refer to the “Assistance or Service” section in your “Use and Care Guide.”

Optional Equipment: (Not supplied with dryer)

Refer to your “Use and Care Guide” for information about accessories available for your dryer.

3

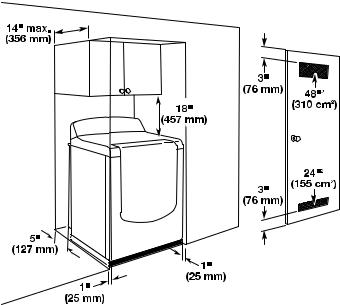

LOCATION REQUIREMENTS

You will need:

■■ A location allowing for proper exhaust installation. See “Venting Requirements.”

■■ A separate 30 amp circuit.

■■ If using power supply cord, a grounded electrical outlet located within 2 ft. (610 mm) of either side of dryer. See “Electrical Requirements.”

■■ Floor must support dryer weight of 200 lbs. (90.7 kg). Also consider weight of companion appliance.

■■ Level floor with maximum slope of 1" (25 mm) under entire dryer. If slope is greater than 1" (25 mm), clothes may not tumble properly and automatic sensor cycles may not operate correctly.

■■ For a garage installation, place dryer at least 18" (457 mm) above floor.

■■ Steam models only: Cold water faucets located within 4 ft. (1.2 m) of the water fill valves, and water pressure of 20-100 psi (137.9-689.6 kPa). You may use the water supply for your washer using the “Y” connector and short hose (if needed) which are provided.

For each arrangement, consider allowing more space for ease of installation and servicing; spacing for companion appliances and clearances for walls, doors, and floor moldings. Space must be large enough to allow door to fully open. Add spacing on all sides of dryer to reduce noise transfer. If a closet door or louvered door is installed, top and bottom air openings

in door are required.

IMPORTANT: Do not operate, install, or store dryer where

it will be exposed to water, weather, or at temperatures below 45° F (7° C). Lower temperatures may cause dryer not to shut off at end of automatic sensor cycles, resulting in longer drying times.

Check code requirements. Some codes limit, or do not permit, installing dryer in garages, closets, mobile homes, or sleeping quarters. Contact your local building inspector.

INSTALLATION CLEARANCES

Location must be large enough to allow dryer door to open fully.

DRYER DIMENSIONS

Side view with open door dimensions:

Back view:

Bottom view:

NOTE: Most installations require a minimum of 5" (127 mm) clearance behind dryer for exhaust vent with elbow. See “Venting Requirements.”

4

Spacing for recessed area or closet installation

All dimensions show recommended spacing allowed, with tested spacing of 0" (0 mm) clearance on sides and rear.

■■ Additional spacing should be considered for ease of installation and servicing.

■■ Additional clearances might be required for wall, door, and floor moldings.

■■ Additional spacing should be considered on all sides of the dryer to reduce noise transfer.

■■ For closet installation, with a door, minimum ventilation openings in the top and bottom of the door are required. Louvered doors with equivalent ventilitation openings are acceptable.

■■ Companion appliance spacing should also be considered.

Mobile home - Additional installation requirements:

This dryer is suitable for mobile home installations. The installation must conform to the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280 (formerly the Federal Standard for Mobile home construction and Safety, Title 24, HUD Part 280) or Standard CAN/CSAZ240 MH.

Mobile home installations require:

■■ Metal exhaust system hardware, available for purchase from your dealer. For further information, see “Assistance or Service” section in your “Use and Care Guide.”

■■ Special provisions must be made in mobile homes to introduce outside air into dryer. Openings (such as a nearby window) should be at least twice as large as dryer exhaust opening.

ELECTRICAL REQUIREMENTS

It is your responsibility:

■■ To contact a qualified electrical installer.

■■ To be sure that the electrical connection is adequate and in conformance with the National Electrical Code, ANSI/NFPA 70 - latest edition and all local codes and ordinances.

The National Electrical Code requires a 4-wire power supply connection for homes built after 1996, dryer circuits involved in remodeling after 1996, and all mobile home installations.

A copy of the above code standards can be obtained from: National Fire Protection Association, One Batterymarch Park, Quincy, MA 02269.

■■ To supply the required 3 or 4 wire, single phase, 120/240 volt, 60 Hz, AC only electrical supply (or 3 or 4 wire, 120/208 volt electrical supply, if specified on the serial/rating plate) on a separate 30-amp circuit, fused on both sides of the line. Connect to an individual branch circuit. Do not have a fuse in the neutral or grounding circuit.

■■ Do not use an extension cord.

■■ If codes permit and a separate ground wire is used, it is recommended that a qualified electrician determine that the ground path is adequate.

Electrical Connection

To properly install your dryer, you must determine the type of electrical connection you will be using and follow the instructions provided for it here.

■■ This dryer is manufactured ready to install with a 3-wire electrical supply connection. The neutral ground conductor is permanently connected to the neutral conductor (white wire) within the dryer. If the dryer is installed with a 4-wire electrical supply connection, the neutral ground conductor must be removed from the external ground connector (green screw), and secured under the neutral terminal (center or white wire) of the terminal block. When the neutral ground conductor is secured under the neutral terminal (center or white wire) of the terminal block, the dryer cabinet is isolated from the neutral conductor.

■■ If local codes do not permit the connection of a neutral ground wire to the neutral wire, see “Optional 3-wire connection” section.

■■ A 4-wire power supply connection must be used when the appliance is installed in a location where grounding through the neutral conductor is prohibited. Grounding through the neutral is prohibited for (1) new branch-circuit installations,

(2) mobile homes, (3) recreational vehicles, and (4) areas where local codes prohibit grounding through the neutral conductors.

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with clothes dryers. The kit should contain:

■■ A UL listed 30-amp power supply cord, rated 120/240 volt minimum. The cord should be type SRD or SRDT and be at least 4 ft. (1.22 m) long. The wires that connect to

the dryer must end in ring terminals or spade terminals with upturned ends.

■■ A UL listed strain relief.

5

If your outlet looks like this:

|

|

|

|

|

Then choose a 4-wire power supply cord with |

|

|

|

|

|

ring or spade terminals and UL listed strain |

|

|

|

|

|

relief. The 4-wire power supply cord, at least |

|

|

|

|

|

|

|

|

|

|

|

4 ft. (1.22 m) long, must have 4 10-gauge solid |

|

|

|

|

|

|

|

|

|

|

|

copper wires and match a 4-wire receptacle of |

|

4-wire |

NEMA Type 14-30 R. The ground wire (ground |

|||

|

conductor) may be either green or bare. The |

||||

receptacle |

neutral conductor must be identified by a |

||||

(14-30R) |

white cover. |

||||

|

|

|

|

|

|

If your outlet looks like this:

Then choose a 3-wire power supply cord with ring or spade terminals and UL listed strain relief. The 3-wire power supply cord, at least 4 ft. (1.22 m) long, must have 3 10-gauge solid copper wires and match a 3-wire receptacle of

NEMA Type 10-30R.

3-wire receptacle (10-30R)

If connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire) and be:

■■ Flexible armored cable or nonmetallic sheathed copper cable (with ground wire), covered with flexible metallic conduit. All current-carrying wires must be insulated.

■■ 10-gauge solid copper wire (do not use aluminum) at least 5 ft. (1.52 m) long.

INSTALL LEVELING LEGS

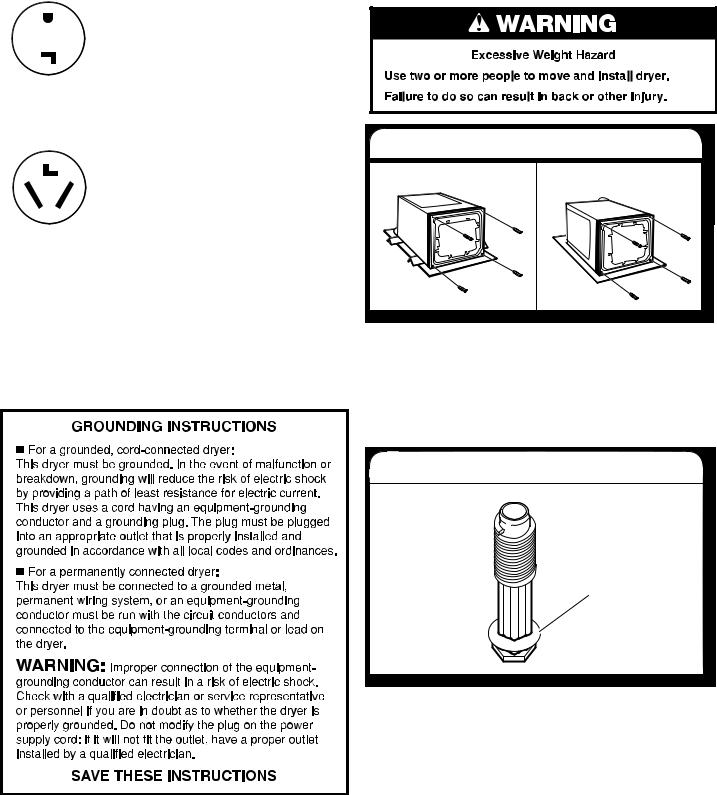

1. Prepare dryer for leveling legs |

To avoid damaging floor, use a large flat piece of cardboard from dryer carton; place under entire dryer. Firmly grasp dryer body (not console panel) and gently lay dryer down on cardboard.

IMPORTANT: If laying dryer on its back, use the cardboard corner posts the dryer was packed with to avoid damaging the back of the dryer. Lay the dryer on its side if you do not have the cardboard corner posts the dryer was packed with.

2. Screw in leveling legs

Flange

Examine leveling legs. Using a wrench, screw legs into leg holes until foot flange touches the base. Foot is fully installed when bottom of foot is approximately 1/2" (13 mm) from bottom of dryer.

Now stand the dryer on its legs. Slide the dryer until it is close to its final location. Leave enough room for electrical connection and to connect the exhaust vent.

6

Loading...

Loading...